High Step-Up Converter Based on Non-Series Energy Transfer Structure for Renewable Power Applications

Abstract

1. Introduction

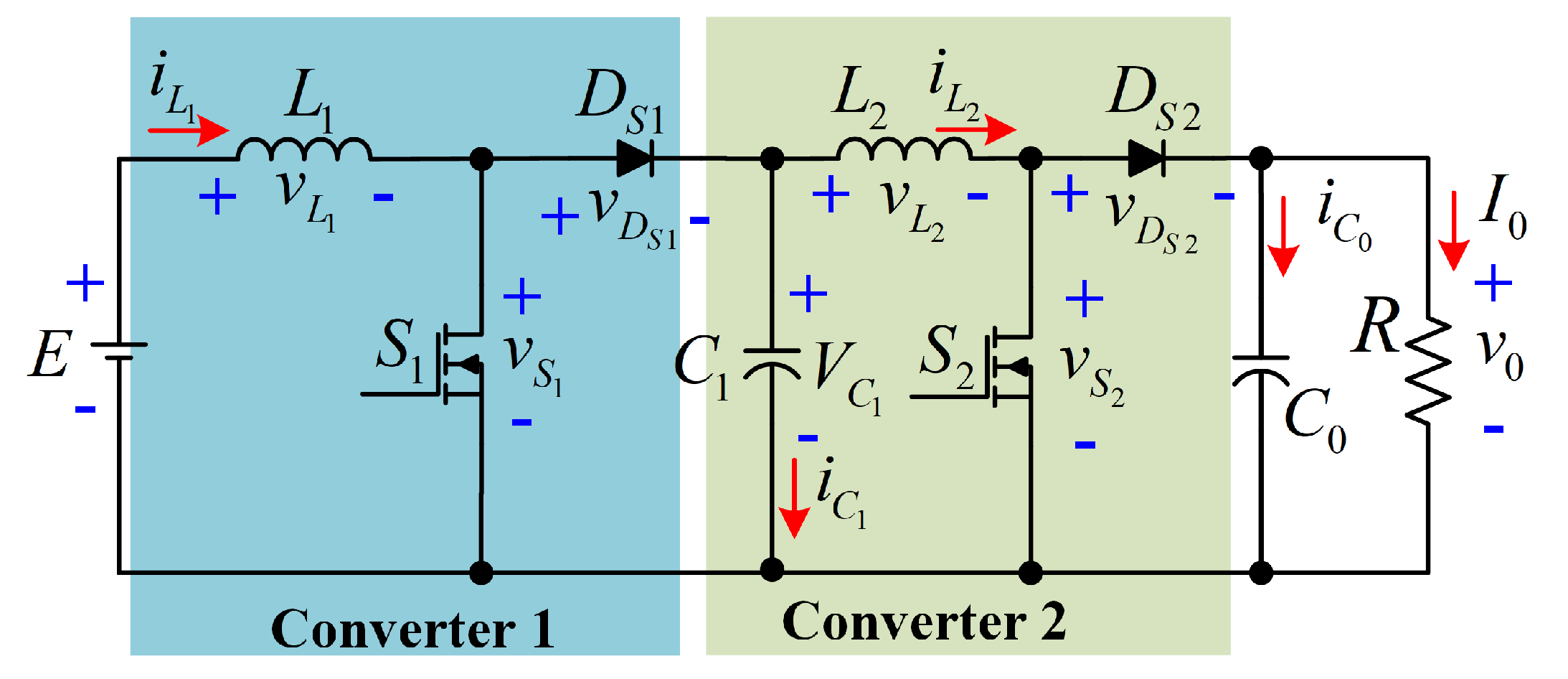

2. Converter Operation

- The study is developed for continuous conduction mode operation (CCM).

- The passive elements (, , , ), the active switches (, ), and the passive switches (, ) are considered as an ideal components.

- The active switches operate under the same duty cycle D. Thus, , is the switching frequency, and is the period of the PWM signal that drives the active switches.

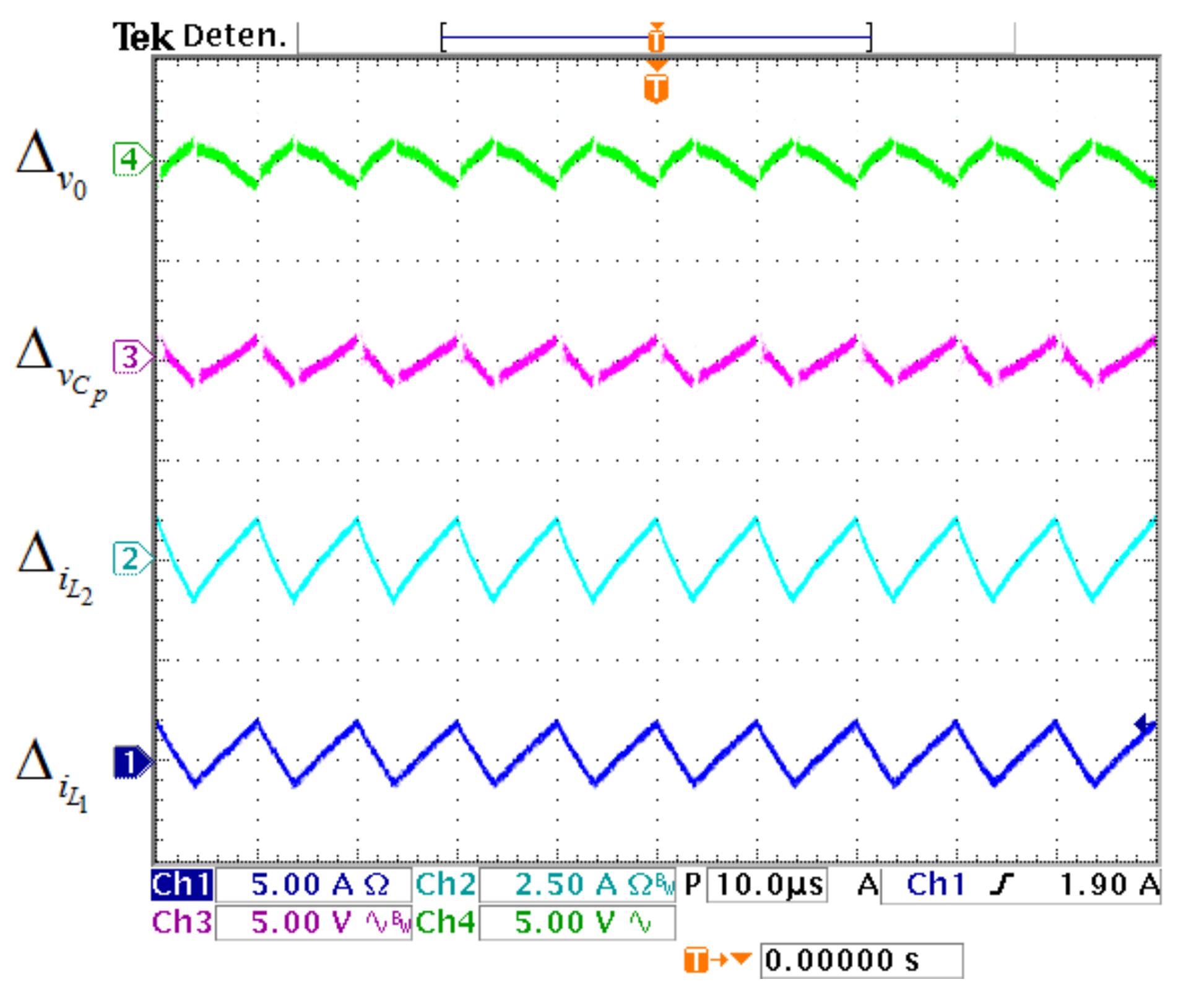

- For steady-state operation, , where and .

3. Converter Analysis

3.1. Converter Voltage Gain

3.2. Steady-State Conditions

3.3. Stress on Semiconductor Devices

3.4. Comparison with Other Quadratic Converters

4. Study of the Power Efficiency

5. Modeling of the Converter

Nonlinear Average Model of the Converter

6. Converter Design

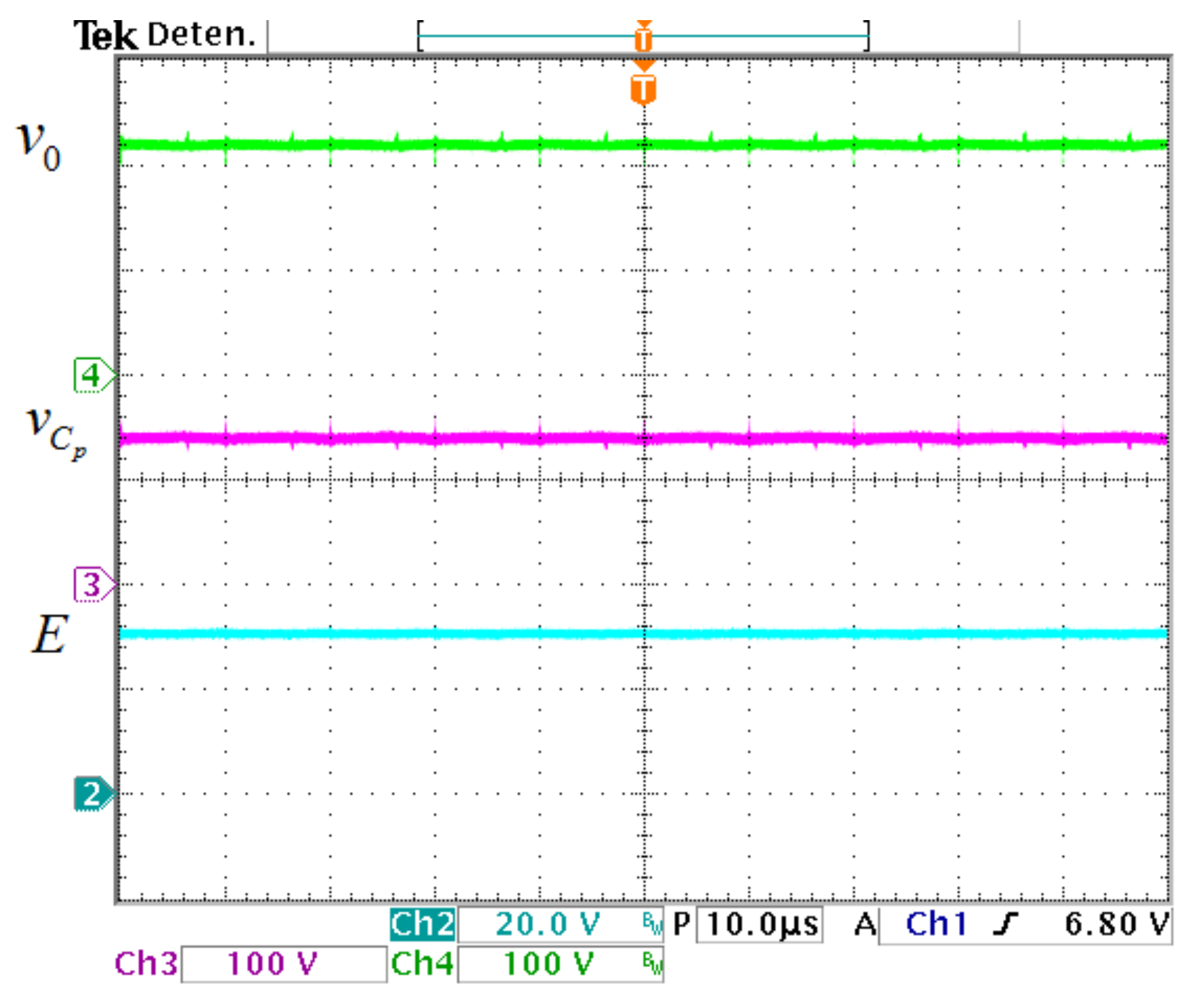

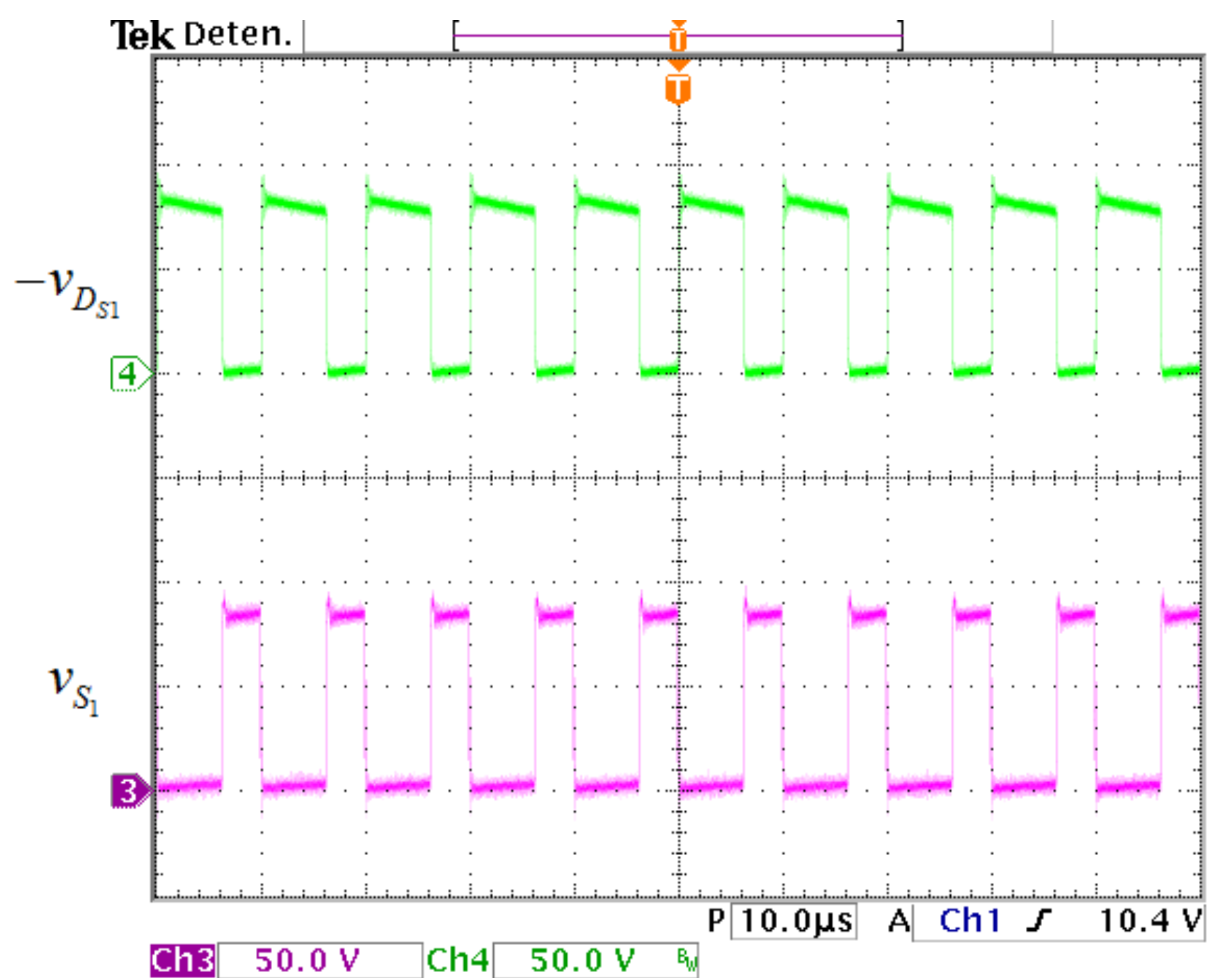

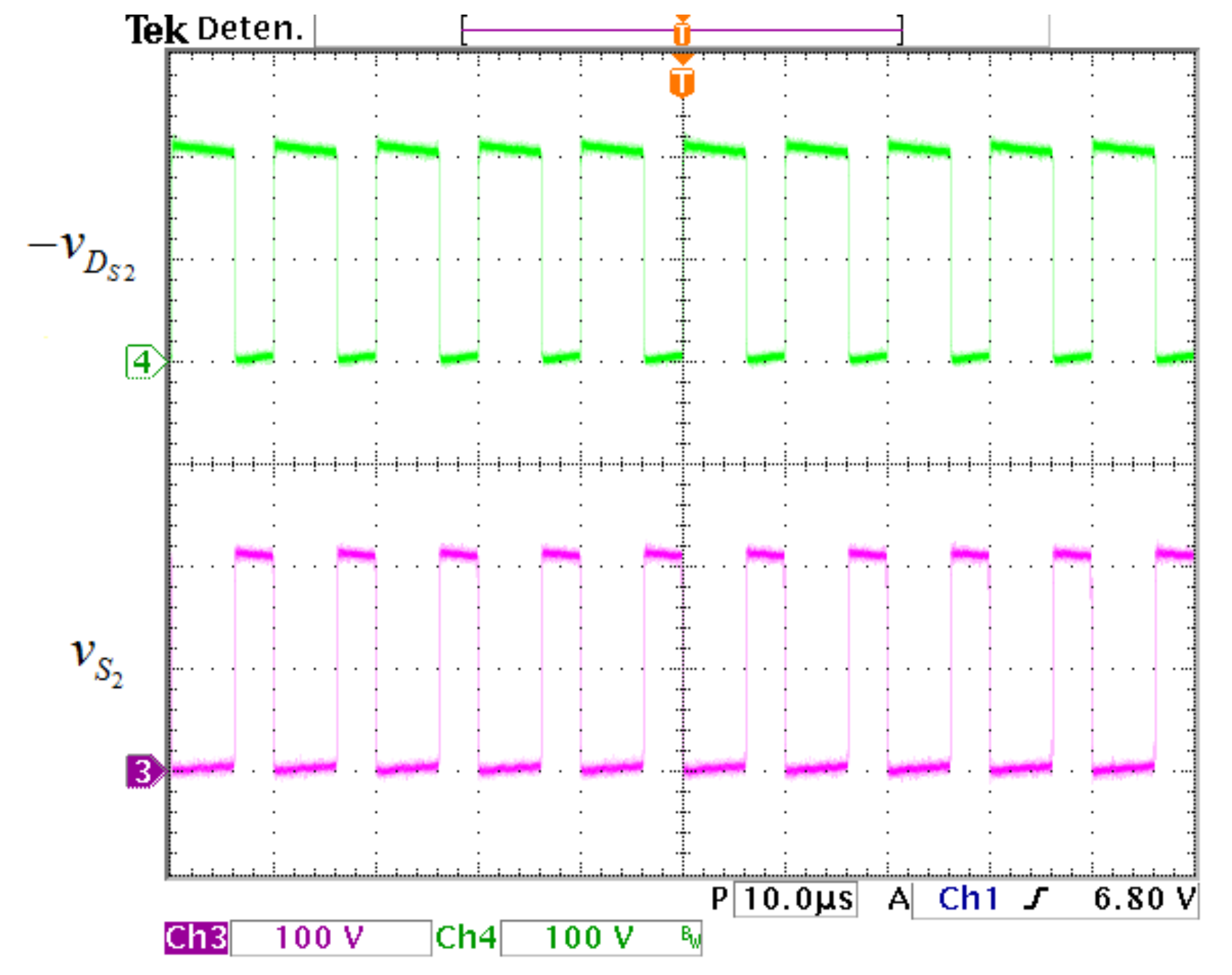

7. Experimental Verification

8. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Singh, K.A.; Chaudhary, K. Design and development of a new three-phase AC-DC single-stage wind energy conversion system. IET Power Electron. 2021, 14, 302–312. [Google Scholar] [CrossRef]

- Saganeiti, L.; Pilogallo, A.; Faruolo, G.; Scorza, F.; Murgante, B. Territorial Fragmentation and Renewable Energy Source Plants: Which Relationship? Sustainability 2020, 12, 1828. [Google Scholar] [CrossRef]

- Mohan Appikonda, M.; Kaliaperumal, D. Signal flow graph model and control of dual input boost converter with voltage multiplier cell. Int. J. Electron. Commun. 2020, 125, 153345. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Fuzzy Rule-Based and Particle Swarm Optimisation MPPT Techniques for a Fuel Cell Stack. Energies 2019, 12, 936. [Google Scholar] [CrossRef]

- Tseng, K.; Cheng, C.; Chen, C. High Step-Up Interleaved Boost Converter for Distributed Generation Using Renewable and Alternative Power Sources. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 713–722. [Google Scholar] [CrossRef]

- Hoang, K.D.; Lee, H. Accurate Power Sharing with Balanced Battery State of Charge in Distributed DC Microgrid. IEEE Trans. Ind. Electron. 2019, 66, 1883–1893. [Google Scholar] [CrossRef]

- Kong, X.; Khambadkone, A.M. Analysis and Implementation of a High Efficiency, Interleaved Current-Fed Full Bridge Converter for Fuel Cell System. IEEE Trans. Power Electron. 2007, 22, 543–550. [Google Scholar] [CrossRef]

- Hasanpour, S.; Baghramian, A.; Mojallali, H. A Modified SEPIC-Based High Step-Up DC–DC Converter with Quasi-Resonant Operation for Renewable Energy Applications. IEEE Trans. Ind. Electron. 2019, 66, 3539–3549. [Google Scholar] [CrossRef]

- Parada Salado, J.G.; Herrera Ramirez, C.A.; Soriano Sanchez, A.G.; Rodriguez Licea, M.A. Nonlinear Stabilization Controller for the Boost Converter with a Constant Power Load in Both Continuous and Discontinuous Conduction Modes. Micromachines 2021, 12, 512. [Google Scholar] [CrossRef]

- Diaz-Saldierna, L.H.; Leyva-Ramos, J.; Langarica-Cordoba, D.; Morales-Saldaña, J.A. Control strategy of switching regulators for fuel-cell power applications. IET Renew. Power Gener. 2017, 11, 799–805. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Ghazi, R.; Nikbahar, A.; Eydi, M. A new enhanced-boost switched-capacitor quasi Z-source network. IET Power Electron. 2021, 12, 412–421. [Google Scholar] [CrossRef]

- Shreelakshmi, M.P.; Moumita, D.; Vivek, A. Design and Development of a Novel High Voltage Gain, High-Efficiency Bidirectional DC–DC Converter for Storage Interface. IEEE Trans. Ind. Electron. 2019, 66, 4490–4501. [Google Scholar]

- Valdez-Resendiz, J.E.; Rosas-Caro, J.C.; Mayo-Maldonado, J.C.; Llamas-Terres, A. Quadratic boost converter based on stackable switching stages. IET Power Electron. 2018, 11, 1373–1381. [Google Scholar] [CrossRef]

- Langarica-Córdoba, D.; Diaz-Saldierna, L.H.; Leyva-Ramos, J. Fuel-cell energy processing using a quadratic boost converter for high conversion ratios. In Proceedings of the 2015 IEEE 6th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Aachen, Germany, 22–25 June 2015. [Google Scholar]

- Morales-Saldana, J.A.; Carbajal-Gutierrez, E.E.; Leyva-Ramos, J. Modeling of switch-mode dc-dc cascade converters. IEEE Trans. Aerosp. Electron. Syst. 2002, 38, 295–299. [Google Scholar] [CrossRef]

- Luo, F.L.; Ye, H. Positive output cascade boost converters. IEE Proc. Electr. Power Appl. 2004, 151, 590–606. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, Y.; Bian, Q.; Guan, Y.; Xu, D.; Wang, Y. A Single Switch Quadratic Boost High Step Up DC–DC Converter. IEEE Trans. Ind. Electron. 2019, 66, 4387–4397. [Google Scholar] [CrossRef]

- Marsala, G.; Pucci, M.; Rabbeni, R.; Vitale, G. Analysis and design of a dc-dc converter with high boosting and reduced current ripple for PEM FC. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar]

- Gu, Y.; Chen, Y.; Zhang, B.; Qiu, D.; Xie, F. High Step-Up DC–DC Converter With Active Switched LC-Network for Photovoltaic Systems. IEEE Trans. Energy Convers. 2019, 34, 321–329. [Google Scholar] [CrossRef]

- Pires, B.F.; Cordeiro, A.; Foito, D.; Silva, J.F. High Step-Up DC–DC Converter for Fuel Cell Vehicles Based on Merged Quadratic Boost–Ćuk. IEEE Trans. Veh. Technol. 2019, 68, 7521–7530. [Google Scholar] [CrossRef]

- Tseng, K.-C.; Huang, H.-S.; Cheng, C.-A. Integrated boost-forward-flyback converter with high step-up for green energy power-conversion applications. IET Power Electron. 2021, 14, 27–37. [Google Scholar] [CrossRef]

- Babaei, E.; Varesi, K.; Vosoughi, N. Calculation of critical inductance in n-input buck dc–dc converter. IET Power Electron. 2016, 19, 2434–2444. [Google Scholar] [CrossRef]

- López-Santos, O.; Martínez-Salamero, L.; García, G.; Valderrama-Blavi, H.; Mercuri, D.O. Efficiency analysis of a sliding-mode controlled quadratic boost converter. IET Power Electron. 2013, 6, 364–373. [Google Scholar] [CrossRef]

- Van Dijk, E.; Spruijt, J.N.; O’Sullivan, D.M.; Klaassens, J.B. PWM-switch modeling of DC-DC converters. IEEE Trans. Power Electron. 1995, 10, 659–665. [Google Scholar] [CrossRef]

- Carbajal-Gutierrez, E.E.; Morales-Saldana, J.A.; Leyva-Ramos, J. Modeling of a single-switch quadratic buck converter. IEEE Trans. Aerosp. Electron. Syst. 2005, 41, 1450–1456. [Google Scholar] [CrossRef]

- Ortiz-Lopez, M.G.; Leyva-Ramos, J.; Carbajal-Gutierrez, E.E.; Morales-Saldana, J.A. Modelling and analysis of switch-mode cascade converters with a single active switch. IET Power Electron. 2008, 1, 478–487. [Google Scholar] [CrossRef]

| Components | Proposed Converter | QBC-CS Ref. [15] | QBC-SS Ref. [16] | QBC-CF Ref. [17] | QBC-TR Ref. [18] |

|---|---|---|---|---|---|

| Capacitors | 2 | 2 | 2 | 4 | 2 |

| Inductors | 2 | 2 | 2 | 1 | 2 |

| Diodes | 2 | 2 | 3 | 5 | 4 |

| Switches | 2 | 2 | 1 | 1 | 1 |

| Transformers | 0 | 0 | 0 | 1 | 0 |

| Gain (CCM) |

| Inductors | |

| Capacitors | |

| Diodes | |

| Switches | |

| Drivers | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diaz-Saldierna, L.H.; Leyva-Ramos, J. High Step-Up Converter Based on Non-Series Energy Transfer Structure for Renewable Power Applications. Micromachines 2021, 12, 689. https://doi.org/10.3390/mi12060689

Diaz-Saldierna LH, Leyva-Ramos J. High Step-Up Converter Based on Non-Series Energy Transfer Structure for Renewable Power Applications. Micromachines. 2021; 12(6):689. https://doi.org/10.3390/mi12060689

Chicago/Turabian StyleDiaz-Saldierna, Luis Humberto, and Jesus Leyva-Ramos. 2021. "High Step-Up Converter Based on Non-Series Energy Transfer Structure for Renewable Power Applications" Micromachines 12, no. 6: 689. https://doi.org/10.3390/mi12060689

APA StyleDiaz-Saldierna, L. H., & Leyva-Ramos, J. (2021). High Step-Up Converter Based on Non-Series Energy Transfer Structure for Renewable Power Applications. Micromachines, 12(6), 689. https://doi.org/10.3390/mi12060689