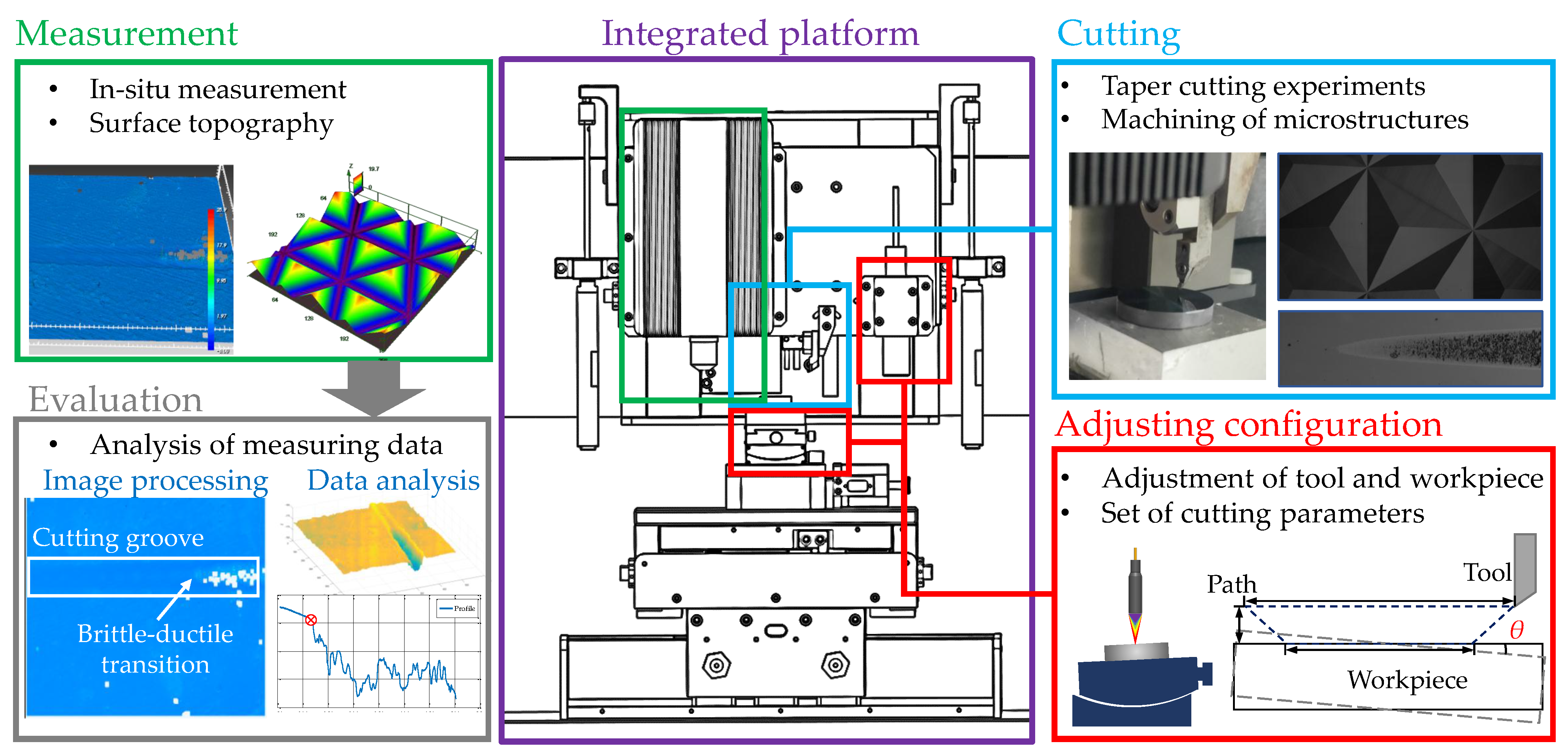

A Self-Established “Machining-Measurement-Evaluation” Integrated Platform for Taper Cutting Experiments and Applications

Abstract

:1. Introduction

2. Taper-Cutting Experiment and Measurement Evaluation Method

2.1. Method of the Taper-Cutting Experiments

2.2. Measurement and Evaluation Method for the BDTD

- (1)

- Considering the characteristics of the collected 3D point cloud and the calculation efficiency of the algorithm, for the data point , calculate the average distance between it and its four neighbouring points, which is expressed as

- (2)

- Calculate the mean and standard deviation of the average distance of all data points .

- (3)

- Judge the size relationship between the average distance of . If it satisfiesthe point is considered to be a normal data point and retained. If the following formula is not satisfied, it means that the numerical deviation of this point is large, and it is a gross error deletion. Considering the characteristics of the white light interferometric sensor and the conclusions of different t value experiments, the value of the threshold t is generally set to 2 in this algorithm.

- (1)

- Perform average filtering on row or column data with three sub-filters. Let k be the median filtering range, and the three sub-filters are

- (2)

- The median value of the filtering results of the three sub-filters of each data point is calculated as the median filtering calculation result for that point.

3. System Design and Construction

4. Experimental Process and Results

4.1. Taper-Cutting Experiment and Comparison of Results

4.2. Application—Microprism Array Preparation

5. Conclusions

- (1)

- An integrated cutting and measurement platform was designed by using an angular displacement stage to adjust the posture of the workpiece, using a spectral confocal sensor to measure the slope of the workpiece and adjusting it in real time so as to realize the tool’s oblique downward removal of the material and obtain high-quality concavity in the slot used for observation and measurement.

- (2)

- A small white light sensor was used for in situ observation and integrated into the integrated cutting and measurement platform to directly obtain the three-dimensional shape information of the material, thus aiming at the problem of brittleness by removing the regional distortion, optimizing the white light solution, and improving the display effect. The surface was leveled, and the BDTD of the material could be quickly and accurately obtained.

- (3)

- An experimental platform was built, and the results were compared with those of an ultra-precision machining tool to prove that the platform was stable and reliable and that the proposed measurement evaluation method was feasible. At the same time, the platform was also shown to be able to perform high-precision preparation of microstructure arrays.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, F.Z.; Zhang, X.D.; Weckmann, A.; Zhang, G.X.; Evans, C. Manufacturing and measurement of freeform optics. CIRP Ann. Manuf. 2013, 62, 823–846. [Google Scholar] [CrossRef]

- Hatefi, S.; Abou-El-Hossein, K. Review of single-point diamond turning process in terms of ultra-precision optical surface roughness. Int. J. Adv. Manuf. Technol. 2020, 106, 2167–2187. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, L.; Wang, Y.; Lin, B.; Shi, C. Mechanism study on ultrasonic vibration assisted face grinding of hard and bright materials. J. Manuf. Process. 2020, 50, 520–527. [Google Scholar] [CrossRef]

- Zhou, M.; Zhao, P. Prediction of critical cutting depth for ductile-brittle transition in ultrasonic vibration assisted grinding of optical glasses. Int. J. Adv. Manuf. Technol. 2016, 86, 1775–1784. [Google Scholar] [CrossRef]

- Kurita, M.; Tokoro, H.; Takahashi, K.; Kino, M. A new manufacturing system for free form and large optics. Adv. Opt. Mech. Technol. Telesc. Instrum. IV 2020, 86, 1775–1784. [Google Scholar]

- You, K.; Yan, G.; Luo, X.; Gilchrist, M.D.; Fang, F.Z. Advances in laser assisted machining of hard and brittle materials. J. Manuf. Process. 2020, 58, 677–692. [Google Scholar] [CrossRef]

- Fang, F.Z.; Wu, H.; Zhou, W.; Hu, X. A study on mechanism of nano-cutting single crystal silicon. J. Mater. Process. Technol. 2007, 184, 407–410. [Google Scholar] [CrossRef]

- Lawn, B.R.; Borrero-Lopez, O.; Huang, H.; Zhang, H. Micromechanics of machining and wear in hard and brittle materials. J. Am. Ceram. Soc. 2021, 104, 5–22. [Google Scholar] [CrossRef]

- Bifano, T.G.; Dow, T.A.; Scattergood, R.O. Ductile-regime grinding: A new technology for machining brittle materials. J. Eng. Ind. 1991, 113, 184–189. [Google Scholar] [CrossRef]

- Chen, J.B.; Fang, Q.H.; Wang, C.C.; Du, J.K.; Liu, F. Theoretical study on brittle-ductile transition behavior in elliptical ultrasonic assisted grinding of hard brittle materials. Precis. Eng. 2016, 46, 104–117. [Google Scholar] [CrossRef]

- Cheng, J.; Wu, J.; Gong, Y.D.; Wen, X.L.; Wen, Q. Experimental study on the single grit interaction behavior and brittle-ductile transition of grinding with a diamond micro-grinding tool. Int. J. Adv. Manuf. Technol. 2016, 91, 1029–1226. [Google Scholar]

- Huang, H.; Lawn, B.R.; Cook, R.F. Critique of materials—Based models of ductile machining in brittle solids. J. Am. Ceram. Soc. 2020, 103, 6096–6100. [Google Scholar] [CrossRef]

- Lai, M.; Zhang, X.; Fang, F.; Bi, M. Fundamental investigation on partially overlapped nano-cutting of monocrystalline germanium. Precis. Eng. 2017, 49, 160–168. [Google Scholar] [CrossRef]

- Fang, F.Z.; Wu, H.; Liu, Y.C. Modelling and experimental investigation on nanometric cutting of monocrystalline silicon. Int. J. Mach. Tools Manuf. 2005, 45, 1681–1686. [Google Scholar] [CrossRef]

- Xiao, G.; Ren, M.; To, S. A Study of Mechanics in Brittle–Ductile Cutting Mode Transition. Micromachines 2018, 9, 49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Venkatachalam, S.; Li, X.; Liang, S.Y. Predictive modeling of transition undeformed chip thickness in ductile-regime micro-machining of single crystal brittle materials. J. Mater. Process. Technol. 2009, 209, 3306–3319. [Google Scholar] [CrossRef]

- Xiao, G.B.; To, S.; Jelenković, E.V. Effects of non-amorphizing hydrogen ion implantation on anisotropy in micro cutting of silicon. J. Mater. Process. Technol. 2015, 225, 439–450. [Google Scholar] [CrossRef]

- Yan, J.; Asami, T.; Harada, H.; Kuriyagawa, T. Fundamental investigation of subsurface damage in single crystalline silicon caused by diamond machining. Precis. Eng. 2009, 33, 378–386. [Google Scholar] [CrossRef]

- Gu, W.; Zhu, Z.; Zhu, W.; Lu, L.; To, S.; Xiao, G.; Kuriyagawa, T. Identification of the critical depth-of-cut through 2-D image of the cutting region resulted from taper cutting of brittle materials. Meas. Sci. Technol. 2018, 29, 55003. [Google Scholar] [CrossRef]

- Mizumoto, Y.; Maas, P.; Kakinuma, Y.; Min, S. Investigation of the cutting mechanisms and the anisotropic ductility of monocrystalline sapphire. CIRP Ann. Manuf. Technol. 2017, 66, 89–92. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Zhang, Y.; Jia, D.; Zhang, X.; Hou, Y.; Li, R.; Wang, J. Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions. Int. J. Mach. Tools Manuf. 2017, 122, 56–65. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Fang, H.; Tian, R. Influence of cutting parameters on the ductile-brittle transition of single-crystal calcium fluoride during ultra-precision cutting. Int. J. Adv. Manuf. Technol. 2017, 89, 219–225. [Google Scholar] [CrossRef]

- Zhao, W.; Hong, H.; Wang, H. Mechanism of Unstable Material Removal Modes in Micro Cutting of Silicon Carbide. Micromachines 2019, 10, 696. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, W.; Liu, X.; Lu, W.; Yu, N.; Chen, L.; Zhou, L.; Chang, S. A novel white light interference based AFM head. J. Light. Technol. 2017, 35, 3604–3610. [Google Scholar] [CrossRef]

- Fang, F.Z.; Liu, B.; Xu, Z.W. Nanometric cutting in a scanning electron microscope. Precis. Eng. 2015, 41, 145–152. [Google Scholar] [CrossRef]

| Hardware | Travel and Range | Accuracy | Others |

|---|---|---|---|

| X/Y/Z axes | 200 mm | 200 nm | / |

| SC sensor | 55 m | Full-scale | Numerical aperture 45 |

| WLI sensor | 270 m × 337 m | 10 nm | Numerical aperture 40 |

| Parameters | Value |

|---|---|

| Material | Monocrystalline germanium |

| Tool noise radius | 1.507 mm |

| Tool rake angle | 0 |

| Cutting speed | 2 mm/s |

| Tilt angle | ≈1:3000 |

| Maximum cutting depth | 1–2 m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Li, Z.; Zhu, L.; Dong, Y.; Liu, L.; Miao, L.; Zhang, X. A Self-Established “Machining-Measurement-Evaluation” Integrated Platform for Taper Cutting Experiments and Applications. Micromachines 2021, 12, 929. https://doi.org/10.3390/mi12080929

Yang X, Li Z, Zhu L, Dong Y, Liu L, Miao L, Zhang X. A Self-Established “Machining-Measurement-Evaluation” Integrated Platform for Taper Cutting Experiments and Applications. Micromachines. 2021; 12(8):929. https://doi.org/10.3390/mi12080929

Chicago/Turabian StyleYang, Xudong, Zexiao Li, Linlin Zhu, Yuchu Dong, Lei Liu, Li Miao, and Xiaodong Zhang. 2021. "A Self-Established “Machining-Measurement-Evaluation” Integrated Platform for Taper Cutting Experiments and Applications" Micromachines 12, no. 8: 929. https://doi.org/10.3390/mi12080929