A Fast-Responding Electro-Activated Shape Memory Polymer Composite with Embedded 3D Interconnected Graphene Foam

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of 3DGF

2.2. Synthesis of E-SMP

2.3. Preparation of GF-SMP

2.4. Characterization

3. Results and Discussion

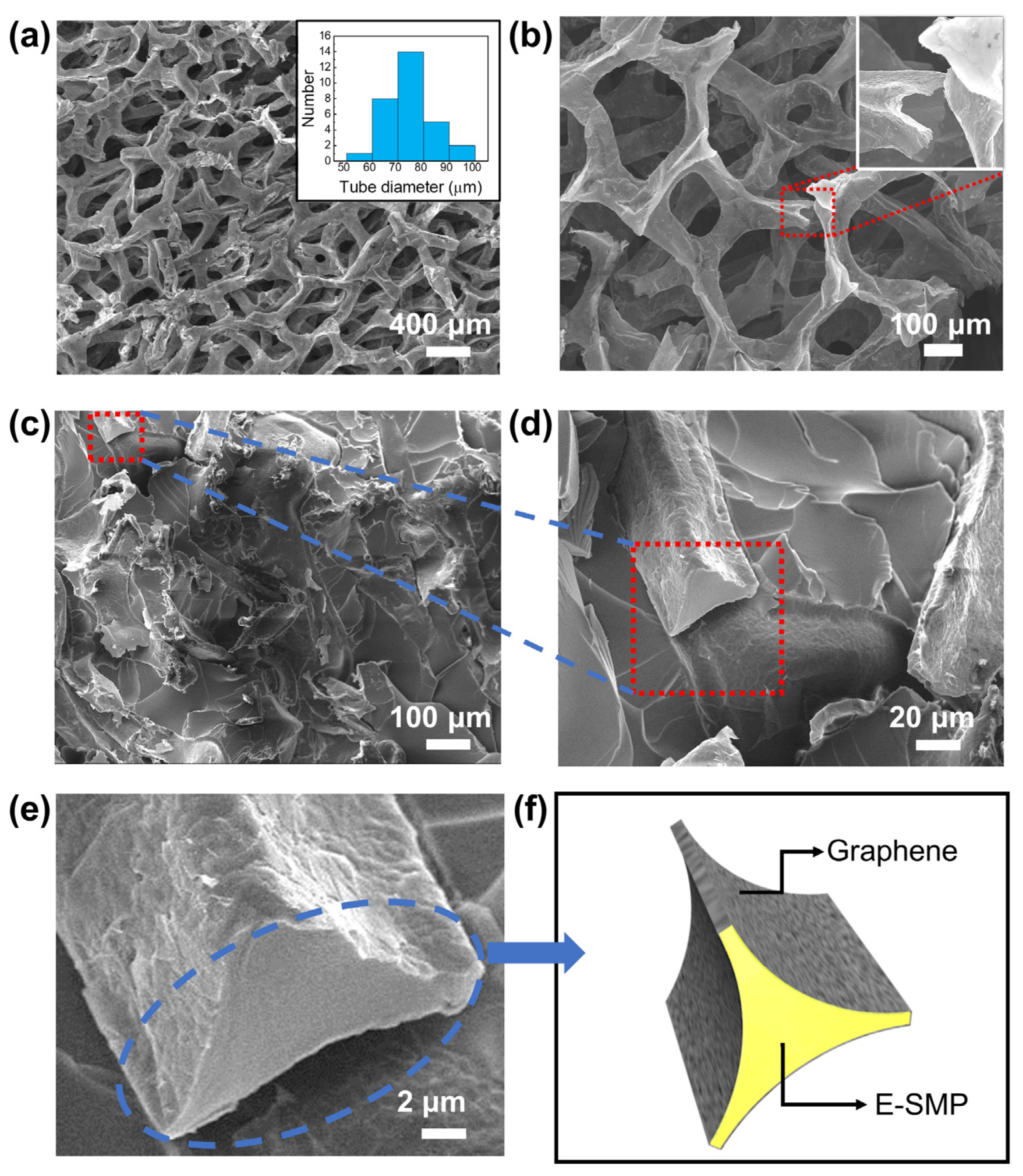

3.1. Microstructure

3.2. Thermal Conductivity

3.3. Electrical Conductivity

3.4. Mechanical Properties

3.5. Shape Memory Performance

3.6. Exhibitions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McCracken, J.M.; Donovan, B.R.; White, T.J. Materials as Machines. Adv. Mater. 2020, 32, 1906564. [Google Scholar] [CrossRef]

- Delaey, J.; Dubruel, P.; Van Vlierberghe, S. Shape-Memory Polymers for Biomedical Applications. Adv. Funct. Mater. 2020, 30, 1909047. [Google Scholar] [CrossRef]

- Ze, Q.; Kuang, X.; Wu, S.; Wong, J.; Montgomery, S.M.; Zhang, R.; Kovitz, J.M.; Yang, F.; Qi, H.J.; Zhao, R. Magnetic Shape Memory Polymers with Integrated Multifunctional Shape Manipulation. Adv. Mater. 2020, 32, 1906657. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-Response, Stiffness-Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Adv. Funct. Mater. 2019, 29, 1806698. [Google Scholar] [CrossRef]

- Herath, H.M.C.M.; Epaarachchi, J.A.; Islam, M.M.; Al-Azzawi, W.; Leng, J.; Zhang, F. Structural performance and photothermal recovery of carbon fibre reinforced shape memory polymer. Sci. Technol. 2018, 167, 206–214. [Google Scholar] [CrossRef]

- Xiao, Y.Y.; Jiang, Z.C.; Tong, X.; Zhao, Y. Biomimetic Locomotion of Electrically Powered “Janus” Soft Robots Using a Liquid Crystal Polymer. Adv. Mater. 2019, 31, 1903452. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, Z.; Li, H.; Li, H.; Xiong, Y.; Zhu, X.; Lan, H.; Ge, Q. Fractal-Based Stretchable Circuits via Electric-Field-Driven Microscale 3D Printing for Localized Heating of Shape Memory Polymers in 4D Printing. ACS Appl. Mater. Interfaces 2021, 13, 41414–41423. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, C.; Zhao, H.; Wang, L. Photothermal-triggered shape memory coatings with active repairing and corrosion sensing properties. J. Mater. Chem. A 2021, 9, 22509–22521. [Google Scholar] [CrossRef]

- Shivakumar, R.; Leong, F.N.; Tsang, S.H.; Teo, E.H.T. Effect of loading fraction of three-dimensional graphene foam (3D-C) on thermal, mechanical, and shape memory properties of 3D-C/SMP composite. Mater. Res. Bull. 2021, 142, 111378. [Google Scholar] [CrossRef]

- Tiwari, N.; Shaikh, A.A.; Malek, N.I. Modification of the multiphase shape memory composites with functionalized graphene nanoplatelets: Enhancement of thermomechanical and interfacial properties. Mater. Today Chem. 2022, 24, 100826. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Schubert, D.W. Highly Sensitive Ultrathin Flexible Thermoplastic Polyurethane/Carbon Black Fibrous Film Strain Sensor with Adjustable Scaffold Networks. Nano-Micro Lett. 2021, 13, 64. [Google Scholar] [CrossRef] [PubMed]

- Cortés, A.; Cosola, A.; Sangermano, M.; Campo, M.; González Prolongo, S.; Pirri, C.F.; Jiménez-Suárez, A.; Chiappone, A. DLP 4D-Printing of Remotely, Modularly, and Selectively Controllable Shape Memory Polymer Nanocomposites Embedding Carbon Nanotubes. Adv. Funct. Mater. 2021, 31, 2106774. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Q.; Bo, Y.; Zhang, C.; Lv, Y.; Fu, X.; He, W.; Fan, X.; Liang, J.; Huang, Y.; et al. Highly Stretchable Shape Memory Self-Soldering Conductive Tape with Reversible Adhesion Switched by Temperature. Nano-Micro. Lett. 2021, 13, 124. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Gao, Y.; Huang, Q.; Guo, X.; Yang, A.; Zhang, Y.; Zhuang, Q.; Chen, D.; Chen, L.; Ju, X.; et al. Inkjet-Printed Xerogel Scaffolds Enabled Room-Temperature Fabrication of High-Quality Metal Electrodes for Flexible Electronics. Adv. Funct. Mater. 2022, 32, 2203730. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Tian, W.; Xie, J.; Liu, Y. Thermoelectric Responsive Shape Memory Graphene/Hydro-Epoxy Composites for Actuators. Micromachines 2016, 7, 145. [Google Scholar] [CrossRef] [PubMed]

- D’Elia, E.; Ahmed, H.S.; Feilden, E.; Saiz, E. Electrically-responsive graphene-based shape-memory composites. Appl. Mater. Today 2019, 15, 185–191. [Google Scholar] [CrossRef]

- Bhawal, P.; Ganguly, S.; Das, T.K.; Mondal, S.; Choudhury, S.; Das, N.C. Superior electromagnetic interference shielding effectiveness and electro-mechanical properties of EMA-IRGO nanocomposites through the in-situ reduction of GO from melt blended EMA-GO composites. Compos. Part. B—Eng. 2018, 134, 46–60. [Google Scholar] [CrossRef]

- Das, T.K.; Bhawal, P.; Ganguly, S.; Mondal, S.; Das, N.C. A facile green synthesis of amino acid boosted Ag decorated reduced graphene oxide nanocomposites and its catalytic activity towards 4-nitrophenol reduction. Surf. Interfaces 2018, 13, 79–91. [Google Scholar] [CrossRef]

- Zaman, I.; Phan, T.T.; Kuan, H.-C.; Meng, Q.; Bao La, L.T.; Luong, L.; Youssf, O.; Ma, J. Epoxy/graphene platelets nanocomposites with two levels of interface strength. Polymer 2011, 52, 1603–1611. [Google Scholar] [CrossRef]

- Keramati, M.; Ghasemi, I.; Karrabi, M.; Azizi, H.; Sabzi, M. Incorporation of surface modified graphene nanoplatelets for development of shape memory PLA nanocomposite. Fiber. Polymer 2016, 17, 1062–1068. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, L.; Shi, J.; Hou, X.; Wang, Q.; Zhang, Y.; Wang, Y.; Bai, N.; Yang, J.; Zhang, J.; et al. Shape-Programmable Interfacial Solar Evaporator with Salt-Precipitation Monitoring Function. ACS Nano 2021, 15, 5752–5761. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; Li, J.; Guo, A.; Xiao, X. High temperature electromagnetic shielding shape memory polymer composite. Chem. Eng. J. 2021, 408, 127365. [Google Scholar] [CrossRef]

- Shao, L.-H.; Zhao, B.; Zhang, Q.; Xing, Y.; Zhang, K. 4D printing composite with electrically controlled local deformation. Extrem. Mech. Lett. 2020, 39, 100793. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.; Zhang, X.; Hasan, S.W.; Tian, Z.Q.; Zhou, J.; Yin, Z. Thermal transport measurement of three-dimensional graphene powders for application in energy devices. Mater. Today Energy 2021, 19, 100582. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, S.; Chen, X.; Tang, T.; Mijowska, E. Three dimensional graphene/carbonized metal-organic frameworks based high-performance supercapacitor. Carbon 2020, 157, 55–63. [Google Scholar] [CrossRef]

- Bo, Z.; Ying, C.; Yang, H.; Wu, S.; Yang, J.; Kong, J.; Yang, S.; Zhou, Y.; Yan, J.; Cen, K. Highly Thermo-Conductive Three-Dimensional Graphene Aqueous Medium. Nano-Micro. Lett. 2020, 12, 138. [Google Scholar] [CrossRef]

- Ben-Shimon, Y.; Reddy, S.K.; Ya’akobovitz, A. Graphene foam resonators: Fabrication and characterization. Nano Res. 2022, 15, 225–229. [Google Scholar] [CrossRef]

- Idowu, A. Graphene Foam Reinforced Shape Memory Polymer Epoxy Composites. Ph.D. Thesis, Florida International University, Miami, FL, USA, 2019. [Google Scholar]

- Fei, W.; Zhou, J.; Guo, W. Low-voltage Driven Graphene Foam Thermoacoustic Speaker. Small 2015, 11, 2252–2256. [Google Scholar] [CrossRef]

- Wu, J.; Xu, H.; Zhang, J. Raman Spectroscopy of Graphene. Acta Chim. Sinica 2014, 72, 301–318. [Google Scholar] [CrossRef]

- Zweid, M.N.; Ubaid, A.Q.; Kamas, A.S. Study of Thermal Conductivity and Hardness Test of Carbon Black / Polymer Micro Composite. J. Phys. Conf. Ser. 2021, 1892, 012003. [Google Scholar] [CrossRef]

- Zambrzycki, M.; Sokolowski, K.; Gubernat, M.; Fraczek-Szczypta, A. Effect of Secondary Carbon Nanofillers on the Electrical, Thermal, and Mechanical Properties of Conductive Hybrid Composites Based on Epoxy Resin and Graphite. Materials 2021, 14, 4169. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Jang, S.; Choi, S.; Yang, J.; Kim, J.; Choi, D. Analysis of Shape Memory Behavior and Mechanical Properties of Shape Memory Polymer Composites Using Thermal Conductive Fillers. Micromachines 2021, 12, 1107. [Google Scholar] [CrossRef] [PubMed]

- Qi, X.; Xiu, H.; Wei, Y.; Zhou, Y.; Guo, Y.; Huang, R.; Bai, H.; Fu, Q. Enhanced shape memory property of polylactide/thermoplastic poly(ether)urethane composites via carbon black self-networking induced co-continuous structure. Compos. Sci. Technol. 2017, 139, 8–16. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, G.; Cui, X.; Liu, T.; Liu, Z.; Wang, K. Electroactive shape memory effect of radiation cross-linked SBS/LLDPE composites filled with carbon black. Colloid Polymer Sci. 2014, 292, 2311–2317. [Google Scholar] [CrossRef]

- Wei, K.; Zhu, G.; Tang, Y.; Li, X. Electroactive shape-memory effects of hydro-epoxy/carbon black composites. Polymer J. 2012, 45, 671–675. [Google Scholar] [CrossRef]

- Yu, K.; Zhang, Z.; Liu, Y.; Leng, J. Carbon nanotube chains in a shape memory polymer/carbon black composite: To significantly reduce the electrical resistivity. Appl. Phys. Lett. 2011, 98, 074102. [Google Scholar] [CrossRef]

- Kausar, A. Physical properties and shape memory behavior of thermoplastic polyurethane/poly(ethylene-alt-maleic anhydride) blends and graphene nanoplatelet composite. Iran. Polymer J. 2016, 25, 945–955. [Google Scholar] [CrossRef]

- Sabzi, M.; Babaahmadi, M.; Rahnama, M. Thermally and Electrically Triggered Triple-Shape Memory Behavior of Poly(vinyl acetate)/Poly(lactic acid) Due to Graphene-Induced Phase Separation. ACS Appl. Mater. Interfaces 2017, 9, 24061–24070. [Google Scholar] [CrossRef] [PubMed]

- Sabzi, M.; Babaahmadi, M.; Samadi, N.; Mahdavinia, G.R.; Keramati, M.; Nikfarjam, N. Graphene network enabled high speed electrical actuation of shape memory nanocomposite based on poly(vinyl acetate). Polymer Int. 2017, 66, 665–671. [Google Scholar] [CrossRef]

- Liu, T.; Huang, R.; Qi, X.; Dong, P.; Fu, Q. Facile preparation of rapidly electro-active shape memory thermoplastic polyurethane/polylactide blends via phase morphology control and incorporation of conductive fillers. Polymer 2017, 114, 28–35. [Google Scholar] [CrossRef]

- Mahapatra, S.S.; Yadav, S.K.; Yoo, H.J.; Ramasamy, M.S.; Cho, J.W. Tailored and strong electro-responsive shape memory actuation in carbon nanotube-reinforced hyperbranched polyurethane composites. Sensor Actuat. B—Chem. 2014, 193, 384–390. [Google Scholar] [CrossRef]

- Liu, X.; Li, H.; Zeng, Q.; Zhang, Y.; Kang, H.; Duan, H.; Guo, Y.; Liu, H. Electro-active shape memory composites enhanced by flexible carbon nanotube/graphene aerogels. J. Mater. Chem. A 2015, 3, 11641–11649. [Google Scholar] [CrossRef]

- Idowu, A.; Boesl, B.; Agarwal, A. 3D graphene foam-reinforced polymer composites—A review. Carbon 2018, 135, 52–71. [Google Scholar] [CrossRef]

- Bustillos, J.; Zhang, C.; Boesl, B.; Agarwal, A. Three-Dimensional Graphene Foam-Polymer Composite with Superior Deicing Efficiency and Strength. ACS Appl. Mater. Interfaces 2018, 10, 5022–5029. [Google Scholar] [CrossRef]

- Chauhan SBhushan, R.K. Improvement in mechanical performance due to hybridization of carbon fiber/epoxy composite with carbon black. Adv. Compos. Hybrid. Mater. 2018, 1, 602–611. [Google Scholar] [CrossRef]

- Kashyap, A.; Singh, N.P.; Arora, S.; Singh, V.; Gupta, V.K. Effect of amino-functionalization of MWCNTs on the mechanical and thermal properties of MWCNTs/epoxy composites. Bull. Mater. Sci. 2020, 43, 43. [Google Scholar] [CrossRef]

- Belmonte, A.; Guzmán, D.; Fernández-Francos, X.; De la Flor, S. Effect of the Network Structure and Programming Temperature on the Shape-Memory Response of Thiol-Epoxy “Click” Systems. Polymers 2015, 7, 2146–2164. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Zhou, J.; Rong, J.; Hu, C. A Fast-Responding Electro-Activated Shape Memory Polymer Composite with Embedded 3D Interconnected Graphene Foam. Micromachines 2022, 13, 1589. https://doi.org/10.3390/mi13101589

Zhou Y, Zhou J, Rong J, Hu C. A Fast-Responding Electro-Activated Shape Memory Polymer Composite with Embedded 3D Interconnected Graphene Foam. Micromachines. 2022; 13(10):1589. https://doi.org/10.3390/mi13101589

Chicago/Turabian StyleZhou, Yucheng, Jianxin Zhou, Jiasheng Rong, and Cong Hu. 2022. "A Fast-Responding Electro-Activated Shape Memory Polymer Composite with Embedded 3D Interconnected Graphene Foam" Micromachines 13, no. 10: 1589. https://doi.org/10.3390/mi13101589

APA StyleZhou, Y., Zhou, J., Rong, J., & Hu, C. (2022). A Fast-Responding Electro-Activated Shape Memory Polymer Composite with Embedded 3D Interconnected Graphene Foam. Micromachines, 13(10), 1589. https://doi.org/10.3390/mi13101589