Comparative Analysis on the Effect of Surface Reflectance for Laser 3D Scanner Calibrator

Abstract

:1. Introduction

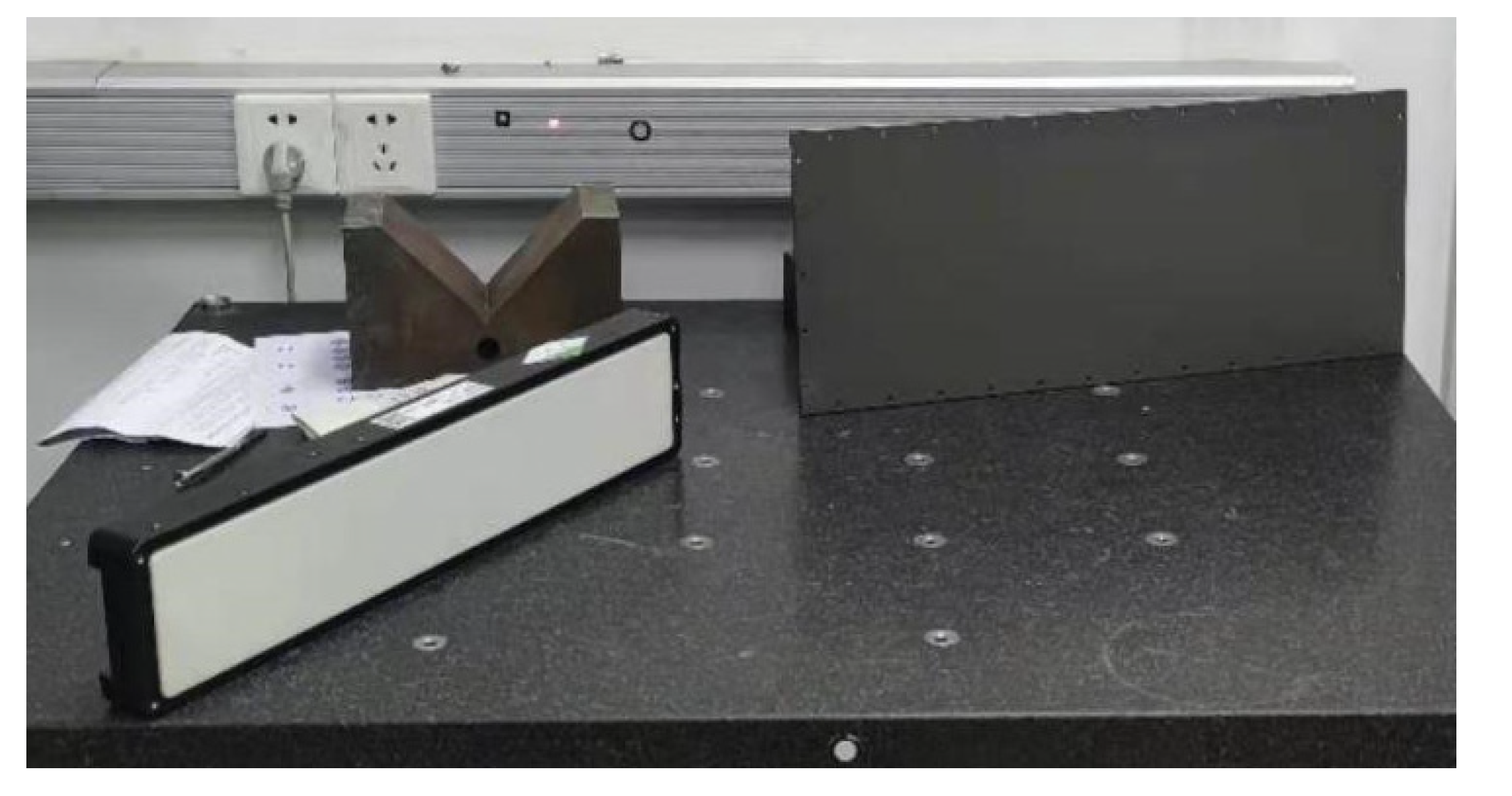

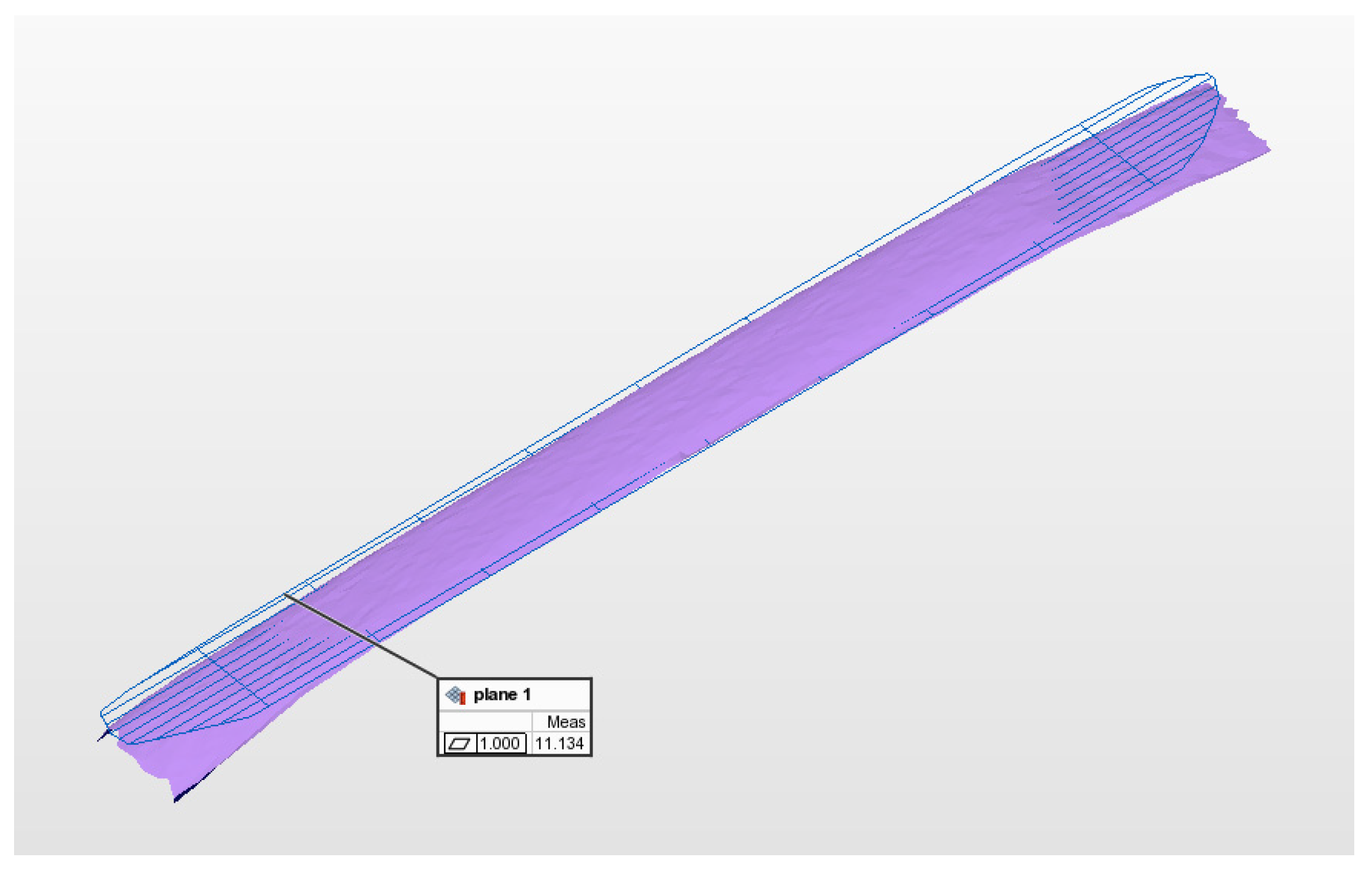

2. Materials and Methods

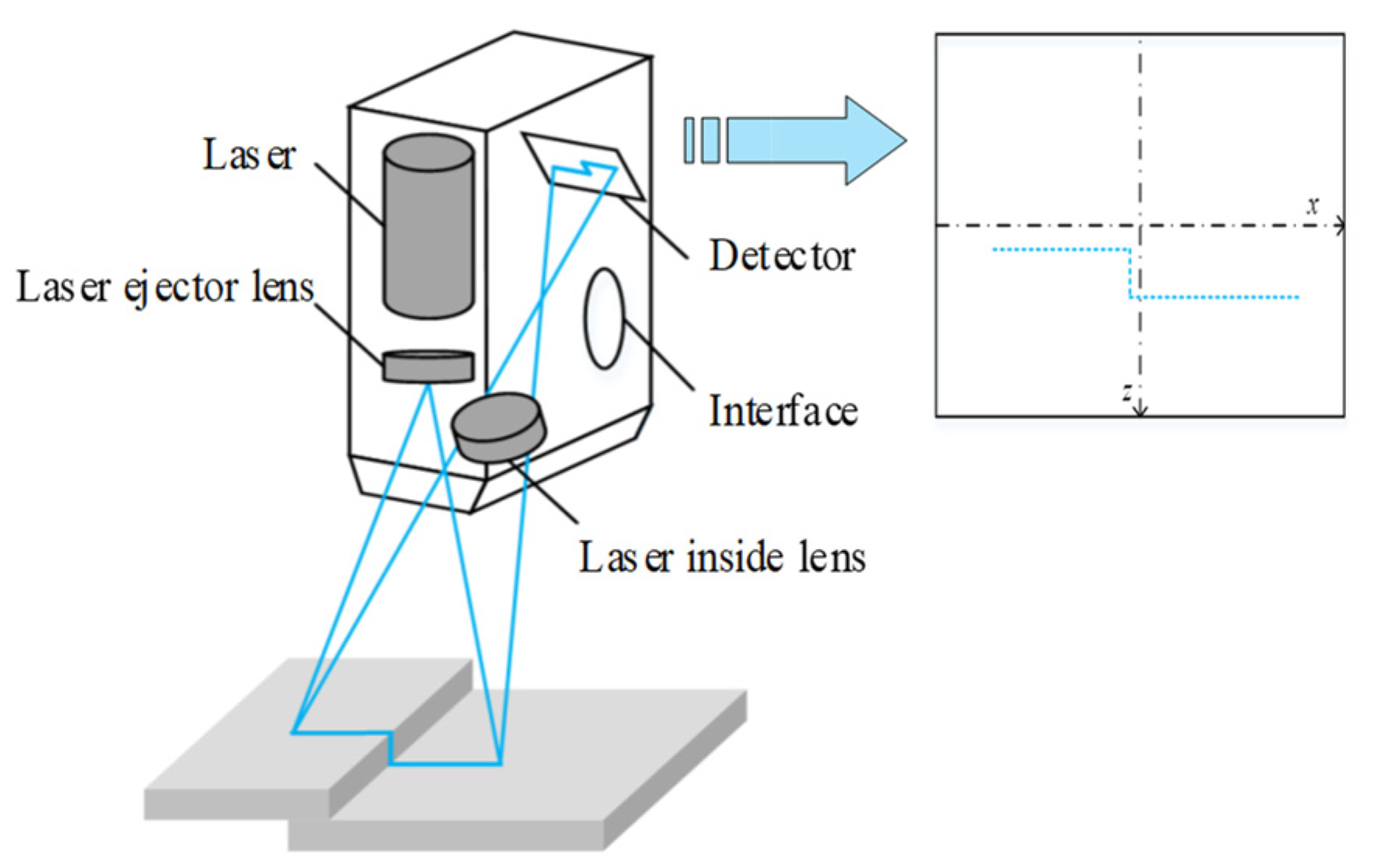

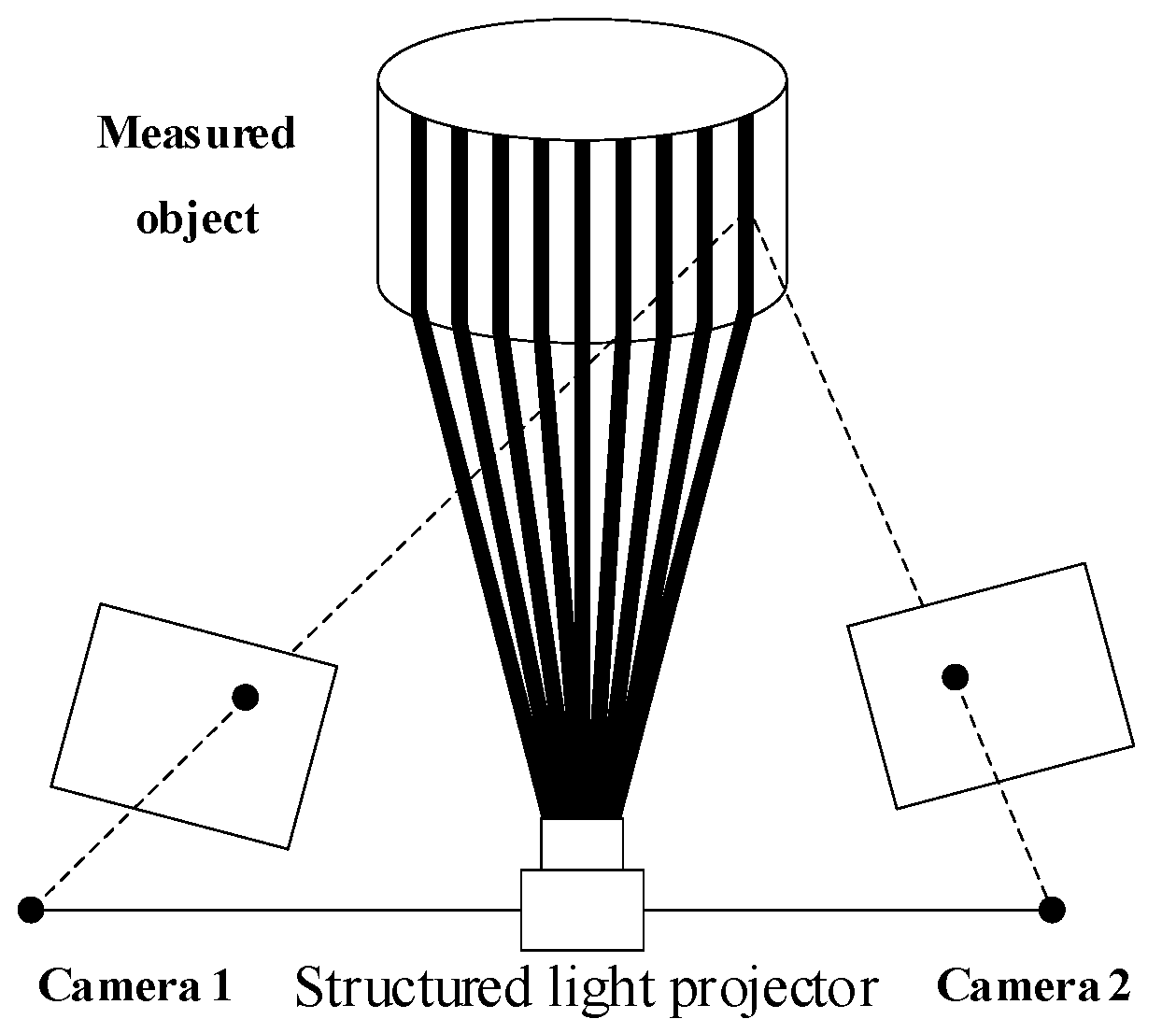

2.1. Principle of Laser Scanning Measurement

2.2. Effect of Incident Angle and Reflectance on 3D Scanning

3. Experiment

3.1. Reflectance Measurement of the Standard Spheres

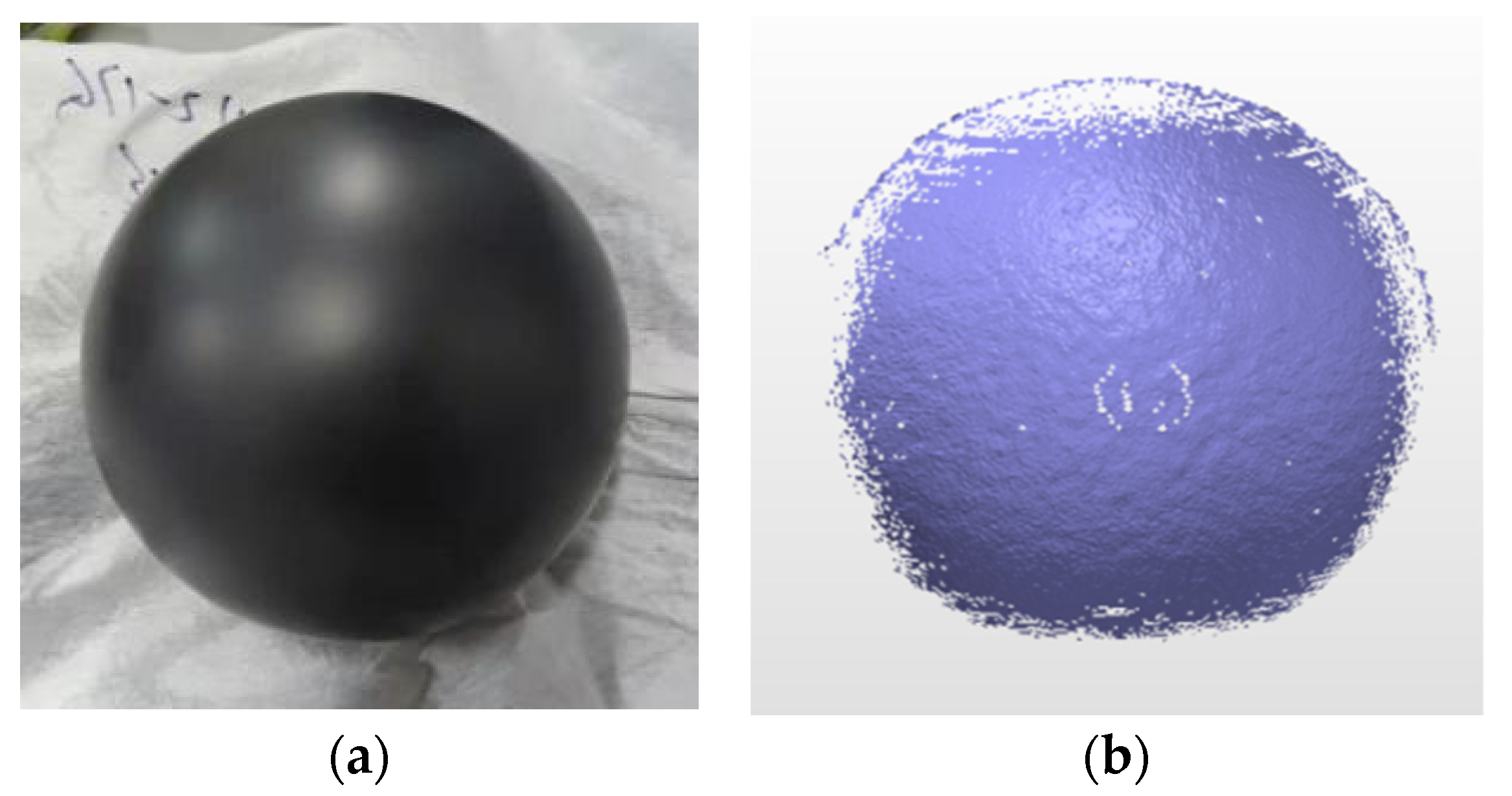

3.2. Calibration Experiment of Ceramic Standard Spheres Scanning with Large Reflectance Difference

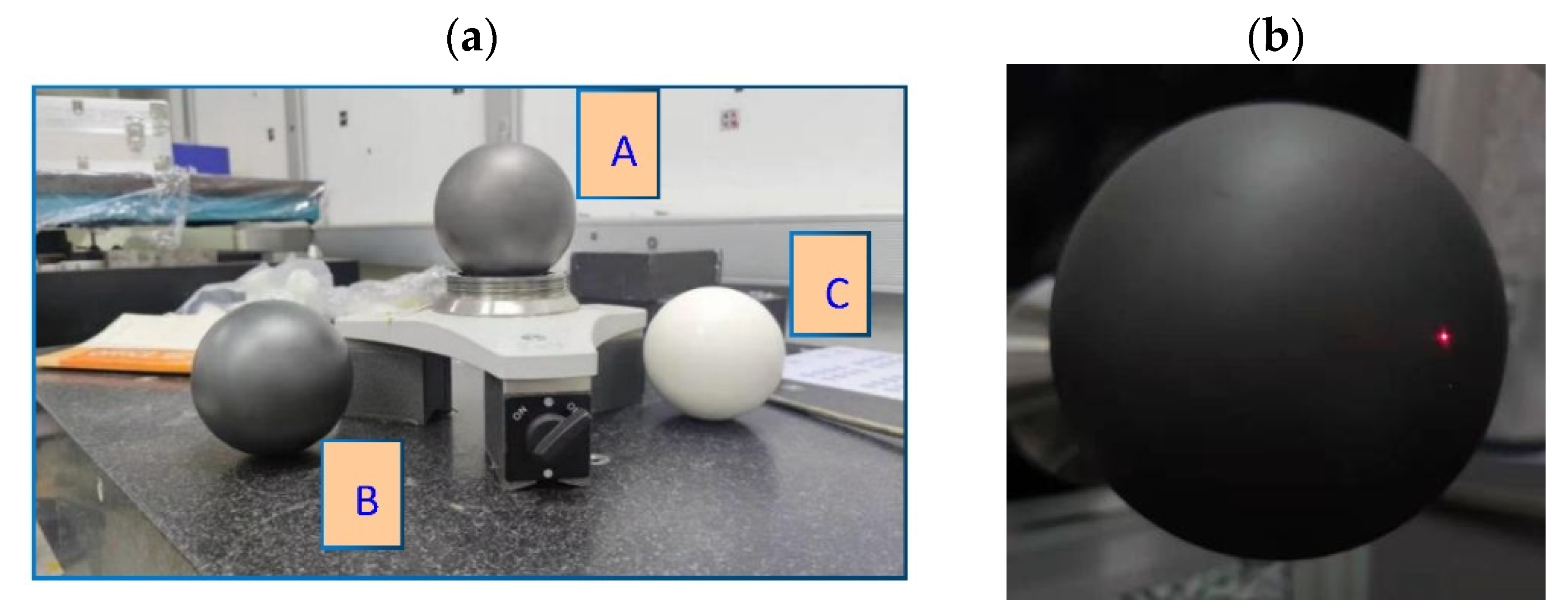

3.3. Standard Spheres Scanning Calibration Experiments for Different Materials and Reflectance

3.4. Contrast Experiment of Plane Scanning

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, Y.; Deng, C.; Wu, X.; Ao, L. Three dimensional measurement system for the dynamic deformation of aero-engine blade profile. Int. J. Artif. Intell. 2020, 29, 2040014. [Google Scholar] [CrossRef]

- Yang, J.; Qi, S.; Wu, W.; Fang, D. A novel sum and difference conical beam-scanning reflector antenna. IEEE Access 2020, 8, 103291–103300. [Google Scholar] [CrossRef]

- Zhu, W.; Qi, G.; Zhang, Q.; Wang, Y.; Ou, J. A non-contact measurement method of cabin capacity based on structured light vision. In Proceedings of the 2016 IEEE International Conference on Mechatronics and Automation, Harbin, China, 7–10 August 2016. [Google Scholar]

- Goba, I.; L’Hostis, G.; Guerlain, P. In-situ non-contact 3D optical deformation measurement of large capacity composite tank based on close-range photogrammetry. Opt. Laser. Eng. 2019, 119, 37–55. [Google Scholar]

- Gong, Q.; Zhu, B. Application analysis of three-dimensional laser scanning technology in engineering surveying and mapping. World Nonferrous Met. 2019. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, D.; Jin, S.; Ren, Y.; Li, Y. On Path Generation Method for Laser Cleaning Robot Based on Line Structured Light. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020. [Google Scholar]

- Tang, Q.; Zhang, G.; Zhang, C.; Zhao, B. Reflection grating spectrometer based on AOTF. In Sixth Symposium on Novel Photoelectronic Detection Technology and Application; SPIE: Bellingham, WA, USA, 2020; Volume 11455, p. 114555Y. [Google Scholar]

- Miao, C.; Tippur, H.V. A simplified reflection-mode digital gradient sensing technique for measuring surface slopes, curvatures and topography. Opt. Laser. Eng. 2020, 124, 105843. [Google Scholar] [CrossRef]

- Wang, R.; Law, A.; Kong, Z.; Garcia, D.; Yang, S. Development of structured light 3d-scanner with high spatial resolution and its applications for additive manufacturing quality assurance. Int. J. Adv. Manuf. Technol. 2021, 117, 845–862. [Google Scholar] [CrossRef]

- Li, W.; Fan, J.; Li, S.; Tian, Z.; Yang, J. Calibrating 3d scanner in the coordinate system of optical tracker for image-to-patient registration. Front. Neurorobotics 2021, 15, 636772. [Google Scholar] [CrossRef]

- Li, F.; Li, H.; Kim, M.K.; Lo, K.C. Laser scanning based surface flatness measurement using flat mirrors for enhancing scan coverage range. Remote Sens. 2021, 13, 714. [Google Scholar] [CrossRef]

- Zaimovic-Uzunovic, N.; Lemes, S. Influences of Surface Parameters on Laser 3D Scanning. In Proceedings of the IMEKO Conference Proceedings: International Symposium on Measurement and Quality Control, Osaka, Japan, 5–9 September 2010; pp. D024–D026. [Google Scholar]

- Wen, Y.; Hu, J.; Pagilla, P.R. A Novel Robotic System for Finishing of Freeform Surfaces. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 5571–5577. [Google Scholar]

- Andrej, C.; Lars, T.; Olav, E. Laser Scanning and Parametrization of Weld Grooves with Reflective Surfaces. Sensors 2021, 21, 479. [Google Scholar]

- David, A.G.; Jesus, M.; David, S.; Karun, V.; Menelaos, K.P. Narrow-angle scatter of reflectivity-suppressing nanostructured surfaces. Opt. Eng. 2020, 59, 103106. [Google Scholar]

- Tania, D.; Kallol, B. Topometry of metal surfaces using reflection of polarized light. Optik 2021, 243, 167448. [Google Scholar]

- Amzajerdian, F. Analysis of Technology for Compact Coherent Lidar, (13 August 1996–30 June 1997). In Farzin Amzajerdian Center For Applied Optics; University of Alabama In Huntsville: Huntsville, AL, USA, 1997. [Google Scholar]

- Zhang, S.; Duan, X.; Zeng, C.; Shi, K.; Zhang, X.; Bi, Q.; Wang, Y. Pose calibration for 2d laser profiler integrated in five-axis machine tools. IOP Conf. Ser. Mater. Sci. Eng. 2020, 831, 012022. [Google Scholar] [CrossRef]

- Madhusudanan, H.; Liu, X.; Chen, W.; Li, D.; Sun, Y. Automated Eye-in-Hand Robot-3D Scanner Calibration for Low Stitching Errors. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May 2020–31 August 2020; pp. 8906–8912. [Google Scholar]

- Xue, J.; Li, G.; Wang, Z.; Xie, X. A novel stripe extraction scheme for the multi-line structured light systems. In Proceedings of the 2021 IEEE International Symposium on Circuits and Systems (ISCAS), Daegu, Korea, 22–28 May 2021; pp. 1–5. [Google Scholar]

- Oh, S.H.; Park, J.S.; Ryu, J.J.; Song, I.S.; Jung, S.K. Three-dimensional reproducibility of the soft tissue landmarks taken by structured-light facial scanner in accordance with the head position change. Healthcare 2021, 9, 428. [Google Scholar] [CrossRef]

- Tian, B. Application of terrestrial laser scanning (tls) in the architecture, engineering and construction (aec) industry. Sensors 2021, 22, 265. [Google Scholar]

- Carrea, D.; Abellan, A.; Humair, F.; Matasci, B.; Derron, M.H.; Jaboyedoff, M. Correction of terrestrial lidar intensity channel using oren–nayar reflectance model: An application to lithological differentiation. Isprs. J. Photogramm. 2016, 113, 17–29. [Google Scholar] [CrossRef]

- Xia, G.F.; Chun-Mei, H.U.; Cao, B.Z.; Tian-Shuo, L.I. Study on the influence of laser incident angle on the reflection intensity of the point cloud. Laser J. 2016, 37, 11–13. (In Chinese) [Google Scholar]

- Tirelli, C.; Manzo, C.; Curci, G.; Bassani, C. Evaluation of the aerosol type effect on the surface reflectance retrieval using chris/proba images over land. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2015, XL-7/W3, 1311–1316. [Google Scholar] [CrossRef]

- Mukupa, W.; Roberts, W.R.; Hancock, C.M.; Almanasir, K. Correction of Terrestrial LiDAR Data Using a Hybrid Model. Int. Fed. Surv. 2017, 1–27. [Google Scholar]

- Shourt, W.V.; Besuner, R.; Silber, J.; Dunlop, P.; Tarle, G. Precision alignment and integration of DESI’s focal plane using a laser tracker. In Ground-Based and Airborne Telescopes VIII; SPIE: Bellingham, WA, USA, 2020. [Google Scholar]

- Nfmk, A.; Pm, B.; Res, A.; Ejwa, B.; Mpb, C. Assessing firmness in mango comparing broadband and miniature spectrophotometers—Sciencedirect. Infrared Phys. Technol. 2021, 115, 103733. [Google Scholar]

- Pan, B.Z.; Tang, J. Best-fitting sphere of aspheric surface based on spherical aberration. Opt. Rev. 2020, 27, 332–338. [Google Scholar] [CrossRef]

- Lou, L.; Tang, K.; Fang, Z.; Wang, Y.; Chen, B.; Guo, T.; Feng, X.; Liu, S.; Wang, W.; Zheng, Y. 14.2 An early fusion complementary RADAR-LiDAR TRX in 65nm CMOS supporting gear-shifting subcm resolution for smart sensing and imaging. In Proceedings of the 2021 IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 13–22 February 2021; pp. 220–222. [Google Scholar]

- Fang, Z.; Lou, L.; Tang, K.; Wang, W.; Wang, Y.; Guo, T.; Yang, C.; Zheng, Y. Wide Field-of-View Locating and Multimodal Vital Sign Monitoring Based on X -Band CMOS-Integrated Phased-Array Radar Sensor. IEEE Trans. Microw. Theory Technol. 2020, 68, 4054–4065. [Google Scholar] [CrossRef]

- Fang, Z.; Tang, K.; Lou, L.; Wang, W.; Chen, B.; Wang, Y.; Zheng, Y. A Silicon-Based Adaptable Edge Coherent Radar Platform for Seamless Health Sensing and Cognitive Interactions with Human Subjects. IEEE Trans. Biomed. Circuits Syst. 2022, 16, 138–152. [Google Scholar] [CrossRef] [PubMed]

| No. | Materials | Surface Treatment | Surface Reflectance |

|---|---|---|---|

| 1 | Metal | Matte | 15% |

| 2 | Ceramics (black) | Matte | 11% |

| 3 | Ceramics (white) | Matte | 60% |

| Materials | Pts | Diameter | Deviation | RMS | RMS Fixed Radius |

|---|---|---|---|---|---|

| Metal | 862 | 101.463 | −0.137 | 0.009 | 0.011 |

| Ceramics (black) | 949 | 101.313 | −0.287 | 0.013 | 0.019 |

| Ceramics (white) | 892 | 99.709 | −0.291 | 0.099 | 0.102 |

| Materials | Surface Treatment | Surface Reflectance | RMS | RMS Fixed Radius |

|---|---|---|---|---|

| Metal | Matte | 15% | 0.009 | 0.011 |

| Ceramics (black) | Matte | 11% | 0.013 | 0.019 |

| Ceramics (white) | Matte | 60% | 0.099 | 0.102 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ou, J.; Xu, T.; Gan, X.; He, X.; Li, Y.; Qu, J.; Zhang, W.; Cai, C. Comparative Analysis on the Effect of Surface Reflectance for Laser 3D Scanner Calibrator. Micromachines 2022, 13, 1607. https://doi.org/10.3390/mi13101607

Ou J, Xu T, Gan X, He X, Li Y, Qu J, Zhang W, Cai C. Comparative Analysis on the Effect of Surface Reflectance for Laser 3D Scanner Calibrator. Micromachines. 2022; 13(10):1607. https://doi.org/10.3390/mi13101607

Chicago/Turabian StyleOu, Jia, Tingfa Xu, Xiaochuan Gan, Xuejun He, Yan Li, Jiansu Qu, Wei Zhang, and Cunliang Cai. 2022. "Comparative Analysis on the Effect of Surface Reflectance for Laser 3D Scanner Calibrator" Micromachines 13, no. 10: 1607. https://doi.org/10.3390/mi13101607

APA StyleOu, J., Xu, T., Gan, X., He, X., Li, Y., Qu, J., Zhang, W., & Cai, C. (2022). Comparative Analysis on the Effect of Surface Reflectance for Laser 3D Scanner Calibrator. Micromachines, 13(10), 1607. https://doi.org/10.3390/mi13101607