The Effect of Fin Shape on the Heat Transfer and the Solution Time of a Microchannel Evaporator in a CO2 Air Conditioning System—A Numerical Investigation

Abstract

1. Introduction

2. Methodology

2.1. Design of Evaporator Model

2.2. Mathematical Model

2.3. Numerical Simulation

2.4. Experimental Setup

3. Results and Discussion

4. Conclusions

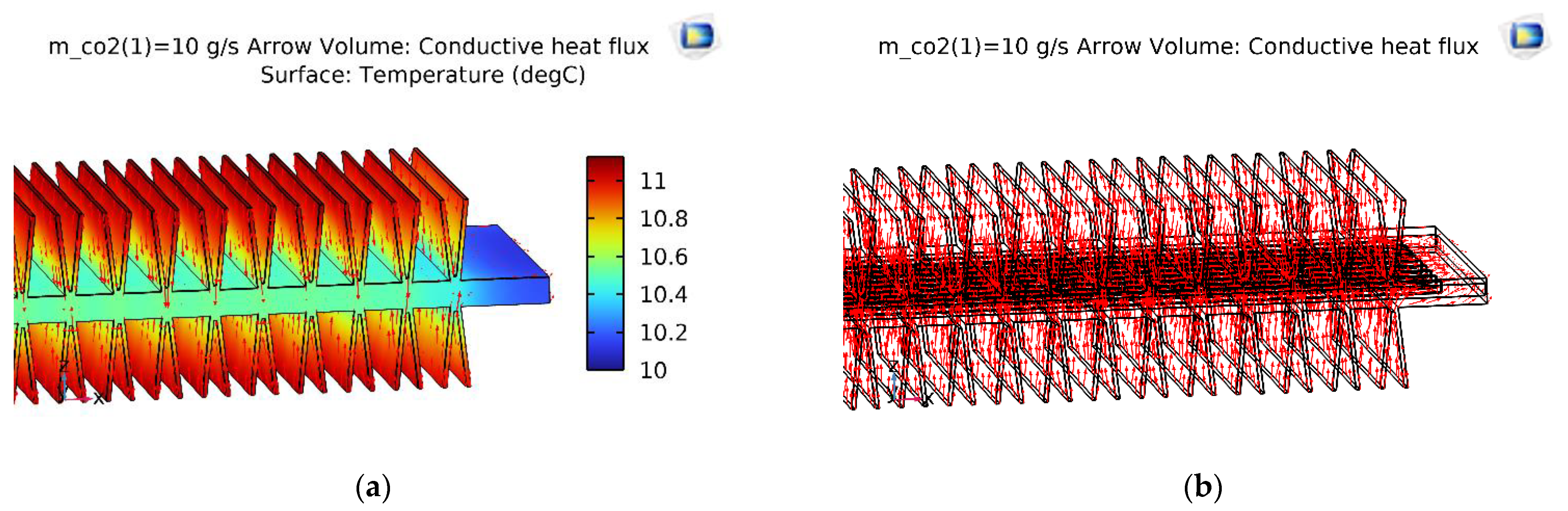

- The mathematical model, the boundary conditions, the meshing method and the PARDISO solver were applied to numerically simulate a microchannel evaporator model. The numerical results were in good agreement with those obtained from the experimental results, with an error of less than 10%.

- For the system under consideration and for the same heat transfer area and the heat transfer coefficient for the air side, the effect of the fin shape on the heat transfer of a microchannel evaporator was not different. However, the solution time and the physical memory for the straight fins were 1.3 and 1.45 times those of the V-fins, respectively. Under the same conditions, the V-fin shape should be used for numerical simulation and not the straight fin shape.

- The evaporation of the refrigerant in the microchannel evaporator took place in four passes. The normal heat flux from the air through the fins and tubes was almost reached at 1550 W/m2 at the evaporative temperature of 10 °C.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, M.H.; Bullard, C.W. Air-side performance of brazed aluminum heat exchangers under dehumidifying conditions. Int. J. Refrig. 2002, 25, 924–934. [Google Scholar] [CrossRef]

- Kim, M.; Bullard, C.W. Air-side thermal hydraulic performance of multi-louvered fin aluminum heat exchangers. Int. J. Refrig. 2002, 25, 390–400. [Google Scholar] [CrossRef]

- Okbaz, A.; Pınarbaşı, A.; Olcay, A.B. Experimental investigation of effect of different tube row-numbers, fin pitches and operating conditions on thermal and hydraulic performances of louvered and wavy finned heat exchangers. Int. J. Therm. Sci. 2020, 151, 106256. [Google Scholar] [CrossRef]

- Ayad, F.; Benelmir, R.; Idris, M. Thermal-hydraulic experimental study of louvered fin-and-flat-tube heat exchanger under wet conditions with variation of inlet humidity ratio. Appl. Therm. Eng. 2021, 183, 116218. [Google Scholar] [CrossRef]

- Hsieh, C.T.; Jang, J.Y. Parametric study and optimization of louver finned-tube heat exchangers by Taguchi method. Appl. Therm. Eng. 2012, 42, 101–110. [Google Scholar] [CrossRef]

- Jang, J.Y.; Chen, C.C. Optimization of louvered-fin heat exchanger with variable louver angles. Appl. Therm. Eng. 2015, 91, 138–150. [Google Scholar] [CrossRef]

- Kim, M.H.; Pettersen, J.; Bullard, C.W. Fundamental process and system design issues in CO2 vapor compression systems. Prog. Energy Combust. Sci. 2004, 30, 119–174. [Google Scholar] [CrossRef]

- Choi, K.I.; Pamitran, A.S.; Oh, J.T. Two-phase flow heat transfer of CO2 vaporization in smooth horizontal minichannels. Int. J. Refrig. 2007, 30, 767–777. [Google Scholar] [CrossRef]

- Brix, W.; Kærn, M.R.; Elmegaard, B. Modelling distribution of evaporating CO2 in parallel minichannels. Int. J. Refrig. 2010, 33, 1086–1094. [Google Scholar] [CrossRef]

- Nguyen, T.; Dang, T.; Vo, K. Experimental Investigation on a Microchannel Evaporator of CO2 Air Conditioning System with an Internal Heat Exchanger. Int. J. Emerg. Res. Manag. Technol. 2017, 6, 40–45. [Google Scholar] [CrossRef]

- Jin, J.; Chen, J.; Chen, Z. Development and validation of a microchannel evaporator model for a CO2 air-conditioning system. Appl. Therm. Eng. 2011, 31, 137–146. [Google Scholar] [CrossRef]

- Yun, R.; Kim, Y.; Park, C. Numerical analysis on a microchannel evaporator designed for CO2 air-conditioning systems. Appl. Therm. Eng. 2007, 27, 1320–1326. [Google Scholar] [CrossRef]

- Kim, M.H.; Bullard, C.W. Development of a microchannel evaporator model for a CO2 air-conditioning system. Energy 2001, 26, 931–948. [Google Scholar] [CrossRef]

- Dang, T.; Teng, J.T. Comparison on the heat transfer and pressure drop of the microchannel and minichannel heat exchangers. Heat Mass Transf. 2011, 47, 1311–1322. [Google Scholar] [CrossRef]

- Dang, T.; Teng, J.; Chu, J. A study on the simulation and experiment of a microchannel counter-flow heat exchanger. Appl. Therm. Eng. 2010, 30, 2163–2172. [Google Scholar] [CrossRef]

- Patiño, J.; Llopis, R.; Sánchez, D.; Sanz-Kock, C.; Cabello, R.; Torrella, E. A comparative analysis of a CO2 evaporator model using experimental heat transfer correlations and a flow pattern map. Int. J. Heat Mass Transf. 2014, 71, 361–375. [Google Scholar] [CrossRef]

- Yang, J.; Ning, S. Experimental and Numerical Study of Double-Pipe Evaporators Designed for CO2 Transcritical Systems. Processes 2019, 7, 547. [Google Scholar] [CrossRef]

- Comsol Software, M. Heat Transfer Module, Version 6.0, 2021, Inc. 100 District Avenue Burlington, MA 01803, USA. Available online: https://www.comsol.com/heat-transfer-module (accessed on 30 June 2022).

- EES. Engineering Equation Solver; F-Chart MdthaSoftware Inc.: Madison, WI, USA, 2005; Available online: https://fchartsoftware.com/ees/ (accessed on 30 June 2022).

- REFPROP. REFPROP. NIST Refrigerant Properties Database 23; Version 9; Gaithersburg, MD, USA, 2013. Available online: https://www.nist.gov/srd/refprop (accessed on 30 June 2022).

- Dorin. Mario Dorin innovation, Compiobbi (FI), Italy, Version 19.1. [Online]. Available online: https://www.dorin.com/en/Software/ (accessed on 30 June 2022).

| Name | Specifications of Straight Fin | Specifications of V-Fin |

|---|---|---|

| Heat transfer area of evaporator (m2) | 2.5 | 2.5 |

| Evaporator Size (L × H × W) (mm) | 330 × 285 × 16 | 330 × 285 × 16 |

| Flat tube size (mm) | 1.3 × 300 × 16 | 1.3 × 300 × 16 |

| Number of microchannels in a flat tube | 10 | 10 |

| Microchannel size (mm) | 0.6 × 1.2 | 0.6 × 1.2 |

| Fin size (mm) | 4.1 × 0.1 × 16 | 4.05 × 0.1 × 16 |

| Fin pitch (mm) | 1.1 | 1.1 |

| Angle of fin (deg) | 0° | 13.8° |

| Number of fins per flat tube | 536 | 536 |

| Heat transfer area of a flat tube (m2) | 81.3 × 10−3 | 81.3 × 10−3 |

| Number of flat tubes in each pass | 3-4-5-6-6-5 | 3-4-5-6-6-5 |

| Pass Number | Inlet Parameter | Outlet Parameter |

|---|---|---|

| 1 | T1_i = 10 °C, p1_i = 45 bar; Ta = 25 °C, ha = 110 W/(m2K) x1_i = 0.61, mp_1 = 30/3 = 10 g/s | T1_o, p1_o, x1_o |

| 2 | T1_o, p1_o Ta = 25 °C, ha = 110 W/(m2K) x2_i = x1_o, mp_2 = 30/4 = 7.5 g/s | T2_o, p2_o, x2_o |

| 3 | T2_o, p2_o Ta = 25 °C, ha = 110 W/(m2K) x3_i = x2_o, mp_3 = 30/5 = 6 g/s | T3_o, p3_o, x3_o |

| 4 | T3_o, p3_o Ta = 25 °C, ha = 110 W/(m2K) x4_i = x3_o, mp_3 = 30/6 = 5 g/s | T4_o, p4_o, x4_o |

| Testing Apparatus | Accuracy | Range |

|---|---|---|

| Infrared thermal camera, Fluke Ti9 | 2% | −20~250 °C |

| Thermometer, Extech 421,509 | 0.75% of rdg | −20~250 °C |

| Thermocouples, T—Type | ±0.1 °C | 0~100 °C |

| Digital volumetric flow rate meter | ±0.5% FS | 400 to 5000 l/h |

| Pressure sensor, SENSYS—Korea | ±0.5 FS | 0~100 bar |

| Types | All Domains (Elements) | All Boundaries (Elements) | Solution Time (s) | Physical Memory (GB) |

|---|---|---|---|---|

| Straight fins | 601,833 | 121,428 | 1653 | 9.7 |

| V-fins | 618,006 | 122,592 | 1268 | 6.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.; Dang, T. The Effect of Fin Shape on the Heat Transfer and the Solution Time of a Microchannel Evaporator in a CO2 Air Conditioning System—A Numerical Investigation. Micromachines 2022, 13, 1648. https://doi.org/10.3390/mi13101648

Nguyen T, Dang T. The Effect of Fin Shape on the Heat Transfer and the Solution Time of a Microchannel Evaporator in a CO2 Air Conditioning System—A Numerical Investigation. Micromachines. 2022; 13(10):1648. https://doi.org/10.3390/mi13101648

Chicago/Turabian StyleNguyen, Tronghieu, and Thanhtrung Dang. 2022. "The Effect of Fin Shape on the Heat Transfer and the Solution Time of a Microchannel Evaporator in a CO2 Air Conditioning System—A Numerical Investigation" Micromachines 13, no. 10: 1648. https://doi.org/10.3390/mi13101648

APA StyleNguyen, T., & Dang, T. (2022). The Effect of Fin Shape on the Heat Transfer and the Solution Time of a Microchannel Evaporator in a CO2 Air Conditioning System—A Numerical Investigation. Micromachines, 13(10), 1648. https://doi.org/10.3390/mi13101648