Progress in the Preparation and Characterization of Convex Blazed Gratings for Hyper-Spectral Imaging Spectrometer: A Review

Abstract

1. Introduction

2. Functions and Applications of Convex Blazed Gratings

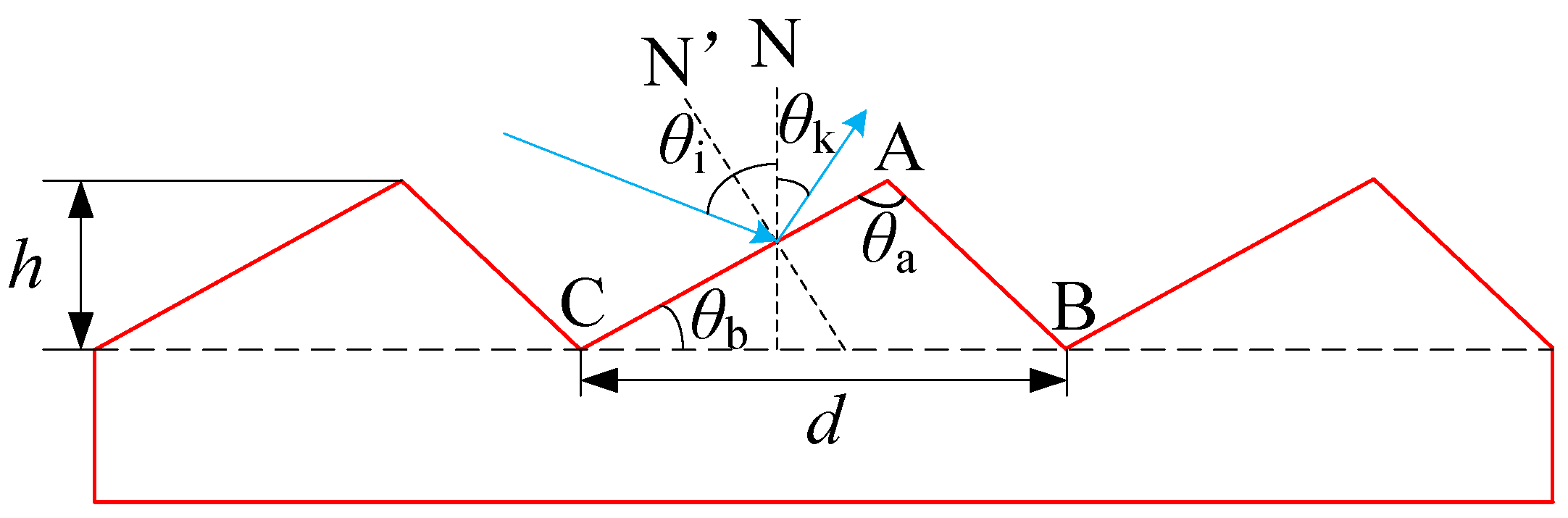

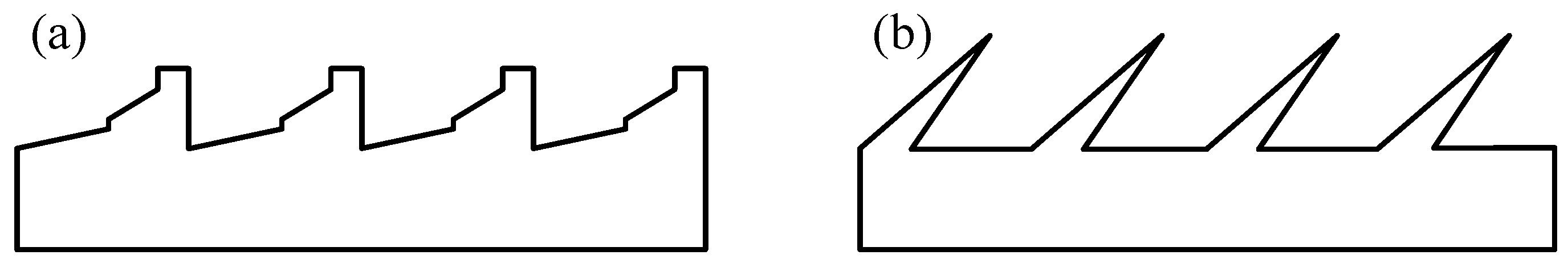

2.1. The Effect of Grating Groove Shape on the Spectral Range

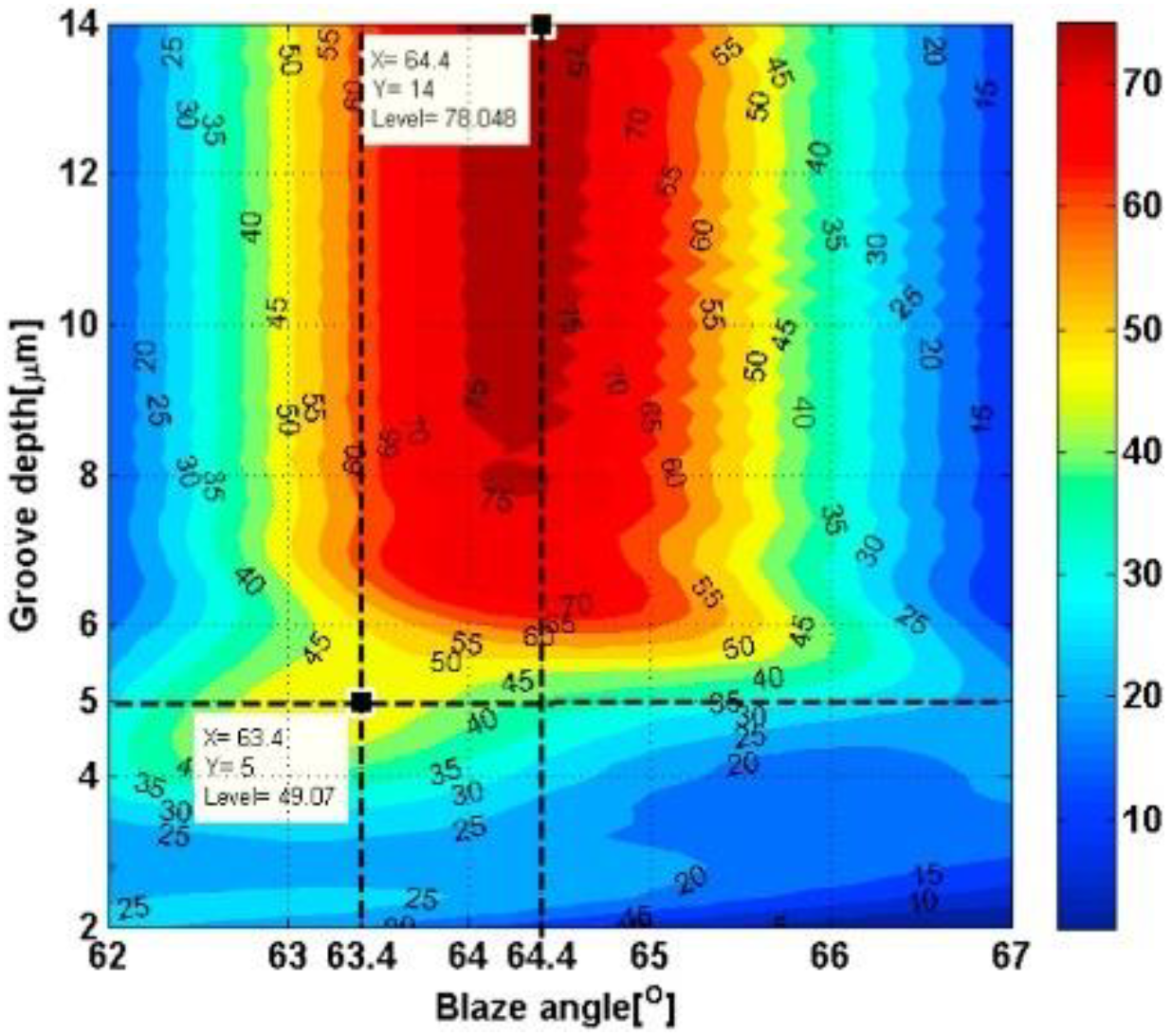

2.2. Effect of Grating Structure Parameters on Diffraction Efficiency

3. Fabrication Capability of Convex Blazed Gratings

3.1. High-Energy Density Beam Processing

3.1.1. Electron Beam Lithography

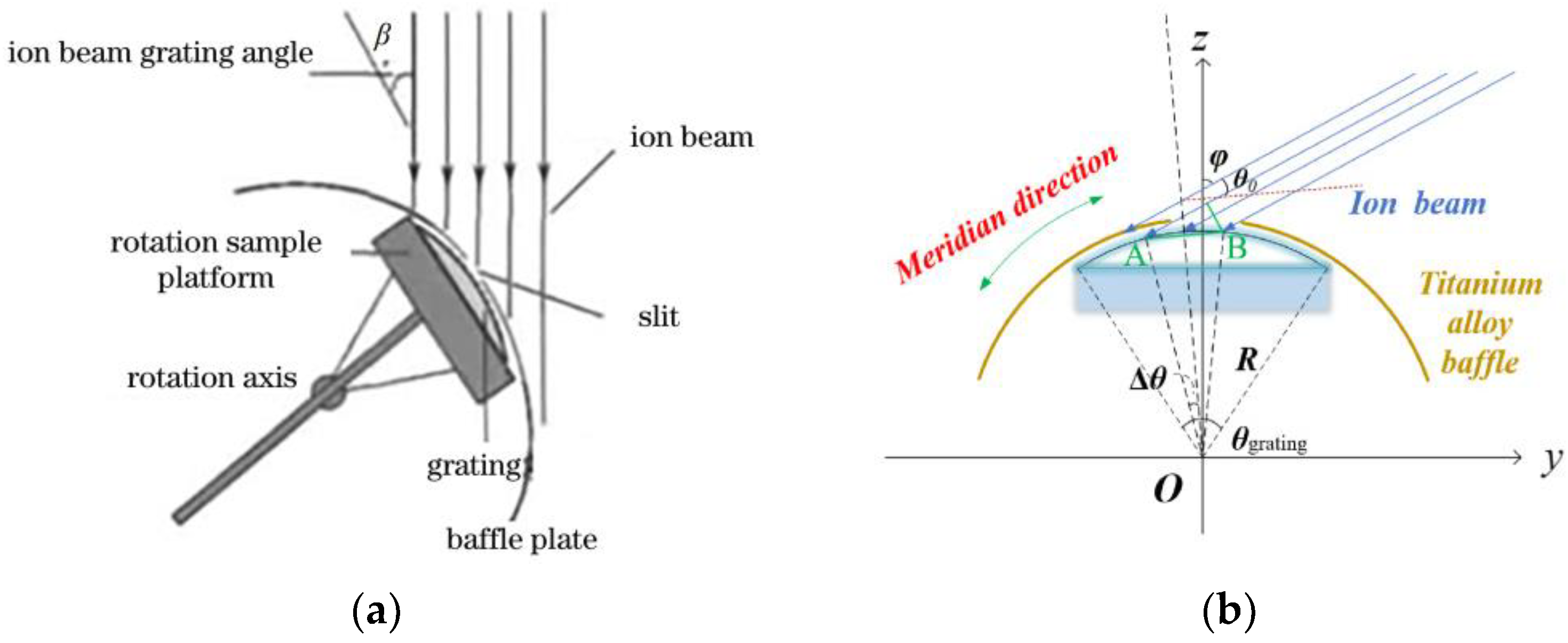

3.1.2. Ion Beam Etching

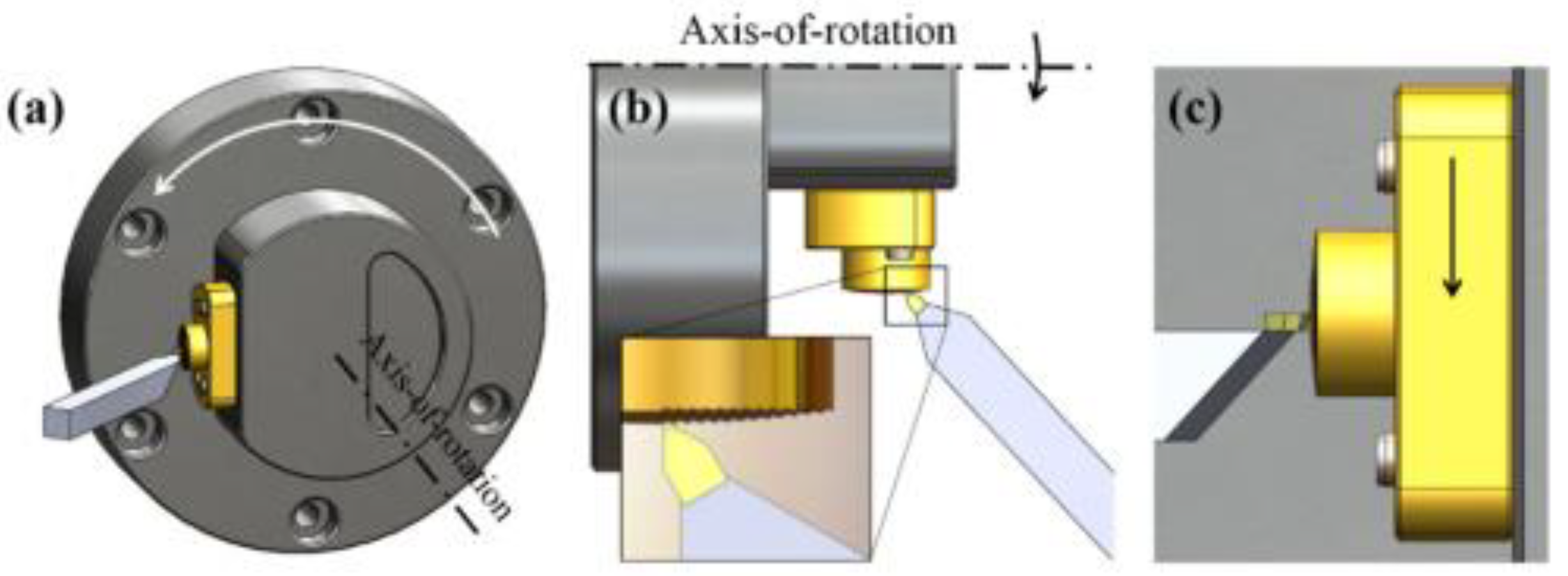

3.2. Ultra-Precision Machining Technology

3.3. Chemically Assisted Manufacturing Process

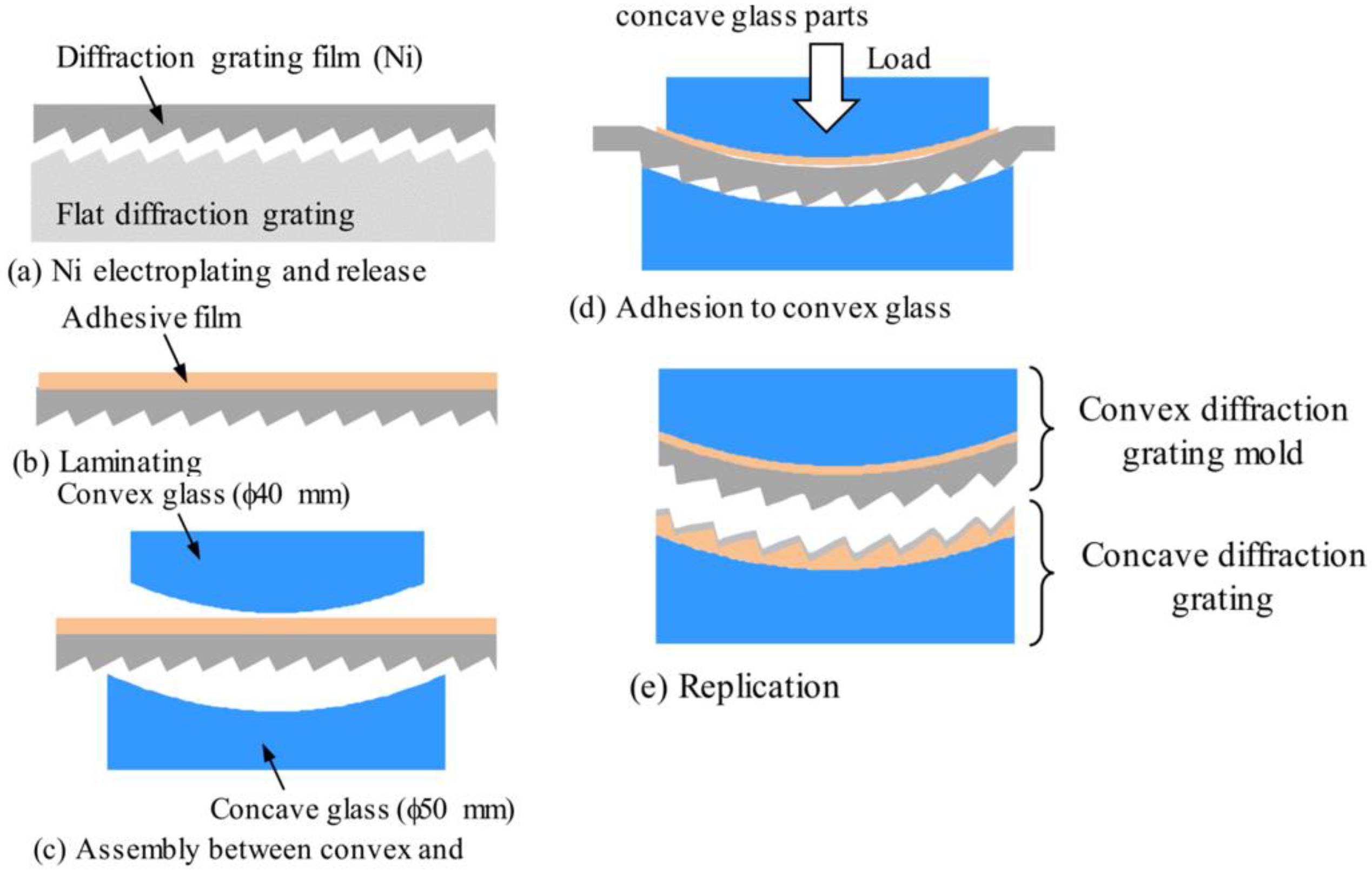

3.4. Other Feasible Processes

4. Adaptability of Manufacturing Processes at Different Scales (Summary of Processing Limits)

5. Quality Characterization of Convex Blazed Gratings for Hyper-Spectral Imaging Spectrometer

5.1. Contact Measurement

5.2. Non-Contact Measurement

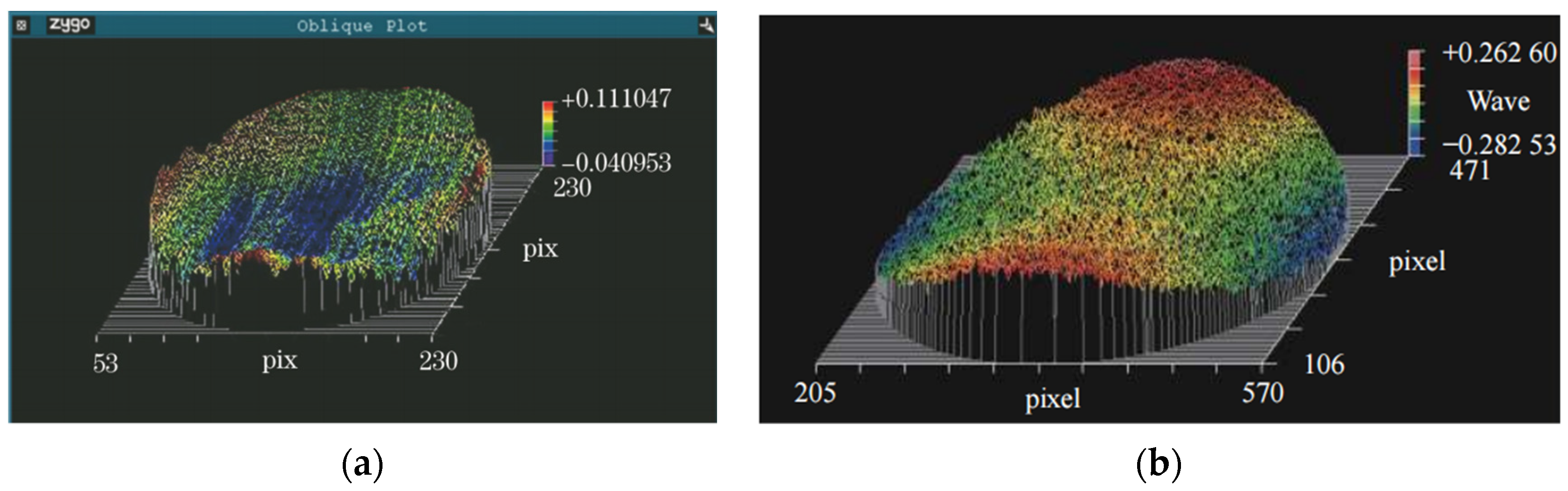

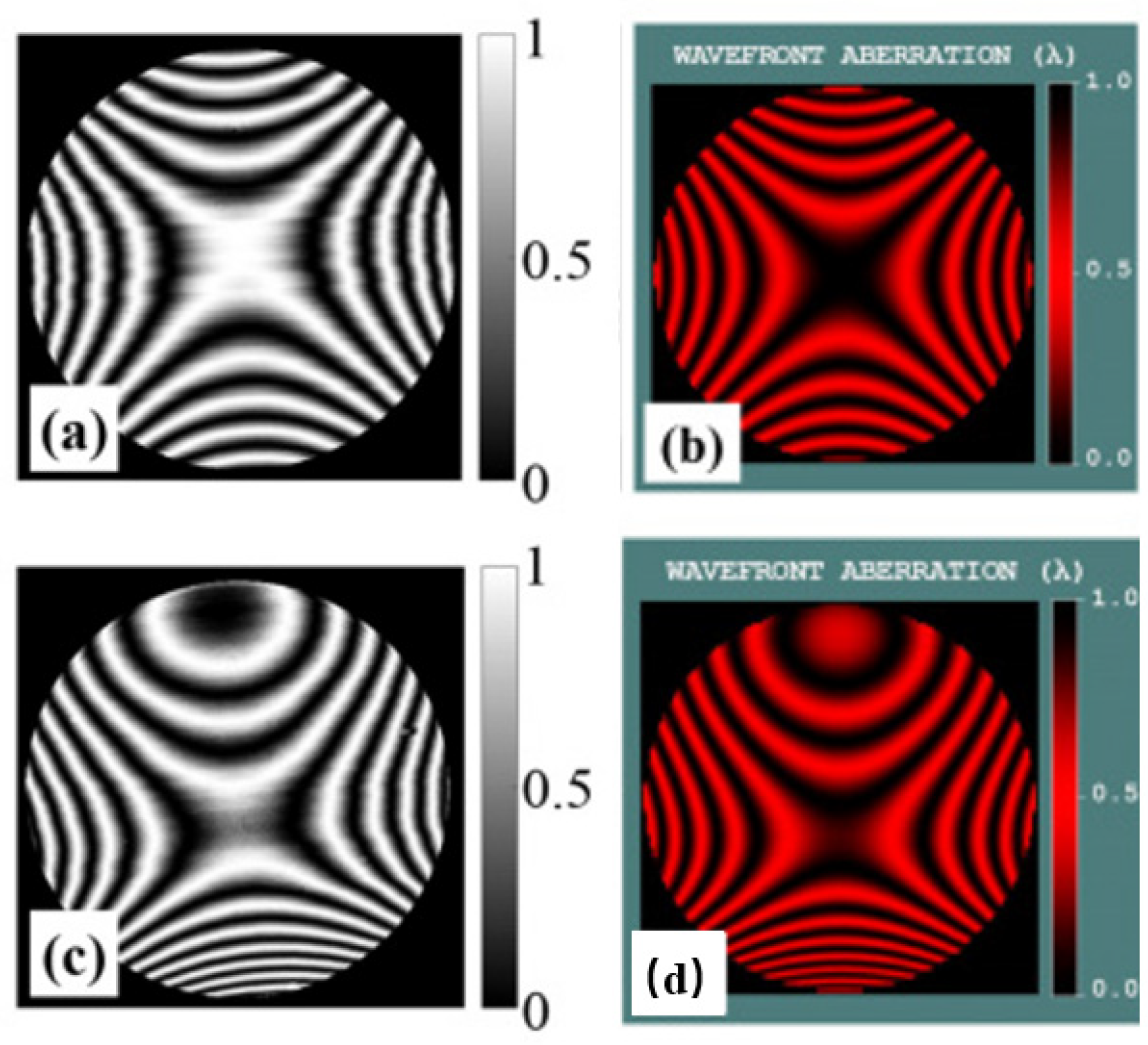

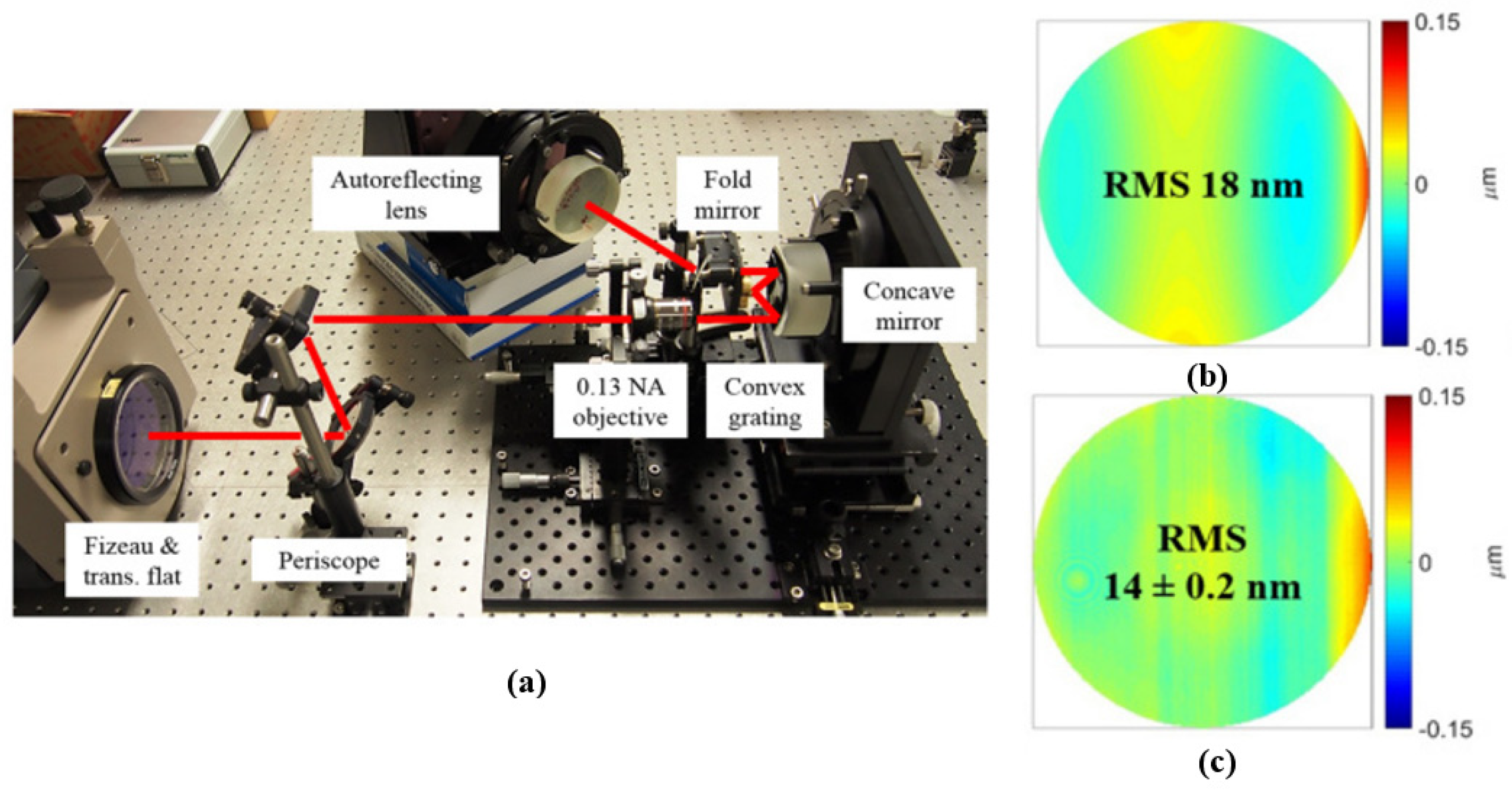

5.2.1. Direct Wavefront Measurement Method

5.2.2. Nulling Wavefront Metrology Method

5.2.3. Nonnull Interferometric Testing

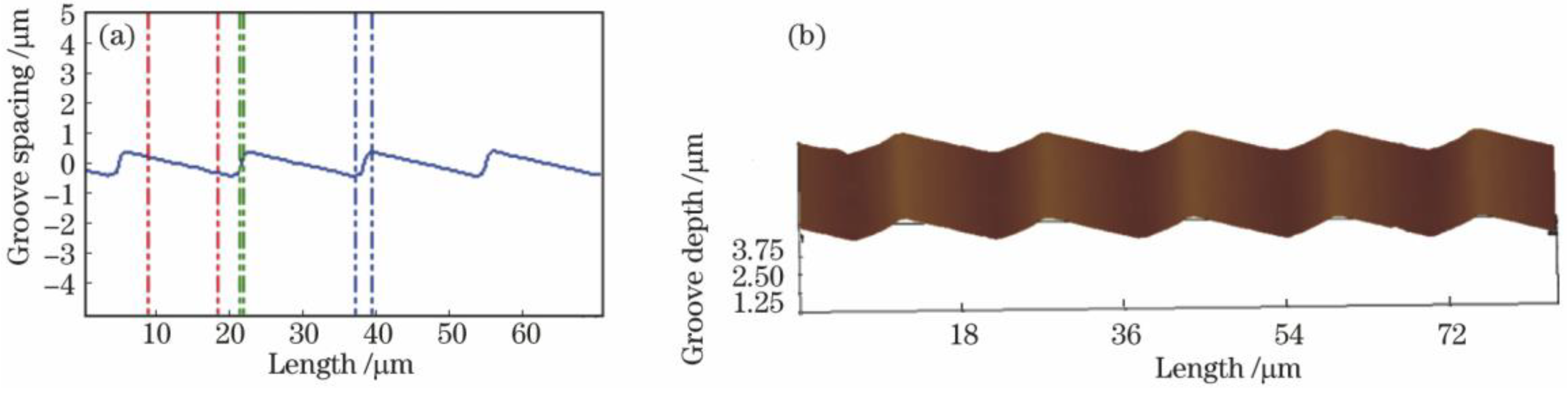

5.2.4. Grating Profile Accuracy Detection and Surface Shape Error Characterization

5.2.5. Stitching Measurements of Freeform Diffraction Microstructures

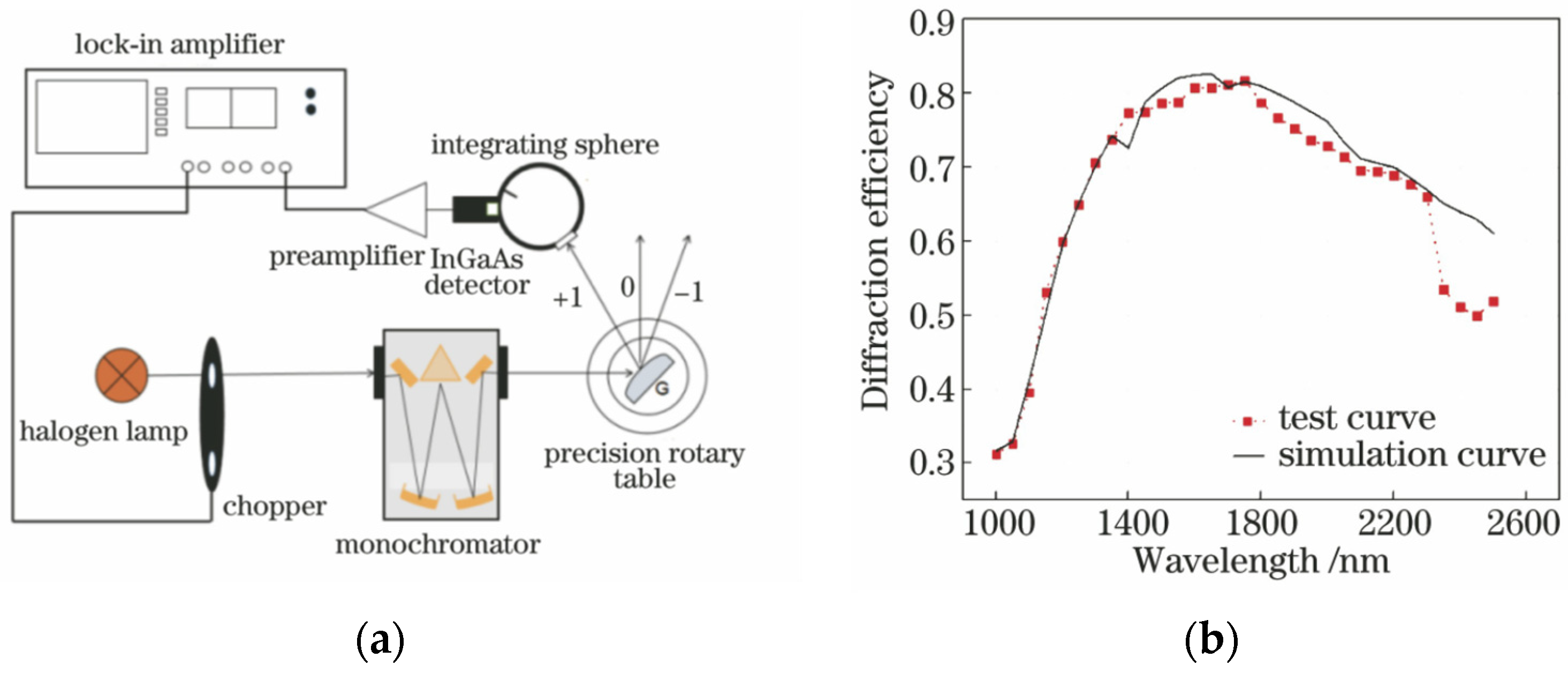

5.3. Diffraction Efficiency Test

6. Conclusions and Potential for Future Development

- (1)

- Freeform blazed gratings have broader application prospects than planar gratings.

- (2)

- The technology for efficient ultra-precise preparation of freeform blazed gratings needs to be developed.

- (3)

- Ultra-precision machining technology is applicable to the processing of high-curvature freeform surface blazed gratings.

- (4)

- Stitching measurements are essential for the complete characterization of machining accuracy of freeform blazed gratings.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, S.; Zhou, Y.; Zhang, H.; Xiong, Z.; To, S. Advances in ultra-precision machining of micro-structured functional surfaces and their typical applications. Int. J. Mach. Tools Manuf. 2019, 142, 16–41. [Google Scholar] [CrossRef]

- Hutley, M.C. Diffraction Gratings; Academic Press: New York, NY, USA, 1982. [Google Scholar]

- Born, M.; Wolf, E. Principles of Optics; Macmillan: New York, NY, USA, 2005. [Google Scholar]

- Loewen, E.G.; Nevière, M.; Maystre, D. Grating efficiency theory as it applies to blazed and holographic gratings. Appl. Opt. 1977, 16, 2711–2721. [Google Scholar] [CrossRef]

- Wood, R.W. LXXXV, The echelette grating for the infra-red. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1910, 20, 770–778. [Google Scholar] [CrossRef]

- Offner, A. Unit Power Imaging Catoptric Anastigmat. U.S. Patent 3748015 A, 24 July 1973. [Google Scholar]

- Mertz, L. Concentric spectrographs. Appl. Opt. 1977, 16, 3122–3124. [Google Scholar] [CrossRef]

- Chrisp, M.P. Convex Diffraction Grating Imaging Spectrometer. U.S. Patent 5880834, 9 March 1999. [Google Scholar]

- Shen, Y.H.; Ni, Z.J.; Huang, Y.S.; Sheng, B.; Xu, B.L.; Guo, M.Q.; Xu, M.J. Analytical design of a high-performing+ 1st order diffraction convex grating imaging spectrometer. Appl. Opt. 2020, 59, 3760–3765. [Google Scholar] [CrossRef]

- Xue, Q.; Yang, J.; Huang, L.; Bai, H.; Lu, J. Wideband, high spectral resolution UV convex grating imaging spectrometer based on an Offner structure. Appl. Opt. 2022, 61, 3371–3380. [Google Scholar] [CrossRef]

- Hu, Y.; Chang, J.; Ji, Z.; Chen, W.; Li, Y.; Li, D. Construction method for designing a spectrometer with variable spectral resolution and wide bandwidth using multiple off-axis convex gratings. Opt. Express 2022, 30, 2472–2486. [Google Scholar] [CrossRef]

- Zhu, J.; Shen, W. Design and manufacture of compact long-slit spectrometer for hyperspectral remote sensing. Optik 2021, 247, 167896. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, X.; Zhao, Z.; Shen, W. Long-slit polarization-insensitive imaging spectrometer for wide-swath hyperspectral remote sensing from a geostationary orbit. Opt. Express 2021, 29, 26851–26864. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Li, B.; Zhang, X. Optical system design of spaceborne infrared dual-band hyperspectral imager. In Proceedings of the Eighth Symposium on Novel Photoelectronic Detection Technology and Applications, Kunming, China, 9–11 November 2021; Volume 12169, pp. 1214–1220. [Google Scholar]

- Marcq, E.; Montmessin, F.; Lasue, J.; Bézard, B.; Jessup, K.L.; Lee, Y.J.; Wilson, C.F.; Lustrement, B.; Rouanet, N.; Guignan, G. Instrumental requirements for the study of Venus’ cloud top using the UV imaging spectrometer VeSUV. Adv. Space Res. 2021, 68, 275–291. [Google Scholar] [CrossRef]

- Kazanskiy, N.; Ivliev, N.; Podlipnov, V.; Skidanov, R. An airborne Offner imaging hyperspectrometer with radially-fastened primary elements. Sensors 2020, 20, 3411. [Google Scholar] [CrossRef]

- Skidanov, R.V.; Blank, V.A. A dual-range spectrometer based on the Offner scheme. Comput. Opt. 2016, 40, 968–971. [Google Scholar] [CrossRef]

- Reimers, J.; Bauer, A.; Thompson, K.P.; Rolland, J.P. Freeform spectrometer enabling increased compactness. Light Sci. Appl. 2017, 6, e17026. [Google Scholar] [CrossRef] [PubMed]

- De Clercq, C.; Moreau, V.; Jamoye, J.F.; Marchi, A.Z.; Gloesener, P. ELOIS: An innovative spectrometer design using a free-form grating. In Proceedings of the Optical Systems Design 2015: Optical Design and Engineering VI, Jena, Germany, 7–10 September 2015; Volume 9626, pp. 407–415. [Google Scholar]

- Wei, L.; Feng, L.; Zhou, J.; Jing, J.; Li, Y. Optical design of Offner-Chrisp imaging spectrometer with freeform surfaces. In Proceedings of the Optical Design and Testing VII, Beijing, China, 12–14 October 2016; Volume 10021, pp. 395–402. [Google Scholar]

- Wang, H.; Zhu, J.; Chen, X.; Shen, W. Optical design of geostationary wide swath imaging spectrometer with freeform surfaces. In Proceedings of the Eighth Symposium on Novel Photoelectronic Detection Technology and Applications, Kunming, China, 9–11 November 2021; Volume 12169, pp. 1063–1073. [Google Scholar]

- Yang, T.; Cheng, D.; Wang, Y. Freeform imaging spectrometer design using a point-by-point design method. Appl. Opt. 2018, 57, 4718–4727. [Google Scholar] [CrossRef]

- Muslimov, E.R.; Ferrari, M.; Hugot, E.; Bouret, J.C.; Neiner, C.; Lombardo, S.; Lemaitre, G.R.; Grange, R.; Guskov, I.A. Design and modeling of spectrographs with holographic gratings on freeform surfaces. Opt. Eng. 2018, 57, 125105. [Google Scholar] [CrossRef]

- Moreau, V.; Borguet, B.; Jamoye, J.F.; Maresi, L.; Marchi, A.Z.; Miranda, M. Freeform grating-based hyperspectral instruments: When SmallSat solutions benefit to big missions. In Proceedings of the Session VII: Advanced Technologies I, Logan, UT, USA, 3–8 August 2019. [Google Scholar]

- Borguet, B.; Moreau, V.; Marchi, A.Z.; Miranda, M.; Cotel, A. CHIMA: Design and Performances of a Freeform Grating High Spectral Resolution Spectro-Imager. In Proceedings of the Freeform Optics, Washington, DC, USA, 10–12 June 2019; p. FM4B.2. [Google Scholar]

- Feng, A.; Zhao, S.; Han, J.; Tan, F.; Zeng, C.; Ji, Y. High spectral resolution compact Offner spectrometer based on the aberration-reduced convex holographic gratings recorded by spherical waves under Rowland circle mounting. Appl. Opt. 2022, 61, 3893–3900. [Google Scholar] [CrossRef]

- Loewen, E.G.; Popov, E. Diffraction Gratings and Applications; CRC Press: Boca Raton, FL, USA, 1997; pp. 50–56. [Google Scholar]

- Mouroulis, P.; Wilson, D.W.; Maker, P.D.; Muller, R.E. Convex Grating Types for Concentric Imaging Spectrometers. Appl. Opt. 1998, 37, 7200–7208. [Google Scholar] [CrossRef] [PubMed]

- Borguet, B.; Moreau, V.; Santandrea, S.; Versluys, J.; Bourdoux, A. The challenges of broadband performances within a compact imaging spectrometer: The ELOIS solution. In Proceedings of the International Conference on Space Optics—ICSO 2020, Online, 30 March–2 April 2021; Volume 11852, pp. 572–582. [Google Scholar]

- Yang, F.; Chen, X.; Zhao, Z.; Liu, Q.; Shen, W. Optical design of a broadband Offner imaging spectrometer for the asteroid exploration. In Proceedings of the AOPC 2020: Optical Sensing and Imaging Technology, Beijing, China, 30 November–2 December 2020; Volume 11567, pp. 10–17. [Google Scholar]

- Calcines, A.; Bourgenot, C.; Sharples, R. Design of freeform diffraction gratings: Performance, limitations and potential applications. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation III, Austin, TX, USA, 10–15 June 2018; Volume 10706, pp. 1431–1443. [Google Scholar]

- Sabushimike, B.; Horugavye, G.; Habraken, S. Optimization of a multiblaze grating in reflection using a free-form profile. Appl. Opt. 2018, 57, 5048–5056. [Google Scholar] [CrossRef]

- Sabushimike, B.; Horugavye, G.; Habraken, S.; Jamoye, J.F.; Moreau, V. New design and modelization of a Convex Grating for an hyperspectral imager of the Chandrayaan 2 instrument for the moon probe in the infrared. Int. J. Latest Res. Sci. Technol. 2019, 8, 1–11. [Google Scholar]

- Backlund, J.P.; Wilson, D.W.; Muller, R.E. Structured-groove phase gratings for control and optimization of the spectral efficiency. In Proceedings of the Diffractive Optics and Micro-Optics, Rochester, NY, USA, 10–13 October 2004; p. DMB6. [Google Scholar]

- Zhang, S.; Mi, X.; Zhang, Q.; Feng, S.; Yu, H.; Qi, X. Groove shape characteristics of echelle gratings with high diffraction efficiency. Opt. Commun. 2017, 387, 401–404. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, J. Analysis and comparison of the scalar diffraction theory and coupled-wave theory about grating. Laser J. 2004, 25, 31–34. [Google Scholar]

- Xiong, Z.; He, W.; Wang, Q.; Liu, Z.; Fu, Y.; Kong, D. Design and optimization method of a convex blazed grating in the Offner imaging spectrometer. Appl. Opt. 2021, 60, 383–391. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.W.; Ying, J.X. Optimization of the Two Parameters of Classical Blaze Grating in Littrow Mount. In Advanced Materials Research; Trans Tech Publications Ltd.: Bach, Switzerland, 2012; Volume 535, pp. 1332–1336. [Google Scholar]

- Fujita, T.; Nishihara, H.; Koyama, J. Blazed gratings and Fresnel lenses fabricated by electron-beam lithography. Opt. Lett. 1982, 7, 578–580. [Google Scholar] [CrossRef] [PubMed]

- Wilson, D.W.; Maker, P.D.; Muller, R.E.; Mouroulis, P.Z.; Backlund, J. Recent advances in blazed grating fabrication by electron-beam lithography. In Proceedings of the Current Developments in Lens Design and Optical Engineering IV, San Diego, CA, USA, 3–8 August 2003; Volume 5173, pp. 115–126. [Google Scholar]

- Maker, P.; Muller, R.; Wilson, D.; Mouroulis, P. New convex grating types manufactured by electron beam lithography. In Diffractive Optics and Micro-Optics; Optica Publishing Group: Washington, DC, USA, 1998. [Google Scholar]

- Zamkotsian, F.; Zhurminsky, I.; Lanzoni, P.; Tchoubaklian, N.; Schneider, C.; Fricke, S.; Schnieper, M.; Lütolf, F.; Luitot, C.; Costes, V. Convex blazed gratings for high throughput spectrographs in space missions. In Proceedings of the International Conference on Space Optics—ICSO 2018, Chania, Greece, 9–12 October 2018; Volume 11180, pp. 1882–1890. [Google Scholar]

- Zamkotsian, F.; Zhurminsky, I.; Lanzoni, P.; Tchoubaklian, N.; Lütolf, F.; Schnieper, M.; Schneider, C.; Fricke, S.; Fouchier, M.; Zerrad, M.; et al. Blazed gratings on convex substrates for high throughput spectrographs for Earth and Universe observation. In Proceedings of the International Conference on Space Optics—ICSO 2020, Online, 30 March–2 April 2021; Volume 11852, pp. 263–274. [Google Scholar]

- Burkhardt, M.; Rathje, T.; Lehr, D.; Erdmann, L.; Helgert, M.; Triebel, P.; Diehl, T.; Gatto, A.; van der Valk, N.; Vink, R.; et al. Manufacturing method for monolithic freeform Offner-gratings for hyper-spectral imaging. In Proceedings of the Sensors, Systems, and Next-Generation Satellites XXIII, Strasbourg, France, 9–12 September 2019; Volume 11151, pp. 146–157. [Google Scholar]

- Wang, D.; Zhang, D.; Xu, B.; Hao, F.; Huang, Y.; Li, B.; Shen, Y. Fabrication of a holographic mask with high consistency for convex blazed grating. Laser Phys. 2022, 32, 065203. [Google Scholar] [CrossRef]

- Osterried, K.; Heidemann, K.F.; Nelles, B. Groove profile modification of blazed gratings by dip coating with hardenable liquids. Appl. Opt. 1998, 37, 8002–8007. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, Q.; Wu, J. Groove profile modification of convex blazed gratings by dip (spin) coating with photoresist. In Proceedings of the 2013 International Conference on Optical Instruments and Technology: Micro/Nano Photonics and Fabrication, Beijing, China, 17–19 November 2013; Volume 9047, pp. 80–88. [Google Scholar]

- Haibin, W.; Jianhong, L.Q.W. Fabrication of Convex Blazed Grating by Ar~+ Ion-Beam Etching. Acta Opt. Sin. 2011, 4, 0405002. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, H.; Sun, P.; Wu, J. Fabrication of the convex blazed grating. In Proceedings of the Holography, Diffractive Optics, and Applications IV, Beijing, China, 18–20 October 2010; Volume 7848, pp. 189–195. [Google Scholar]

- Liu, Q.; Wu, J.; Chen, M.; Cheng, Y. The fabrication of the holographic dual-blazed grating. In Proceedings of the 2013 International Conference on Optical Instruments and Technology: Micro/Nano Photonics and Fabrication, Beijing, China, 17–19 November 2013; Volume 9047, pp. 102–108. [Google Scholar]

- Liu, Q.; Wu, J.; Zhou, Y.; Gao, F. The convex grating with high efficiency for hyperspectral remote sensing. In Proceedings of the Hyperspectral Remote Sensing Applications and Environmental Monitoring and Safety Testing Technology, Beijing, China, 9–11 May 2016; Volume 10156, pp. 403–409. [Google Scholar]

- Shen, C.; Tan, X.; Jiao, Q.; Zhang, W.; Wu, N.; Bayan, H.; Qi, X. Convex blazed grating of high diffraction efficiency fabricated by swing ion-beam etching method. Opt. Express 2018, 26, 25381–25398. [Google Scholar] [CrossRef]

- Fang, F.Z.; Zhang, X.D.; Weckenmann, A.; Zhang, G.X.; Evans, C. Manufacturing andmeasurement of freeform optics. CIRP Ann.–Manuf. Technol. 2013, 62, 823–846. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Schönemann, L. Generation of discontinuous microstructures byDiamond Micro Chiseling. CIRP Ann.–Manuf. Technol. 2014, 63, 49–52. [Google Scholar] [CrossRef]

- Davies, M.A.; Dutterer, B.S.; Suleski, T.J.; Silny, J.F.; Kim, E.D. Diamond machining of diffraction gratings for imaging spectrometers. Precis. Eng. 2012, 36, 334–338. [Google Scholar] [CrossRef]

- Lee, C.; Lee, S.K. Fabrication and molding testing of the blazed gratings for microoptics applications. Key Eng. Mater. 2010, 447, 396–400. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Riemer, O.; Gläbe, R.; Lünemann, B.; von Kopylow, C.; Dankwart, C.; Meier, A. Submicron functional surfaces generated by diamond machining. CIRP Ann.–Manuf. Technol. 2010, 59, 535–538. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Huang, R.; Kumar, A.S.; Liu, K. High-efficiency swinging-rotating diamond shaping of Fresnel lenses on roller molds. CIRP Ann. 2018, 67, 121–124. [Google Scholar] [CrossRef]

- Meier, A. Diamond turning of diffractive microstructures. Precis. Eng. 2015, 42, 253–260. [Google Scholar] [CrossRef]

- Holthusen, A.-K.; Riemer, O.; Schmütz, J.; Meier, A. Mold machining and injection molding of diffractive microstructures. J. Manuf. Process. 2017, 26, 290–294. [Google Scholar] [CrossRef]

- Lee, C.; Kuriyagawa, T.; Woo, D.K.; Lee, S.K. Optimizing the fabrication process of a high-efficiency blazed grating through diamond ruling and molding. J. Micromech. Microeng. 2010, 20, 055028. [Google Scholar] [CrossRef]

- Xu, D.; Owen, J.D.; Papa, J.C.; Reimers, J.; Suleski, T.J.; Troutman, J.R.; Davies, M.A.; Thompson, K.P.; Rolland, J.P. Design, fabrication, and testing of convex reflective diffraction gratings. Optics Express 2017, 25, 15252. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.-W.; Yan, J.; Lin, S.-C. Diamond turning of high-precision roll-to-roll imprinting molds for fabricating subwavelength gratings. Opt. Eng. 2016, 55, 064105. [Google Scholar] [CrossRef]

- Tan NY, J.; Zhou, G.; Liu, K.; Kumar, A.S. Diamond shaping of blazed gratings on freeform surfaces. Precis. Eng. 2021, 72, 899–911. [Google Scholar] [CrossRef]

- Zhizhong, Z.; Zhong, Y.; Liancun, X. Development and application of shortwave infrared convex blazed grating with high diffraction efficiency. Acta Opt. Sin. 2020, 40, 1205002. [Google Scholar] [CrossRef]

- Graham, C.; Girkin, J.M.; Bourgenot, C. Freeform based hYperspectral imager for MOisture Sensing (FYMOS). Opt. Express 2021, 29, 16007–16018. [Google Scholar] [CrossRef] [PubMed]

- Bourgenot, C.; Robertson, D.J.; Stelter, D.; Eikenberry, S. Towards freeform curved blazed gratings using diamond machining. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation II, Edinburgh, UK, 26 June–1 July 2016; Volume 9912, pp. 1135–1142. [Google Scholar]

- Bourgenot, C.; Calcines, A.; Sharples, R. New opportunities of freeform gratings using diamond machining. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation III, Austin, TX, USA, 10–15 June 2018; Volume 10706, pp. 596–604. [Google Scholar]

- Li, H.; Peng, X.; Guan, C.; Hu, H. Ultra-Precision Cutting and Characterization of Reflective Convex Spherical Blazed Grating Elements. Micromachines 2022, 13, 1115. [Google Scholar] [CrossRef] [PubMed]

- Marchi, A.Z.; Borguet, B. Freeform Grating Spectrometers for Hyperspectral Space Applications: Status of ESA Programs. In Proceedings of the International Optical Design Conference, Denver, CO, USA, 9–13 July 2017; Optica Publishing Group: Washington, DC, USA, 2017. JTh2B.5. [Google Scholar]

- Li, L.; Allen, Y.Y.; Huang, C.; Grewell, D.A.; Benatar, A.; Chen, Y. Fabrication of diffractive optics by use of slow tool servo diamond turning process. Opt. Eng. 2006, 45, 113401. [Google Scholar] [CrossRef]

- Meier, A.; Riemer, O.; Brinksmeier, E. Diamond machining of holograms using fine rectangular shaped cutting tools. Int. J. Autom. Technol. 2016, 10, 16–22. [Google Scholar] [CrossRef]

- Cobb, J.M.; Comstock, L.E.; Dewa, P.G.; Dunn, M.M.; Flint, S.D. Advances in diamond-turned surfaces enable unique cost-effective optical system solutions. In Proceedings of the Ground-Based and Airborne Instrumentation for Astronomy, Orlando, FL, USA, 24–31 May 2006; Volume 6269, pp. 541–549. [Google Scholar]

- Vannoni, M.; La Civita, D.; Follath, R.; Samoylova, L.; Siewert, F.; Sinn, H. Design of soft X-ray gratings for free electron lasers: From specification to characterization. In Proceedings of the Modeling Aspects in Optical Metrology IV, Munich, Germany, 13–16 May 2013; Volume 8789, pp. 360–368. [Google Scholar]

- Voronov, D.L.; Lum, P.; Naulleau, P.; Gullikson, E.M.; Fedorov, A.V.; Padmore, H.A. X-ray diffraction gratings: Precise control of ultra-low blaze angle via anisotropic wet etching. Appl. Phys. Lett. 2016, 109, 043112. [Google Scholar] [CrossRef]

- Voronov, D.L.; Warwick, T.; Gullikson, E.M.; Salmassi, F.; Naulleau, P.; Artemiev, N.A.; Lum, P.; Padmore, H.A. High efficiency diffraction grating for EUV lithography beamline monochromator. In Proceedings of the Advances in X-ray/EUV Optics and Components XI, San Diego, CA, USA, 28 August–1 September 2016; Volume 9963, pp. 17–23. [Google Scholar]

- Voronov, D.L.; Park, S.; Gullikson, E.M.; Salmassi, F.; Padmore, H.A. 6000 lines/mm blazed grating for a high-resolution X-ray spectrometer. Opt. Express 2022, 30, 28783–28794. [Google Scholar] [CrossRef]

- Mouroulis, P.; Hartley, F.; Wilson, D.; White, V.E.; Shori, A.; Nguyen, S.; Zhang, M.; Feldman, M. Blazed grating fabrication through gray-scale Xray lithography. Opt. Express 2003, 11, 270–281. [Google Scholar] [CrossRef]

- Breidne, M.; Johansson, S.; Nilsson, L.E.; Åhlèn, H. Blazed holographic gratings. Opt. Acta Int. J. Opt. 1979, 26, 1427–1441. [Google Scholar] [CrossRef]

- Aono, T.; Ebata, Y.; Matsui, S.; Watanabe, T. Curved Diffraction Grating, Production Method Therefor, and Optical Device. EP Patent EP2977795, 27 January 2016. [Google Scholar]

- Aono, T.; Ebata, Y.; Yaegashi, K.; Matsui, S. Two-Dimensional Curving Techniques from Flat Diffraction Grating to Concave Diffraction Grating. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1728–1731. [Google Scholar]

- Horugavye, G.; Sabushimike, B.; Habraken, S. Monitoring of Diffraction Efficiency, During Replication Process of a Diffraction Grating on Convex Substrate by Solvent Vapor Assisted Imprinting Lithography. NanoWorld J. 2020, 5, 41–48. [Google Scholar] [CrossRef][Green Version]

- Guo, P.; Liu, Q.; Su, Y.; Lu, Y.; Wu, J. Fabrication of convex blazed grating by native substrate grating mask. In Proceedings of the Sixth International Conference on Optical and Photonic Engineering (icOPEN 2018), Shanghai, China, 8–11 May 2018; Volume 10827, pp. 523–529. [Google Scholar]

- Yushi, Z.; Wenjun, H.; Zhiying, L.; Yuegang, F. Development of convex blazed grating in coded aperture spectral imager. Infrared Laser Eng. 2022, 51, 20220007. (In Chinese) [Google Scholar]

- Xu, D.; Reimers, J.; Papa, J.C.; Owen, J.D.; Davies, M.A.; Suleski, T.J.; Thompson, K.P.; Rolland, J.P. Testing of a convex reflective diffraction grating. In Proceedings of the Optical Fabrication and Testing, Denver, CO, USA, 9–13 July 2017; p. OM2B-3. [Google Scholar]

- Liu, W.; Yuan, Q.; Wang, R.; Ji, W.; Xue, Y.; Ma, J.; Wang, L.; Gao, Z. Nonnull interferometric testing of spherical gratings under Littrow conditions with opposite diffraction orders. Appl. Opt. 2020, 59, 6360–6367. [Google Scholar] [CrossRef] [PubMed]

- Roeder, M.; Thiele, S.; Hera, D.; Pruss, C.; Guenther, T.; Osten, W.; Zimmermann, A. Fabrication of curved diffractive optical elements by means of laser direct writing, electroplating, and injection compression molding. J. Manuf. Process. 2019, 47, 402–409. [Google Scholar] [CrossRef]

- Mishra, V.; Sabui, D.; Yuvaraj, T.P.; Burada, D.R.; Karar, V.; Khan, G.S. Fabrication and characterization of diffracto-freeform optics. In Proceedings of the Optical Manufacturing and Testing XIII, Online, CA, USA, 24 August–4 September 2020; Volume 11487, pp. 220–226. [Google Scholar]

- Guo, J.; Zhai, D.; Chen, S.; Lu, W. High-resolution white light scanning stitching measurement of full-surface microstructure. In Proceedings of the Eighth Symposium on Novel Photoelectronic Detection Technology and Applications, Kunming, China, 9–11 November 2021; Volume 12169, pp. 2770–2781. [Google Scholar]

- Ma, Z.; Qi, X.; Li, X.; Zhang, S.; Yu, H.; Yu, H.; Jiao, Q. Measuring method of diffraction efficiency for plane grating based on Fourier spectral technology. Appl. Opt. 2016, 55, 522–528. [Google Scholar] [CrossRef]

- Liu, P.; Chen, X.; Zhou, J.; Zhao, Z.C.; Liu, Q.; Luo, C.; Wang, X.F.; Tang, M.-X.; Shen, W.M. Measurement system for diffraction efficiency of convex gratings. In Proceedings of the Pacific Rim Laser Damage 2017: Optical Materials for High-Power Lasers, Shanghai, China, 21–24 May 2017; Volume 10339, pp. 147–154. [Google Scholar]

| Preparation Method | Ultra-Precision Diamond Turning | Ion Beam Etching | E-Beam Direct Writing | X-ray Lithography |

|---|---|---|---|---|

| Spectral range | Visible-LWIR | UV-NIR | Visible-NIR | Visible-NIR |

| Convex vector height | Almost unlimited | Practically unlimited | Less than 4 mm | Meet the production of thick line grating |

| Base dimension | Small | Large | Small | Large |

| Grating period | Low reticle density | High reticle density | High reticle density (greater than 1 μm) | High reticle density (greater than 3 μm) |

| Grating groove shape | Arbitrary groove shape | Sinusoidal, rectangular, triangular groove shape | Arbitrary groove shape | Arbitrary groove shape |

| Diffraction efficiency | High (high requirements for machining accuracy) | High (technological difficulty) | High | High |

| Stray light | Higher | Low | Less than 5 × 10−4 | Less than 10−4 |

| Roughness | Less than 10 nm | Low | Low | Low |

| Wavefront quality | Low | High | High | High |

| Manufacturing cost | Lower | Higher | High | High |

| General material | Al, Cu, NiP, and other metal materials | Fused quartz, RB-SiC, GaAs, PMMA, K9 | Silicon, glass | Silicon nitride |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Peng, X.; Guan, C.; Hu, H. Progress in the Preparation and Characterization of Convex Blazed Gratings for Hyper-Spectral Imaging Spectrometer: A Review. Micromachines 2022, 13, 1689. https://doi.org/10.3390/mi13101689

Li H, Peng X, Guan C, Hu H. Progress in the Preparation and Characterization of Convex Blazed Gratings for Hyper-Spectral Imaging Spectrometer: A Review. Micromachines. 2022; 13(10):1689. https://doi.org/10.3390/mi13101689

Chicago/Turabian StyleLi, Huang, Xiaoqiang Peng, Chaoliang Guan, and Hao Hu. 2022. "Progress in the Preparation and Characterization of Convex Blazed Gratings for Hyper-Spectral Imaging Spectrometer: A Review" Micromachines 13, no. 10: 1689. https://doi.org/10.3390/mi13101689

APA StyleLi, H., Peng, X., Guan, C., & Hu, H. (2022). Progress in the Preparation and Characterization of Convex Blazed Gratings for Hyper-Spectral Imaging Spectrometer: A Review. Micromachines, 13(10), 1689. https://doi.org/10.3390/mi13101689