Compact Magnetic Force Microscope (MFM) System in a 12 T Cryogen-Free Superconducting Magnet

Abstract

:1. Introduction

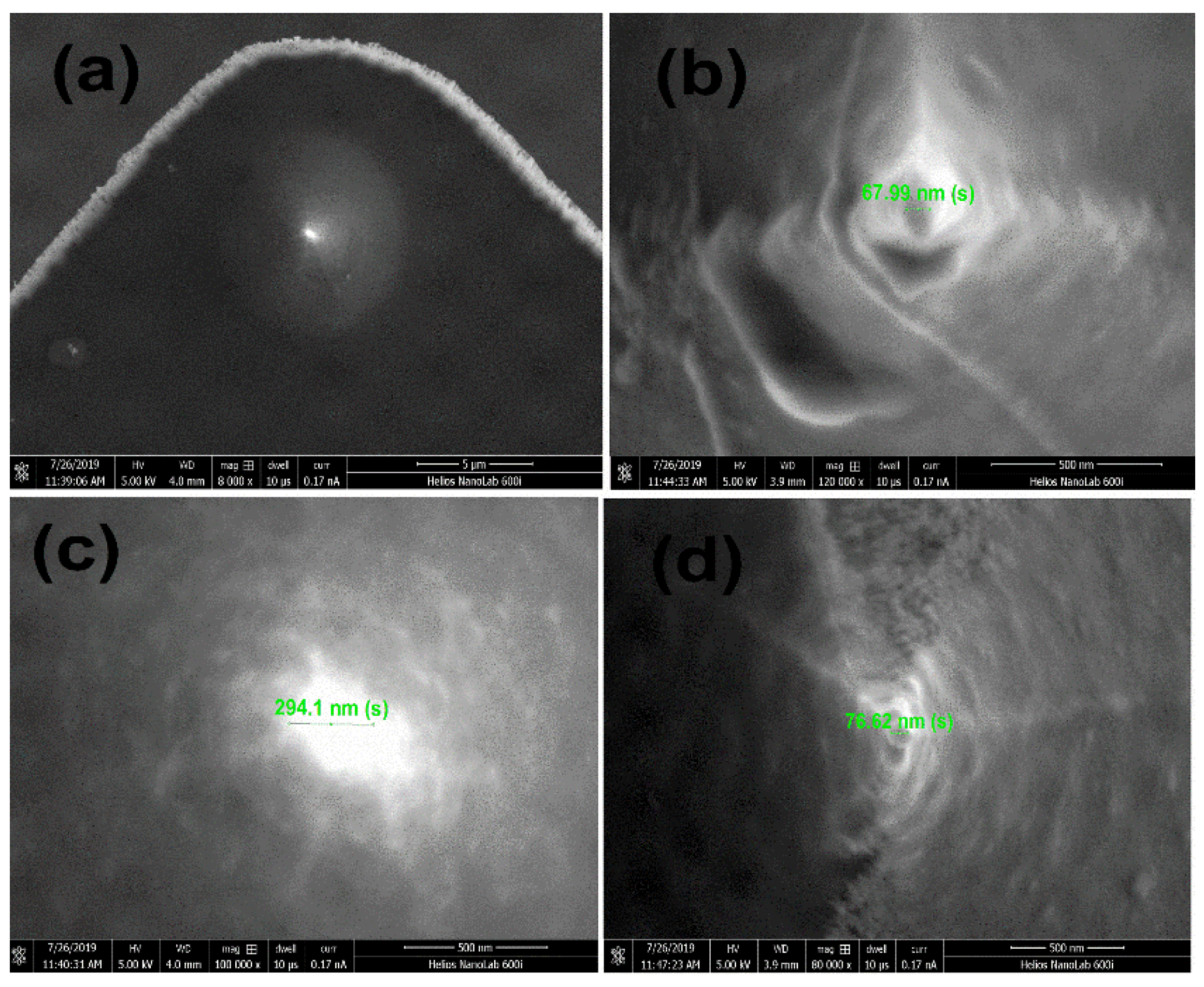

2. Materials and Methods

3. System Design

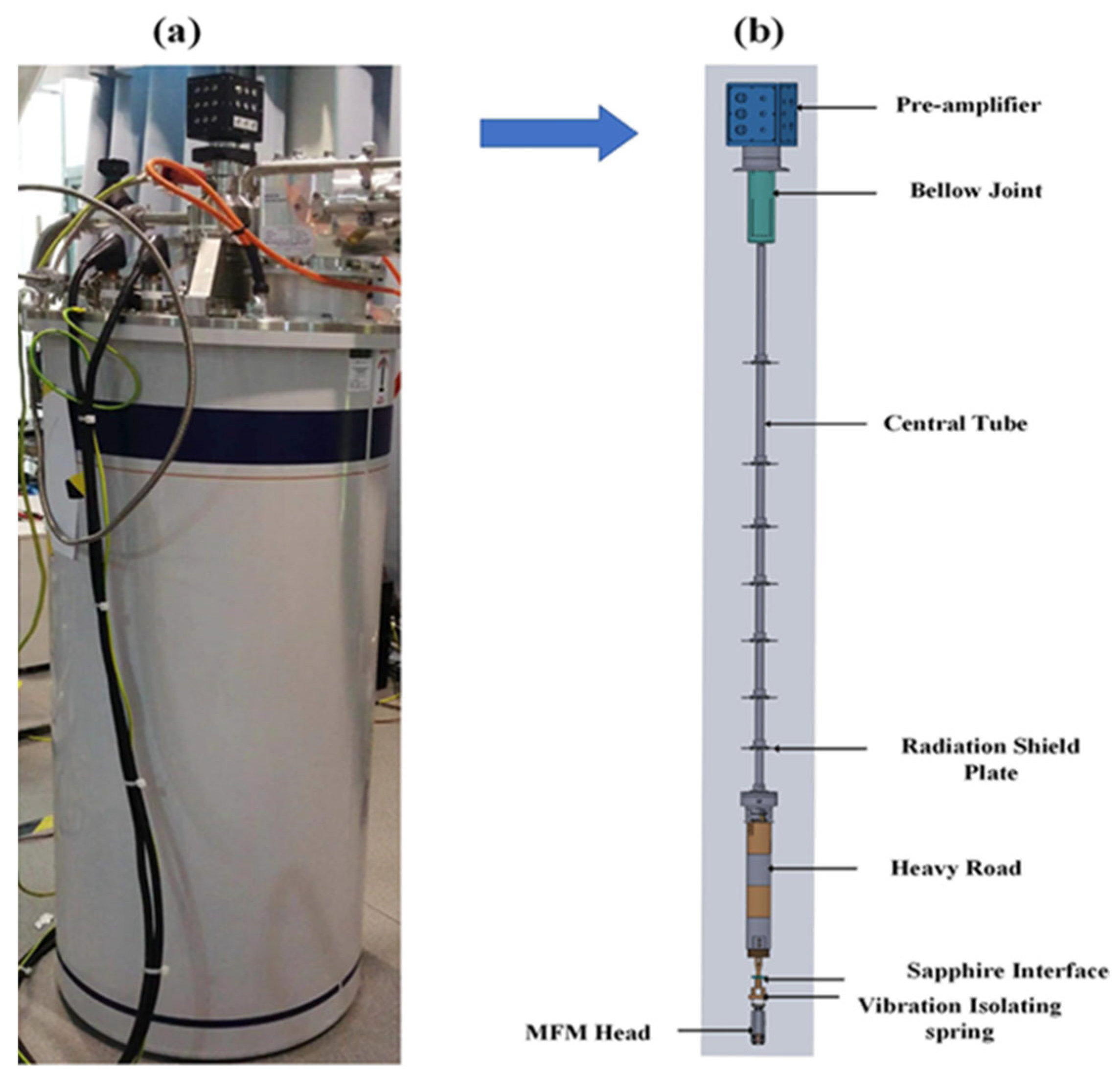

3.1. Cooling System

3.2. Design of Pre-Amplifier Board

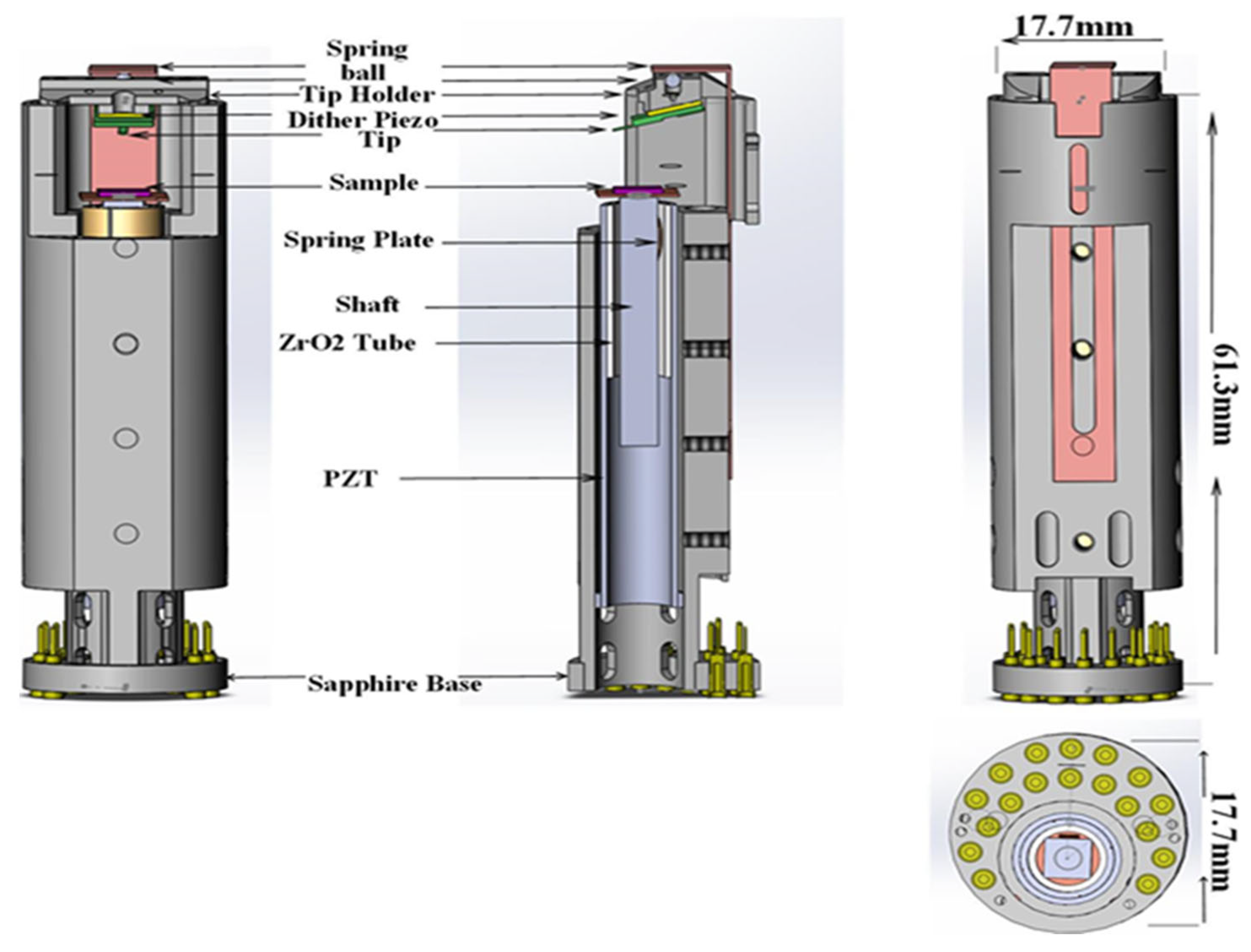

3.3. MFM Head

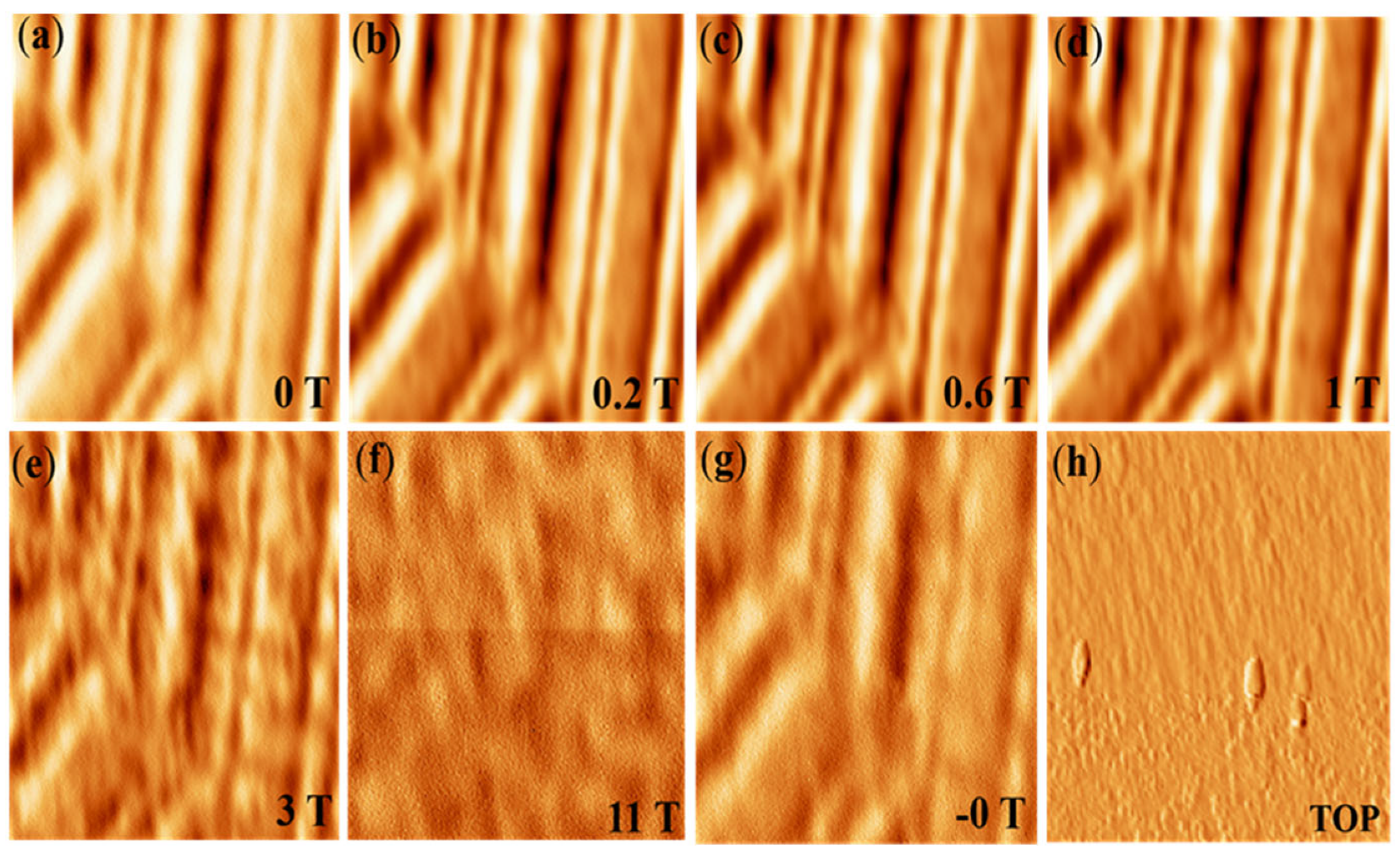

4. Performance Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schneider, M. Magnetic Domain Studies. Phys. Bull. 1969, 20, 535. [Google Scholar] [CrossRef]

- Rawlings, C.; Durkan, C. Performing Quantitative MFM Measurements on Soft Magnetic Nanostructures. Nanotechnology 2012, 23, 455701. [Google Scholar] [CrossRef] [PubMed]

- Sohn, J.S.; Lee, D.; Cho, E.; Kim, H.S.; Sul, S.C.; Lee, B.K.; Lee, M.B.; Moon, C.; Park, N.C. Fabrication and MFM Study of 60 Nm Track-Pitch Discrete Track Media. Nanotechnology 2011, 22, 035305. [Google Scholar] [CrossRef] [PubMed]

- Binnig, G.; Rohrer, H. Scanning Tunneling Microscopy—From Birth to Adolescence (Nobel Lecture). Angew. Chemie Int. Ed. Engl. 1987, 26, 606–614. [Google Scholar] [CrossRef]

- Hug, H.J.; Stiefel, B.; Van Schendel, P.J.A.; Moser, A.; Martin, S.; Güntherodt, H.J. A Low Temperature Ultrahigh Vaccum Scanning Force Microscope. Rev. Sci. Instrum. 1999, 70, 3625–3640. [Google Scholar] [CrossRef]

- Giessibl, F.J. Surface by Atomic Force Microscopy. Science 1995, 267, 68. [Google Scholar] [CrossRef] [Green Version]

- Sáenz, J.J.; García, N.; Grütter, P.; Meyer, E.; Heinzelmann, H.; Wiesendanger, R.; Rosenthaler, L.; Hidber, H.R.; Güntherodt, H.J. Observation of Magnetic Forces by the Atomic Force Microscope. J. Appl. Phys. 1987, 62, 4293–4295. [Google Scholar] [CrossRef]

- Bennewitz, R.; Baratoff, A.; Meyer, E.; Bammerlin, M.; Guggisberg, M.; Scha, S. Dynamic Force Microscopy of Copper Surfaces: Atomic Resolution and Distance Dependence of Tip-Sample Interaction and Tunneling Current. Phys. Rev. B 2000, 62, 944–949. [Google Scholar]

- Cai, K.; Yang, M.; Ju, H.; Wang, S.; Ji, Y.; Li, B.; Edmonds, K.W.; Sheng, Y.; Zhang, B.; Zhang, N.; et al. Electric Field Control of Deterministic Current-Induced Magnetization Switching in a Hybrid Ferromagnetic/Ferroelectric Structure. Nat. Mater. 2017, 16, 712–716. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, H.L.; Cao, J.; Li, Y.C.; Yang, M.Y.; Xia, K.; Zhao, J.H.; Wang, K.Y. Control of Magnetic Anisotropy in Epitaxial Co2MnAl Thin Films through Piezo-Voltage-Induced Strain. J. Appl. Phys. 2019, 125, 082503. [Google Scholar] [CrossRef]

- Wang, K.Y.; Rushforth, A.W.; Grant, V.A.; Campion, R.P.; Edmonds, K.W.; Staddon, C.R.; Foxon, C.T.; Gallagher, B.L.; Wunderlich, J.; Williams, D.A. Domain Imaging and Domain Wall Propagation in (Ga, Mn) As Thin Films with Tensile Strain. J. Appl. Phys. 2007, 101, 106101. [Google Scholar] [CrossRef]

- Feng, Q.; Jin, F.; Zhou, H.; Wang, L.; Meng, W.; Zhang, K.; Wang, J.; Zhang, J.; Hou, Y.; Lu, Q.; et al. Induced Formation of Structural Domain Walls and Their Confinement on Phase Dynamics in Strained Manganite Thin Films. Adv. Mater. 2018, 30, 1805353. [Google Scholar] [CrossRef]

- Wang, L.; Feng, Q.; Kim, Y.; Kim, R.; Lee, K.H.; Pollard, S.D.; Shin, Y.J.; Zhou, H.; Peng, W.; Lee, D.; et al. Ferroelectrically Tunable Magnetic Skyrmions in Ultrathin Oxide Heterostructures. Nat. Mater. 2018, 17, 1087–1094. [Google Scholar] [CrossRef]

- Hunstig, M. Piezoelectric Inertia Motors-a Critical Review of History, Concepts, Design, Applications, and Perspectives. Actuators 2017, 6, 7. [Google Scholar] [CrossRef] [Green Version]

- Pan, S.H.; Hudson, E.W.; Davis, J.C. 3He Refrigerator Based Very Low-Temperature Scanning Tunneling Microscope. Rev. Sci. Instrum. 1999, 70, 1459–1463. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, D.; Wu, S. A Cryogen-Free Low-Temperature Scanning Tunneling Microscope Capable of Inelastic Electron Tunneling Spectroscopy. Rev. Sci. Instrum. 2016, 87, 063701. [Google Scholar] [CrossRef]

- Kasai, J.; Koyama, T.; Yokota, M.; Iwaya, K. Development of a Near-5-Kelvin, Cryogen-Free, Pulse-Tube Refrigerator-Based Scanning Probe Microscope. Rev. Sci. Instrum. 2022, 93, 043711. [Google Scholar] [CrossRef]

- Smith, A.R.; Shih, C.K. New Variable Low-Temperature Scanning Tunneling Microscope for Use in Ultrahigh Vacuum. Rev. Sci. Instrum. 1995, 66, 2499–2503. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Wang, Z.; Hou, Y.; Lu, Q. A Compact High Field Magnetic Force Microscope. Ultramicroscopy 2014, 147, 133–136. [Google Scholar] [CrossRef]

- Meng, W.; Zhao, K.; Wang, J.; Zhang, J.; Feng, Q.; Wang, Z.; Geng, T.; Guo, T.; Hou, Y.; Pi, L.; et al. 30 T Scanning Tunnelling Microscope in a Hybrid Magnet with Essentially Non-Metallic Design. Ultramicroscopy 2020, 212, 112975. [Google Scholar] [CrossRef]

- Takahashi, H.; Ando, K.; Shirakawa, Y. Self-Sensing Piezoresistive Cantilever and Its Magnetic Force Microscopy Applications. Ultramicroscopy 2002, 91, 63–72. [Google Scholar] [CrossRef]

- Wren, T.; Puttock, R.; Gribkov, B.; Vdovichev, S.; Kazakova, O. Switchable Bi-Stable Multilayer Magnetic Probes for Imaging of Soft Magnetic Structures. Ultramicroscopy 2017, 179, 41–46. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Feng, Q.; Lee, H.G.; Ko, E.K.; Lu, Q.; Noh, T.W. Controllable Thickness Inhomogeneity and Berry Curvature Engineering of Anomalous Hall Effect in SrRuO3 Ultrathin Films. Nano Lett. 2020, 20, 2468–2477. [Google Scholar] [CrossRef] [Green Version]

- Xiang, K.; Hou, Y.; Wang, J.; Zhang, J.; Feng, Q.; Wang, Z.; Meng, W.; Lu, Q.; Lu, Y. A Piezoelectric Rotatable Magnetic Force Microscope System in a 10 T Cryogen-Free Superconducting Magnet. Rev. Sci. Instrum. 2022, 93, 093706. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abas, A.; Geng, T.; Meng, W.; Wang, J.; Feng, Q.; Zhang, J.; Wang, Z.; Hou, Y.; Lu, Q. Compact Magnetic Force Microscope (MFM) System in a 12 T Cryogen-Free Superconducting Magnet. Micromachines 2022, 13, 1922. https://doi.org/10.3390/mi13111922

Abas A, Geng T, Meng W, Wang J, Feng Q, Zhang J, Wang Z, Hou Y, Lu Q. Compact Magnetic Force Microscope (MFM) System in a 12 T Cryogen-Free Superconducting Magnet. Micromachines. 2022; 13(11):1922. https://doi.org/10.3390/mi13111922

Chicago/Turabian StyleAbas, Asim, Tao Geng, Wenjie Meng, Jihao Wang, Qiyuan Feng, Jing Zhang, Ze Wang, Yubin Hou, and Qingyou Lu. 2022. "Compact Magnetic Force Microscope (MFM) System in a 12 T Cryogen-Free Superconducting Magnet" Micromachines 13, no. 11: 1922. https://doi.org/10.3390/mi13111922

APA StyleAbas, A., Geng, T., Meng, W., Wang, J., Feng, Q., Zhang, J., Wang, Z., Hou, Y., & Lu, Q. (2022). Compact Magnetic Force Microscope (MFM) System in a 12 T Cryogen-Free Superconducting Magnet. Micromachines, 13(11), 1922. https://doi.org/10.3390/mi13111922