An Optimization Design Method of Rigid-Flexible Soft Fingers Based on Dielectric Elastomer Actuators

Abstract

1. Introduction

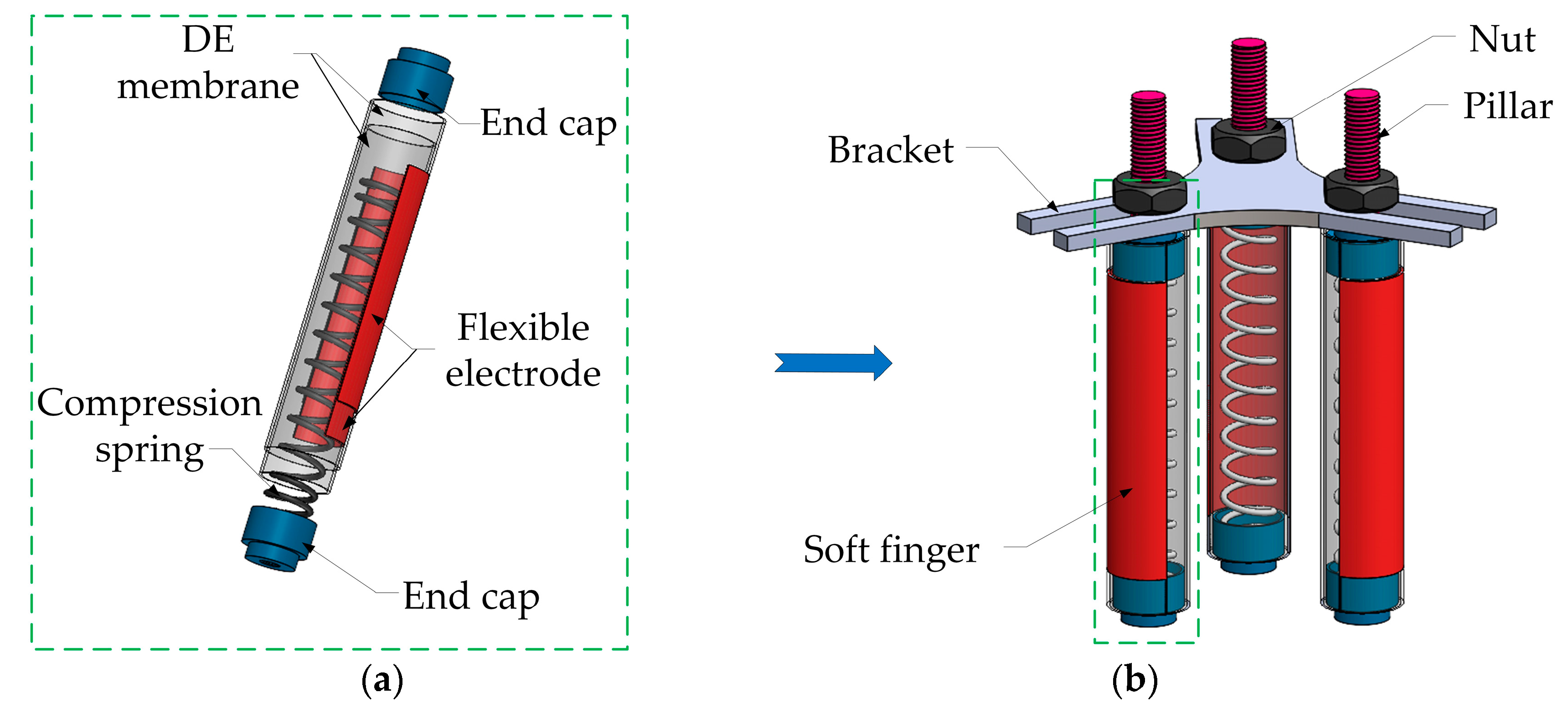

2. Structural Design and Theoretical Model Analysis of the Soft Finger

2.1. Structural Design of the Soft Finger

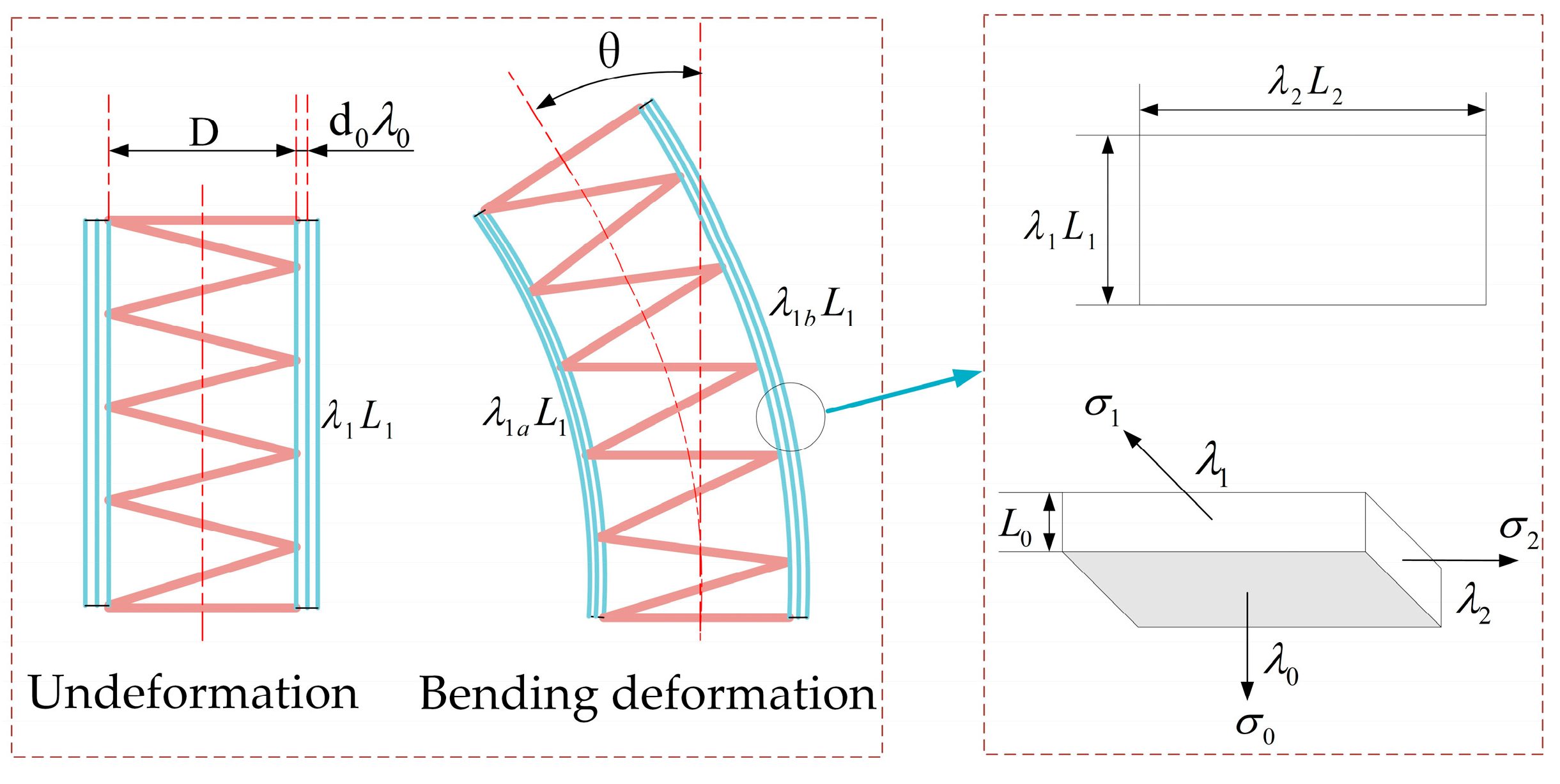

2.2. Theoretical Basis of the Soft Finger

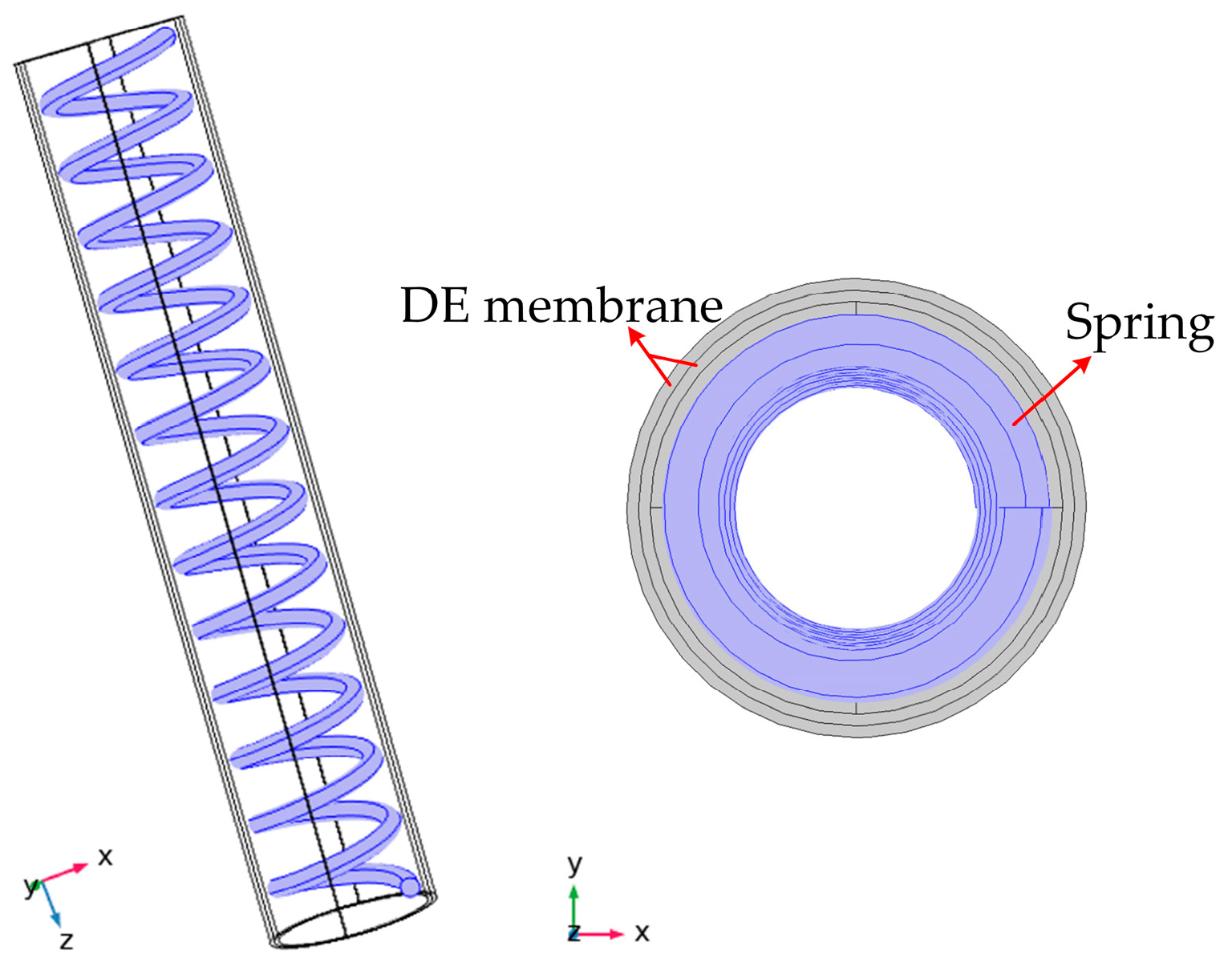

2.3. Finite Element Analysis of the Soft Finger

2.3.1. Simulation of the DE Membrane

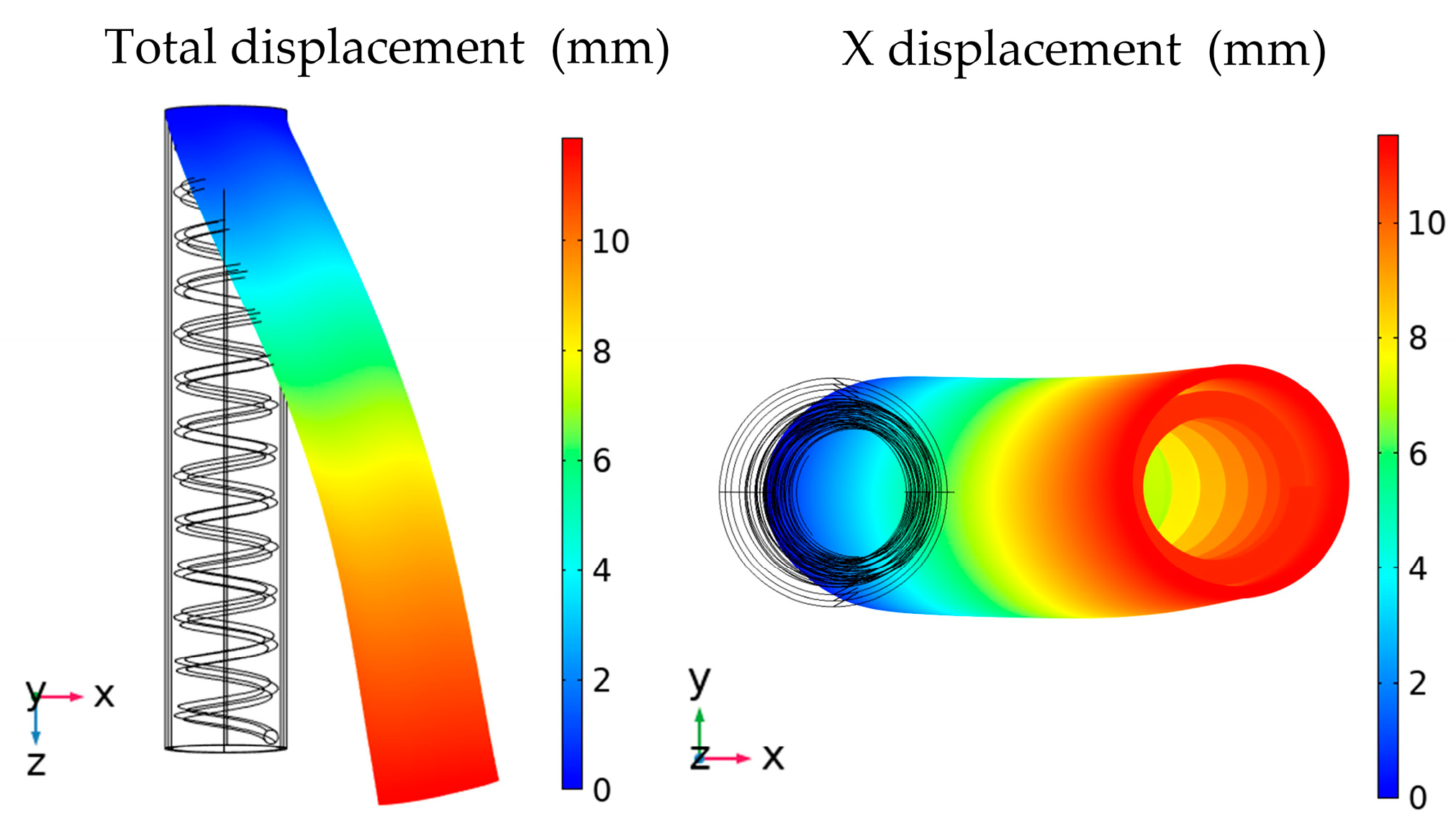

2.3.2. Boundary Conditions and the Simulation of the Soft Finger

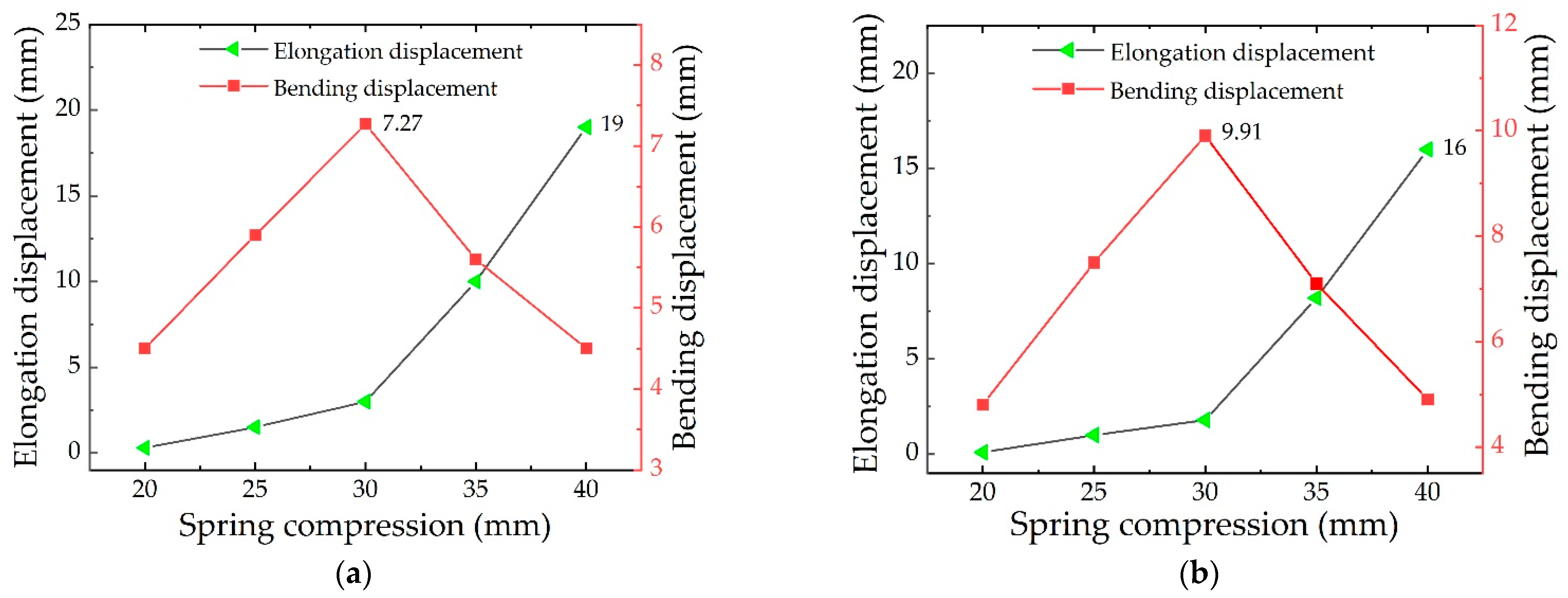

2.3.3. Numerical Analysis with the Different Compressions of the Spring

2.3.4. Numerical Analysis with the Different Pre-stretching ratios of the DE Membrane

3. Results and Discussion of the Soft Finger

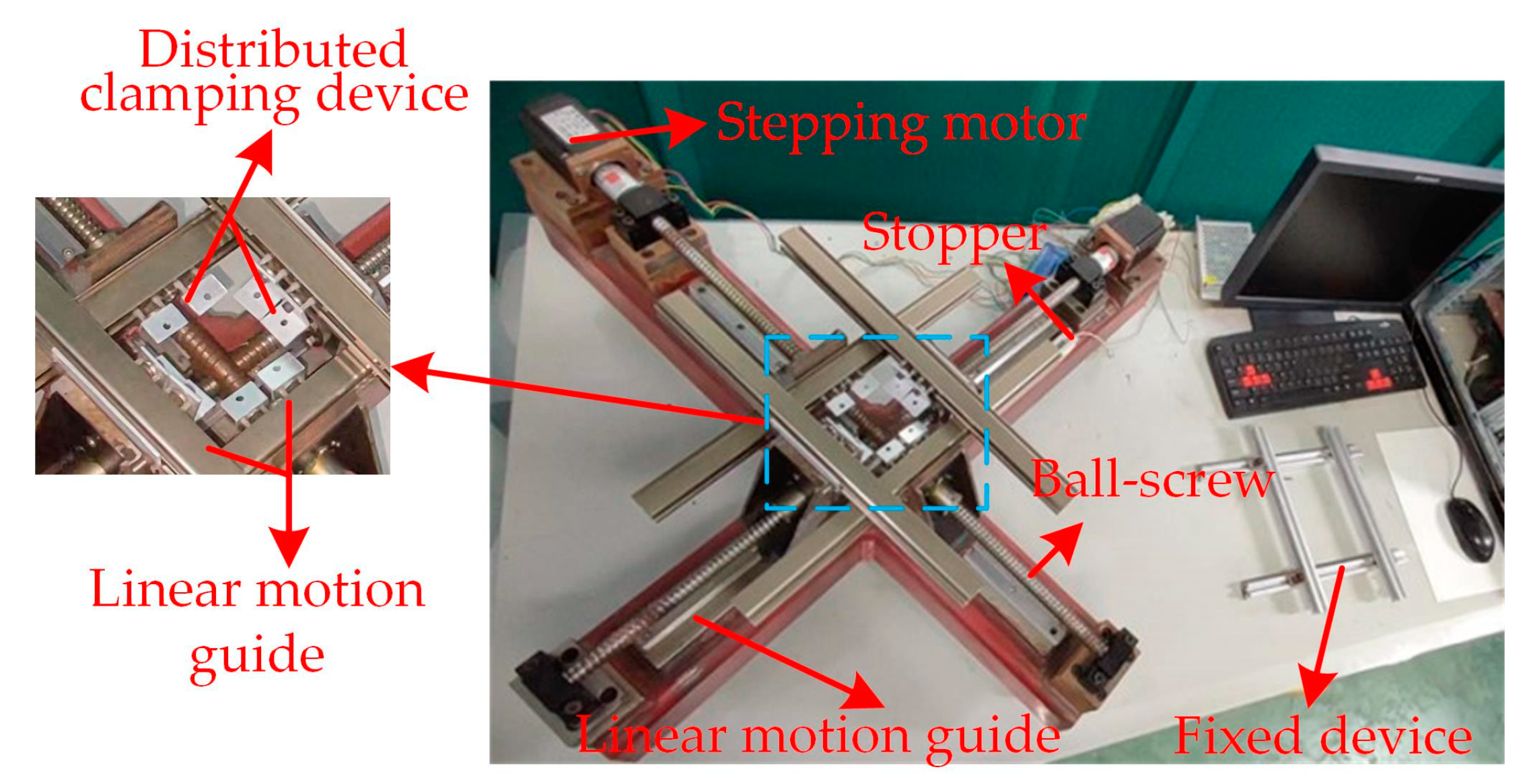

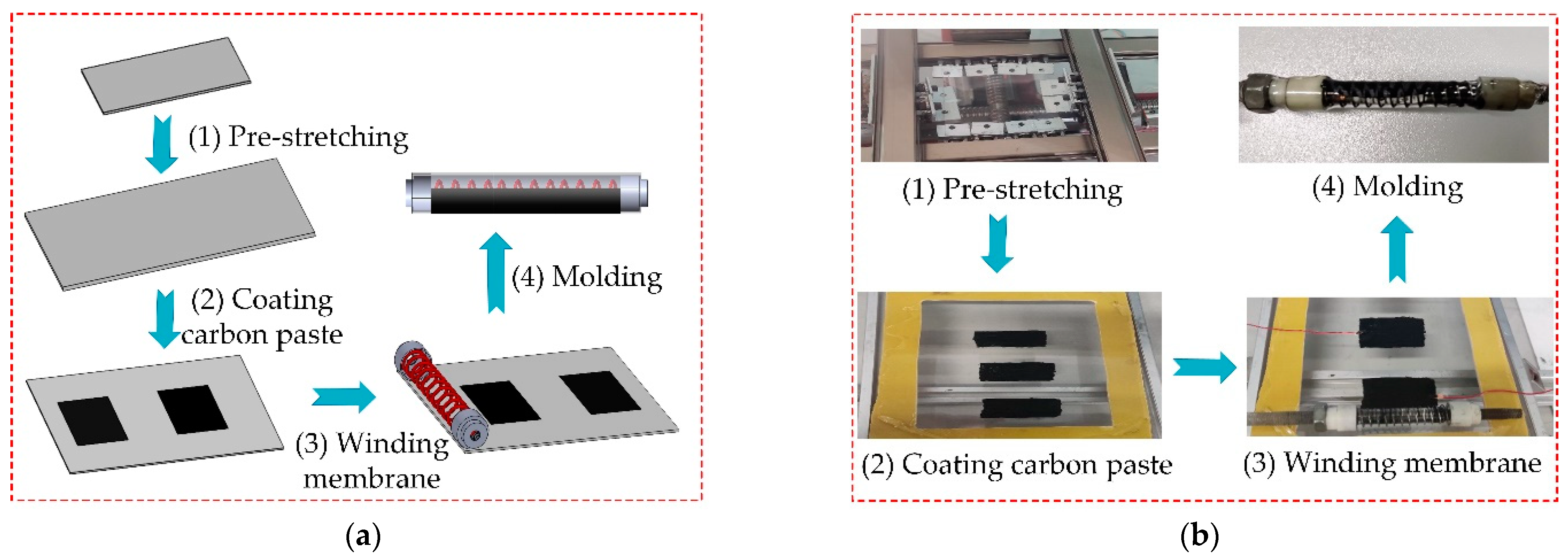

3.1. Experimental Preparation of the Soft Finger

3.2. Analysis of the Experimental Results

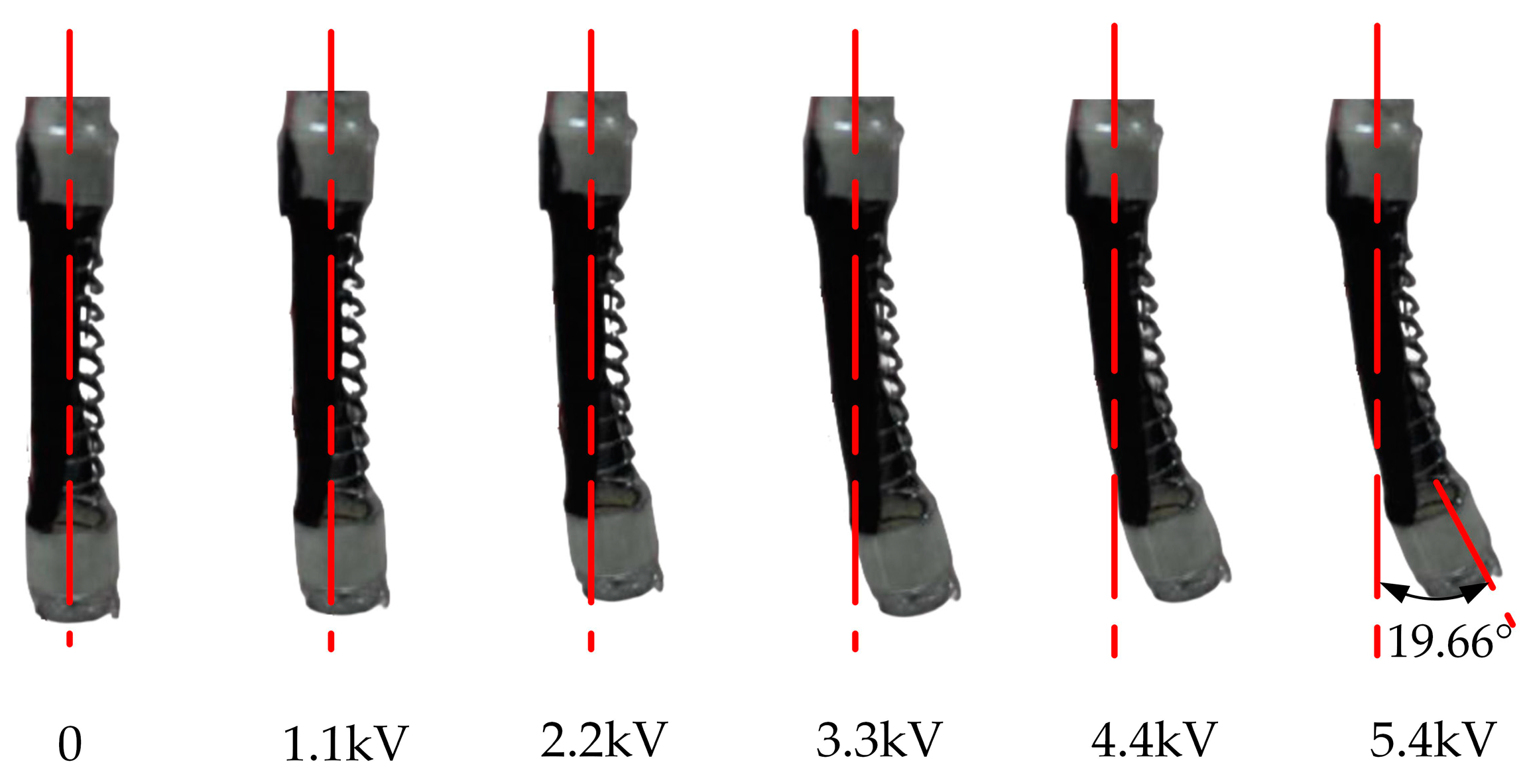

3.2.1. Experimental Analysis with the Different Compressions of the Spring

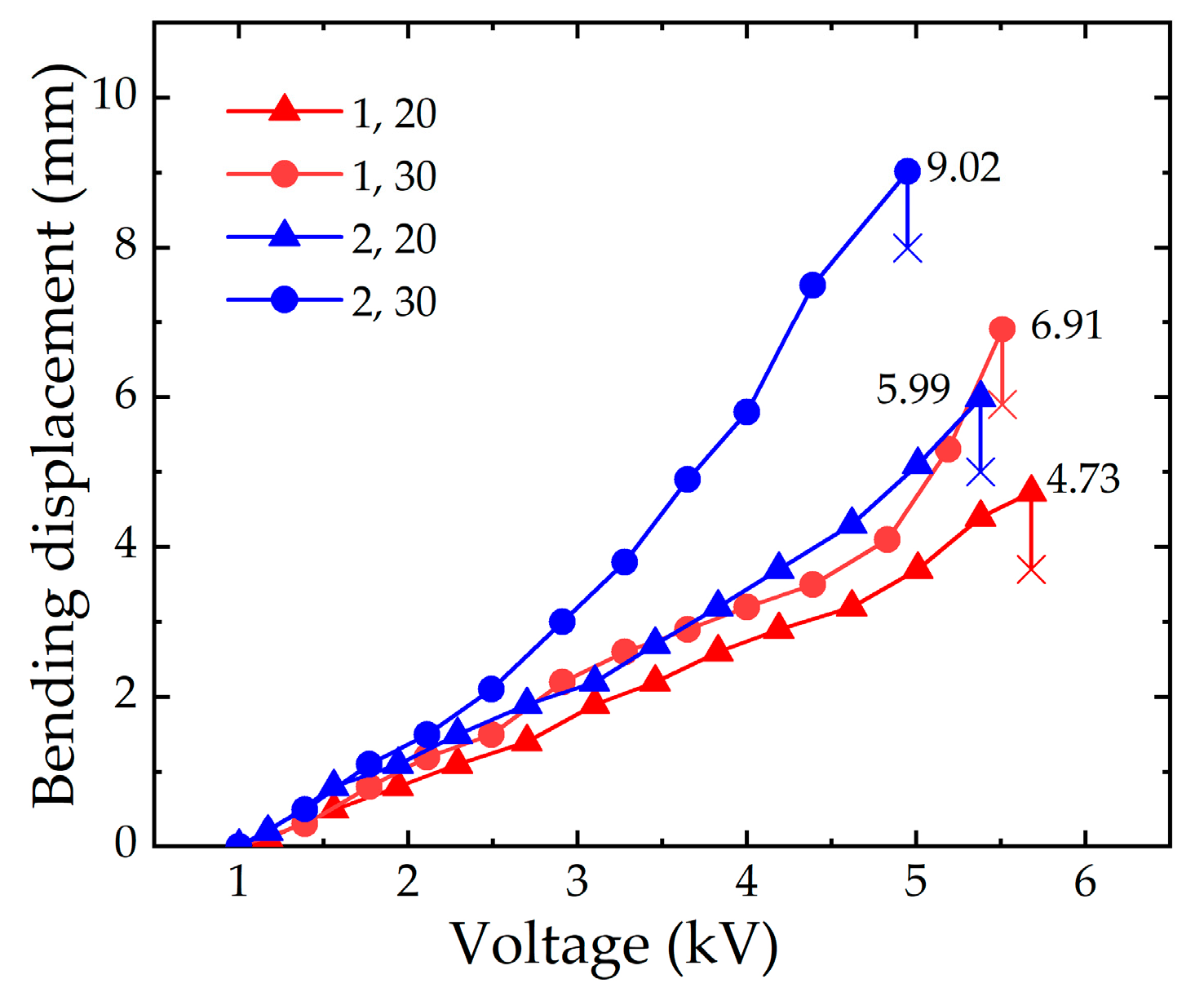

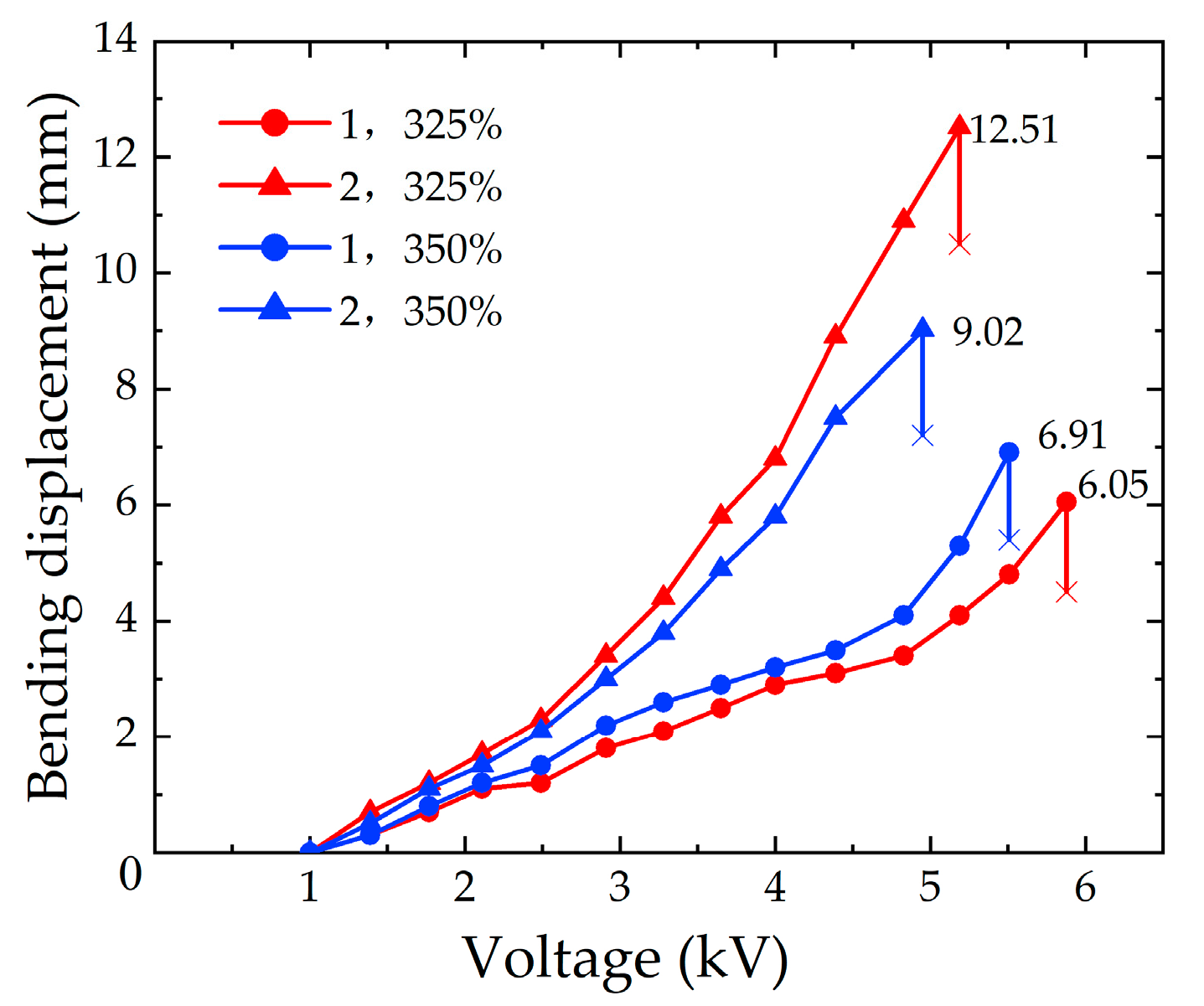

3.2.2. Experimental Analysis with Different Pre-stretching ratios of the DE Membrane

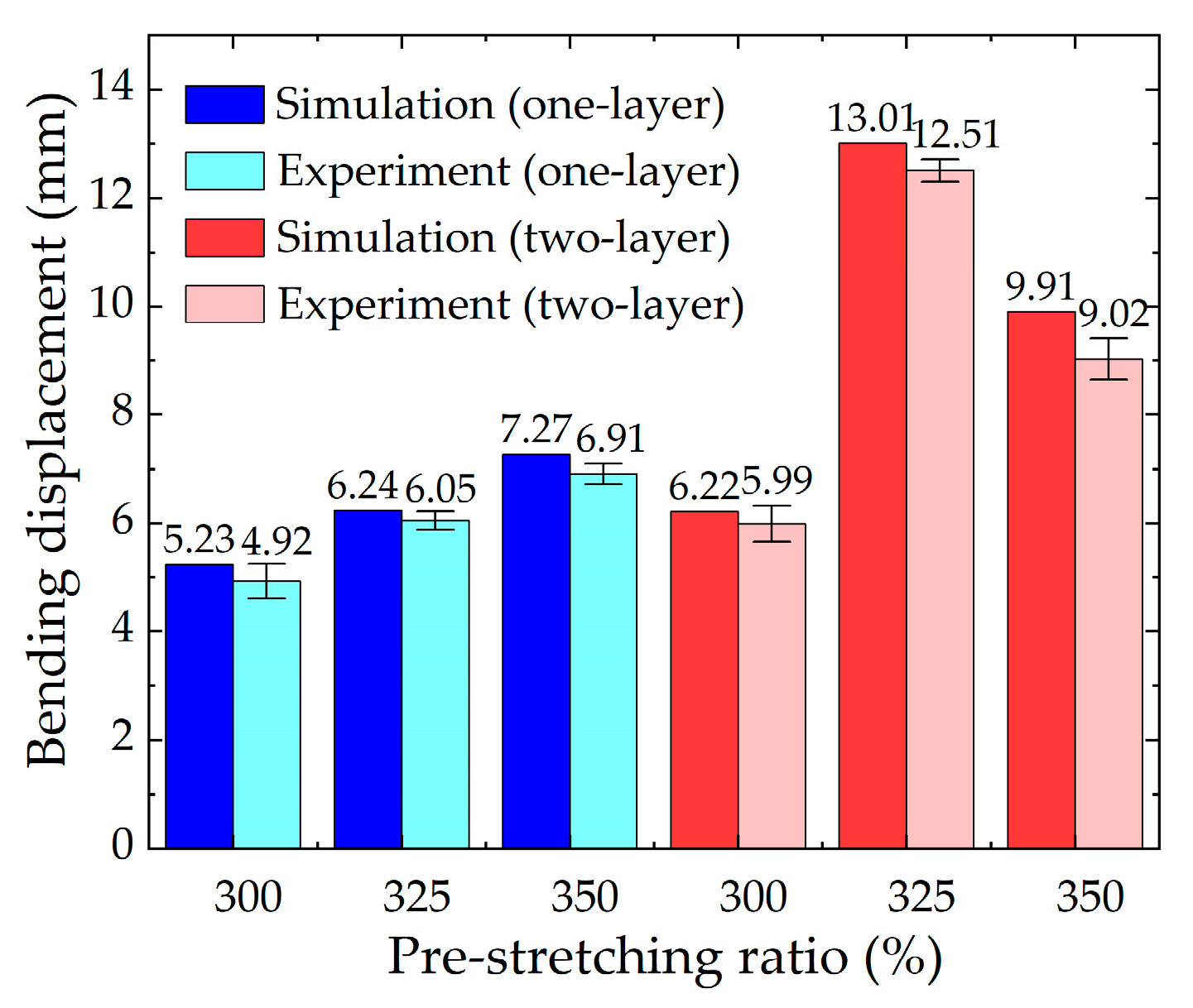

3.2.3. Comparison of the Numerical Analysis and the Experimental Results

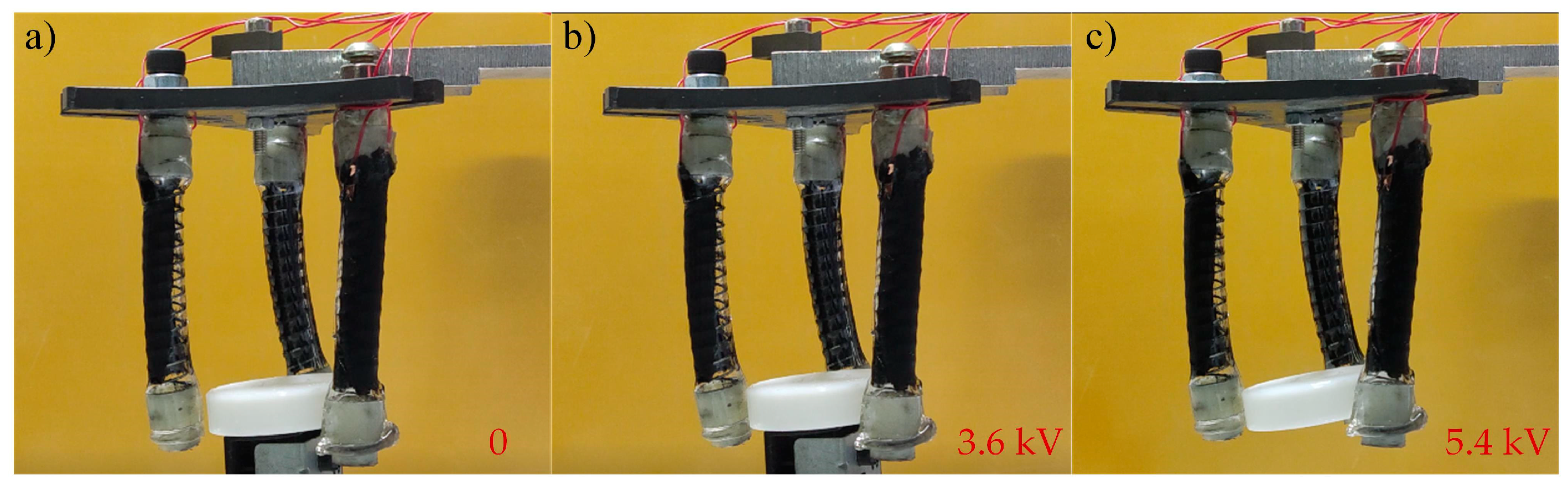

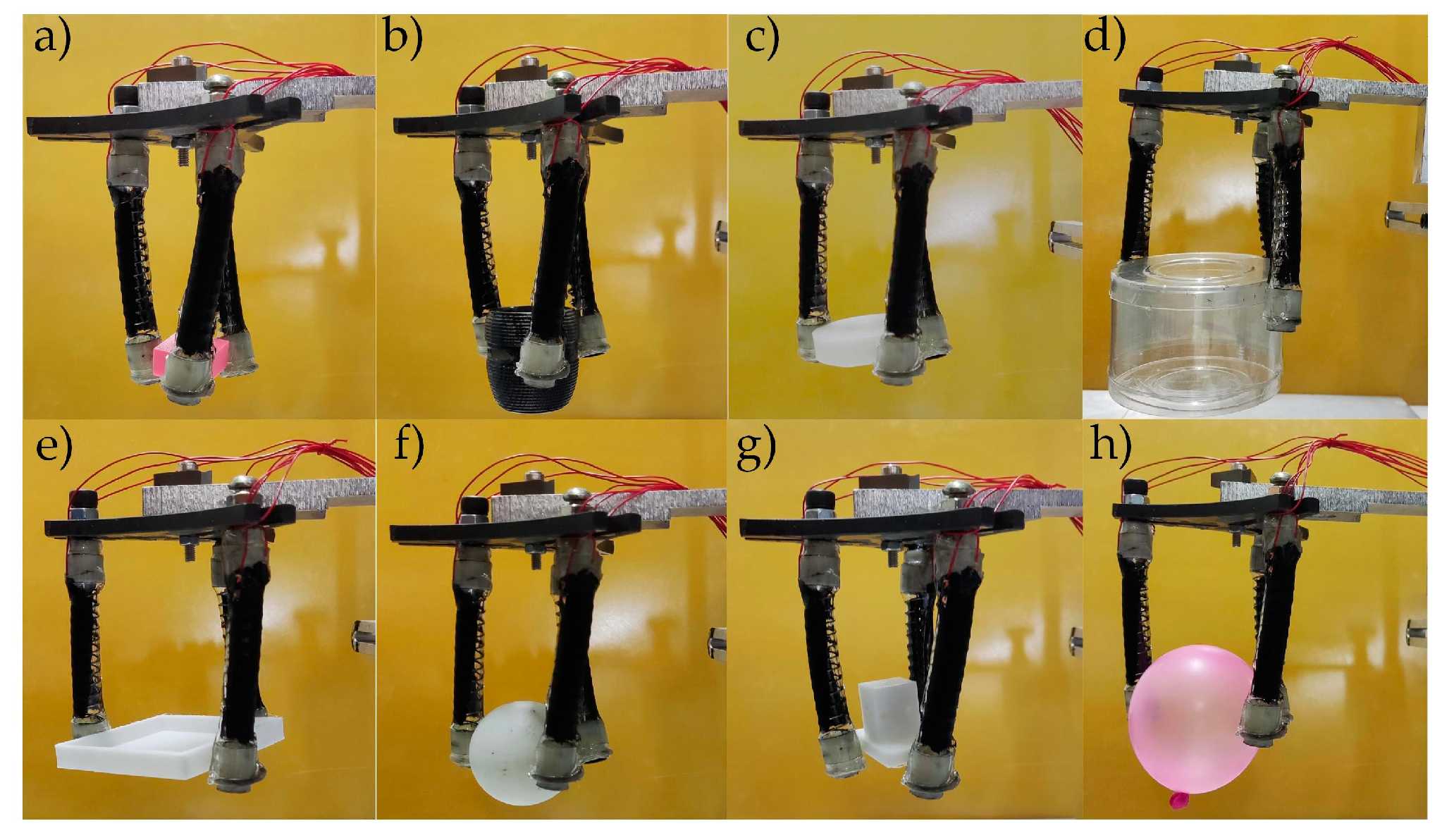

3.3. Application of the Soft Finger

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.R.; Liu, L.W.; Liu, Y.J.; Leng, J.S. Dielectric Elastomer Spring-Roll Bending Actuators: Applications in Soft Robotics and Design. Soft Robot. 2019, 6, 69–81. [Google Scholar] [CrossRef]

- Deimel, R.; Brock, O. A novel type of compliant and underactuated robotic hand for dexterous grasping. Int. J. Robot. Res. 2016, 35, 161–185. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Ding, L.W.; Dai, N.; Mu, X.M.; Xie, S.H.; Cheng, X.S. Design of soft multi-material pneumatic actuators based on principal strain field. Mater. Des. 2019, 182, 108000. [Google Scholar] [CrossRef]

- Morales, D.S.G.; Ibrahim, S.; Cao, B.H.; Raatz, A. Design and Characterization of a 3D Printed Soft Pneumatic Actuator. New Trends Mech. Mach. Sci. 2020, 7, 488–495. [Google Scholar] [CrossRef]

- Lee, J.H.; Yoon, S.C.; Hugo, R. Long Shape Memory Alloy Tendon-based Soft Robotic Actuators and Implementation as a Soft Gripper. Nature 2019, 9, 11251. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Kim, D.R.; Ahn, S.H. Curved shape memory alloy-based soft actuators and application to soft gripper. Compos. Struct. 2017, 176, 398–406. [Google Scholar] [CrossRef]

- Li, Z.; Huang, R.; Liu, Z.S. A Periodic Deformation Mechanism of a Soft Actuator for Crawling and Grasping. Adv. Mater. Technol. 2019, 4, 1900653. [Google Scholar] [CrossRef]

- He, Q.G.; Wang, Z.J.; Wang, Y.; Minori, A.; Tolley, M.T.; Cai, S.Q. Electrically controlled liquid crystal elastomer–based soft tubular actuator with multimodal actuation. Sci. Adv. 2019, 5, eaax5746. [Google Scholar] [CrossRef]

- Ge, G.; Lu, Y.; Qu, X.Y.; Zhao, W.; Ren, Y.F.; Wang, W.J.; Wang, Q.; Huang, W.; Dong, X.C. Muscle-Inspired Self-Healing Hydrogels for Strain and Temperature Sensor. ACS NANO 2020, 14, 218–228. [Google Scholar] [CrossRef]

- Ge, G.; Zhang, Y.Z.; Zhang, W.L.; Yuan, W.; El-Demellawi, J.K.; Zhang, P.; Di, F.E.; Dong, X.C.; Husam, A.N. Ti3C2Tx MXene-Activated Fast Gelation of Stretchable and Self-Healing Hydrogels: A Molecular Approach. ACS NANO 2021, 15, 2698–2706. [Google Scholar] [CrossRef]

- Lotfiani, A.; Yi, X.L.; Shao, Z.F.; Zhao, H.C.; Parkestani, A.N. Analytical modeling and optimization of a corrugated soft pneumatic finger considering the performance of pinch and power grasps. Extrem. Mech. Lett. 2021, 44, 2352–4316. [Google Scholar] [CrossRef]

- Luo, Z.J.; Wang, S.; Cheng, G.G.; Yuan, N.Y.; Ding, J.N. Designing, Manufacturing and Controlling of the Elastic Materials Based Bionic Hand. J. Mech. Eng. 2019, 55, 69–75. [Google Scholar] [CrossRef]

- Lotfiani, A.; Zhao, H.C.; Shao, Z.F.; Yi, X.L. Torsional Stiffness Improvement of a Soft Pneumatic Finger Using Embedded Skeleton. J. Mech. Robot. 2019, 12, 011016. [Google Scholar] [CrossRef]

- Hao, T.Z.; Xiao, H.P.; Liu, S.H.; Gu, J.F. Flexible and stable grasping by multi-jointed pneumatic actuator mimicking the human finger-impacts of structural parameters on performance. Smart Mater. Struct. 2021, 30, 125019. [Google Scholar] [CrossRef]

- Lau, G.K.; Heng, K.R.; Ahmed, A.S.; Shrestha, M. Dielectric elastomer fingers for versatile grasping and nimble pinching. Appl. Phys. Lett. 2017, 110, 182906. [Google Scholar] [CrossRef]

- Witchuda, T.K.; Ardi, W.; Ayato, M.; Mao, Z.B.; Maeda, S.J. Soft Robotic Gripper Based on Multi-Layers of Dielectric Elastomer Actuators. Robot. Mechatron. 2021, 33, 968–974. [Google Scholar] [CrossRef]

- Wang, N.F.; Cui, C.Y.; Guo, H.; Chen, B.C.; Zhang, X.M. Advances in dielectric elastomer actuation technology. Technol. Sci. 2018, 10, 1512–1527. [Google Scholar] [CrossRef]

- Yang, G.; Xiao, L.F.; Tran, D.; Ju, K.; Bo, Q.; Li, J. Dielectric elastomer actuators based on stretchable and self-healable hydrogel electrodes. R. Soc. Open Sci. 2019, 6, 182145. [Google Scholar] [CrossRef]

- David, M.C.; Rosset, S.; Besse, N.; Shea, H. Multifunctional shape memory electrodes for dielectric elastomer actuators enabling high holding force and low-voltage multisegment addressing. Smart Mater. Struct. 2017, 26, 025015. [Google Scholar] [CrossRef]

- Allen, D.P.; Bolívar, E.; Farmer, S.; Voit, W.; Gregg, R.D. Mechanical Simplification of Variable-Stiffness Actuators Using Dielectric Elastomer Transducers. Actuators 2019, 8, 44. [Google Scholar] [CrossRef]

- Chen, F.Y.; Ren, Z.X.; Lau, G.K. Maximal strengths of dielectric elastomer fingers for a passive grip. Smart Mater. Struct. 2022, 31, 045014. [Google Scholar] [CrossRef]

- Nguyen, T.T.D.; Li, J.; Sun, L.J.; Tran, D.; Xuan, F.Z. Viscoelasticity Modeling of Dielectric Elastomers by Kelvin Voigt-Generalized Maxwell Model. Polymers 2021, 13, 2203. [Google Scholar] [CrossRef]

- Zhou, F.H.; Yang, X.X.; Xiao, Y.H.; Zhu, Z.Q.; Xu, Z.B. Electromechanical analysis and simplified modeling of dielectric elastomer multilayer bending actuator. AIP Adv. 2020, 10, 055003. [Google Scholar] [CrossRef]

- Liu, F.; An, N.; Sun, W.J.; Zhou, J.X. Designing Soft Mobile Machines Enabled by Dielectric Elastomer Minimum Energy Structures. Polymers 2022, 14, 1466. [Google Scholar] [CrossRef]

- Pei, Q.; Pelrine, R.; Standford, S.; Kornbluh, R. Electroelastomer rolls and their application for biomimetic walking robots. Synth. Met. 2003, 135, 129–131. [Google Scholar] [CrossRef]

- Zhang, J.S.; Chen, H.L.; Tang, L.L.; Li, B.; Sheng, J.J.; Liu, L. Modelling of spring roll actuators based on viscoelastic dielectric elastomers. Appl. Phys. A 2015, 119, 825–835. [Google Scholar] [CrossRef]

| Property | Value | Unit |

|---|---|---|

| Shear Elasticity μ1 | 24,940 | Pa |

| Shear Elasticity μ2 | 57,340 | Pa |

| Shear Elasticity μ3 | −57,400 | Pa |

| Parameter α1 | 1.2814 | - |

| Parameter α2 | 3.0164 | - |

| Parameter α3 | 3.0158 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouyang, F.; Guan, Y.; Yu, C.; Yang, X.; Cheng, Q.; Chen, J.; Zhao, J.; Zhang, Q.; Guo, Y. An Optimization Design Method of Rigid-Flexible Soft Fingers Based on Dielectric Elastomer Actuators. Micromachines 2022, 13, 2030. https://doi.org/10.3390/mi13112030

Ouyang F, Guan Y, Yu C, Yang X, Cheng Q, Chen J, Zhao J, Zhang Q, Guo Y. An Optimization Design Method of Rigid-Flexible Soft Fingers Based on Dielectric Elastomer Actuators. Micromachines. 2022; 13(11):2030. https://doi.org/10.3390/mi13112030

Chicago/Turabian StyleOuyang, Fuhao, Yuanlin Guan, Chunyu Yu, Xixin Yang, Qi Cheng, Jiawei Chen, Juan Zhao, Qinghai Zhang, and Yang Guo. 2022. "An Optimization Design Method of Rigid-Flexible Soft Fingers Based on Dielectric Elastomer Actuators" Micromachines 13, no. 11: 2030. https://doi.org/10.3390/mi13112030

APA StyleOuyang, F., Guan, Y., Yu, C., Yang, X., Cheng, Q., Chen, J., Zhao, J., Zhang, Q., & Guo, Y. (2022). An Optimization Design Method of Rigid-Flexible Soft Fingers Based on Dielectric Elastomer Actuators. Micromachines, 13(11), 2030. https://doi.org/10.3390/mi13112030