Applications of Graphene-Based Materials in Sensors: A Review

Abstract

:1. Introduction

2. Application of Graphene Materials in Biosensors

3. Application of Graphene in Physical Sensors

4. Application of Graphene in Chemical Sensors

5. Challenges and Prospect

- (a)

- Improve the sensitivity of the sensor and shorten the response time;

- (b)

- Combined with flexible materials, it can be extended to a large area.

| Preparation Method | Basic Principles | Characteristic |

|---|---|---|

| micromechanical exfoliation | The mechanical force is used to overcome the van der Waals force between graphene and separate graphene [79]. | Single graphene was obtained for the first time, and the process is complex, which cannot realize large-scale production [80]. |

| chemical vapor deposition | Pyrolytic carbon was formed on the surface of the metal substrate with a carbon compound as a precursor. By controlling the reaction conditions, the pyrolytic carbon forms graphene through nucleation and repolymerization [80]. | A large area and high-quality graphene can be prepared by using copper foil as a substrate [81,82]. |

| epitaxial growth | The crystal structure is grown from another crystal structure using lattice matching [80]. | One or two layers of graphene can be obtained under harsh preparation conditions [80]. |

| the reduction of graphene oxide (GO) solution | Graphene was obtained by the reduction of graphite oxide [83]. | With low cost and high yield, it can be produced on a large scale [80]. |

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, X.; Cui, H.; Gui, Y. Synthesis of Graphene-Based Sensors and Application on Detecting SF6 Decomposing Products: A Review. Sensors 2017, 17, 363. [Google Scholar] [CrossRef]

- Jiang, H.J. Chemical Preparation of Graphene-Based Nanomaterials and Their Applications in Chemical and Biological Sensors. Small 2011, 7, 2413–2427. [Google Scholar] [CrossRef]

- Avouris, P. Graphene: Electronic and photonic properties and devices. Nano Lett. 2010, 10, 4285. [Google Scholar] [CrossRef]

- Yang, W.R.; Ratinac, K.R.; Ringer, S.P.; Thordarson, P.; Gooding, J.J.; Braet, F. Carbon nanomaterials in biosensors: Should you use nanotubes or graphene? Angew. Chem. Int. Ed. 2010, 49, 2114. [Google Scholar] [CrossRef]

- Mohanty, N.; Berry, V. Graphene-based single-bacterium resolution biodevice and DNA transistor: Interfacing graphene derivatives with nanoscale and microscale biocomponents. Nano Lett. 2008, 8, 4469–4476. [Google Scholar] [CrossRef]

- Zhao, Z.; Gan, Q.Z. Electrochemical Sensors Based on Carbon Nanotubes. Electroanalysis 2002, 14, 1609–1613. [Google Scholar] [CrossRef]

- Kruss, S.; Hilmer, A.J.; Zhang, J.; Reuel, N.F.; Mu, B.; Strano, M.S. Carbon nanotubes as optical biomedical sensors. Adv. Drug Deliv. Rev. 2013, 65, 1933–1950. [Google Scholar] [CrossRef]

- Strozzi, V.V.; Smirnov, L.I.M.; Pellicano, F. Nonlinear normal modes, resonances and energy exchange in single-walled carbon nanotubes. Int. J. Non-Linear Mech. 2020, 120, 103398. [Google Scholar] [CrossRef]

- Strozzi, F.P. Nonlinear Resonance Interaction between Conjugate Circumferential Flexural Modes in Single-Walled Carbon Nanotubes. Shock Vib. 2019, 2019, 3241698. [Google Scholar] [CrossRef]

- Khan, S.A.; Saqib, M.; Rehman, M.M.; Mutee Ur Rehman, H.M.; Rahman, S.A.; Yang, Y.; Kim, S.; Kim, W.-Y. A Full-Range Flexible and Printed Humidity Sensor Based on a Solution-Processed P(VDF-TrFE)/Graphene-Flower Composite. Nanomaterials 2021, 11, 1915. [Google Scholar] [CrossRef]

- Avouris, P.; Dimitrakopoulos, C. Graphene: Synthesis and applications. Mater. Today 2012, 15, 86–97. [Google Scholar] [CrossRef]

- Pinto, A.M.; Gonçalves, I.C.; Magalhães, F.D. Graphene-based materials biocompatibility: A review. Colloids Surf. B Biointerfaces 2013, 111, 188–202. [Google Scholar] [CrossRef]

- Yavari, F.; Koratkar, N. Graphene-Based Chemical Sensors. J. Phys. Chem. Lett. 2012, 3, 1746–1753. [Google Scholar] [CrossRef]

- Shaukat, R.A.; Khan, M.U.; Saqib, Q.M.; Chougale, M.Y.; Kim, J.; Bae, J. All range highly linear and sensitive humidity sensor based on 2D material TiSi2 for real-time monitoring. Sens. Actuators B Chem. 2021, 345, 130371. [Google Scholar] [CrossRef]

- Rehman, H.M.M.U.; Rehman, M.M.; Saqib, M.; Khan, S.A.; Khan, M.; Yang, Y.; Kim, S.; Rahman, S.A.; Kim, W.-Y. Highly Efficient and Wide Range Humidity Response of Biocompatible Egg White Thin Film. Nanomaterials 2021, 11, 1815. [Google Scholar] [CrossRef]

- Sikarwar, S.; Yadav, B.C. Opto-electronic humidity sensor: A review. Sens. Actuators A Phys. 2015, 233, 54–70. [Google Scholar] [CrossRef]

- Dubey, A.; Dave, S.; Lakhani, M.; Sharma, A. Applications of graphene for communication, electronics and medical fields: A review. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 2435–2439. [Google Scholar] [CrossRef]

- Mansuriya, B.D.; Altintas, Z. Applications of Graphene Quantum Dots in Biomedical Sensors. Sensors 2020, 20, 1072. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pirzada, M.; Altintas, Z. Nanomaterials for Healthcare Biosensing Applications. Sensors 2019, 19, 5311. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zeng, Z.; Xiao, F.-X.; Phan, H.; Chen, S.; Yu, Z.; Wang, R.; Nguyen, T.-Q.; Yang Tan, T.T. Unraveling the cooperative synergy of zero-dimensional graphene quantum dots and metal nanocrystals enabled by layer-by-layer assembly. J. Mater. Chem. A 2018, 6, 1700–1713. [Google Scholar] [CrossRef]

- Faridabad, F.; Sanati, A.L. Graphene Quantum Dots in Electrochemical Sensors/Biosensors. Curr. Anal. Chem. 2018, 15, 103–123. [Google Scholar] [CrossRef]

- Chen, W.; Lv, G.; Hu, W.; Li, D.; Chen, S.; Dai, Z. Synthesis and applications of graphene quantum dots: A review. Nanotechnol. Rev. 2018, 7, 157–185. [Google Scholar] [CrossRef]

- Rakovich, A.; Rakovich, T. Semiconductor: Versus graphene quantum dots as fluorescent probes for cancer diagnosis and therapy applications. J. Mater. Chem. B 2018, 6, 2690–2712. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, D.; Chen, J.-F.; Dai, L. Recent Advances in Graphene Quantum Dots for Fluorescence Bioimaging from Cells through Tissues to Animals. Part. Part. Syst. Charact. 2015, 32, 515–523. [Google Scholar] [CrossRef]

- Savas, S.; Altintas, Z. Graphene Quantum Dots as Nanozymes for Electrochemical Sensing of Yersinia enterocolitica in Milk and Human Serum. Materials 2019, 12, 2189. [Google Scholar] [CrossRef] [Green Version]

- Zheng, P.; Wu, N. Fluorescence and Sensing Applications of Graphene Oxide and Graphene Quantum Dots: A Review. Chem. Asian J. 2017, 12, 2343–2353. [Google Scholar] [CrossRef]

- Cui, F.; Ji, J.; Sun, J.; Wang, J.; Wang, H.; Zhang, Y.; Ding, H.; Lu, Y.; Xu, D.; Sun, X. A novel magnetic fluorescent biosensor based on graphene quantum dots for rapid, efficient, and sensitive separation and detection of circulating tumor cells. Anal. Bioanal. Chem. 2019, 411, 985–995. [Google Scholar] [CrossRef]

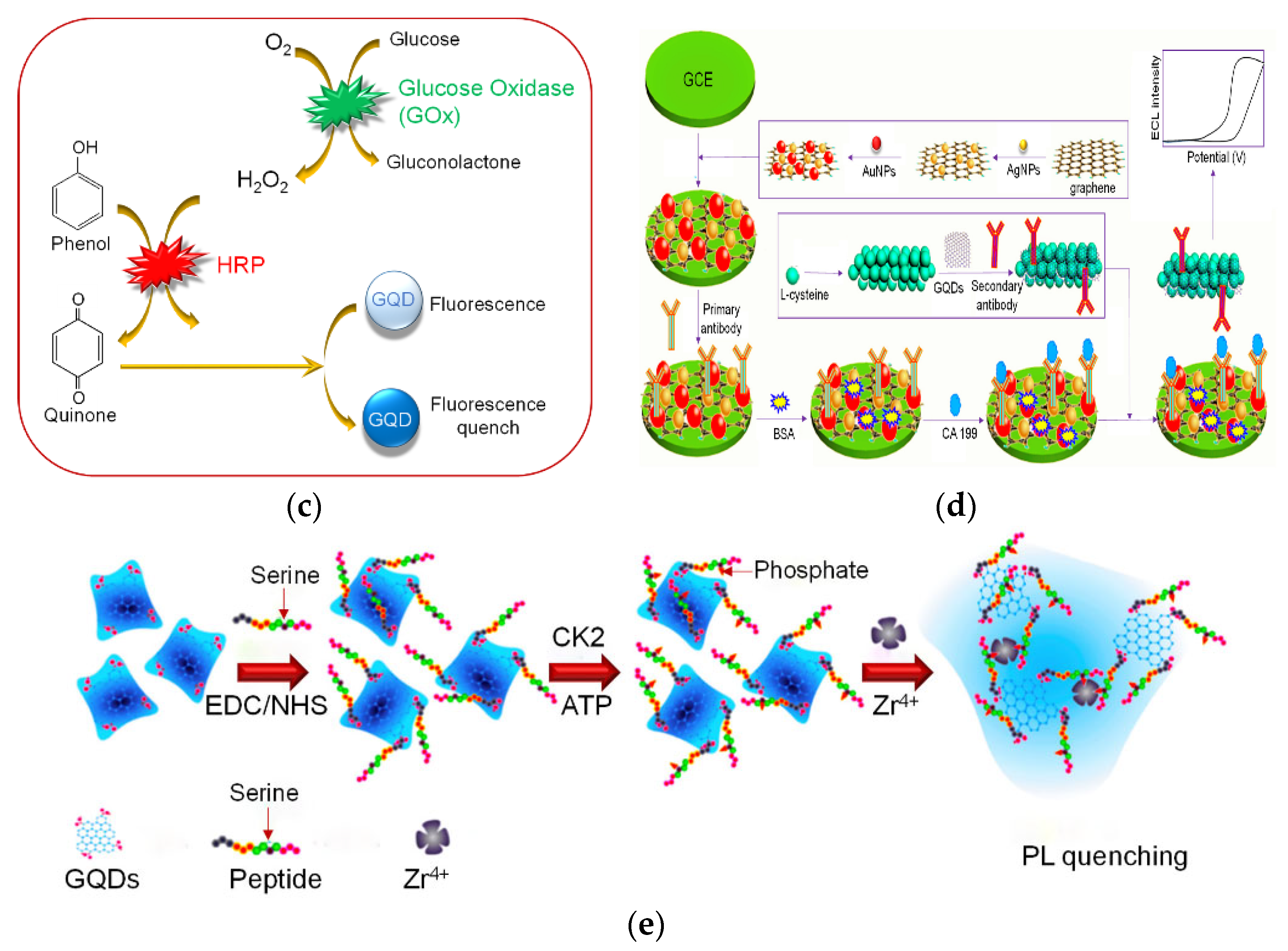

- Wang, B.; Shen, J.; Huang, Y.; Liu, Z.; Zhuang, H. Graphene Quantum Dots and Enzyme-Coupled Biosensor for Highly Sensitive Determination of Hydrogen Peroxide and Glucose. Int. J. Mol. Sci. 2018, 19, 1696. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Liu, W.; Ma, C.; Zhang, Y.; Wang, X.; Yu, J.; Song, X. Gold-silver nanocomposite-functionalized graphene-based electrochemiluminescence immunosensor using graphene quantum dots coated porous PtPd nano chains as labels. Electrochim. Acta 2014, 123, 470–476. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Liang, R.-P.; Bai, J.-M.; Qiu, J.-D. Using Graphene Quantum Dots as Photoluminescent Probes for Protein Kinase Sensing. Anal. Chem. 2013, 85, 9148–9155. [Google Scholar] [CrossRef]

- Ab Halim, N.F.; Ahmad, M.N.; Noor, A.M. Amino acids sensor based on graphene sheet/congo red-molecular imprinted polymer Organic-Thin-Film Transistor for biomedical application. In Proceedings of the 7th 2014 Biomedical Engineering International Conference, Fukuoka, Japan, 26–28 November 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Qiu, H.; Luo, C.; Sun, M.; Lu, F.; Fan, L.; Li, X. A chemiluminescence sensor for determination of epinephrine using graphene oxide magnetite molecularly imprinted polymers. Carbon 2012, 50, 4052–4060. [Google Scholar]

- Shu, H.; Lulu, R.; Juan, G.; Hong, Z.; Chao, Z.; Tianxi, L. The preparation of graphene hybrid films decorated with poly[2-methoxy-5(2′ethylhexyloxy)1,4-phenylene viny lene] particles prepared by nonsolvent induced precipitate in. Carbon 2012, 50, 216224. [Google Scholar]

- Ying, L.; Xin, L.; Tunku, D.; Jingyao, Q.; Xijiang, H. Graphene oxide-based molecularly imprinted polymer platform for detecting endocrine-disrupting chemicals. Carbon 2010, 48, 34273433. [Google Scholar]

- Hummers, W.Z.; Offerman, R.E. Preparation of Graphitic Oxide. J. Am. Chern. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Li, D.; Muller, M.B.; Gilje, S.; Kaner, R.B.; Wallace, G.G. Processable aqueous dispersions of graphene nanosheets. Nat. Nanotechnol. 2008, 3, 101105. [Google Scholar] [CrossRef]

- Syahir, A.; Usui, K.; Tomizaki, K.-Y.; Kajikawa, K.; Mihara, H. Label and Label-Free Detection Techniques for Protein Microarrays. Microarrays 2015, 4, 228–244. [Google Scholar] [CrossRef] [Green Version]

- Moussilli, M.M.; El Falou, A.R.; Shubair, R.M. On the Design of Graphene Surface Plasmon Resonance Sensors for Medical Applications. In Proceedings of the 2018 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, Boston, MA, USA, 8–13 July 2018; pp. 1399–1400. [Google Scholar] [CrossRef]

- Sharma, A.K.; Jha, R.; Gupta, B.D. Fiber-Optic Sensors Based on Surface Plasmon Resonance: A Comprehensive Review. IEEE Sens. J. 2007, 7, 1118–1129. [Google Scholar] [CrossRef]

- Savitha, K.S.; Sharan, R.P. Detection of an oncological cell for breast cancer by using SPR technology. In Proceedings of the 3rd International Conference on Computing for Sustainable Global Development, New Delhi, India, 16–18 March 2016. [Google Scholar]

- Fu, H.; Zhang, S.; Chen, H.; Weng, J. Graphene Enhances the Sensitivity of Fiber-Optic Surface Plasmon Resonance Biosensor. IEEE Sens. J. 2015, 15, 5478–5482. [Google Scholar] [CrossRef]

- Warner, J.H.; Schaffel, F.; Rummeli, M.; Bachmatiuk, A. Graphene: Fundamentals and Emergent Applications; Newnes: London, UK, 2012. [Google Scholar]

- Vashishth, P.; Sen, P. A Novel Method for Fabricating Graphene Sensors in Channel for Biomedical Applications. In Proceedings of the 2018 IEEE 13th Annual International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Singapore, 22–26 April 2018; pp. 405–408. [Google Scholar] [CrossRef]

- Chen, Y.; Gong, X.-L.; Gai, J.-G. Progress and Challenges in Transfer of Large-Area Graphene Films. Adv. Sci. 2016, 3, 1500343. [Google Scholar] [CrossRef]

- Kang, J.; Shin, D.; Bae, S.; Hong, B.H. Graphene transfer: Key for applications. Nanoscale 2012, 4, 5527–5537. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Cai, W.; Borysiak, M.; Han, B.; Chen, D.; Piner, R.D.; Colombo, L.; Ruoff, R.S. Transfer of Large-Area Graphene Films for High-Performance Transparent Conductive Electrodes. Nano Lett. 2009, 9, 4359–4363. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Lu, C.-C.; Yeh, C.-H.; Jin, C.; Suenaga, K.; Chiu, P.-W. Graphene Annealing: How Clean Can It Be? Nano Lett. 2011, 12, 414–419. [Google Scholar] [CrossRef] [PubMed]

- Shakthivel, D.; Yogeswaran, N.; Dahiya, R.S. Towards graphene based flexible force sensor. In Proceedings of the 2017 IEEE Sensors, Glasgow, UK, 29 October 2017–1 November 2017; pp. 1–3. [Google Scholar] [CrossRef] [Green Version]

- Taube Navaraj, W.; García Núñez, C.; Shakthivel, D.; Vinciguerra, V.; Labeau, F.; Gregory, D.H.; Dahiya, R. Nanowire FET Based Neural Element for Robotic Tactile Sensing Skin. Front. Neurosci. 2017, 11, 501. [Google Scholar] [CrossRef] [PubMed]

- Yogeswaran, N.; Dang, W.; Navaraj, W.T.; Shakthivel, D.; Khan, S.; Polat, E.O.; Gupta, S.; Heidari, H.; Kaboli, M.; Lorenzelli, L.; et al. New materials and advances in making electronic skin for interactive Roboto. Adv. Robot. 2015, 29, 1359–1373. [Google Scholar] [CrossRef] [Green Version]

- Dang, W.; Vinciguerra, V.; Lorenzelli, L.; Dahiya, R. Printable stretchable interconnects. Flex. Print. Electron. 2017, 2, 013003. [Google Scholar] [CrossRef]

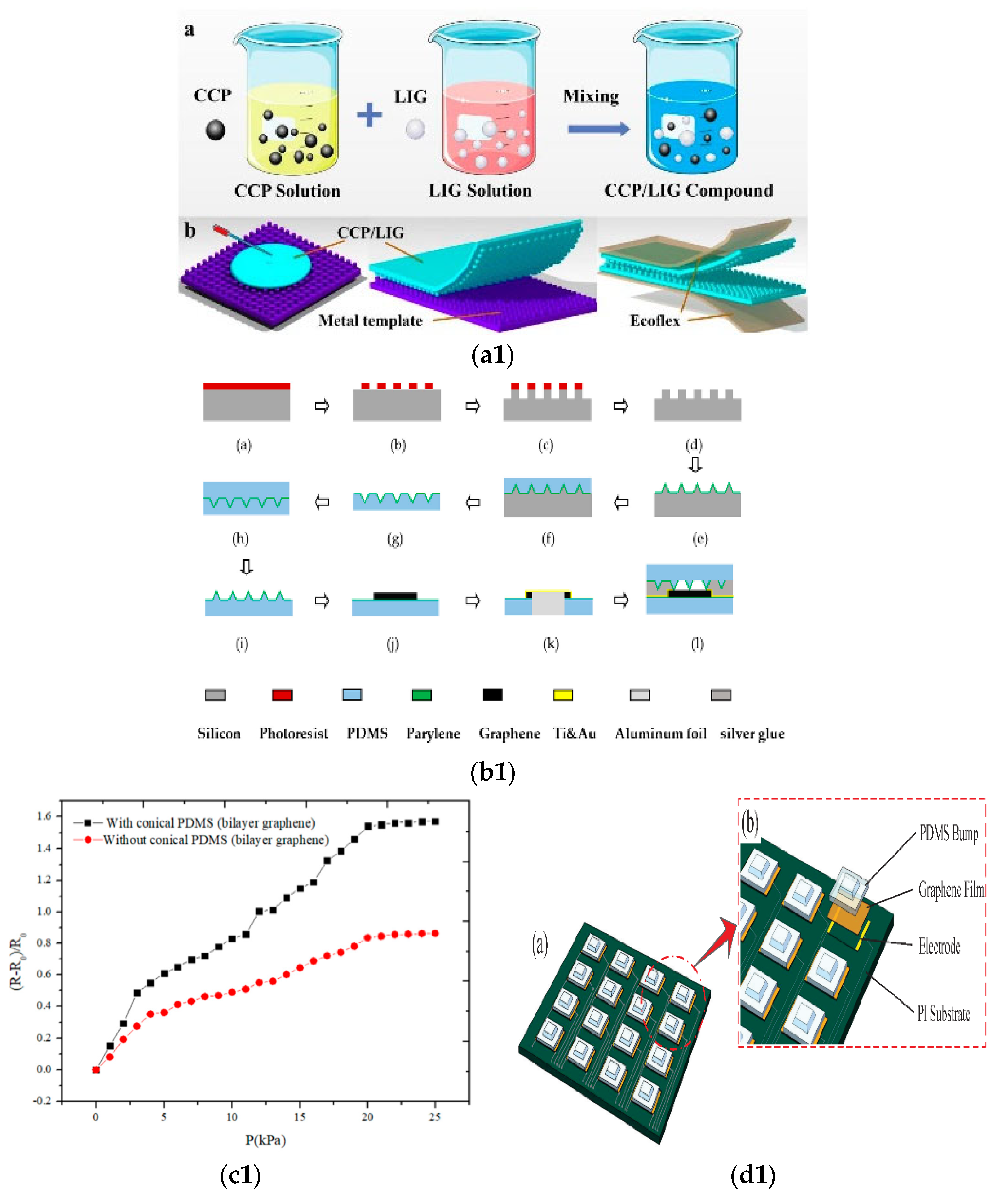

- Wu, W.; Han, C.; Liang, R.; Xu, J.; Li, B.; Hou, J.; Tang, T.; Zeng, Z.; Li, J. Fabrication and Performance of Graphene Flexible Pressure Sensor with Micro/Nano Structure. Sensors 2021, 21, 7022. [Google Scholar] [CrossRef]

- Soldano, C.; Mahmood, A.; Dujardin, E. Production, properties and potential of graphene. Carbon 2010, 48, 2127–2150. [Google Scholar] [CrossRef] [Green Version]

- Bunch, J.S.; Verbridge, S.S.; Alden, J.S.; van der Zande, A.M.; Parpia, J.M.; Craighead, H.G.; McEuen, P.L. Impermeable Atomic Membranes from Graphene Sheets. Nano Lett. 2008, 8, 2458–2462. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Song, M.; Hao, J.; Wu, K.; Li, C.; Hu, C. Visible light laser-induced graphene from phenolic resin: A new approac0h for directly writing graphene-based electrochemical devices on various substrates. Carbon 2018, 127, 287–296. [Google Scholar] [CrossRef]

- Popov, V.I.; Kotin, I.A.; Nebogatikova, N.A.; Smagulova, S.A.; Antonova, I.V. Graphene-PEDOT: PSS humidity sensors for highly sensitive, low-cost, high-reliable, flexible, and printed electronics. Materials 2019, 12, 3477. [Google Scholar] [CrossRef] [Green Version]

- Ruan, X.; Wang, R.; Luo, J.; Yao, Y.; Liu, T. Experimental and modeling study of CO2 laser writing induced polyimide carbonization process. Mater. Des. 2018, 160, 1168–1177. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, R.; Hao, X.; Liu, G. Design of Flexible Pressure Sensor Based on Conical Microstructure PDMS-Bilayer Graphene. Sensors 2021, 21, 289. [Google Scholar] [CrossRef] [PubMed]

- Lü, X.; Yang, J.; Qi, L.; Bao, W.; Zhao, L.; Chen, R. High Sensitivity Flexible Electronic Skin Based on Graphene Film. Sensors 2019, 19, 794. [Google Scholar] [CrossRef] [Green Version]

- Joo, Y.S.; Yoon, J.Y.; Ha, J.W.; Kim, T.H.; Lee, S.W.; Lee, B.M.; Pang, C.Y.; Hong, Y.T. Highly Sensitive and Bendable Capacitive Pressure Sensor and Its Application to 1 V Operation Pressure-Sensitive Transistor. Adv. Electron. Mater. 2017, 3, 1600455. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, X.; Zhong, L.; Pang, K.; Chen, Y.; Wanga, M.; Liu, W. A Flexible Dual-Modal Sensing System for Synchronous Pressure and Inertial Monitoring of Finger Movement. IEEE Sens. J. 2021, 21, 10483–10490. [Google Scholar] [CrossRef]

- Asadi, S.; He, Z.; Heydari, F.; Li, D.; Yuce, M.R.; Alan, T. Graphene Elastomer Electrodes for Medical Sensing Applications: Combining High Sensitivity, Low Noise and Excellent Skin Compatibility to Enable Continuous Medical Monitoring. IEEE Sens. J. 2021, 21, 13967–13975. [Google Scholar] [CrossRef]

- Douglas, C.I.; Nunez, C.G.; Gibson, D.; Caffio, M. Development of Flexible and High Sensitivity Graphene Foam Based Pressure Sensors. In Proceedings of the 2021 13th Spanish Conference on Electron Devices (CDE), Sevilla, Spain, 3–5 February 2021; pp. 141–144. [Google Scholar] [CrossRef]

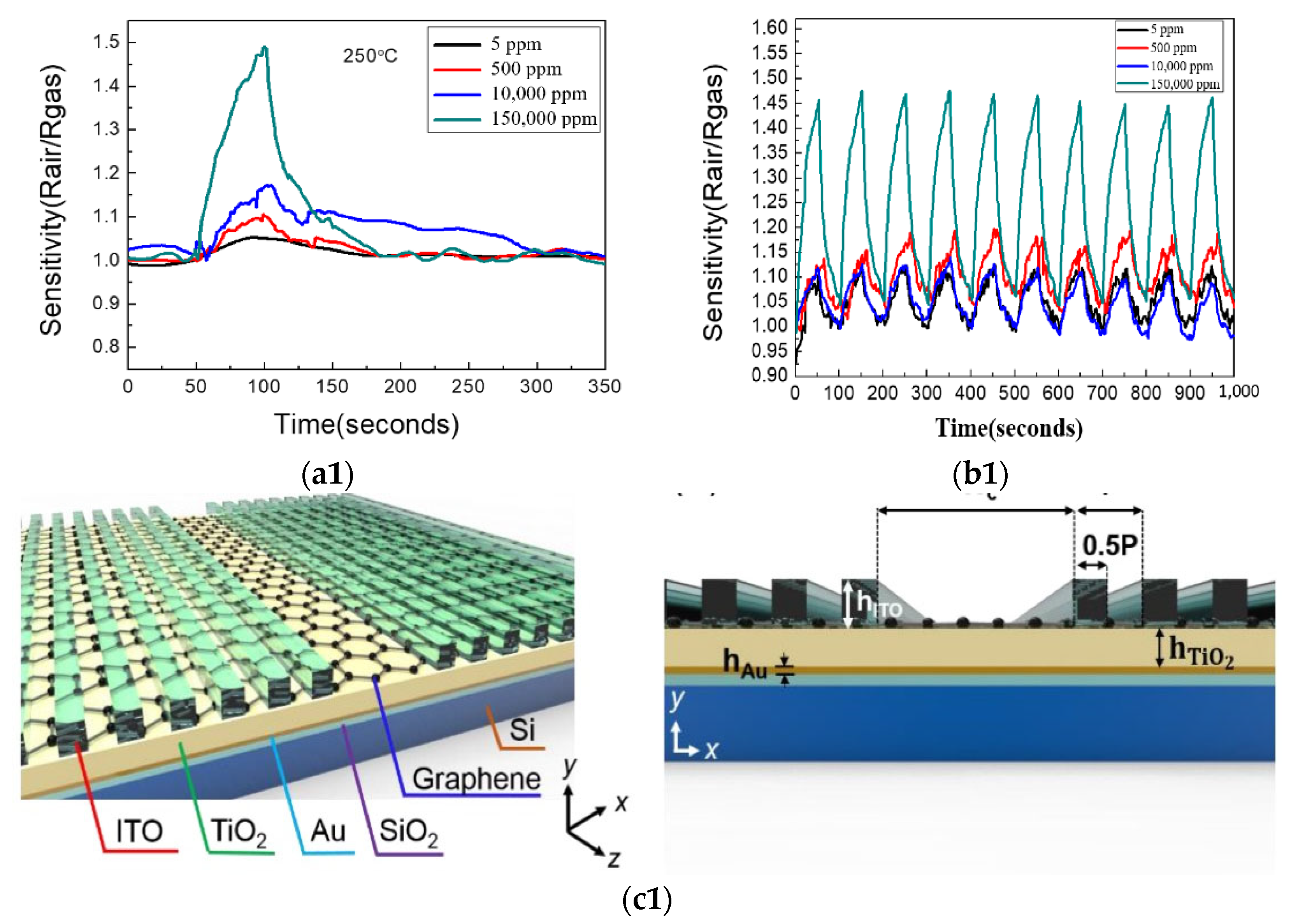

- Ghods, M.M.; Rezaei, P. Graphene-Based Fabry-Perot Resonator for Chemical Sensing Applications at Mid-Infrared Frequencies. IEEE Photon-Technol. Lett. 2018, 30, 1917–1920. [Google Scholar] [CrossRef]

- Tang, X.; Lahem, D.; Raskin, J.-P.; Gerard, P.; Geng, X.; Andre, N.; Debliquy, M. A Fast and Room-Temperature Operation Ammonia Sensor Based on Compound of Graphene with Polypyrrole. IEEE Sens. J. 2018, 18, 9088–9096. [Google Scholar] [CrossRef]

- Ja’Afar, P.N.S.S.; Razali, N.M.; Zaidi, N.F.A.; Ahmad, F.; Omar, M.; Ismail, A.K.; Rosdi, N.; Yaacob, M.H.; Hamzah, A.; Kaidi, H.M.; et al. Graphene Coated Optical Fiber Tip Sensor for Nitrate Sensing Application. In Proceedings of the 2020 IEEE 8th International Conference on Photonics (ICP), Kelantan, Malaysia, 16–18 March 2020; pp. 3–4. [Google Scholar] [CrossRef]

- Lu, Y.-M.; Tseng, C.-F.; Lan, B.-Y.; Hsieh, C.-F. Fabrication of Graphene/Zinc Oxide Nano-Heterostructure for Hydrogen Sensing. Materials 2021, 14, 6943. [Google Scholar] [CrossRef]

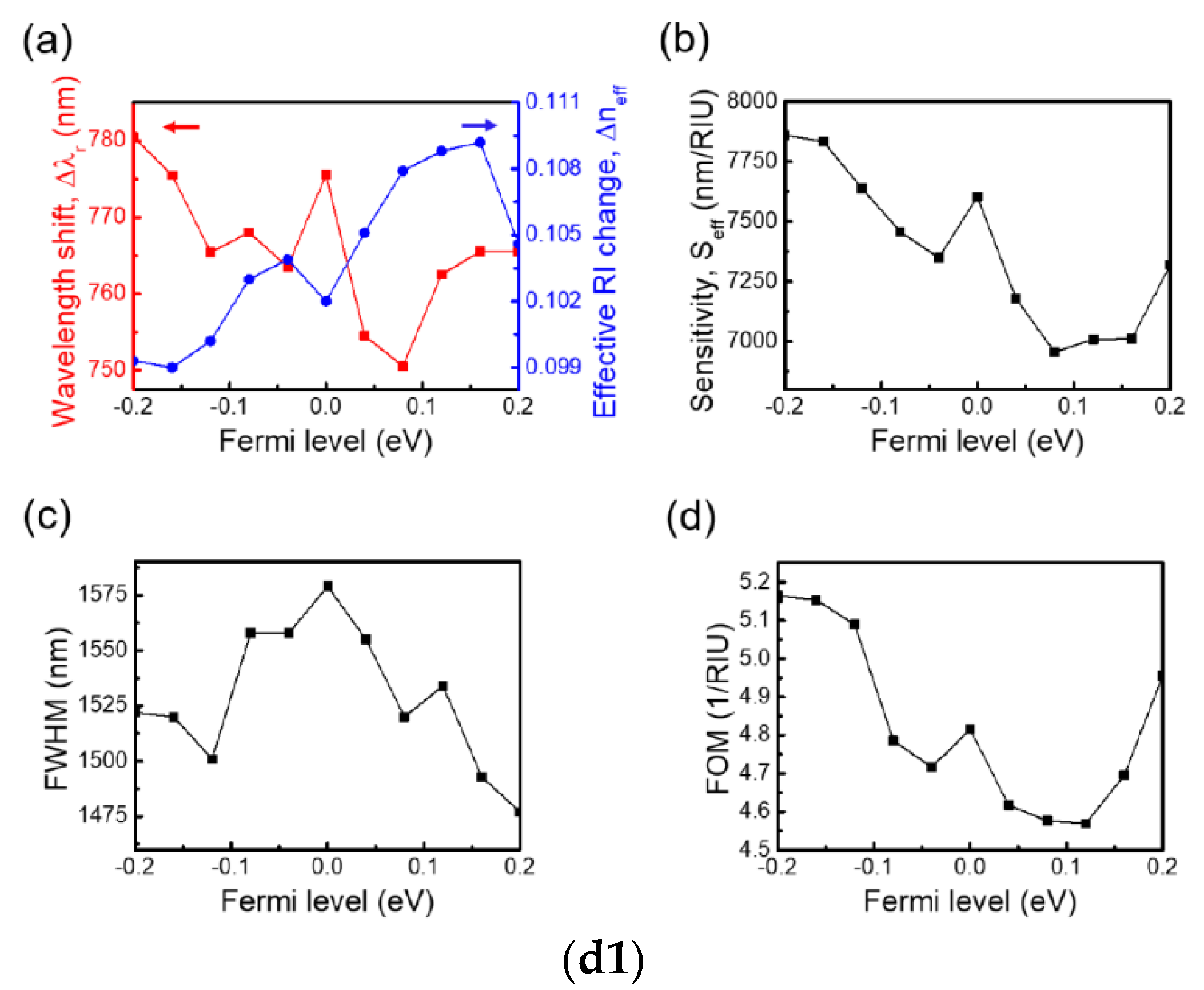

- Yang, C.-S.; Cheng, Y.-S.; Hsu, Y.-C.; Chung, Y.-C.; Hung, J.-T.; Liu, C.-H.; Hsu, J.-C.; Chen, C.-Y.; Yang, C.-R.; Li, Y.-T.; et al. Hybrid Graphene-Based Photonic-Plasmonic Biochemical Sensor with a Photonic and Acoustic Cavity Structure. Crystals 2021, 11, 1175. [Google Scholar] [CrossRef]

- Karmakar, S.; Kundu, S.K.; Bandyopadhyay, S.K.; Gangopadhyay, M.; Taki, G.S. Importance of transition metal modified graphene-based non-enzymatic blood glucose sensors. In Proceedings of the 2020 4th International Conference on Electronics, Materials Engineering & Nano-Technology (IEMENTech), Kolkata, India, 2–4 October 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Smovzh, D.; Kostogrud, I.; Boyko, E. Preparation of Copper Surface for Monolayer Graphene CVD Method Synthesis. In Proceedings of the 2020 7th International Congress on Energy Fluxes and Radiation Effects (EFRE), Tomsk, Russia, 14–26 September 2020; pp. 1136–1139. [Google Scholar] [CrossRef]

- Sha, R.; Durai, L.; Badhulika, S. Facile in-situ preparation of few-layered reduced graphene oxide–niobium pentoxide composite for non-enzymatic glucose monitoring. In Proceedings of the 2018 4th IEEE International Conference on Emerging Electronics (ICEE), Bengaluru, India, 17–19 December 2018; pp. 1–4. [Google Scholar] [CrossRef]

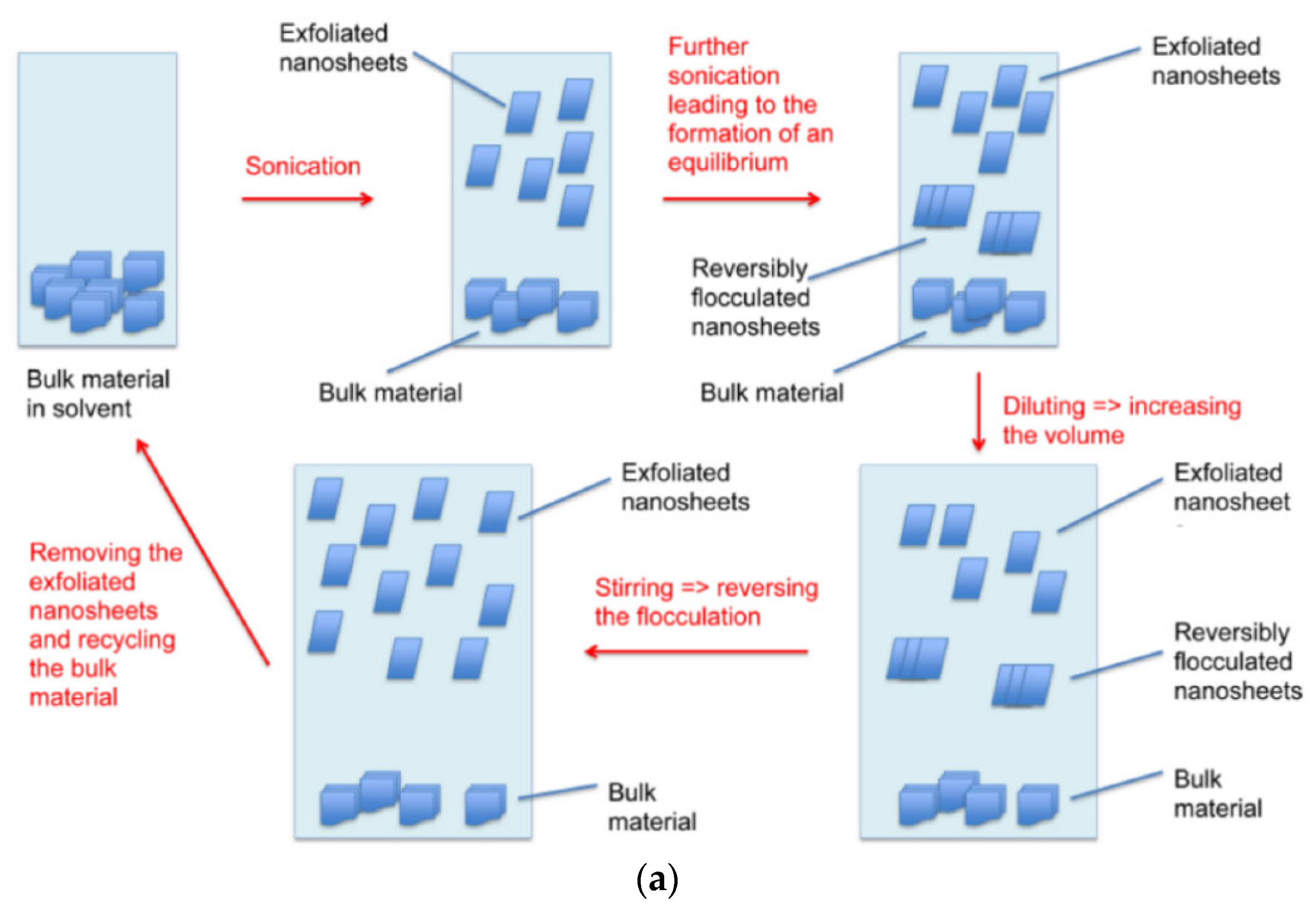

- Goni, F.; Chemelli, A.; Uhlig, F. High-Yield Production of Selected 2D Materials by Understanding Their Sonication-Assisted Liquid-Phase Exfoliation. Nanomaterials 2021, 11, 3253. [Google Scholar] [CrossRef]

- Baker, S.N.; Baker, G.A. Luminescent carbon nanodots: Emergent nanolights. Angew. Chem. Int. Ed. 2010, 49, 6726. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Cui, X.; Li, L.S.J. Synthesis of large, stable colloidal graphene quantum dots with tunable size. Am. Chem. Soc. 2010, 132, 5944. [Google Scholar] [CrossRef] [PubMed]

- Cordaro, A.; Neri, G.; Sciortino, M.T.; Scala, A.; Piperno, A. Graphene-Based Strategies in Liquid Biopsy and in Viral Diseases Diagnosis. Nanomaterials 2020, 10, 1014. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Bai, W.; Dong, C.; Guo, R.; Liu, Z. An ultrasensitive electrochemical DNA biosensor based on graphene/Au nanorod/polythionine for human papillomavirus DNA detection. Biosens. Bioelectron. 2015, 68, 442–446. [Google Scholar] [CrossRef]

- Qiu, G.; Gai, Z.; Tao, Y.; Schmitt, J.; Kullak-Ublick, G.A.; Wang, J. Dual-functional plasmonic photothermal biosensors for highly accurate severe acute respiratory syndrome coronavirus 2 detection. ACS Nano 2020, 14, 5268–5277. [Google Scholar] [CrossRef] [Green Version]

- Seo, G.; Lee, G.; Kim, M.J.; Baek, S.-H.; Choi, M.; Ku, K.B.; Lee, C.-S.; Jun, S.; Park, D.; Kim, H.G.; et al. Rapid detection of covid-19 causative virus (SARS-CoV-2) in human nasopharyngeal swab specimens using field-effect transistor-based biosensor. ACS Nano 2020, 14, 5135–5142. [Google Scholar] [CrossRef] [Green Version]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Sheng, W. Preparation of Graphene and Its Performance Analysis. In Proceedings of the 2016 IEEE 3rd International Conference on Cyber Security and Cloud Computing (CSCloud), Beijing China, 25–27 June 2016; pp. 216–219. [Google Scholar] [CrossRef]

- Gao, L.; Ren, W.; Zhao, J.; Ma, L.P.; Chen, Z.; Cheng, H.M. Efficient growth of high-quality graphene films on Cu foils by ambient pressure chemical vapor deposition. Appl. Phys. Lett. 2010, 97, 183109. [Google Scholar]

- Bhaviripudi, S.; Jia, X.; Dresselhaus, M.S.; Kong, J. Role of Kinetic Factors in Chemical Vapor Deposition Synthesis of Uniform Large Area Graphene Using Copper Catalyst. Nano Lett. 2010, 10, 4128. [Google Scholar] [CrossRef]

- Bai, H.; Li, C.; Shi, G. Functional composite materials based on chemically converted graphene oxide. Adv. Mater. 2011, 23, 1088. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Bao, S.; Wang, X. Applications of Graphene-Based Materials in Sensors: A Review. Micromachines 2022, 13, 184. https://doi.org/10.3390/mi13020184

Liu J, Bao S, Wang X. Applications of Graphene-Based Materials in Sensors: A Review. Micromachines. 2022; 13(2):184. https://doi.org/10.3390/mi13020184

Chicago/Turabian StyleLiu, Jihong, Siyu Bao, and Xinzhe Wang. 2022. "Applications of Graphene-Based Materials in Sensors: A Review" Micromachines 13, no. 2: 184. https://doi.org/10.3390/mi13020184