Design and Modeling of a Curved Beam Compliant Mechanism with Six Degrees of Freedom

Abstract

1. Introduction

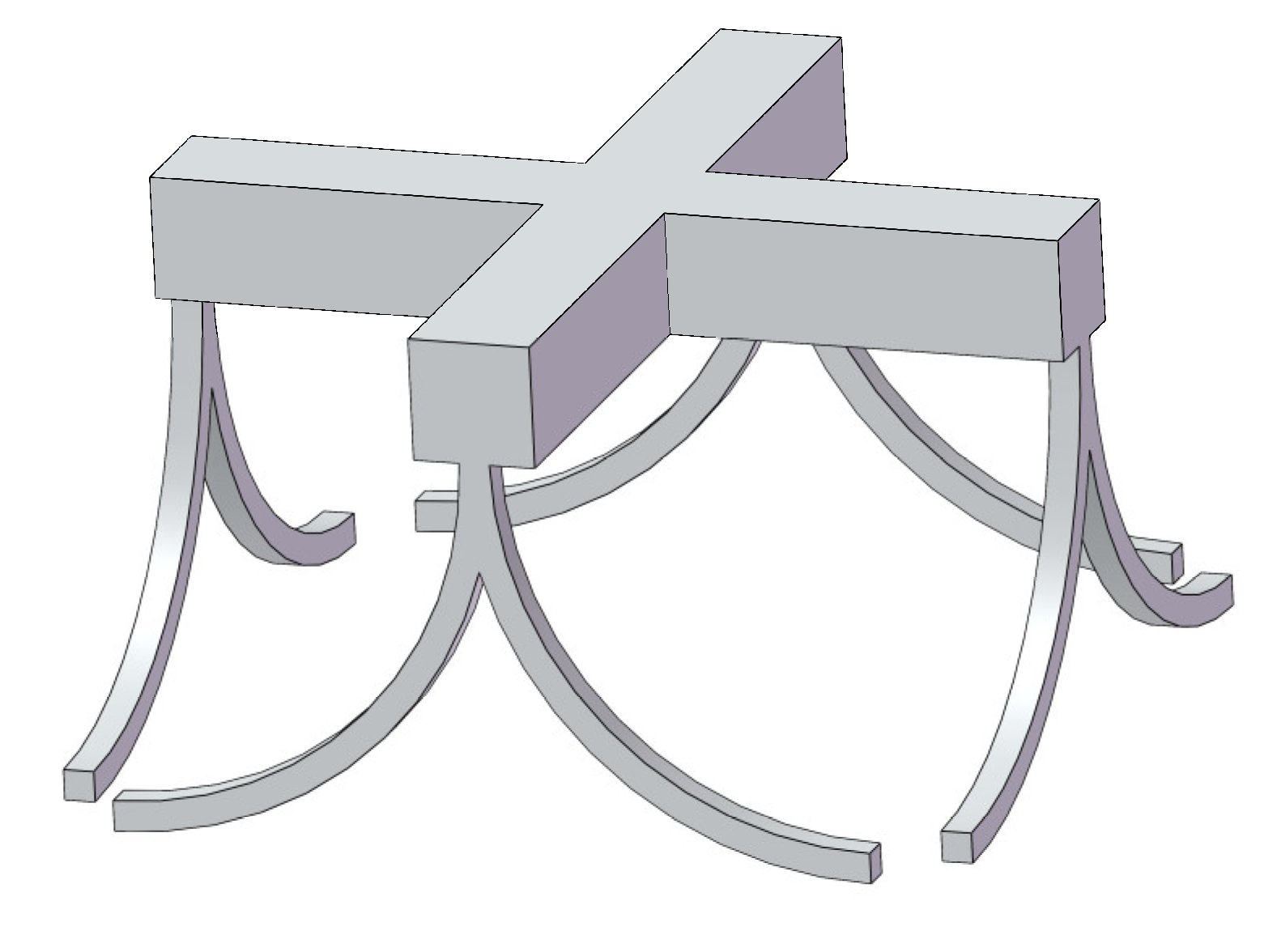

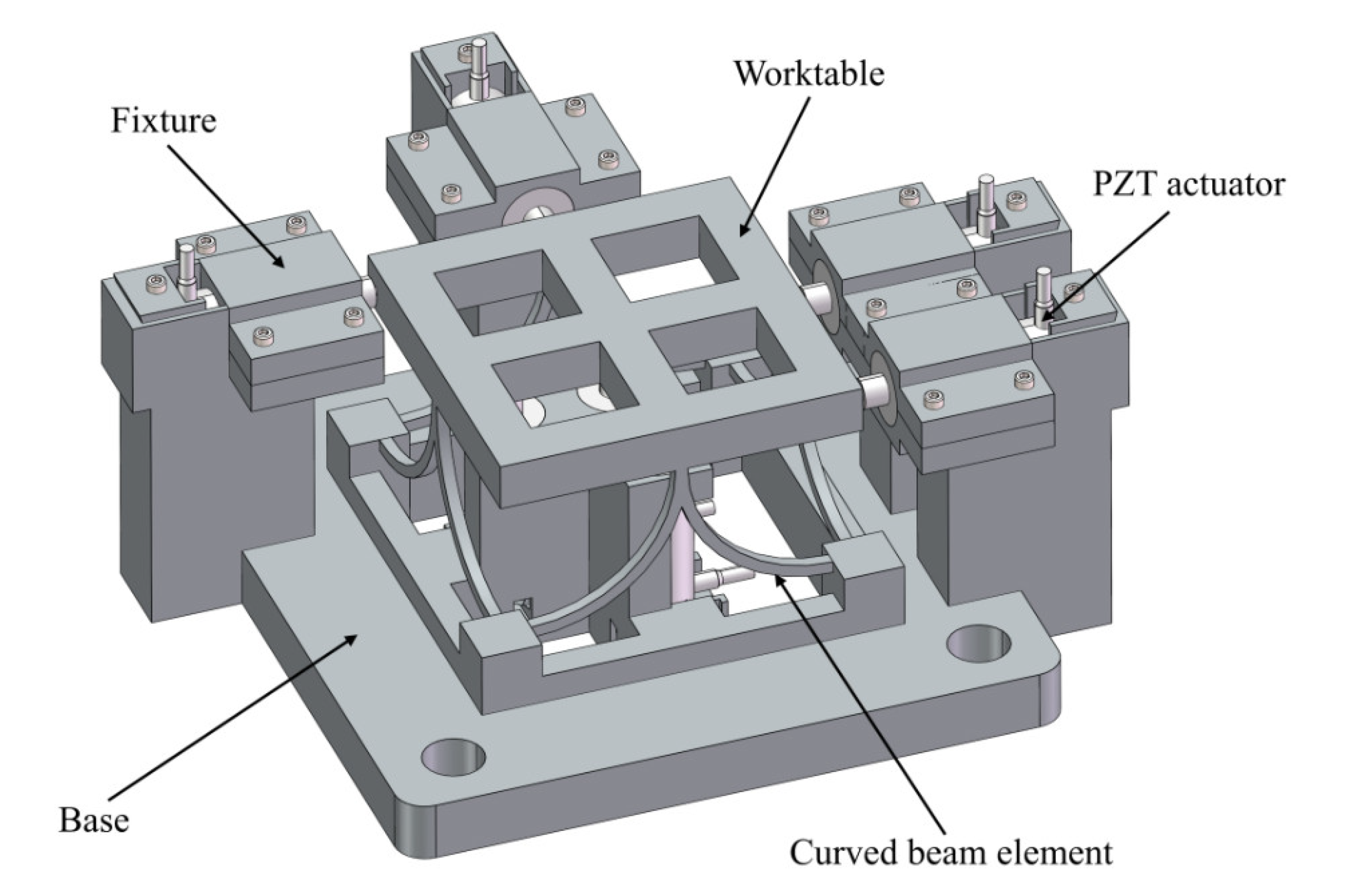

2. Design of the Compliant Mechanism Based on Curved Beam Compliant Element

3. Modeling of the Compliant Mechanism with Isogeometric Analysis

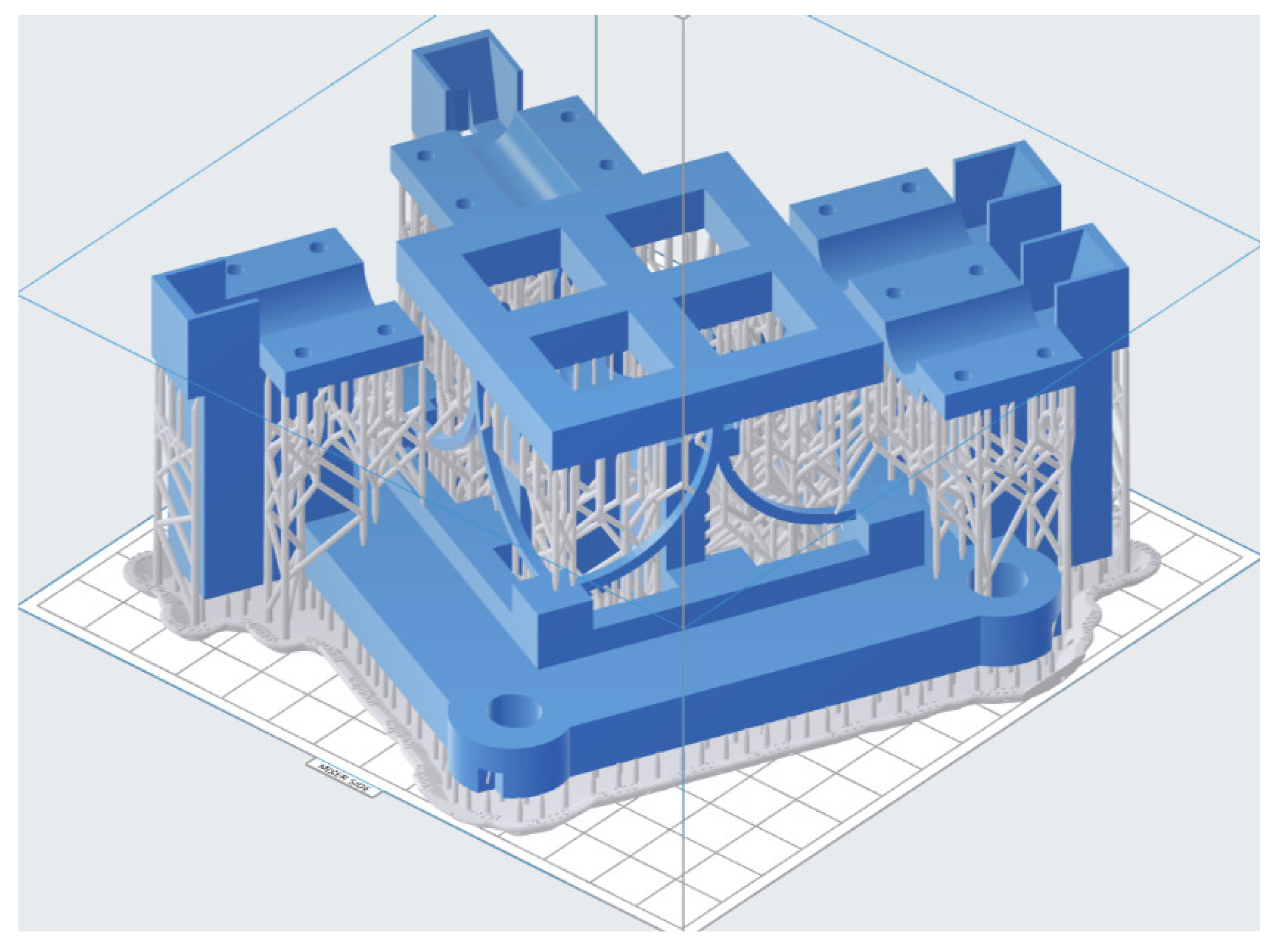

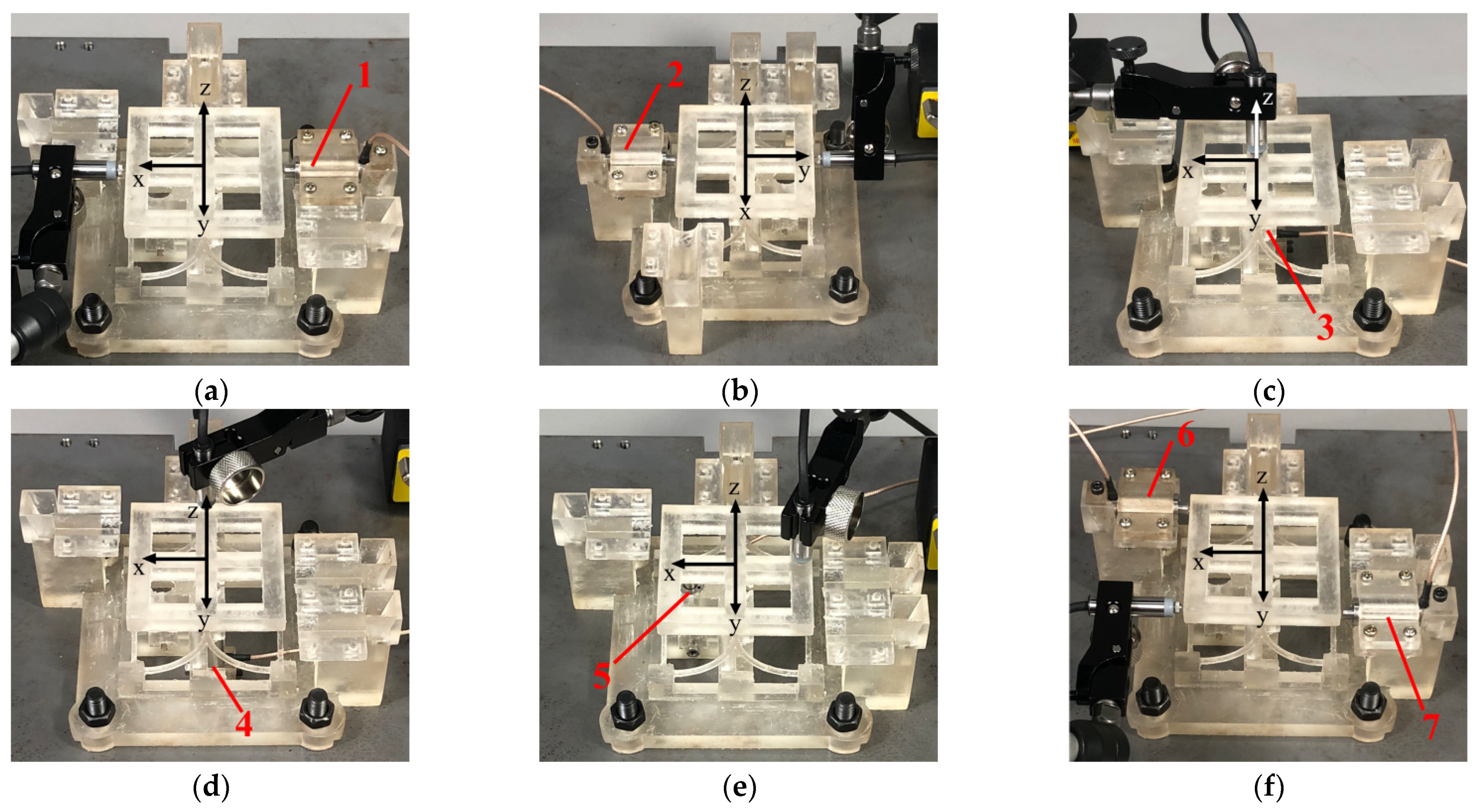

4. Manufacturing and Experiment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tian, Y.; Shirinzadeh, B.; Zhang, D. Design and dynamics of a 3-DOF flexure-based parallel mechanism for micro/nano manipulation. Microelectron. Eng. 2010, 87, 230–241. [Google Scholar] [CrossRef]

- Li, H.; Hao, G.; Kavanagh, R.C. A New XYZ Compliant Parallel Mechanism for Micro-/Nano-Manipulation: Design and Analysis. Micromachines 2016, 7, 23. [Google Scholar] [CrossRef]

- Zhu, W.-L.; Duan, F.; Zhang, X.; Zhu, Z.; Ju, B.-F. A new diamond machining approach for extendable fabrication of micro-freeform lens array. Int. J. Mach. Tools Manuf. 2018, 124, 134–148. [Google Scholar] [CrossRef]

- Chen, X.; Deng, Z.; Hu, S.; Gao, J.; Gao, X. Design of a Compliant Mechanism Based Four-Stage Amplification Piezoelectric-Driven Asymmetric Microgripper. Micromachines 2019, 11, 25. [Google Scholar] [CrossRef] [PubMed]

- Shoshani, O.; Shaw, S.W. Resonant modal interactions in micro/nano-mechanical structures. Nonlinear Dyn. 2021, 104, 1801–1828. [Google Scholar] [CrossRef]

- Gauthier, M.; Piat, E. Control of a particular micro-macro positioning system applied to cell micromanipulation. IEEE Trans. Autom. Sci. Eng. 2006, 3, 264–271. [Google Scholar] [CrossRef]

- Wang, P.; Xu, Q. Design and Testing of a Flexure-Based Constant-Force Stage for Biological Cell Micromanipulation. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1114–1126. [Google Scholar] [CrossRef]

- Chen, N.; Tian, C. Design, modeling and testing of a 3-DOF flexible piezoelectric thin sheet nanopositioner. Sens. Actuators A Phys. 2021, 323, 112660. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, X.; Meng, G. Development of A New Type of 2-DOF Piezo-Actuated Pseudo-Decoupled Compliant Mechanism for Elliptical Vibration Machining. Micromachines 2019, 10, 122. [Google Scholar] [CrossRef]

- Yong, Y.K. A new preload mechanism for a high-speed piezoelectric stack nanopositioner. Mechatronics 2016, 36, 159–166. [Google Scholar] [CrossRef]

- Ling, M.; Howell, L.L.; Cao, J.; Chen, G. Kinetostatic and Dynamic Modeling of Flexure-Based Compliant Mechanisms: A Survey. Appl. Mech. Rev. 2020, 72, 030802. [Google Scholar] [CrossRef]

- Ling, M.; Cao, J.; Howell, L.L.; Zeng, M. Kinetostatic modeling of complex compliant mechanisms with serial-parallel substructures: A semi-analytical matrix displacement method. Mech. Mach. Theory 2018, 125, 169–184. [Google Scholar] [CrossRef]

- Tian, Y.; Shirinzadeh, B.; Zhang, D.; Zhong, Y. Three flexure hinges for compliant mechanism designs based on dimensionless graph analysis. Precis. Eng. 2010, 34, 92–100. [Google Scholar] [CrossRef]

- Hopkins, J.B.; Culpepper, M.L. Synthesis of multi-degree of freedom, parallel flexure system concepts via freedom and constraint topology (FACT). Part II: Practice. Precis. Eng. 2010, 34, 271–278. [Google Scholar] [CrossRef]

- Hopkins, J.B.; McCalib, D. Synthesizing multi-axis flexure systems with decoupled actuators. Precis. Eng. 2016, 46, 206–220. [Google Scholar] [CrossRef]

- Nelson, T.G.; Avila, A.; Howell, L.L.; Herder, J.L.; Machekposhti, D.F. Origami-inspired sacrificial joints for folding compliant mechanisms. Mech. Mach. Theory 2019, 140, 194–210. [Google Scholar] [CrossRef]

- Pinskier, J.; Shirinzadeh, B.; Clark, L.; Qin, Y. Development of a 4-DOF haptic micromanipulator utilizing a hybrid parallel-serial flexure mechanism. Mechatronics 2018, 50, 55–68. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, Y.; Wu, R.-J.; He, C.-Y.; Guang, C.-H. Dynamic analysis of a hybrid compliant mechanism with flexible central chain and cantilever beam. Mech. Mach. Theory 2021, 155, 104095. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, T.; Wang, L. Design, Development, and Application of a Compact Flexure-Based Decoupler With High Motion Transmission Efficiency and Excellent Input Decoupling Performance. IEEE/ASME Trans. Mechatron. 2017, 22, 1071–1081. [Google Scholar] [CrossRef]

- Yu, J.; Lu, D.; Hao, G. Design and analysis of a compliant parallel pan-tilt platform. Meccanica 2015, 51, 1559–1570. [Google Scholar] [CrossRef]

- Ruiz, A.; Campa, F.J.; Roldán-Paraponiaris, C.; Altuzarra, O.; Pinto, C. Experimental validation of the kinematic design of 3-PRS compliant parallel mechanisms. Mechatronics 2016, 39, 77–88. [Google Scholar] [CrossRef]

- Zhu, D.; Zhan, W. Topology optimization of a 6-DOF spatial compliant mechanism based on Stewart propotype platform. Acta Mech. Sin. 2019, 35, 1044–1059. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, C.; Yang, B.; Chen, S.L.; Fang, Z.; Li, R.; Yang, G. The design and kinetostatic modeling of 3PPR planar compliant parallel mechanism based on compliance matrix method. Rev. Sci. Instrum. 2019, 90, 045102. [Google Scholar] [CrossRef]

- Telleria, M.J.; Culpepper, M.L. Understanding the drivers for the development of design rules for the synthesis of cylindrical flexures. Mech. Sci. 2012, 3, 25–32. [Google Scholar] [CrossRef][Green Version]

- Imani, B.M.; Hashemian, S.A. Nurbs-Based Profile Reconstruction using Constrained Fitting Techniques. J. Mech. 2012, 28, 407–412. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Hashemian, A.; Moetakef-Imani, B.; Hadidimoud, S. Isogeometric analysis of free-form Timoshenko curved beams including the nonlinear effects of large deformations. Acta Mech. Sin. 2018, 34, 728–743. [Google Scholar] [CrossRef]

- Choit, J.K.; Lim, J.K. General curved beam elements based on the assumed strain fields. Comput. Struct. 1995, 55, 379–386. [Google Scholar] [CrossRef]

- Hu, Q.; Xia, Y.; Zou, R.; Hu, P. A global formulation for complex rod structures in isogeometric analysis. Int. J. Mech. Sci. 2016, 115, 736–745. [Google Scholar] [CrossRef]

- Cazzani, A.; Malagù, M.; Turco, E.; Stochino, F. Constitutive models for strongly curved beams in the frame of isogeometric analysis. Math. Mech. Solids 2015, 21, 182–209. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, X.; Yang, D. Isogeometric method based in-plane and out-of-plane free vibration analysis for Timoshenko curved beams. Struct. Eng. Mech. 2016, 59, 503–526. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Cottrell, J.A.; Bazilevs, Y. Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput. Methods Appl. Mech. Eng. 2005, 194, 4135–4195. [Google Scholar] [CrossRef]

| Load | ux/mm | uy/mm | uz/mm | θx/Rad | θy/Rad | θz/Rad |

|---|---|---|---|---|---|---|

| 120 N | 1.73 10−2 | 1.71 10−2 | 8.30 10−3 | 1.064 | 1.065 | 0.561 |

| Driving Direction | ux/mm | uy/mm | uz/mm | θx/Rad | θy/Rad | θz/Rad |

|---|---|---|---|---|---|---|

| Fx | 1.57 10−2 | −1.90 10−3 | 1.90 10−3 | 2.33 10−5 | 4.50 10−5 | −8.33 10−6 |

| Fy | 1.10 10−3 | 1.58 10−2 | 1.80 10−3 | −3.50 10−5 | 1.33 10−5 | 1.13 10−5 |

| Fz | −1.60 10−3 | 1.60 10−3 | 1.48 10−2 | −6.66 10−5 | 3.83 10−5 | −1.07 10−5 |

| Mx | −2.00 10−3 | −2.50 10−3 | −7.50 10−3 | 3.40 10−4 | −1.83 10−5 | −2.16 10−5 |

| My | 1.50 10−3 | −2.40 10−3 | −7.60 10−3 | 3.33 10−6 | 3.43 10−4 | −2.33 10−5 |

| Mz | −6.00 10−4 | −2.90 10−3 | 2.40 10−3 | −1.83 10−5 | −4.83 10−5 | 3.10 10−4 |

| Driving Direction | Fx | Fy | Fz | Mx | My | Mz |

|---|---|---|---|---|---|---|

| The slope of the isogeometric analysis results | 1.44 10−4 | 1.42 10−4 | 6.92 10−5 | 8.87 10−3 | 8.88 10−3 | 4.67 10−3 |

| The slope of the experimental data | 1.35 10−4 | 1.37 10−4 | 1.30 10−4 | 2.97 10−6 | 2.97 10−6 | 2.69 10−6 |

| Driving Force/Moment | Fx | Fy | Fz | Mx | My | Mz |

|---|---|---|---|---|---|---|

| The slope from isogeometric analysis after dimensionless process | 1 | 0.986 | 0.479 | 1 | 1.002 | 0.527 |

| The slope from experimental data after dimensionless process | 1 | 1.017 | 0.969 | 1 | 1.002 | 0.625 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.; Wang, J.; Xiong, W.; Hu, Q.; Liu, H.; Wang, Q. Design and Modeling of a Curved Beam Compliant Mechanism with Six Degrees of Freedom. Micromachines 2022, 13, 208. https://doi.org/10.3390/mi13020208

Lin S, Wang J, Xiong W, Hu Q, Liu H, Wang Q. Design and Modeling of a Curved Beam Compliant Mechanism with Six Degrees of Freedom. Micromachines. 2022; 13(2):208. https://doi.org/10.3390/mi13020208

Chicago/Turabian StyleLin, Sheng, Jiacheng Wang, Wenkang Xiong, Qingyuan Hu, Hui Liu, and Qi Wang. 2022. "Design and Modeling of a Curved Beam Compliant Mechanism with Six Degrees of Freedom" Micromachines 13, no. 2: 208. https://doi.org/10.3390/mi13020208

APA StyleLin, S., Wang, J., Xiong, W., Hu, Q., Liu, H., & Wang, Q. (2022). Design and Modeling of a Curved Beam Compliant Mechanism with Six Degrees of Freedom. Micromachines, 13(2), 208. https://doi.org/10.3390/mi13020208