Research Progress of Graphene Nano-Electromechanical Resonant Sensors—A Review

Abstract

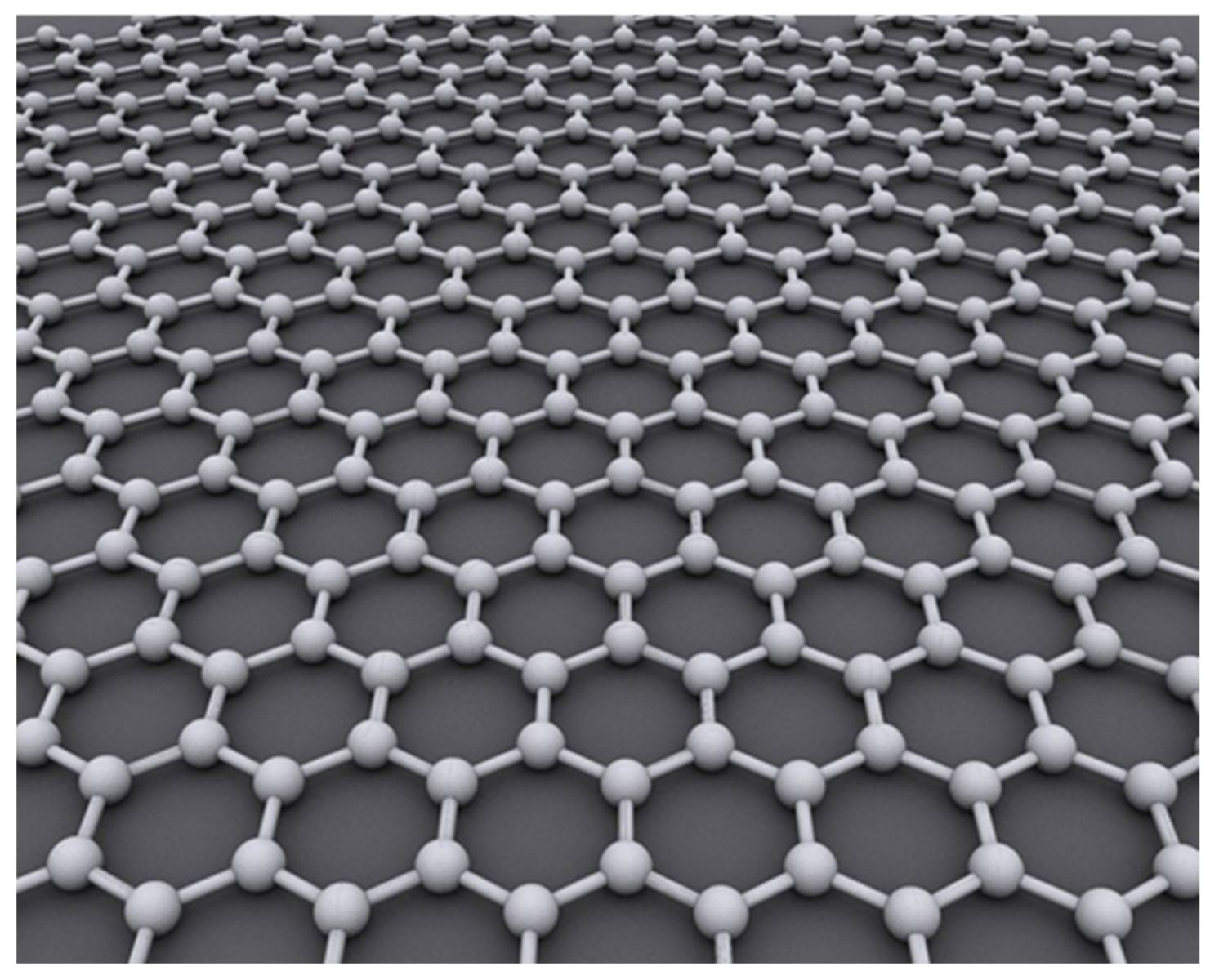

:1. Introduction

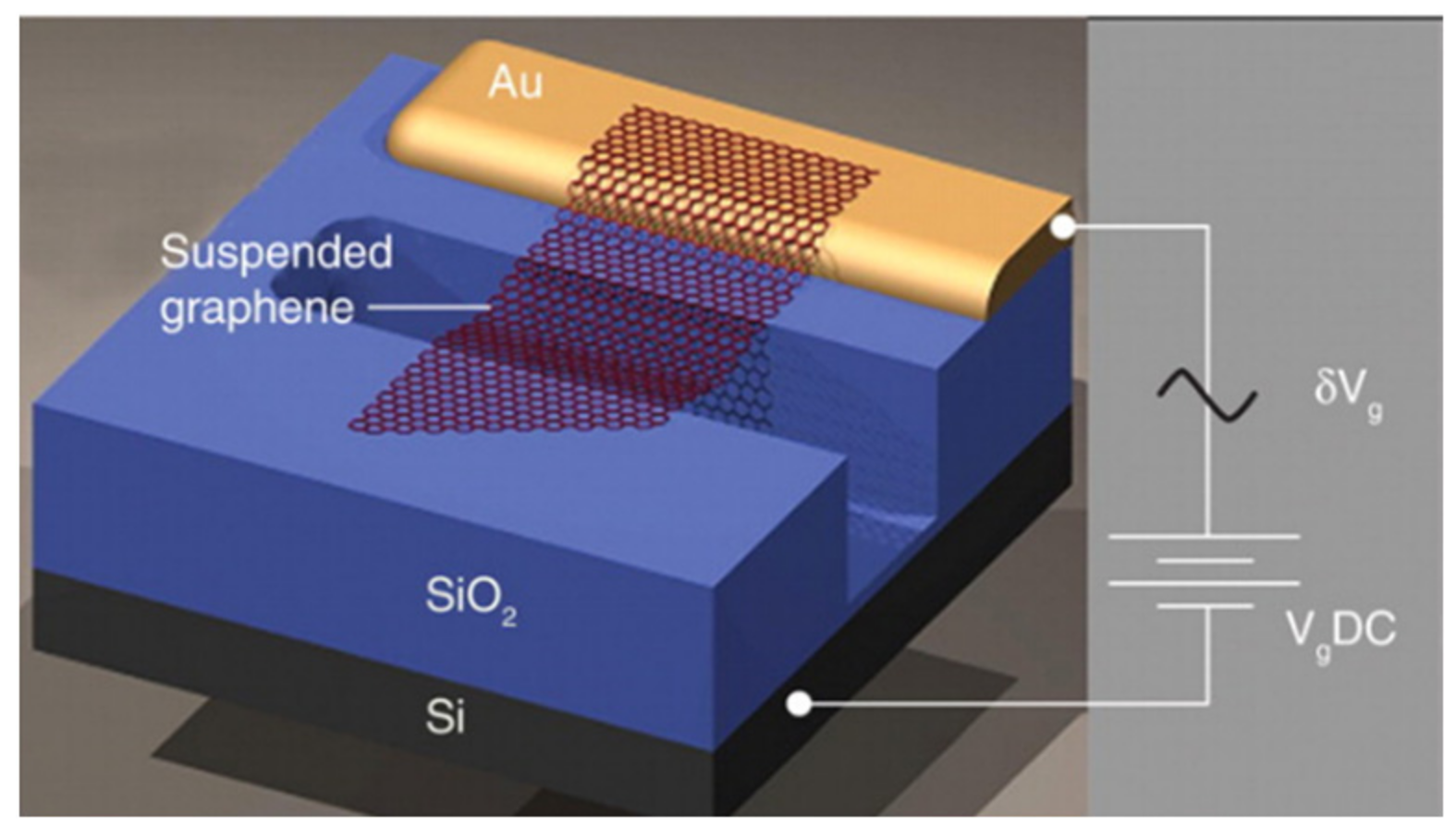

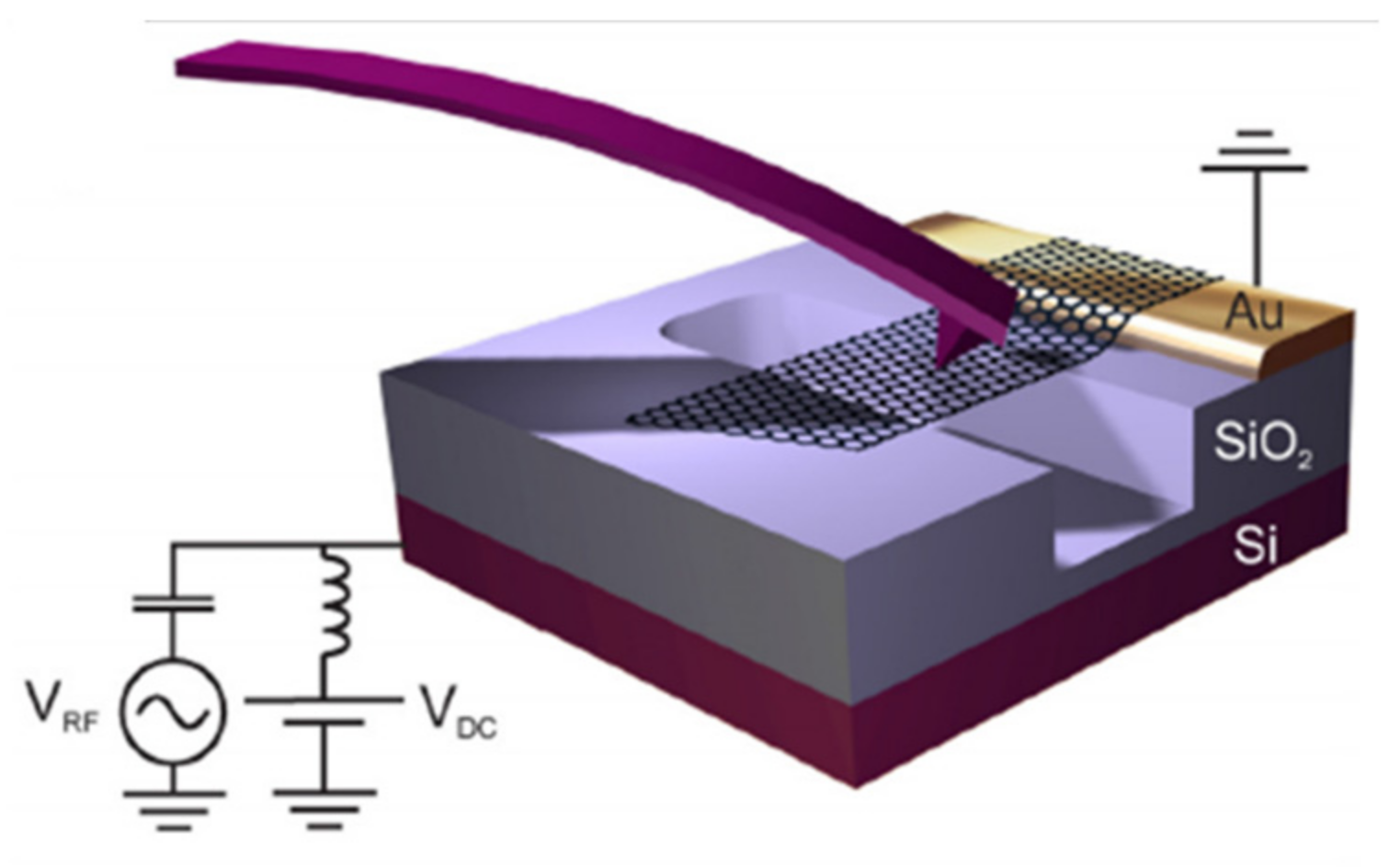

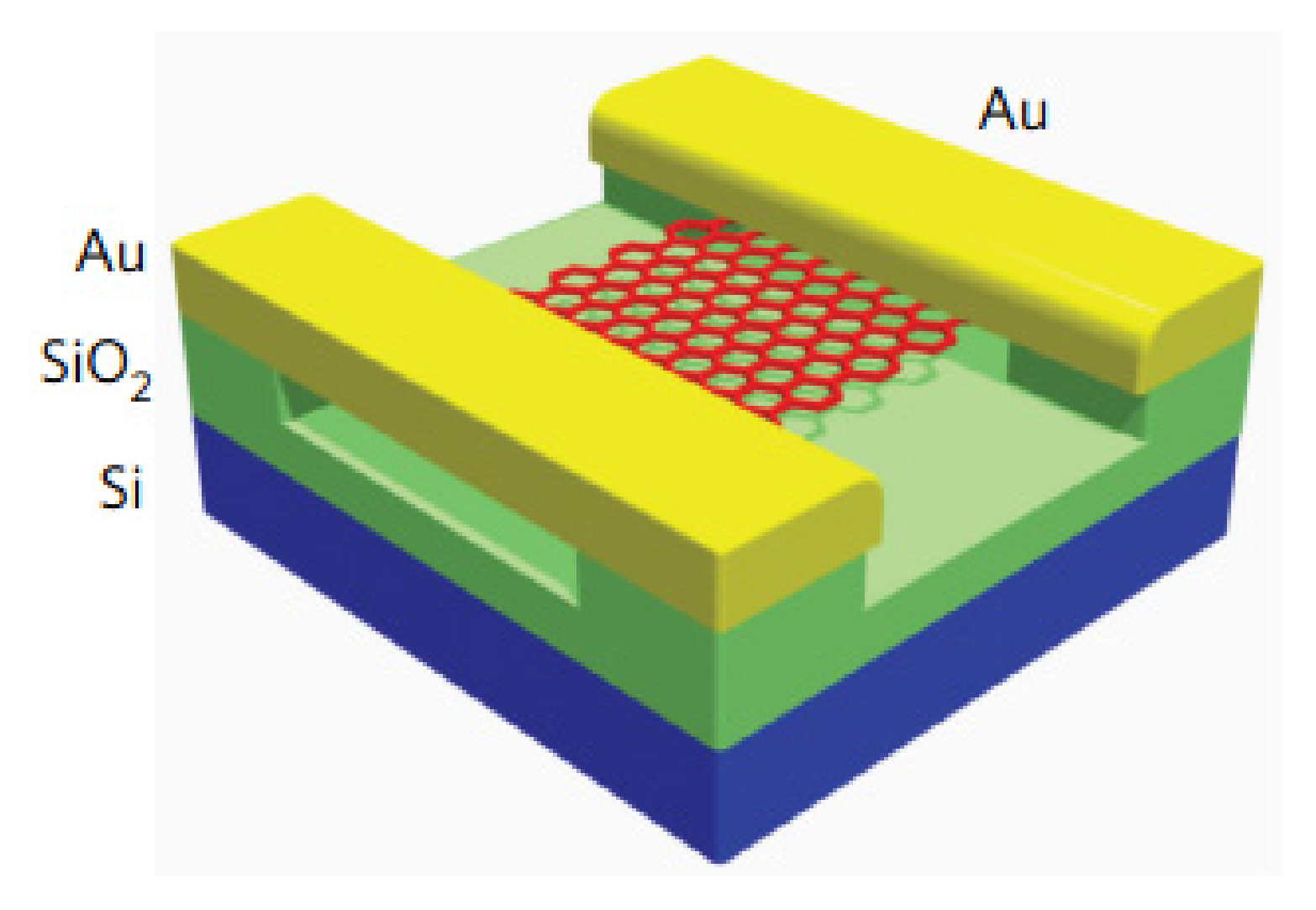

2. Principle Prototype of Graphene Resonator

3. Vibration Characteristics of Graphene Resonant Sheet

3.1. Molecular Structural Mechanics

3.2. Non-Local Elastic Theory

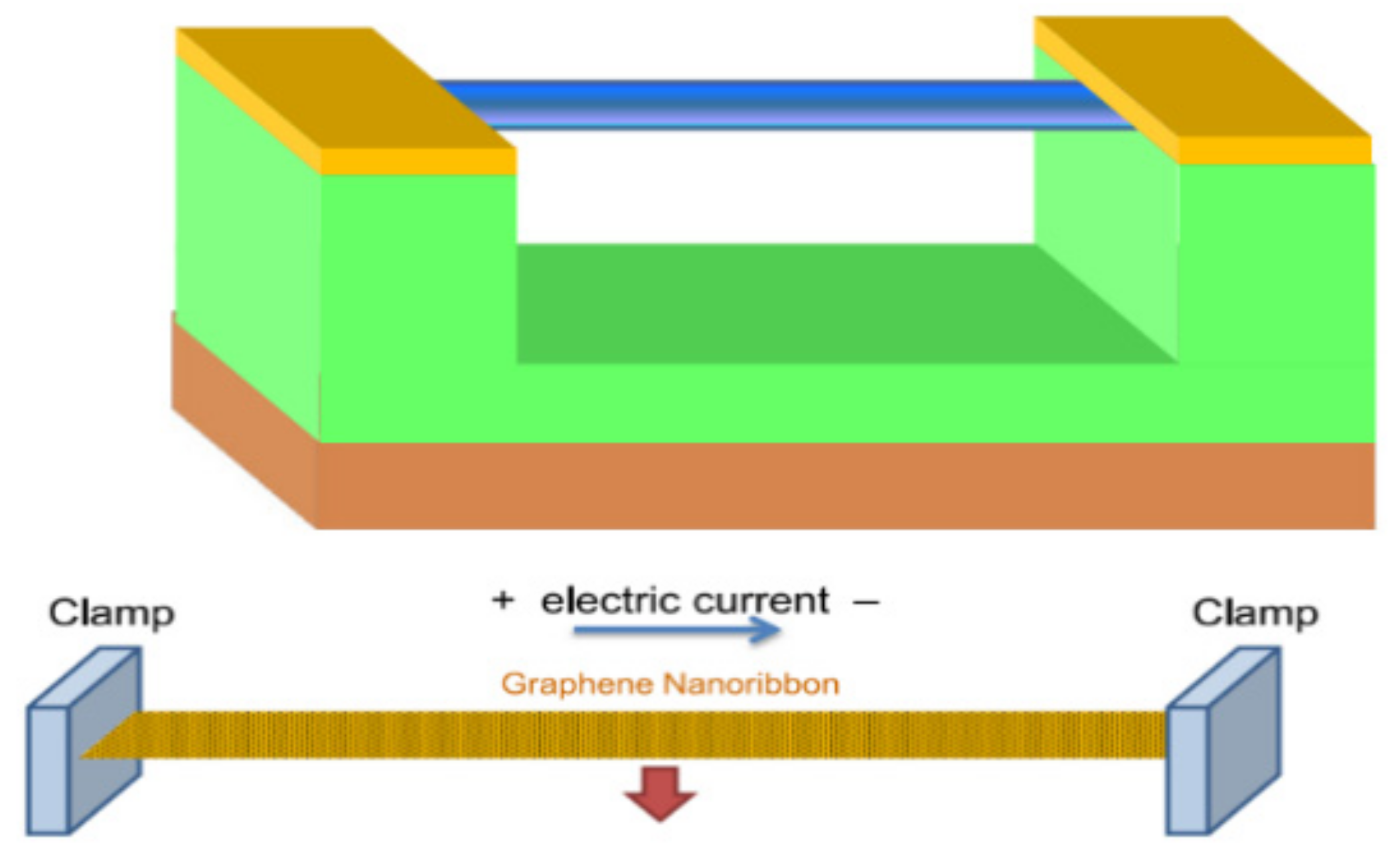

3.3. Molecular Dynamics

3.4. Summary

4. Preparation of Graphene Resonators

5. Application of Graphene Resonators in NEMS

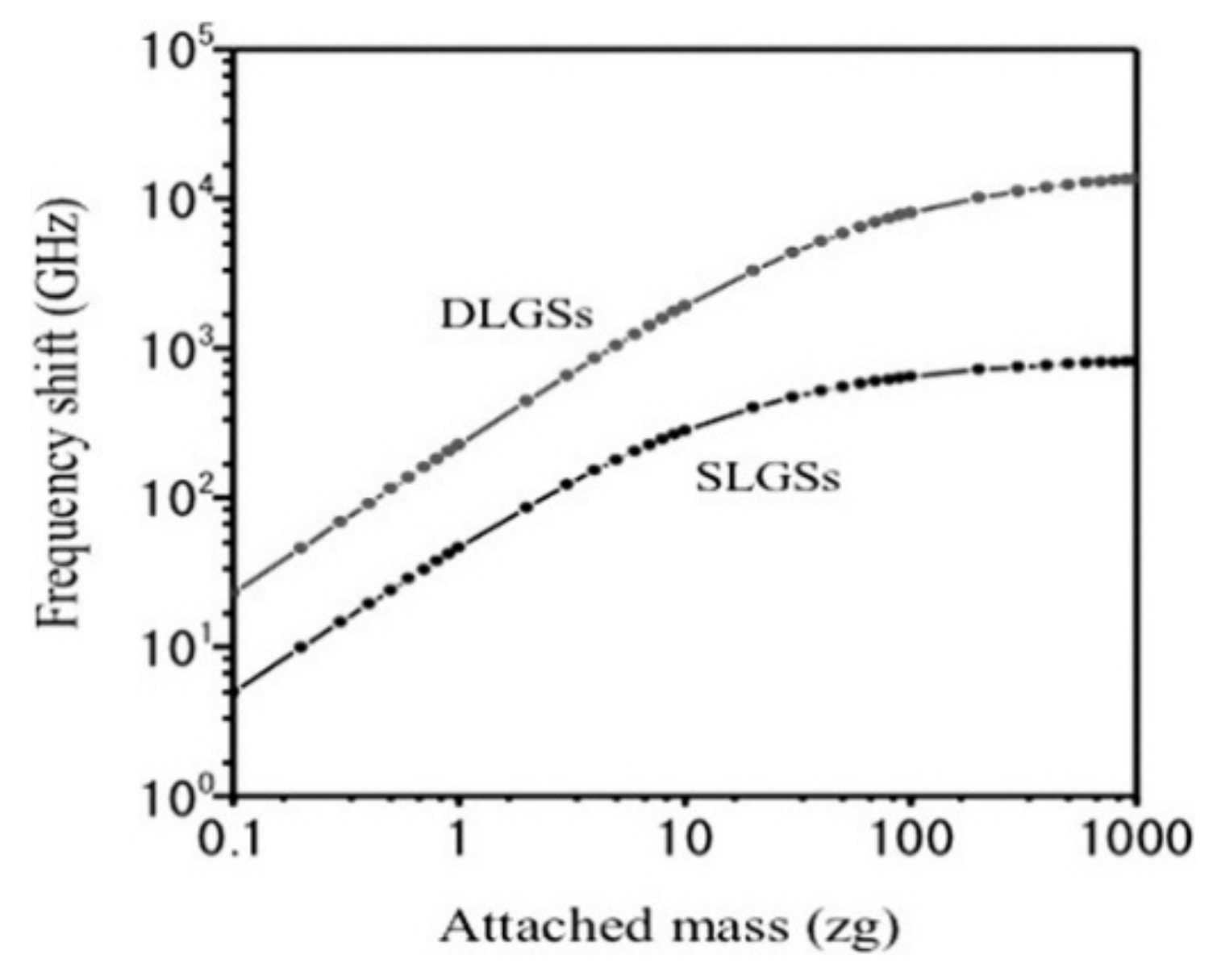

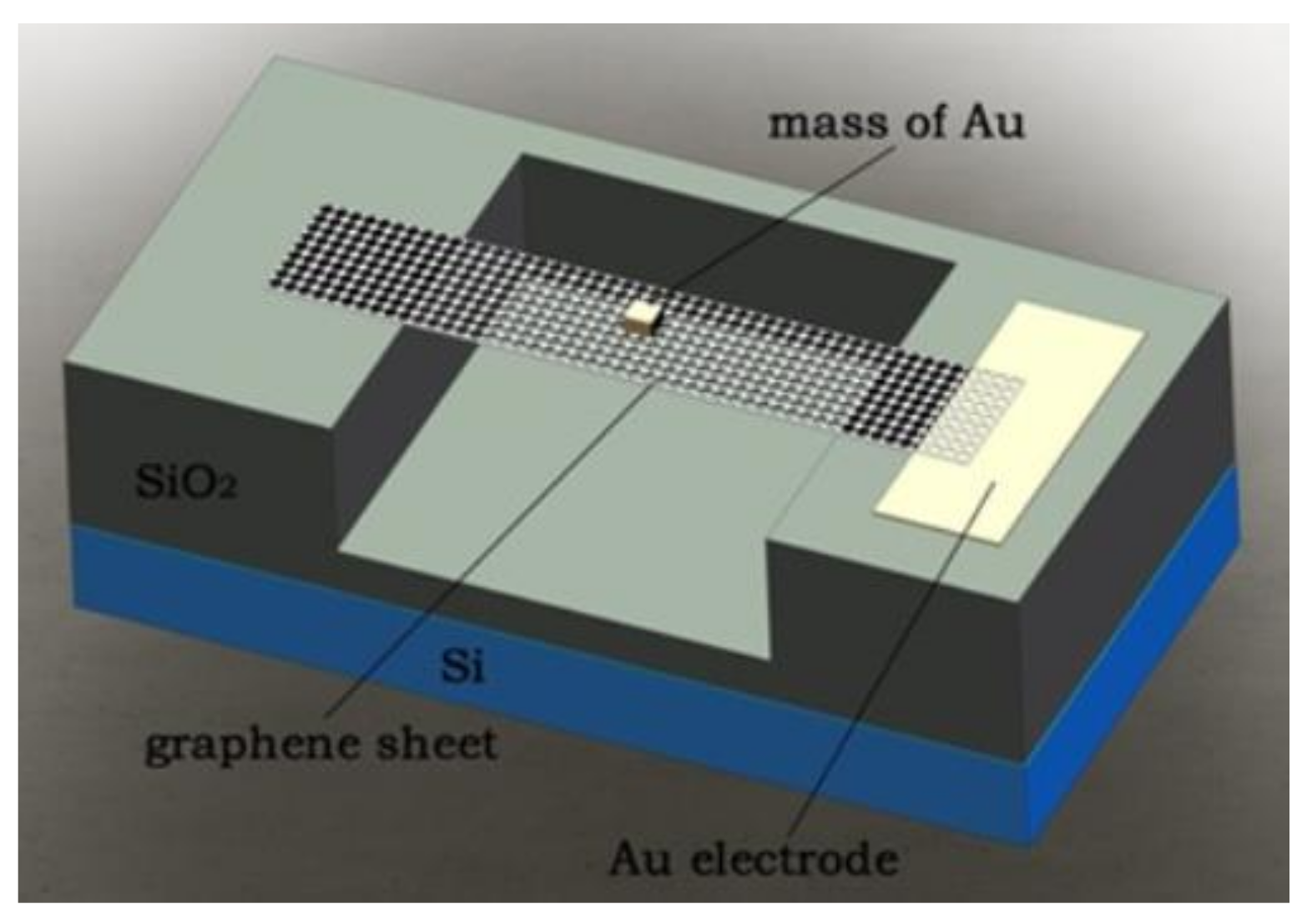

5.1. Graphene Resonant Mass Sensor

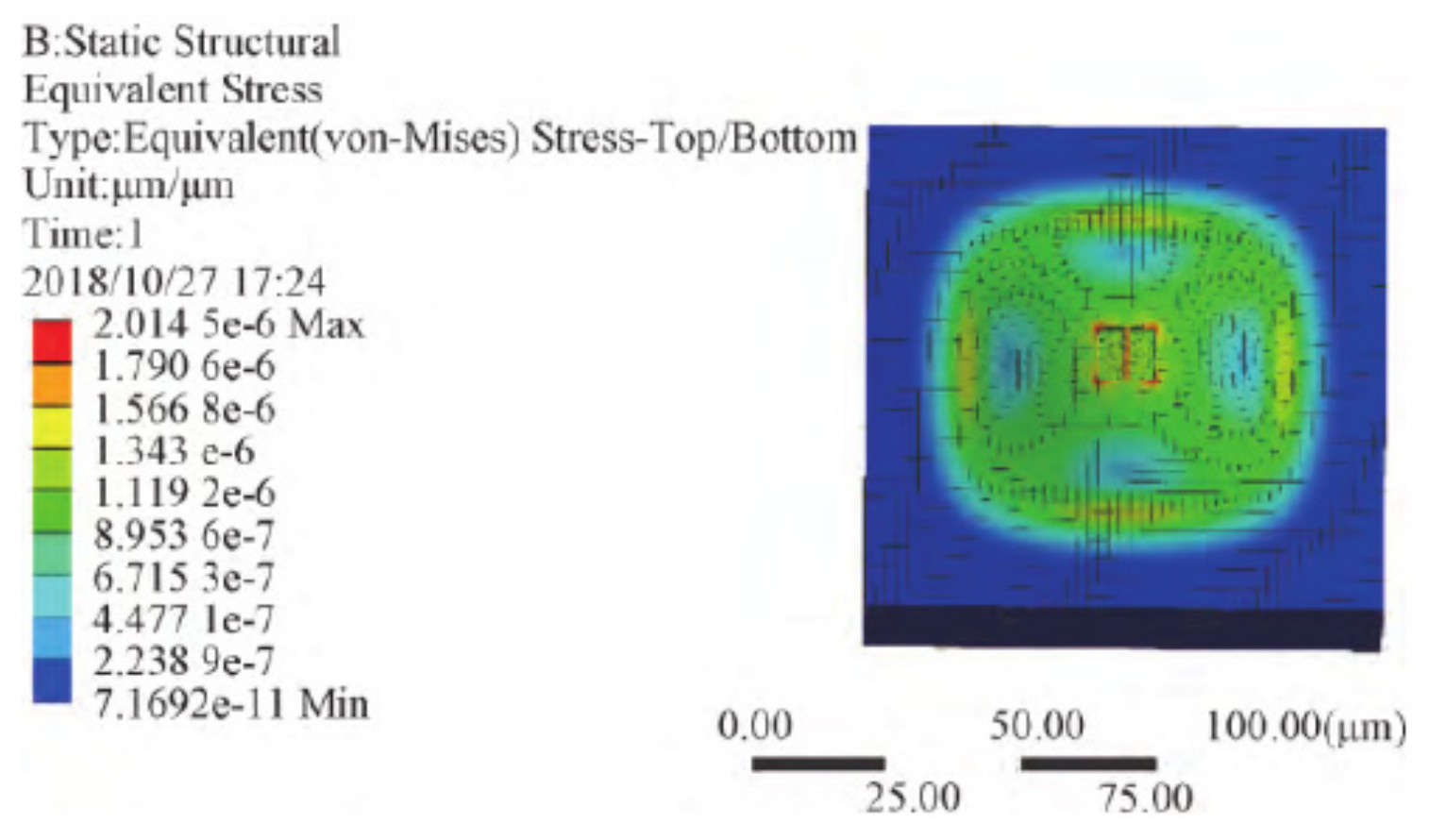

5.2. Graphene Resonant Pressure Sensor

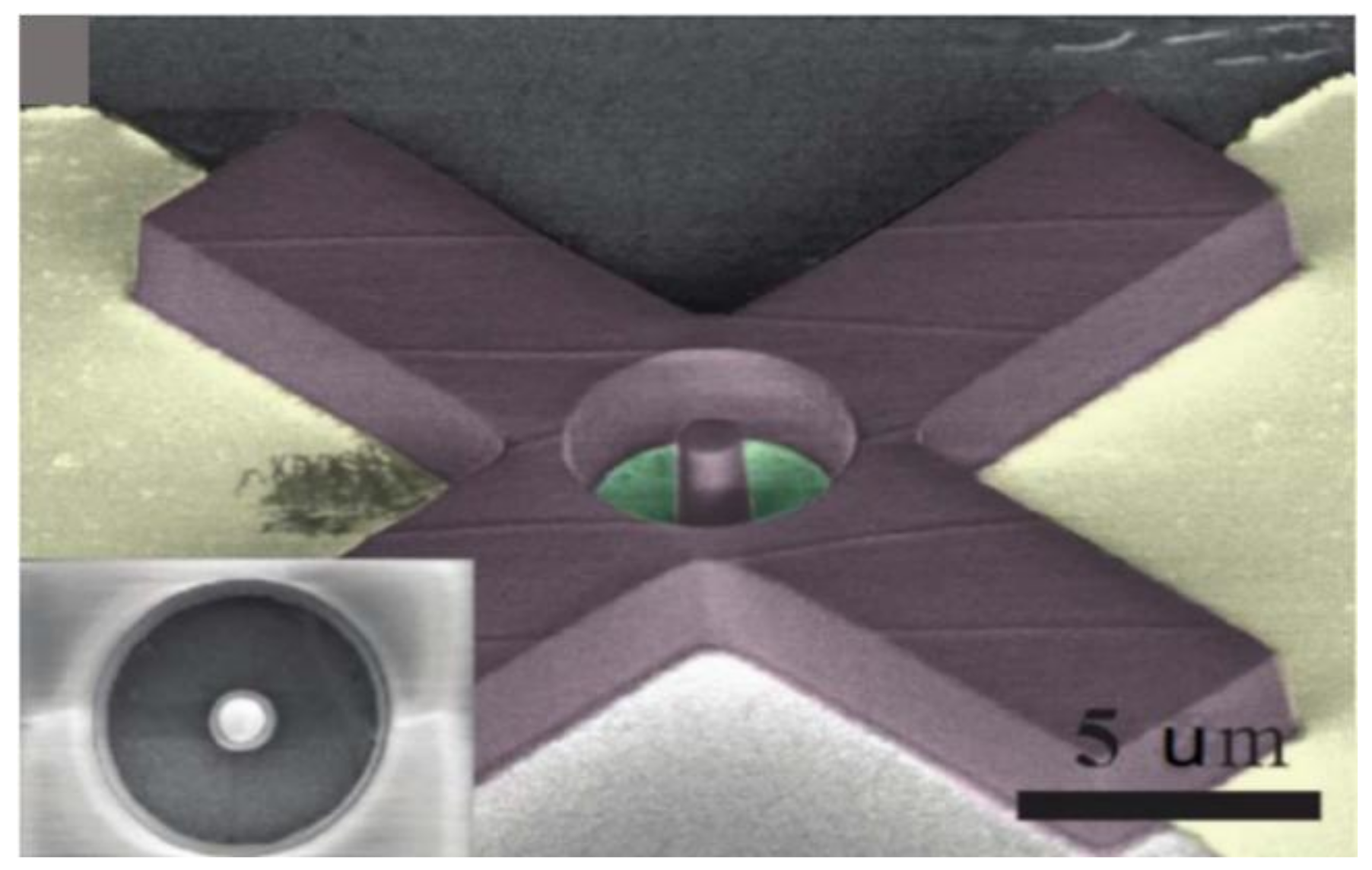

5.3. Graphene Resonant Inertial Sensor

6. Conclusions

- (1)

- Process. It is still difficult to prepare high-quality graphene with a regular shape, but it is easy to introduce initial stress and strain in the process of graphene matrix transfer. This affects the tunability of graphene resonators. In addition, the effect of electrostatic force, temperature and other interference factors should be fully considered.

- (2)

- Overall structure design. The existing literature mainly studies the effect of sensing on graphene resonators from the perspective of the graphene resonator itself, but the research related to the overall structure modeling and optimization analysis of the sensor is not sufficient. A perfect structure is helpful in improving the measurement sensitivity and measurement range of the sensor, and is thus convenient for the design of device processing technology. Overall structure design of graphene resonant NEMS sensors needs to adequately consider the reasonable processing technology, boundary conditions and actual working conditions, reasonably using the theoretical and simulation analysis methods.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burrer, C.; Esteve, J. A novel resonant silicon accelerometer in bulk-micromachining technology. Sens. Actuators A Phys. 1995, 46, 185–189. [Google Scholar] [CrossRef]

- Aikele, M.; Bauer, K.; Ficker, W.; Neubauer, F.; Prechtel, U.; Schalk, J.; Seidel, H. Resonant accelerometer with self-test. Sens. Actuators A Phys. 2001, 92, 161–167. [Google Scholar] [CrossRef]

- Bauer, K.; Aikele, M.; Ficker, W.; Koppenhagen, K.; Schalk, J. Self-Test for Resonant Structure Sensors Applied to a Tuning Fork Gyro and a Resonant Accelerometer; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Jeong, C.; Seok, S.; Lee, B.; Kim, H.; Chun, K. A study on resonant frequency and Q factor tunings for MEMS vibratory gyroscopes. J. Micromech. Microeng. 2004, 14, 1530–1536. [Google Scholar] [CrossRef]

- Yan, L.; Shangchun, F.; Zhanshe, G.; Jing, L.; Le, C. Study of dynamic characteristics of resonators for MEMS resonant vibratory gyroscopes. Microsyst. Technol. 2012, 18, 639–647. [Google Scholar] [CrossRef]

- Eernisse, E.P.; Ward, R.W.; Wiggins, R.B. Survey of quartz bulk resonator sensor technologies. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1988, 35, 323–330. [Google Scholar] [CrossRef]

- Brand, O.; Baltes, H. Micromachined Resonant Sensors—An Overview. Sens. Update 1998, 4, 3–51. [Google Scholar] [CrossRef]

- Cheng, R.; Zhao, Y.; Li, C.; Tian, B.; Yu, Z.; Liu, K. Design and fabrication of a resonant pressure sensor by combination of DETF quartz resonator and silicon diaphragm. Microsyst. Technol. 2015, 21, 631–640. [Google Scholar] [CrossRef]

- Reza, A.; Behraad, B.; Joshua, L.; Frederic, N. Micromachined Resonators: A Review. Micromachines 2016, 7, 160. [Google Scholar]

- Zhao, C.; Montaseri, M.H.; Wood, G.; Pu, S.H.; Seshia, A.; Kraft, M. A review on coupled MEMS resonators for sensing applications utilizing mode localization. Sens. Actuators A Phys. 2016, 249, 93–111. [Google Scholar] [CrossRef]

- Platz, D.; Schmid, U. Vibrational modes in MEMS resonators. J. Micromech. Microeng. 2019, 29, 123001. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Liang, Y.; Zhou, J. Recent Progress of Graphene Doping. Acta Chim. Sin. 2014, 72, 367. [Google Scholar] [CrossRef] [Green Version]

- Ni, Z.H.; Wang, H.M.; Kasim, J.; Fan, H.M.; Yu, T.; Wu, Y.H.; Feng, Y.P.; Shen, Z.X. Graphene thickness determination using reflection and contrast spectroscopy. Nano Lett. 2007, 7, 2758–2763. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.-H.; Kim, P.; Choi, J.-Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef]

- Khan, Z.H.; Kermany, A.R.; Öchsner, A.; Iacopi, F. Mechanical and electromechanical properties of graphene and their potential application in MEMS. J. Phys. D Appl. Phys. 2017, 50, 053003. [Google Scholar] [CrossRef] [Green Version]

- Novoselov, K.S.; Jiang, Z.; Zhang, Y.; Morozov, S.V.; Stormer, H.L.; Zeitler, U.; Maan, J.C.; Boebinger, G.S.; Kim, P.; Geim, A.K. Room-Temperature Quantum Hall Effect in Graphene. Science 2007, 315, 1379. [Google Scholar] [CrossRef] [Green Version]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine Structure Constant Defines Visual Transparency of Graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.-H.; Jang, C.; Xiao, S.; Ishigami, M.; Fuhrer, M.S. Intrinsic and extrinsic performance limits of graphene devices on SiO2. Nat. Nanotechnol. 2008, 3, 206–209. [Google Scholar] [CrossRef]

- Bolotin, K.I.; Sikes, K.J.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H.L. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Tang, T.-T.; Girit, C.; Hao, Z.; Martin, M.C.; Zettl, A.; Crommie, M.F.; Shen, Y.R.; Wang, F. Direct observation of a widely tunable bandgap in bilayer graphene. Nature 2009, 459, 820–823. [Google Scholar] [CrossRef] [PubMed]

- Xia, S.-X.; Zhai, X.; Wang, L.-L.; Wen, S.-C. Polarization-independent plasmonic absorption in stacked anisotropic 2D material nanostructures. Opt. Lett. 2020, 45, 93–96. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, X.; Rukhlenko, I.D.; Chen, H.-T.; Zhu, W. Electrically Tunable Metasurface with Independent Frequency and Amplitude Modulations. ACS Photonics 2019, 7, 265–271. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, H.; Yin, J.; Zhang, R.; Jile, H.; Xu, D.; Yi, Z.; Zhou, Z.; Cai, S.; Yan, P. Multi-band, tunable, high figure of merit, high sensitivity single-layer patterned graphene—Perfect absorber based on surface plasmon resonance. Sci. Direct Diam. Relat. Mater. 2021, 116, 108393. [Google Scholar] [CrossRef]

- Xu, K.-D.; Li, J.; Zhang, A.; Chen, Q. Tunable multi-band terahertz absorber using a single-layer square graphene ring structure with T-shaped graphene strips. Opt. Express 2020, 28, 11482–11492. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Liu, X. Study on the Biocompatibility of Carboxyl Ion Implanted Graphene and Carboxyl Functionalized Graphene. Master’s Thesis, Tianjin Normal University, Tianjin, China, 2015. [Google Scholar]

- Bunch, J.S.; Verbridge, S.S.; Alden, J.S.; van der Zande, A.M.; Parpia, J.M.; Craighead, H.G.; McEuen, P.L. Impermeable Atomic Membranes from Graphene Sheets. Nano Lett. 2008, 8, 2458–2462. [Google Scholar] [CrossRef] [Green Version]

- Ponomarenko, L.A.; Schedin, F.; Katsnelson, M.I.; Yang, R.; Hill, E.W.; Novoselov, K.S.; Geim, A.K. Chaotic Dirac Billiard in Graphene Quantum Dots. Science 2008, 320, 356–358. [Google Scholar] [CrossRef] [Green Version]

- Lau, C.N.; Bao, W.; Velasco, J. Properties of suspended graphene membranes. Mater. Today 2012, 15, 238–245. [Google Scholar] [CrossRef]

- Castellanos-Gomez, A.; Singh, V.; van der Zant, H.S.J.; Steele, G.A. Mechanics of freely-suspended ultrathin layered materials. Ann. Phys. 2014, 527, 27–44. [Google Scholar] [CrossRef] [Green Version]

- Bunch, J.S.; van der Zande, A.M.; Verbridge, S.S.; Frank, I.W.; Tanenbaum, D.M.; Parpia, J.M.; Craighead, H.G.; McEuen, P.L. Electromechanical Resonators from Graphene Sheets. Science 2007, 315, 490–493. [Google Scholar] [CrossRef] [Green Version]

- Zang, X.; Zhou, Q.; Chang, J.; Liu, Y.; Lin, L. Graphene and carbon nanotube (CNT) in MEMS/NEMS applications. Microelectron. Eng. 2015, 132, 192–206. [Google Scholar] [CrossRef]

- Chen, C.; Hone, J. Graphene nanoelectromechanical systems. Proc. IEEE 2013, 101, 1766–1779. [Google Scholar] [CrossRef]

- Liu, J.; Jalali, M.; Mahshid, S.; Wachsmann-Hogiu, S. Are plasmonic optical biosensors ready for use in point-of-need applications? Analyst 2019, 145, 364–384. [Google Scholar] [CrossRef] [Green Version]

- Al Jahdaly, B.; Elsadek, M.; Ahmed, B.; Farahat, M.; Taher, M.; Khalil, A. Outstanding Graphene Quantum Dots from Carbon Source for Biomedical and Corrosion Inhibition Applications: A Review. Sustainability 2021, 13, 2127. [Google Scholar] [CrossRef]

- Zheng, X.; Khaoulani, S.; Ktari, N.; Lo, M.; Khalil, A.; Zerrouki, C.; Fourati, N.; Chehimi, M. Towards Clean and Safe Water: A Review on the Emerging Role of Imprinted Polymer-Based Electrochemical Sensors. Sensors 2021, 21, 4300. [Google Scholar] [CrossRef]

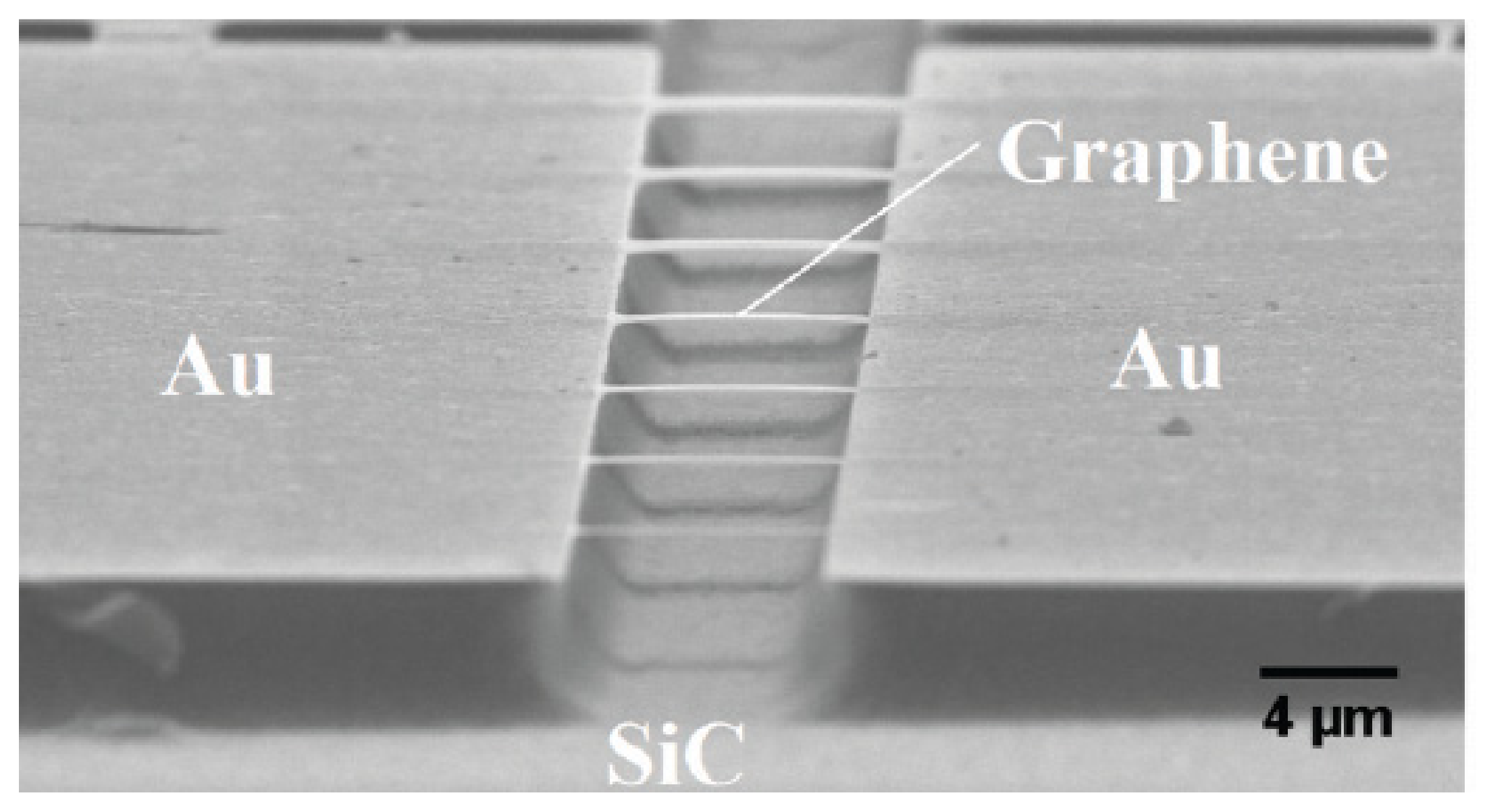

- Shivaraman, S.; Barton, R.A.; Yu, X.; Alden, J.; Herman, L.; Chandrashekhar, M.; Park, J.; Mceuen, P.L.; Parpia, J.M.; Craighead, H.G. Free-standing epitaxial graphene. Nano Lett. 2009, 9, 3100–3105. [Google Scholar] [CrossRef] [Green Version]

- Riedl, C.; Coletti, C.; Iwasaki, T.; Zakharov, A.A.; Starke, U. Quasi-Free-Standing Epitaxial Graphene on SiC Obtained by Hydrogen Intercalation. Phys. Rev. Lett. 2009, 103, 246804. [Google Scholar] [CrossRef] [Green Version]

- Luo, D.; Zhang, G.; Liu, J.; Sun, X. Evaluation Criteria for Reduced Graphene Oxide. J. Phys. Chem. C 2011, 115, 11327–11335. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Eda, G.; Fanchini, G.; Chhowalla, M. Large-area ultrathin films of reduced graphene oxide as a transparent and flexible electronic material. Nat. Nanotechnol. 2008, 3, 270–274. [Google Scholar] [CrossRef]

- Alfonso, R.; Xiaoting, J.; John, H.; Daniel, N.; Hyungbin, S.; Vladimir, B.; Dresselhaus, M.S.; Jing, K. Large area, few-layer graphene films on arbitrary substrates by chemical vapor deposition. Nano Lett. 2009, 9, 30–35. [Google Scholar]

- Kong, J.; Cecco, A.R.; Dresselhaus, M.S. Large-Area Single- and Few-Layer Graphene on Arbitrary Substrates. U.S. Patent 8,535,533, 17 September 2013. [Google Scholar]

- Hwangbo, Y.; Lee, C.-K.; Kim, S.-M.; Kim, J.-H.; Kim, K.-S.; Jang, B.; Lee, H.-J.; Lee, S.-K.; Kim, S.S.; Ahn, J.-H.; et al. Fracture Characteristics of Monolayer CVD-Graphene. Sci. Rep. 2014, 4, 4439. [Google Scholar] [CrossRef] [Green Version]

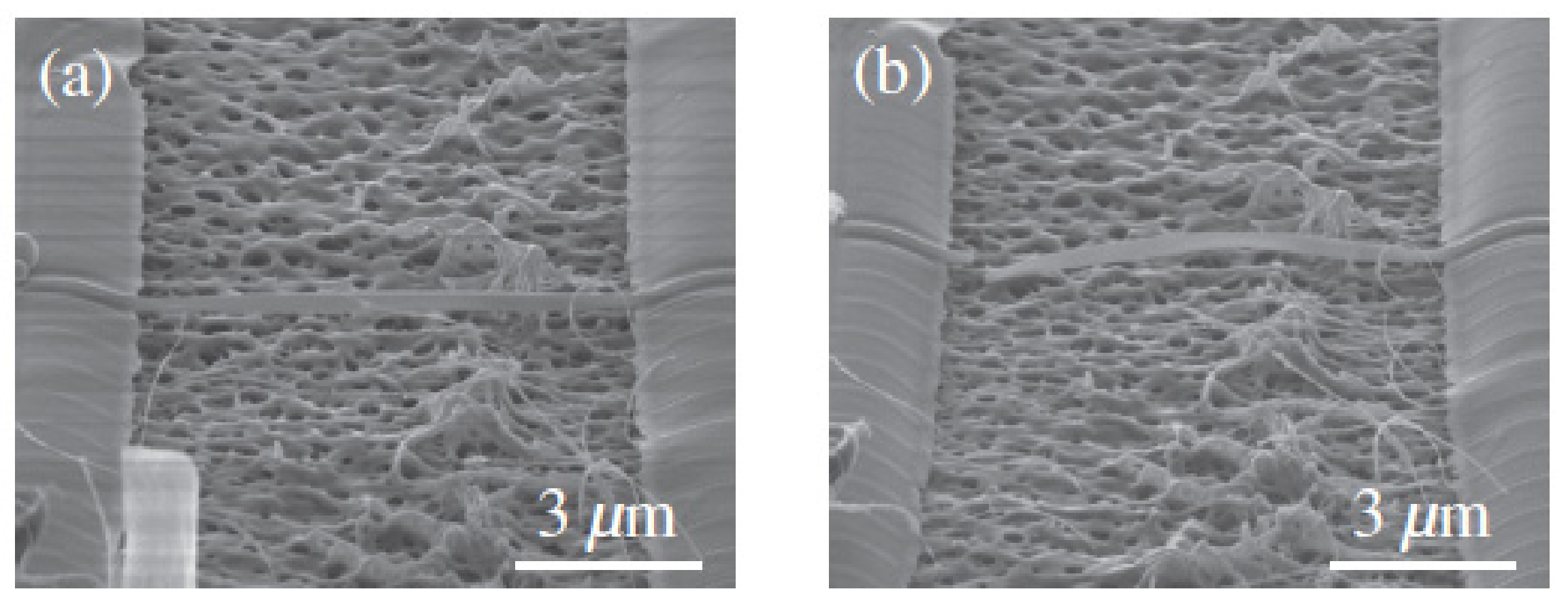

- Fan, X.; Smith, A.D.; Forsberg, F.; Wagner, S.; Schröder, S.; Akbari, S.S.A.; Fischer, A.C.; Villanueva, L.G.; Östling, M.; Lemme, M.C.; et al. Manufacture and characterization of graphene membranes with suspended silicon proof masses for MEMS and NEMS applications. Microsyst. Nanoeng. 2020, 6, 17. [Google Scholar] [CrossRef] [Green Version]

- Lee, G.-H.; Cooper, R.C.; An, S.J.; Lee, S.; van der Zande, A.; Petrone, N.; Hammerberg, A.G.; Lee, C.; Crawford, B.; Oliver, W.; et al. High-Strength Chemical-Vapor–Deposited Graphene and Grain Boundaries. Science 2013, 340, 1073–1076. [Google Scholar] [CrossRef]

- Milaninia, K.M.; Baldo, M.A.; Reina, A.; Kong, J. All graphene electromechanical switch fabricated by chemical vapor deposition. Appl. Phys. Lett. 2009, 95, 183105. [Google Scholar] [CrossRef]

- Hage, F.S.; Radtke, G.; Kepaptsoglou, D.M.; Lazzeri, M.; Ramasse, Q.M. Single-atom vibrational spectroscopy in the scanning transmission electron microscope. Science 2020, 367, 1124–1127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garcia-Sanchez, D.; van der Zande, A.M.; Paulo, A.S.; Lassagne, B.; McEuen, P.L.; Bachtold, A. Imaging Mechanical Vibrations in Suspended Graphene Sheets. Nano Lett. 2008, 8, 1399–1403. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Rosenblatt, S.; Bolotin, K.I.; Kalb, W.; Kim, P.; Kymissis, I.; Stormer, H.L.; Heinz, T.F.; Hone, J. Performance of monolayer graphene nanomechanical resonators with electrical readout. Nat. Nanotechnol. 2009, 4, 861–867. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oshidari, Y.; Hatakeyama, T.; Kometani, R.; Warisawa, S.; Ishihara, S. High Quality Factor Graphene Resonator Fabrication Using Resist Shrinkage-Induced Strain. Appl. Phys. Express 2012, 5, 117201. [Google Scholar] [CrossRef]

- Lee, S.; Chen, C.; Deshpande, V.V.; Lee, G.-H.; Lee, I.; Lekas, M.; Gondarenko, A.; Yu, Y.-J.; Shepard, K.L.; Kim, P.; et al. Electrically integrated SU-8 clamped graphene drum resonators for strain engineering. Appl. Phys. Lett. 2013, 102, 153101. [Google Scholar] [CrossRef] [Green Version]

- Atalaya, J.; Isacsson, A.; Kinaret, J.M. Continuum Elastic Modeling of Graphene Resonators. Nano Lett. 2008, 8, 4196–4200. [Google Scholar] [CrossRef] [Green Version]

- Scarpa, F.; Adhikari, S.; Phani, S. Effective elastic mechanical properties of single layer graphene sheets. Nanotechnology 2009, 20, 065709. [Google Scholar] [CrossRef]

- Georgantzinos, S.; Giannopoulos, G.; Katsareas, D.; Kakavas, P.; Anifantis, N. Size-dependent non-linear mechanical properties of graphene nanoribbons. Comput. Mater. Sci. 2011, 50, 2057–2062. [Google Scholar] [CrossRef]

- Rouhi, S.; Ansari, R. Atomistic finite element model for axial buckling and vibration analysis of single-layered graphene sheets. Phys. E Low-Dimens. Syst. Nanostruct. 2011, 44, 764–772. [Google Scholar] [CrossRef]

- Sakhaee-Pour, A.; Ahmadian, M.; Vafai, A. Applications of single-layered graphene sheets as mass sensors and atomistic dust detectors. Solid State Commun. 2008, 145, 168–172. [Google Scholar] [CrossRef]

- Lee, H.-L.; Hsu, J.-C.; Lin, S.-Y.; Chang, W.-J. Sensitivity analysis of single-layer graphene resonators using atomic finite element method. J. Appl. Phys. 2013, 114, 123506. [Google Scholar] [CrossRef]

- Wu, Y.; Hui, Y.; Guo, D. Modeling of graphene-based sensor for super sensitivity application in bio-molecular detection. In Proceedings of the 10th IEEE International Conference on Anti-Counterfeiting, Security, and Identification (ASID), Xiamen, China, 23–25 September 2016. [Google Scholar]

- Shen, Z.-B.; Tang, H.-L.; Li, D.-K.; Tang, G.-J. Vibration of single-layered graphene sheet-based nanomechanical sensor via nonlocal Kirchhoff plate theory. Comput. Mater. Sci. 2012, 61, 200–205. [Google Scholar] [CrossRef]

- Murmu, T.; Pradhan, S.C. Vibration analysis of nano-single-layered graphene sheets embedded in elastic medium based on nonlocal elasticity theory. J. Appl. Phys. 2009, 105, 064319. [Google Scholar] [CrossRef]

- Arash, B.; Wang, Q. Vibration of Single- and Double-Layered Graphene Sheets. J. Nanotechnol. Eng. Med. 2011, 2, 011012. [Google Scholar] [CrossRef]

- Chang, W.-J.; Lee, H.-L. Mass detection using a double-layer circular graphene-based nanomechanical resonator. J. Appl. Phys. 2014, 116, 034303. [Google Scholar] [CrossRef]

- Jiang, R.W.; Shen, B.Z.; Tang, G.J. Vibration analysis of a single-layered graphene sheet-based mass sensor using the Galerkin strip distributed transfer function method. Acta Mech. 2016, 227, 2899–2910. [Google Scholar] [CrossRef]

- Shen, Z.B.; Jiang, R.W.; Zhang, L.; Tang, G.J. Nonlocal Galerkin Strip Transfer Function Method for Vibration of Double-Layered Graphene Mass Sensor. J. Solid Mech. 2018, 31, 14. [Google Scholar] [CrossRef]

- Kwon, O.K.; Lee, J.H.; Park, J.; Kim, K.-S.; Kang, J.W. Molecular dynamics simulation study on graphene-nanoribbon-resonators tuned by adjusting axial strain. Curr. Appl. Phys. 2013, 13, 360–365. [Google Scholar] [CrossRef]

- Kwon, O.; Lee, K.; Hwang, G.Y.; Kang, H.J. Molecular dynamics modeling and simulations to understand gate-tunable graphene-nanoribbon-resonator. Phys. E Low-Dimens. Syst. Nanostruct. 2012, 45, 194–200. [Google Scholar] [CrossRef]

- Kang, J.W.; Kim, H.-W.; Kim, K.-S.; Lee, J.H. Molecular dynamics modeling and simulation of a graphene-based nanoelectromechanical resonator. Curr. Appl. Phys. 2013, 13, 789–794. [Google Scholar] [CrossRef]

- Kim, S.Y.; Cho, S.-Y.; Kang, J.W.; Kwon, O.K. Molecular dynamics simulation study on mechanical responses of nanoindented monolayer-graphene-nanoribbon. Phys. E Low-Dimens. Syst. Nanostruct. 2013, 54, 118–124. [Google Scholar] [CrossRef]

- Jiang, S.; Shi, S.; Wang, X. Nanomechanics and vibration analysis of graphene sheets via a 2D plate model. J. Phys. D Appl. Phys. 2013, 47, 45104. [Google Scholar] [CrossRef]

- Gong, X.; Jiang, S.; Wang, X.; Sheng, L.; Wang, S. Finite element analysis of graphene resonator tuned by pressure difference. In Proceedings of the International Conference on Electronic Packaging Technology, Chengdu, China, 12–15 August 2014. [Google Scholar]

- Zhang, C. Study on Resonance Characteristics of Single-Layer Graphene Resonator. Master’s Thesis, Beihang University, Beijing, China, 2016. [Google Scholar]

- Xing, W.-W.; Zhang, C.-X.; Fan, S.-C. Progress in graphene resonance properties. J. Inorg. Mater. 2016, 7, 673–680. [Google Scholar]

- Park, S.K.; Gao, X.L. Bernoulli-Euler beam model based on a modified couple stress theory. J. Micromech. Microeng. 2006, 16, 2355. [Google Scholar] [CrossRef]

- Sun, C.T.; Zhang, H. Size-dependent elastic moduli of platelike nanomaterials. J. Appl. Phys. 2003, 93, 1212–1218. [Google Scholar] [CrossRef]

- Robinson, J.T.; Zalalutdinov, M.; Baldwin, J.W.; Snow, E.S.; Wei, Z.; Sheehan, P.; Houston, B.H. Wafer-scale Reduced Graphene Oxide Films for Nanomechanical Devices. Nano Lett. 2008, 8, 3441–3445. [Google Scholar] [CrossRef]

- Suk, J.W.; Kitt, A.; Magnuson, C.W.; Hao, Y.; Ahmed, S.; An, J.; Swan, A.K.; Goldberg, B.B.; Ruoff, R.S. Transfer of CVD-Grown Monolayer Graphene onto Arbitrary Substrates. ACS Nano 2011, 5, 6916–6924. [Google Scholar] [CrossRef]

- Ying, F.; Chen, K. Dry transfer of chemical-vapor-deposition-grown graphene onto liquid-sensitive surfaces for tunnel junction applications. Nanotechnology 2015, 26, 035302. [Google Scholar]

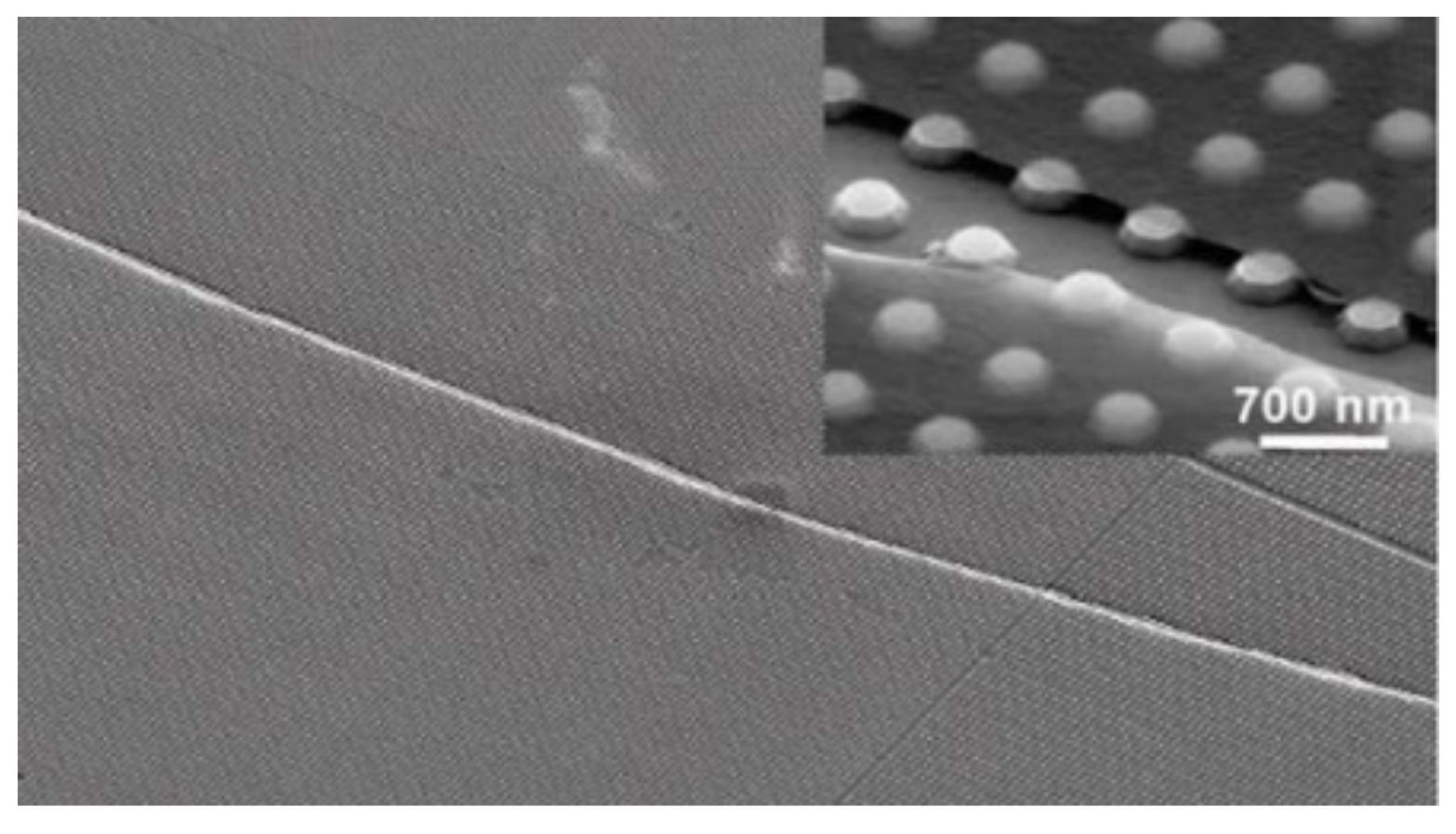

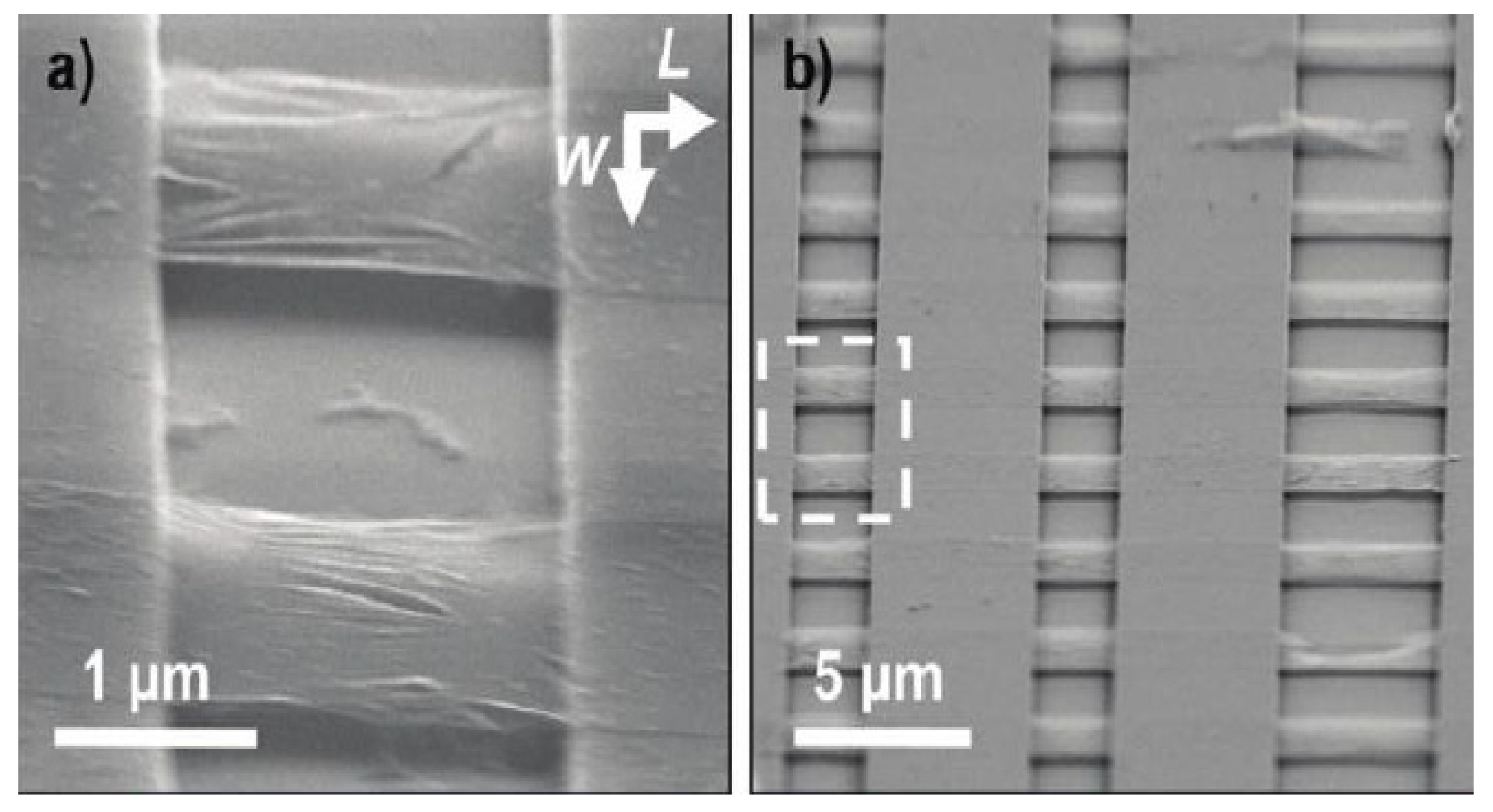

- Van der Zande, A.M.; Barton, R.A.; Alden, J.S.; Ruiz-Vargas, C.S.; Whitney, W.S.; Pham, P.H.Q.; Park, J.; Parpia, J.M.; Craighead, H.G.; McEuen, P.L. Large-Scale Arrays of Single-Layer Graphene Resonators. Nano Lett. 2010, 10, 4869–4873. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef] [Green Version]

- Gao, M.; Pan, Y.; Huang, L.; Hu, H.; Zhang, L.Z.; Guo, H.M.; Du, S.; Gao, H.-J. Epitaxial growth and structural property of graphene on Pt (111). Appl. Phys. Lett. 2011, 98, 033101. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, H.; Shi, D.; Sun, J.; Du, S.; Liu, F.; Gao, H.J. Highly Ordered, Millimeter-Scale, Continuous, Single-Crystalline Graphene Monolayer Formed on Ru (0001); John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Tombros, N.; Veligura, A.; Junesch, J.; Berg, J.J.V.D.; Zomer, P.J.; Wojtaszek, M.; Marun, I.J.V.; Jonkman, H.T.; Van Wees, B.J. Large yield production of high mobility freely suspended graphene electronic devices on a polydimethylglutarimide based organic polymer. J. Appl. Phys. 2011, 109, 93702. [Google Scholar] [CrossRef] [Green Version]

- Kwon, O.K.; Kim, K.-S.; Park, J.; Kang, J.W. Molecular dynamics modeling and simulations of graphene-nanoribbon-resonator-based nanobalance as yoctogram resolution detector. Comput. Mater. Sci. 2013, 67, 329–333. [Google Scholar] [CrossRef]

- Fazelzadeh, S.A.; Ghavanloo, E. Nanoscale mass sensing based on vibration of single-layered graphene sheet in thermal environments. Acta Mech. Sin. 2014, 30, 84–91. [Google Scholar] [CrossRef]

- Karličić, D.; Kozić, P.; Adhikari, S.; Cajić, M.; Murmu, T.; Lazarević, M. Nonlocal mass-nanosensor model based on the damped vibration of single-layer graphene sheet influenced by in-plane magnetic field. Int. J. Mech. Sci. 2015, 96, 132–142. [Google Scholar] [CrossRef]

- Natsuki, T.; Shi, J.-X.; Ni, Q.-Q. Vibration analysis of nanomechanical mass sensor using double-layered graphene sheets resonators. J. Appl. Phys. 2013, 114, 094307. [Google Scholar] [CrossRef]

- Dai, M.D.; Kim, C.-W.; Eom, K. Nonlinear vibration behavior of graphene resonators and their applications in sensitive mass detection. Nanoscale Res. Lett. 2012, 7, 499. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiao, X.; Li, S.-C.; Xing, C.; Xing, W.-W. Stress-Insensitive Resonant Graphene Mass Sensing via Frequency Ratio. Sensors 2019, 19, 3027. [Google Scholar] [CrossRef] [Green Version]

- Xiao, X.; Fan, S.-C.; Li, C. The Effect of Edge Mode on Mass Sensing for Strained Graphene Resonators. Micromachines 2021, 12, 189. [Google Scholar] [CrossRef]

- Patel, R.; Mathew, J.P.; Borah, A.; Deshmukh, M.M. Low tension graphene drums for electromechanical pressure sensing. 2D Mater. 2016, 3, 011003. [Google Scholar] [CrossRef]

- Wang, Q.; Hong, W.; Dong, L. Graphene “microdrums” on a freestanding perforated thin membrane for high sensitivity MEMS pressure sensors. Nanoscale 2016, 8, 7663–7671. [Google Scholar] [CrossRef]

- Yumei, S. Effect of Pressure Sensing on Resonant Graphene Membrane. Master’s Thesis, Beihang University, Beijing, China, 2017. [Google Scholar]

- Jiang, S.; Gong, X.; Guo, X.; Wang, X. Potential application of graphene nanomechanical resonator as pressure sensor. Solid State Commun. 2014, 193, 30–33. [Google Scholar] [CrossRef]

- Fan Shangchun, Z.J.; Liming, Z. Study on sensitive structure of graphene resonant pressure sensor. J. Zhengzhou Univ. 2019, 40, 6. [Google Scholar]

- Fan, S.; Weiwei, X. A Double Graphene Resonant Beam Pressure Sensor; Beihang University: Beijing, China, 2017. [Google Scholar]

- Bunch, J.S.; Dunn, M.L. Adhesion mechanics of graphene membranes. Solid State Commun. 2012, 152, 1359–1364. [Google Scholar] [CrossRef] [Green Version]

- Koenig, S.; Boddeti, N.; Dunn, M.; Bunch, J.S. Ultrastrong adhesion of graphene membranes. Nat. Nanotechnol. 2011, 6, 543–546. [Google Scholar] [CrossRef]

- Lu, Z.; Dunn, M.L. van der Waals adhesion of graphene membranes. J. Appl. Phys. 2010, 107, 2458. [Google Scholar] [CrossRef]

- Kang, J.W.; Lee, J.H.; Hwang, H.J.; Kim, K.S. Developing accelerometer based on graphene nanoribbon resonators. Phys. Lett. A 2012, 376, 3248–3255. [Google Scholar] [CrossRef]

- Kang, J.W.; Park, J.H.; Lee, G.Y.; Kim, K.S. Molecular Dynamics Simulation on Crossroad-Type Graphene-Resonator Accelerometer. J. Comput. Theor. Nanosci. 2015, 12, 4186–4190. [Google Scholar] [CrossRef]

- Hurst, A.M.; Lee, S.; Cha, W.; Hone, J. A graphene accelerometer. In Proceedings of the 28th IEEE International Conference on Micro Electro Mechanical Systems, Estorial, Portugal, 18–22 January 2015. [Google Scholar]

- Jie, W.; Hu, F.; Wang, X.; Qin, S. Acceleration sensing based on graphene resonator. In Proceedings of the International Conference on Photonics & Optical Engineering, Kaohsiung, Taiwan, 4–7 April 2017. [Google Scholar]

- Shi, F.-T.; Fan, S.-C.; Li, C.; Peng, X.-B. Modeling and Analysis of a Novel Ultrasensitive Differential Resonant Graphene Micro-Accelerometer with Wide Measurement Range. Sensors 2018, 18, 2266. [Google Scholar] [CrossRef] [Green Version]

- Matsui, K.; Inaba, A.; Oshidari, Y.; Takei, Y.; Takahashi, H.; Takahata, T.; Kometani, R.; Matsumoto, K.; Shimoyama, I. Mechanical properties of few layer graphene cantilever. In Proceedings of the IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014. [Google Scholar]

- Blees, M.K.; Barnard, A.W.; Rose, P.A.; Roberts, S.P.; McGill, K.L.; Huang, P.Y.; Ruyack, A.R.; Kevek, J.W.; Kobrin, B.; Muller, D.A.; et al. Graphene kirigami. Nature 2015, 524, 204–207. [Google Scholar] [CrossRef]

- Lu, Y.; Guo, Z.-S.; Fan, S.-C. An Ultrahigh-Sensitivity Graphene Resonant Gyroscope. Nanomaterials 2021, 11, 1890. [Google Scholar] [CrossRef]

| Graphene Shape | Sensitive Method | Analysis Method | Sensitivity Analysis | Year/Author |

|---|---|---|---|---|

| Drum Shape | Pressure Direct Sensitive | Experimental Verification | 1Torr | 2016 Raj [93] |

| Pressure Direct Sensitive | Experimental Verification | 2.8 × 10−5 mbar−1 | 2016 Qiugu Wang [94] | |

| Pressure Direct Sensitive | Experimental Verification | 0.298 kHz/kPa (10~1000)kPa | 2016 She [95] | |

| Beam Shape | Secondary sensitive | Finite Element Simulation | 26.838 kHz/kPa (0–1000)kPa | 2014 Jiang [96] |

| Secondary sensitive | Finite Element Simulation | 81.3 Hz/Pa (0–10) kPa | 2016 Fan [97] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, S.-C.; Lu, Y.; Zhao, P.-C.; Shi, F.-T.; Guo, Z.-S.; Xing, W.-W. Research Progress of Graphene Nano-Electromechanical Resonant Sensors—A Review. Micromachines 2022, 13, 241. https://doi.org/10.3390/mi13020241

Fan S-C, Lu Y, Zhao P-C, Shi F-T, Guo Z-S, Xing W-W. Research Progress of Graphene Nano-Electromechanical Resonant Sensors—A Review. Micromachines. 2022; 13(2):241. https://doi.org/10.3390/mi13020241

Chicago/Turabian StyleFan, Shang-Chun, Yang Lu, Peng-Cheng Zhao, Fu-Tao Shi, Zhan-She Guo, and Wei-Wei Xing. 2022. "Research Progress of Graphene Nano-Electromechanical Resonant Sensors—A Review" Micromachines 13, no. 2: 241. https://doi.org/10.3390/mi13020241

APA StyleFan, S.-C., Lu, Y., Zhao, P.-C., Shi, F.-T., Guo, Z.-S., & Xing, W.-W. (2022). Research Progress of Graphene Nano-Electromechanical Resonant Sensors—A Review. Micromachines, 13(2), 241. https://doi.org/10.3390/mi13020241