Influence of Annealing Temperature on Optical Properties of Sandwiched ZnO/Metal/ZnO Transparent Conductive Thin Films

Abstract

:1. Introduction

2. Experiment

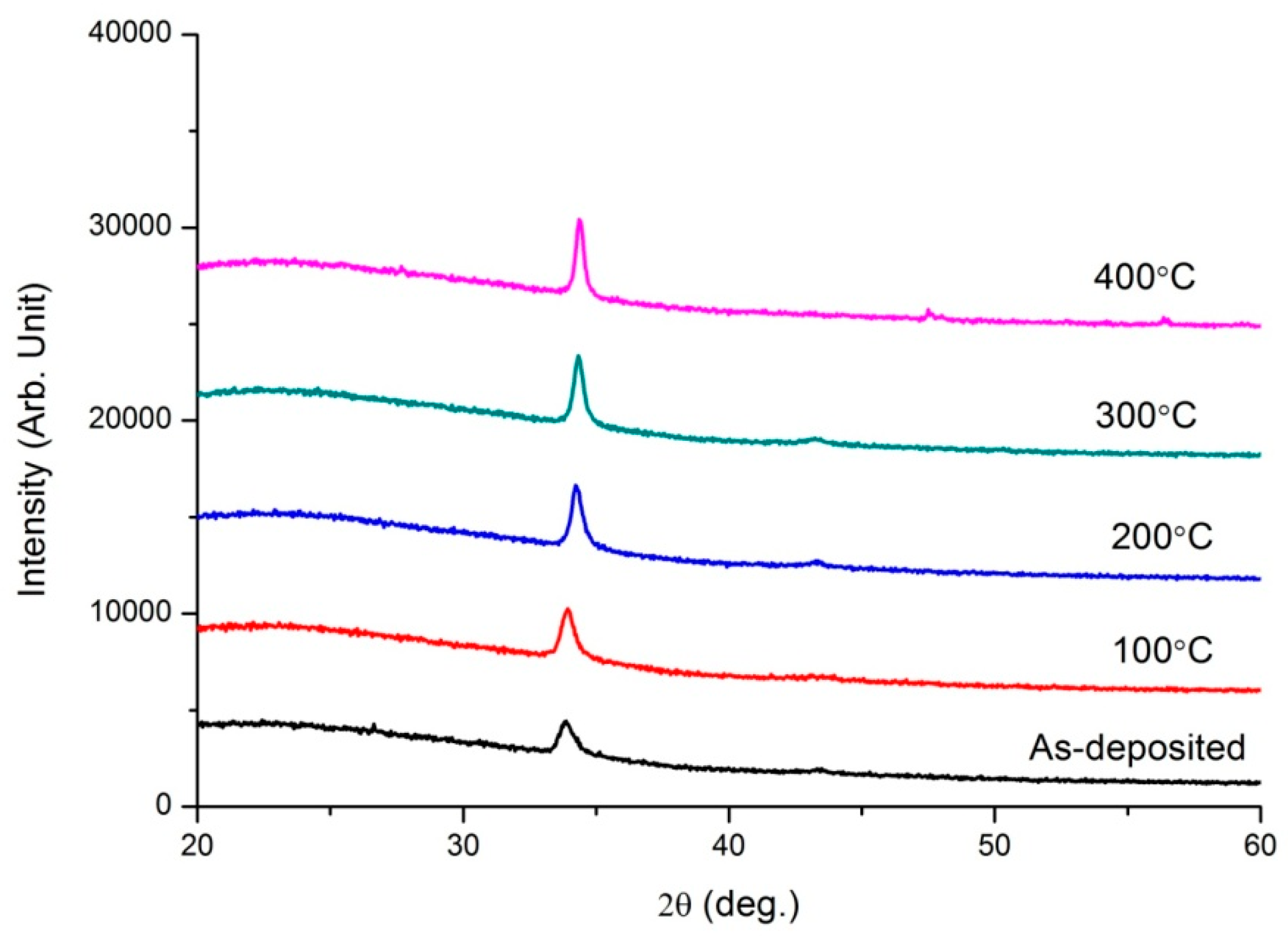

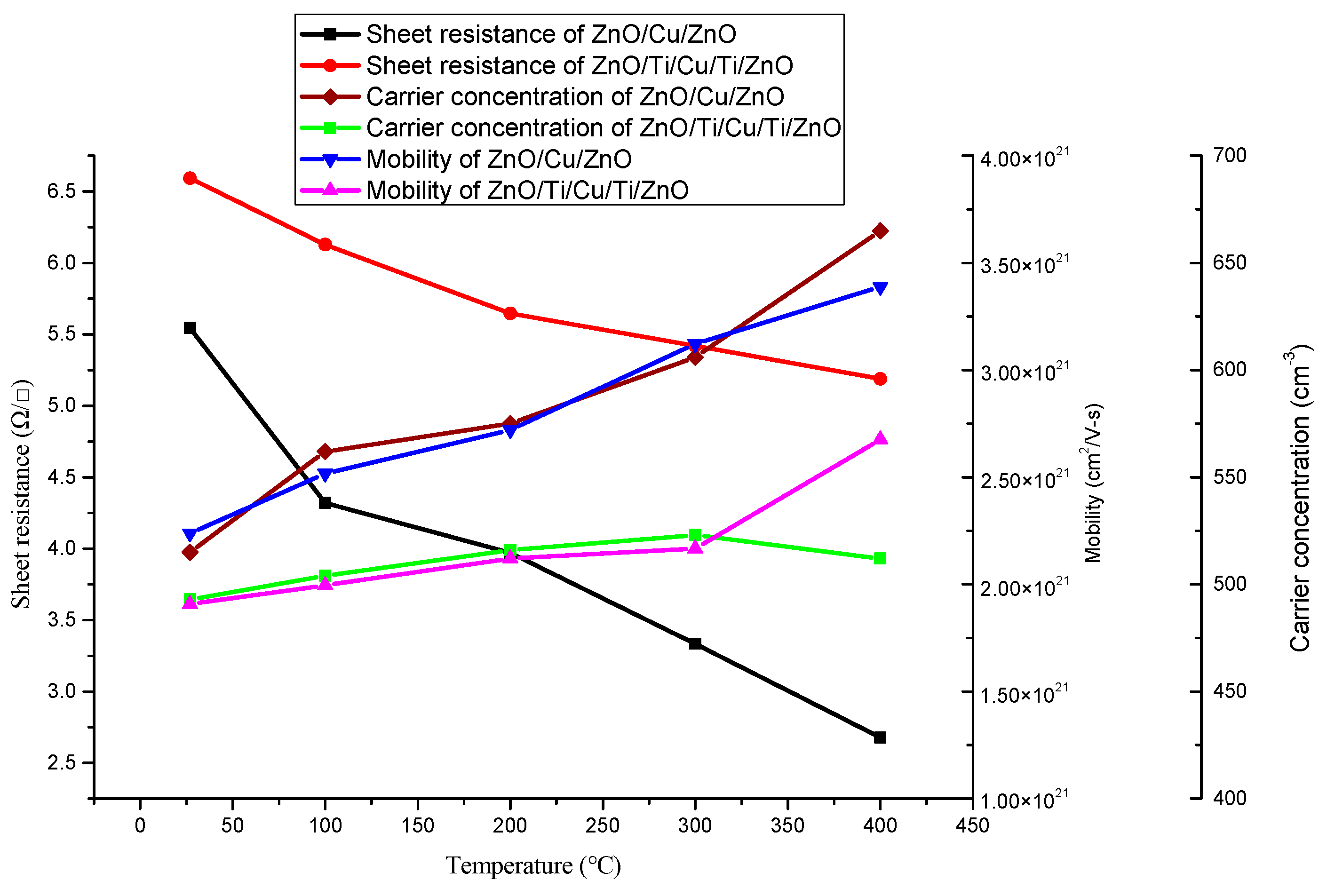

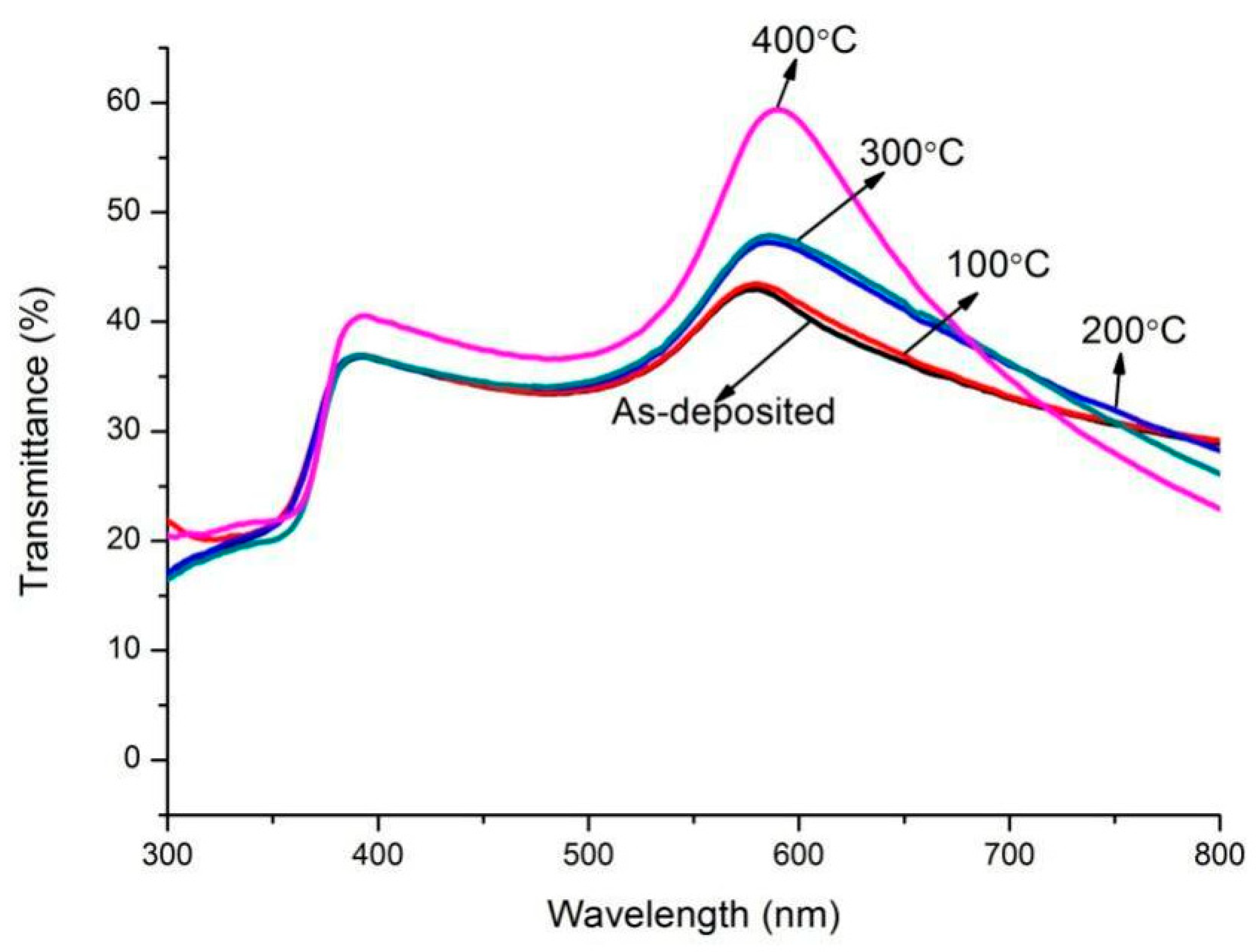

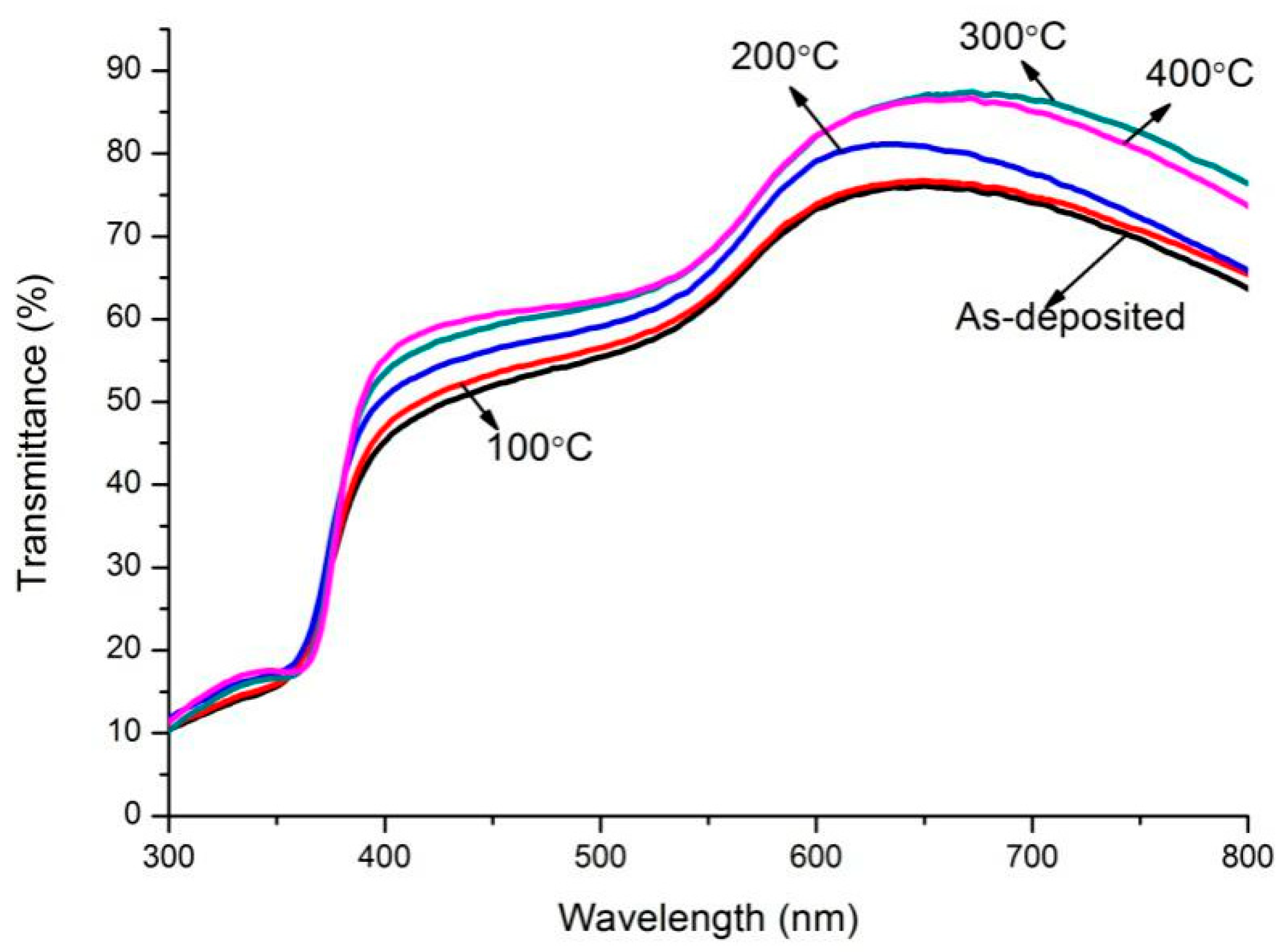

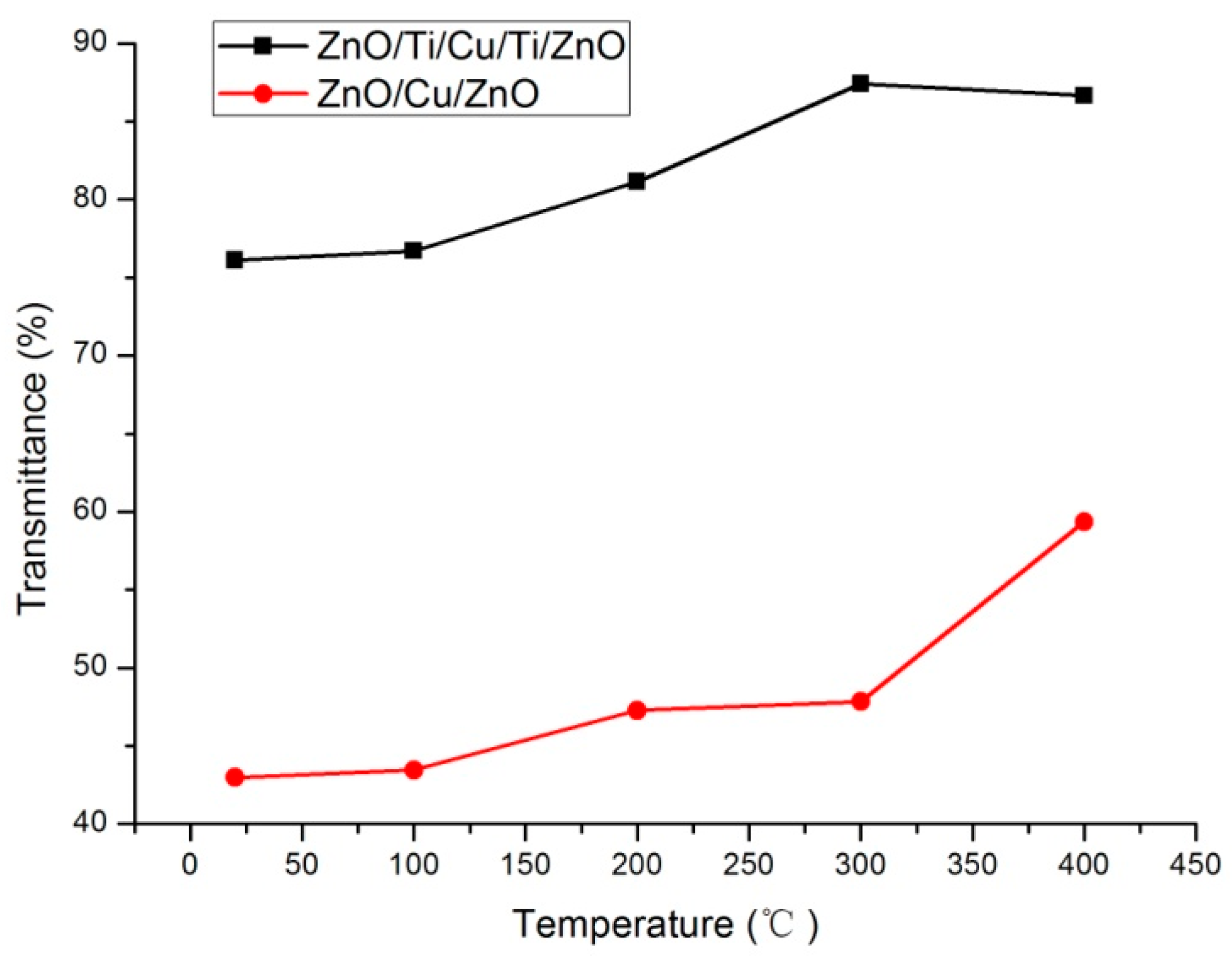

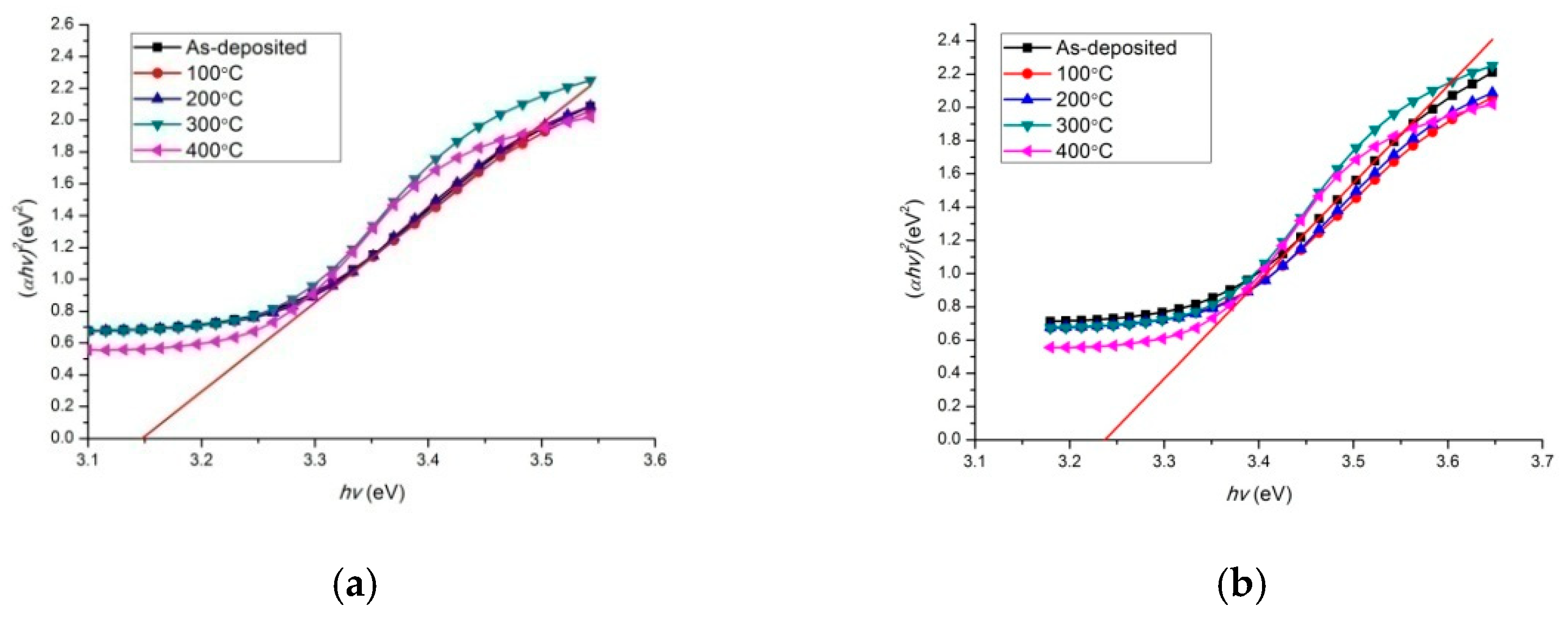

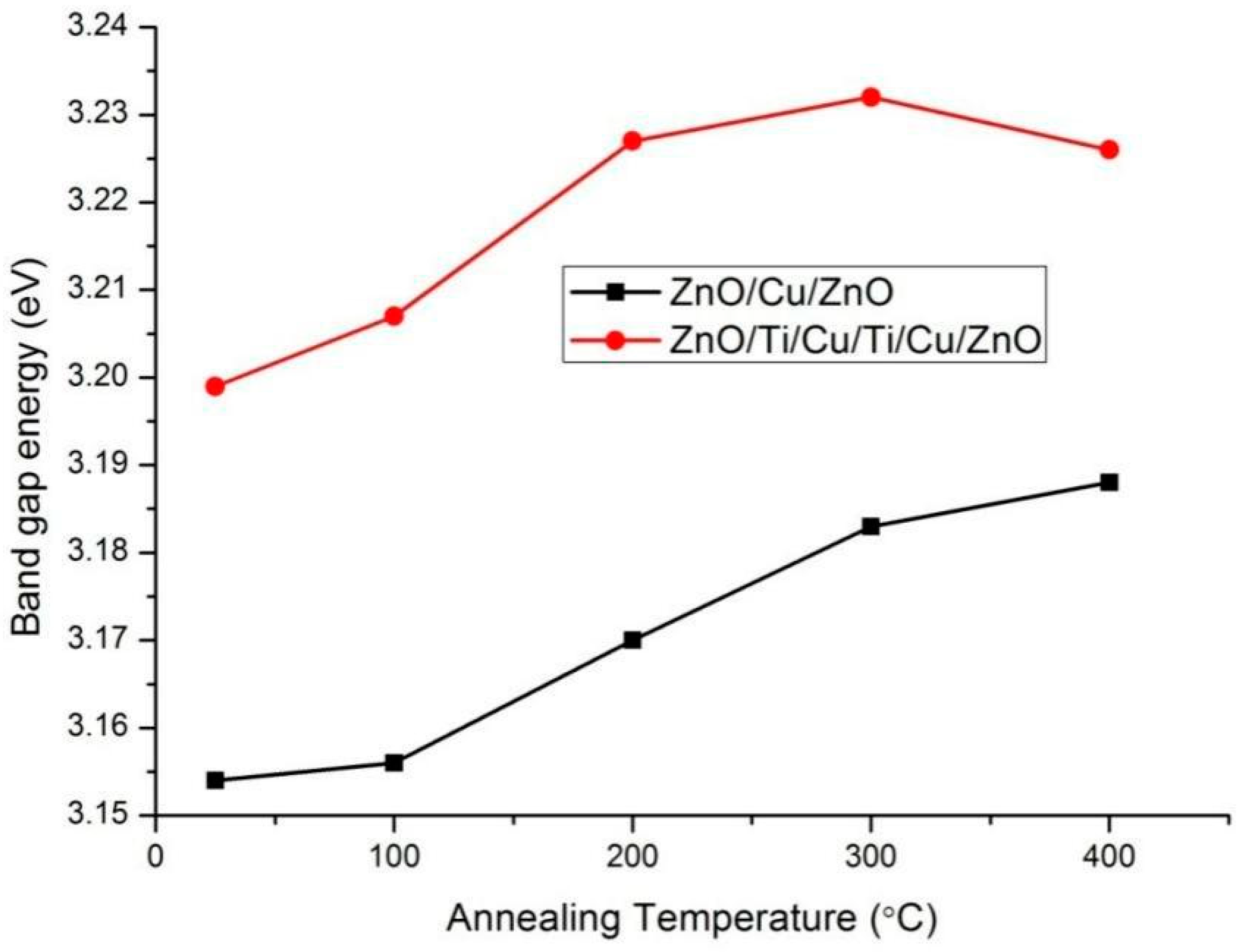

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, Y.-S.; Tseng, W.-C. Effect of Al Nanoparticles on the Microstructure, Electrical, and Optical Properties of AZO/Al/AZO Trilayer Thin Film. J. Electron. Mater. 2011, 41, 437–441. [Google Scholar] [CrossRef]

- Yu, M.; Wang, G.; Zhao, R.; Liu, E.; Chen, T. Improved interfacial wetability in Cu/ZnO and its role in ZnO/Cu/ZnO sandwiched transparent electrodes. J. Mater. Sci. Technol. 2020, 37, 123–127. [Google Scholar] [CrossRef]

- Zaabat, S.; Challali, F.; Chakaroun, M.; Boudine, B.; Boudrioua, A. Investigation and Comparison of Electrical and Optical Properties of RF Sputtered CU Doped ZnO and ZnO/Cu/ZnO Multilayer Films. J. New Technol. Mater. 2019, 9, 45–50. [Google Scholar] [CrossRef]

- Namoune, A.; Touam, T.; Chelouche, A. Thickness, annealing and substrate effects on structural, morphological, optical and waveguiding properties of RF sputtered ZnO thin films. J. Mater. Sci. Mater. 2017, 28, 12207–12219. [Google Scholar] [CrossRef]

- Liu, X.Y.; Li, Y.A.; Liu, S.; Wu, H.-L.; Cui, H.-N. ZnO/Cu/ZnO multilayer films: Structure optimization and investigation on photoelectric properties. Thin Solid Films 2012, 520, 5372–5377. [Google Scholar] [CrossRef]

- Liang, Y.C.; Deng, X.S. Microstructure evolution and optical properties of c-axis-oriented ZnO thin films incorporated with silver nanoisland layers. Ceram. Int. 2014, 40, 1687–1692. [Google Scholar] [CrossRef]

- He, X.X.; Wang, W.J.; Li, S.H.; Liu, Y.L.; Zheng, W.Q.; Shi, Q.; Luo, X. Experimental and theoretical analysis of ZnO/Au/ZnO transparent conducting thin films. Vacuum 2015, 120, 17–21. [Google Scholar] [CrossRef]

- Lee, B.-S.; Kim, C.-I.; Joo, Y.-H. The Optical and Electrical Characteristics for ZnO/Al/ZnO Multilayer Films Deposited by RF Sputtering. J. Nanoelectron. Optoelectron. 2015, 10, 402–407. [Google Scholar] [CrossRef]

- Li, W.Y.; Jiang, L.X.; Yin, G.L.; Wang, Y.-Y.; Yu, Z.; He, D.-N. Preparation and characterization of ZnO/Cu/ZnO transparent conductive films. Rare Met. 2013, 32, 273–277. [Google Scholar] [CrossRef]

- Lin, Q.; Yang, S.; Jing, W.; Wang, C.; Jiang, Z. Numerical Simulation on Optical Characteristics of ZnO/Cu/ZnO Thin Film. J. Nanosci. Nanotechnol. 2016, 16, 873–877. [Google Scholar] [CrossRef]

- Sahu, D.R.; Huang, J.L. Properties of ZnO/Cu/ZnO multilayer films deposited by simultaneous RF and DC magnetron sputtering at different substrate temperatures. Microelectron. J. 2007, 38, 299–303. [Google Scholar] [CrossRef]

- Wang, L.; Chen, W.D.; Ling, L. Investigation of the optical and electrical properties of ZnO/Cu/ZnO multilayer structure for transparent conductive electrodes by magnetron sputtering. J. Mater. Sci. Mater. Electron. 2016, 28, 3458–3466. [Google Scholar] [CrossRef]

- Wang, T.; Ma, H.P.; Yang, J.G.; Zhu, J.-T.; Zhang, H.; Feng, J.; Ding, S.-J.; Lu, H.-L.; Zhang, D.W. Investigation of the optical and electrical properties of ZnO/Cu/ZnO multilayers grown by atomic layer deposition. J. Alloys Compd. 2018, 744, 381–385. [Google Scholar] [CrossRef]

- Wang, M.; Ji, J.; Luo, S.; Jiang, L.; Ma, J.; Xie, X.; Ping, Y.; Ge, J. Sol-gel-derived ZnO/Cu/ZnO multilayer thin films and their optical and electrical properties. Mater. Sci. Semicond. Process. 2016, 51, 55–59. [Google Scholar] [CrossRef]

- Ionescu, M.; Bensebaa, F.; Luan, B.L. Study of optical and electrical properties of ZnO(Cu) multilayers deposited on flexible substrate. Thin Solid Films 2012, 525, 162–166. [Google Scholar] [CrossRef]

- Sahu, D.R.; Huang, J.L. Dependence of film thickness on the electrical and optical properties of ZnO-Cu-ZnO multilayers. Appl. Surf. Sci. 2006, 253, 915–918. [Google Scholar] [CrossRef]

- Song, S.; Yang, T.; Lv, M.; Li, Y.; Xin, Y.; Jiang, L.; Wu, Z.; Han, S. Effect of Cu layer thickness on the structural, optical and electrical properties of AZO/Cu/AZO tri-layer films. Vacuum 2010, 85, 39–44. [Google Scholar] [CrossRef]

- Li, W.; Zhong, J.; Zhang, K.; Wang, Y.-Y.; Yin, G.; He, D.-n. Effects of Annealing on Properties of ZnO/Cu/ZnO Transparent Conductive Film. J. Mater. Eng. 2015, 43, 44–48. [Google Scholar]

- Lee, J.H.; Yeo, B.W.; Park, B.O. Transparent conducting ZnO:Al, In and Sn thin films deposited by the sol-gel nethod. Thin Solid Films 2003, 126, 94–99. [Google Scholar] [CrossRef]

- Sahu, D.; Huang, J.-L. The properties of ZnO/Cu/ZnO multilayer films before and after annealing in the different atmosphere. Thin Solid Films 2007, 516, 208–211. [Google Scholar] [CrossRef]

- Ghosh, D.S.; Chen, T.L.; Pruneri, V. Ultrathin Cu-Ti bilayer transparent conductors with enhanced figure-of-merit and stability. Appl. Phys. Lett. 2010, 96, 091106. [Google Scholar] [CrossRef]

- Park, J.S.; Kim, T.S.; Son, K.S.; Lee, E.; Jung, J.S.; Lee, K.-H.; Maeng, W.-J.; Kim, H.-S.; Kim, E.S.; Park, K.-B.; et al. Ti/Cu bilayer electrodes for SiNx-passivated Hf-In-Zn-O thin film transistors: Device performance and contact resistance. Appl. Phys. Lett. 2010, 97, 590. [Google Scholar] [CrossRef] [Green Version]

- Han, Z.; Zhu, P.; Xu, L.; Kannan, C.S.; Guo, S.; Liu, J.; Koppala, S.; Ju, S. Electrochemical properties of the IrO2-Ta2O5 coated anodes with Al/Ti and Cu/Ti layered composites substrates. J. Alloys Compd. 2018, 769, 210–217. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: Cambridge, MA, USA, 1985. [Google Scholar]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

- Lee, G.; Yamamoto, Y.; Kourogi, M.; Ohtsu, M. Blue shift in room temperature photoluminescence from photo-chemical vapor deposited ZnO films. Thin Solid Films 2001, 386, 117–120. [Google Scholar] [CrossRef]

- Montero, J.; Herrero, J.; Guillén, C. Preparation of reactively sputtered Sb-doped SnO2 thin films: Structural, electrical and optical properties. Sol. Energy Mater. Sol. Cells 2010, 94, 612–616. [Google Scholar] [CrossRef]

- Sivaramakrishnan, K.; Alford, T.L. Metallic conductivity and the role of copper in ZnO/Cu/ZnO thin films for flexible electronics. Appl. Phys. Lett. 2009, 94, 052104. [Google Scholar] [CrossRef]

- Sivaramakrishnan, K.; Theodore, N.D.; Moulder, J.F.; Alford, T.L. The role of copper in ZnO/Cu/ZnO thin films for flexible electronics. J. Appl. Phys. 2009, 106, 063510. [Google Scholar] [CrossRef]

- Minemoto, T.; Negami, T.; Nishiwaki, S.; Takakura, H.; Hamakawa, Y. Preparation of Zn1−xMgxO films by radio frequency magnetron sputtering. Thin Solid Films 2000, 372, 173–176. [Google Scholar] [CrossRef]

- Choopun, S.; Vispute, R.D.; Yang, W.; Sharma, R.P.; Venkatesan, T. Realization of Band Gap above 5.0 eV in Metastable Cubic-Phase MgxZn1−xO Alloy Films. Appl. Phys. Lett. 2002, 80, 1529–1531. [Google Scholar] [CrossRef]

- Tiwari, A.; Bhosle, V.M.; Ramachandran, S.; Sudhakar, N.; Narayan, J.; Budak, S.; Gupta, A. Ferromagnetism in Co doped CeO2: Observation of a giant magnetic moment with a high Curie temperature. Appl. Phys. Lett. 2006, 88, 160. [Google Scholar] [CrossRef] [Green Version]

- Lin, Q.; Zhao, N.; Jiang, Z.; Meng, Q.; Chen, F. Electrical and optical properties of metal-sandwiched ZnO/Ti/Cu/Ti/ZnO transparent conductive thin film. Micro Nano Lett. 2018, 13, 1511–1515. [Google Scholar] [CrossRef]

| Wavelength (nm) | Refractive Index | Extinction Coefficient | |||

|---|---|---|---|---|---|

| ZnO | Cu | Ti | Cu | Ti | |

| 387.44 | 2.264 | 1.231 | 1.500 | 2.068 | 2.12 |

| 413.27 | 2.181 | 1.185 | 1.590 | 2.208 | 2.17 |

| 442.79 | 2.122 | 1.168 | 1.680 | 2.363 | 2.25 |

| 476.85 | 2.078 | 1.152 | 1.750 | 2.504 | 2.34 |

| 516.58 | 2.045 | 1.12 | 1.810 | 2.603 | 2.47 |

| 539.04 | 2.032 | 1.038 | 1.860 | 2.592 | 2.56 |

| 563.55 | 2.019 | 0.826 | 1.920 | 2.602 | 2.67 |

| 590.38 | - | 0.468 | 2.010 | 2.809 | 2.77 |

| 619.9 | - | 0.272 | 2.110 | 3.326 | 2.88 |

| 652.53 | - | 0.214 | 2.220 | 3.667 | 2.99 |

| 688.78 | - | 0.213 | 2.360 | 4.043 | 3.11 |

| 729.294 | - | 0.223 | 2.540 | 4.433 | 3.23 |

| 826.53 | - | 0.26 | 2.980 | 5.26 | 3.32 |

| Figure | Sheet Resistance (Ω/sq;) | Figure of Merit |

|---|---|---|

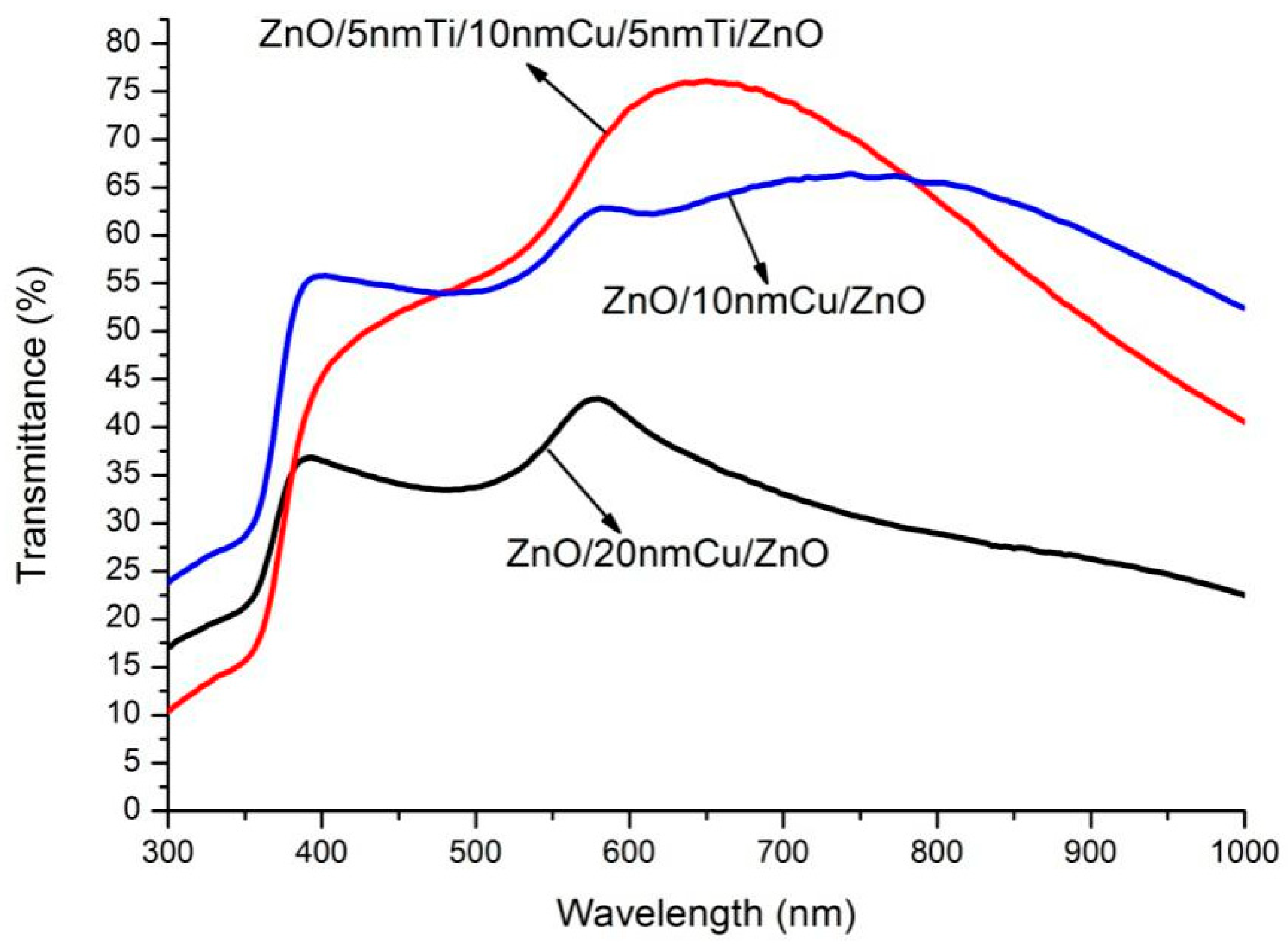

| ZnO/10nm Cu/ZnO | 10.1 | 0.00181 |

| ZnO/20nm Cu/ZnO | 5.5 | 0.00004 |

| ZnO/5nm Ti/10nm Cu/5nm Ti/ZnO | 6.6 | 0.01060 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Q.; Zhang, F.; Zhao, N.; Yang, P. Influence of Annealing Temperature on Optical Properties of Sandwiched ZnO/Metal/ZnO Transparent Conductive Thin Films. Micromachines 2022, 13, 296. https://doi.org/10.3390/mi13020296

Lin Q, Zhang F, Zhao N, Yang P. Influence of Annealing Temperature on Optical Properties of Sandwiched ZnO/Metal/ZnO Transparent Conductive Thin Films. Micromachines. 2022; 13(2):296. https://doi.org/10.3390/mi13020296

Chicago/Turabian StyleLin, Qijing, Fuzheng Zhang, Na Zhao, and Ping Yang. 2022. "Influence of Annealing Temperature on Optical Properties of Sandwiched ZnO/Metal/ZnO Transparent Conductive Thin Films" Micromachines 13, no. 2: 296. https://doi.org/10.3390/mi13020296