Effect of Porosity on Dynamic Response of Additive Manufacturing Ti-6Al-4V Alloys

Abstract

:1. Introduction

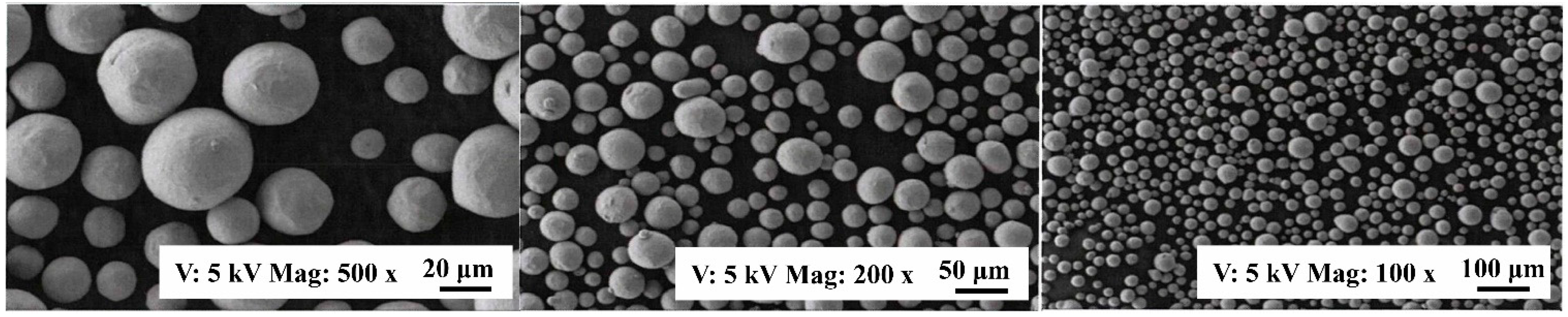

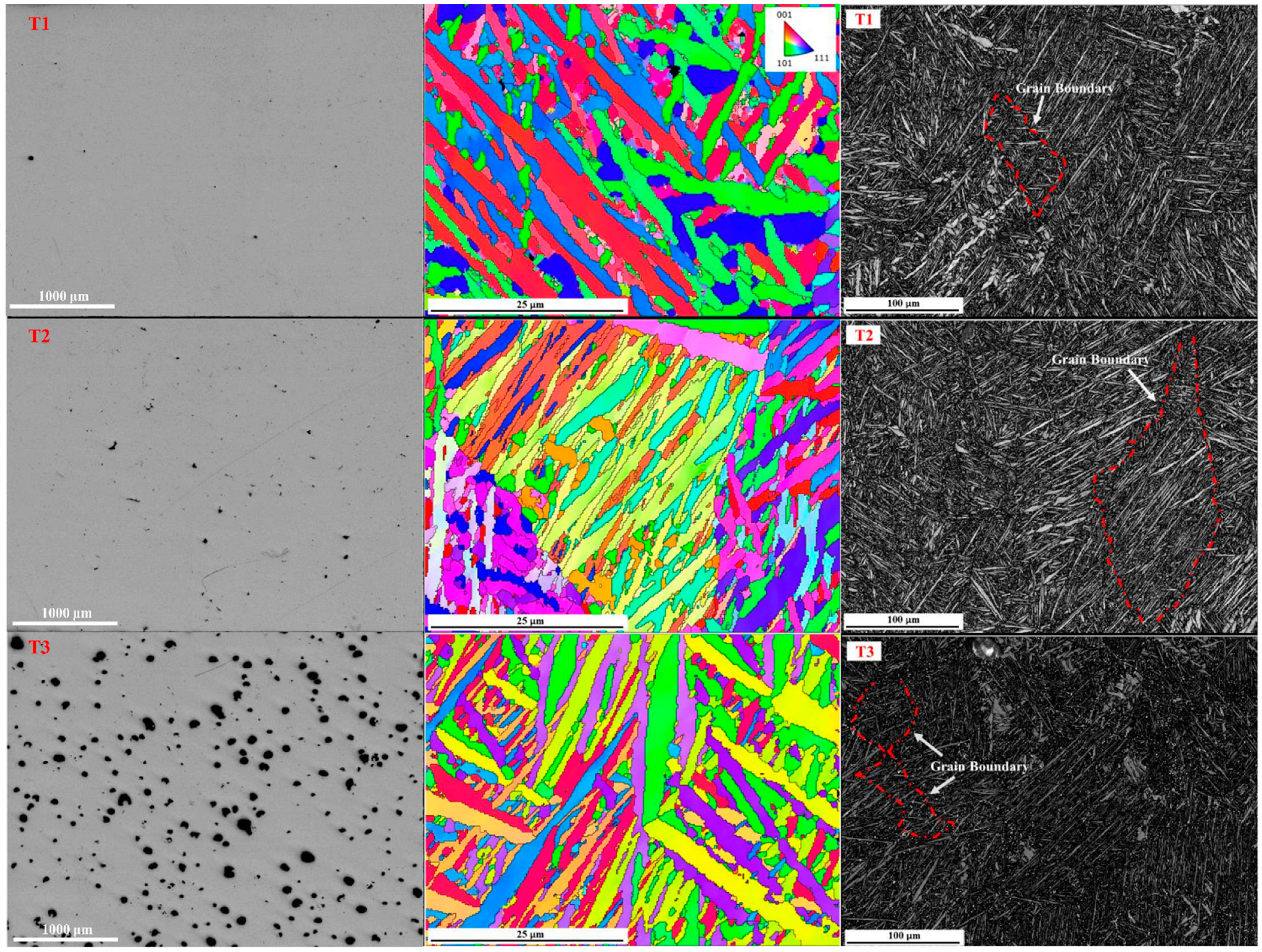

2. Material Manufacturing and Characterization

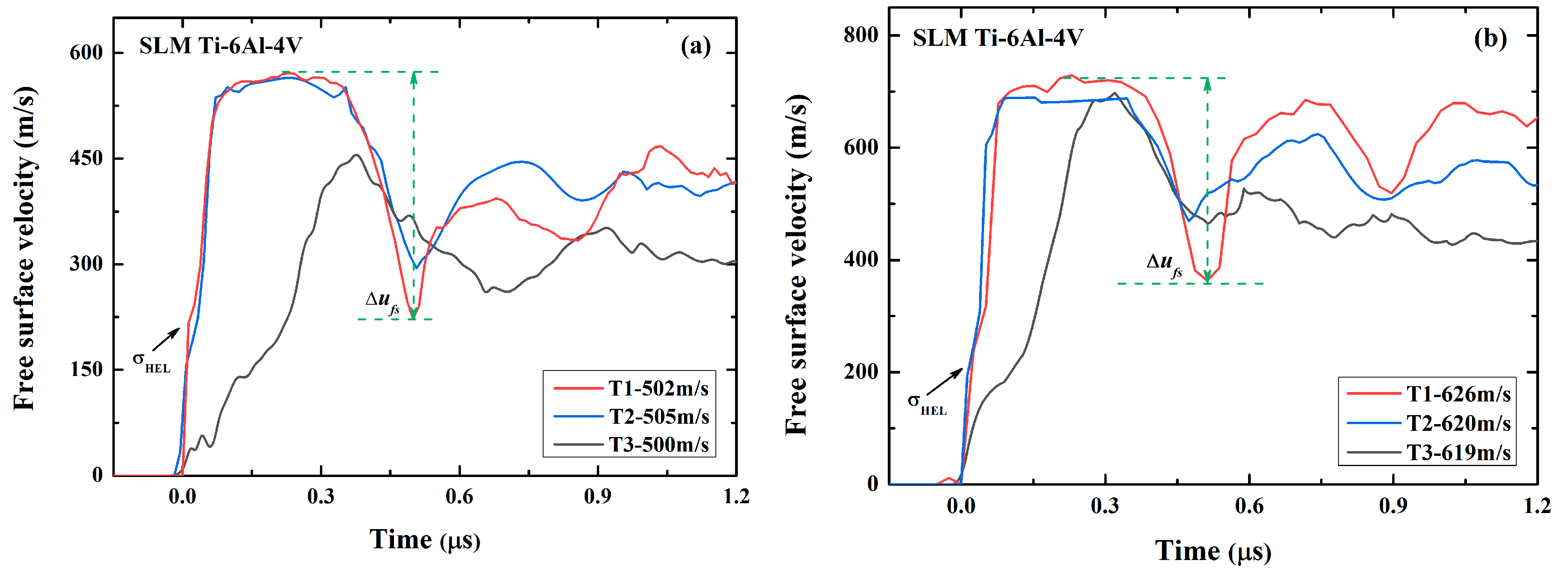

3. Shock-Wave Experiments and Results

3.1. Planar Impact Experiments

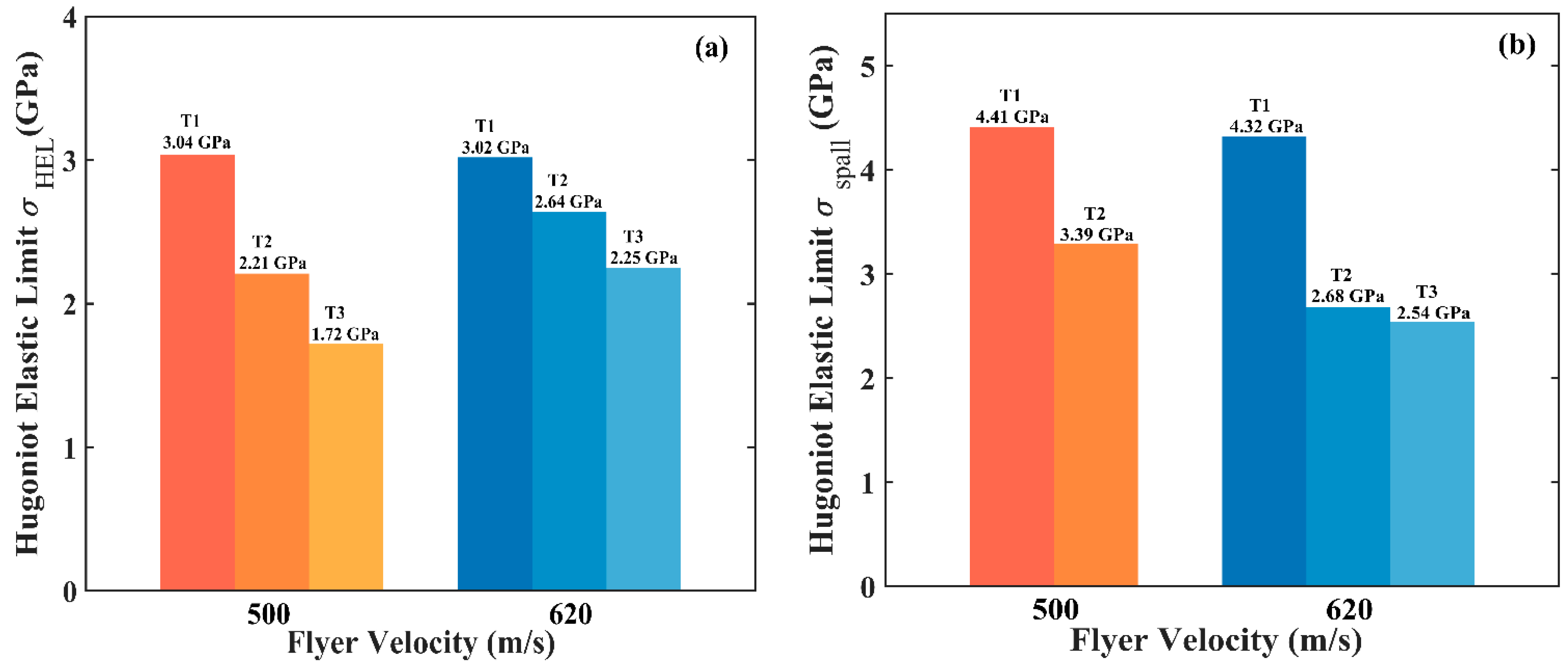

3.2. Results and Discussion

4. Conclusions

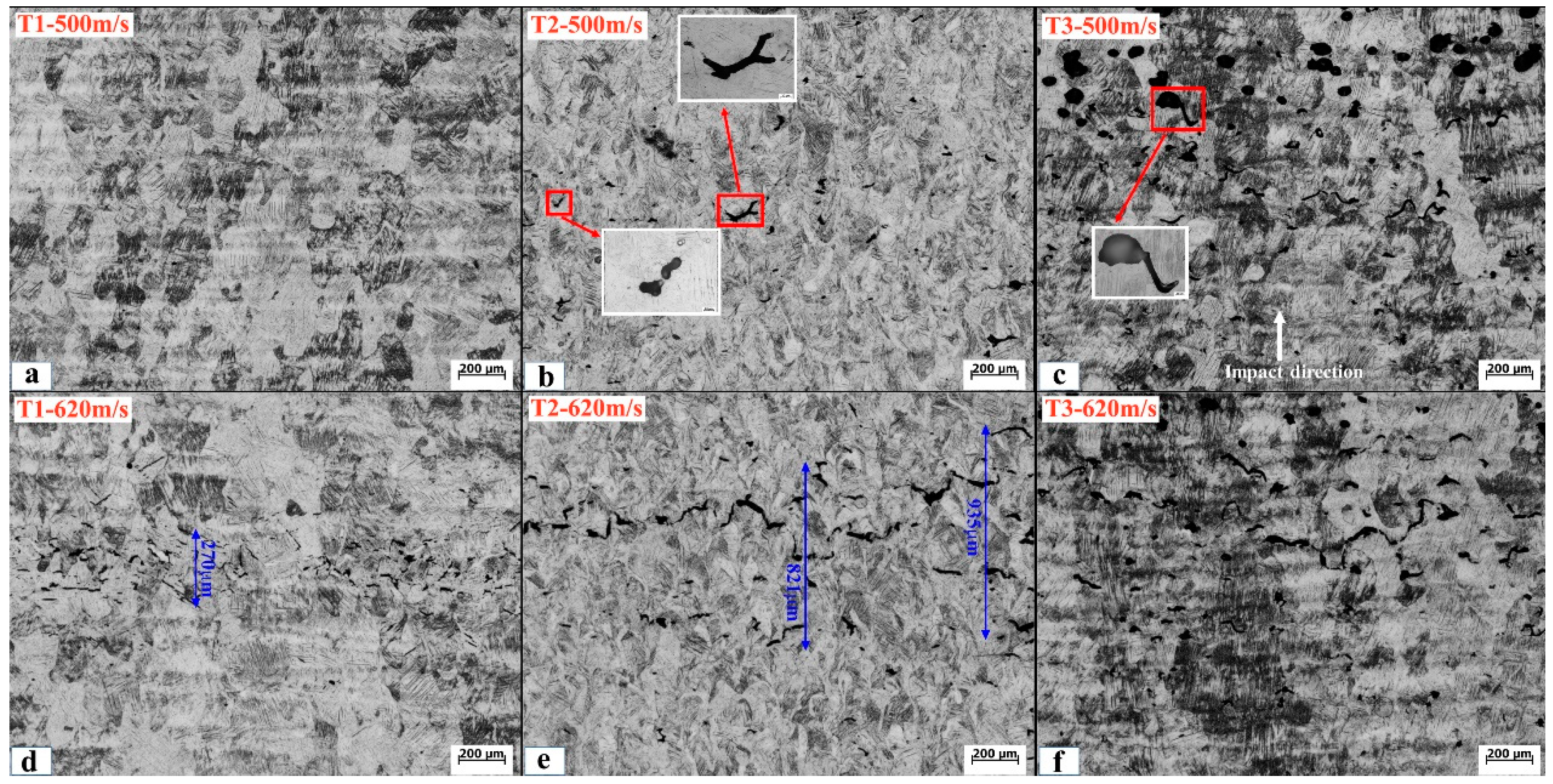

- SLM TC4 with different porosities show observably different dynamic characteristics in the free-surface particle velocity profiles. The increase in porosity significantly degrades the dynamic mechanical properties, including the Hugoniot elastic limit and the spall strength.

- Dense samples show better tensile-resistant properties than porous samples, while porous samples show a good energy absorption capability than dense samples.

- Shock-recovery characterizations indicate that, in porous samples, void collapse and energy absorption occur in the impact stage and cracks mainly originate from widely distributed voids.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yap, C.; Chua, C.; Dong, Z.; Liu, Z.; Zhang, D.; Loh, L.; Sing, S. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Aboutaleb, A.M.; Bian, L.; Shamsaei, N.; Thompson, S.M. Systematic optimization of Laser-based Additive Manufacturing for multiple mechanical properties. In Proceedings of the 2016 IEEE International Conference on Automation Science and Engineering (CASE), Fort Worth, TX, USA, 21 August 2016; pp. 780–785. [Google Scholar]

- Antonysamy, A.A. Microstructure, Texture and Mechanical Property Evolution during Additive Manufacturing of Ti6Al4V Alloy for Aerospace Applications. Master’s Thesis, University of Manchester, Manchester, UK, 2012. [Google Scholar]

- Yakout, M.; Cadamuro, A.; Elbestawi, M.A.; Veldhuis, S.C. The selection of process parameters in additive manufacturing for aerospace alloys. Int. J. Adv. Manuf. Technol. 2017, 92, 2081–2098. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloy Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Maamoun, A.; Xue, Y.; Elbestawi, M.; Veldhuis, S. Effect of selective laser melting process parameters on the quality of al alloy parts: Powder characterization, density, surface roughness, and dimensional accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maamoun, A.; Xue, Y.; Elbestawi, M.; Veldhuis, S. The effect of selective laser melting process parameters on the microstructure and mechanical properties of Al6061 and AlSi10Mg alloys. Materials 2018, 12, 12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, K.V.; Rometsch, P.; Jarvis, T.; Rao, J.; Cao, S.; Davies, C.; Wu, X. Porosity formation mechanisms and fatigue response in Al-Si-Mg alloys made by selective laser melting. Mater. Sci. Eng. A 2018, 712, 166–174. [Google Scholar] [CrossRef]

- Baufeld, B. Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Technol. 2011, 211, 1146–1158. [Google Scholar] [CrossRef]

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 54, 3118–3132. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D MIcro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of materials qualification needs of metal additive manufacturing. JOM 2016, 68, 747–764. [Google Scholar] [CrossRef] [Green Version]

- Sames, W.J.; List, F.A.; Pannala, S.; DeHoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Hudson, J.A.; Liu, E.; Crampin, S. The mechanical properties of materials with interconnected cracks and pores. Geophys. J. Int. 1996, 124, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Lu, G.; Xiao, G. Mechanical Properties of Porous Materials. J. Porous Mater. 1999, 6, 359–368. [Google Scholar] [CrossRef]

- Zhao, B.; Gain, A.K.; Ding, W. A review on metallic porous materials: Pore formation, mechanical properties, and their applications. Int. J. Adv. Manuf. Technol. 2018, 95, 2641–2659. [Google Scholar] [CrossRef]

- Valdez, M. Induced porosity in super alloy 718 through the laser additive manufacturing process: Microstructure and mechanical properties. J. Alloy Compd. 2017, 725, 757–764. [Google Scholar] [CrossRef]

- Martin, A.A.; Calta, N.P.; Khairallah, S.A. Dynamics of pore formation during laser powder bed fusion additive manufacturing. Nat. Commun. 2019, 10, 1987. [Google Scholar] [CrossRef] [Green Version]

- Branch, B.; Lonita, A.; Clements, B.E. Controlling Shockwave dynamics using architecture in periodic porous materials. J. Appl. Phys. 2017, 121, 135102. [Google Scholar] [CrossRef] [Green Version]

- Gangireddy, S.; Faierson, E.J.; Mishra, R.S. Influences of Post-processing, Location, Orientation, and Induced Porosity on the Dynamic Compression Behavior of Ti–6Al–4V Alloy Built Through Additive Manufacturing. J. Dynam. Behav. Mater. 2018, 4, 441–451. [Google Scholar] [CrossRef]

- Jones, D.R.; Fensin, S.J.; Dippo, O.; Beal, R.A.; Iii, G. Spall fracture in additive manufactured Ti-6Al-4V. J. Appl. Phys. 2016, 120, 1–8. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2018, 58, 3303–3312. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the texture formation of selective laser melted Ti-6Al-4V. Metall. Mater. Trans. A 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Kelly, S.M.; Kampe, S.L. Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part i. microstructural characterization. Metall. Mater. Trans. A 2004, 35, 1861–1867. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Zhu, L.; Wang, X.; Wang, D. Investigation into the microstructure and dynamic compressive properties of selective laser melted Ti–6Al–4V alloy with different heating treatments. Mater. Sci. Eng. A 2020, 805, 140561. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Semiatin, S.L. The laser additive manufacture of Ti-6Al-4V. JOM 2001, 53, 40–42. [Google Scholar] [CrossRef]

- Keist, J.S.; Palmer, T.A. Role of geometry on properties of additively manufactured Ti-6Al-4V structures fabricated using laser based directed energy deposition. Mater. Des. 2016, 106, 482–494. [Google Scholar] [CrossRef]

- Kanel, G.I. Distortion of the wave profiles in an elastoplastic body upon spalling. J. Appl. Mech. Tech. Phys. 2001, 42, 358–362. [Google Scholar] [CrossRef]

- P’erez-Ruiz, J.D.; Lacalle, L.N.L.; Urbikain, G.; Pereira, O.; Martínez, S.; Bris, J. On the relationship between cutting forces and anisotropy features in the milling of LPBF Inconel 718 for near net shape parts. Int. J. Mach. Tool Manuf. 2021, 170, 103801. [Google Scholar] [CrossRef]

- Weng, J.; Wang, X.; Ma, Y.; Tan, H.; Cai, L.; Li, J.; Liu, C. A compact all-fiber displacement interferometer for measuring the foil velocity driven by laser. Rev. Sci. Instrum. 2008, 79, 113101. [Google Scholar] [CrossRef]

- Weng, J.; Tan, H.; Wang, X.; Ma, Y. Optical-fiber interferometer for velocity measurements with picosecond resolution. Appl. Phys. Lett. 2006, 89, 4669. [Google Scholar] [CrossRef]

- Xiao, D.; Fan, Q.; Xu, C.; Zhang, X. Measurement methods of ultrasonic transducer sensitivity. Ultrasonics 2016, 68, 150–154. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Wang, F.; Tan, C.; Wang, S.; Yu, X.; Jiang, J. Shock-induced mechanical response and spall fracture behavior of an extra-low interstitial grade Ti–6Al–4V alloy. Mater. Sci. Eng. A 2013, 578, 247–255. [Google Scholar] [CrossRef]

- Gray, G.T., III; Livescu, V.; Rigg, P.A.; Trujillo, C.P.; Fensin, S.J. Structure/property (constitutive and spallation response) of additively manufactured 316l stainless steel. Acta Mater. 2017, 138, 140–149. [Google Scholar] [CrossRef]

| Element | Al (wt.%) | V (wt.%) | O (wt.%) | N (wt.%) | C (wt.%) | H (wt.%) | Fe (wt.%) | Ti (wt.%) | |

|---|---|---|---|---|---|---|---|---|---|

| Condition | |||||||||

| Powder | 5.5~6.75 | 3.5~4.5 | <0.2 | <0.05 | <0.08 | <0.015 | <0.3 | Balance | |

| Workpiece | 5.98 | 4.11 | 0.12 | 0.022 | 0.013 | 0.010 | 0.029 | Balance | |

| Sample | Power (W) | Scan Velocity (mm/s) | Track Width (mm) | Cl (km/s) | Cs (km/s) | Cb (km/s) | Density (g/cm3) | Porosities |

|---|---|---|---|---|---|---|---|---|

| T1 | 370 | 1000 | 0.10 | 6.36 | 3.20 | 5.18 | 4.422 | 0.29% |

| T2 | 280 | 1400 | 0.14 | 6.19 | 3.13 | 5.02 | 4.396 | 0.88% |

| T3 | 200 | 500 | 0.10 | 5.85 | 3.06 | 4.67 | 4.195 | 5.41% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Cai, J.; Li, Z.; Jiao, Z.; Hu, L.; Hu, J. Effect of Porosity on Dynamic Response of Additive Manufacturing Ti-6Al-4V Alloys. Micromachines 2022, 13, 408. https://doi.org/10.3390/mi13030408

Cui Y, Cai J, Li Z, Jiao Z, Hu L, Hu J. Effect of Porosity on Dynamic Response of Additive Manufacturing Ti-6Al-4V Alloys. Micromachines. 2022; 13(3):408. https://doi.org/10.3390/mi13030408

Chicago/Turabian StyleCui, Yihang, Jiacheng Cai, Zhiguo Li, Zhenyu Jiao, Ling Hu, and Jianbo Hu. 2022. "Effect of Porosity on Dynamic Response of Additive Manufacturing Ti-6Al-4V Alloys" Micromachines 13, no. 3: 408. https://doi.org/10.3390/mi13030408