Acoustics-Actuated Microrobots

Abstract

:1. Introduction

2. The Manufacturing of Microrobots

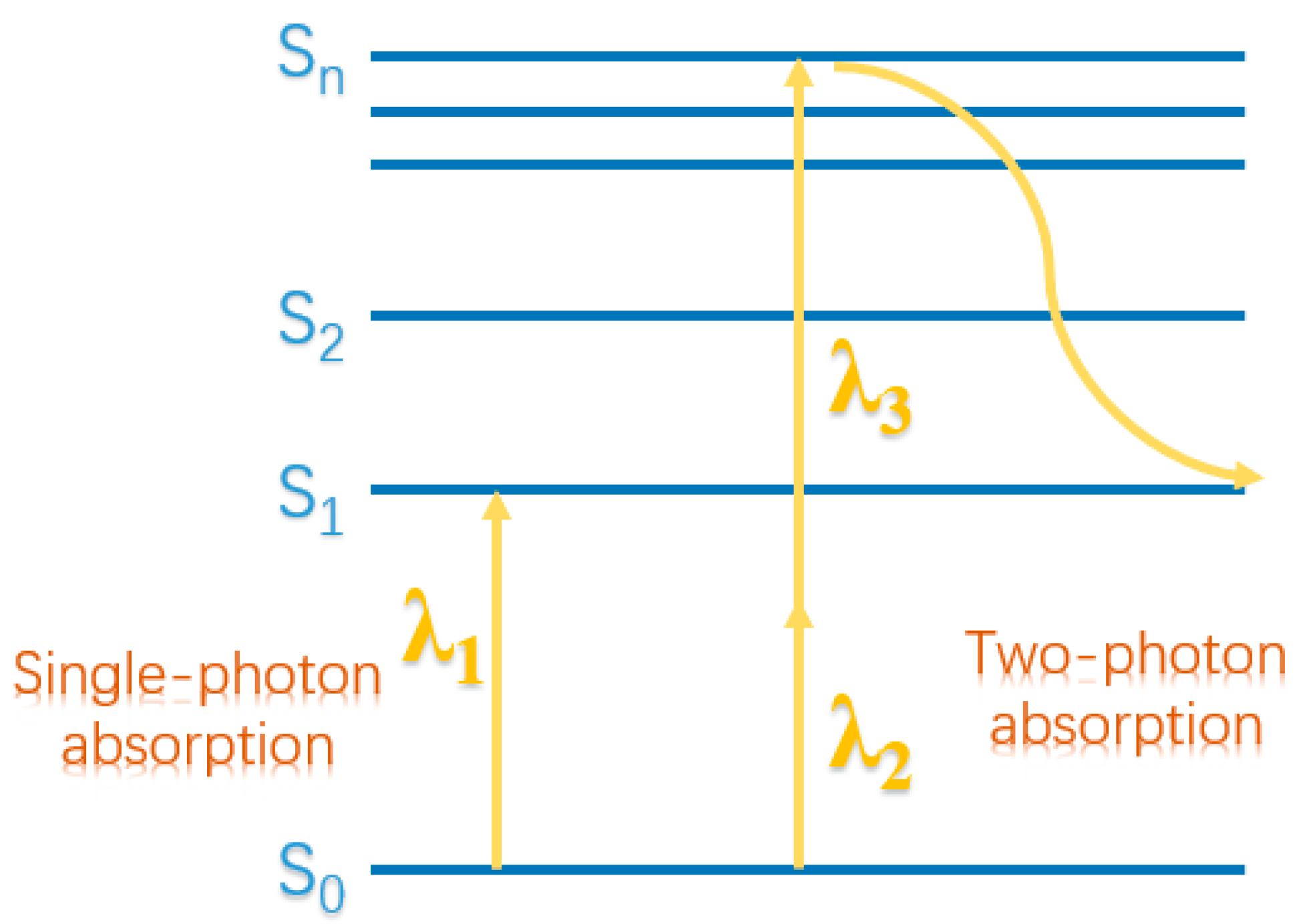

2.1. 3D Printing

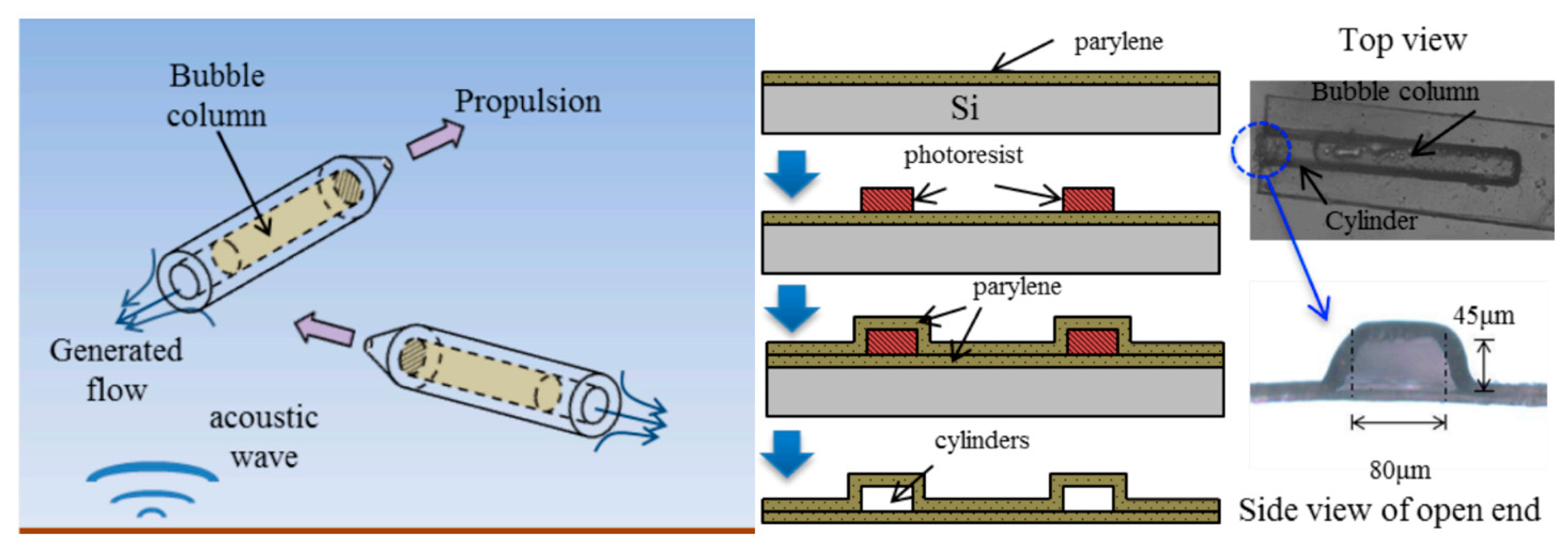

2.2. Photolithography

3. Types of Acoustics-Actuated Microrobots

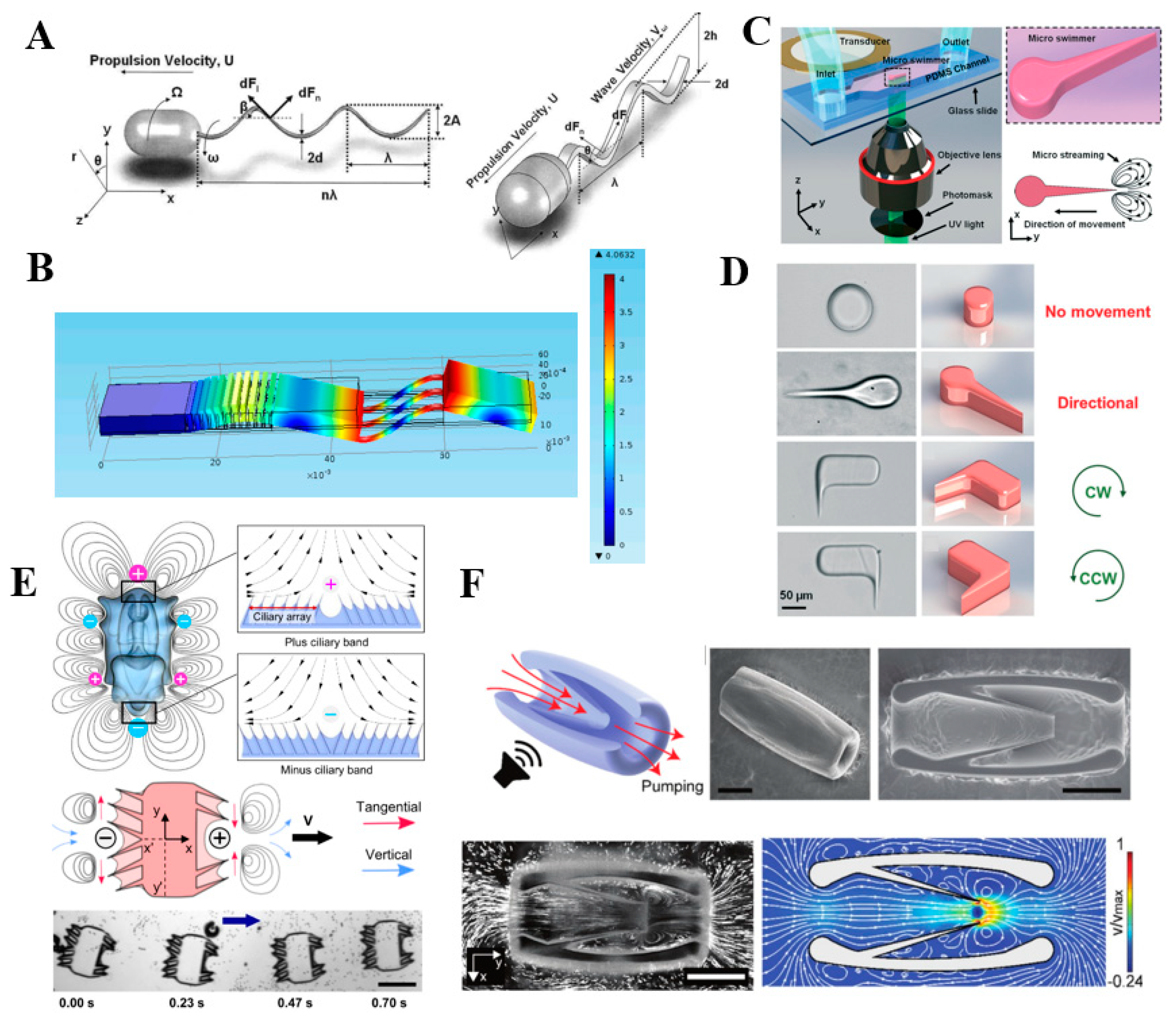

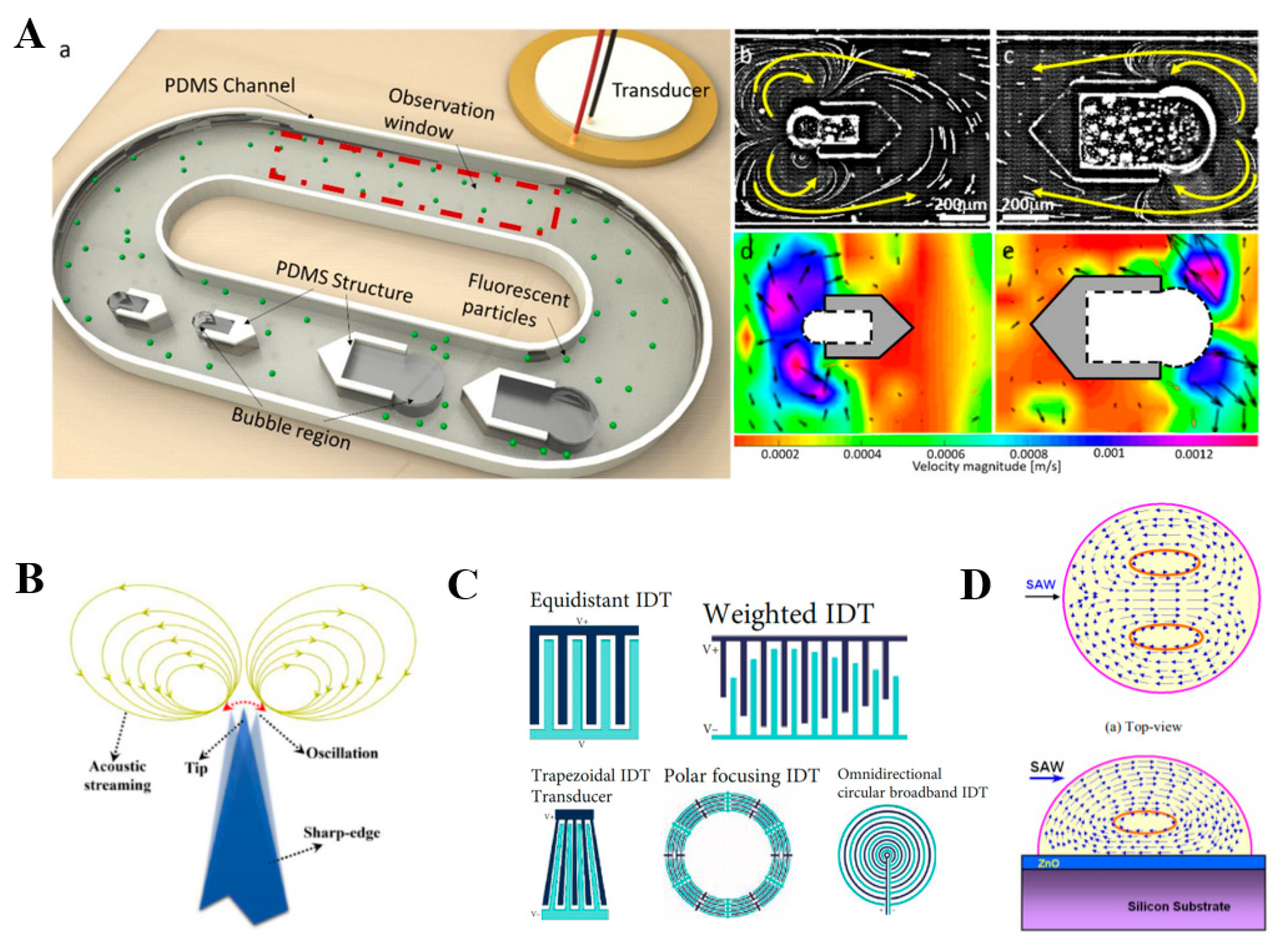

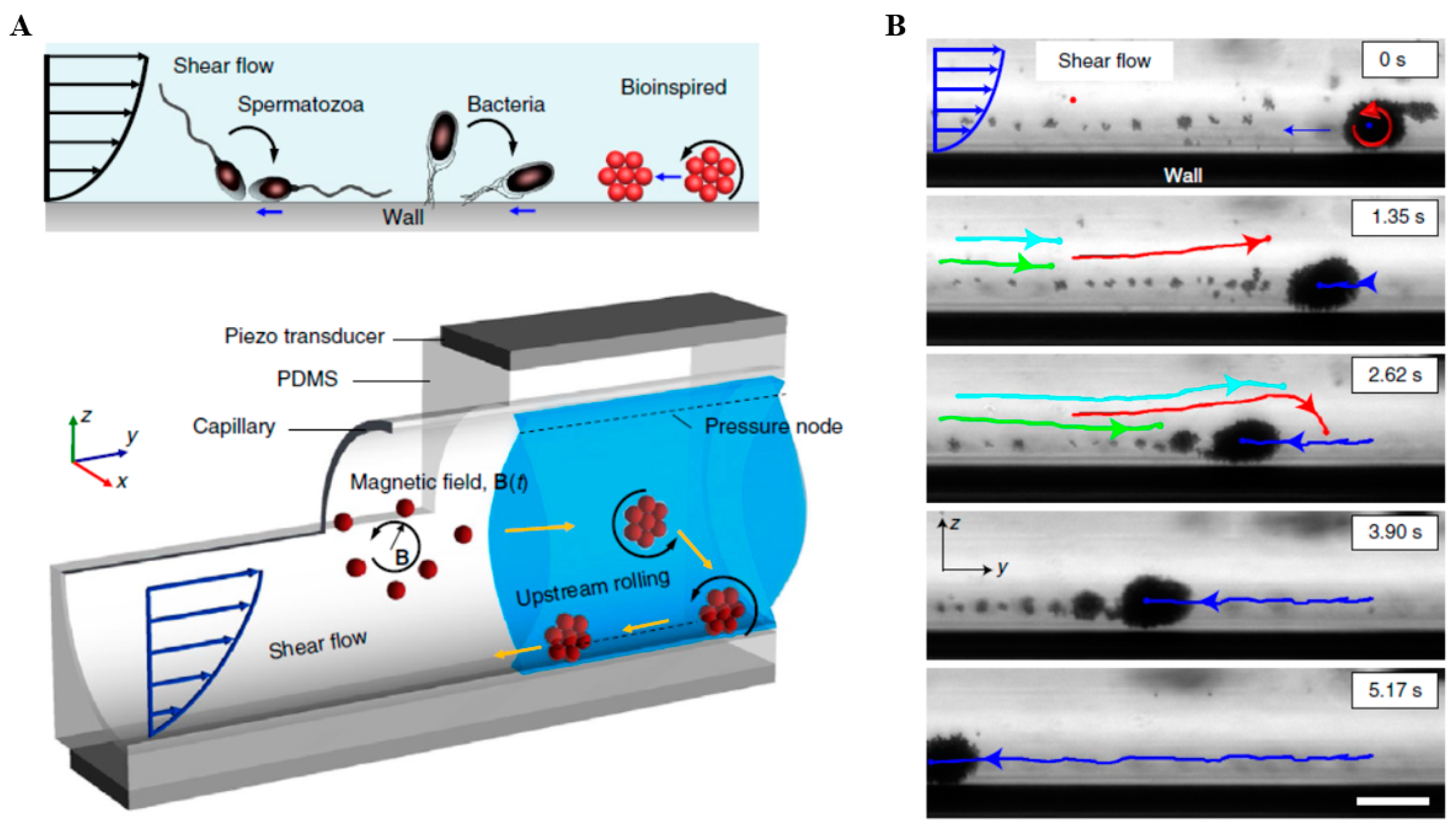

3.1. Bubble Propulsion

3.2. Sharp-Edge Propulsion

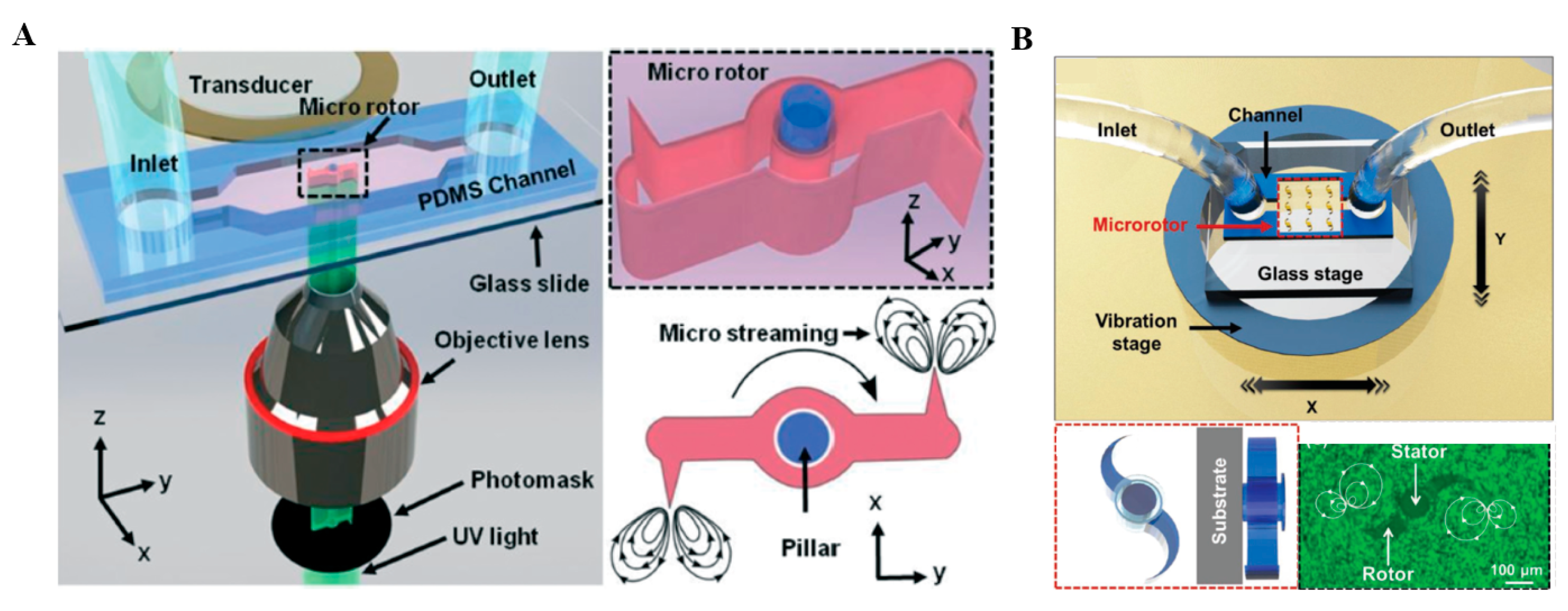

3.3. In-Situ Microrotor

4. Applications

4.1. Targeted Drug Delivery

4.2. Microfluidic Operation

4.3. Microsurgery

5. Current Challenges and Future Perspectives

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Feynman, R.P. There’s plenty of room at the bottom data storage. J. Microelectromech. Syst. 1992, 1, 60–66. [Google Scholar] [CrossRef]

- Halder, A.; Sun, Y. Biocompatible propulsion for biomedical micro/nano robotics. Biosens. Bioelectron. 2019, 139, 111334. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Cho, S. Mini and Micro Propulsion for Medical Swimmers. Micromachines 2014, 5, 97–113. [Google Scholar]

- Saggiorato, G.; Elgeti, J.; Winkler, R.G.; Gompper, G. Conformations, hydrodynamic interactions, and instabilities of sedimenting semiflexible filaments. Soft Matter 2015, 11, 7337–7344. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Volpe, G.; Buttinoni, I.; Vogt, D.; Kümmerer, H.J.; Bechinger, C. Microswimmers in patterned environments. Soft Matter 2011, 7, 8810–8815. [Google Scholar] [CrossRef] [Green Version]

- Parmar, J.; Ma, X.; Katuri, J.; Simmchen, J.; Stanton, M.M.; Trichet-Paredes, C.; Soler, L.; Sanchez, S. Nano and micro architectures for self-propelled motors. Sci. Technol. Adv. Mater. 2015, 16, 014802. [Google Scholar] [CrossRef] [PubMed]

- Grosjean, G.; Lagubeau, G.; Darras, A.; Hubert, M.; Lumay, G.; Vandewalle, N. Remote control of self-assembled microswimmers. Sci. Rep. 2015, 5, 16035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, D.; Lu, M.; Nourhani, A.; Lammert, P.E.; Stratton, Z.; Muddana, H.S.; Crespi, V.H.; Huang, T.J. Selectively manipulable acoustic-powered microswimmers. Sci. Rep. 2015, 5, 9744. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mijalkov, M.; Volpe, G. Sorting of chiral microswimmers. Soft Matter 2013, 9, 6376–6381. [Google Scholar] [CrossRef] [Green Version]

- Edwards, M.R.; Carlsen, R.W.; Zhuang, J.; Sitti, M. Swimming characterization of Serratia marcescens for bio-hybrid microrobotics. JMBR 2014, 9, 47–60. [Google Scholar]

- Simmchen, J.; Katuri, J.; Uspal, W.E.; Popescu, M.N.; Tasinkevych, M.; Sánchez, S. Topographical pathways guide chemical microswimmers. Nat. Commun. 2016, 7, 10598. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, W.; Li, J.; Leong, Y.J.; Rozen, I.; Qu, X.; Dong, R.; Wu, Z.; Gao, W.; Chung, P.H.; Wang, J.; et al. 3D-Printed Artificial Microfish. Adv. Mater. 2015, 27, 4411–4417. [Google Scholar] [CrossRef] [Green Version]

- Katuri, J.; Seo, K.D.; Kim, D.S.; Sanchez, S. Artificial micro-swimmers in simulated natural environments. Lab Chip 2016, 16, 1101–1105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peyer, K.E.; Zhang, L.; Nelson, B.J. Bio-inspired magnetic swimming microrobots for biomedical applications. Nanoscale 2013, 5, 1259–1272. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Shen, L.; Zhao, X.; Chen, H.; Xiao, Y.; Zhang, Y.; Yang, X.; Zhang, J.; Wei, J.; Hao, N. Acoustofluidic micromixers: From rational design to lab-on-a-chip applications. Appl. Mater. Today 2022, 26, 101356. [Google Scholar] [CrossRef]

- Chen, Z.; Pei, Z.; Zhao, X.; Zhang, J.; Wei, J.; Hao, N. Acoustic microreactors for chemical engineering. Chem. Eng. J. 2022, 433, 133258. [Google Scholar] [CrossRef]

- Hao, N.; Pei, Z.; Liu, P.; Bachman, H.; Naquin, T.D.; Zhang, P.; Zhang, J.; Shen, L.; Yang, S.; Yang, K.; et al. Acoustofluidics-Assisted Fluorescence-SERS Bimodal Biosensors. Small 2020, 16, 2005179. [Google Scholar] [CrossRef] [PubMed]

- Carlsen, R.W.; Sitti, M. Bio-hybrid cell-based actuators for microsystems. Small 2014, 10, 3831–3851. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Duan, W.; Ahmed, S.; Mallouk, T.E.; Sen, A. Small power: Autonomous nano- and micromotors propelled by self-generated gradients. Nano Today 2013, 8, 531–554. [Google Scholar] [CrossRef]

- Ahmed, S.; Gentekos, D.T.; Fink, C.A.; Mallouk, T.E. Self-Assembly of Nanorod Motors into Geometrically Regular Multimers and Their Propulsion by Ultrasound. Acs Nano 2014, 8, 11053–11060. [Google Scholar] [CrossRef]

- Qian, J.Y.; Hou, C.W.; Li, X.J.; Jin, Z.J. Actuation Mechanism of Microvalves: A Review. Micromachines 2020, 11, 172. [Google Scholar] [CrossRef] [Green Version]

- Cao, H.X.; Jung, D.; Lee, H.S.; Go, G.; Nan, M.; Choi, E.; Kim, C.S.; Park, J.O.; Kang, B. Micromotor Manipulation Using Ultrasonic Active Traveling Waves. Micromachines 2021, 12, 192. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Duan, W.; Ahmed, S.; Sen, A.; Mallouk, T.E. From one to many: Dynamic assembly and collective behavior of self-propelled colloidal motors. Acc. Chem. Res. 2015, 48, 1938–1946. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.; Wang, W.; Mair, L.O.; Fraleigh, R.D.; Li, S.; Castro, L.A.; Hoyos, M.; Huang, T.J.; Mallouk, T.E. Steering acoustically propelled nanowire motors toward cells in a biologically compatible environment using magnetic fields. Langmuir 2013, 29, 16113–16118. [Google Scholar] [CrossRef] [PubMed]

- Shabaniverki, S.; Juarez, J.J. Directed Assembly of Particles for Additive Manufacturing of Particle-Polymer Composites. Micromachines 2021, 12, 935. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Peyer, K.E.; Nelson, B.J. Artificial bacterial flagella for micromanipulation. Lab Chip 2010, 10, 2203–2215. [Google Scholar] [CrossRef] [PubMed]

- Nosrati, R.; Driouchi, A.; Yip, C.M.; Sinton, D. Two-dimensional slither swimming of sperm within a micrometre of a surface. Nat. Commun. 2015, 6, 8703. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fornell, A.; Soderback, P.; Liu, Z.; De Albuquerque Moreira, M.; Tenje, M. Fabrication of Silicon Microfluidic Chips for Acoustic Particle Focusing Using Direct Laser Writing. Micromachines 2020, 11, 113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hao, N.; Liu, P.; Bachman, H.; Pei, Z.; Zhang, P.; Rufo, J.; Wang, Z.; Zhao, S.; Huang, T.J. Acoustofluidics-Assisted Engineering of Multifunctional Three-Dimensional Zinc Oxide Nanoarrays. ACS Nano 2020, 14, 6150–6163. [Google Scholar] [CrossRef]

- Hao, N.; Wang, Z.; Liu, P.; Becker, R.; Yang, S.; Yang, K.; Pei, Z.; Zhang, P.; Xia, J.; Shen, L.; et al. Acoustofluidic multimodal diagnostic system for Alzheimer’s disease. Biosens. Bioelectron. 2022, 196, 113730. [Google Scholar] [CrossRef] [PubMed]

- Dijkink, R.J.; van der Dennen, J.P.; Ohl, C.D.; Prosperetti, A. The ‘acoustic scallop’: A bubble-powered actuator. J. Micromech. Microeng. 2006, 16, 1653–1659. [Google Scholar] [CrossRef]

- Compton, B.G.; Lewis, J.A. 3D-printing of lightweight cellular composites. Adv. Mater. 2014, 26, 5930–5935. [Google Scholar] [CrossRef]

- Armand, M.; Tarascon, J.M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef] [PubMed]

- del Campo, A.; Arzt, E. Fabrication approaches for generating complex micro- and nanopatterns on polymeric surfaces. Chem. Rev. 2008, 108, 911–945. [Google Scholar] [CrossRef]

- Kawata, S.; Sun, H.B.; Tanaka, T.; Takada, K. Finer features for functional microdevices—Micromachines can be created with higher resolution using two-photon absorption. Nature 2001, 412, 697–698. [Google Scholar] [CrossRef] [PubMed]

- Derby, B. Printing and Prototyping of Tissues and Scaffolds. Science 2012, 338, 921–926. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lewis, J.A.; Ahn, B.Y. Three-dimensional printed electronics. Nature 2015, 518, 42–43. [Google Scholar] [CrossRef] [PubMed]

- Park, J.U.; Hardy, M.; Kang, S.J.; Barton, K.; Adair, K.; Mukhopadhyay, D.K.; Lee, C.Y.; Strano, M.S.; Alleyne, A.G.; Georgiadis, J.G.; et al. High-resolution electrohydrodynamic jet printing. Nat. Mater. 2007, 6, 782–789. [Google Scholar] [CrossRef] [PubMed]

- Sutanto, E.; Shigeta, K.; Kim, Y.K.; Graf, P.G.; Hoelzle, D.J.; Barton, K.L.; Alleyne, A.G.; Ferreira, P.M.; Rogers, J.A. A multimaterial electrohydrodynamic jet (E-jet) printing system. J. Micromech. Microeng. 2012, 22, 045008. [Google Scholar] [CrossRef] [Green Version]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Xu, C.; Zipfel, W.; Shear, J.B.; Williams, R.M.; Webb, W.W. Multiphoton fluorescence excitation: New spectral windows for biological nonlinear microscopy. Proc. Natl. Acad. Sci. USA 1996, 93, 10763–10768. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, Y.; Wang, H.; Ma, Z.; Yang, J.K.W.; Ai, Y. Acoustic Vibration-Induced Actuation of Multiple In-situ microrotors in Microfluidics. Adv. Mater. Technol. 2020, 5, 2000323. [Google Scholar] [CrossRef]

- Garcia, R.; Knoll, A.W.; Riedo, E. Advanced scanning probe lithography. Nat. Nanotechnol. 2014, 9, 577–587. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bates, C.M.; Maher, M.J.; Janes, D.W.; Ellison, C.J.; Willson, C.G. Block Copolymer Lithography. Macromolecules 2014, 47, 2–12. [Google Scholar] [CrossRef]

- Kim, J.; Hanna, J.A.; Byun, M.; Santangelo, C.D.; Hayward, R.C. Designing Responsive Buckled Surfaces by Halftone Gel Lithography. Science 2012, 335, 1201–1205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chibana, T.; Nakano, H.; Hata, H.; Kodachi, N.; Sano, N.; Arakawa, M.; Matsuoka, Y.; Kawasaki, Y.; Mori, S.; Chiba, K. Development status of a 193-nm immersion exposure tool. In Proceedings of the SPIE 31st International Symposium on Advanced Lithography, San Jose, CA, USA, 15 March 2006. [Google Scholar]

- Streefkerk, B.; Baselmans, J.; Gehoel-van Ansem, W.; Mulkens, J.; Hoogendam, C.; Hoogendorp, M.; Flagello, D.; Sewell, H.; Graeupner, P. Extending optical lithography with immersion. In Proceedings of the Conference on Optical and Microlithography, Santa Clara, CA, USA, 28 May 2004; pp. 285–305. [Google Scholar]

- Chen, Y. Nanofabrication by electron beam lithography and its applications: A review. Microelectron. Eng. 2015, 135, 57–72. [Google Scholar] [CrossRef]

- Arshak, K.; Mihov, M.; Nakahara, S.; Arshak, A.; McDonagh, D. A novel focused-ion-beam lithography process for sub-100 nanometer technology nodes. Superlattice. Microst. 2004, 36, 335–343. [Google Scholar] [CrossRef]

- Lin, C.H.; Cheng, B.; Li, T.Y.; Retamal, J.R.D.; Wei, T.C.; Fu, H.C.; Fang, X.; He, J.H. Orthogonal Lithography for Halide Perovskite Optoelectronic Nanodevices. Acs Nano 2019, 13, 1168–1176. [Google Scholar] [CrossRef] [PubMed]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale. Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feng, J.; Cho, S.K. Micro Propulsion in Liquid by Oscillating Bubbles. In Proceedings of the 26th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Taipei, Taiwan, 20–24 January 2013; pp. 63–66. [Google Scholar]

- Kaynak, M.; Ozcelik, A.; Nama, N.; Nourhani, A.; Lammert, P.E.; Crespi, V.H.; Huang, T.J. Acoustofluidic actuation of in situ fabricated microrotors. Lab Chip 2016, 16, 3532–3537. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaynak, M.; Ozcelik, A.; Nourhani, A.; Lammert, P.E.; Crespi, V.H.; Huang, T.J. Acoustic actuation of bioinspired microswimmers. Lab Chip 2017, 17, 395–400. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Riley, N. Steady streaming. Annu. Rev. Fluid Mech. 2001, 33, 43–65. [Google Scholar] [CrossRef]

- Leighton, T.G.; Baik, K.; Jiang, J. The use of acoustic inversion to estimate the bubble size distribution in pipelines. Proc. R. Soc. A Math. Phys. Eng. Sci. 2012, 468, 2461–2484. [Google Scholar] [CrossRef]

- Crum, L.A. Bjerknes forces on bubbles in a stationary sound field. J. Acoust. Soc. Am. 1975, 57, 1363–1370. [Google Scholar] [CrossRef]

- Feng, J.; Yuan, J.; Cho, S.K. Micropropulsion by an acoustic bubble for navigating microfluidic spaces. Lab Chip 2015, 15, 1554–1562. [Google Scholar] [CrossRef]

- Bertin, N.; Spelman, T.A.; Stephan, O.; Gredy, L.; Bouriau, M.; Lauga, E.; Marmottant, P. Propulsion of Bubble-Based Acoustic Microswimmers. Phys. Rev. Appl. 2015, 4, 064012. [Google Scholar] [CrossRef] [Green Version]

- Aghakhani, A.; Yasa, O.; Wrede, P.; Sitti, M. Acoustically powered surface-slipping mobile microrobots. Proc. Natl. Acad. Sci. USA 2020, 117, 3469–3477. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jeong, J.; Jang, D.; Kim, D.; Lee, D.; Chung, S.K. Acoustic bubble-based drug manipulation: Carrying, releasing and penetrating for targeted drug delivery using an electromagnetically actuated microrobot. Sens. Actuators A phys. 2020, 306, 111973. [Google Scholar] [CrossRef]

- Stanton, M.M.; Trichet-Paredes, C.; Sanchez, S. Applications of three-dimensional (3D) printing for microswimmers and bio-hybrid robotics. Lab Chip 2015, 15, 1634–1637. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stanton, M.M.; Simmchen, J.; Ma, X.; Miguel-López, A.; Sánchez, S. Biohybrid Janus Motors Driven by Escherichia coli. Adv. Mater. Interfaces 2016, 3, 1500505. [Google Scholar] [CrossRef]

- Elgeti, J.; Winkler, R.G.; Gompper, G. Physics of microswimmers--single particle motion and collective behavior: A review. Rep. Prog. Phys. 2015, 78, 056601. [Google Scholar] [CrossRef]

- Nama, N.; Huang, P.H.; Huang, T.J.; Costanzo, F. Investigation of acoustic streaming patterns around oscillating sharp edges. Lab Chip 2014, 14, 2824–2836. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lighthill, J. Acoustic streaming. J. Sound Vib. 1978, 61, 391–418. [Google Scholar] [CrossRef]

- Riley, N. Acoustic streaming. Theor. Comp. Fluid Dyn. 1998, 10, 349–356. [Google Scholar] [CrossRef]

- Behkam, B.; Sitti, M. Design Methodology for Biomimetic Propulsion of Miniature Swimming Robots. Propuls. Miniat. Swim. Robot. 2006, 128, 36–43. [Google Scholar] [CrossRef] [Green Version]

- House, C.; Piepmeier, J.; Burkhardt, J.; Firebaugh, S. Analysis of flapping mechanism for acoustically actuated microrobotics. In Proceedings of the 2014 Spring Symposium: From Lab to Life: Field Based Applications of MEMS & NEMS (MAMNA), Baltimore, MD, USA, 3 March 2014. [Google Scholar]

- Dillinger, C.; Nama, N.; Ahmed, D. Ultrasound-activated ciliary bands for microrobotic systems inspired by starfish. Nat. Commun. 2021, 12, 6455. [Google Scholar] [CrossRef] [PubMed]

- Kaynak, M.; Dirix, P.; Sakar, M.S. Addressable Acoustic Actuation of 3D Printed Soft Robotic Microsystems. Adv. Sci. (Weinh) 2020, 7, 2001120. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Zhao, K.; Peng, H.; Li, H.; Liu, W. Local Enhanced Microstreaming for Controllable High-Speed Acoustic Rotary Microsystems. Phys. Rev. Appl. 2019, 11, 044064. [Google Scholar] [CrossRef]

- Lu, X.; Zhao, K.; Liu, W.; Yang, D.; Shen, H.; Peng, H.; Guo, X.; Li, J.; Wang, J. A Human Microrobot Interface Based on Acoustic Manipulation. ACS Nano 2019, 13, 11443–11452. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Soto, F.; Li, J.; Li, T.; Liang, Y.; Wang, J. Topographical Manipulation of Microparticles and Cells with Acoustic Microstreaming. ACS Appl. Mater. Interfaces 2017, 9, 38870–38876. [Google Scholar] [CrossRef]

- Jang, D.; Jeong, J.; Song, H.; Chung, S.K. Targeted drug delivery technology using untethered microrobots: A review. J. Micromech. Microeng. 2019, 29, 053002. [Google Scholar] [CrossRef]

- Garcia-Gradilla, V.; Orozco, J.; Sattayasamitsathit, S.; Soto, F.; Kuralay, F.; Pourazary, A.; Katzenberg, A.; Gao, W.; Shen, Y.; Wang, J. Functionalized Ultrasound-Propelled Magnetically Guided Nanomotors: Toward Practical Biomedical Applications. Acs Nano 2013, 7, 9232–9240. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Gradilla, V.; Sattayasamitsathit, S.; Soto, F.; Kuralay, F.; Yardimci, C.; Wiitala, D.; Galarnyk, M.; Wang, J. Ultrasound-propelled nanoporous gold wire for efficient drug loading and release. Small 2014, 10, 4154–4159. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Zhou, Q.; Yu, J.; Xu, T.; Deng, Y.; Tang, T.; Feng, Q.; Bian, L.; Zhang, Y.; Ferreira, A.; et al. Magnetite Nanostructured Porous Hollow Helical Microswimmers for Targeted Delivery. Adv. Funct. Mater. 2015, 25, 5333–5342. [Google Scholar] [CrossRef]

- Wei, Y.; Lu, X.; Shen, H.; Peng, H.; Yuan, Z.; Guo, X.; Liu, W. An Acousto-Microrobotic Interface with Vision-Feedback Control. Adv. Mater. Technol. 2021, 6, 2100470. [Google Scholar] [CrossRef]

- Kwon, J.O.; Yang, J.S.; Chae, J.B.; Chung, S.K. Micro-object manipulation in a microfabricated channel using an electromagnetically driven microrobot with an acoustically oscillating bubble. Sens. Actuators A phys. 2014, 215, 77–82. [Google Scholar] [CrossRef]

- Gao, Y.; Wu, M.; Lin, Y.; Zhao, W.; Xu, J. Acoustic bubble-based bidirectional micropump. Microfluid. Nanofluidics 2020, 24, 29. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, P.; Zhao, X.; Huang, L.; Xiao, Y.; Zhang, Y.; Zhang, J.; Hao, N. Sharp-edge acoustic microfluidics: Principles, structures, and applications. Appl. Mater. Today 2021, 25, 101239. [Google Scholar] [CrossRef]

- Wang, Z.; Xiong, X.; Qian, L.; Wang, J.; Fei, Y.; Tian, M. Research on the Progress of Interdigital Transducer (IDT) for Structural Damage Monitoring. J. Sens. 2021, 2021, 6630658. [Google Scholar]

- Sritharan, K.; Strobl, C.J.; Schneider, M.F.; Wixforth, A.; Guttenberg, Z. Acoustic mixing at low Reynold’s numbers. Appl. Phys. Lett. 2006, 88, 054102. [Google Scholar] [CrossRef]

- Bennes, J.; Alzuaga, S.; Cherioux, F.; Ballandras, S.; Vairac, P.; Manceau, J.F.; Bastien, F. Detection and high-precision positioning of liquid droplets using SAW systems. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 2146–2151. [Google Scholar] [CrossRef] [PubMed]

- Meng, A.H.; Nam-Trung, N.; White, R.M. Focused Flow Micropump Using Ultrasonic Flexural Plate Waves. Biomed. Microdevices 2000, 2, 169–174. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Du, X.Y.; Luo, J.K.; Flewitt, A.J.; Milne, W.I.; Lee, D.S.; Park, N.M.; Maeng, S.; Kim, S.H.; Choi, Y.J.; et al. SAW streaming in ZnO surface acoustic wave micromixer and micropump. In Proceedings of the 6th IEEE Sensors Conference, Atlanta, GA, USA, 28–31 October 2007; pp. 478–483. [Google Scholar]

- Jang, L.S.; Chao, S.H.; Holl, M.R.; Meldrum, D.R. Resonant Mode-hopping Micromixing. Sens. Actuators A Phys. 2007, 138, 179–186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khalil, I.S.M.; Mandy, D.; El Sharkawy, A.; Moustafa, R.R.; Tabak, A.F.; Mitwall, M.E.; Hesham, S.; Hamdi, N.; Klingner, A.; Mohamed, A.; et al. Mechanical Rubbing of Blood Clots Using Helical Robots Under Ultrasound Guidance. IEEE Robot. Autom. Lett. 2018, 3, 1112–1119. [Google Scholar] [CrossRef]

- Ahmed, D.; Sukhov, A.; Hauri, D.; Rodrigue, D.; Gian, M.; Harting, J.; Nelson, B. Bio-inspired Acousto-magnetic Microswarm Robots with Upstream Motility. Nat. Mach. Intell. 2021, 3, 116–124. [Google Scholar] [CrossRef] [PubMed]

- Magdanz, V.; Khalil, I.S.M.; Simmchen, J.; Furtado, G.P.; Mohanty, S.; Gebauer, J.; Xu, H.; Klingner, A.; Aziz, A.; Medina-Sanchez, M.; et al. IRONSperm: Sperm-templated soft magnetic microrobots. Sci. Adv. 2020, 6, eaba5855. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Collins, D.J.; Guo, J.; Ai, Y. Mechanical Properties Based Particle Separation via Traveling Surface Acoustic Wave. Anal. Chem. 2016, 88, 11844–11851. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Chen, C.; Wang, Z.; Bachman, H.; Ouyang, Y.; Huang, P.H.; Sadovsky, Y.; Huang, T.J. Separating extracellular vesicles and lipoproteins via acoustofluidics. Lab Chip 2019, 19, 1174–1182. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Destgeer, G.; Kim, H.; Cho, Y.; Sung, H.J. In-droplet microparticle washing and enrichment using surface acoustic wave-driven acoustic radiation force. Lab Chip 2018, 18, 2936–2945. [Google Scholar] [CrossRef] [PubMed]

- Ceylan, H.; Giltinan, J.; Kozielski, K.; Sitti, M. Mobile microrobots for bioengineering applications. Lab Chip 2017, 17, 1705–1724. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Actuation Method | Advantages | Major Limitations |

|---|---|---|

| Magnetic actuation | Biocompatible power supply; Relatively reliable operability; Strong penetration; Long action time | Microrobots are difficult to fabricate because of their special shape; Difficulty in selective microrobot control |

| Biological actuation | Biocompatible power supply; Combination of the actuating and sensing capabilities; Natural suitability for physiological fluids; Relatively high efficiency | Needs of a particular environment containing proper nutrients for fueling the microrobot |

| Chemical actuation | Fast actuation speed; Use of biocompatible fuel such as urea, glucose, H2O, and acids in self-phoretic propulsion | High risk of in vivo cross-reactivity; Insufficient propulsion accuracy; Short action time; Lack of instantaneous feedback |

| Acoustic actuation | Biocompatible power supply; Capability to control microrobot deep inside of the body; Strong penetration; High flexibility; Low power consumption; Long action time | Requirements of proper instrumentation for in vivo use; The material and design requirements of microrobots are relatively strict |

| Propulsion Type | Principle | Advantages | Disadvantages |

|---|---|---|---|

| Bubble propulsion | Bubbles’ vibration produces a source of net momentum | Fast and strong propulsion | Narrow frequency selection range; Bubbles may burst; Hard operation |

| Sharp-edge propulsion | Sharp-edge’s vibration generates propulsion | Wide frequency selection range; Simple manufacturing, and operation | Low propulsion |

| In-situ microrotor | Similar to sharp-edge propulsion, but there is a fixed axis in the center | In-situ propulsion; Low fluid influence | Complex design |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Zhang, J.; Fang, B.; Zhao, X.; Hao, N. Acoustics-Actuated Microrobots. Micromachines 2022, 13, 481. https://doi.org/10.3390/mi13030481

Xiao Y, Zhang J, Fang B, Zhao X, Hao N. Acoustics-Actuated Microrobots. Micromachines. 2022; 13(3):481. https://doi.org/10.3390/mi13030481

Chicago/Turabian StyleXiao, Yaxuan, Jinhua Zhang, Bin Fang, Xiong Zhao, and Nanjing Hao. 2022. "Acoustics-Actuated Microrobots" Micromachines 13, no. 3: 481. https://doi.org/10.3390/mi13030481

APA StyleXiao, Y., Zhang, J., Fang, B., Zhao, X., & Hao, N. (2022). Acoustics-Actuated Microrobots. Micromachines, 13(3), 481. https://doi.org/10.3390/mi13030481