Investigation of Solvent-Assisted In-Mold Bonding of Cyclic Olefin Copolymer (COC) Microfluidic Chips

Abstract

1. Introduction

2. Experiments and Methods

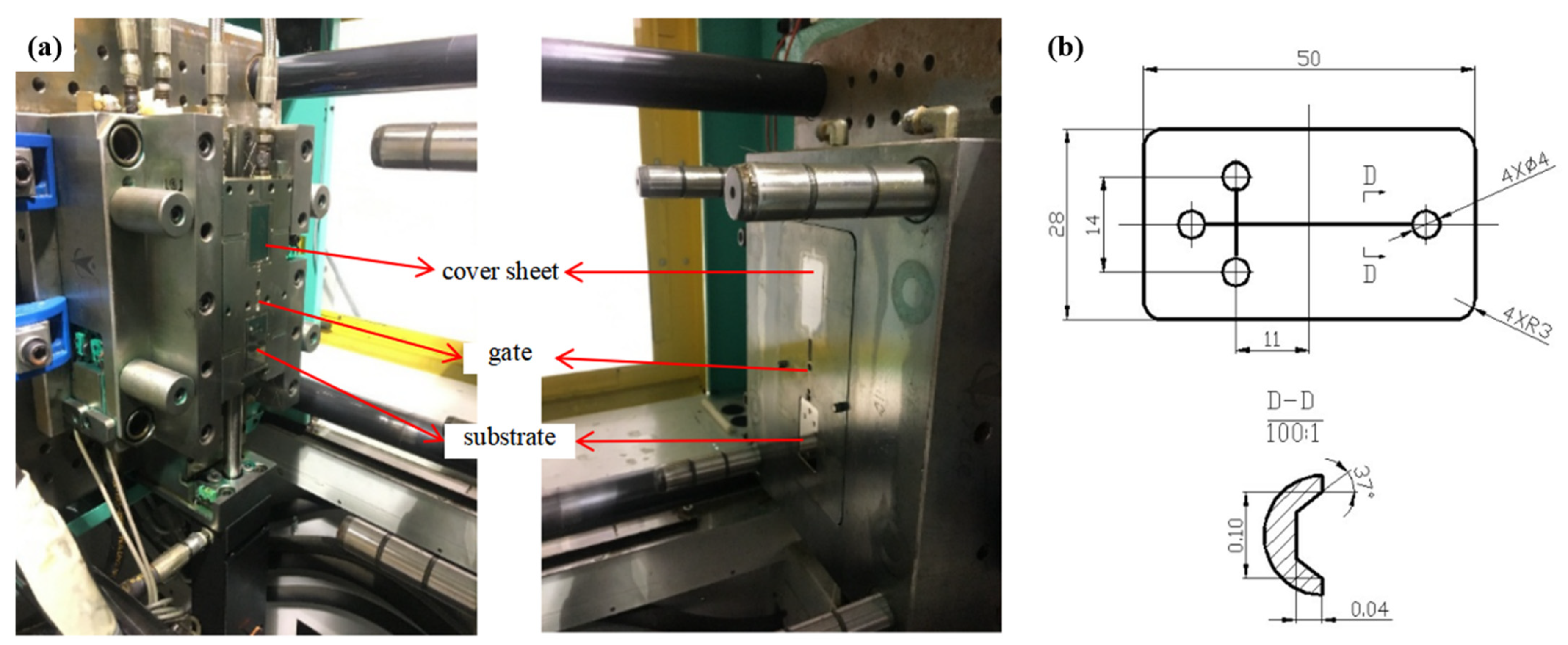

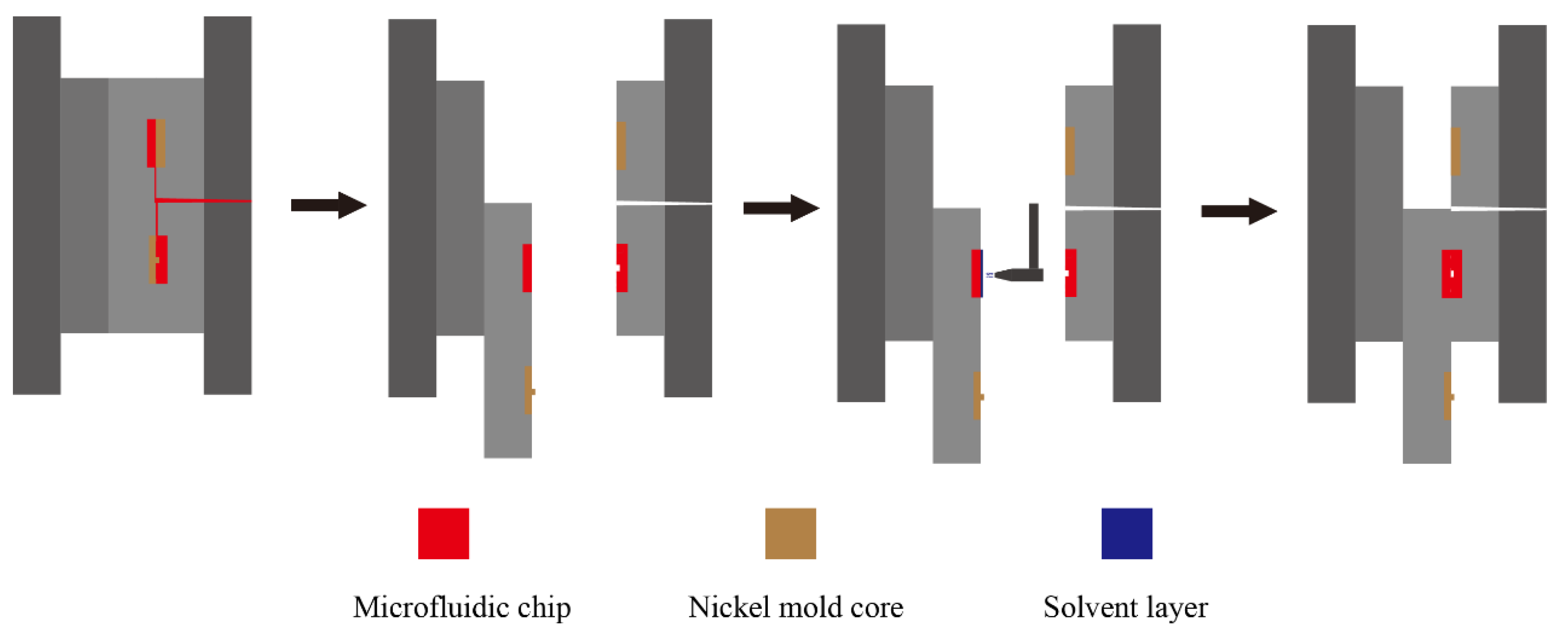

2.1. Injection Molding and Solvent-Assisted In-Mold Bonding

2.2. Solvent Selection in Solvent-Assisted Bonding

2.3. Polymer–Solvent Compatibility

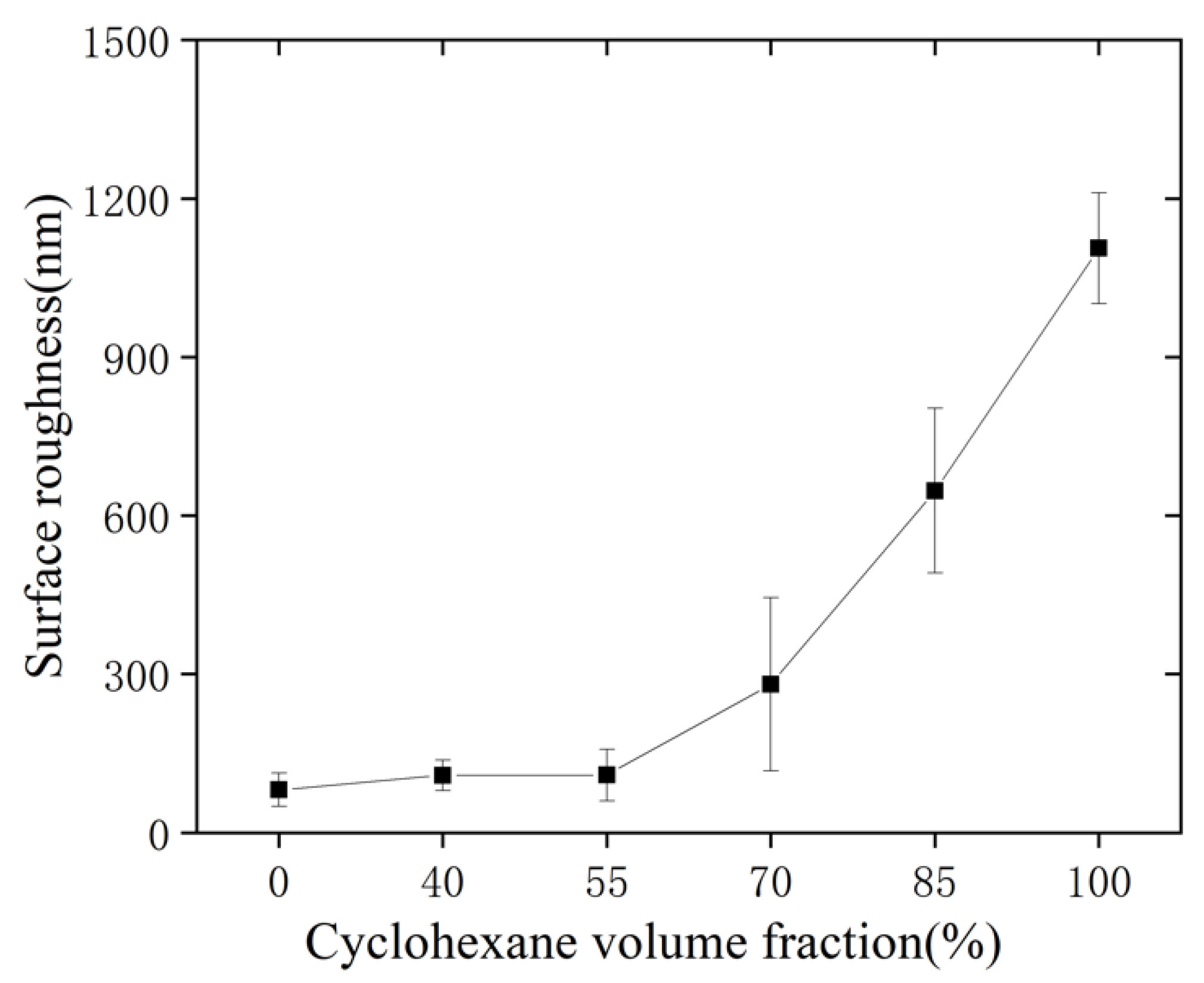

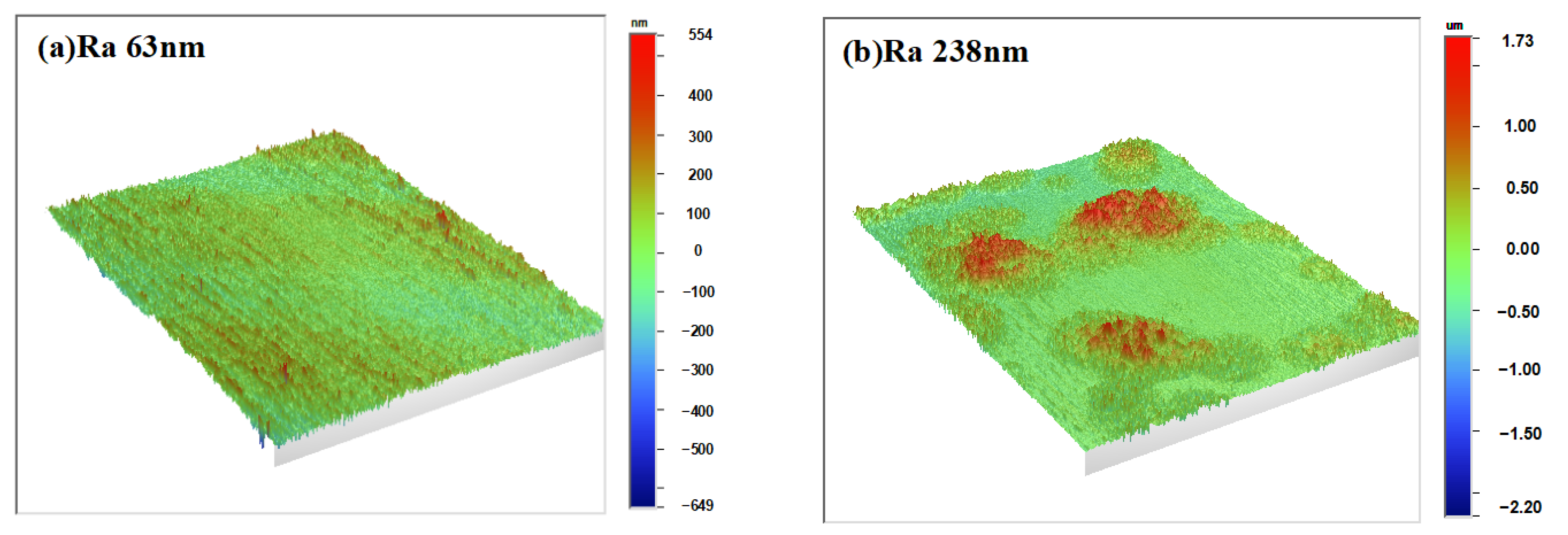

2.3.1. Surface Roughness

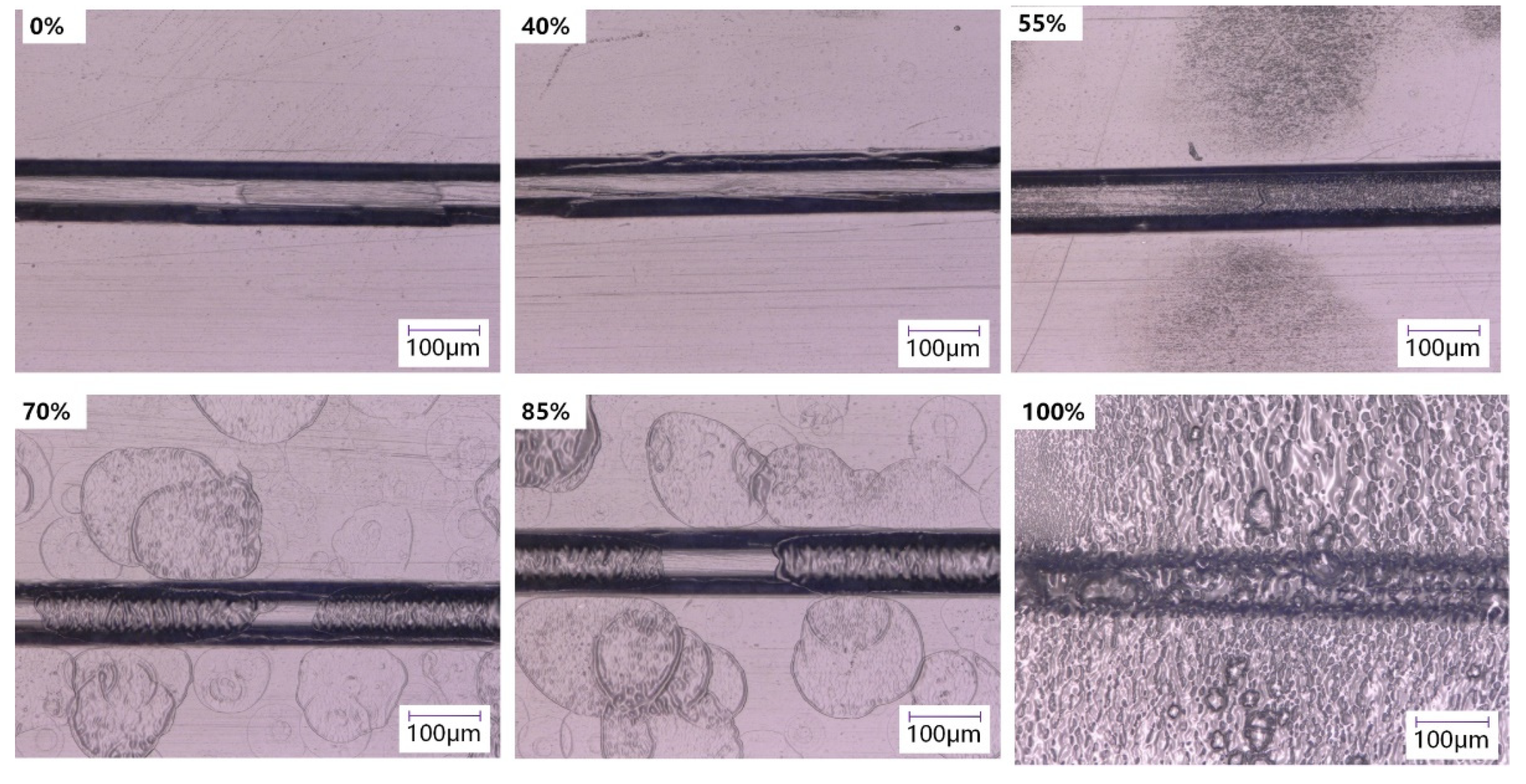

2.3.2. Microchannel Morphology

2.3.3. Contact Angle

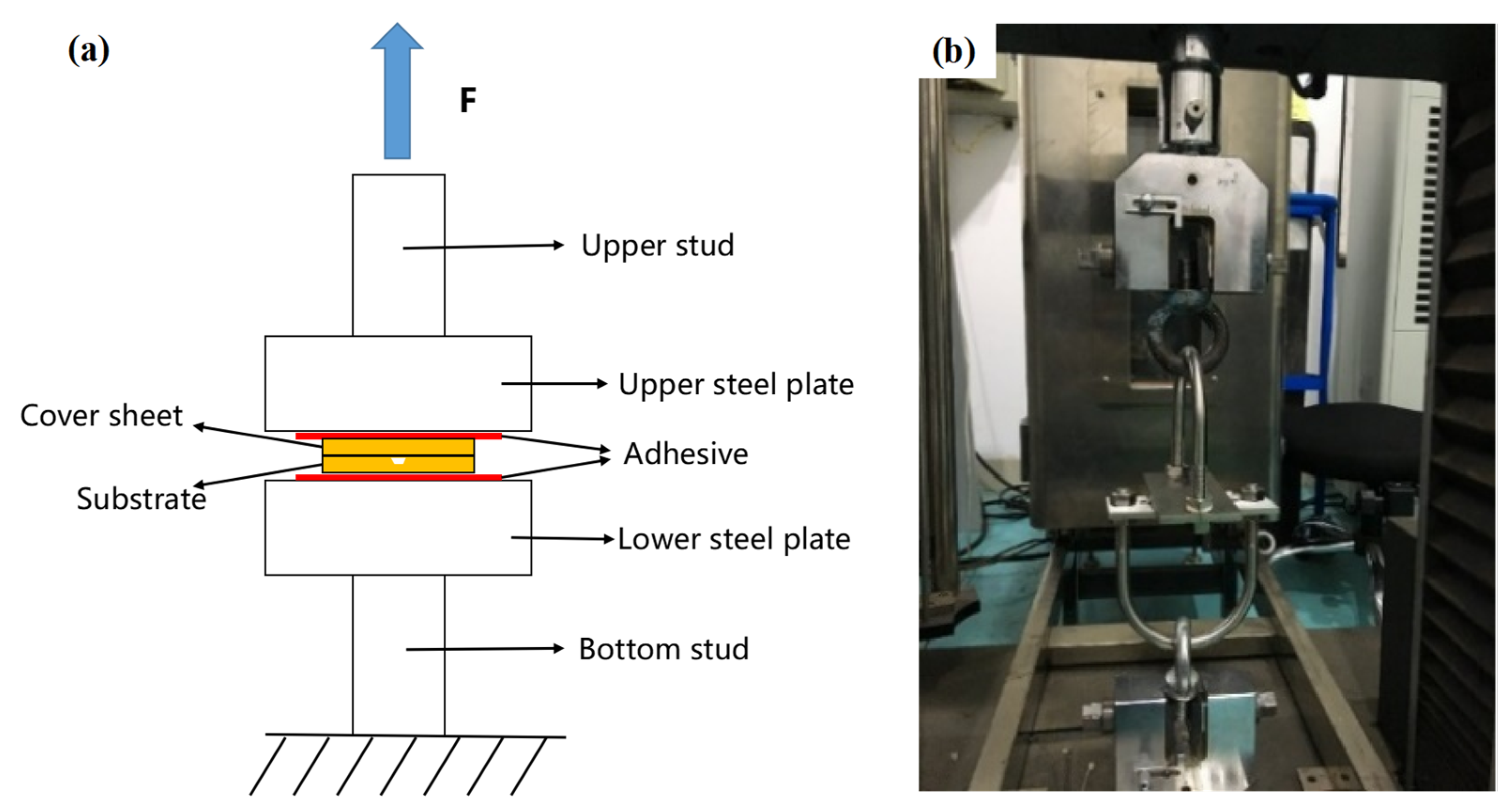

2.4. Bonding Quality Characterization

3. Results and Discussion

3.1. Analysis of Polymer–Solvent Compatibility

3.2. Analysis of In-Mold Solvent-Assisted Bonding Quality

3.3. Process Optimization and Leakage Testing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yong, L.; Jiang, X. Why microfluidics? Merits and trends in chemical synthesis. Lab Chip 2017, 17, 3960–3978. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, Y.; Fu, Q.; Lin, M.; Zhou, J. Reciprocating-flowing on-a-chip enables ultra-fast immunobinding for multiplexed rapid elisa detection of SARS-CoV-2 antibody. Biosens. Bioelectron. 2020, 176, 112920. [Google Scholar] [CrossRef] [PubMed]

- Tymm, C.; Zhou, J.; Tadimety, A.; Burklund, A.; Zhang, J. Scalable covid-19 detection enabled by lab-on-chip biosensors. Cell. Mol. Bioeng. 2020, 13, 313–329. [Google Scholar] [CrossRef] [PubMed]

- Breshears, L.E.; Nguyen, B.T.; Akarapipad, P.; Sosnowski, K.; Kaarj, K.; Quirk, G.; Uhrlaub, J.L.; Nikolich-Zugich, J.; Worobey, M.; Yoon, J.Y. Sensitive, smartphone-based SARS-CoV-2 detection from clinical saline gargle samples. PNAS Nexus 2022, 1, pgac028. [Google Scholar] [CrossRef]

- Focaroli, S.; Mazzitelli, S.; Falconi, M.; Luca, G.; Nastruzzi, C. Preparation and validation of low cost microfluidic chips using a shrinking approach. Lab Chip 2014, 14, 4007–4016. [Google Scholar] [CrossRef]

- Wang, L.; Liu, W.; Li, S.; Liu, T.; Yan, X.; Shi, Y.; Cheng, Z.; Chen, C. Fast fabrication of microfluidic devices using a low-cost prototyping method. Microsyst. Technol. 2016, 22, 677–686. [Google Scholar] [CrossRef]

- Chia-Wen, T. Polymer microfluidics: Simple, low-cost fabrication process bridging academic lab research to commercialized production. Micromachines 2016, 7, 225. [Google Scholar] [CrossRef]

- Donohoe, A.; Lacour, G.; Harrison, D.J.; Diamond, D.; Mccaul, M. Fabrication of rugged and reliable fluidic chips for autonomous environmental analyzers using combined thermal and pressure bonding of polymethyl methacrylate layers. ACS Omega 2019, 4, 21131–21140. [Google Scholar] [CrossRef]

- Harutaka, M. Thermal and ultrasonic bonding between planar polyethylene terephthalate, acrylonitrile butadiene styrene, and polycarbonate substrates. Int. J. Adhes. Adhes. 2018, 84, 394–405. [Google Scholar] [CrossRef]

- Zhou, M.; Xiong, X.; Drummer, D.; Jiang, B. Molecular dynamics simulation on the effect of bonding pressure on thermal bonding of polymer microfluidic chip. Polymers 2019, 11, 557. [Google Scholar] [CrossRef]

- Berry, S.B.; Jing, J.L.; Berthier, J.; Berthier, E.; Theberge, A.B. Droplet incubation and splitting in open microfluidic channels. Anal. Methods 2019, 11, 4528–4536. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Hui, Y. A hybrid adhesive bonding of pmma and pcb with an application on microchip electrophoresis. Anal. Methods 2019, 11, 1229–1236. [Google Scholar] [CrossRef]

- Geczy, R.; Sticker, D.; Bovet, N.; Häfeli, U.O.; Kutter, J.P. Chloroform compatible, thiol-ene based replica molded micro chemical devices as an alternative to glass microfluidic chips. Lab Chip 2019, 19, 798–806. [Google Scholar] [CrossRef] [PubMed]

- Poulsen, C.E.; Kistrup, K.; Andersen, N.K.; Taboryski, R.J.; Hansen, M.F.; Wolff, A. Laser ablated micropillar energy directors for ultrasonic welding of microfluidic systems. J. Micromech. Microeng. 2016, 26, 067001. [Google Scholar] [CrossRef]

- Tsao, C.-W.; Syu, W.-C. Bonding of thermoplastic microfluidics by using dry adhesive tape. RSC Adv. 2020, 10, 30289–30296. [Google Scholar] [CrossRef]

- Ohlin, M.; Iranmanesh, I.; Christakou, A.E.; Wiklund, M. Temperature-controlled mpa-pressure ultrasonic cell manipulation in a microfluidic chip. Lab Chip 2015, 15, 3341–3349. [Google Scholar] [CrossRef]

- Mekaru, H. Thermal bonding of polyimide to form sealed microchannels. Jpn. J. Appl. Phys. 2017, 56, 06GM04. [Google Scholar] [CrossRef]

- Qu, X.; Li, J.; Yin, Z. A novel bonding method for large scale poly(methyl methacrylate) micro- and nanofluidic chip fabrication. Jpn. J. Appl. Phys. 2018, 57, 47001. [Google Scholar] [CrossRef]

- Guan, T.; Yuket, S.; Cong, H.; Carton, D.W.; Zhang, N. Permanent hydrophobic surface treatment combined with solvent vapor-assisted thermal bonding for mass production of cyclic olefin copolymer microfluidic chips. ACS Omega 2022, 7, 20104–20117. [Google Scholar] [CrossRef]

- Cong, H.; Zhang, N. Perspectives in translating microfluidic devices from laboratory prototyping into scale-up production. Biomicrofluidics 2022, 16, 021301. [Google Scholar] [CrossRef]

- Chu, C.P.; Jiang, B.Y.; Weng, C.; Jiang, F.Z. Microchannel deformation of polymer chip in in-mold bonding. Int. Polym. Proc. 2014, 29, 245–251. [Google Scholar] [CrossRef]

- Tsao, C.W.; Hromada, L.; Liu, J.; Kumar, P.; DeVoe, D.L. Low temperature bonding of pmma and coc microfluidic substrates using uv/ozone surface treatment. Lab Chip 2007, 7, 499–505. [Google Scholar] [CrossRef] [PubMed]

- Ng, S.P.; Wiria, F.E.; Tay, N.B. Low distortion solvent bonding of microfluidic chips. Procedia Eng. 2016, 141, 130–137. [Google Scholar] [CrossRef][Green Version]

- Faghih, M.M.; Sharp, M.K. Solvent-based bonding of pmma–pmma for microfluidic applications. Microsyst. Technol. 2019, 25, 3547–3558. [Google Scholar] [CrossRef]

- Keller, N.; Nargang, T.M.; Runck, M.; Kotz, F.; Rapp, B.E. Tacky cyclic olefin copolymer: A biocompatible bonding technique for the fabrication of microfluidic devices in coc. Lab Chip 2016, 16, 1561. [Google Scholar] [CrossRef]

- Chu, C.; Jiang, B.; Zhu, L.; Jiang, F. A process analysis for microchannel deformation and bonding strength by in-mold bonding of microfluidic chips. J. Polym. Eng. 2015, 35, 267–275. [Google Scholar] [CrossRef]

- Koydemir, H.C.; Kulah, H.; Ozgen, C. Solvent compatibility of parylene c film layer. J. Microelectromecha. Syst. 2014, 23, 298–307. [Google Scholar] [CrossRef]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal. Chem. 2003, 75, 6544–6554. [Google Scholar] [CrossRef]

- Azouz, A.B.; Murphy, S.; Karazi, S.; Vázquez, M.; Brabazon, D. Fast fabrication process of microfluidic devices based on cyclic olefin copolymer. Mater. Manuf. Process. 2014, 29, 93–99. [Google Scholar] [CrossRef]

- Mair, D.A.; Rolandi, M.; Snauko, M.; Noroski, R.; Svec, F.; Fréchet, J.M.J. Room-temperature bonding for plastic high-pressure microfluidic chips. Anal. Chem. 2007, 79, 5097–5102. [Google Scholar] [CrossRef]

- Hansen, C.M. Hansen Solubility Parameters: A Users Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007; p. 544. [Google Scholar] [CrossRef]

| Materials | Solubility [(J/cm3)1/2] | Polarity | ||

|---|---|---|---|---|

| Dispersion Force | Polar Force | Hydrogen Bonding | ||

| Cyclohexane | 16.7 | 16.7 | 0.0 | 0.2 |

| Isopropanol | 23.4 | 15.5 | 6.1 | 16.4 |

| COC | 17.7 | 17.3 | 3.1 | 2.1 |

| Serial Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Cyclohexane volume fraction/v/v% | 100 | 85 | 70 | 55 | 40 | 0 |

| Solubility parameters/(J/cm3)1/2 | 16.7 | 17.7 | 18.7 | 19.7 | 20.7 | 23.4 |

| Experimental Factors | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Cyclohexane volume fraction/v/v% | 100 | 85 | 70 | 55 | 40 |

| Solvent dosage/mL | 0 | 0.5 | 1 | 1.5 | 2 |

| Bonding pressure/MPa | 1 | 2 | 3 | 4 | 5 |

| Bonding time/s | 120 | 180 | 240 | 300 | 360 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Jiang, B.; Li, X.; Zhou, M. Investigation of Solvent-Assisted In-Mold Bonding of Cyclic Olefin Copolymer (COC) Microfluidic Chips. Micromachines 2022, 13, 965. https://doi.org/10.3390/mi13060965

Li Q, Jiang B, Li X, Zhou M. Investigation of Solvent-Assisted In-Mold Bonding of Cyclic Olefin Copolymer (COC) Microfluidic Chips. Micromachines. 2022; 13(6):965. https://doi.org/10.3390/mi13060965

Chicago/Turabian StyleLi, Qiang, Bingyan Jiang, Xianglin Li, and Mingyong Zhou. 2022. "Investigation of Solvent-Assisted In-Mold Bonding of Cyclic Olefin Copolymer (COC) Microfluidic Chips" Micromachines 13, no. 6: 965. https://doi.org/10.3390/mi13060965

APA StyleLi, Q., Jiang, B., Li, X., & Zhou, M. (2022). Investigation of Solvent-Assisted In-Mold Bonding of Cyclic Olefin Copolymer (COC) Microfluidic Chips. Micromachines, 13(6), 965. https://doi.org/10.3390/mi13060965