Effect of Textured Dimples on the Tribological Behavior of WC/Co Cemented Carbide in Dry Sliding with Al2O3/WC Ceramic

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

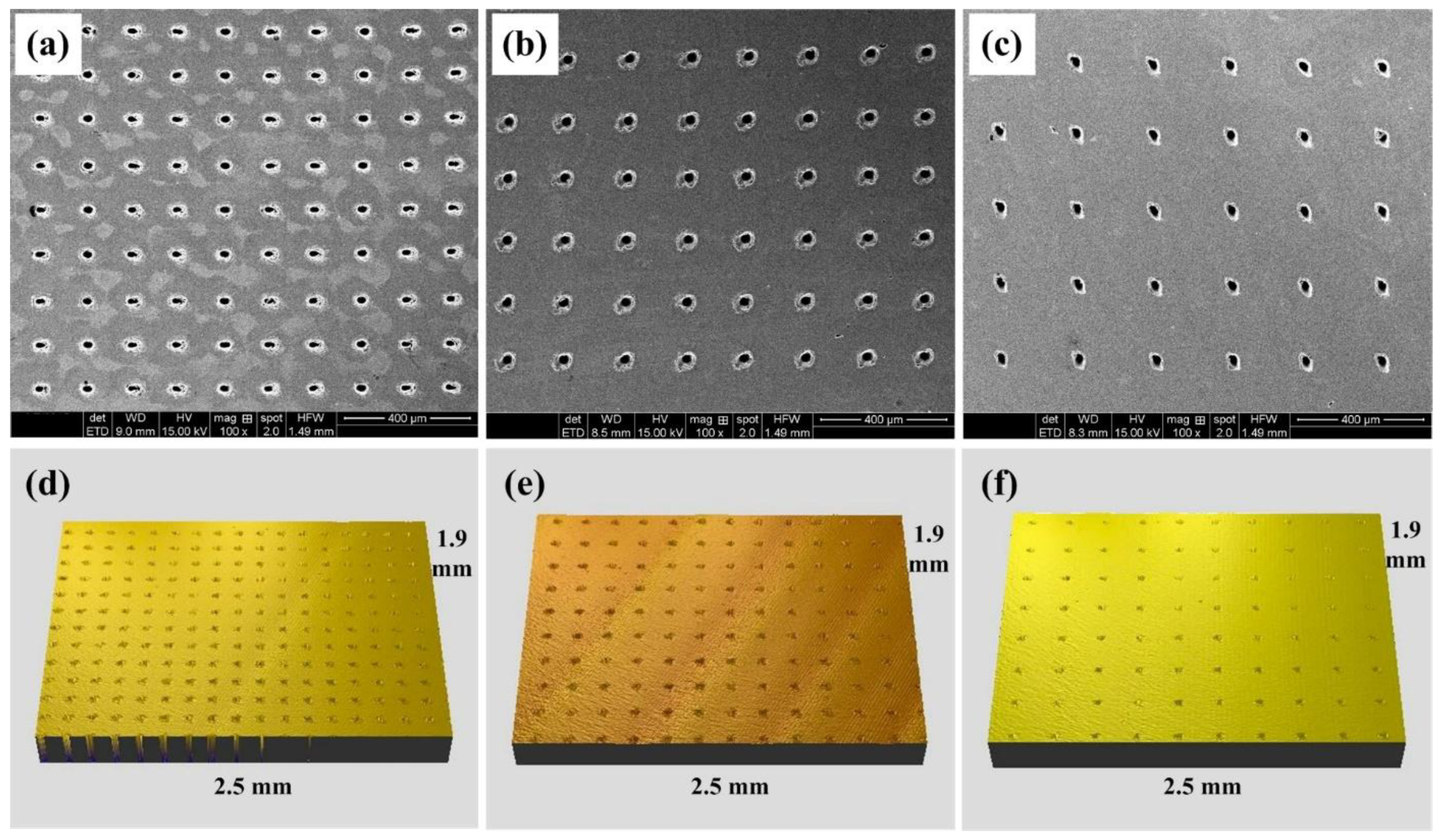

2.2. Preparation of Textured Dimples

2.3. Friction and Wear Test

3. Results and Discussion

3.1. Friction Coefficient

3.2. Wear Loss of the Ceramic Ball

3.3. Worn Surface of the Cemented Carbide Disk

3.4. Discussion

4. Conclusions

- (1)

- Textured cemented carbide can reduce the average friction coefficient by about 30% compared to the smooth sample, while textured cemented carbide with solid lubricants can reduce the average friction coefficient by about 50%. The density of textured dimples has no obvious influence on the friction coefficient under the present conditions.

- (2)

- The wear rates of worn ceramic balls continue to decline as the sliding speed changes from 20 m/min to 100 m/min for all the samples. The wear rates of the ceramic balls can be reduced by 40~50% for textured samples and approximately 65% for textured samples with solid lubricants compared to the untextured ones.

- (3)

- The mechanism for improving the tribological properties of cemented carbide materials is that the textured dimples can store lubricants and capture wear debris, which would play an important role in promoting the engineering application of surface texturing in cemented carbide materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vishnoi, M.; Kumar, P.; Murtaza, Q. Surface texturing techniques to enhance tribological performance: A review. Surf. Interfaces 2021, 27, 101463. [Google Scholar] [CrossRef]

- Fan, H.; Su, Y.; Song, J.; Wan, H.; Hu, L.; Zhang, Y. Design of “double layer” texture to obtain superhydrophobic and high wear-resistant PTFE coatings on the surface of Al2O3/Ni layered ceramics. Tribol. Int. 2019, 136, 455–461. [Google Scholar] [CrossRef]

- Jain, A.; Bajpai, V. Mechanical micro-texturing and characterization on Ti6Al4V for the improvement of surface properties. Surf. Coat. Technol. 2019, 380, 125087. [Google Scholar] [CrossRef]

- Faria, D.; Madeira, S.; Buciumeanu, M.; Silva, F.S.; Carvalho, O. Novel laser textured surface designs for improved zirconia implants performance. Mater. Sci. Eng. 2020, 108, 110390. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Wang, B.; Song, Q.; Wan, Y.; Chen, L. Surface Characterization and Tribological Performance of Anodizing Micro-Textured Aluminum-Silicon Alloys. Materials 2019, 12, 1862. [Google Scholar] [CrossRef] [Green Version]

- Conradi, M.; Sever, T.; Gregorcic, P.; Kocijan, A. Short- and Long-Term Wettability Evolution and Corrosion Resistance of Uncoated and Polymer-Coated Laser-Textured Steel Surface. Coatings 2019, 9, 592. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Zhang, Z.; Guan, Y.; Zheng, H. Comparison of the effect of typical patterns on friction and wear properties of chromium alloy prepared by laser surface texturing. Opt. Laser Technol. 2018, 106, 272–279. [Google Scholar] [CrossRef]

- Qiao, J.; Zhu, L.N.; Yue, W.; Fu, Z.Q.; Kang, J.J.; Wang, C.B. The effect of attributes of micro-shapes of laser surface texture on the wettability of WC-CrCo metal ceramic coatings. Surf. Coat. Technol. 2018, 334, 429–437. [Google Scholar] [CrossRef]

- Niemczewska-Wojcik, M.; Piekoszewski, W. The surface texture and its influence on the tribological characteristics of a friction pair: Metal–polymer. Arch. Civ. Mech. Eng. 2017, 17, 344–353. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Wu, Z.; Wu, F. High friction and low wear properties of laser-textured ceramic surface under dry friction. Opt. Laser Technol. 2017, 93, 24–32. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372, 21–41. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.; Zhu, H.; Yang, H. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Zanet, A.D.; Casalegno, V.; Salvo, M. Laser surface texturing of ceramics and ceramic composite materials—A review. Ceram. Int. 2021, 47, 7307–7320. [Google Scholar] [CrossRef]

- Zhao, G.; Xin, L.; Li, L.; Zhang, Y.; He, N.; Hansen, H.N. Cutting force model and damage formation mechanism in milling of 70wt% Si/Al composite. Chin. J. Aeronaut. 2022; in press. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Wang, X.; Meng, R. Effect of laser surface textures combined with multi-solid lubricant coatings on the tribological properties of Al2O3/TiC ceramic. Wear 2015, 342–343, 1–12. [Google Scholar] [CrossRef]

- Ji, M.; Zhang, H.; Xu, J.; Li, C.; Yu, D.; Chen, M.; Mansori, M.E. Toward the mechanisms of surface texturing on the wear behavior of dental zirconia ceramics under dry and saliva lubricated conditions. Wear 2021, 484–485, 203845. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Effect of WEDM surface texturing on Al2O3/TiCN composite ceramic tools in dry cutting of hardened steel. Ceram. Int. 2018, 44, 2510–2523. [Google Scholar] [CrossRef]

- Yusuf, Y.; Ghazali, M.J.; Otsuka, Y.; Ohnuma, K.; Morakul, S.; Nakamura, S.; Abdollah, M.F. Antibacterial properties of laser surface-textured TiO2/ZnO ceramic coatings. Ceram. Int. 2020, 46, 3949–3959. [Google Scholar] [CrossRef]

- Hari, B.N.V.; Narayanan, N.S.; Baskar, N.; Sriraman, N.; Suraj Nanduru, V.S.P. Performance of ceramic cutting tool with groove and cross-chevron surface textures filled with semi-solid lubricants. Mater. Today 2022, 63, 504–509. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, X.; Du, Z.; Zhu, Z.; Wu, Z.; Liu, L. Synergistic effect of surface textures and DLC coatings for enhancing friction and wear performances of Si3N4/TiC ceramic. Ceram. Int. 2022, 48, 514–524. [Google Scholar] [CrossRef]

- Liu, C.; Herzog, S.; Deng, Y.; Kaletsch, A.; Oster, P.; Broeckmann, C. Influence of laser surface texturing on the flexural strength of Al2O3 and Si3N4. J. Eur. Ceram. Soc. 2022, 42, 4286–4295. [Google Scholar] [CrossRef]

- Liu, H.; Tong, Z.; Gu, J.; Yang, D.; Liu, C.; Wang, X.; Ren, X. Effect of laser surface texturing depth and pattern on the bond strength and corrosion performance of phosphate conversion coating on magnesium alloy. Opt. Laser Technol. 2022, 153, 108164. [Google Scholar] [CrossRef]

- Zhang, K.; Shi, X.; Xue, Y.; Huang, Q.; Wu, C. Effects of composite textured surface on friction characteristics of 42CrMo steel under grease lubrication. Wear 2022, 504–505, 204419. [Google Scholar] [CrossRef]

- Yuan, S.; Lin, N.; Wang, W.; Zhang, H.; Liu, Z.; Yu, Y.; Zeng, Q.; Wu, Y. Correlation between surface textural parameter and tribological behaviour of four metal materials with laser surface texturing (LST). Appl. Surf. Sci. 2022, 583, 152410. [Google Scholar] [CrossRef]

- Li, H.; Xu, W.; Li, L.; Xia, H.; Chen, X.; Chen, B.; Song, X.; Tan, C. Enhancing the wettability for 4043 aluminum alloy on 301L stainless steel via chemical-etched surface texturing. J. Mater. Processing Technol. 2022, 305, 117577. [Google Scholar] [CrossRef]

- Dai, F.Z.; Geng, J.; Tan, W.S.; Ren, X.D.; Lu, J.Z.; Huang, S. Friction and wear on laser textured Ti6Al4V surface subjected to laser shock peening with contacting foil. Opt. Laser Technol. 2018, 103, 142–150. [Google Scholar] [CrossRef]

- Wei, Y.; Resendiz, J.; Tomkowski, R.; Liu, X. An Experimental Study of Micro-Dimpled Texture in Friction Control under Dry and Lubricated Conditions. Micromachines 2022, 13, 70. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Yang, S.; Zheng, M. Analysis of synergistic friction reduction effect on micro-textured cemented carbide surface by laser processing. Opt. Laser Technol. 2022, 155, 108343. [Google Scholar] [CrossRef]

| Composition (wt%) | Hardness (HRA) | Thermal Conductivity (W/m·k) | Thermal Expansion Coefficient (10−6/k) | Density (g/cm3) |

|---|---|---|---|---|

| WC +6%Co | 91.0 | 79.6 | 4.8 | 15.2 |

| Composition (wt%) | Hardness (HRA) | Thermal Conductivity (W/m·k) | Thermal Expansion Coefficient (10−6/k) | Density (g/cm3) |

|---|---|---|---|---|

| Al2O3 +35%WC +10%Co | 89.0 | 45.2 | 3.5 | 10.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wu, Z. Effect of Textured Dimples on the Tribological Behavior of WC/Co Cemented Carbide in Dry Sliding with Al2O3/WC Ceramic. Micromachines 2022, 13, 1269. https://doi.org/10.3390/mi13081269

Chen J, Wu Z. Effect of Textured Dimples on the Tribological Behavior of WC/Co Cemented Carbide in Dry Sliding with Al2O3/WC Ceramic. Micromachines. 2022; 13(8):1269. https://doi.org/10.3390/mi13081269

Chicago/Turabian StyleChen, Jiansong, and Ze Wu. 2022. "Effect of Textured Dimples on the Tribological Behavior of WC/Co Cemented Carbide in Dry Sliding with Al2O3/WC Ceramic" Micromachines 13, no. 8: 1269. https://doi.org/10.3390/mi13081269

APA StyleChen, J., & Wu, Z. (2022). Effect of Textured Dimples on the Tribological Behavior of WC/Co Cemented Carbide in Dry Sliding with Al2O3/WC Ceramic. Micromachines, 13(8), 1269. https://doi.org/10.3390/mi13081269