Low Leakage Current and High Breakdown Field AlGaN/GaN MIS-HEMTs Using PECVD-SiNx as a Gate Dielectric

Abstract

:1. Introduction

2. Device Fabrication

3. Results and Discussion

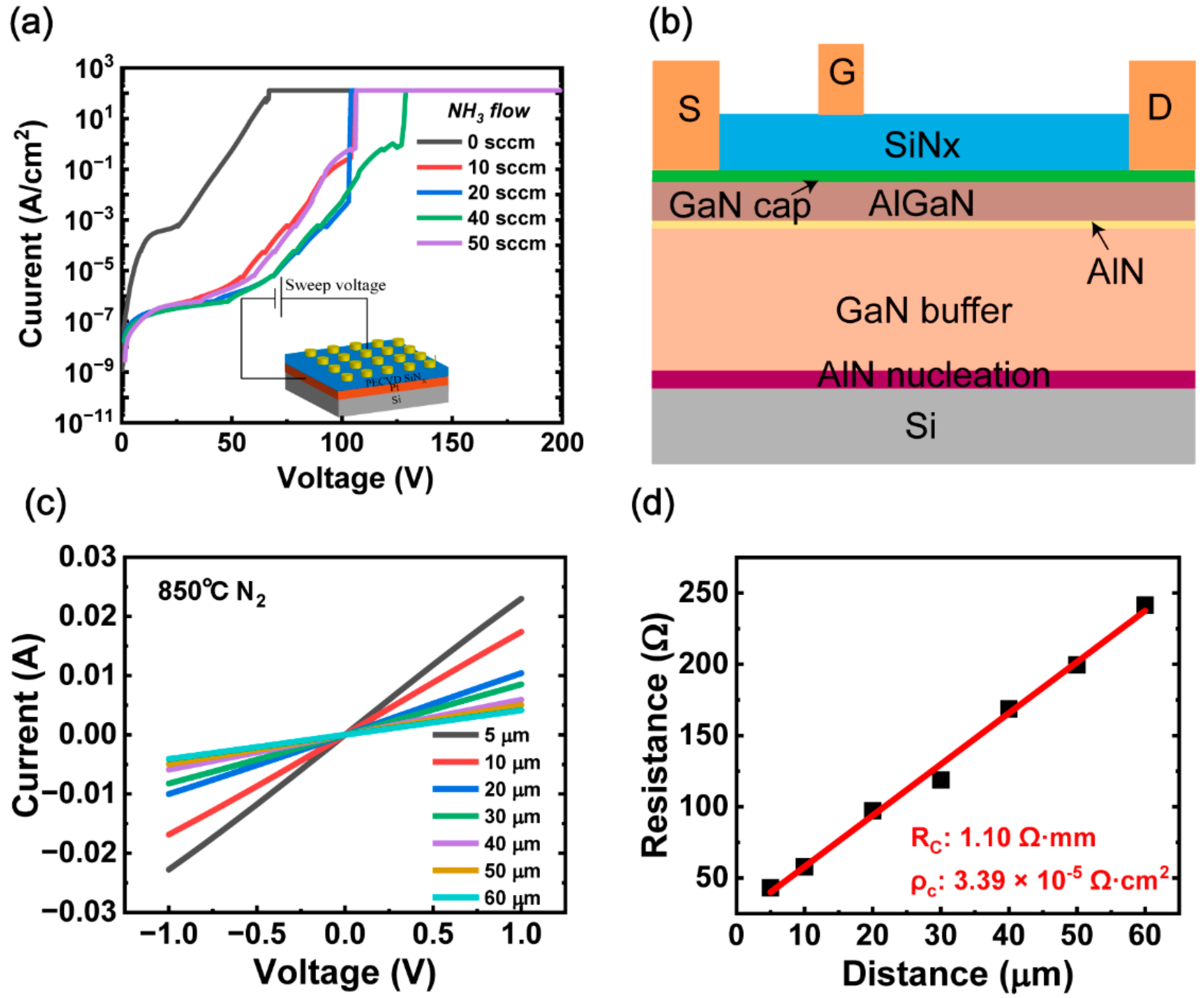

3.1. Material Optimization Characteristics

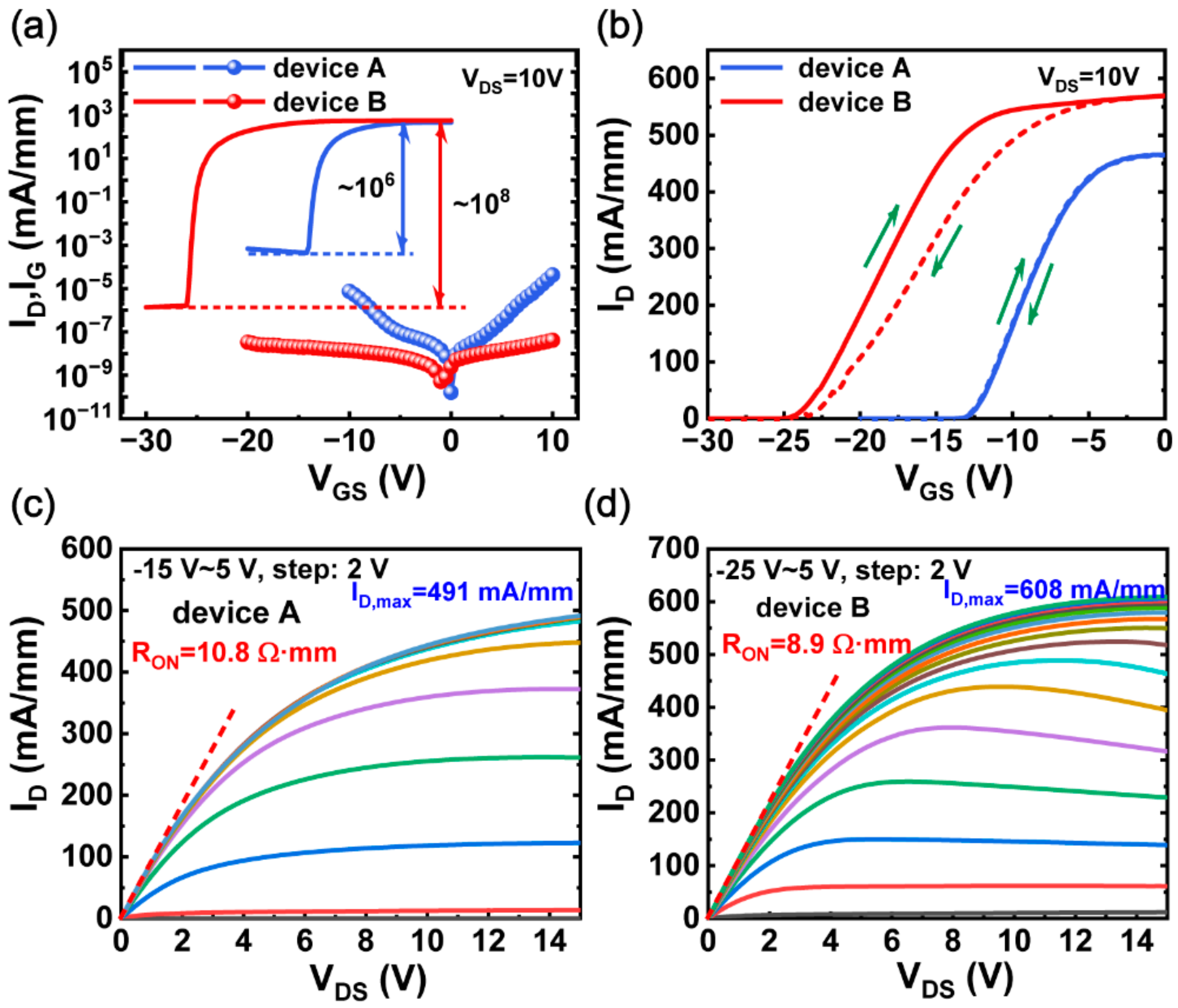

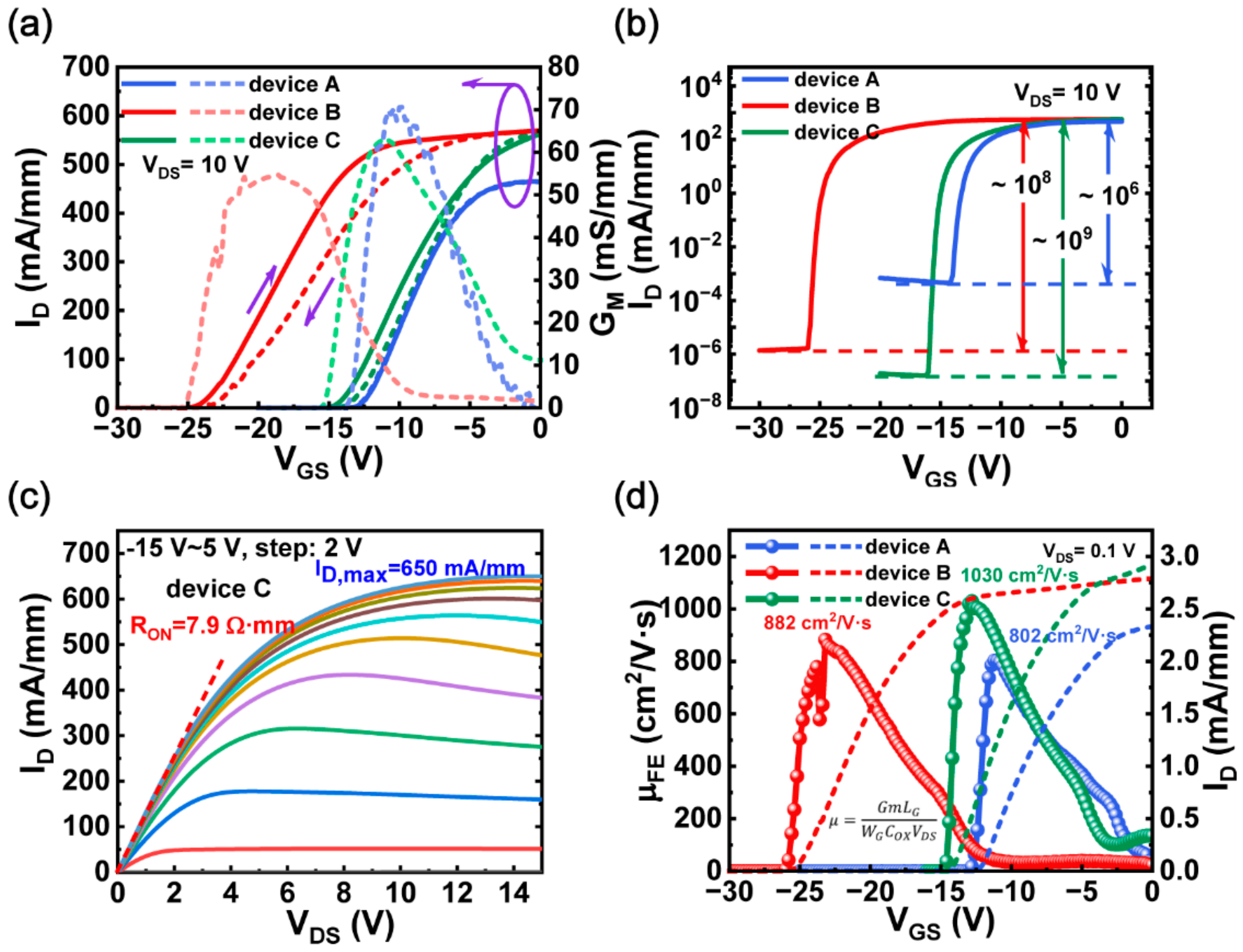

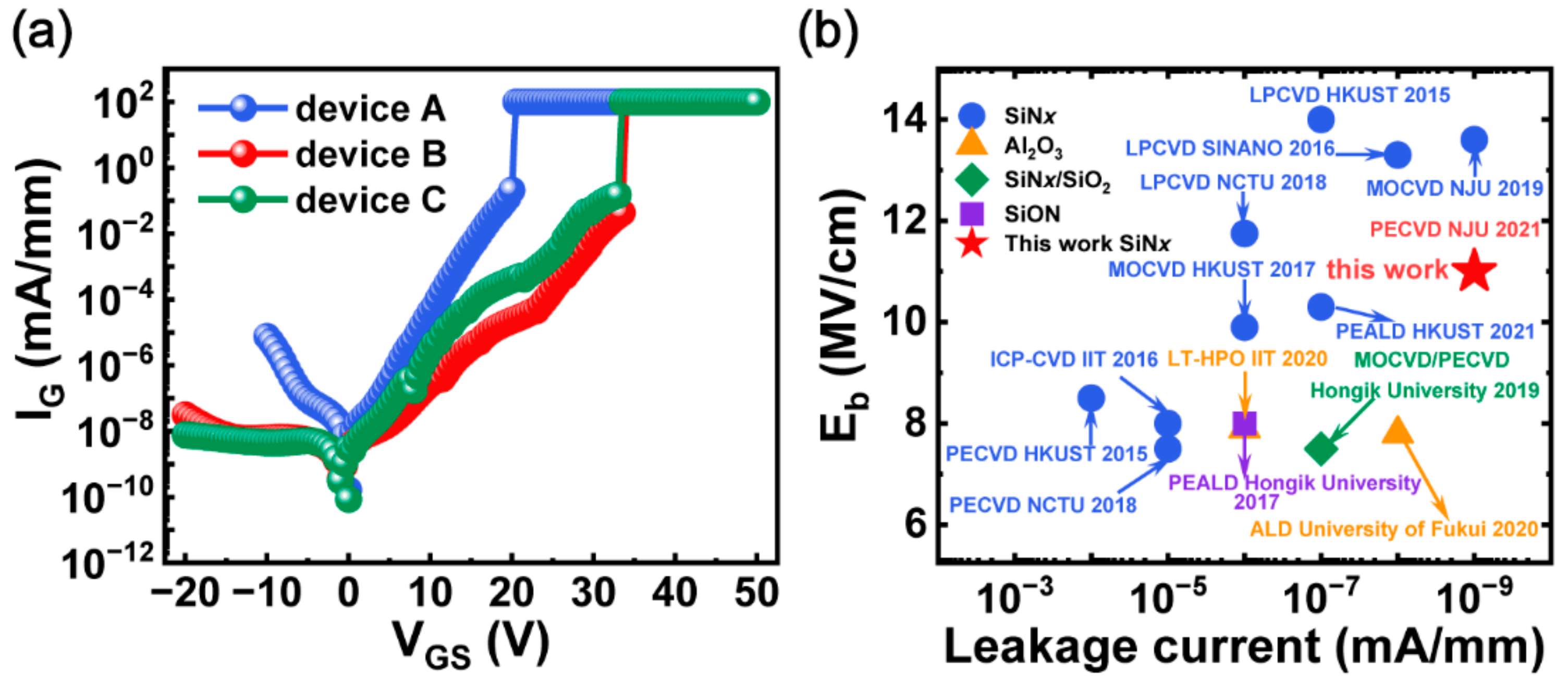

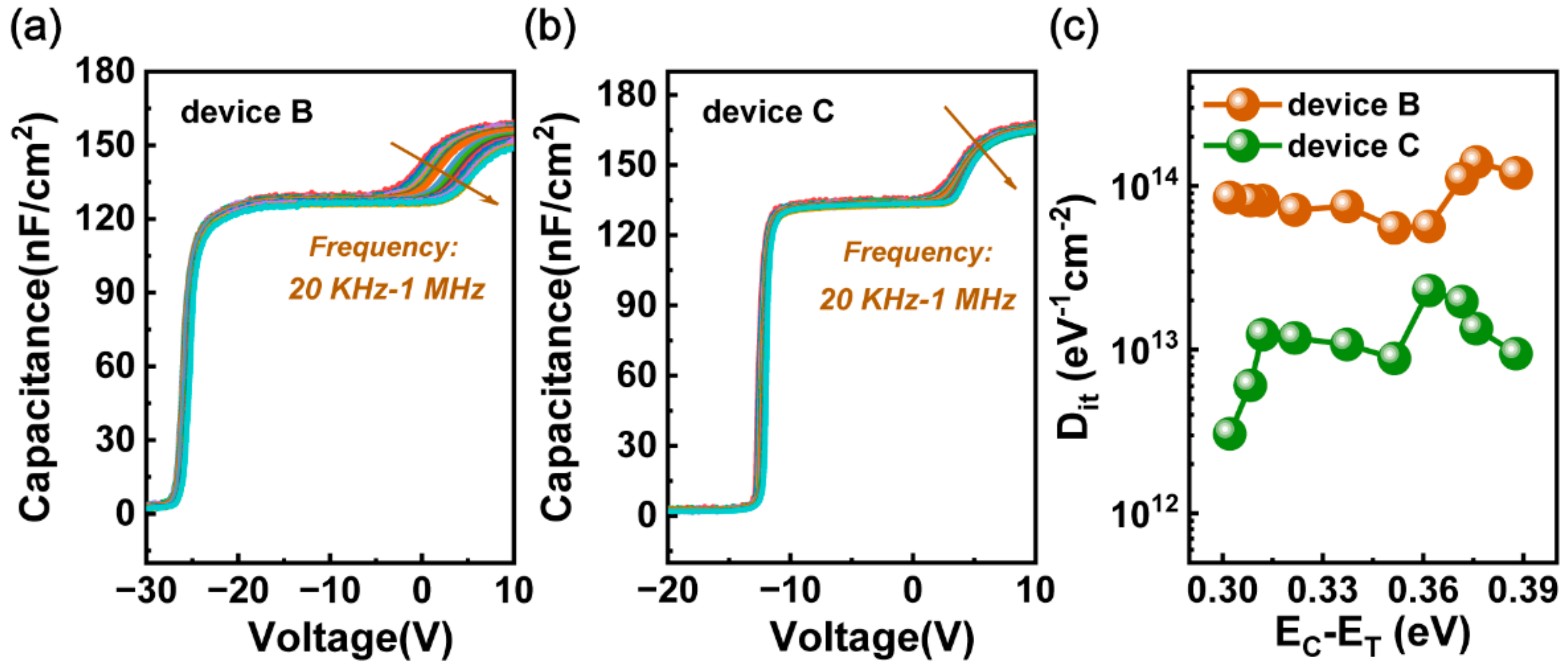

3.2. Interface Optimization Characteristics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tang, Z.; Jiang, Q.; Lu, Y.; Huang, S.; Yang, S.; Tang, X.; Chen, K.J. 600-V normally off SiNx/AlGaN/GaN MIS-HEMT with large gate swing and low current collapse. IEEE Electron Device Lett. 2013, 34, 1373–1375. [Google Scholar] [CrossRef]

- Hernández-Gutiérrez, C.A.; Kudriavtsev, Y.; Cardona, D.; Hernández, A.G.; Camas-Anzueto, J.L. Optical, electrical, and chemical characterization of nanostructured InxGa1-xN formed by high fluence In+ ion implantation into GaN. Opt. Mater. 2021, 111, 110541. [Google Scholar] [CrossRef]

- Cho, G.; Cha, H.Y.; Kim, H. Influence of Oxygen-Plasma Treatment on In-Situ SiN/AlGaN/GaN MOSHEMT with PECVD SiO2 Gate Insulator. Materials 2019, 12, 3968. [Google Scholar] [CrossRef] [PubMed]

- Hua, M.; Liu, C.; Yang, S.; Liu, S.; Fu, K.; Dong, Z.; Cai, Y.; Zhang, B.; Chen, K.J. Characterization of Leakage and Reliability of SiNx Gate Dielectric by Low-Pressure Chemical Vapor Deposition for GaN-based MIS-HEMTs. IEEE Trans. Electron Devices 2015, 62, 3215–3222. [Google Scholar] [CrossRef]

- Hua, M.; Liu, C.; Yang, S.; Liu, S.; Fu, K.; Dong, Z.; Cai, Y.; Zhang, B.; Chen, K.J. GaN-Based Metal-Insulator-Semiconductor High-Electron-Mobility Transistors Using Low-Pressure Chemical Vapor Deposition SiNx as Gate Dielectric. IEEE Electron Device Lett. 2015, 36, 448–450. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, G.; Zhang, X.; Deng, X.; Li, S.; Fan, Y.; Sun, S.; Song, L.; Tan, S.; Wu, D.; et al. Studies on High-Voltage GaN-on-Si MIS-HEMTs Using LPCVD Si3N4as Gate Dielectric and Passivation Layer. IEEE Trans. Electron Devices 2016, 63, 731–738. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, C.; Chen, Y.; Lu, X.; Tang, C.W.; Lau, K.M. Investigation of In Situ SiN as Gate Dielectric and Surface Passivation for GaN MISHEMTs. IEEE Trans. Electron Devices 2017, 64, 832–839. [Google Scholar] [CrossRef]

- Wang, H.-C.; Lumbantoruan, F.J.; Hsieh, T.-E.; Wu, C.-H.; Lin, Y.-C.; Chang, E.Y. High-Performance LPCVD-SiNx/InAlGaN/GaN MIS-HEMTs with 850-V 0.98-mΩ·cm2 for Power Device Applications. IEEE J. Electron Devices Soc. 2018, 6, 1136–1141. [Google Scholar] [CrossRef]

- Cheng, L.; Xu, W.; Pan, D.; Liang, H.; Wang, R.; Zhu, Y.; Ren, F.; Zhou, D.; Ye, J.; Chen, D.; et al. Gate-first AlGaN/GaN HEMT technology for enhanced threshold voltage stability based on MOCVD-grown in situ SiNx. J. Phys. D Appl. Phys. 2021, 54, 015105. [Google Scholar] [CrossRef]

- Dutta, G.; DasGupta, N.; DasGupta, A. Low-Temperature ICP-CVD SiNx as Gate Dielectric for GaN-Based MIS-HEMTs. IEEE Trans. Electron Devices 2016, 63, 4693–4701. [Google Scholar] [CrossRef]

- Asubar, J.T.; Kawabata, S.; Tokuda, H.; Yamamoto, A.; Kuzuhara, M. Enhancement-Mode AlGaN/GaN MIS-HEMTs with High VTH and High IDmax Using Recessed-Structure with Regrown AlGaN Barrier. IEEE Electron Device Lett. 2020, 41, 693–696. [Google Scholar] [CrossRef]

- Kanaga, S.; Dutta, G.; Kushwah, B.; DasGupta, N.; DasGupta, A. Low Temperature and High Pressure Oxidized Al2O3 as Gate Dielectric for AlInN/GaN MIS-HEMTs. IEEE Trans. Device Mater. Reliab. 2020, 20, 613–621. [Google Scholar] [CrossRef]

- Kim, H.-S.; Han, S.-W.; Jang, W.-H.; Cho, C.-H.; Seo, K.-S.; Oh, J.; Cha, H.-Y. Normally-off GaN-on-Si MISFET Using PECVD SiON Gate Dielectric. IEEE Electron Device Lett. 2017, 38, 1090–1093. [Google Scholar] [CrossRef]

- Huang, S.; Yang, S.; Roberts, J.; Chen, K.J. Threshold Voltage Instability in Al2O3/GaN/AlGaN/GaN Metal–Insulator–Semiconductor High-Electron Mobility Transistors. Jpn. J. Appl. Phys. 2011, 50, 110202. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, S.; Jiang, Q.; Tang, Z.; Li, B.; Chen, K.J. Characterization of VT-instability in enhancement-mode Al2O3-AlGaN/GaN MIS-HEMTs. Phys. Status Solidi C 2013, 10, 1397–1400. [Google Scholar] [CrossRef]

- Ma, X.-H.; Zhu, J.-J.; Liao, X.-Y.; Yue, T.; Chen, W.-W.; Hao, Y. Quantitative characterization of interface traps in Al2O3/AlGaN/GaN metal-oxide-semiconductor high-electron-mobility transistors by dynamic capacitance dispersion technique. Appl. Phys. Lett. 2013, 103, 033510. [Google Scholar] [CrossRef]

- Yang, S.; Tang, Z.; Wong, K.-Y.; Lin, Y.-S.; Liu, C.; Lu, Y.; Huang, S.; Chen, K.J. High-Quality Interface in Al2O3/GaN/AlGaN/GaN MIS Structures with In Situ Pre-Gate Plasma Nitridation. IEEE Electron Device Lett. 2013, 34, 1497–1499. [Google Scholar] [CrossRef]

- Hove, M.V.; Boulay, S.; Bahl, S.R.; Stoffels, S.; Kang, X.; Wellekens, D.; Geens, K.; Delabie, A.; Decoutere, S. CMOS Process-Compatible High-Power Low-Leakage AlGaN/GaN MISHEMT on Silicon. IEEE Electron Device Lett. 2012, 33, 667–669. [Google Scholar] [CrossRef]

- Maier, D.; Alomari, M.; Grandjean, N.; Carlin, J.-F.; Diforte-Poisson, M.-A.; Dua, C.; Chuvilin, A.; Troadec, D.; Gaquiere, C.; Kaiser, U.; et al. Testing the Temperature Limits of GaN-Based HEMT Devices. IEEE Trans. Device Mater. Reliab. 2010, 10, 427–436. [Google Scholar] [CrossRef]

- Yota, J.; Hander, J.; Saleh, A.A. A comparative study on inductively-coupled plasma high-density plasma, plasma-enhanced, and lowpressure chemical vapor deposition silicon nitride films. J. Vac. Sci. Technol. A 2000, 18, 372–376. [Google Scholar] [CrossRef]

- Guler, I. Optical and structural characterization of silicon nitride thin films deposited by PECVD. Mater. Sci. Eng. B 2019, 246, 21–26. [Google Scholar] [CrossRef]

- Piccirillo, A.; Gobbi, A.L. Physical-Electrical Properties of Silicon Nitride Deposited by PECVD on III–V Semiconductors. J. Electrochem. Soc. 1990, 137, 3910–3917. [Google Scholar] [CrossRef]

- Zambrano-Serrano, M.A.; Hernández, C.A.; de Melo, O.; Behar, M.; Gallardo-Hernández, S.; Casallas-Moreno, Y.L.; Ponce, A.; Hernandez-Robles, A.; Bahena-Uribe, D.; Yee-Rendón, C.M.; et al. Effects of heavy Si doping on the structural and optical properties of n-GaN/AlN/Si(111) heterostructures. Mater. Res. Express 2022, 9, 065903. [Google Scholar] [CrossRef]

- Pan, L.; Dong, X.; Li, Z.; Luo, W.; Ni, J. Influence of the AlN nucleation layer on the properties of AlGaN/GaN heterostructure on Si (1 1 1) substrates. Appl. Surf. Sci. 2018, 447, 512–517. [Google Scholar] [CrossRef]

- Greco, G.; Prystawko, P.; Leszczyński, M.; Lo Nigro, R.; Raineri, V.; Roccaforte, F. Electro-structural evolution and Schottky barrier height in annealed Au/Ni contacts onto p-GaN. J. Appl. Phys. 2011, 110, 123703. [Google Scholar] [CrossRef]

- Hernández-Gutierrez, C.A.; Kudriavtsev, Y.; Mota, E.; Hernández, A.G.; Escobosa-Echavarría, A.; Sánchez-Resendiz, V.; Casallas-Moreno, Y.L.; López-López, M. A new method of making ohmic contacts to p-GaN. Nucl. Instrum. Methods Phys. Res. B 2016, 388, 35–40. [Google Scholar] [CrossRef]

- Huang, T.; Jiang, H.; Bergsten, J.; Lau, K.M.; Rorsman, N. Enhanced gate stack stability in GaN transistors with gate dielectric of bilayer SiNx by low pressure chemical vapor deposition. Appl. Phys. Lett. 2018, 113, 232102. [Google Scholar] [CrossRef]

- Nayak, S.K.; Gupta, M.; Shivaprasad, S.M. Structural, optical and electronic properties of a Mg incorporated GaN nanowall network. RSC Adv. 2017, 7, 25998–26005. [Google Scholar] [CrossRef]

- Siddique, A.; Ahmed, R.; Anderson, J.; Holtz, M.; Piner, E.L. Improved Electrical Properties of AlGaN/GaN High-Electron-Mobility Transistors by In Situ Tailoring the SiNx Passivation Layer. ACS Appl. Mater. Interfaces 2021, 13, 18264–18273. [Google Scholar] [CrossRef]

- Gupta, M.; Rathi, V.K.; Thangaraj, R.; Agnihotri, O.P. The preparation, properties and applications of silicon nitride thin films deposited by plasma-enhanced chemical vapor deposition. Thin Solid Films 1991, 204, 77–106. [Google Scholar] [CrossRef]

- Hashizume, T.; Nakasaki, R. Discrete surface state related to nitrogen-vacancy defect on plasma-treated GaN surfaces. Appl. Phys. Lett. 2002, 80, 4564–4566. [Google Scholar] [CrossRef]

- Puzyrev, Y.S.; Roy, T.; Beck, M.; Tuttle, B.R.; Schrimpf, R.D.; Fleetwood, D.M.; Pantelides, S.T. Dehydrogenation of defects and hot-electron degradation in GaN high-electron-mobility transistors. J. Appl. Phys. 2011, 109, 034501. [Google Scholar] [CrossRef]

- Liu, S.-C.; Chen, B.-Y.; Lin, Y.-C.; Hsieh, T.-E.; Wang, H.-C.; Chang, E.Y. GaN MIS-HEMTs with Nitrogen Passivation for Power Device Applications. IEEE Electron Device Lett. 2014, 35, 1001–1003. [Google Scholar]

- Liu, S.-C.; Trinh, H.-D.; Dai, G.-M.; Huang, C.-K.; Dee, C.-F.; Majlis, B.Y.; Biswas, D.; Chang, E.Y. Effective surface treatment for GaN metal–insulator–semiconductor high-electron-mobility transistors using HF plus N2 plasma prior to SiN passivation. Jpn. J. Appl. Phys. 2016, 55, 01AD06. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, X.; Hou, B.; Ma, M.; Zhu, Q.; Chen, L.; Yang, L.; Zhang, P.; Zhou, X.; Hao, Y. Comparative Study on Charge Trapping Induced Vth Shift for GaN-Based MOS-HEMTs with and without Thermal Annealing Treatment. IEEE Trans. Electron Devices 2018, 65, 5343–5349. [Google Scholar] [CrossRef]

- Lu, X.; Jiang, H.; Liu, C.; Zou, X.; Lau, K.M. Off-state leakage current reduction in AlGaN/GaN high electron mobility transistors by combining surface treatment and post-gate annealing. Semicond. Sci. Technol. 2016, 31, 055019. [Google Scholar] [CrossRef]

- Lin, S.; Wang, M.; Xie, B.; Wen, C.P.; Yu, M.; Wang, J.; Hao, Y.; Wu, W.; Huang, S.; Chen, K.J.; et al. Reduction of Current Collapse in GaN High-Electron Mobility Transistors Using a Repeated Ozone Oxidation and Wet Surface Treatment. IEEE Electron Device Lett. 2015, 36, 757–759. [Google Scholar]

- Yang, S.; Zheng, Z.; Zhang, L.; Song, W.; Chen, K.J. GaN MIS-HEMTs with Surface Reinforcement for Suppressed Hot-Electron-Induced Degradation. IEEE Electron Device Lett. 2021, 42, 489–492. [Google Scholar] [CrossRef]

- Mizue, C.; Hori, Y.; Miczek, M.; Hashizume, T. Capacitance–Voltage Characteristics of Al2O3/AlGaN/GaN Structures and State Density Distribution at Al2O3/AlGaN Interface. Jpn. J. Appl. Phys. 2011, 50, 021001. [Google Scholar] [CrossRef]

- Yang, S.; Liu, S.; Lu, Y.; Liu, C.; Chen, K.J. AC-Capacitance Techniques for Interface Trap Analysis in GaN-Based Buried-Channel MIS-HEMTs. IEEE Trans. Electron Devices 2015, 62, 1870–1878. [Google Scholar] [CrossRef]

| Samples | Si | N | N/Si |

|---|---|---|---|

| SiNx-W/O NH3 | 34.43 | 25.7 | 0.75 |

| SiNx-W/NH3 | 28.1 | 29.52 | 1.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Guo, H.; Wang, R.; Pan, D.; Chen, P.; Chen, D.; Lu, H.; Zhang, R.; Zheng, Y. Low Leakage Current and High Breakdown Field AlGaN/GaN MIS-HEMTs Using PECVD-SiNx as a Gate Dielectric. Micromachines 2022, 13, 1396. https://doi.org/10.3390/mi13091396

Gao X, Guo H, Wang R, Pan D, Chen P, Chen D, Lu H, Zhang R, Zheng Y. Low Leakage Current and High Breakdown Field AlGaN/GaN MIS-HEMTs Using PECVD-SiNx as a Gate Dielectric. Micromachines. 2022; 13(9):1396. https://doi.org/10.3390/mi13091396

Chicago/Turabian StyleGao, Xiaohui, Hui Guo, Rui Wang, Danfeng Pan, Peng Chen, Dunjun Chen, Hai Lu, Rong Zhang, and Youdou Zheng. 2022. "Low Leakage Current and High Breakdown Field AlGaN/GaN MIS-HEMTs Using PECVD-SiNx as a Gate Dielectric" Micromachines 13, no. 9: 1396. https://doi.org/10.3390/mi13091396

APA StyleGao, X., Guo, H., Wang, R., Pan, D., Chen, P., Chen, D., Lu, H., Zhang, R., & Zheng, Y. (2022). Low Leakage Current and High Breakdown Field AlGaN/GaN MIS-HEMTs Using PECVD-SiNx as a Gate Dielectric. Micromachines, 13(9), 1396. https://doi.org/10.3390/mi13091396