AMOLED Pixel Circuit Using LTPO Technology Supporting Variable Frame Rate from 1 to 120 Hz for Portable Displays

Abstract

:1. Introduction

2. The Operation of the Proposed Pixel Circuit

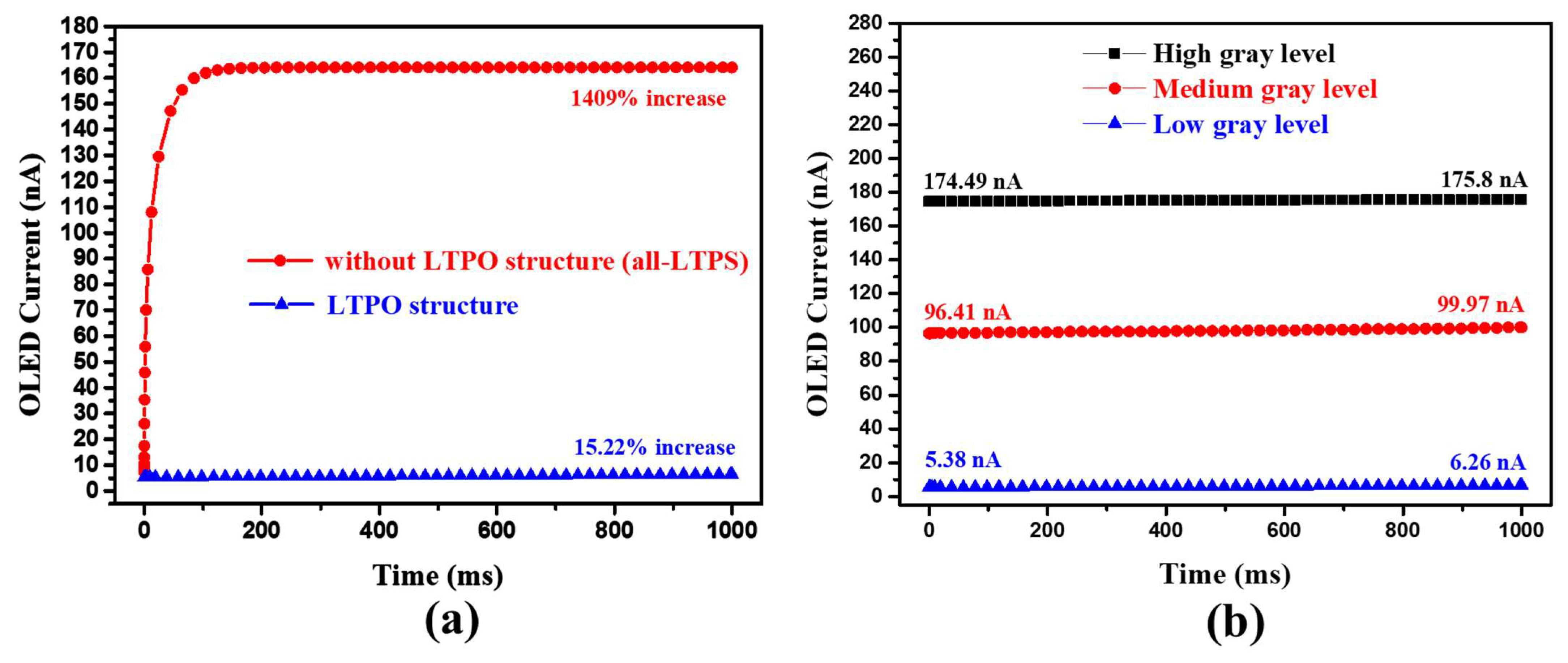

2.1. Reset Stage

2.2. Programming Stage

2.3. Holding Stage

2.4. Emission Stage

3. Analysis of Storage Capacitor

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tang, C.W. An overview of organic electroluminescent materials and devices. J. Soc. Inf. Disp. 1997, 5, 11–14. [Google Scholar] [CrossRef]

- Choi, S.; Kang, C.M.; Byun, C.W.; Cho, H.; Kwon, B.H.; Han, J.H.; Yang, J.H.; Shin, J.W.; Hwang, C.S.; Cho, N.S.; et al. Thin-film transistor-driven vertically stacked full-color organic light-emitting diodes for high-resolution active-matrix displays. Nat. Commun. 2020, 11, 2732. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.-J.; Jung, M.-H.; Park, S.-H.; Kim, O. Voltage-Programming-Based Pixel Circuit to Compensate for Threshold Voltage and Mobility Using Natural Capacitance of Organic Light-Emitting Diode. Jpn. J. Appl. Phys. 2010, 49, 03CD01. [Google Scholar] [CrossRef]

- Vosniadis, P.; Siskos, S. A new threshold-voltage compensation technique of IGZO and LTPS for AMOLED display pixel circuit. In Proceedings of the 2017 Panhellenic Conference on Electronics and Telecommunications (PACET), Xanthi, Greece, 17–18 November 2017; pp. 1–4. [Google Scholar]

- Watakabe, H.; Jinnai, T.; Suzumura, I.; Hanada, A.; Onodera, R.; Tada, M.; Mochizuki, K.; Tanaka, H.; Ito, T. 39-2: Development of Advanced LTPS TFT Technology for Low Power Consumption and Narrow Border LCDs. In SID Symposium Digest of Technical Papers; Wiley: Hoboken, NJ, USA, 2019; Volume 50, pp. 541–544. [Google Scholar]

- Lin, C.-L.; Hung, C.-C.; Chen, P.-S.; Lai, P.-C.; Cheng, M.-H. New Voltage-Programmed AMOLED Pixel Circuit to Compensate for Nonuniform Electrical Characteristics of LTPS TFTs and Voltage Drop in Power Line. IEEE Trans. Electron Devices 2014, 61, 2454–2458. [Google Scholar] [CrossRef]

- Fan, C.-L.; Chen, Y.-C.; Yang, C.-C.; Tsai, Y.-K.; Huang, B.-R. Novel LTPS-TFT Pixel Circuit with OLED Luminance Compensation for 3D AMOLED Displays. J. Disp. Technol. 2016, 12, 425–428. [Google Scholar] [CrossRef]

- Lin, C.-S.; Chen, Y.-C.; Chang, T.-C.; Li, H.-W.; Chen, S.-C.; Jian, F.-Y.; Chuang, Y.-S.; Chen, T.-C.; Chen, Y.-C.; Tai, Y.-H. Analysis of Anomalous Capacitance Induced by TAGIDL in p-Channel LTPS TFTs. J. Electrochem. Soc. 2010, 157, H1003. [Google Scholar] [CrossRef]

- Lin, C.-L.; Chang, J.-H.; Lai, P.-C.; Shih, L.-W.; Chen, S.-C.; Cheng, M.-H. Pixel Circuit With Leakage Prevention Scheme for Low-Frame-Rate AMOLED Displays. IEEE J. Electron Devices Soc. 2020, 8, 235–240. [Google Scholar] [CrossRef]

- Im, C.; Kim, J.; Cho, N.-K.; Park, J.; Lee, E.G.; Lee, S.-E.; Na, H.-J.; Gong, Y.J.; Kim, Y.S. Analysis of interface phenomena for high-performance dual-stacked oxide thin-film transistors via equivalent circuit modeling. ACS Appl. Mater. Interfaces 2021, 13, 51266–51278. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-L.; Lai, P.-C.; Chen, P.-S.; Wu, W.-L. Pixel Circuit With Parallel Driving Scheme for Compensating Luminance Variation Based on a-IGZO TFT for AMOLED Displays. J. Disp. Technol. 2016, 12, 1681–1687. [Google Scholar] [CrossRef]

- Steudel, S.; van der Steen, J.-L.P.; Nag, M.; Ke, T.H.; Smout, S.; Bel, T.; van Diesen, K.; de Haas, G.; Maas, J.; de Riet, J.; et al. Power saving through state retention in IGZO-TFT AMOLED displays for wearable applications. J. Soc. Inf. Disp. 2017, 25, 222–228. [Google Scholar] [CrossRef] [Green Version]

- Aman, M.; Takeda, Y.; Ito, K.; Yamamoto, K.; Tanaka, K.; Matsukizono, H.; Nakamura, W.; Makita, N. Reliability improvement of IGZO-TFT in hybrid process with LTPS. J. SID. 2021, 29, 416–427. [Google Scholar] [CrossRef]

- Chang, T.-K.; Lin, C.-W.; Chang, S. 39-3: Invited Paper: LTPO TFT Technology for AMOLEDs. In SID Symposium Digest of Technical Papers; Wiley: Hoboken, NJ, USA, 2019; Volume 50, pp. 545–548. [Google Scholar]

- Yonebayashi, R.; Tanaka, K.; Okada, K.; Yamamoto, K.; Yamamoto, K.; Uchida, S.; Nakamura, W. High refresh rate and low power consumption AMOLED panel using top-gate n-oxide and p-LTPS TFTs. J. SID 2020, 28, 350–359. [Google Scholar] [CrossRef]

- Fu, J.; An, J.; Liao, C.; Liang, J.; Dai, C.; Zhang, X.; Zhang, S. P-17: Design of AMOLED Pixel Circuit Using LTPO TFTs with Enhanced Reliability. In SID Symposium Digest of Technical Papers; Wiley: Hoboken, NJ, USA, 2021; Volume 51, pp. 1116–1119. [Google Scholar]

- Hsieh, H.H.; Tsai, T.T.; Chang, C.Y.; Hsu, S.F.; Chuang, C.S.; Lin, Y. Active-matrix organic light-emitting diode displays with indium gallium zinc-oxide thin-film transistors and normal, inverted, and transparent organic light-emitting diodes. J. Soc. Inf. Disp. 2011, 19, 323–328. [Google Scholar] [CrossRef]

- Lai, P.-C.; Lin, C.-L.; Kanicki, J. Novel Top-Anode OLED/a-IGZO TFTs Pixel Circuit for 8K4K AM-OLEDs. IEEE Trans. Electron Devices 2018, 66, 436–444. [Google Scholar] [CrossRef]

- Lin, C.-L.; Lai, P.-C.; Shih, L.-W.; Hung, C.-C.; Lin, T.-Y.; Liu, K.-H.; Wang, T.-H. Compensation Pixel Circuit to Improve Image Quality for Mobile AMOLED Displays. IEEE J. Solid-State Circuits 2018, 54, 489–500. [Google Scholar] [CrossRef]

- Lin, C.-L.; Lai, P.-C.; Chang, J.-H.; Chen, S.-C.; Tsai, C.-L.; Koa, J.-L.; Cheng, M.-H.; Shih, L.-W.; Hsu, W.-C. Leakage-Prevention Mechanism to Maintain Driving Capability of Compensation Pixel Circuit for Low Frame Rate AMOLED Displays. IEEE Trans. Electron Devices 2021, 68, 2313–2319. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| (W/L)T1 (μm) | 3/10 | ELVDD (V) | 5 |

| (W/L)T2−T6 (μm) | 3/3 | ELVSS (V) | 0 |

| CST (pF) | 0.1 | Scan, Em (V) | −1~5 |

| COLED (pF) | 0.4 | VDATA (V) | −0.1~1.9 |

| Emission period for 120 Hz (ms) | 8.33 | ||

| Emission period for 1 Hz (s) | 1 | ||

| Reference | This Study | Ref. [14] | Ref. [16] | Ref. [19] | Ref. [20] |

|---|---|---|---|---|---|

| Structure | 6T1C | 6T1C | 7T1C | 6T2C | 7T1C |

| Total signal lines | 5 | 8 | 7 | 7 | 6 |

| Frame rate | 1–120 Hz | 1–60 Hz | 1–120 Hz | 120 Hz | 15–60 Hz |

| Resolution | 1920 × 1080 | 368 × 448 | 1920 × 1080 | 1920 × 1080 | 320 × 360 |

| Power voltage (VDD − VSS) | 5 V | N/A | 7 V | 4.8 V | 6.6 V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, C.-L.; Chen, C.-Y.; Liu, S.-Y.; Lin, W.-Y. AMOLED Pixel Circuit Using LTPO Technology Supporting Variable Frame Rate from 1 to 120 Hz for Portable Displays. Micromachines 2022, 13, 1505. https://doi.org/10.3390/mi13091505

Fan C-L, Chen C-Y, Liu S-Y, Lin W-Y. AMOLED Pixel Circuit Using LTPO Technology Supporting Variable Frame Rate from 1 to 120 Hz for Portable Displays. Micromachines. 2022; 13(9):1505. https://doi.org/10.3390/mi13091505

Chicago/Turabian StyleFan, Ching-Lin, Chun-Yuan Chen, Shih-Yang Liu, and Wei-Yu Lin. 2022. "AMOLED Pixel Circuit Using LTPO Technology Supporting Variable Frame Rate from 1 to 120 Hz for Portable Displays" Micromachines 13, no. 9: 1505. https://doi.org/10.3390/mi13091505

APA StyleFan, C.-L., Chen, C.-Y., Liu, S.-Y., & Lin, W.-Y. (2022). AMOLED Pixel Circuit Using LTPO Technology Supporting Variable Frame Rate from 1 to 120 Hz for Portable Displays. Micromachines, 13(9), 1505. https://doi.org/10.3390/mi13091505