Integration of Inkjet Printed Graphene as a Hole Transport Layer in Organic Solar Cells

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

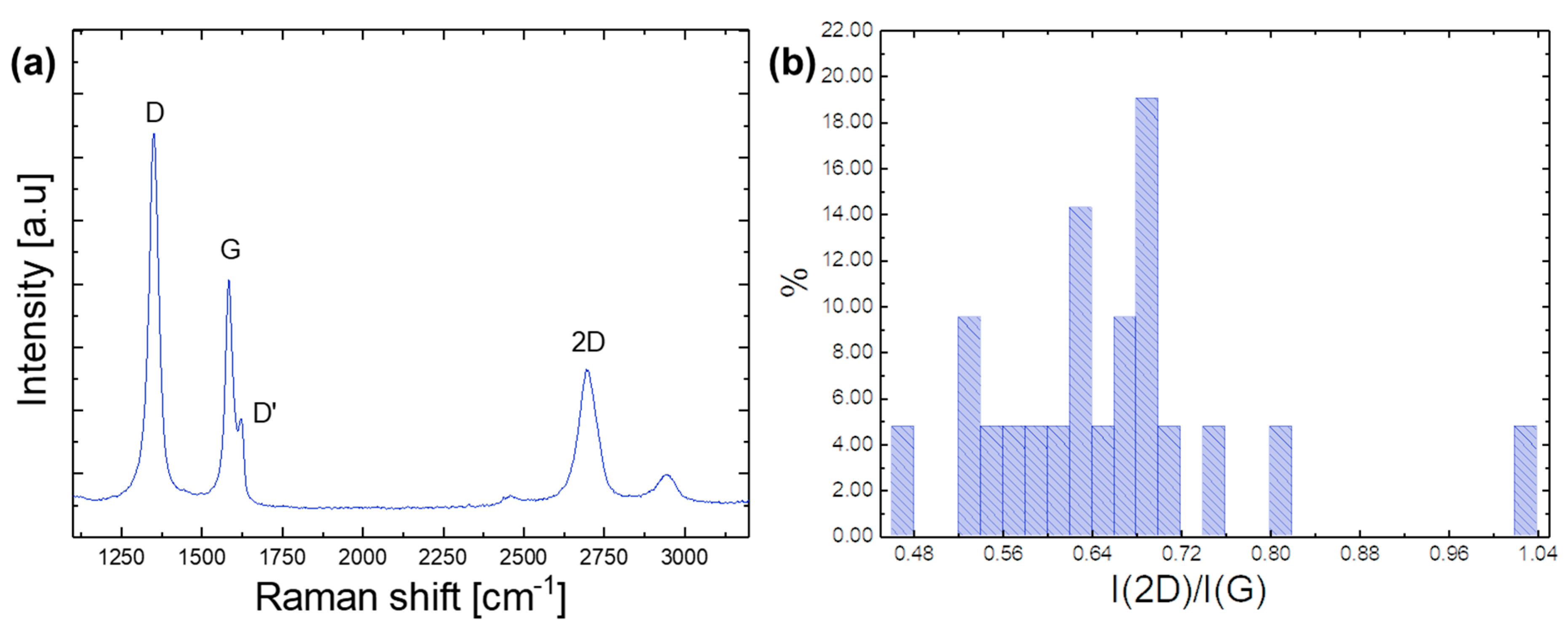

3.1. Characterization of Graphene Flakes

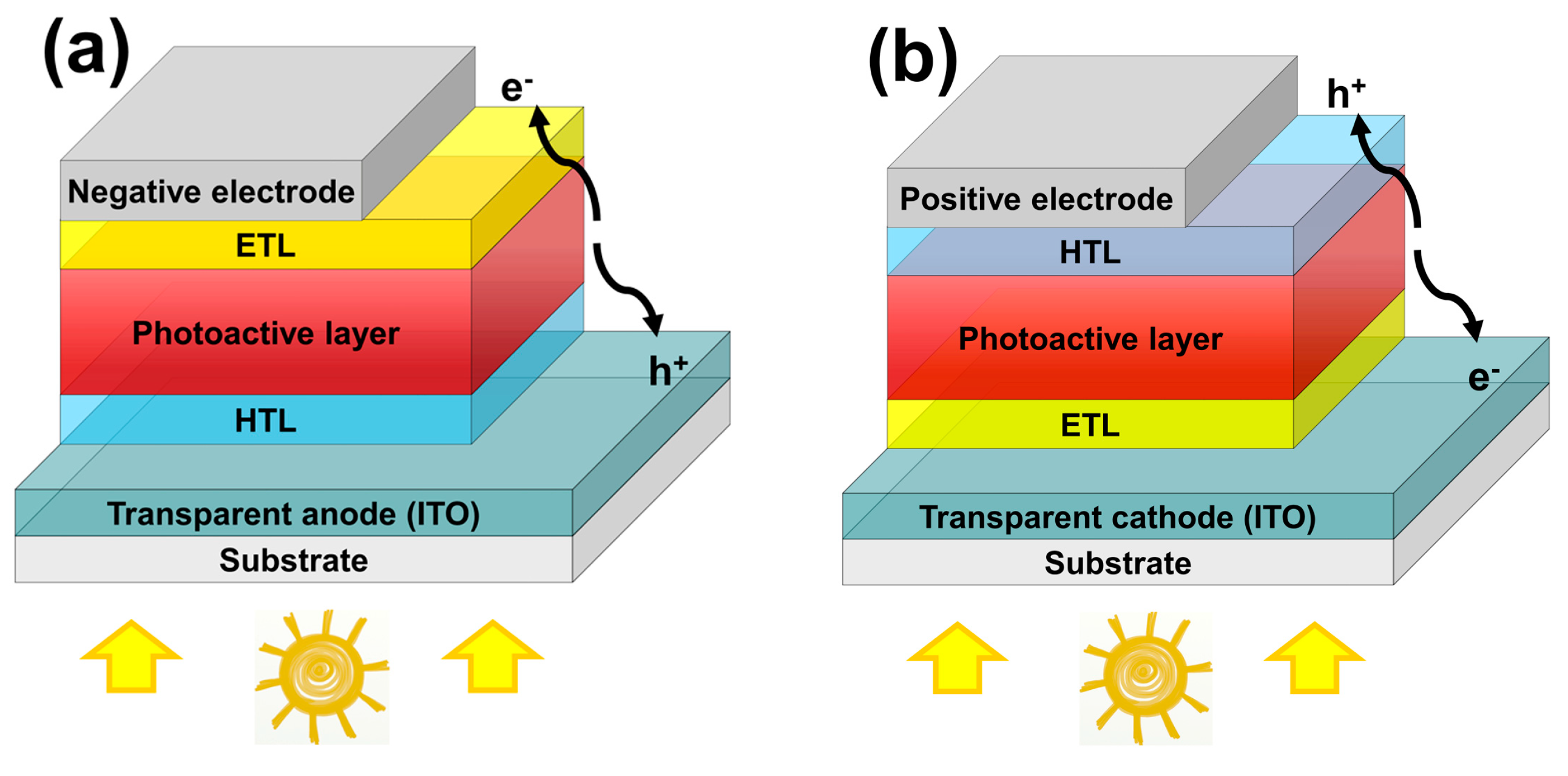

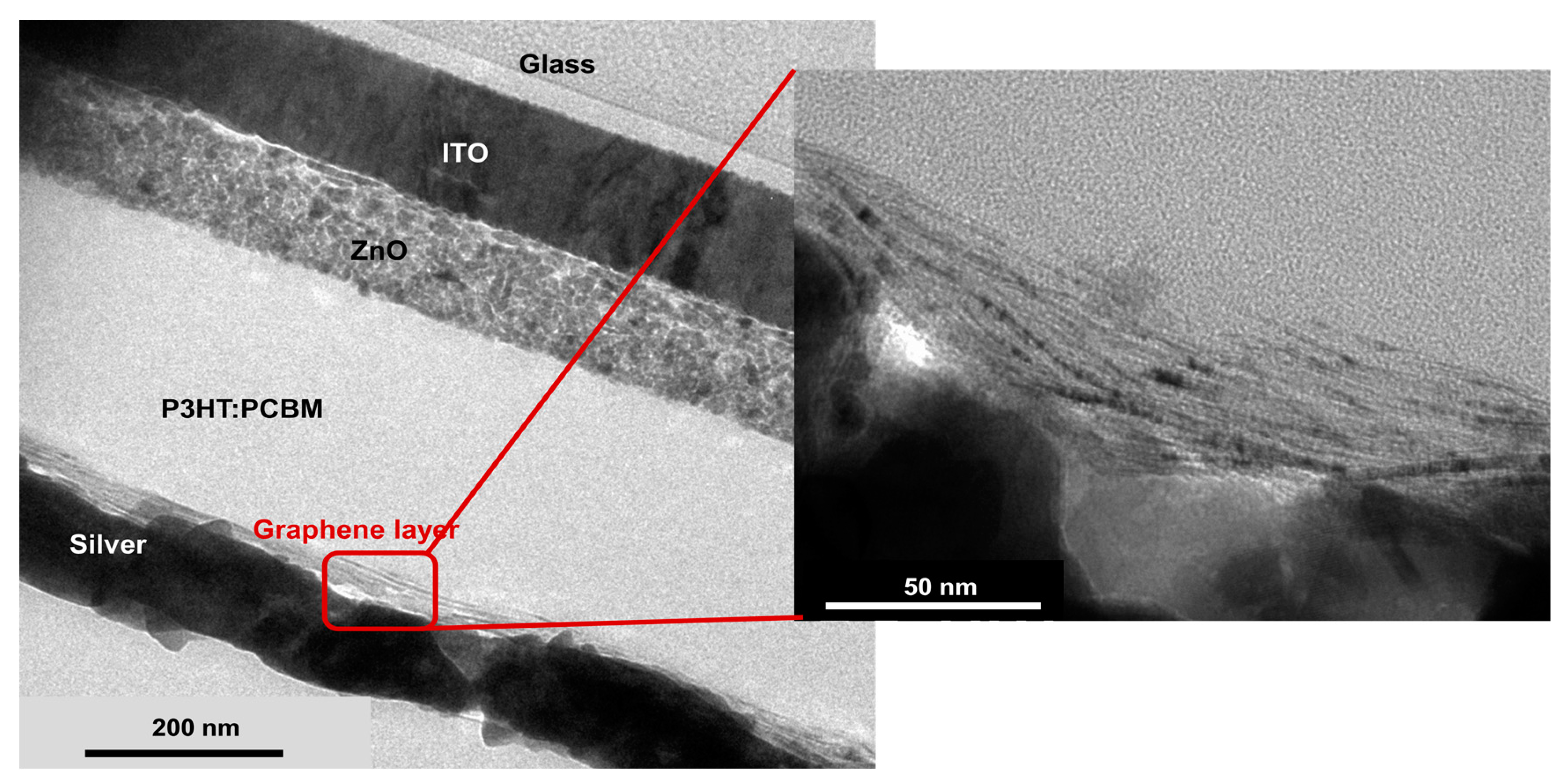

3.2. Fabrication of Solar Cells with Graphene Ink as a Hole-Transport-Layer

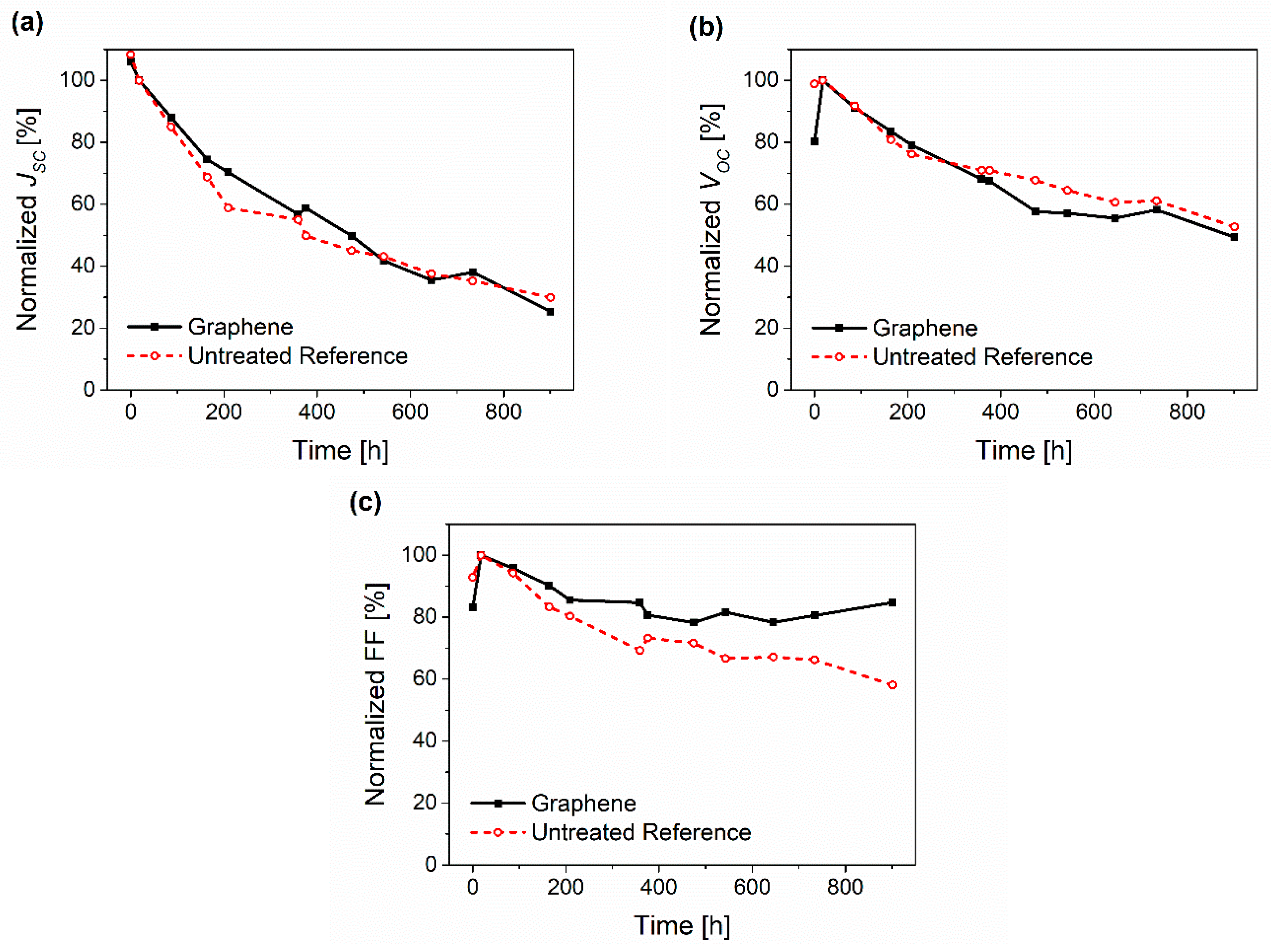

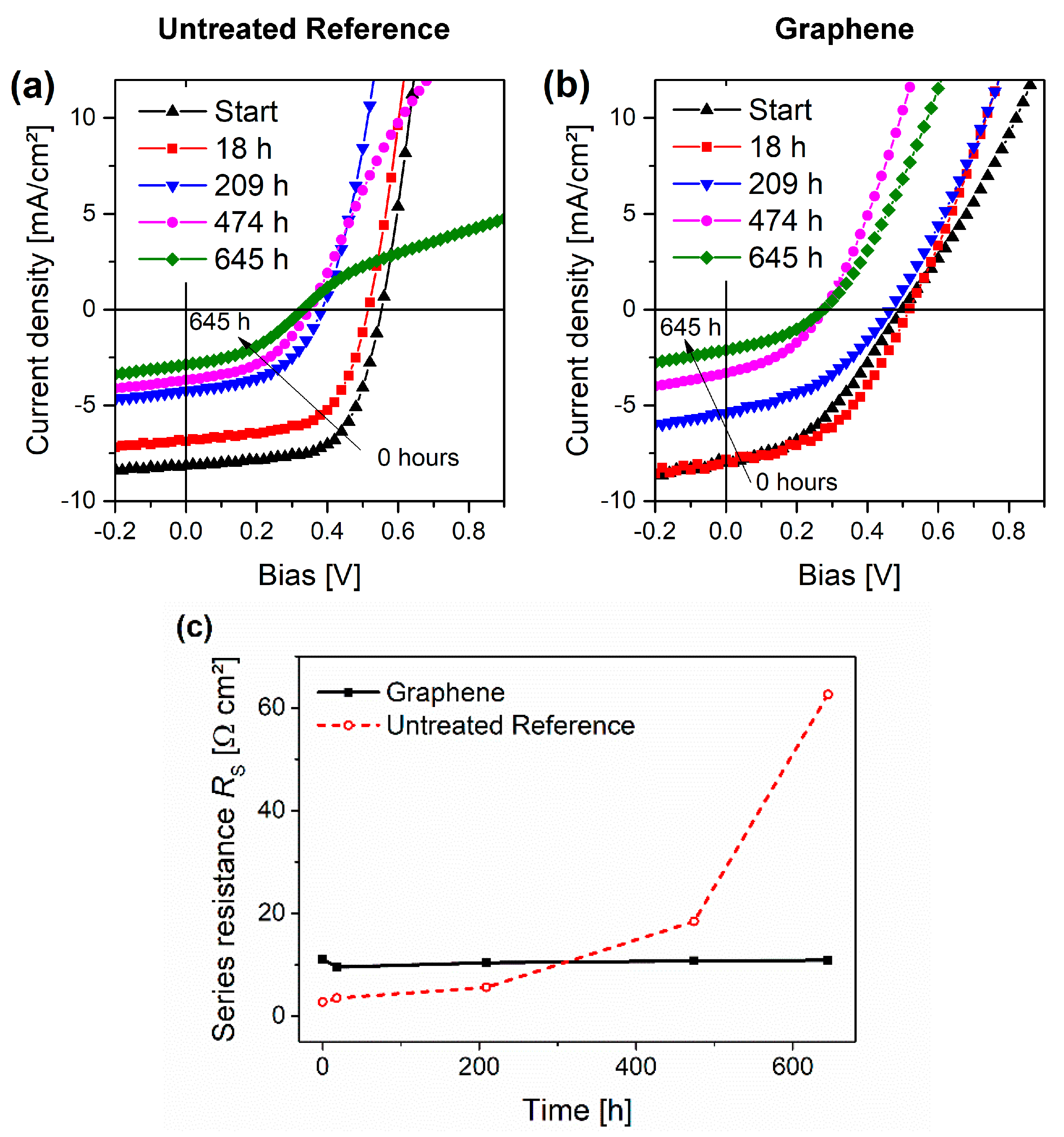

3.3. Evaluation of the Solar Cells and Lifetime Studies

4. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sariciftci, N.S.; Smilowitz, L.; Heeger, A.J.; Wudl, F. Photoinduced Electron Transfer from a Conducting Polymer to Buckminsterfullerene. Science 1992, 258, 1474–1476. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Firdaus, Y.; Isikgor, F.H.; Nugraha, M.I.; Yengel, E.; Harrison, G.T.; Hallani, R.; El-Labban, A.; Faber, H.; Ma, C.; et al. Self-Assembled Monolayer Enables Hole Transport Layer-Free Organic Solar Cells with 18% Efficiency and Improved Operational Stability. ACS Energy Lett. 2020, 5, 2935–2944. [Google Scholar] [CrossRef]

- Karki, A.; Gillett, A.J.; Friend, R.H.; Nguyen, T.-Q. The Path to 20% Power Conversion Efficiencies in Nonfullerene Acceptor Organic Solar Cells. Adv. Energy Mater. 2021, 11, 2003441. [Google Scholar] [CrossRef]

- Gao, W.; Qi, F.; Peng, Z.; Lin, F.R.; Jiang, K.; Zhong, C.; Kaminsky, W.; Guan, Z.; Lee, C.-S.; Marks, T.J.; et al. Achieving 19% Power Conversion Efficiency in Planar-Mixed Heterojunction Organic Solar Cells Using a Pseudosymmetric Electron Acceptor. Adv. Mater. 2022, 34, 2202089. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Gao, Y.; Lai, H.; Li, Y.; Wu, Z.; Chen, Z.; Sun, R.; Ren, J.; Zhang, C.; He, F.; et al. Asymmetric Side-Chain Substitution Enables a 3D Network Acceptor with Hydrogen Bond Assisted Crystal Packing and Enhanced Electronic Coupling for Efficient Organic Solar Cells. Energy Environ. Sci. 2022, 15, 4601–4611. [Google Scholar] [CrossRef]

- Zhan, L.; Li, S.; Li, Y.; Sun, R.; Min, J.; Chen, Y.; Fang, J.; Ma, C.-Q.; Zhou, G.; Zhu, H.; et al. Manipulating Charge Transfer and Transport via Intermediary Electron Acceptor Channels Enables 19.3% Efficiency Organic Photovoltaics. Adv. Energy Mater. 2022, 12, 2201076. [Google Scholar] [CrossRef]

- Ma, R.; Jiang, X.; Fu, J.; Zhu, T.; Yan, C.; Wu, K.; Müller-Buschbaum, P.; Li, G. Revealing the Underlying Solvent Effect on Film Morphology in High-Efficiency Organic Solar Cells through Combined Ex Situ and in Situ Observations. Energy Environ. Sci. 2023, 16, 2316–2326. [Google Scholar] [CrossRef]

- Han, C.; Wang, J.; Zhang, S.; Chen, L.; Bi, F.; Wang, J.; Yang, C.; Wang, P.; Li, Y.; Bao, X. Over 19% Efficiency Organic Solar Cells by Regulating Multidimensional Intermolecular Interactions. Adv. Mater. 2023, 35, 2208986. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Bi, P.; Chen, Z.; Qiao, J.; Li, J.; Wang, W.; Zheng, Z.; Zhang, S.; Hao, X.; et al. Binary Organic Solar Cells with 19.2% Efficiency Enabled by Solid Additive. Adv. Mater. 2023, 35, 2301583. [Google Scholar] [CrossRef]

- Fu, J.; Fong, P.W.K.; Liu, H.; Huang, C.-S.; Lu, X.; Lu, S.; Abdelsamie, M.; Kodalle, T.; Sutter-Fella, C.M.; Yang, Y.; et al. 19.31% Binary Organic Solar Cell and Low Non-Radiative Recombination Enabled by Non-Monotonic Intermediate State Transition. Nat. Commun. 2023, 14, 1760. [Google Scholar] [CrossRef]

- Yuan, J.; Zhang, Y.; Zhou, L.; Zhang, G.; Yip, H.-L.; Lau, T.-K.; Lu, X.; Zhu, C.; Peng, H.; Johnson, P.A.; et al. Single-Junction Organic Solar Cell with over 15% Efficiency Using Fused-Ring Acceptor with Electron-Deficient Core. Joule 2019, 3, 1140–1151. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, M.; Wan, S.; Yin, P.; Wang, P.; Cai, D.; Liu, F.; Zheng, Q. Efficient Organic Solar Cells from Molecular Orientation Control of M-Series Acceptors. Joule 2021, 5, 197–209. [Google Scholar] [CrossRef]

- Guo, Q.; Guo, Q.; Geng, Y.; Tang, A.; Zhang, M.; Du, M.; Sun, X.; Zhou, E. Recent Advances in PM6:Y6-Based Organic Solar Cells. Mater. Chem. Front. 2021, 5, 3257–3280. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Cai, G.; Zhang, Y.; Lu, X.; Lin, Y. Selenium Heterocyclic Electron Acceptor with Small Urbach Energy for As-Cast High-Performance Organic Solar Cells. J. Am. Chem. Soc. 2020, 142, 18741–18745. [Google Scholar] [CrossRef]

- Li, C.; Zhou, J.; Song, J.; Xu, J.; Zhang, H.; Zhang, X.; Guo, J.; Zhu, L.; Wei, D.; Han, G.; et al. Non-Fullerene Acceptors with Branched Side Chains and Improved Molecular Packing to Exceed 18% Efficiency in Organic Solar Cells. Nat. Energy 2021, 6, 605–613. [Google Scholar] [CrossRef]

- Ma, R.; Yan, C.; Fong, P.W.-K.; Yu, J.; Liu, H.; Yin, J.; Huang, J.; Lu, X.; Yan, H.; Li, G. In Situ and Ex Situ Investigations on Ternary Strategy and Co-Solvent Effects towards High-Efficiency Organic Solar Cells. Energy Environ. Sci. 2022, 15, 2479–2488. [Google Scholar] [CrossRef]

- Ma, R.; Fan, Q.; Dela Peña, T.A.; Wu, B.; Liu, H.; Wu, Q.; Wei, Q.; Wu, J.; Lu, X.; Li, M.; et al. Unveiling the Morphological and Physical Mechanism of Burn-in Loss Alleviation by Ternary Matrix toward Stable and Efficient All-Polymer Solar Cells. Adv. Mater. 2023, 35, 2212275. [Google Scholar] [CrossRef]

- Wang, X.; Sun, Q.; Gao, J.; Wang, J.; Xu, C.; Ma, X.; Zhang, F. Recent Progress of Organic Photovoltaics with Efficiency over 17%. Energies 2021, 14, 4200. [Google Scholar] [CrossRef]

- Cravino, A.; Schilinsky, P.; Brabec, C.J. Characterization of Organic Solar Cells: The Importance of Device Layout. Adv. Funct. Mater. 2007, 17, 3906–3910. [Google Scholar] [CrossRef]

- Günes, S.; Neugebauer, H.; Sariciftci, N.S. Conjugated Polymer-Based Organic Solar Cells. Chem. Rev. 2007, 107, 1324–1338. [Google Scholar] [CrossRef]

- Mozer, A.J.; Sariciftci, N.S. Conjugated Polymer Photovoltaic Devices and Materials. Comptes Rendus Chim. 2006, 9, 568–577. [Google Scholar] [CrossRef]

- Krebs, F.C. Fabrication and Processing of Polymer Solar Cells: A Review of Printing and Coating Techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Espinosa, N.; García-Valverde, R.; Urbina, A.; Lenzmann, F.; Manceau, M.; Angmo, D.; Krebs, F.C. Life Cycle Assessment of ITO-Free Flexible Polymer Solar Cells Prepared by Roll-to-Roll Coating and Printing. Sol. Energy Mater. Sol. Cells 2012, 97, 3–13. [Google Scholar] [CrossRef]

- Eggenhuisen, T.M.; Galagan, Y.; Biezemans, A.F.K.V.; Slaats, T.M.W.L.; Voorthuijzen, W.P.; Kommeren, S.; Shanmugam, S.; Teunissen, J.P.; Hadipour, A.; Verhees, W.J.H.; et al. High Efficiency, Fully Inkjet Printed Organic Solar Cells with Freedom of Design. J. Mater. Chem. A 2015, 3, 7255–7262. [Google Scholar] [CrossRef]

- Yang, F.; Huang, Y.; Li, Y.; Li, Y. Large-Area Flexible Organic Solar Cells. Npj Flex. Electron. 2021, 5, 30. [Google Scholar] [CrossRef]

- Lau, G.-K.; Shrestha, M. Ink-Jet Printing of Micro-Electro-Mechanical Systems (MEMS). Micromachines 2017, 8, 194. [Google Scholar] [CrossRef]

- Sumaiya, S.; Kardel, K.; El-Shahat, A. Organic Solar Cell by Inkjet Printing—An Overview. Technologies 2017, 5, 53. [Google Scholar] [CrossRef]

- Kastner, J.; Faury, T.; Außerhuber, H.M.; Obermüller, T.; Leichtfried, H.; Haslinger, M.J.; Liftinger, E.; Innerlohinger, J.; Gnatiuk, I.; Holzinger, D.; et al. Silver-Based Reactive Ink for Inkjet-Printing of Conductive Lines on Textiles. Microelectron. Eng. 2017, 176, 84–88. [Google Scholar] [CrossRef]

- Kastner, J.; Gnatiuk, I.; Wagner, M.; Holzinger, D.; Rudelstorfer, V.; Hesser, G.; Fuchsbauer, A.; Hild, S. Grinded Nano-Graphite Inkjet Inks for Application in Organic Solar Cells. Nanotechnology 2018, 30, 045601. [Google Scholar] [CrossRef]

- Kulha, P.; Chitturi, N.C.; Plasch, M.; Kastner, J.; Kurzmann, J.; Mühlberger, M.; Fechtig, D. Inkjet-Printed Capacitive Sensors and Electronic Structures; In Proceedings of the IMAPS flash Conference, Brno, Czech Republic, 24–25 October 2019.

- Xia, Z.; Cai, T.; Li, X.; Zhang, Q.; Shuai, J.; Liu, S. Recent Progress of Printing Technologies for High-Efficient Organic Solar Cells. Catalysts 2023, 13, 156. [Google Scholar] [CrossRef]

- Ruscello, M.; Sarkar, T.; Levitsky, A.; Matrone, G.M.; Droseros, N.; Schlisske, S.; Sachs, E.; Reiser, P.; Mankel, E.; Kowalsky, W.; et al. Nanocomposite of Nickel Oxide Nanoparticles and Polyethylene Oxide as Printable Hole Transport Layer for Organic Solar Cells. Sustain. Energy Fuels 2019, 3, 1418–1426. [Google Scholar] [CrossRef]

- Xu, H.; Zou, H.; Zhou, D.; Zeng, G.; Chen, L.; Liao, X.; Chen, Y. Printable Hole Transport Layer for 1.0 cm2 Organic Solar Cells. ACS Appl. Mater. Interfaces 2020, 12, 52028–52037. [Google Scholar] [CrossRef] [PubMed]

- Schackmar, F.; Eggers, H.; Frericks, M.; Richards, B.S.; Lemmer, U.; Hernandez-Sosa, G.; Paetzold, U.W. Perovskite Solar Cells with All-Inkjet-Printed Absorber and Charge Transport Layers. Adv. Mater. Technol. 2021, 6, 2000271. [Google Scholar] [CrossRef]

- Patel, V.D.; Gupta, D. Solution-Processed Metal-Oxide Based Hole Transport Layers for Organic and Perovskite Solar Cell: A Review. Mater. Today Commun. 2022, 31, 103664. [Google Scholar] [CrossRef]

- Anrango-Camacho, C.; Pavón-Ipiales, K.; Frontana-Uribe, B.A.; Palma-Cando, A. Recent Advances in Hole-Transporting Layers for Organic Solar Cells. Nanomaterials 2022, 12, 443. [Google Scholar] [CrossRef]

- Kong, T.; Yang, G.; Fan, P.; Yu, J. Solution-Processable NiOx:PMMA Hole Transport Layer for Efficient and Stable Inverted Organic Solar Cells. Polymers 2023, 15, 1875. [Google Scholar] [CrossRef]

- Sherafatipour, G.; Benduhn, J.; Patil, B.R.; Ahmadpour, M.; Spoltore, D.; Rubahn, H.-G.; Vandewal, K.; Madsen, M. Degradation Pathways in Standard and Inverted DBP-C70 Based Organic Solar Cells. Sci. Rep. 2019, 9, 4024. [Google Scholar] [CrossRef]

- Yang, S.; Yu, H. The Modification of ZnO Surface with Natural Antioxidants to Fabricate Highly Efficient and Stable Inverted Organic Solar Cells. Chem. Eng. J. 2023, 452, 139658. [Google Scholar] [CrossRef]

- Yao, J.; Qiu, B.; Zhang, Z.-G.; Xue, L.; Wang, R.; Zhang, C.; Chen, S.; Zhou, Q.; Sun, C.; Yang, C.; et al. Cathode Engineering with Perylene-Diimide Interlayer Enabling over 17% Efficiency Single-Junction Organic Solar Cells. Nat. Commun. 2020, 11, 2726. [Google Scholar] [CrossRef]

- Chen, C.; Xue, P.; Lu, H.; Wang, J.; Jia, B.; Li, Y.; Qin, D.; Lin, Y.; Zhan, X. A Novel, Weakly N-Doped Cathode-Modifying Layer in Organic Solar Cells. Energy Technol. 2021, 9, 2100281. [Google Scholar] [CrossRef]

- Shaheen, S.E.; Brabec, C.J.; Sariciftci, N.S.; Padinger, F.; Fromherz, T.; Hummelen, J.C. 2.5% Efficient Organic Plastic Solar Cells. Appl. Phys. Lett. 2001, 78, 841. [Google Scholar] [CrossRef]

- Wang, J.-C.; Lu, C.-Y.; Hsu, J.-L.; Lee, M.-K.; Hong, Y.-R.; Perng, T.-P.; Horng, S.-F.; Meng, H.-F. Efficient Inverted Organic Solar Cells without an Electron Selective Layer. J. Mater. Chem. 2011, 21, 5723. [Google Scholar] [CrossRef]

- Shi, S.; Hou, Y.; Yang, T.; Huang, C.; Yao, S.; Zhao, C.; Liu, Y.; Zhang, Z.; Liu, T.; Zou, B. Simple Solvent Treatment Enabled Improved PEDOT:PSS Performance toward Highly Efficient Binary Organic Solar Cells. ACS Omega 2022, 7, 41789–41795. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.; Zeng, M.; Li, Y.; Liu, T.; Luo, Z.; Xu, Y.; Li, P.; Zheng, N.; Li, J.; Li, Y.; et al. Rational Anode Engineering Enables Progresses for Different Types of Organic Solar Cells. Adv. Energy Mater. 2021, 11, 2100492. [Google Scholar] [CrossRef]

- Hermerschmidt, F.; Savva, A.; Georgiou, E.; Tuladhar, S.M.; Durrant, J.R.; McCulloch, I.; Bradley, D.D.C.; Brabec, C.J.; Nelson, J.; Choulis, S.A. Influence of the Hole Transporting Layer on the Thermal Stability of Inverted Organic Photovoltaics Using Accelerated-Heat Lifetime Protocols. ACS Appl. Mater. Interfaces 2017, 9, 14136–14144. [Google Scholar] [CrossRef]

- Lin, Y.; Adilbekova, B.; Firdaus, Y.; Yengel, E.; Faber, H.; Sajjad, M.; Zheng, X.; Yarali, E.; Seitkhan, A.; Bakr, O.M.; et al. 17% Efficient Organic Solar Cells Based on Liquid Exfoliated WS2 as a Replacement for PEDOT:PSS. Adv. Mater. 2019, 31, 1902965. [Google Scholar] [CrossRef]

- Chu, K.; Li, W.; Dong, H.; Tang, F. Modeling the Thermal Conductivity of Graphene Nanoplatelets Reinforced Composites. Europhys. Lett. 2012, 100, 36001. [Google Scholar] [CrossRef]

- Tewari, A.; Böhm, S. Chapter 8—Graphene Based Nano-Inks for Electronic Industries. In Smart Multifunctional Nano-Inks; Gupta, R.K., Nguyen, T.A., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2023; pp. 197–226. ISBN 978-0-323-91145-0. [Google Scholar]

- Subramanyam, B.V.R.S.; Mahakul, P.C.; Sa, K.; Raiguru, J.; Mahanandia, P. Investigation of Improvement in Stability and Power Conversion Efficiency of Organic Solar Cells Fabricated by Incorporating Carbon Nanostructures in Device Architecture. J. Phys. Mater. 2020, 3, 045004. [Google Scholar] [CrossRef]

- Kolonelou, E.; Loupou, E.; Sakellis, E.; Papathanassiou, A.N. Pressure and Temperature Dependence of the Electric Modulus and Loss Factor of Poly(Vinyl Alcohol)/Poly(Vinylidene Fluoride) Blends Reinforced with Nano—Graphene Platelets. J. Phys. Chem. Solids 2023, 178, 111277. [Google Scholar] [CrossRef]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Velasco Davoise, L.; Díez-Pascual, A.M.; Peña Capilla, R. Application of Graphene-Related Materials in Organic Solar Cells. Materials 2022, 15, 1171. [Google Scholar] [CrossRef]

- Kim, J.; Sarker, A.K.; Park, Y.; Kwak, J.; Song, H.-J.; Lee, C. Study on Graphene Oxide as a Hole Extraction Layer for Stable Organic Solar Cells. RSC Adv. 2021, 11, 27199–27206. [Google Scholar] [CrossRef]

- Ji, S.; Min, B.K.; Kim, S.K.; Myung, S.; Kang, M.; Shin, H.-S.; Song, W.; Heo, J.; Lim, J.; An, K.-S.; et al. Work Function Engineering of Graphene Oxide via Covalent Functionalization for Organic Field-Effect Transistors. Appl. Surf. Sci. 2017, 419, 252–258. [Google Scholar] [CrossRef]

- Kymakis, E.; Konios, D. Chapter 9—Graphene Oxide-Like Materials in Organic and Perovskite Solar Cells. In The Future of Semiconductor Oxides in Next-Generation Solar Cells; Lira-Cantu, M., Ed.; Metal Oxides; Elsevier: Amsterdam, The Netherlands, 2018; pp. 357–394. ISBN 978-0-12-811165-9. [Google Scholar]

- Díez-Pascual, A.M. Development of Graphene-Based Polymeric Nanocomposites: A Brief Overview. Polymers 2021, 13, 2978. [Google Scholar] [CrossRef]

- Li, S.-S.; Tu, K.-H.; Lin, C.-C.; Chen, C.-W.; Chhowalla, M. Solution-Processable Graphene Oxide as an Efficient Hole Transport Layer in Polymer Solar Cells. ACS Nano 2010, 4, 3169–3174. [Google Scholar] [CrossRef] [PubMed]

- Jeon, Y.-J.; Yun, J.-M.; Kim, D.-Y.; Na, S.-I.; Kim, S.-S. Moderately Reduced Graphene Oxide as Hole Transport Layer in Polymer Solar Cells via Thermal Assisted Spray Process. Appl. Surf. Sci. 2014, 296, 140–146. [Google Scholar] [CrossRef]

- Nicasio-Collazo, J.; Maldonado, J.-L.; Salinas-Cruz, J.; Barreiro-Argüelles, D.; Caballero-Quintana, I.; Vázquez-Espinosa, C.; Romero-Borja, D. Functionalized and Reduced Graphene Oxide as Hole Transport Layer and for Use in Ternary Organic Solar Cell. Opt. Mater. 2019, 98, 109434. [Google Scholar] [CrossRef]

- Lloyd, M.T.; Peters, C.H.; Garcia, A.; Kauvar, I.V.; Berry, J.J.; Reese, M.O.; McGehee, M.D.; Ginley, D.S.; Olson, D.C. Influence of the Hole-Transport Layer on the Initial Behavior and Lifetime of Inverted Organic Photovoltaics. Sol. Energy Mater. Sol. Cells 2011, 95, 1382–1388. [Google Scholar] [CrossRef]

- Yan, H.; Jo, T.; Okuzaki, H. Highly Conductive and Transparent Poly(3,4-Ethylenedioxythiophene)/Poly(4-Styrenesulfonate) (PEDOT/PSS) Thin Films. Polym. J. 2009, 41, 1028–1029. [Google Scholar] [CrossRef]

- Norrman, K.; Madsen, M.V.; Gevorgyan, S.A.; Krebs, F.C. Degradation Patterns in Water and Oxygen of an Inverted Polymer Solar Cell. J. Am. Chem. Soc. 2010, 132, 16883–16892. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Li, Y.; Zafar, S.; Yang, S.; Chen, J.; Zhou, H.; Zhang, Y. Recent Progress in Hole-Transporting Layers of Conventional Organic Solar Cells with p–i–n Structure. Adv. Funct. Mater. 2022, 32, 2205398. [Google Scholar] [CrossRef]

- Kawano, K.; Pacios, R.; Poplavskyy, D.; Nelson, J.; Bradley, D.D.C.; Durrant, J.R. Degradation of Organic Solar Cells Due to Air Exposure. Sol. Energy Mater. Sol. Cells 2006, 90, 3520–3530. [Google Scholar] [CrossRef]

- Das, S.; Sudhagar, P.; Kang, Y.S.; Choi, W. Graphene Synthesis and Application for Solar Cells. J. Mater. Res. 2014, 29, 299–319. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Colombo, L.; Yu, G.; Stoller, M.; Tozzini, V.; Ferrari, A.C.; Ruoff, R.S.; Pellegrini, V. Graphene, Related Two-Dimensional Crystals, and Hybrid Systems for Energy Conversion and Storage. Science 2015, 347, 1246501. [Google Scholar] [CrossRef]

- Torrisi, F.; Hasan, T.; Wu, W.; Sun, Z.; Lombardo, A.; Kulmala, T.S.; Hsieh, G.-W.; Jung, S.; Bonaccorso, F.; Paul, P.J.; et al. Inkjet-Printed Graphene Electronics. ACS Nano 2012, 6, 2992–3006. [Google Scholar] [CrossRef]

- Ramalingam, P.; Pusuluri, S.T.; Periasamy, S.; Veerabahu, R.; Kulandaivel, J. Role of Deoxy Group on the High Concentration of Graphene in Surfactant/Water Media. RSC Adv. 2013, 3, 2369. [Google Scholar] [CrossRef]

- Lotya, M.; Hernandez, Y.; King, P.J.; Smith, R.J.; Nicolosi, V.; Karlsson, L.S.; Blighe, F.M.; De, S.; Wang, Z.; McGovern, I.T.; et al. Liquid Phase Production of Graphene by Exfoliation of Graphite in Surfactant/Water Solutions. J. Am. Chem. Soc. 2009, 131, 3611–3620. [Google Scholar] [CrossRef] [PubMed]

- Basko, D.M.; Piscanec, S.; Ferrari, A.C. Electron-Electron Interactions and Doping Dependence of the Two-Phonon Raman Intensity in Graphene. Phys. Rev. B 2009, 80, 165413. [Google Scholar] [CrossRef]

- Ferrari, A.C. Raman Spectroscopy of Graphene and Graphite: Disorder, Electron–Phonon Coupling, Doping and Nonadiabatic Effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman Spectra of Disordered and Amorphous Carbon. Phys. Rev. B 2000, 61, 14095. [Google Scholar] [CrossRef]

- Casiraghi, C.; Hartschuh, A.; Qian, H.; Piscanec, S.; Georgi, C.; Fasoli, A.; Novoselov, K.S.; Basko, D.M.; Ferrari, A.C. Raman Spectroscopy of Graphene Edges. Nano Lett. 2009, 9, 1433–1441. [Google Scholar] [CrossRef] [PubMed]

- Dupont, S.R.; Oliver, M.; Krebs, F.C.; Dauskardt, R.H. Interlayer Adhesion in Roll-to-Roll Processed Flexible Inverted Polymer Solar Cells. Sol. Energy Mater. Sol. Cells 2012, 97, 171–175. [Google Scholar] [CrossRef]

- Hintz, H.; Egelhaaf, H.-J.; Lüer, L.; Hauch, J.; Peisert, H.; Chassé, T. Photodegradation of P3HT−A Systematic Study of Environmental Factors. Chem. Mater. 2011, 23, 145–154. [Google Scholar] [CrossRef]

- Chaudhary, S.; Lu, H.; Müller, A.M.; Bardeen, C.J.; Ozkan, M. Hierarchical Placement and Associated Optoelectronic Impact of Carbon Nanotubes in Polymer-Fullerene Solar Cells. Nano Lett. 2007, 7, 1973–1979. [Google Scholar] [CrossRef]

- Tay, B.K.; Sheeja, D.; Lau, S.P.; Guo, J.X. Study of Surface Energy of Tetrahedral Amorphous Carbon Films Modified in Various Gas Plasma. Diam. Relat. Mater. 2003, 12, 2072–2076. [Google Scholar] [CrossRef]

- Zeng, H.; Zhu, X.; Liang, Y.; Guo, X. Interfacial Layer Engineering for Performance Enhancement in Polymer Solar Cells. Polymers 2015, 7, 333–372. [Google Scholar] [CrossRef]

- Tountas, M.; Georgiadou, D.G.; Zeniou, A.; Seintis, K.; Soultati, A.; Polydorou, E.; Gardelis, S.; Douvas, A.M.; Speliotis, T.; Tsikritzis, D.; et al. Plasma Induced Degradation and Surface Electronic Structure Modification of Poly(3-Hexylthiophene) Films. Polym. Degrad. Stab. 2018, 149, 162–172. [Google Scholar] [CrossRef]

- Nelson, J. The Physics of Solar Cells; Imperial College Press: London, UK, 2003; ISBN 978-1-84816-823-7. [Google Scholar]

- Melios, C.; Centeno, A.; Zurutuza, A.; Panchal, V.; Giusca, C.E.; Spencer, S.; Silva, S.R.P.; Kazakova, O. Effects of Humidity on the Electronic Properties of Graphene Prepared by Chemical Vapour Deposition. Carbon 2016, 103, 273–280. [Google Scholar] [CrossRef]

- N’Konou, K.; Torchio, P. Optical Absorption Enhancement by Inserting ZnO Optical Spacer in Plasmonic Organic Solar Cells. J. Nanophotonics 2017, 12, 012502. [Google Scholar] [CrossRef]

- Yu, Y.-J.; Zhao, Y.; Ryu, S.; Brus, L.E.; Kim, K.S.; Kim, P. Tuning the Graphene Work Function by Electric Field Effect. Nano Lett. 2009, 9, 3430–3434. [Google Scholar] [CrossRef]

- Bruna, M.; Ott, A.K.; Ijäs, M.; Yoon, D.; Sassi, U.; Ferrari, A.C. Doping Dependence of the Raman Spectrum of Defected Graphene. ACS Nano 2014, 8, 7432–7441. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-J.; Zeng, J.-J. Tuning the Work Function of Graphene by Ultraviolet Irradiation. Appl. Phys. Lett. 2013, 102, 183120. [Google Scholar] [CrossRef]

- Jung, N.; Kim, N.; Jockusch, S.; Turro, N.J.; Kim, P.; Brus, L. Charge Transfer Chemical Doping of Few Layer Graphenes: Charge Distribution and Band Gap Formation. Nano Lett. 2009, 9, 4133–4137. [Google Scholar] [CrossRef]

- Imamura, G.; Saiki, K. Synthesis of Nitrogen-Doped Graphene on Pt(111) by Chemical Vapor Deposition. J. Phys. Chem. C 2011, 115, 10000–10005. [Google Scholar] [CrossRef]

- Bianco, G.V.; Losurdo, M.; Giangregorio, M.M.; Capezzuto, P.; Bruno, G. Exploring and Rationalising Effective N-Doping of Large Area CVD-Graphene by NH3. Phys. Chem. Chem. Phys. 2014, 16, 3632. [Google Scholar] [CrossRef]

- Wu, G.; Tang, X.; Meyyappan, M.; Lai, K.W.C. Doping Effects of Surface Functionalization on Graphene with Aromatic Molecule and Organic Solvents. Appl. Surf. Sci. 2017, 425, 713–721. [Google Scholar] [CrossRef]

- Wehling, T.O.; Lichtenstein, A.I.; Katsnelson, M.I. First-Principles Studies of Water Adsorption on Graphene: The Role of the Substrate. Appl. Phys. Lett. 2008, 93, 202110. [Google Scholar] [CrossRef]

- Shim, J.; Lui, C.H.; Ko, T.Y.; Yu, Y.-J.; Kim, P.; Heinz, T.F.; Ryu, S. Water-Gated Charge Doping of Graphene Induced by Mica Substrates. Nano Lett. 2012, 12, 648–654. [Google Scholar] [CrossRef]

- Ziegler, D.; Gava, P.; Güttinger, J.; Molitor, F.; Wirtz, L.; Lazzeri, M.; Saitta, A.M.; Stemmer, A.; Mauri, F.; Stampfer, C. Variations in the Work Function of Doped Single- and Few-Layer Graphene Assessed by Kelvin Probe Force Microscopy and Density Functional Theory. Phys. Rev. B 2011, 83, 235434. [Google Scholar] [CrossRef]

- Jørgensen, M.; Norrman, K.; Krebs, F.C. Stability/Degradation of Polymer Solar Cells. Sol. Energy Mater. Sol. Cells 2008, 92, 686–714. [Google Scholar] [CrossRef]

- Seemann, A.; Sauermann, T.; Lungenschmied, C.; Armbruster, O.; Bauer, S.; Egelhaaf, H.-J.; Hauch, J. Reversible and Irreversible Degradation of Organic Solar Cell Performance by Oxygen. Sol. Energy 2011, 85, 1238–1249. [Google Scholar] [CrossRef]

- Laquai, F.; Andrienko, D.; Deibel, C.; Neher, D. Charge Carrier Generation, Recombination, and Extraction in Polymer–Fullerene Bulk Heterojunction Organic Solar Cells. In Elementary Processes in Organic Photovoltaics; Leo, K., Ed.; Springer International Publishing: Cham, Switzerland, 2017; Volume 272, pp. 267–291. ISBN 978-3-319-28336-4. [Google Scholar]

- Waldauf, C.; Scharber, M.C.; Schilinsky, P.; Hauch, J.A.; Brabec, C.J. Physics of Organic Bulk Heterojunction Devices for Photovoltaic Applications. J. Appl. Phys. 2006, 99, 104503. [Google Scholar] [CrossRef]

- Qi, B.; Wang, J. Open-Circuit Voltage in Organic Solar Cells. J. Mater. Chem. 2012, 22, 24315–24325. [Google Scholar] [CrossRef]

- Nanditha, D.M.; Dissanayake, M.; Hatton, R.A.; Curry, R.J.; Silva, S.R.P. Operation of a Reversed Pentacene-Fullerene Discrete Heterojunction Photovoltaic Device. Appl. Phys. Lett. 2007, 90, 113505. [Google Scholar] [CrossRef]

- Schafferhans, J.; Baumann, A.; Wagenpfahl, A.; Deibel, C.; Dyakonov, V. Oxygen Doping of P3HT:PCBM Blends: Influence on Trap States, Charge Carrier Mobility and Solar Cell Performance. Org. Electron. 2010, 11, 1693–1700. [Google Scholar] [CrossRef]

- Yang, Q.-D.; Ng, T.-W.; Lo, M.-F.; Wong, N.-B.; Lee, C.-S. Enhanced Storage/Operation Stability of Small Molecule Organic Photovoltaics Using Graphene Oxide Interfacial Layer. Org. Electron. 2012, 13, 3220–3225. [Google Scholar] [CrossRef]

- Lloyd, M.T.; Olson, D.C.; Lu, P.; Fang, E.; Moore, D.L.; White, M.S.; Reese, M.O.; Ginley, D.S.; Hsu, J.W.P. Impact of Contact Evolution on the Shelf Life of Organic Solar Cells. J. Mater. Chem. 2009, 19, 7638–7642. [Google Scholar] [CrossRef]

- Zhou, X.; Dong, X.; Liu, Y.; Wang, W.; Wei, W.; Chen, J.; Liu, T.; Zhou, Y. Effect of Wetting Surfactants on the Work Function of PEDOT:PSS for Organic Solar Cells. ACS Appl. Energy Mater. 2022, 5, 3766–3772. [Google Scholar] [CrossRef]

- Hoppe, H.; Sariciftci, N.S. Organic Solar Cells: An Overview. J. Mater. Res. 2004, 19, 1924–1945. [Google Scholar] [CrossRef]

- Chen, L.; Du, D.; Sun, K.; Hou, J.; Ouyang, J. Improved Efficiency and Stability of Polymer Solar Cells Utilizing Two-Dimensional Reduced Graphene Oxide: Graphene Oxide Nanocomposites as Hole-Collection Material. ACS Appl. Mater. Interfaces 2014, 6, 22334–22342. [Google Scholar] [CrossRef]

- Bouzidi, K.; Chegaar, M.; Aillerie, M. Solar Cells Parameters Evaluation from Dark I-V Characteristics. Energy Procedia 2012, 18, 1601–1610. [Google Scholar] [CrossRef]

- Lattante, S. Electron and Hole Transport Layers: Their Use in Inverted Bulk Heterojunction Polymer Solar Cells. Electronics 2014, 3, 132–164. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Lombardo, A.; Hasan, T.; Sun, Z.; Colombo, L.; Ferrari, A. Production and processing of graphene and 2d crystals. Mater. Today 2012, 15, 564–589. [Google Scholar] [CrossRef]

- Thomsen, C.; Reich, S. Double resonant raman scattering in graphite. Phys. Rev. Lett. 2000, 85, 5214–5217. [Google Scholar] [CrossRef] [PubMed]

- Baranov, A.; Bekhterev, A.; Bobovich, Y.; Petrov, V.I. Interpretation of certain characteristics in Raman spectra of graphite and glassy carbon. Opt. Spectrosc. 1987, 62, 612–616. [Google Scholar]

- Pócsik, I.; Hundhausen, M.; Koós, M.; Ley, L. Origin of the D peak in the Raman spectrum of microcrystalline graphite. J. Non-Cryst. Solids 1998, 227–230, 1083–1086. [Google Scholar] [CrossRef]

- Piscanec, S.; Lazzeri, M.; Mauri, F.; Ferrari, A.; Robertson, J. Kohn Anomalies and Electron-Phonon Interactions in Graphite. Phys. Rev. Lett. 2004, 93, 185503. [Google Scholar] [CrossRef]

- Ferrari, A.; Meyer, J.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.; Roth, S.; et al. Raman Spectrum of Graphene and Graphene Layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef]

- Ferrari, A.; Rodil, S.; Robertson, J. Interpretation of infrared and Raman spectra of amorphous carbon nitrides. Phys. Rev. B 2003, 67, 155306. [Google Scholar] [CrossRef]

| HTL | Printing Passes | JSC [mA/cm2] | VOC [V] | FF [%] | Average PCE Max [%] | PCE Max [%] |

|---|---|---|---|---|---|---|

| PEDOT:PSS | --- | 7.07 ± 0.22 | 0.54 ± 0.01 | 63 ± 4 | 2.41 ± 0.15 | 2.59 |

| graphene | 10 | 7.55 ± 0.47 | 0.50 ± 0.03 | 44 ± 4 | 1.65 ± 0.15 | 1.85 |

| graphene | 15 | 7.44 ± 0.11 | 0.51 ± 0.01 | 48 ± 3 | 1.82 ± 0.14 | 2.00 |

| graphene | 20 | 10.21 ± 0.71 | 0.41 ± 0.01 | 41 ± 1 | 1.72 ± 0.12 | 1.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kastner, J.; Tomarchio, F.; Decorde, N.; Kehrer, M.; Hesser, G.; Fuchsbauer, A. Integration of Inkjet Printed Graphene as a Hole Transport Layer in Organic Solar Cells. Micromachines 2023, 14, 1858. https://doi.org/10.3390/mi14101858

Kastner J, Tomarchio F, Decorde N, Kehrer M, Hesser G, Fuchsbauer A. Integration of Inkjet Printed Graphene as a Hole Transport Layer in Organic Solar Cells. Micromachines. 2023; 14(10):1858. https://doi.org/10.3390/mi14101858

Chicago/Turabian StyleKastner, Julia, Flavia Tomarchio, Nicolas Decorde, Matthias Kehrer, Günter Hesser, and Anita Fuchsbauer. 2023. "Integration of Inkjet Printed Graphene as a Hole Transport Layer in Organic Solar Cells" Micromachines 14, no. 10: 1858. https://doi.org/10.3390/mi14101858

APA StyleKastner, J., Tomarchio, F., Decorde, N., Kehrer, M., Hesser, G., & Fuchsbauer, A. (2023). Integration of Inkjet Printed Graphene as a Hole Transport Layer in Organic Solar Cells. Micromachines, 14(10), 1858. https://doi.org/10.3390/mi14101858