Design and Analysis of a Hybrid Displacement Amplifier Supporting a High-Performance Piezo Jet Dispenser

Abstract

:1. Introduction

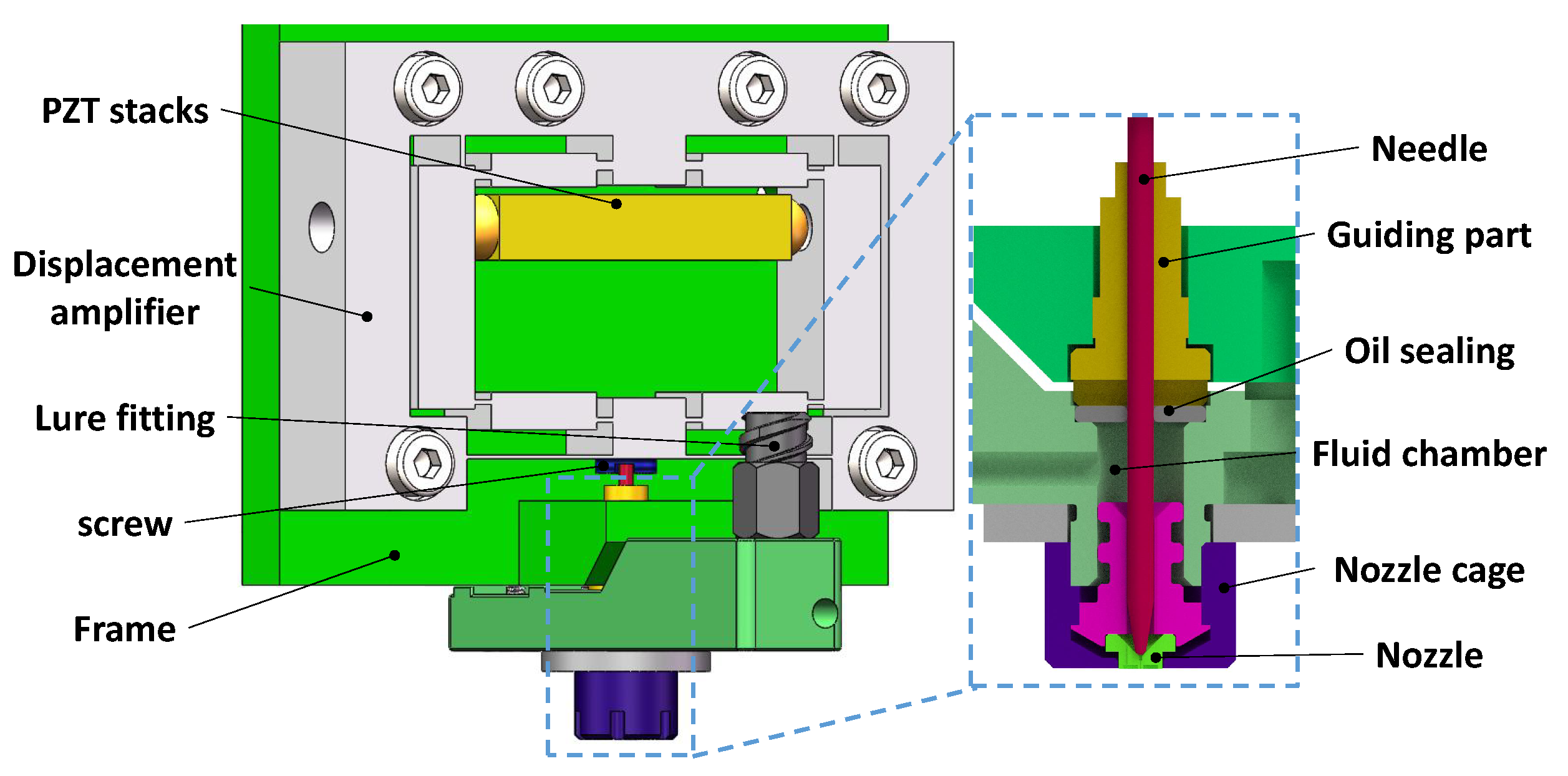

2. Mechanical Design

2.1. Design Motivation

2.2. Mechanical Structure

3. Theoretical Analysis

3.1. Bridge-Arm

3.2. Guiding Beam

3.3. Lever Mechanism-Based Input End

3.4. Overall Mechanism

4. Finite Element Analysis

4.1. Dimensional Parameter Analysis and Optimization

- There is an optimal value of (1.1 mm), for a fixed value of , to make the HBLB maximum output displacement. This is similar to the conclusions drawn from Figure 9.

- The output displacement of the HBLB increases with a decrease in when is fixed and it is greater than 0.8 mm.

- The natural frequency of the HBLB increases with an increase in either or .

4.2. Mechanical Performance

5. Experimental Validation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HBLB | Hybrid Bridge-lever-bridge |

| BTAM | Bridge-type Amplifier Mechanism |

| FEA | Finite Element Analysis |

| PZT | Piezoactuator |

References

- Huang, X.; Ge, G.; She, M.; Ma, Q.; Lu, Y.; Zhao, W.; Shen, Q.; Wang, Q.; Shao, J. Self-Healing Hydrogel with Multiple Dynamic Interactions for Multifunctional Epidermal Sensor. Appl. Surf. Sci. 2022, 598, 153803. [Google Scholar] [CrossRef]

- Hong, Y.; Zou, J.; Ge, G.; Xiao, W.; Gao, L.; Shao, J.; Dong, X. Finite element modeling simulation-assisted design of integrated microfluidic chips for heavy metal ion stripping analysis. J. Phys. D Appl. Phys. 2017, 50, 415303. [Google Scholar] [CrossRef]

- Gong, Y.; Zhang, Y.Z.; Fang, S.; Sun, Y.; Niu, J.; Lai, W.Y. Wireless Human–Machine Interface Based on Artificial Bionic Skin with Damage Reconfiguration and Multisensing Capabilities. ACS Appl. Mater. Interfaces 2022, 14, 47300–47309. [Google Scholar] [CrossRef]

- Gong, Y.; Zhang, Y.Z.; Fang, S.; Liu, C.; Niu, J.; Li, G.; Li, F.; Li, X.; Cheng, T.; Lai, W.Y. Artificial intelligent optoelectronic skin with anisotropic electrical and optical responses for multi-dimensional sensing. Appl. Phys. Rev. 2022, 9, 021403. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, X.; Wen, Z.; Ren, J.; Liu, P. A novel flexure-based vertical nanopositioning stage with large travel range. Rev. Sci. Instruments 2015, 86, 105112. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Ma, Y.; Wang, F.; Lu, K.; Zhang, D. A novel XYZ micro/nano positioner with an amplifier based on L-shape levers and half-bridge structure. Sens. Actuators A Phys. 2020, 302, 111777. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Xu, Q. Design and control of a novel compliant constant-force gripper based on buckled fixed-guided beams. IEEE/ASME Trans. Mechatronics 2016, 22, 476–486. [Google Scholar] [CrossRef]

- Trimzi, M.A.; Ham, Y.B.; An, B.C.; Choi, Y.M.; Park, J.H.; Yun, S.N. Development of a piezo-driven liquid jet dispenser with hinge-lever amplification mechanism. Micromachines 2020, 11, 117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, G.; Wang, N.; Zhou, C.; Li, J. A simplified analysis method for the piezo jet dispenser with a diamond amplifier. Sensors 2018, 18, 2115. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Liu, J.; Li, K.; Liu, Y. Piezoelectric micro-jet devices: A review. Sens. Actuators A Phys. 2019, 297, 111552. [Google Scholar] [CrossRef]

- Lu, S.; Chen, X.; Zheng, H.; Zhao, Y.; Long, Y. Simulation and experiment on droplet volume for the needle-type piezoelectric jetting dispenser. Micromachines 2019, 10, 623. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Xie, W.; Peng, W.; Li, F.; He, Y. Fundamentals and Applications of ZnO-Nanowire-Based Piezotronics and Piezo-Phototronics. Micromachines 2023, 14, 47. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Chen, F.; Sun, L.; Dong, W. Design of a linear walking stage based on two types of piezoelectric actuators. Sens. Actuators A Phys. 2021, 332, 112067. [Google Scholar] [CrossRef]

- Lai, L.J.; Zhu, Z.N. Design, modeling and testing of a novel flexure-based displacement amplification mechanism. Sens. Actuators A Phys. 2017, 266, 122–129. [Google Scholar] [CrossRef]

- Tang, H.; Gao, J.; Chen, X.; Yu, K.M.; To, S.; He, Y.; Chen, X.; Zeng, Z.; He, S.; Chen, C.; et al. Development and repetitive-compensated PID control of a nanopositioning stage with large-stroke and decoupling property. IEEE Trans. Ind. Electron. 2017, 65, 3995–4005. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, P.; Lu, S.; Yan, P. Design and modeling of a piezo-driven three-dimensional bridge-type amplification mechanism with input/output guiding constraint. Rev. Sci. Instruments 2022, 93, 025005. [Google Scholar] [CrossRef] [PubMed]

- Ham, Y.B.; An, B.C.; Trimzi, M.A.; Park, J.H.; Yun, S.N. Numerical Analysis on Piezoelectrically Driven Jet Dispensing Mechanism for Nanoliter Droplet of High Viscosity Liquid. J. Nanosci. Nanotechnol. 2019, 19, 1843–1847. [Google Scholar] [CrossRef] [PubMed]

- Howell, L.L. Compliant mechanisms. In 21st Century Kinematics; Springer: Berlin/Heidelberg, Germany, 2013; pp. 189–216. [Google Scholar]

- Zhu, W.L.; Zhu, Z.; Guo, P.; Ju, B.F. A novel hybrid actuation mechanism based XY nanopositioning stage with totally decoupled kinematics. Mech. Syst. Signal Process. 2018, 99, 747–759. [Google Scholar] [CrossRef]

- Ling, M. A general two-port dynamic stiffness model and static/dynamic comparison for three bridge-type flexure displacement amplifiers. Mech. Syst. Signal Process. 2019, 119, 486–500. [Google Scholar] [CrossRef]

- Chen, N.; Liu, X. Dynamic Modeling and Attitude Decoupling Control for a 3-DOF Flexible Piezoelectric Nano-Positioning Stage Based on ADRC. Micromachines 2022, 13, 1591. [Google Scholar] [CrossRef]

- Huang, W.; Sun, M. Design, analysis, and experiment on a novel stick-slip piezoelectric actuator with a lever mechanism. Micromachines 2019, 10, 863. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tajdari, F.; Berkhoff, A.P.; Naves, M.; Nijenhuis, M.; de Boer, A. A low-profile flexural displacement-converter mechanism for piezoelectric stack actuators. Sens. Actuators A Phys. 2020, 313, 112198. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.; Xu, Z.; Qin, F.; Wang, Z.; Zhao, H. Achieving smooth motion and high-speed for piezoelectric stick–slip actuator based on the two-stage lever principle. Rev. Sci. Instruments 2021, 92, 125001. [Google Scholar] [CrossRef]

- Li, Z.; Liu, P.; Yan, P. Design and Analysis of a Novel Flexure-Based Dynamically Tunable Nanopositioner. Micromachines 2021, 12, 212. [Google Scholar] [CrossRef]

- Tian, Y.; Shirinzadeh, B.; Zhang, D.; Alici, G. Development and dynamic modelling of a flexure-based Scott–Russell mechanism for nano-manipulation. Mech. Syst. Signal Process. 2009, 23, 957–978. [Google Scholar] [CrossRef]

- Zheng, H.; Lu, S.; Zhai, Q.; Huang, B.; Long, Y.; Zhao, Y.; Qi, J. Simulation and experiment of a diamond-type micro-displacement amplifier driven by piezoelectric actuator. J. Eng. 2020, 2020, 141–147. [Google Scholar] [CrossRef]

- Lu, S.; Cao, G.; Zheng, H.; Li, D.; Shi, M.; Qi, J. Simulation and experiment on droplet formation and separation for needle-type micro-liquid jetting dispenser. Micromachines 2018, 9, 330. [Google Scholar] [CrossRef] [Green Version]

- Bu, Z.; Lin, S.; Huang, X.; Li, A.; Wu, D.; Zhao, Y.; Luo, Z.; Wang, L. A novel piezostack-driven jetting dispenser with corner-filleted flexure hinge and high-frequency performance. J. Micromech. Microeng. 2018, 28, 075001. [Google Scholar] [CrossRef]

- Wang, F.; Huo, Z.; Liang, C.; Shi, B.; Tian, Y.; Zhao, X.; Zhang, D. A novel actuator-internal micro/nano positioning stage with an arch-shape bridge-type amplifier. IEEE Trans. Ind. Electron. 2018, 66, 9161–9172. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.; Lai, L.; Zhang, L.; Zhu, L. A novel compliant XY micro-positioning stage using bridge-type displacement amplifier embedded with Scott-Russell mechanism. Precis. Eng. 2022, 73, 284–295. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Q. Design and analysis of a totally decoupled flexure-based XY parallel micromanipulator. IEEE Trans. Robot. 2009, 25, 645–657. [Google Scholar]

- Ling, M.; Wang, J.; Wu, M.; Cao, L.; Fu, B. Design and modeling of an improved bridge-type compliant mechanism with its application for hydraulic piezo-valves. Sens. Actuators A Phys. 2021, 324, 112687. [Google Scholar] [CrossRef]

- Tang, H.; Li, Y. Design, analysis, and test of a novel 2-DOF nanopositioning system driven by dual mode. IEEE Trans. Robot. 2013, 29, 650–662. [Google Scholar]

- Koseki, Y.; Tanikawa, T.; Koyachi, N.; Arai, T. Kinematic analysis of a translational 3-dof micro-parallel mechanism using the matrix method. Adv. Robot. 2002, 16, 251–264. [Google Scholar] [CrossRef]

- Liu, P.; Yan, P. A modified pseudo-rigid-body modeling approach for compliant mechanisms with fixed-guided beam flexures. Mech. Sci. 2017, 8, 359–368. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Huang, X.; Lin, S.; Bu, Z.; Jin, H.; Lin, X.; Lin, Z.; Xie, P. Design and experiment of a jetting dispenser with compact amplifying mechanism and low stress in piezostack. J. Intell. Mater. Syst. Struct. 2020, 31, 788–798. [Google Scholar] [CrossRef]

| (mm) | (mm) | (mm) | (mm) |

|---|---|---|---|

| 0.4–1.4 | −2–1.4 | 0.4–1.4 | 1.5–5.5 |

| Young’s Modulus | Yield Strength | Density | Poisson’s Ratio |

|---|---|---|---|

| 71 GPa | 455 MPa | 2810 kg/m | 0.33 |

| Dimension | Blocking Force | Nominal Displacement | Voltage | Stiffness | Frequency |

|---|---|---|---|---|---|

| 7 × 7 × 36 mm | 1960 N | 38 m | 120 V | 49 N/m | 35 kHz |

| Para of structure | |||||||||

| Value (mm) | 1 | 13 | 1.5 | 1 | 6.7 | 25.3 | 13 | 2 | 18 |

| Para of structure | T | ||||||||

| Value (mm) | 1 | 2 | 10 | 0.6 | 3 | 10 | 0.5 | 2 | 6.5 |

| Ref. | Type | Amplification Ratio | Natural Frequency |

|---|---|---|---|

| 1 [19] | Scott-Russell with half-bridge(SRHB) | 5.7 | 667 Hz |

| 2 [31] | Scott-Russell compound bridge-type(SRCBT) | 8.54 | 248 Hz |

| 3 [6] | L-shape levers and half-bridge(LHLSB) | 8.8 | 484 Hz |

| 4 [30] | Arch-Shape Bridge Type | 6.49 | 611.9 Hz |

| 5 [27] | Diamond-type micro-displacement amplifier | 7.8 | 342 Hz |

| 6 [29] | Displacement amplifying mechanism | 7.78 | 469 Hz |

| 7 [37] | Lever amplification | 6.75 | 886 Hz |

| This work | 8.74 | 1229.9 Hz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Yan, P. Design and Analysis of a Hybrid Displacement Amplifier Supporting a High-Performance Piezo Jet Dispenser. Micromachines 2023, 14, 322. https://doi.org/10.3390/mi14020322

Zhou S, Yan P. Design and Analysis of a Hybrid Displacement Amplifier Supporting a High-Performance Piezo Jet Dispenser. Micromachines. 2023; 14(2):322. https://doi.org/10.3390/mi14020322

Chicago/Turabian StyleZhou, Shuai, and Peng Yan. 2023. "Design and Analysis of a Hybrid Displacement Amplifier Supporting a High-Performance Piezo Jet Dispenser" Micromachines 14, no. 2: 322. https://doi.org/10.3390/mi14020322