High-Speed Temperature Control Method for MEMS Thermal Gravimetric Analyzer Based on Dual Fuzzy PID Control

Abstract

1. Introduction

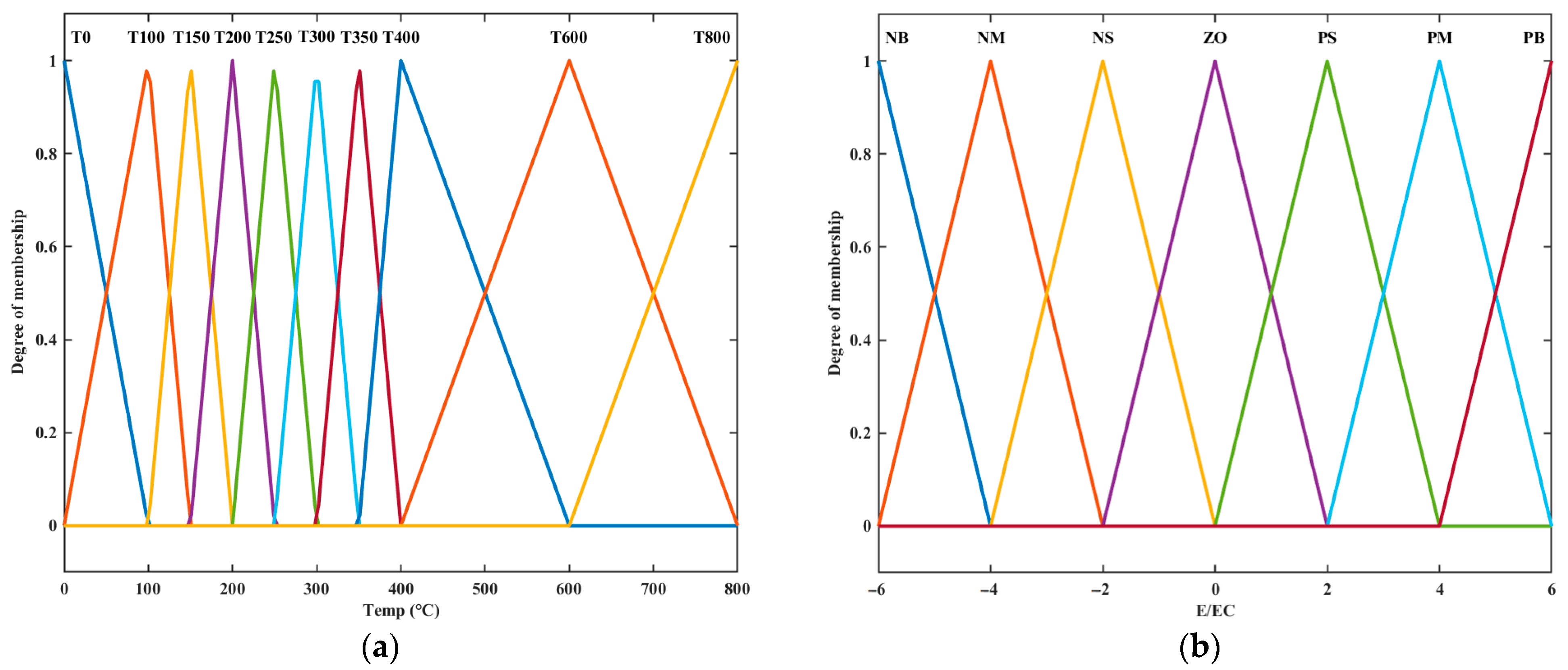

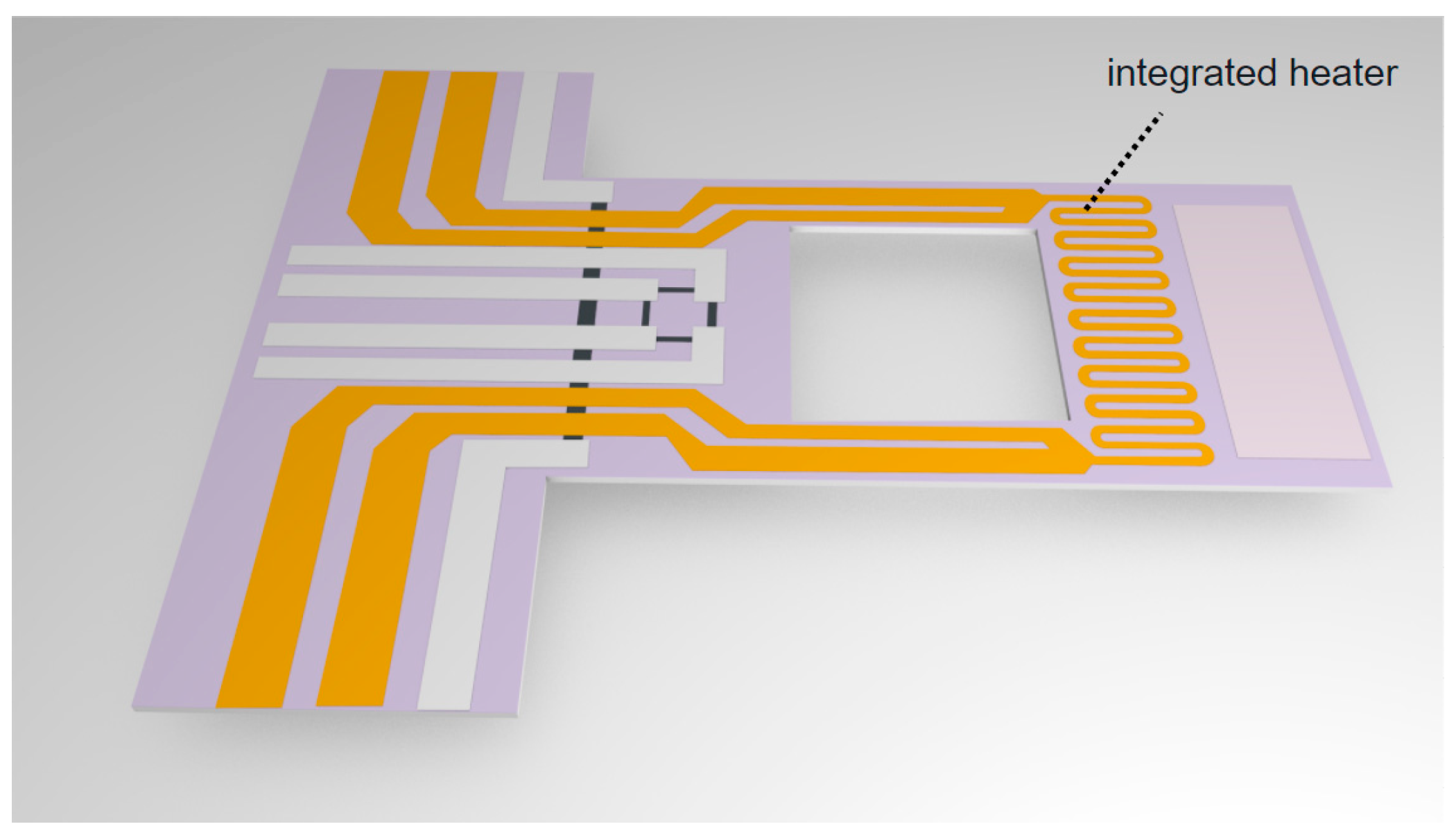

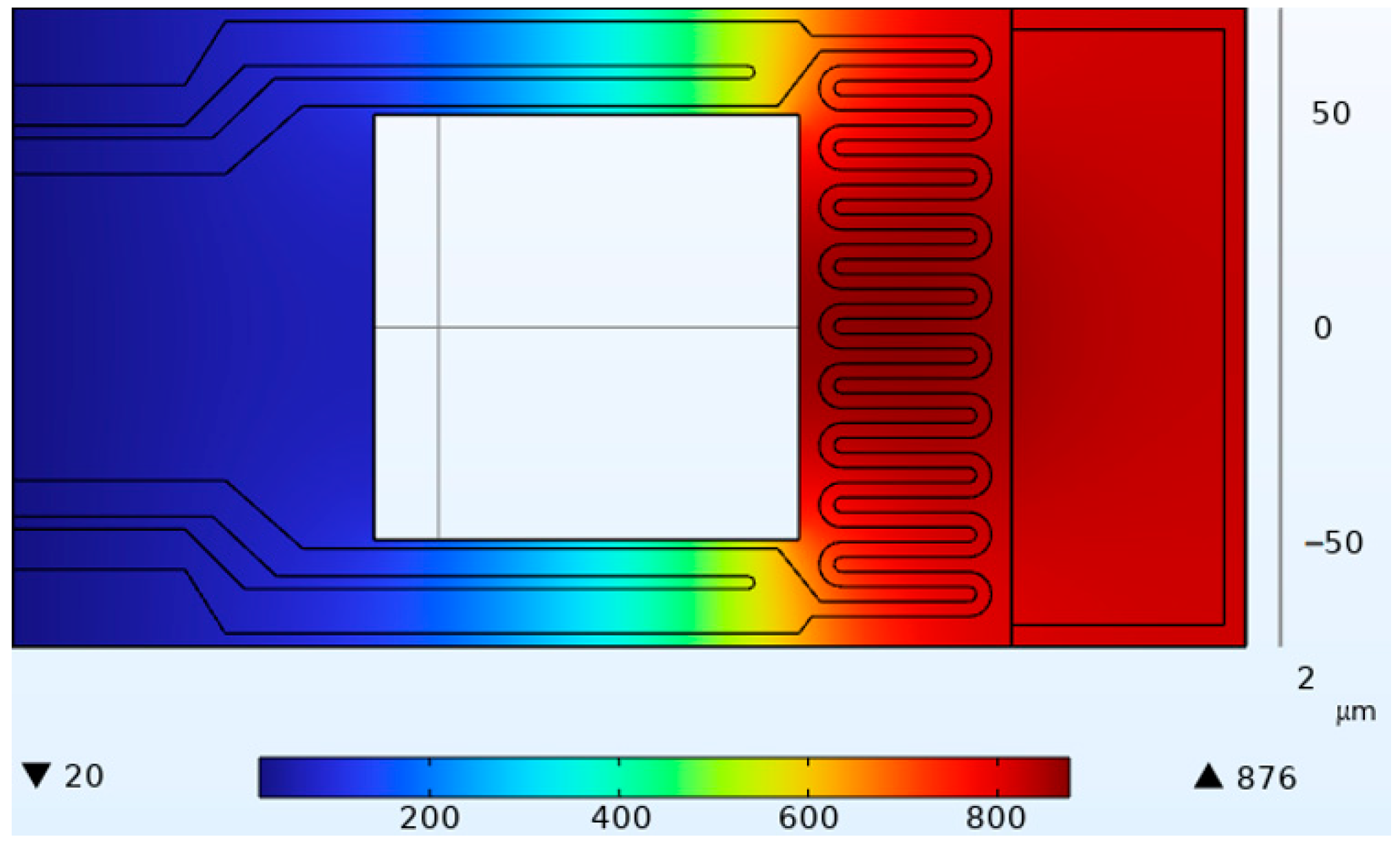

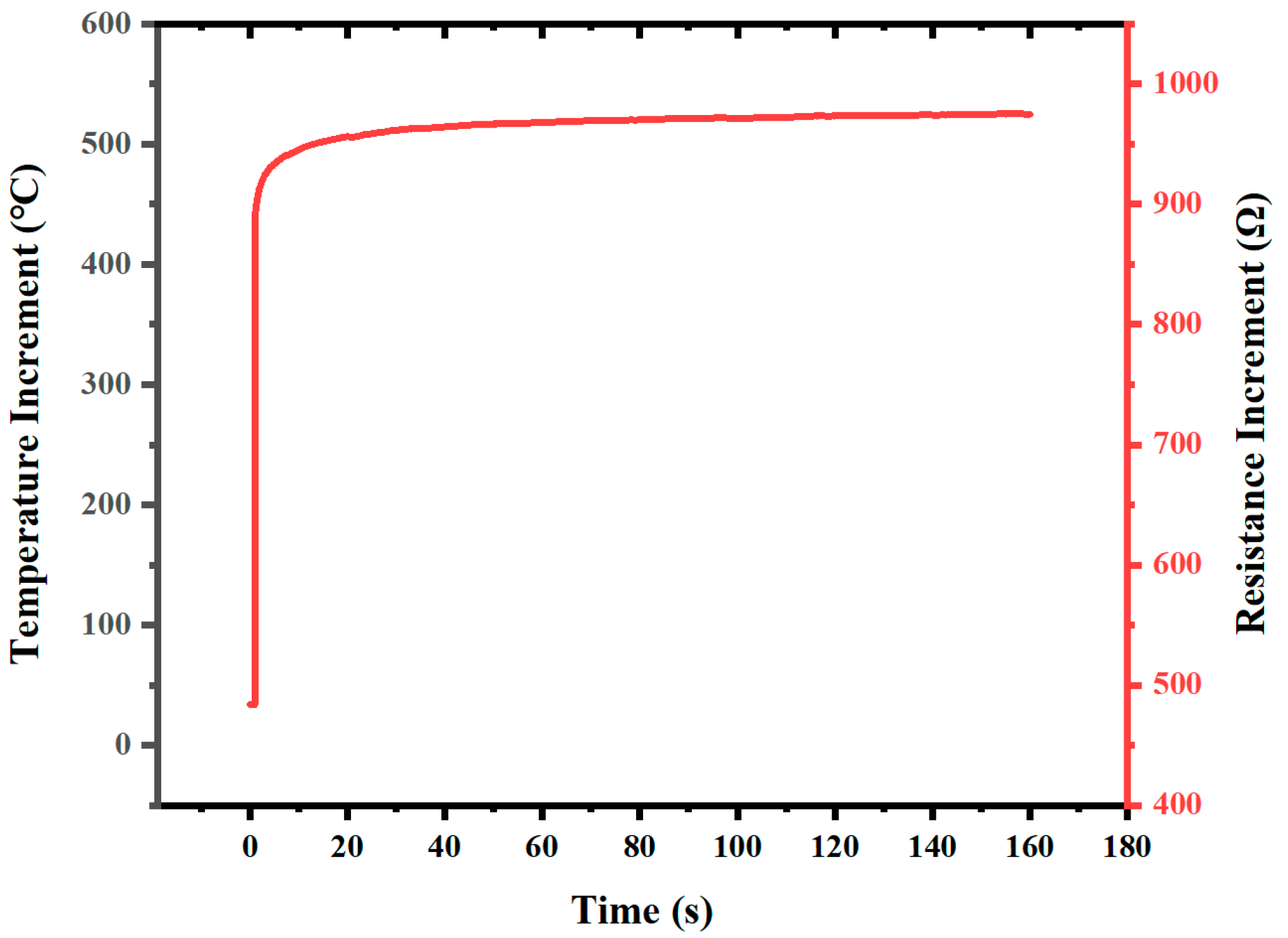

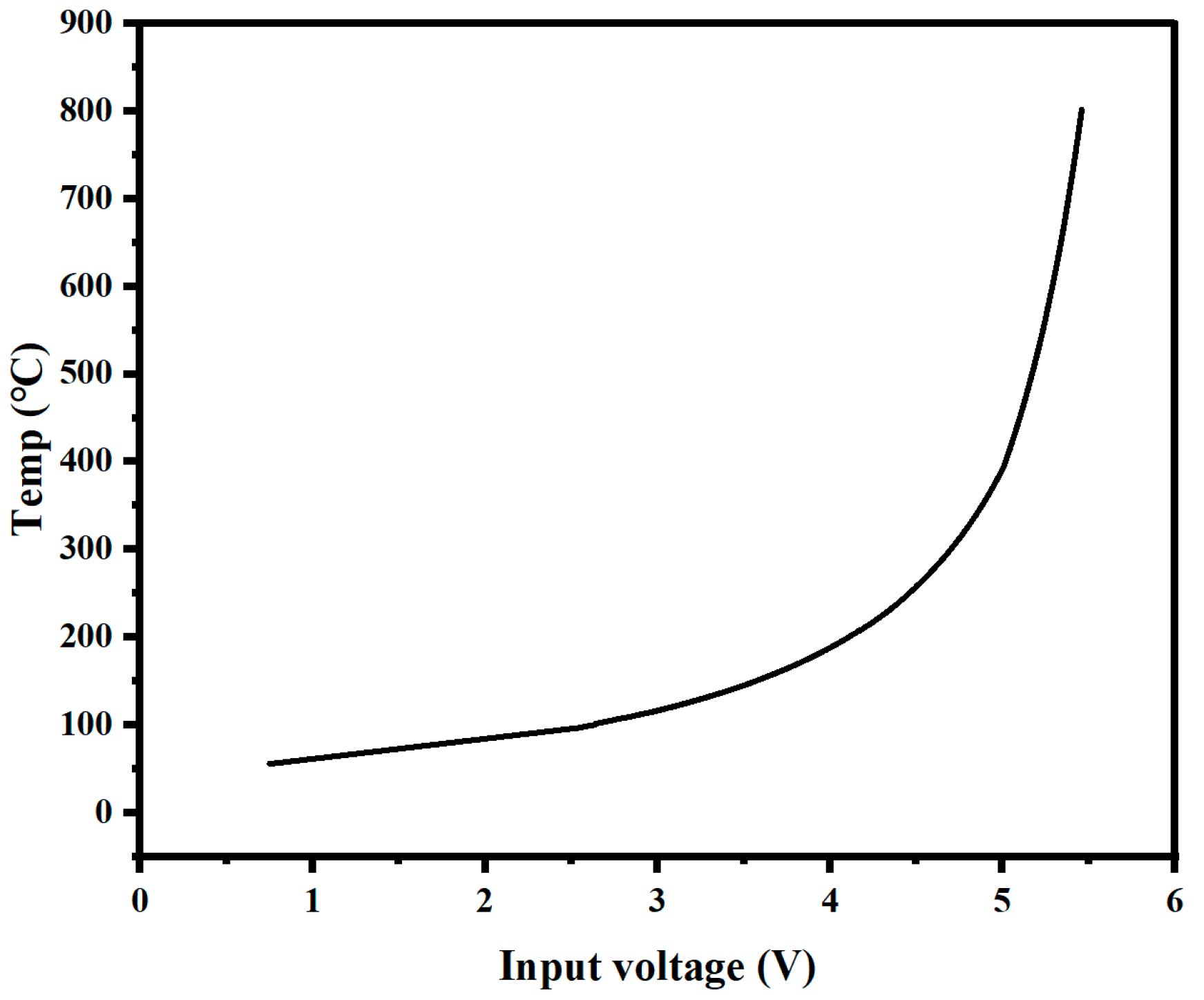

2. Principle of Integrated Microheater

3. Design of Temperature Control Method

3.1. Transfer Function of Controlled Object

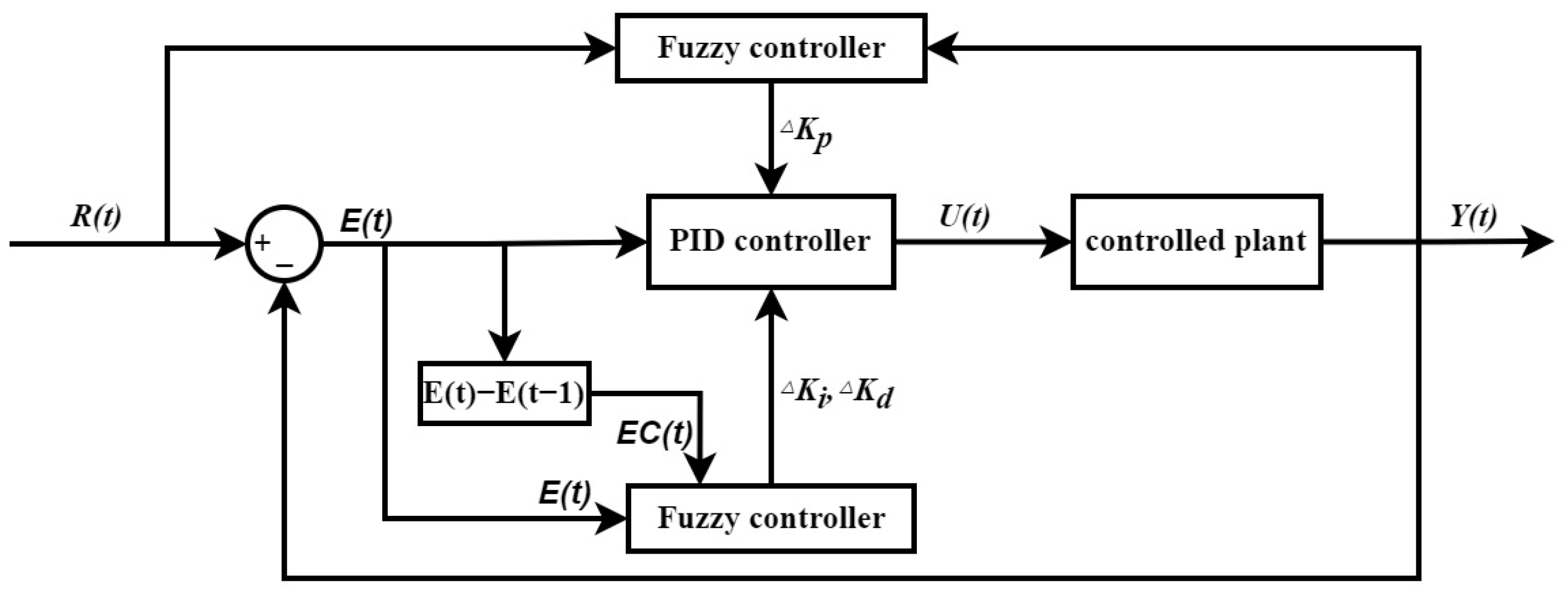

3.2. Select a Temperature Control Scheme

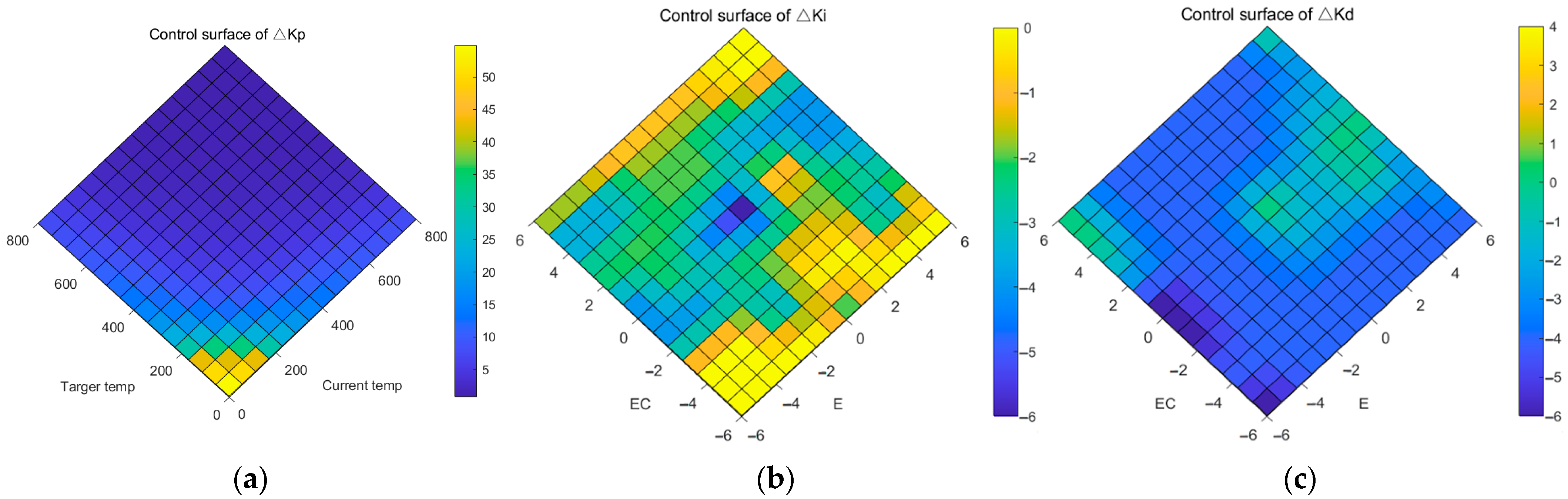

3.3. Nonlinear Adjustment

3.4. Improve Overshoot

| Y(t) | R(t) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T0 | T100 | T150 | T200 | T250 | T300 | T350 | T400 | T600 | T800 | |

| T0 | J1 | A1 | B1 | C1 | D1 | E1 | F1 | G1 | H1 | I1 |

| T100 | A1 | J2 | A2 | B2 | C2 | D2 | E2 | F2 | G2 | H1 |

| T150 | B1 | A2 | J3 | A3 | B3 | C3 | D3 | E3 | F3 | G3 |

| T200 | C1 | B2 | A3 | J4 | A4 | B4 | C4 | D4 | E4 | F4 |

| T250 | D1 | C2 | B3 | A4 | J5 | A5 | B5 | C5 | D5 | E5 |

| T300 | E1 | D2 | C3 | B4 | A5 | J6 | A6 | B6 | C6 | D6 |

| T350 | F1 | E2 | D3 | C4 | B5 | A6 | J7 | A7 | B7 | C7 |

| T400 | G1 | F2 | E3 | D4 | C5 | B6 | A7 | J8 | A8 | B8 |

| T600 | H1 | G2 | F3 | E4 | D5 | C6 | B7 | A8 | J9 | A9 |

| T800 | I1 | H2 | G3 | F4 | E5 | D6 | C7 | B8 | A9 | J10 |

| E(t) | EC(t) | ||||||

|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZO | PS | PM | PB | |

| NB | ZO | ZO | NM | NM | NS | NM | ZO |

| NM | ZO | ZO | NM | NS | NS | NM | ZO |

| NS | ZO | NM | NS | NM | NS | NS | ZO |

| ZO | NS | ZO | NS | NB | NS | NS | ZO |

| PS | ZO | ZO | NS | NM | NM | NS | ZO |

| PM | ZO | NM | NS | NM | NM | ZO | ZO |

| PB | ZO | NM | NM | NM | NM | ZO | ZO |

| E(t) | EC(t) | ||||||

|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZO | PS | PM | PB | |

| NB | NB | NM | NB | NB | NS | ZO | ZO |

| NM | NM | NM | NM | NM | NM | NM | NM |

| NS | NM | NM | NM | NM | NM | NM | NM |

| ZO | NM | NM | NS | ZO | NM | NM | NM |

| PS | NM | NM | NS | NS | NM | NM | NM |

| PM | NM | NM | ZO | ZO | NS | NM | NM |

| PB | NM | NS | NM | ZO | NS | NS | PM |

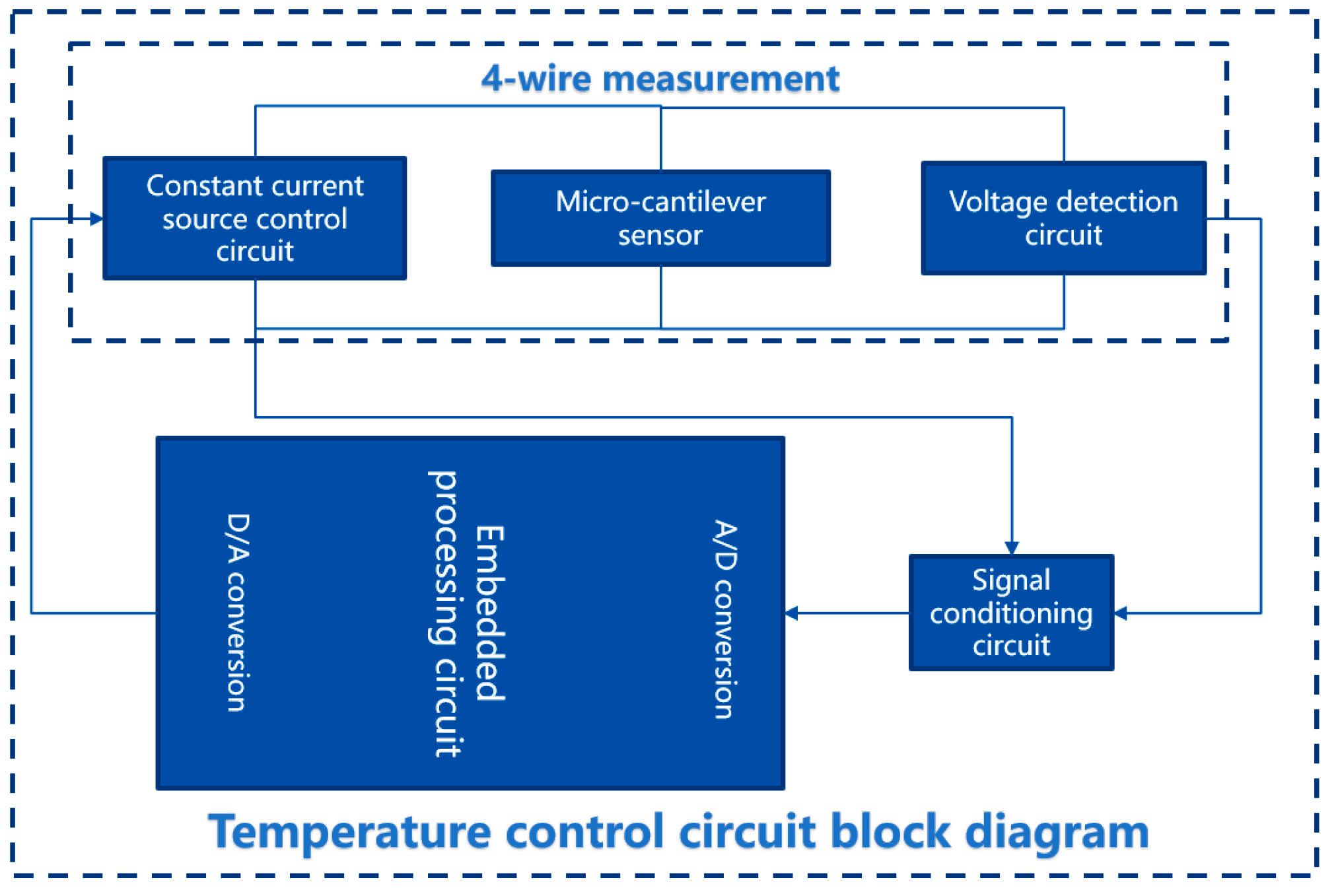

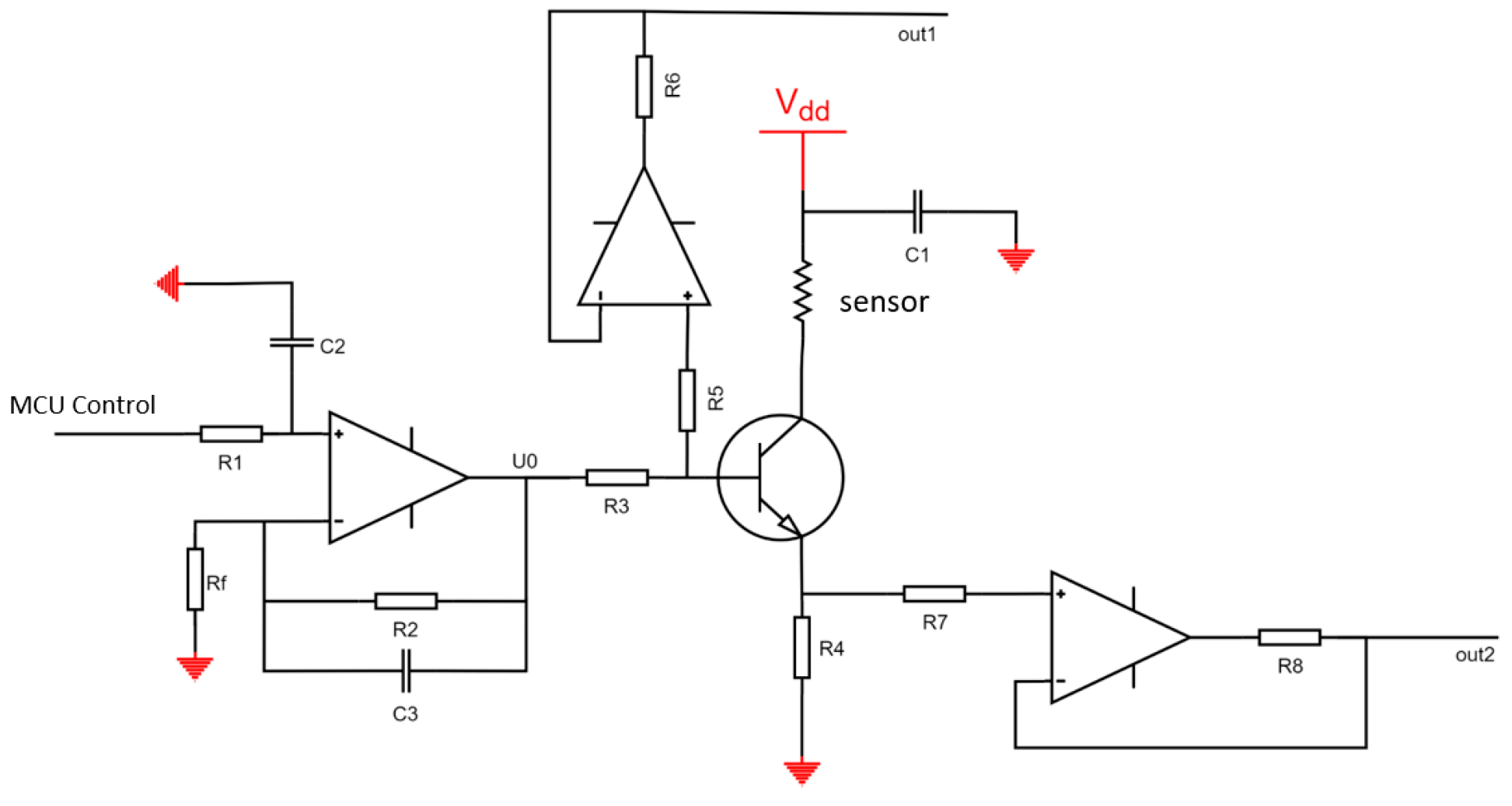

3.5. Hardware System Design

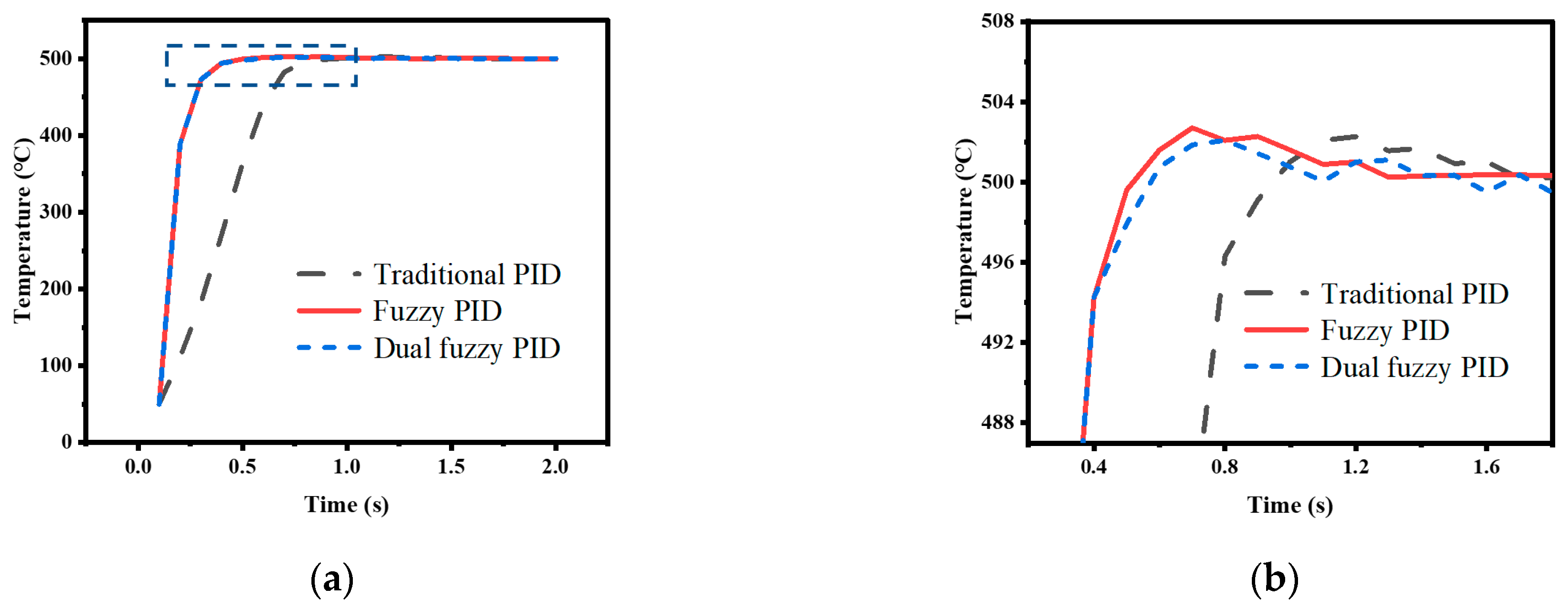

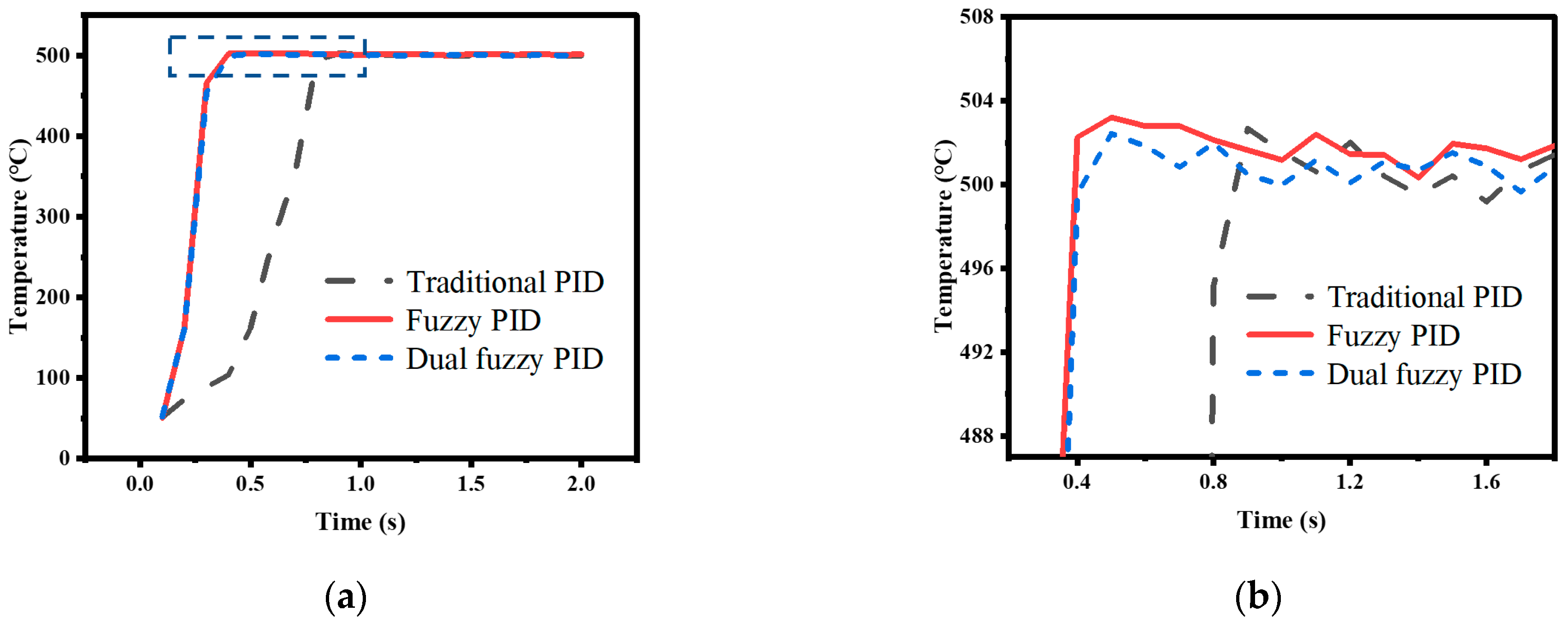

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ozawa, T. Thermal Analysis—Review and prospect. Thermochim. Acta 2000, 355, 35–42. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Criado, J.M.; Pérez-Maqueda, L.A.; Popescu, C.; Sbirrazzuoli, N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim. Acta 2011, 520, 1–19. [Google Scholar] [CrossRef]

- Clarke, T.A.; Thomas, J.M. Extraction of Meaningful Kinetic Parameters from Thermogravimetric Analysis. Nature 1968, 219, 1149–1151. [Google Scholar]

- Yao, F.; Xu, P.; Jia, H. Thermogravimetric Analysis on a Resonant Microcantilever. Anal. Chem. 2022, 94, 9380–9388. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z. Development of Numerical Modeling and Temperature Controller Optimization for Internal Heating Vacuum Furnace. IEEE Acccess 2021, 9, 126765–126773. [Google Scholar] [CrossRef]

- Czajka, K.M. The impact of the thermal lag on the interpretation of cellulose pyrolysis. Energy 2021, 236, 121497. [Google Scholar] [CrossRef]

- Ditzhuijze, G.V.; Staalman, D.; Koorn, A. Identification and model predictive control of a slab reheating furnace. In Proceedings of the International Conference on Control Applications, Glasgow, UK, 18–20 September 2002; Volume 1, pp. 361–366. [Google Scholar]

- Loganathan, S.; Mishra, R.K.; Thomas, S.; Valapa, R.B.; Pugazhenthi, G. Chapter 4—Thermogravimetric Analysis for Characterization of Nanomaterials. In Micro and Nano Technologies; Thomas, S., Thmas, R., Zachariah, A.K., Mishra, R.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 67–108. [Google Scholar]

- Onsree, T.; Tippayawong, N.; Zheng, A. Pyrolysis behavior and kinetics of corn residue pellers and eucalyptuswood chips in a macro thermogravimetric analyzer. Case Stud. Therm. Eng. 2018, 12, 546–556. [Google Scholar]

- Ebrahimpour, O.; Chaouki, J.; Dubois, C. Diffusional effects for the oxidation of SiC powders in thermogravimetric analysis experiments. J. Mater. Sci. 2013, 48, 4396–4407. [Google Scholar] [CrossRef]

- Vekemans, O.; Laviolette, J.P.; Chaouki, J. Thermal behavior of an engineered fuel and its constituents for a large range of heating rates with emphasis on heat transfer limitations. Thermochim. Acta 2015, 601, 54–62. [Google Scholar] [CrossRef]

- Yang, Y.T.; Callegari, C.; Feng, X.L. Zeptogram-Scale Nanomechanical Mass Sensing. Nano Lett. 2006, 6, 583–586. [Google Scholar] [CrossRef]

- Gruber, G.; Urgell, C.; Tavernarakis, A. Mass Sensing for the Advanced Fabrication of Nanomechanical Resonators. Nano Lett. 2019, 19, 6987–6992. [Google Scholar] [CrossRef]

- Saadatkhah, N.; Carillo, G.A.; Ackermann, S. Eperimental me3thods in chemical engineering: Thermogravimetric analysis—TGA. Can. J. Chem. Eng. 2020, 98, 34–43. [Google Scholar] [CrossRef]

- Fong, M.J.B.; Loy, A.C.M.; Chin, B.L.F.; Lam, M.K.; Yusup, S.; Jawad, Z.A. Catalytic pyrolysis of Chlorella vulgaris: Kinetic and thermodynamic analysis. Bioresour. Technol. 2019, 289, 121689. [Google Scholar]

- Marino, A.; Aloise, A.; Hernando, H.; Fermoso, J.; Cozza, D.; Giglio, E.; Migliori, M.; Pizarro, P.; Giordano, G.; Serrano, D.P. ZSM-5 zeolites performance assessment in catalytic pyrolysis of PVC-containing real WEEE plastic wastes. Catal. Today 2022, 390–391, 210–220. [Google Scholar] [CrossRef]

- Inayat, A.; Ahmed, A.; Tariq, R.; Waris, A.; Jamil, F.; Ahmed, S.F.; Ghenai, C.; Park, Y.-K. Techno-Economical Evaluation of Bio-Oil Production via Biomass Fast Pyrolysis Process: A Review. Front. Energy Res. 2022, 9, 113936. [Google Scholar] [CrossRef]

- Mourad, S.; El Ghoul, J.; Khettou, A.; Mari, B.; Abdel All, N.; Khouqeer, G.; El Mir, L.; Khirouni, K. Effect of oxygen annealing treatment on structural, optical and electrical properties of In doped ZnO thin films prepared by PLD technique. Physica B 2022, 626, 413577. [Google Scholar]

- Guillén, C.; Montero, J.; Herrero, J. Influence of N-doping and air annealing on the structural and optical properties of TiO2 thin films deposited by reactive DC sputtering at room temperature. J. Alloys Compd. 2015, 647, 498–506. [Google Scholar]

- To Loan, N.T.; Hien Lan, N.T.; Thuy Hang, N.T.; Quang Hai, N.; Tu Anh, D.T.; Thi Hau, V.; Van Tan, L.; Van Tran, T. CoFe2O4 Nanomaterials: Effect of Annealing Temperature on Characterization, Magnetic, Photocatalytic, and Photo-Fenton Properties. Processes 2019, 7, 885. [Google Scholar] [CrossRef]

- Nakayama, J. Thermal Shock Resistance of Ceramic Materials. In Fracture Mechanics of Ceramics: Volume 2 Microstructure, Materials, and Applications; Bradt, R.C., Hasselman, D.P.H., Lange, F.F., Eds.; Springer: Boston, MA, USA, 1974; pp. 759–778. [Google Scholar]

- Kim, D.; Lee, D.; Lee, S.; Park, K.; Lee, H.-G.; Park, J.Y.; Kim, W.-J. Thermal shock resistance and hoop strength of triplex silicon carbide composite tubes. Int. J. Appl. Ceram. Technol. 2017, 14, 1069–1076. [Google Scholar] [CrossRef]

- Fujii, K.; Yamada, R. Thermal shock resistance of SiC compositionally graded C/C composites. J. Nucl. Mater. 1998, 258–263, 1953–1959. [Google Scholar]

- Lee, C.Y.; Lee, G.B.; Liu, H.H. MEMS-based Temperature Control Systems for DNA Amplification. Int. J. Nonlinear Sci. Numer. Simul. 2002, 3, 215–218. [Google Scholar] [CrossRef]

- Chen, W.; Xin, G. The improvement research of gyroscope temperature control based on self-adaptive ANN. In Proceedings of the 2019 IEEE 4th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chengdu, China, 20–22 December 2019; Volume 1, pp. 2148–2151. [Google Scholar]

- Jiang, Y.; Zhao, Y. Design of temperature compensation system for MEMS gyroscopes based on STM32. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 4th Annual International Workshop on Materials Science and Engineering (IWMSE2018), Xi’an, China, 18–20 May 2018; Volume 381, p. 012139. [Google Scholar]

- Jiang, S.B.; SU, W.G.; Wan, S.; Deng, K.F.; Zhang, W. Study on Temperature Control System Based on a MEMS Heater. J. Peking Univ. (Nat. Sci.) 2019, 43, 94–101. [Google Scholar]

- Chen, J.; Lu, Q.; Bai, J. A Temperature Control Method for Microaccelerometer Chips Based on Genetic Algorithm and Fuzzy PID Control. Micromachines 2021, 12, 1511. [Google Scholar] [CrossRef]

- Lu, T.; Fei, C.; Xuan, L. Intelligent Modeling and Design of a Novel Temperature Control System for a Cantilever-Based Gas-Sensitive Material Analyzer. IEEE Acccess 2021, 9, 21132–21148. [Google Scholar] [CrossRef]

- Chen, G.H.; Li, M.F.; Zhang, J. Application of fuzzy PID improved algorithm in thermogravimetric analysis of furnace temperature control. J. Beijing Jiaotong Univ. 2019, 43, 94–101. [Google Scholar]

- Zhang, S.L.; Ostling, M.; Norstrom, H.; Arnborg, T. On contact resistance measurement using four-terminal Kelvin structures in advanced double-polysilicon bipolar transistor processes. IEEE Trans. Electron Devices 1994, 41, 1414–1420. [Google Scholar] [CrossRef]

| Control Method | Genetic Algorithm-Based Fuzzy PID | Particle Swarm Optimization (PSO)-Based Fuzzy PID | Fuzzy PID Improved Algorithm | Dual Fuzzy PID |

|---|---|---|---|---|

| Temperature control rate (°C/min) | 28 | 20 | 30 | 6000 |

| Control Method | Simulation | Experiment | ||

|---|---|---|---|---|

| tarrival (s) | Eover (‰) | tarrival (s) | Eover (‰) | |

| Traditional PID | 1.0 | 4.53 | 0.9 | 5.35 |

| Fuzzy pid | 0.6 | 5.41 | 0.4 | 6.40 |

| Double-fuzzy PID | 0.6 | 4.17 | 0.5 | 4.86 |

| Temperature Rise at 50 °C | tarrival (s) | Eover (‰) | Power Consumption (mV) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Traditional PID | Fuzzy PID | Double-Fuzzy PID | Traditional PID | Fuzzy PID | Double-Fuzzy PID | Traditional PID | Fuzzy PID | Double-Fuzzy PID | |

| 100 °C | 3.5 | 0.6 | 0.6 | 2.29 | 2.67 | 2.24 | 2.34 | 2.62 | 2.64 |

| 200 °C | 3.2 | 0.4 | 0.5 | 3.55 | 5.50 | 3.15 | 8.19 | 7.86 | 8.70 |

| 300 °C | 1.9 | 0.5 | 0.5 | 3.92 | 4.66 | 3.58 | 11.66 | 13.57 | 13.88 |

| 400 °C | 1.2 | 0.4 | 0.4 | 3.31 | 5.03 | 2.88 | 11.78 | 15.77 | 14.96 |

| 500 °C | 0.9 | 0.4 | 0.5 | 5.35 | 6.40 | 4.86 | 12.80 | 17.39 | 20.14 |

| 600 °C | 0.7 | 0.5 | 0.5 | 5.10 | 6.40 | 4.67 | 13.01 | 22.40 | 21.08 |

| 700 °C | 0.7 | 0.4 | 0.5 | 6.19 | 7.84 | 5.44 | 13.09 | 23.91 | 22.32 |

| 800 °C | 0.8 | 0.5 | 0.5 | 8.17 | 8.85 | 6.06 | 13.70 | 25.96 | 26.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Cao, Z.; Wang, S.; Yao, L.; Yu, H. High-Speed Temperature Control Method for MEMS Thermal Gravimetric Analyzer Based on Dual Fuzzy PID Control. Micromachines 2023, 14, 929. https://doi.org/10.3390/mi14050929

Zhang X, Cao Z, Wang S, Yao L, Yu H. High-Speed Temperature Control Method for MEMS Thermal Gravimetric Analyzer Based on Dual Fuzzy PID Control. Micromachines. 2023; 14(5):929. https://doi.org/10.3390/mi14050929

Chicago/Turabian StyleZhang, Xiaoyang, Zhi Cao, Shanlai Wang, Lei Yao, and Haitao Yu. 2023. "High-Speed Temperature Control Method for MEMS Thermal Gravimetric Analyzer Based on Dual Fuzzy PID Control" Micromachines 14, no. 5: 929. https://doi.org/10.3390/mi14050929

APA StyleZhang, X., Cao, Z., Wang, S., Yao, L., & Yu, H. (2023). High-Speed Temperature Control Method for MEMS Thermal Gravimetric Analyzer Based on Dual Fuzzy PID Control. Micromachines, 14(5), 929. https://doi.org/10.3390/mi14050929