Improvement of AlGaN/GaN HEMTs Linearity Using Etched-Fin Gate Structure for Ka Band Applications

Abstract

1. Introduction

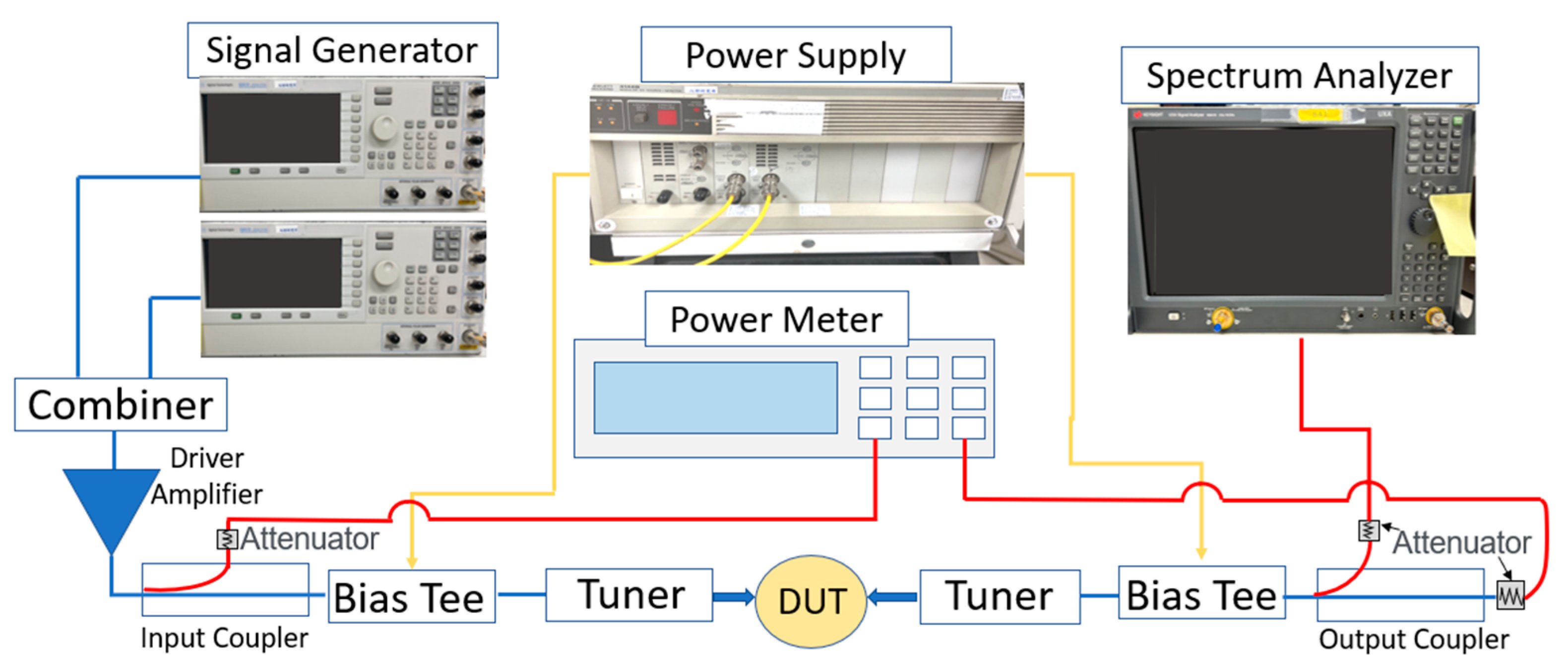

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- del Alamo, J. Nanometre-scale electronics with III–V compound semiconductors. Nature 2011, 479, 317–323. [Google Scholar] [CrossRef] [PubMed]

- del Alamo, J.A. The High-Electron Mobility Transistor at 30: Impressive Accomplishments and Exciting Prospects. In Proceedings of the 2011 International Conference on Compound Semiconductor Manufacturing Technology, Indian Wells, CA, USA, 16–19 May 2011. [Google Scholar]

- Liu, A.-C.; Tu, P.-T.; Langpoklakpam, C.; Huang, Y.-W.; Chang, Y.-T.; Tzou, A.-J.; Hsu, L.-H.; Lin, C.-H.; Kuo, H.-C.; Chang, E.Y. The Evolution of Manufacturing Technology for GaN Electronic Devices. Micromachines 2021, 12, 737. [Google Scholar] [CrossRef] [PubMed]

- O’Hara, J.F.; Ekin, S.; Choi, W.; Song, I. A Perspective on Terahertz Next-Generation Wireless Communications. Technologies 2019, 7, 43. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Yao, J.-N.; Hsu, H.-H.; Wong, Y.-C.; Huang, C.-Y.; Hsu, H.T.; Iwai, H.; Chang, E.Y. Study of the mesa etched tri-gate InAs HEMTs with extremely low SS for low-power logic applications. In Proceedings of the 2018 China Semiconductor Technology International Conference (CSTIC), Shanghai, China, 11–12 March 2018; pp. 1–3. [Google Scholar] [CrossRef]

- Yao, J.-N.; Lin, Y.-C.; Hsu, H.-T.; Yang, K.-C.; Hsu, H.-H.; Sze, S.M.; Chang, E.Y. Evaluation of a 100-nm Gate Length E-Mode InAs High Electron Mobility Transistor With Ti/Pt/Au Ohmic Contacts and Mesa Sidewall Channel Etch for High-Speed and Low-Power Logic Applications. IEEE J. Electron Devices Soc. 2018, 6, 797–802. [Google Scholar] [CrossRef]

- Yeon, S.-J.; Park, M.; Seo, K.-S. Novel sloped etch process for 15 nm InAlAs/InGaAs metamorphic HEMTs. In Proceedings of the 2007 7th IEEE Conference on Nanotechnology (IEEE NANO), Hong Kong, China, 2–5 August 2007; pp. 1152–1155. [Google Scholar] [CrossRef]

- Medjdoub, F.; Zegaoui, M.; Grimbert, B.; Ducatteau, D.; Rolland, N.; Rolland, P.A. First Demonstration of High-Power GaN-on-Silicon Transistors at 40 GHz. IEEE Electron Device Lett. 2012, 33, 1168–1170. [Google Scholar] [CrossRef]

- Palacios, T.; Chakraborty, A.; Rajan, S.; Poblenz, C.; Keller, S.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. High-power AlGaN/GaN HEMTs for Ka-band applications. IEEE Electron Device Lett. 2005, 26, 781–783. [Google Scholar] [CrossRef]

- Lin, Y.C.; Huang, Y.X.; Huang, G.N.; Wu, C.H.; Yao, J.N.; Chu, C.M.; Chang, S.; Hsu, C.C.; Jin, H.L.; Kakushima, K. Enhancement-mode GaN MIS-HEMTs with LaHfOx gate insulator for power application. IEEE Electron Device Lett. 2017, 38, 1101–1104. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Chang, C.-H.; Li, F.-M.; Hsu, L.-H.; Chang, E.Y. Evaluation of TiN/Cu gate metal scheme for AlGaN/GaN high-electron-mobility transistor application. Appl. Phys. Express 2013, 6, 091003. [Google Scholar] [CrossRef]

- Medjdoub, F.; Kabouche, R.; Dogmus, E.; Linge, A.; Zegaoui, M. High Electron Confinement under High Electric Field in RF GaN-on-Silicon HEMTs. Electronics 2016, 5, 12. [Google Scholar] [CrossRef]

- Mishra, U.K.; Shen, L.; Kazior, T.E.; Wu, Y. GaN-Based RF Power Devices and Amplifiers. Proc. IEEE 2008, 96, 287–305. [Google Scholar] [CrossRef]

- Mishra, U.K.; Parikh, P.; Wu, Y.-F. AlGaN/GaN HEMTs—An Overview of Device Operation and Applications. Proc. IEEE 2002, 90, 1022–1031. [Google Scholar] [CrossRef]

- Rüdiger, Q.; Dirk, S.; Erdin, T.; Friedbert, R.; Christian, F.; Sebastian, K.; Müller, S.; Steffen, B.; Birte-Julia, G.; Peter, B. High-power microwave GaN/AlGaN HEMTs and MMICs on SiC and silicon substrates for modern radio communication. Phys. Status Solidi 2018, 215, 1700655. [Google Scholar] [CrossRef]

- Xing, W.; Liu, Z.; Qiu, H.; Ranjan, K.; Gao, Y.; Ng, G.I.; Palacios, T. InAlN/GaN HEMTs on Si With High fT of 250 GHz. IEEE Electron Device Lett. 2018, 39, 75–78. [Google Scholar] [CrossRef]

- Martinez, R.P.; Munzer, D.J.; Zhou, X.Y.; Shankar, B.; Schmidt, E.-M.; Wildnauer, K.; Wu, B.; Murma, B. Best Practices to Quantify Linearity Performance of GaN HEMTs for Power Amplifier Applications. In Proceedings of the 2021 IEEE 8th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Redondo Beach, CA, USA, 7–11 November 2021; pp. 85–89. [Google Scholar] [CrossRef]

- Lin, Y.; Chang, E.Y.; Yamaguchi, H.; Wu, W.; Chang, C. A \delta\delta-Doped InGaP/InGaAs pHEMT With Different Doping Profiles for Device-Linearity Improvement. IEEE Trans. Electron Devices 2007, 54, 1617–1625. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chang, E.Y.; Yamaguchi, H.; Hirayama, Y.; Chang, X.Y.; Chang, C.Y. Device linearity comparison of uniformly doped and /spl delta/-doped In/sub 0.52/Al/sub 0.48/As/In/sub 0.6/Ga/sub 0.4/As metamorphic HEMTs. IEEE Electron Device Lett. 2006, 27, 535–537. [Google Scholar] [CrossRef]

- Wang, H.-C.; Su, H.-F.; Luc, Q.-H.; Lee, C.-T.; Hsu, H.-T.; Chang, E.Y. Improved linearity in AlGaN/GaN HEMTs for millimeter-wave applications by using dual-gate fabrication. ECS J. Solid State Sci. Technol. 2017, 6, 3106–3109. [Google Scholar] [CrossRef]

- Raj, A.; Krishna, A.; Hatui, N.; Romanczyk, B.; Wurm, C.; Guidry, M.; Hamwey, R.; Pakala, N.; Keller, S.; Mishra, U.K. GaN/AlGaN superlattice based E-mode p-channel MES-FinFET with regrown contacts and >50 mA/mm on-current. In Proceedings of the 2021 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA; 2021; pp. 5.4.1–5.4.4. [Google Scholar] [CrossRef]

- Jo, Y.-W.; Son, D.-H.; Won, C.-H.; Im, K.-S.; Seo, J.H.; Kang, I.M.; Lee, J.-H. AlGaN/GaN FinFET With Extremely Broad Transconductance by Side-Wall Wet Etch. IEEE Electron Device Lett. 2015, 36, 1008–1010. [Google Scholar] [CrossRef]

- Zhang, K.; Kong, Y.; Zhu, G.; Zhou, J.; Yu, X.; Kong, C.; Li, Z.; Chen, T. High-Linearity AlGaN/GaN FinFETs for Microwave Power Applications. IEEE Electron Device Lett. 2017, 38, 615–618. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, J.; Sun, R.; Wang, F.; Yao, Y. Numerical investigation on AlGaN/GaN short channel HEMT with AlGaN/InGaN/AlGaN quantum well plate. Superlattices Microstruct. 2018, 120, 753–758. [Google Scholar] [CrossRef]

- Jessen, G.H.; Fitch, R.C.; Gillespie, J.K.; Via, G.; Crespo, A.; Langley, D.; Denninghoff, D.J.; Trejo, M. Short-Channel Effect Limitations on High-Frequency Operation of AlGaN/GaN HEMTs for T-Gate Devices. IEEE Trans. Electron Devices 2007, 54, 2589–2597. [Google Scholar] [CrossRef]

- Yeh, W.-K.; Zhang, W.; Chen, P.-Y.; Yang, Y.-L. The Impact of Fin Number on Device Performance and Reliability for Multi-Fin Tri-Gate n- and p-Type FinFET. IEEE Trans. Device Mater. Reliab. 2018, 18, 555–560. [Google Scholar] [CrossRef]

- Kim, D.-H.; del Alamo, J.A. 30-nm InAs Pseudomorphic HEMTs on an InP Substrate With a Current-Gain Cutoff Frequency of 628 GHz. IEEE Electron Device Lett. 2008, 29, 830–833. [Google Scholar] [CrossRef]

- Chiu, H.-C.; Yang, S.-C.; Chien, F.-T.; Chan, Y.-J. Improved device linearity of AlGaAs/InGaAs HFETs by a second mesa etching. IEEE Electron Device Lett. 2002, 23, 1–3. [Google Scholar] [CrossRef]

- Bailey, M.J. Intermodulation distortion in pseudomorphic HEMTs and an extension of the classical theory. IEEE Trans. Microw. Theory Tech. 2000, 48, 104–110. [Google Scholar] [CrossRef]

- Nagahara, M.; Kikkawa, T.; Adachi, N.; Tateno, Y.; Kato, S.; Yokoyama, M.; Yokogawa, S.; Kimura, T.; Yamaguchi, Y.; Hara, N.; et al. Improved intermodulation distortion profile of AlGaN/GaN HEMT at high drain bias voltage. In Proceedings of the Digest. International Electron Devices Meeting, San Francisco, CA, USA, 8–11 December 2002; pp. 693–696. [Google Scholar] [CrossRef]

| Planar | 1-Etched-Fin | 4-Etched-Fin | 9-Etched-Fin | |

|---|---|---|---|---|

| IDSS (IDS at VGS = 0 V, mA/mm) | 839 | 830 | 822 | 803 |

| Gm, max (mS/mm) | 247 | 261 | 279 | 264 |

| Threshold Voltage (V) | −4.3 | −4.29 | −4.20 | −4.05 |

| IDS-VGS polynomial 1st-order coefficient (a1) | −0.12585 | 0.80071 | 1.06891 | 0.36060 |

| IDS-VGS polynomial 3rd-order coefficient (a3) | −0.07354 | 0.19897 | 0.25904 | 0.06249 |

| a3/a1 | 0.58435 | 0.24849 | 0.24234 | 0.17329 |

| IDS-VGS polynomial 5th-order coefficient (a5) | −0.00137 | 0.00226 | 0.00285 | 0.00023 |

| a5/a1 | 0.01089 | 0.00282 | 0.00267 | 0.00064 |

| Device Type (4 × 50 μm) | DC Bias Point: VDS = 20 V, Operation Frequency: 30 GHz | ||||||

|---|---|---|---|---|---|---|---|

| RF Bias | IDS (mA) | PIMD3 Level at 16 dB Back-Off from P1dB (dBm) | OIP3 (dBm) | P1dB (dBm) | Δ(OIP3-P1dB) (dB) | Gain (dB) | |

| Planar | 0.5 IDSS | 83.90 | −54.82 | 33.97 | 24.73 | 9.24 | 7.38 |

| 1-Etched-Fin | 83.00 | −56.21 | 34.97 | 24.13 | 10.84 | 7.88 | |

| 4-Etched-Fin | 82.20 | −56.72 | 35.72 | 24.46 | 11.26 | 8.12 | |

| 9-Etched-Fin | 80.30 | −55.00 | 33.50 | 23.74 | 9.76 | 7.79 | |

| Planar | 0.375 IDSS | 62.93 | −55.49 | 34.73 | 24.13 | 10.60 | 7.49 |

| 1-Etched-Fin | 62.25 | −56.27 | 35.24 | 23.72 | 11.52 | 7.84 | |

| 4-Etched-Fin | 61.65 | −57.30 | 36.43 | 23.54 | 12.89 | 8.38 | |

| 9-Etched-Fin | 60.23 | −56.86 | 35.42 | 23.56 | 11.86 | 8.25 | |

| Planar | 0.25 IDSS | 41.95 | −52.36 | 28.29 | 21.56 | 6.73 | 7.54 |

| 1-Etched-Fin | 41.50 | −58.17 | 32.00 | 21.43 | 10.57 | 8.08 | |

| 4-Etched-Fin | 41.10 | −59.54 | 32.67 | 21.45 | 11.22 | 8.28 | |

| 9-Etched-Fin | 40.15 | −56.77 | 30.62 | 21.02 | 9.60 | 7.67 | |

| Planar | 0.125 IDSS | 20.98 | −54.73 | 29.45 | 18.36 | 11.09 | 7.39 |

| 1-Etched-Fin | 20.75 | −53.15 | 30.14 | 19.24 | 10.90 | 7.63 | |

| 4-Etched-Fin | 20.55 | −54.11 | 29.74 | 18.76 | 10.98 | 7.84 | |

| 9-Etched-Fin | 20.08 | −50.83 | 26.42 | 18.46 | 7.96 | 7.00 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.-W.; Lin, Y.-C.; Hsu, H.-T.; Gamiz, F.; Chang, E.-Y. Improvement of AlGaN/GaN HEMTs Linearity Using Etched-Fin Gate Structure for Ka Band Applications. Micromachines 2023, 14, 931. https://doi.org/10.3390/mi14050931

Lee M-W, Lin Y-C, Hsu H-T, Gamiz F, Chang E-Y. Improvement of AlGaN/GaN HEMTs Linearity Using Etched-Fin Gate Structure for Ka Band Applications. Micromachines. 2023; 14(5):931. https://doi.org/10.3390/mi14050931

Chicago/Turabian StyleLee, Ming-Wen, Yueh-Chin Lin, Heng-Tung Hsu, Francisco Gamiz, and Edward-Yi Chang. 2023. "Improvement of AlGaN/GaN HEMTs Linearity Using Etched-Fin Gate Structure for Ka Band Applications" Micromachines 14, no. 5: 931. https://doi.org/10.3390/mi14050931

APA StyleLee, M.-W., Lin, Y.-C., Hsu, H.-T., Gamiz, F., & Chang, E.-Y. (2023). Improvement of AlGaN/GaN HEMTs Linearity Using Etched-Fin Gate Structure for Ka Band Applications. Micromachines, 14(5), 931. https://doi.org/10.3390/mi14050931