In Situ H-Radical Surface Treatment on Aluminum Gallium Nitride for High-Performance Aluminum Gallium Nitride/Gallium Nitride MIS-HEMTs Fabrication

Abstract

1. Introduction

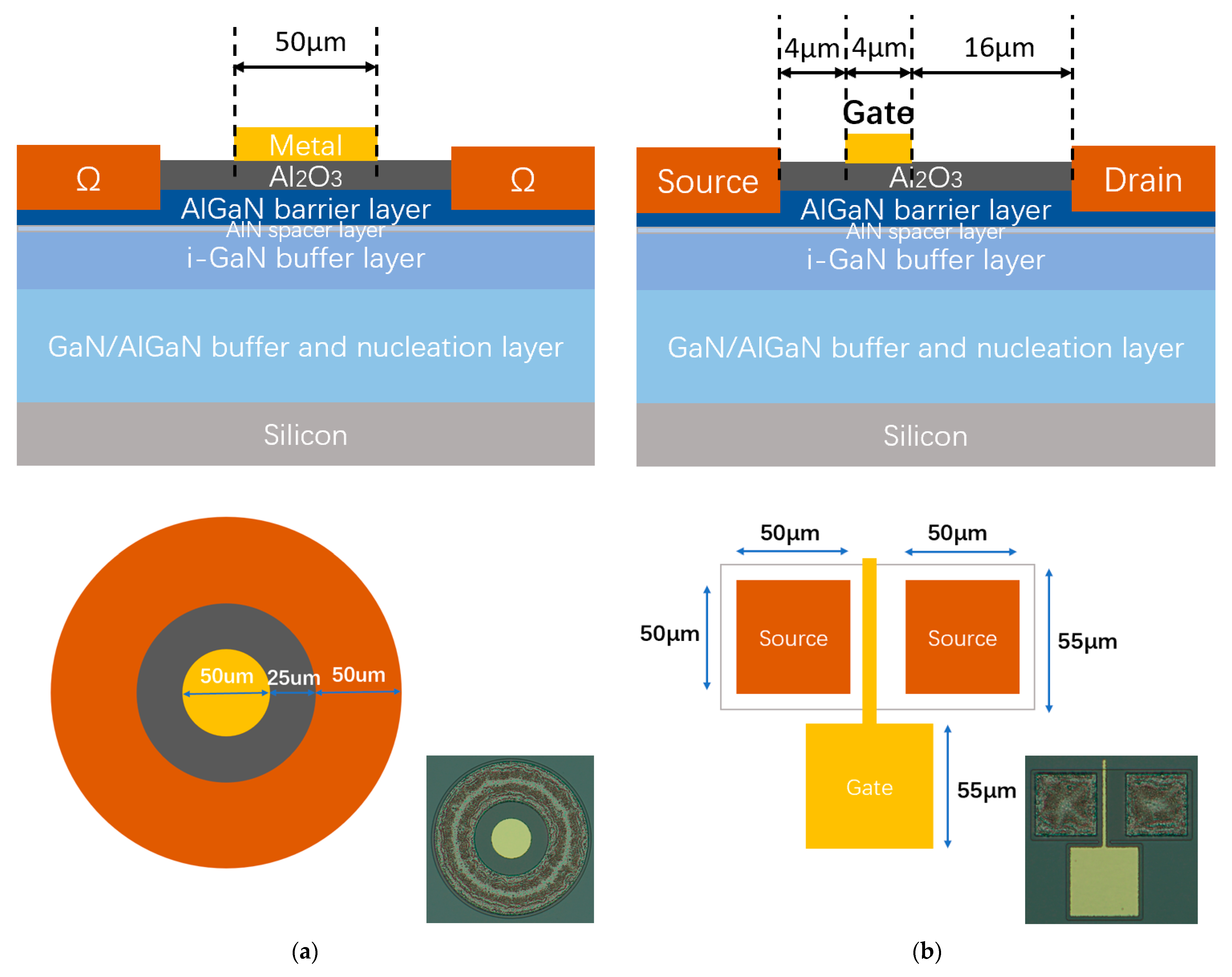

2. Device Characterization

3. Results and Analysis

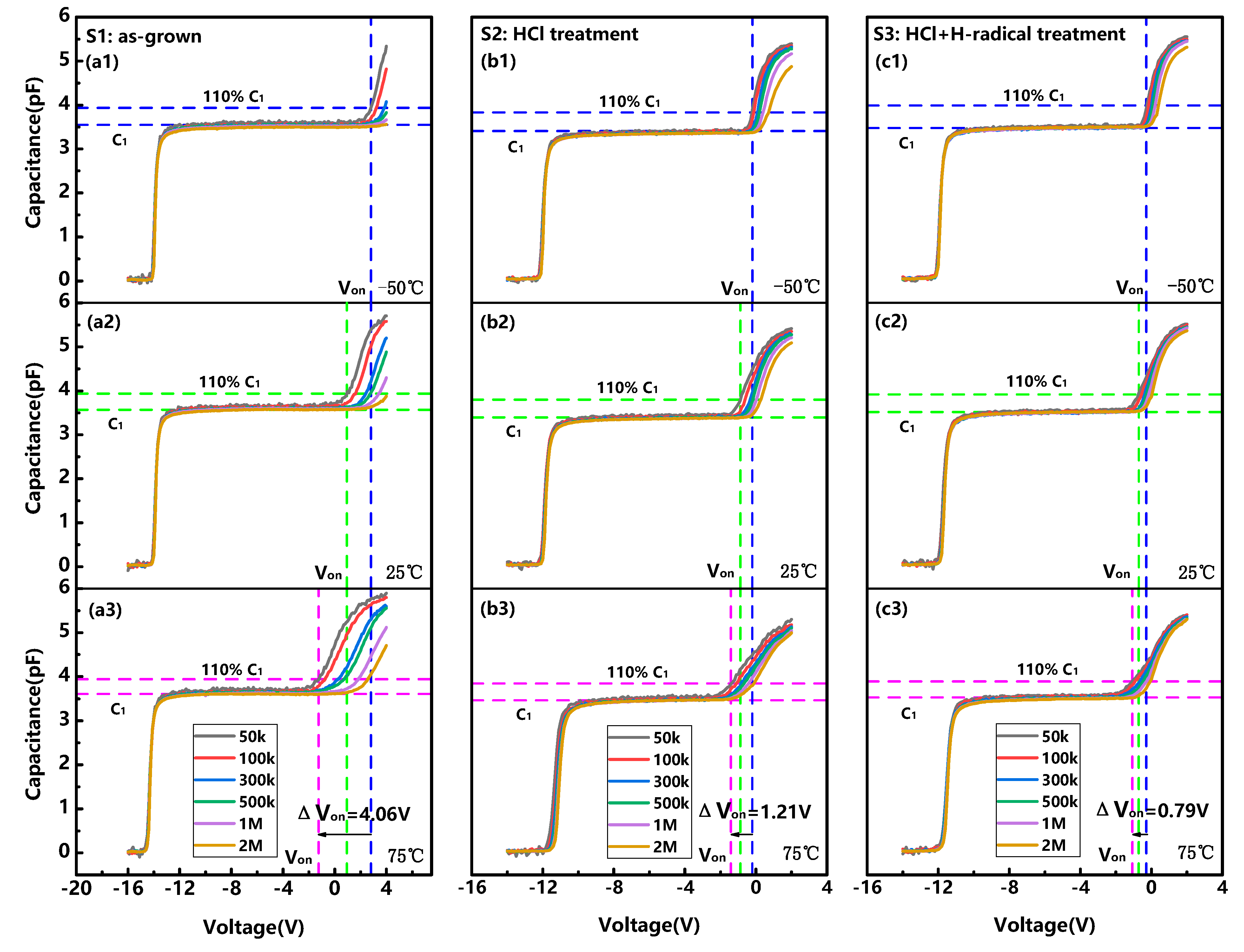

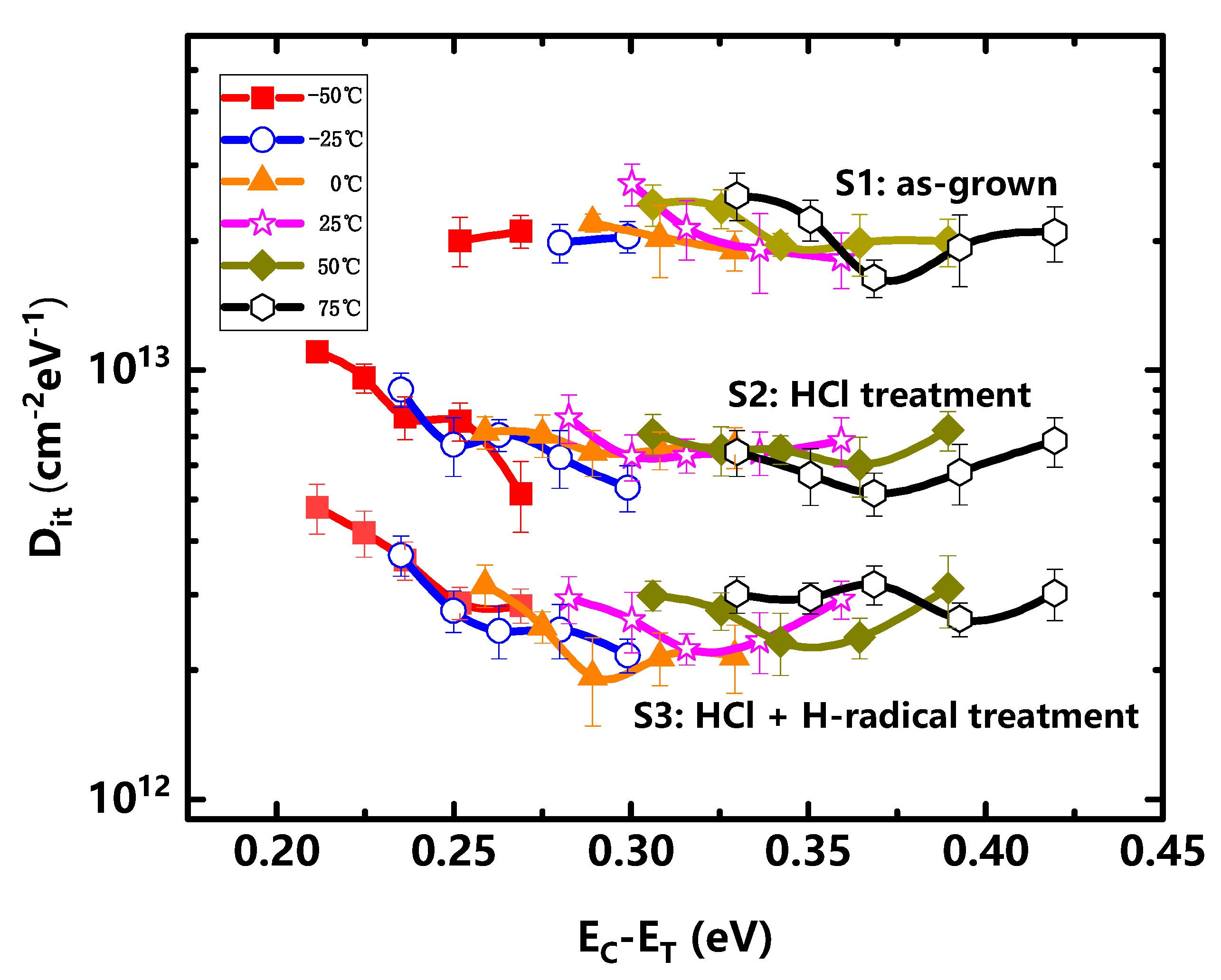

3.1. Capacitance–Voltage Characteristics

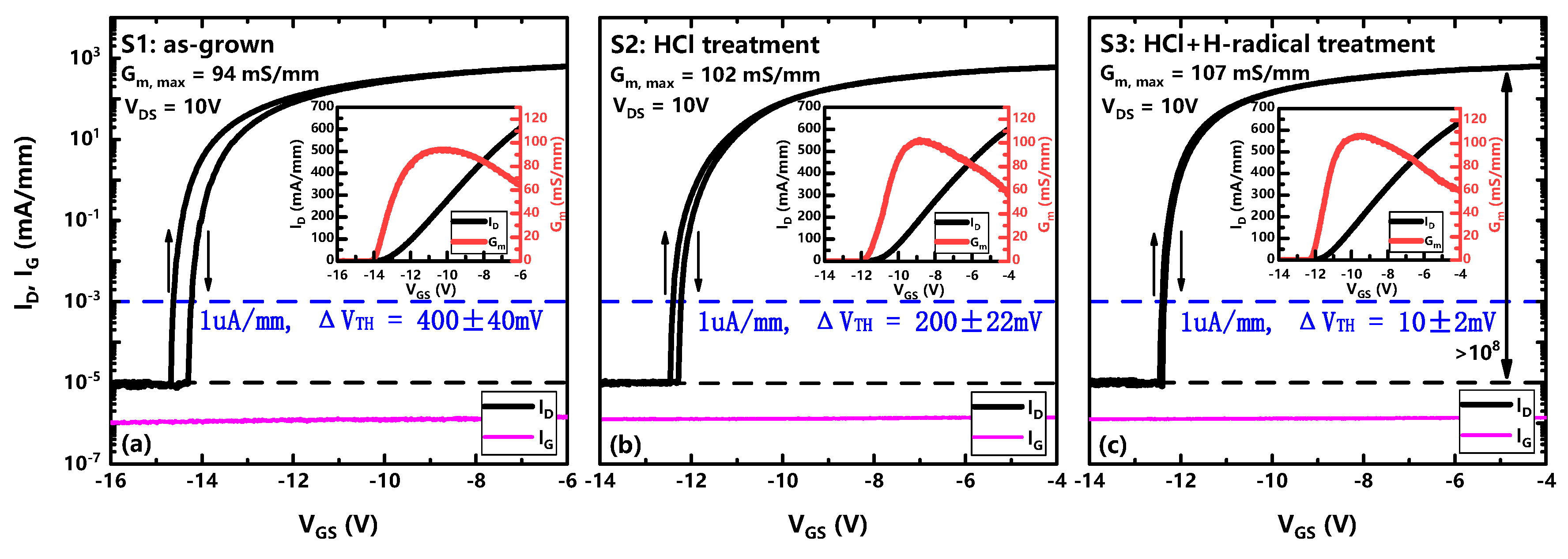

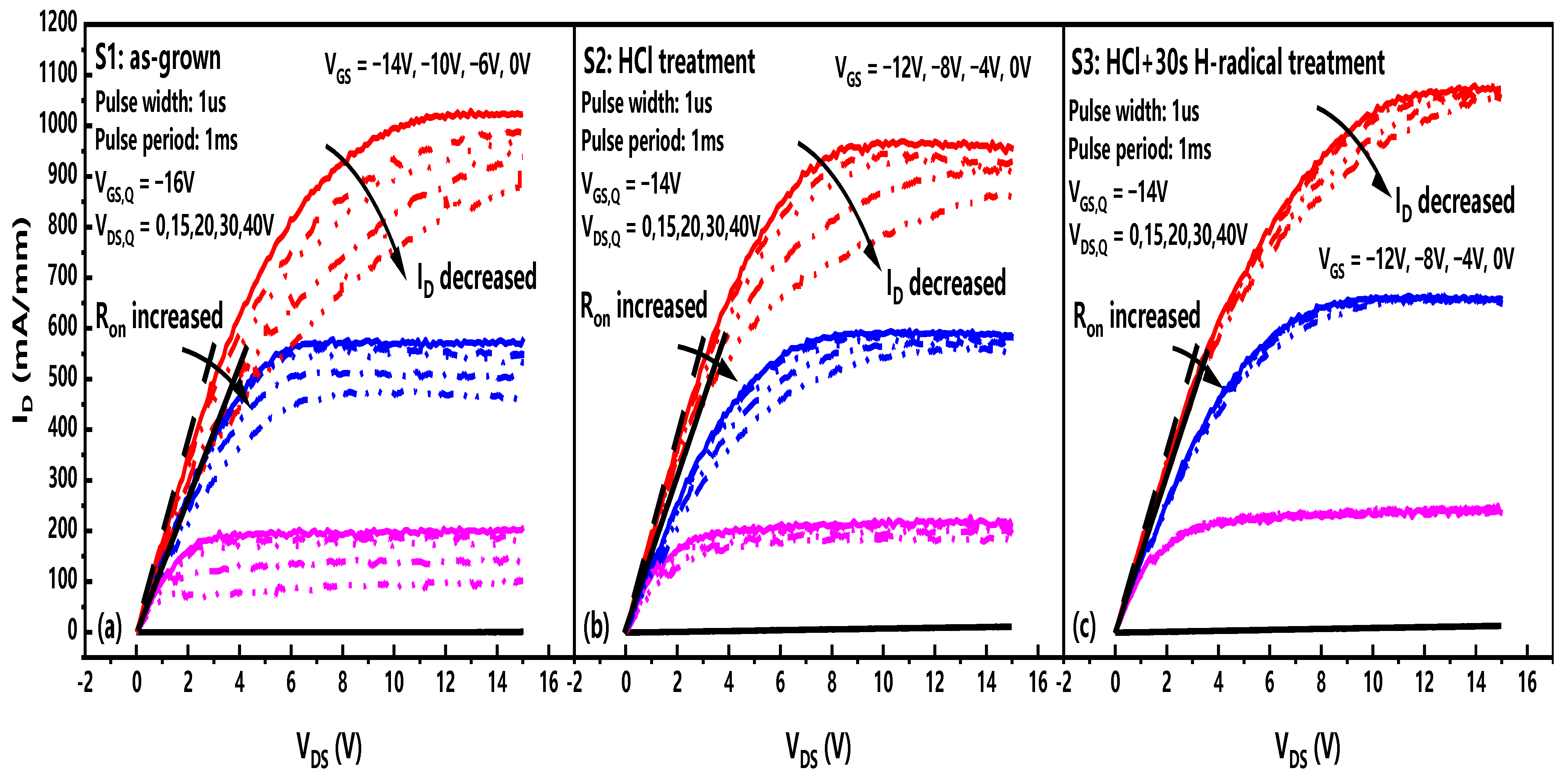

3.2. MIS-HEMT Devices Characteristics

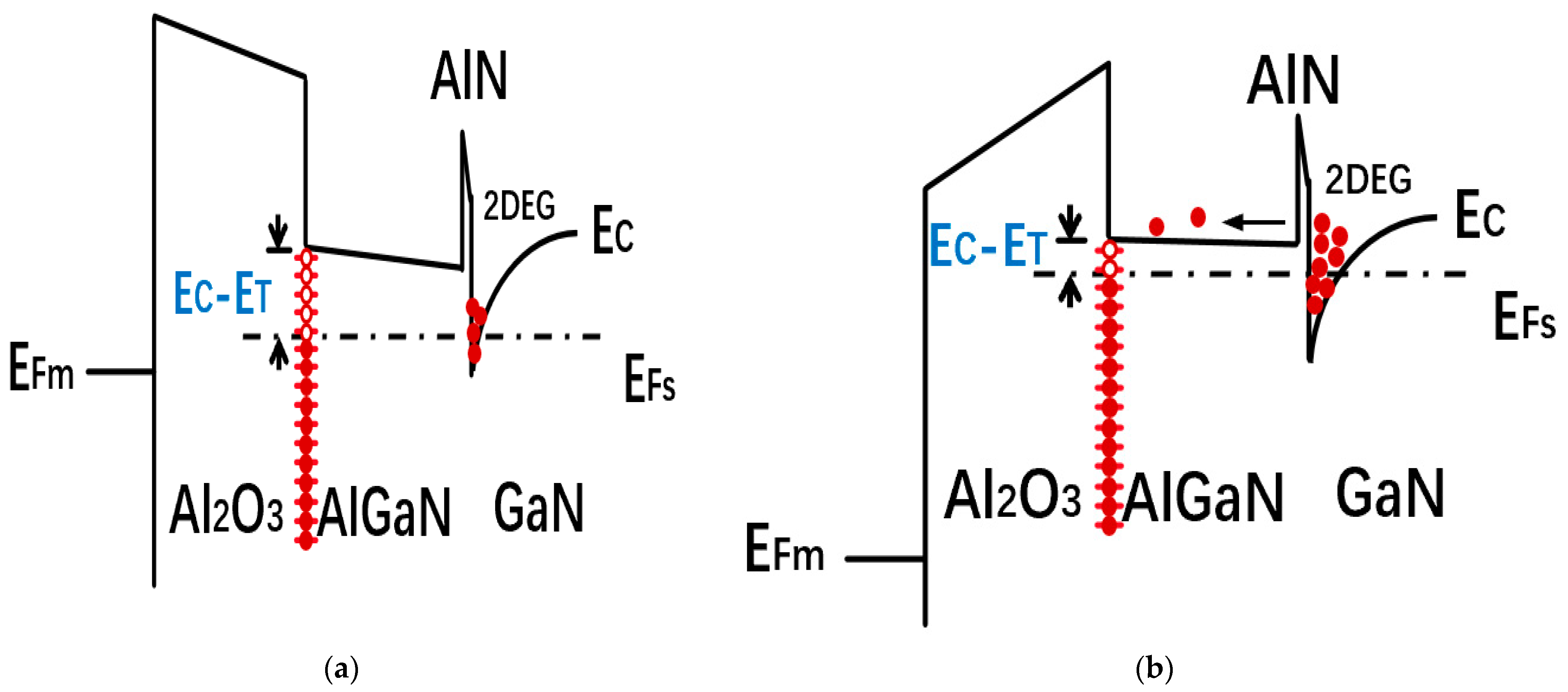

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Treu, M.; Vecino, E.; Pippan, M.; Häberlen, O.; Curatola, G.; Deboy, G.; Kutschak, M.; Kirchner, U. The role of silicon, silicon carbide and gallium nitride in power electronics. In Proceedings of the 2012 International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 10–13 December 2012; pp. 7.1.1–7.1.4. [Google Scholar] [CrossRef]

- Deboy, G.; Treu, M.; Haeberlen, O.; Neumayr, D. Si, SiC and GaN power devices: An unbiased view on key performance indicators. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; pp. 20.2.1–20.2.4. [Google Scholar] [CrossRef]

- Chen, K.J.; Häberlen, O.; Lidow, A.; Tsai, C.I.; Ueda, T.; Uemoto, Y.; Wu, Y. GaN-on-Si Power Technology: Devices and Applications. IEEE Trans. Electron Devices 2017, 64, 779–795. [Google Scholar] [CrossRef]

- Zeng, F.; An, J.X.; Zhou, G.; Li, W.; Wang, H.; Duan, T.; Jiang, L.; Yu, H. A Comprehensive Review of Recent Progress on GaN High Electron Mobility Transistors: Devices, Fabrication and Reliability. Electronics 2018, 7, 377. [Google Scholar] [CrossRef]

- Hsu, L.-H.; Lai, Y.-Y.; Tu, P.-T.; Langpoklakpam, C.; Chang, Y.-T.; Huang, Y.-W.; Lee, W.-C.; Tzou, A.-J.; Cheng, Y.-J.; Lin, C.-H.; et al. Development of GaN HEMTs Fabricated on Silicon, Silicon-on-Insulator, and Engineered Substrates and the Heterogeneous Integration. Micromachines 2021, 12, 1159. [Google Scholar] [CrossRef] [PubMed]

- Modolo, N.; De Santi, C.; Minetto, A.; Sayadi, L.; Sicre, S.; Prechtl, G.; Meneghesso, G.; Zanoni, E.; Meneghini, M. A Physics-Based Approach to Model Hot-Electron Trapping Kinetics in p-GaN HEMTs. IEEE Electron Device Lett. 2021, 42, 673–676. [Google Scholar] [CrossRef]

- Uren, M.J.; Karboyan, S.; Chatterjee, I.; Pooth, A.; Moens, P.; Banerjee, A.; Kuball, M. “Leaky Dielectric” Model for the Suppression of Dynamic Ron in Carbon-Doped AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2017, 64, 2826–2834. [Google Scholar] [CrossRef]

- Kaneko, S.; Kuroda, M.; Yanagihara, M.; Ikoshi, A.; Okita, H.; Morita, T.; Tanaka, K.; Hikita, M.; Uemoto, Y.; Takahashi, S.; et al. Current-collapse-free operations up to 850 V by GaN-GIT utilizing hole injection from drain. In Proceedings of the 2015 IEEE 27th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Hong Kong, China, 10–14 May 2015; pp. 41–44. [Google Scholar] [CrossRef]

- Li, S.; Yang, S.; Han, S.; Sheng, K. Investigation of Temperature-Dependent Dynamic RON of GaN HEMT with Hybrid-Drain under Hard and Soft Switching. In Proceedings of the 2020 32nd International Symposium on Power Semiconductor Devices and ICs (ISPSD), Vienna, Austria, 13–18 September 2020; pp. 306–309. [Google Scholar] [CrossRef]

- Li, S.; Ma, Y.; Zhang, C.; Lu, W.; Liu, M.; Li, M.; Yang, L.; Liu, S.; Wei, J.; Zhang, L.; et al. Physics-Based SPICE Modeling of Dynamic on-State Resistance of p-GaN HEMTs. IEEE Trans. Power Electron. 2023, 38, 7988–7992. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, S.; Xia, L.; Wu, W.; Jin, Y. Study on the Dynamic Ron Degradation in GaN-based Power HEMT. In Proceedings of the 2022 IEEE 5th International Conference on Electronics Technology (ICET), Chengdu, China, 13–16 May 2022; pp. 169–172. [Google Scholar] [CrossRef]

- Würfl, J.; Hilt, O.; Bahat-Treidel, E.; Zhytnytska, R.; Kotara, P.; Brunner, F.; Krueger, O.; Weyers, M. Techniques towards GaN power transistors with improved high voltage dynamic switching properties. In Proceedings of the 2013 IEEE International Electron Devices Meeting, Washington, DC, USA, 9–11 December 2013; pp. 6.1.1–6.1.4. [Google Scholar] [CrossRef]

- Mir, M.A.; Joshi, V.; Chaudhuri, R.R.; Munshi, M.A.; Malik, R.R.; Shrivastava, M. Dynamic Interplay of Surface and Buffer Traps in Determining Drain Current Injection induced Device Instability in OFF-state of AlGaN/GaN HEMTs. In Proceedings of the 2023 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 26–30 March 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Qian, T.; Jin, W.; Bin, Z.; Xin, W.; Meng, L.; Qi, C.; Weng, W.; Xiao, M. Investigation on mechanisms of current saturation in gateless AlGaN/GaN heterostructure device. Jpn. J. Appl. Phys. 2021, 60, 020908. [Google Scholar] [CrossRef]

- Ling, Y.; Meng, Z.; Bin, H.; Min, M.; Mei, W.; Qing, Z.; Jie, Z.; Yang, L.; Li, C.; Xiao, Z.; et al. High Channel Conductivity, Breakdown Field Strength, and Low Current Collapse in AlGaN/GaN/Si δ -Doped AlGaN/GaN:C HEMTs. IEEE Trans. Electron Devices 2019, 66, 1202–1207. [Google Scholar] [CrossRef]

- Sun, H.; Lin, W.; Yin, R.; Chen, J.; Hao, Y.; Shen, B.; Wang, M.; Jin, Y. Evaluation of the border traps in LPCVD Si3N4/GaN/AlGaN/GaN MIS structure with long time constant using quasi-static capacitance voltage method. Jpn. J. Appl. Phys. 2022, 61, 076502. [Google Scholar] [CrossRef]

- Liu, S.; Yang, S.; Tang, Z.; Jiang, Q.; Liu, C.; Wang, M.; Shen, B.; Chen, K.J. Interface/border trap characterization of Al2O3/AlN/GaN metal-oxide-semiconductor structures with an AlN interfacial layer. Appl. Phys. Lett. 2015, 106, 051605. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, W.; Cui, M.; Sun, R.; Liang, Y.C.; Wen, H.; Yang, L.; Supardan, S.N.; Mitrovic, I.Z.; Taylor, S.; et al. Effect of surface treatment on electrical properties of GaN metal–insulator–semiconductor devices with Al2O3 gate dielectric. Jpn. J. Appl. Phys. 2020, 59, 041001. [Google Scholar] [CrossRef]

- Mishra, K.; Laubach, S.; Johnson, K. Localization of oxygen donor states in gallium nitride from first-principles calculations. Phys. Rev. B 2007, 76, 035127. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Huang, S.; Yin, H.; Fan, J.; Wei, K.; Zheng, Y.; Wang, W.; Jiang, H.; Wu, X.; et al. Partially Crystallized Ultrathin Interfaces between GaN and SiNx Grown by Low-Pressure Chemical Vapor Deposition and Interface Editing. ACS Appl. Mater. Interfaces 2021, 13, 7725–7734. [Google Scholar] [CrossRef]

- Huang, S.; Jiang, Q.; Yang, S.; Zhou, C.; Chen, K.J. Effective Passivation of AlGaN/GaN HEMTs by ALD-Grown AlN Thin Film. IEEE Electron Device Lett. 2012, 33, 516–518. [Google Scholar] [CrossRef]

- Vauche, L.; Chanuel, A.; Martinez, E.; Roure, M.-C.; Le Royer, C.; Bécu, S.; Gwoziecki, R.; Plissonnier, M. Study of an Al2O3/GaN Interface for Normally Off MOS-Channel High-Electron-Mobility Transistors Using XPS Characterization: The Impact of Wet Surface Treatment on Threshold Voltage VTH. ACS Appl. Electron. Mater. 2021, 3, 1170–1177. [Google Scholar] [CrossRef]

- Miyazaki, E.; Kishimoto, S.; Mizutani, T. Improvement of the Interface Quality of the Al2O3/III-Nitride Interface by (NH4)2S Surface Treatment for AlGaN/GaN MOSHFETs. IEICE Trans. Electron. 2012, 95, 1337–1342. [Google Scholar] [CrossRef]

- Romero, M.F.; Jiménez, A.; González-Posada, F.; Martín-Horcajo, S.; Calle, F.; Muñoz, E. Impact of N2 Plasma Power Discharge on AlGaN/GaN HEMT Performance. IEEE Trans. Electron Devices 2012, 59, 374–379. [Google Scholar] [CrossRef]

- Shin, S.; Higurashi, E.; Furuyama, K.; Suga, T. Hydrogen radical treatment for surface oxide removal from copper. In Proceedings of the 2017 5th International Workshop on Low Temperature Bonding for 3D Integration (LTB-3D), Tokyo, Japan, 16–18 May 2017; p. 72. [Google Scholar] [CrossRef]

- Furuyama, K.; Yamanaka, K.; Higurashi, E.; Suga, T. Hydrogen radical treatment for indium surface oxide removal and re-oxidation behaviour. In Proceedings of the 2017 5th International Workshop on Low Temperature Bonding for 3D Integration (LTB-3D), Tokyo, Japan, 16–18 May 2017; p. 65. [Google Scholar] [CrossRef]

- Yeom, M.J.; Yang, J.Y.; Lee, C.H.; Heo, J.; Chung, R.B.K.; Yoo, G. Low Subthreshold Slope AlGaN/GaN MOS-HEMT with Spike-Annealed HfO2 Gate Dielectric. Micromachines 2021, 12, 1441. [Google Scholar] [CrossRef]

- Horikawa, K.; Okubo, S.; Kawarada, H.; Hiraiwa, A. Postdeposition annealing effect on the reliability of atomic-layer-deposited Al2O3 films on GaN. J. Vac. Sci. Technol. B 2020, 38, 062207. [Google Scholar] [CrossRef]

- Liad, T.; Enrico, B.; Eldad, T.; Bahat, T.; Frank, B.; Nicole, B.; Sofie, V.; Christophe, D.; Joachim, W.; Oliver, H. Effects of post metallization annealing on Al2O3 atomic layer deposition on n-GaN. Semicond. Sci. Technol. 2022, 38, 015006. [Google Scholar] [CrossRef]

- Capriotti, M.; Lagger, P.; Fleury, C.; Oposich, M.; Bethge, O.; Ostermaier, C.; Strasser, G.; Pogany, D. Modeling small-signal response of GaN-based metal-insulator-semiconductor high electron mobility transistor gate stack in spill-over regime: Effect of barrier resistance and interface states. J. Appl. Phys. 2015, 117, 024506. [Google Scholar] [CrossRef]

- Yang, S.; Liu, S.; Lu, Y.; Liu, C.; Chen, K.J. AC-Capacitance Techniques for Interface Trap Analysis in GaN-Based Buried-Channel MIS-HEMTs. IEEE Trans. Electron Devices 2015, 62, 1870–1878. [Google Scholar] [CrossRef]

- Ramanan, N.; Lee, B.; Misra, V. Comparison of Methods for Accurate Characterization of Interface Traps in GaN MOS-HFET Devices. IEEE Trans. Electron Devices 2015, 62, 546–553. [Google Scholar] [CrossRef]

- Deng, K.; Wang, X.; Huang, S.; Yin, H.; Liu, X. Suppression and characterization of interface states at low-pressure-chemical-vapor-deposited sin /iii-nitride heterostructures. Appl. Surf. Sci. 2021, 542, 148530. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, J.; Guo, J.; Cheng, K.; Mi, M.; Qin, L.; Liu, J.; Jia, F.; Lu, H.; Ma, X.; et al. Improved Breakdown Voltage and Low Damage E-Mode Operation of AlON/AlN/GaN HEMTs Using Plasma Oxidation Treatment. IEEE Electron Device Lett. 2022, 43, 1621–1624. [Google Scholar] [CrossRef]

- Alghamdi, S.; Si, M.; Bae, H.; Zhou, H.; Ye, P.D. Single Pulse Charge Pumping Measurements on GaN MOS-HEMTs: Fast and Reliable Extraction of Interface Traps Density. IEEE Trans. Electron Devices 2020, 67, 444–448. [Google Scholar] [CrossRef]

- Matys, M.; Stoklas, R.; Blaho, M.; Adamowicz, B. Origin of positive fixed charge at insulator/AlGaN interfaces and its control by AlGaN composition. Appl. Phys. Lett. 2017, 110, 243505. [Google Scholar] [CrossRef]

- Strand, J.; Oliver, A.D.; Kaviani, M.; Alexander, L.S. Hole trapping in amorphous HfO2 and Al2O3 as a source of positive charging. Microelectron. Eng. 2017, 178, 235–239. [Google Scholar] [CrossRef]

- Yang, W.; Yuan, J.-S.; Krishnan, B.; Shea, P. Characterization of Deep and Shallow Traps in GaN HEMT Using Multi-Frequency C-V Measurement and Pulse-Mode Voltage Stress. IEEE Trans. Device Mater. Reliab. 2019, 19, 350–357. [Google Scholar] [CrossRef]

- Zhang, J.; He, L.; Li, L.; Ni, Y.; Que, T.; Liu, Z.; Wang, W.; Zheng, J.; Huang, Y.; Chen, J.; et al. High-Mobility Normally OFF Al2O3/AlGaN/GaN MISFET with Damage-Free Recessed-Gate Structure. IEEE Electron Device Lett. 2018, 39, 1720–1723. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, J.; Wang, X.; Wang, C.; Huang, C.; He, J.; Wang, M.; Mo, J.; Hu, Y.; Wu, W. Improved Performance of Fully-Recessed High-Threshold-Voltage GaN MIS-HEMT With in Situ H₂/N₂ Plasma Pretreatment. IEEE Electron Device Lett. 2022, 43, 1021–1024. [Google Scholar] [CrossRef]

- Lin, S.; Wang, M.; Xie, B.; Wen, C.P.; Yu, M.; Wang, J.; Hao, Y.; Wu, W.; Huang, S.; Chen, K.J.; et al. Reduction of Current Collapse in GaN High-Electron Mobility Transistors Using a Repeated Ozone Oxidation and Wet Surface Treatment. IEEE Electron Device Lett. 2015, 36, 757–759. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, G.; Zhang, X.; Deng, X.; Li, S.; Fan, Y.; Sun, S.; Song, L.; Tan, S.; Wu, D.; et al. Studies on High-Voltage GaN-on-Si MIS-HEMTs Using LPCVD Si3N4 as Gate Dielectric and Passivation Layer. IEEE Trans. Electron Devices 2016, 63, 731–738. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Fan, R.; Zhang, P.; Wang, L.; Pan, M.; Wang, Q.; Xie, X.; Xu, S.; Wang, C.; Wu, C.; et al. In Situ H-Radical Surface Treatment on Aluminum Gallium Nitride for High-Performance Aluminum Gallium Nitride/Gallium Nitride MIS-HEMTs Fabrication. Micromachines 2023, 14, 1278. https://doi.org/10.3390/mi14071278

Yang Y, Fan R, Zhang P, Wang L, Pan M, Wang Q, Xie X, Xu S, Wang C, Wu C, et al. In Situ H-Radical Surface Treatment on Aluminum Gallium Nitride for High-Performance Aluminum Gallium Nitride/Gallium Nitride MIS-HEMTs Fabrication. Micromachines. 2023; 14(7):1278. https://doi.org/10.3390/mi14071278

Chicago/Turabian StyleYang, Yannan, Rong Fan, Penghao Zhang, Luyu Wang, Maolin Pan, Qiang Wang, Xinling Xie, Saisheng Xu, Chen Wang, Chunlei Wu, and et al. 2023. "In Situ H-Radical Surface Treatment on Aluminum Gallium Nitride for High-Performance Aluminum Gallium Nitride/Gallium Nitride MIS-HEMTs Fabrication" Micromachines 14, no. 7: 1278. https://doi.org/10.3390/mi14071278

APA StyleYang, Y., Fan, R., Zhang, P., Wang, L., Pan, M., Wang, Q., Xie, X., Xu, S., Wang, C., Wu, C., Xu, M., Jin, J., & Zhang, D. W. (2023). In Situ H-Radical Surface Treatment on Aluminum Gallium Nitride for High-Performance Aluminum Gallium Nitride/Gallium Nitride MIS-HEMTs Fabrication. Micromachines, 14(7), 1278. https://doi.org/10.3390/mi14071278