1. Introduction

SiCp/Al composites made by mechanical stirring and other methods can have the characteristics of high plasticity for metals and high brittleness for ceramics. SiCp/Al composite is widely used in aerospace, electronic packaging, high-speed rail, microwaves and other fields because of its low density, light weight, high specific strength, small thermal expansion coefficient, and other excellent characteristics [

1,

2,

3]. However, SiC particles with high hardness and wear resistance are mixed in SiCp/Al composites, which seriously affects the service life of traditional machining tools and the surface quality of the workpiece. Therefore, non−traditional machining is considered to be one of the most effective machining methods for machining SiCp/Al composites [

4,

5]. Because EDM erodes materials through the electrothermal effect formed between two electrodes, it has no substantial cutting force and avoids the disadvantages of traditional tool machining, so EDM is considered to be an ideal method for machining SiCp/Al composites [

6,

7]. In the process of EDM, with the increase in machining depth, it is difficult for the debris to be thrown into the machining fluid; a large amount of debris becomes stacked at the bottom of the pit, which makes the inter-electrode discharge state unstable and the machining difficult. Therefore, the removal rate of materials becomes a key factor for machining.

Many domestic and foreign scholars achieve have improved the power supply for EDM. Chen et al. designed a micro-generator with multiple micro-resistance capacitors, which can generate high peak current and a short pulse, and greatly improve the material removal rate compared with a single RC circuit [

8]. Chung et al. have conducted in-depth research on capacitive pulse power supplies to improve their energy utilization and reduce energy consumption. In the main circuit, an inductor is used instead of a current-limiting resistor, allowing excess energy to be returned to the power supply, greatly reducing energy loss. Additionally, the capacitor voltage can be adjusted by controlling the open-circuit voltage of the power supply to control its charging and discharging time [

9]. Odulio et al. have developed an energy-saving pulse power supply for flyback EDM, in which the flyback transformer will act as a clamp winding when the load is an open circuit. When the reflected voltage at this clamp winding exceeds the input voltage, diodes D1 and D3 will conduct and will have a regenerative action that returns energy to the source [

10]. Wang et al. proposed a high-frequency pulse power supply with switch controlled capacitor. The total energy charged into the discharge capacitor is controlled by the turn-on time of the switch at the primary side of the flyback converter. All discharge capacitors are charged to the same open-circuit voltage together. The switch connected in series with the discharge capacitor is turned on in high-frequency order, so that the discharge capacitor acts on the gap in turn to generate high-frequency discharge. It is characterized by low power loss, uniform discharge energy, and high discharge frequency [

11]. Wu et al. proposed a pulse power supply based on a pulse generator, which uses a multi intersection stagger buck converter as the main circuit and uses high output voltage circuit to conduct gap breakdown. The multi-interleaving stagger buck converter controls the discharge current waveform to follow the given reference through high-frequency conversion mode operation and uses interleaving control technology to offset the discharge current ripple to a lower value. A high switching frequency is used in rough machining and a small discharge pulse is used in fine machining [

12]. Yang et al. proposed a new bipolar pulse power supply, which uses advanced power electronics technology and has the characteristics of controllable discharge energy in micro EDM. It is possible to achieve a fixed discharge frequency with constant energy consumption in each discharge cycle, which improves processing efficiency [

13].

Proper process parameters can significantly improve the efficiency of EDM, which has been studied by scholars at home and abroad. Tajdeen et al. predicted the influence of response parameters such as peak current, pulse width, and gap voltage on material removal rate (MRR) and surface roughness (SR) through a genetic algorithm. The experimental results show that the material removal rate increases with the increase in pulse width. The peak current has the greatest effect on the surface roughness, and the gap voltage has the least effect. The best input parameters of material removal rate are: peak current 4 A, pulse width 216.883 μs, The gap voltage is 30 V. The best input parameters of surface roughness are peak current 4 A and pulse width 125 μs. The gap voltage is 30 V [

14]. Le conducted EDM on SKD61 steel under finishing and semi-finishing. The experimental results show the peak current (1 A) and pulse width (16 μs) The surface roughness and hardness are better than the high peak current (4 A) and long pulse width (200 μs) results by [

15]. Jose and Paul analyzed the EDM test by Taguchi using the orthogonal method and found that the discharge gap is in direct proportion to the gap voltage, an important parameter that affects the surface roughness and material removal rate of the processed material. The comparison test found that the gap distance of 0.5 mm is the best [

16].

Khan et al. conducted EDM on shape-memory alloy (SM) and found that the power supply voltage caused the most obvious damage to the surface of the machined material [

17]. Sivakumar et al. used peak current, pulse width, and pulse voltage as input parameters to EDM OHNS steel, and found that a lower peak current would produce an ideal material surface roughness [

18]. Ganapathy et al. exploited the Taguchi experiment design and the use of GRA was combined with an L9 orthogonal array. A set of process parameters with a peak current of 21 A, a pulse width of 1000 μs and a voltage of 1.2 kg/cm

2 was obtained by optimizing process parameters such as peak current, pulse width, and open-circuit voltage, using EN-31 steel as the object of study, resulting in a material removal rate of 80.52%ni [

19]. Chandramoulis et al. studied the Taguchi method to optimize the process parameters of copper tungsten electrode steel-processing materials. The research results show that the pulse on time and discharge current have significant effects on the material removal rate and surface roughness, while the pulse off time has the least effect, which has been verified by experiments [

20].

In order to improve the efficiency of the reinforcing particles thrown from the molten pool and explore the influence of the ejecting-explosion EDM processing on the surface roughness of workpiece materials under different electrical parameters, this paper introduces a self-made EDM power supply for processing, and the influence of the open-circuit voltage difference, peak current difference, pulse phase difference and pulse width difference on the material removal rate and surface roughness of the ejecting-explosion EDM power supply is studied experimentally, which is necessary to improve the EDM efficiency. However, the influence of the open-circuit voltage difference, peak current difference, pulse phase difference, and pulse width difference of the ejecting-explosion EDM power supply on the material removal speed and surface roughness is still unclear, so it is particularly important to master the influence of the above parameters on EDM.

2. Experiment on Ejecting-Explosion EDM

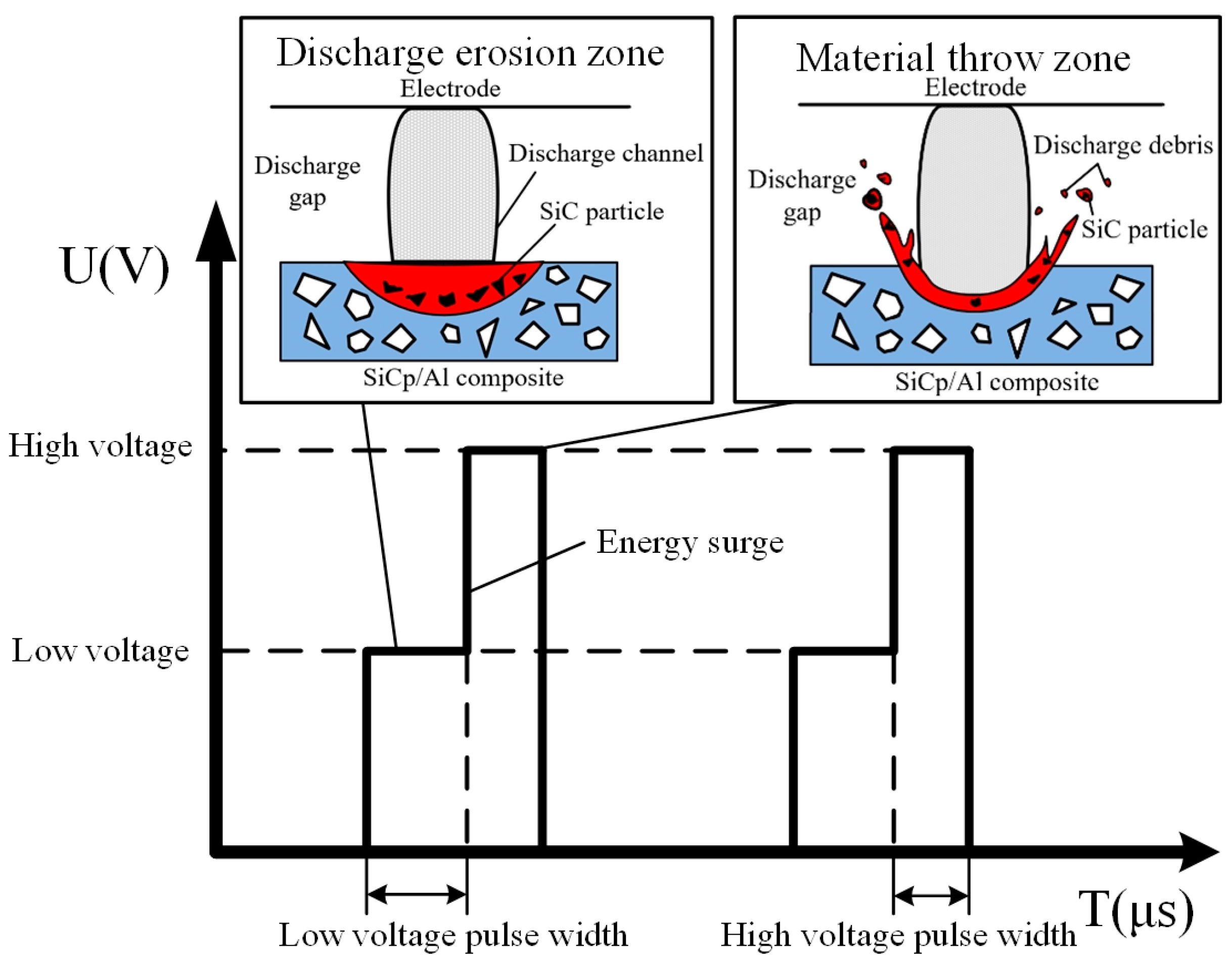

The ejecting-explosion EDM power supply is proposed for particle-reinforced metal matrix composites (PRMMCs), which are difficult to machine. It adopts a high- and low-voltage combined ejecting-explosion method. In order to achieve the purpose of high- and low-voltage composite processing, a control pulse signal with timing logic is generated by the control-pulse-generation device, and the power switch is turned on and off through the corresponding driving circuit, so that the high voltage and low voltage are loaded into the discharge gap according to the control logic to complete the combination of high- and low-voltage waveforms, as shown in

Figure 1. First, the first level of low-voltage pulse has the same function as the ordinary spark pulse power supply. It breaks through the discharge gap and forms a discharge channel, which plays a role in the corrosion of PRMMCs. Due to the great difference in the physical properties of the metal matrix and the reinforced particles, the melting time and required energy of the two materials are not the same. In order to avoid the inefficient process of increasing the discharge energy to melt the reinforced particles and directly throw out the reinforced particles in the form of a solid with molten metal entrainment, after the first low-voltage pulse is completed, the second high-voltage pulse is introduced. This pulse has a higher peak voltage and current, which releases greater energy at the moment of throwing out the material, obtaining greater discharge explosive force. The reinforced particles in the discharge molten pool are thrown out with the molten metal entrainment in the form of a solid, so as to achieve the purpose of the efficient removal of materials.

2.1. Experimental Materials

In this paper, SiCp/Al composites with different volume fractions of SiC particles are used for comparative experiments. Before the experiment, the SiCp/Al composite material with each volume fraction was cut into 20 mm × 20 mm × 10 mm rectangular squares by wire electrical discharge machining, and the specimen was polished from low to high using different mesh sandpaper to remove the oxide layer on the surface of the workpiece, and then the workpiece was cleaned with acetone solution to remove the attached impurities, so as to ensure the reliability of the experimental data and reduce the measurement error. The matrix materials are 6061 aluminum alloy, and the volume fractions of SiC are 20%, 30%, 45%, and 65%. The SiCp/Al composites are mainly prepared by powder metallurgy; after mixing aluminum powder and silicon carbide powder, they are pressed into blanks under vacuum and high pressure, and finally formed SiCp/Al composites after heat treatment. The diameter of 20% volume fraction SiC particles is 7 μm. Both 30% and 45% volume fraction SiC particles have a diameter of 14 μm, and 65% volume fraction SiC particles a diameter of 20 μm. The comparison of the main material performance indexes is shown in

Table 1.

2.2. Ejecting-Explosion EDM Experiment Device

The experiment is based on the EDM experiment platform, including the self-developed CNC machine tool developed and the self-developed ejecting-explosion EDM power supply. The machine tool is controlled by the CNC software. The three axes drive the ball screw through the stepping motor to achieve transmission, which can achieve X, Y, and Z axis CNC positioning control. The working parameters of the machine tool are shown in

Table 2.

The basic parameters of the step wave can be set for the electric ejecting-explosion power supply through the pulse-signal-generation circuit. The machining waveform required to generate power from the pulse generator. When the processing waveform is output from the signal generation circuit, it enters the power amplification circuit. The front end of the power amplifier circuit is an optocoupler isolation circuit. To prevent the high voltage of the rear-end circuit from affecting the operation of the front-end circuit, the optocoupler chip is used for electrical isolation and noise reduction. The signal is transmitted to the MOSFET drive circuit. The MOSFET drive chip is responsible for amplifying the signal generated by the generation circuit to drive the power MOSFET to respond quickly. The high- and low-circuit MOSFET drive signals, respectively, control the “on” and “off” of the series and parallel MOSFET switches, thus controlling the high and low voltage loaded in the discharge gap. Finally, the discharge-gap-detection part provides real-time feedback on the processing status to ensure the stable operation of the processing process. The actual processing is shown in

Figure 2.

2.3. Experimental Design Scheme

The influence of the waveform parameters of the different front and rear of the step wave on the ejecting-explosion EDM effect needs to be studied experimentally. In this paper, the open-circuit voltage difference, peak current difference, pulse phase difference, and pulse width difference of the front and rear of the step wave are changed to study the influence of the rear edge detonation wave on the machining process of SiCp/Al composites. Four groups of continuous pulse machining experiments under the same parameters were carried out to study the influence of the difference of the parameters of the above step wave on the process. The experiment processing time is 1 min, the processing speed is set to about 1 mm/min, the machining pattern is all ejecting-explosion mode, the workpiece material is not broken, and the rest of the experiment parameters are set as shown in

Table 1 and

Table 3.

2.4. Experiment Index and Method

- (1)

Machining removal rate

The material removal rate (MRR mm

3/min) of EDM reflects the processing speed. It refers to the amount of the workpiece material removed per unit of time under certain processing conditions, which is directly related to the processing time and processing efficiency of the workpiece. It is usually divided into mass removal rate and volume removal rate. At present, the volume removal rate is widely used in practice, which can more intuitively reflect the removal of the material. In this paper, the volume removal rate is used, and the formula is expressed as follows:

where

Vs is the volume removal rate (mm

3/min),

V is the volume of workpiece removal (mm

3),

t is the processing time (min), Δ

m is the mass of workpiece removal (g), and

ρ is the workpiece material density (g/mm

3).

The Alicona automatic zoom three-dimensional surface topography instrument is used to measure the surface of the processed workpiece. The three-dimensional surface topography instrument can scan the whole surface of the object vertically by changing the depth of focus. According to the surface condition of the three-dimensional results, the plane is selected, and the plane is used as the reference plane. The depression and the protrusion volume of the set plane are measured, and the built-in difference analysis method in the three-dimensional surface topography instrument is supplemented to measure the volume accurately (by comparing the difference of the three-dimensional morphology front and rear processing, the volume of removal and protrusion is obtained).

- (2)

Machining roughness of pit bottom

Because SiCp/Al composites are not uniform materials, there are SiC reinforced particles in them. If the reinforced particles can be effectively removed, surface protrusions are greatly reduced, and the roughness after processing is also improved. Therefore, the surface quality after processing can be seen macroscopically by measuring the roughness of processing. In this paper, a three-dimensional topography instrument is used to divide and measure the bottom area of the processing pit, so as to reduce the influence of the edge-loss effect caused by the smooth processing of the electrode and reduce the height error of the peak and valley caused by the concave at the bottom, and then the average evaluation is carried out to obtain the comprehensive processing roughness.

3. Analysis on Influencing Factors of Material Removal Speed in Ejecting-Explosion EDM

3.1. Influence of Voltage Difference of HLW

In order to explore the effect of the open-circuit voltage difference between high- and low-voltage waveform loading on the material removal rate of SiCp/Al composites by EDM, different open-circuit voltage differences were selected for EDM continuous pulse machining experiment. Experimental conditions are as follows: high- and low-voltage waveform peak current of 3 A and 5 A, HLW pulse width of 20 μs, low-voltage wave open-circuit voltage is set to 80 V, and high-voltage wave open-circuit voltage is set to 120 V, 140 V, 160 V, 180 V, 200 V. The experiment results show the influence curves of different open-circuit voltage differences on the material removal volume and rate in

Figure 3.

The experimental results shown in

Figure 3 show that the removal rate of SiCp/Al composites with different volume fractions increases with the increase in the open-circuit voltage difference between high- and low-voltage waveform. According to the slope of the curve, it can be seen that with the increase in the open-circuit voltage difference between high- and low-voltage waveform, the growth rate of the removal volume slows down, and the influence of the voltage difference between high- and low-voltage waveform on the removal volume gradually decreases.

This law occurs because as the open-circuit voltage difference between high–low-voltage waveforms increases, the energy released by the pulse power supply between the discharge gaps at the same time also increases, and the material removal volume per unit time also increases. At the same time, the increase in the open-circuit voltage of the high-voltage wave also increases the discharge gap. Combined with the strong explosive force generated by the rear edge, the debris can be discharged more effectively. However, with the increase in the open-circuit voltage value of the high-voltage circuit, the discharge gap becomes larger, the release space of metal steam and working fluid steam generated at high temperature becomes larger, and the pressure increase generated with the increase in energy becomes smaller. Therefore, the explosion force brought by the pressure release decreases with the increase in the voltage difference. At the same time, the volume of removal increases with the increase in the voltage difference. There is more and more debris generated between the poles. The reinforced particles of SiC and the molten product of the aluminum matrix affect the discharge effect. Under the influence of various factors, when the open-circuit voltage difference of the high–low-voltage waveform loading increases to a certain value, the removal rate of the workpiece material and the throwing effect of the debris reach the optimal situation. If the open-circuit voltage difference continues to increase, the effect on the material throwing gradually decreases, and the removal volume gradually tends to a stable value. At the same time, the excessive discharge gap leads to the instability of the machining process, which affects the machining speed and quality. Therefore, combined with the experimental results and theoretical analysis, it can be seen that the high–low-voltage waveform loading open-circuit voltage difference is better processed at 80 V to 100 V.

Due to the poor conductivity of the reinforced particles of SiC, the “shielding” effect is generated during the processing, which blocks the formation of the discharge channel. Therefore, with the increase in the volume fraction of the reinforced particles of SiC, the removal volume is less under the same electrical parameters. However, when the open-circuit voltage difference of the high–low-voltage waveform loading reaches a certain degree, the removal volume of the SiCp/Al composite with a volume fraction of 45% is higher than that of the SiCp/Al composite with a volume fraction of 30%. This is because the ratio of SiC particles and aluminum matrix in the 45% SiCp/Al composite material at 60 V voltage can just make the molten aluminum matrix with SiC particles thrown out, which is larger than the low volume fraction of molten aluminum. However, the shielding effect of reinforced SiC particles in 65% SiCp/Al composites is too obvious, which makes the material achieve less explosive force. Therefore, it is impossible to remove more volume under high-voltage energy, as for 45% SiCp/Al composites. Therefore, it still follows that with the increase in the volume fraction of reinforced particles of SiC, under the same electrical parameters, the removal volume is less regular.

3.2. Influence of Peak Current Difference of HLW

In order to investigate the effect of the peak current difference of high–low-voltage waveform loading on the material removal rate of SiCp/Al composites by EDM, different peak current differences were selected for EDM continuous pulse machining experiment. Experimental conditions are as follows: high–low-voltage waveform loading open-circuit voltage are 80 V and 100 V, respectively; HLW pulse width of 20 μs; low-voltage peak current is set to 4 A; high voltage peak current is set to 5 A, 6 A, 8 A, 10 A, 12 A; and the difference between the peak currents of high–low-voltage waves is 1 A, 2 A, 4 A, 6 A, 8 A. The experimental results show the influence curves of different peak current differences on the material removal volume and rate in

Figure 4.

The experimental results shown in

Figure 4 show that the material removal rate of SiCp/Al composites with different volume fractions increases with the increase in the peak current difference of high–low-voltage waveform loading. However, the curve trends of SiCp/Al composites with low volume fractions of 20% and 30% are very different from those of SiCp/Al composites with high volume fractions of 45% and 60%. It can be seen that the removal volume of SiCp/Al composites with low volume fraction decreases with the increase in the peak current difference of high–low-voltage waveform loading. However, the removal rate decreases significantly after 6 A, while the material removal rate of SiCp/Al composites with high volume fraction increases with the increase in peak current difference between high–low-voltage waveforms.

Although the removal rate of SiCp/Al composites with a low volume fraction increases with the peak current difference of high–low-voltage waveform loading, the increase in removal rate decreases. The removal rate decreases after the peak current difference of high–low-voltage waveform loading reaches 6 A. This is because the peak current of the high-voltage circuit continues to increase, which leads to an increase in discharge energy, increasing the number of charged ions in the discharge channel. A larger current density also increases the kinetic energy of charged particles. The temperature of the discharge channel, the workpiece, and the electrode surface increases under the bombardment of charged particles, and the volume of the melted and vaporized aluminum matrix material increases. After the material is vaporized, the volume becomes larger, the discharge gap pressure becomes larger, and the pressure is released. When the pressure is released and the discharge energy brings a stronger explosive force, the more melted metal is thrown, and the processing efficiency is higher. However, the discharge gap remains unchanged. In the case of an increase in the volume of material removal, a stronger explosive force can discharge more debris, and more residual debris remains between the poles. In the continuous processing process, as the retention accumulates, it affects the processing rate of removal, so the increase in removal rate gradually decreases. When the current difference is too large, the SiC particles are also melted, which leads to a decrease in the material removal rate; in addition, when the current difference is too large, the peak current of the high-voltage circuit is too large, which leads to the charged ion movement being too violent, resulting in more complex reactions between the poles, resulting in poor chip removal and high discharge channel temperature. It is difficult to eliminate ionization, so excessive peak current difference reduces the workpiece removal rate. The SiCp/Al composites with a high volume fraction have a higher proportion of reinforced particles of SiC. The larger the peak current of the high-voltage circuit, the more generated charged particles bombard a higher proportion of reinforced particles of SiC, while the SiC particles have a “shielding” effect on the discharge gap, so the reaction intensity of the charged particles is relatively lower. At the same time, the thermal conductivity of SiC is much larger than that of the aluminum matrix, so the temperature in the discharge channel is relatively lower, and the deionization situation is improved. Therefore, after the current difference of 6 A continues to increase, it still shows a trend of greater removal rate, but the increase in the removal rate also decreases.

3.3. Influence of Peak Current Difference of HLW

In order to explore the effect of the pulse width difference of high–low-voltage waveform loading on the material removal rate of SiCp/Al composites by EDM, different pulse width differences were selected for the EDM continuous pulse machining experiment. Experiment conditions are as follows: high–low-voltage waveform loading open-circuit voltages are 80 V and 160 V; peak current is 3 A and 5 A; low-voltage wave pulse width is set to 35 μs, 30 μs, 20 μs, 10 μs, 5 μs; and high-voltage wave pulse width is set to 5 μs, 10 μs, 20 μs, 30 μs, 35 μs. The influence curves of different pulse width differences on the material removal rate according to the experiment results are shown in

Figure 5.

The experimental results shown in

Figure 5 show that the removal rate of SiCp/Al composites with different volume fractions increases first and then decreases gradually with the increase in pulse width difference because the front wave electrical parameters have a good effect on the removal of SiCp/Al composites. Due to the particularity of SiCp/Al composites, when the workpiece material is removed, there is a reinforced particle of SiC free in the discharge gap, which affects the normal discharge operation of the machining, so the surge energy is provided by the trailing edge high-voltage wave. The pressure difference caused by the formation of energy mutation and the stronger explosive force enhance the throwing of particles of SiC from the workpiece and render the discharge smoother. With the increase in the pulse width of the rear edge high-voltage wave, although the rear edge high-voltage wave can melt more materials and generate greater explosive force, the pressure action time brought by the energy surge moment come relatively forward with the increase in the pulse width difference. Therefore, there is more discharge formed in the discharge gap. At this time, the action time of the high-voltage waveform accounts for more, and the energy generated between the poles is excessive, which also renders the effect of deionization between the poles worse. Therefore, continuous pulse machining leads to a decrease in the removal rate. For the SiCp/Al composite with a volume fraction of 65%, the high-voltage waveform has a long action time; more energy is released, and the reaction is more intense. Due to the presence of more reinforced particles of SiC, the thermal conductivity is greater, the interpolar energy dissipates faster, and the deionization effect is unaffected. When the high-voltage wave action time is longer, the 65% SiCp/Al composite volume fraction is more significant.

3.4. Influence of Phase Difference of HLW

To explore the effect of the pulse phase difference of high–low-voltage waveform loading on the material removal rate of SiCp/Al composites by EDM, different pulse phase difference values were selected for EDM continuous pulse machining experiment. Experiment conditions are as follows: high–low-voltage waveform loading open-circuit voltages are 80 V and 100 V; peak current is 3 A and 5 A; HLW pulse width accounted for 20 μs; high-voltage wave pulse phase is set to 0%, 25%, 50%, 75%, 100%; and the rest of the high-voltage wave pulse is not set at the low-voltage wave pulse. The experiment results show the influence curves of different pulse width differences on the material removal rate in

Figure 6.

The experimental results shown in

Figure 6 show that when the phase difference between the high–low-voltage waveforms becomes larger, the removal rate decreases first and then increases. Because the current high-voltage wave is first loaded in the discharge gap, the high-voltage wave can break through the discharge gap faster, thus forming the discharge channel more quickly. When the high-voltage wave is loaded, the low-voltage wave is loaded in the discharge gap, and the energy is directly released in the discharge gap. Although there is no energy surge in the machining process, the faster breakdown gap makes the energy utilization rate higher, so the removal volume effect is better. When the phase difference becomes slightly larger, the low-voltage wave is loaded for a short period of time, and the gap is not broken down. The high-voltage wave is loaded into the discharge gap, thereby breaking the voltage. The subsequent inter-electrode energy changes are the same, but some of the low-voltage waves release waste energy, so the removal volume is reduced at this time. When the phase difference between the high–low-voltage waves is larger, the low-voltage wave breaks down the discharge gap, and the high-voltage wave is loaded into the discharge gap at this time. At this time, there is a surge of energy, so greater energy release forms a stronger explosive force. At the same time, the instantaneous high temperature vaporizes more metals and working fluids at the same time, forming a greater vapor pressure. The simultaneous action of the two can strip more reinforced particles of SiC and the aluminum matrix melts from the workpiece and discharge gap, so the effect of etching volume is more obvious at this time. However, after the subsequent high-voltage wave loading is completed, the low-voltage wave continues to load. At this time, most of the melting products on the surface of the workpiece have been discharged, and the effect of subsequent low-voltage wave removal is not so obvious. With the maximum phase difference of high–low-voltage waveforms, when the low-voltage wave is fully loaded, the high-voltage wave is loaded again. At this time, the action time of the low-voltage wave is longer, so it has relatively more melts formed on the workpiece material. At this time, the high-voltage wave provides an instantaneous energy surge, and the explosive force and steam pressure are enhanced. More melts and reinforced particles of SiC are peeled off to process the workpiece, so the processing removal volume is the largest at this time, and the removal effect also reaches the best state.

6. Innovation and Prospects for Future Research

Due to the difficulty of SiCp/Al composites, ordinary EDM struggles to achieve the purpose of efficient continuous processing, so this paper introduces a ejecting-explosion EDM power supply to achieve the efficient processability of SiCp/Al composite EDM processing, and obtains the unique process law of SiCp/Al composites. Ejecting-explosion EDM can play an important role in the aerospace field. Fighter hatch covers, aircraft hydraulic components, Mars rover wheels, etc., are inseparable from the efficient processing of SiCp/Al composite materials.

Although this experiment can be used to improve the processing environment and improve the processing efficiency of SiCp/Al composites, the following disadvantages were found in the experiment:

- (1)

Due to the limited research time, the experiment only studies the electrical parameters of the ejecting-explosion EDM process; however, the next step can be to conduct the experimental research on the SiCp/Al composite material for non-electrical parameters such as different electrodes and different working fluids, and establish a more complete database.

- (2)

After the completion of the ejecting-explosion EDM experiment, only the surface quality and material removal rate of the workpiece were analyzed. If the state and elements of the debris after processing of SiCp/Al composites with different volume fractions were analyzed at the same time, the removal method of the ejecting-explosion EDM could be comprehensively explained.