Enhancing EDM Machining Precision through Deep Cryogenically Treated Electrodes and ANN Modelling Approach

Abstract

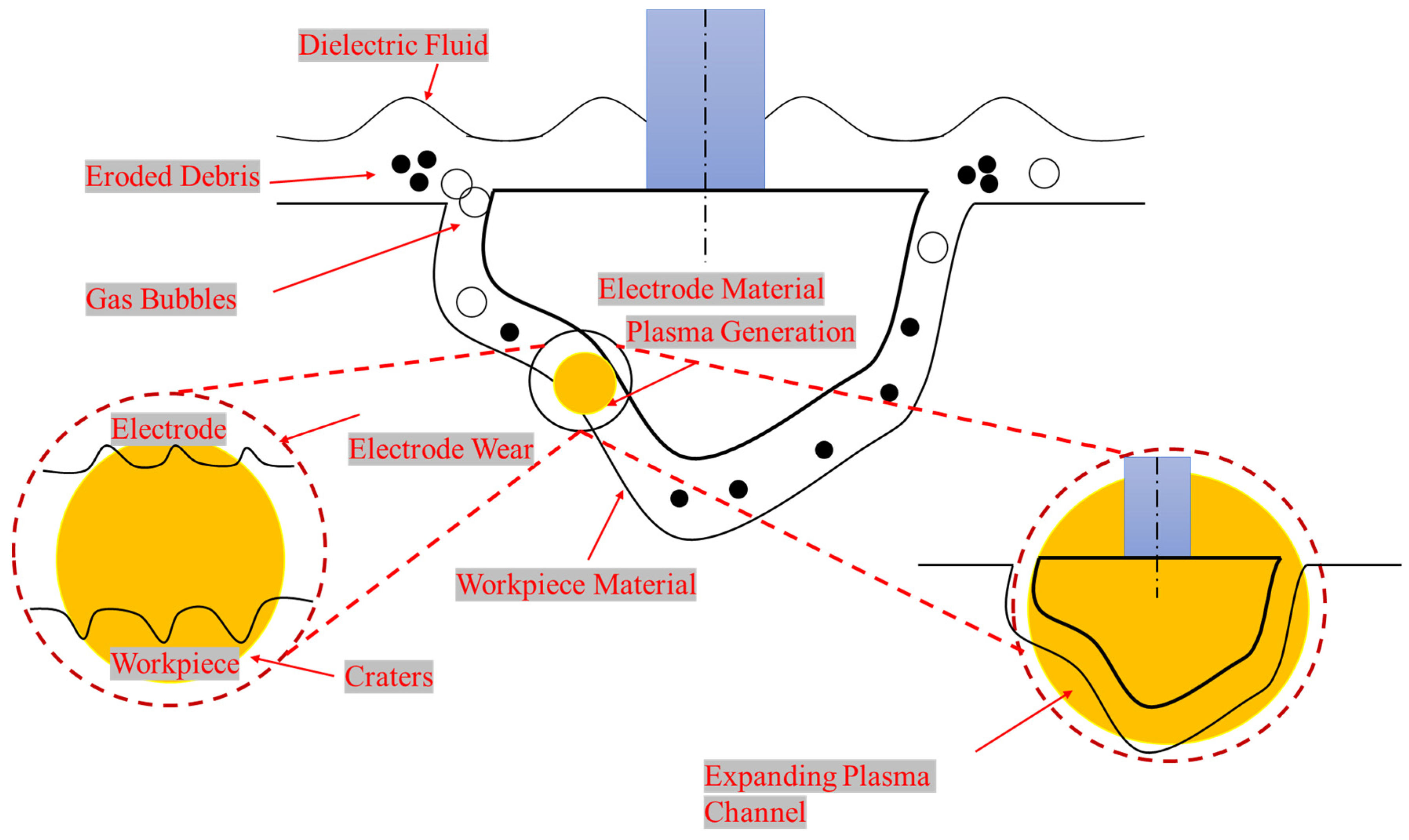

:1. Introduction

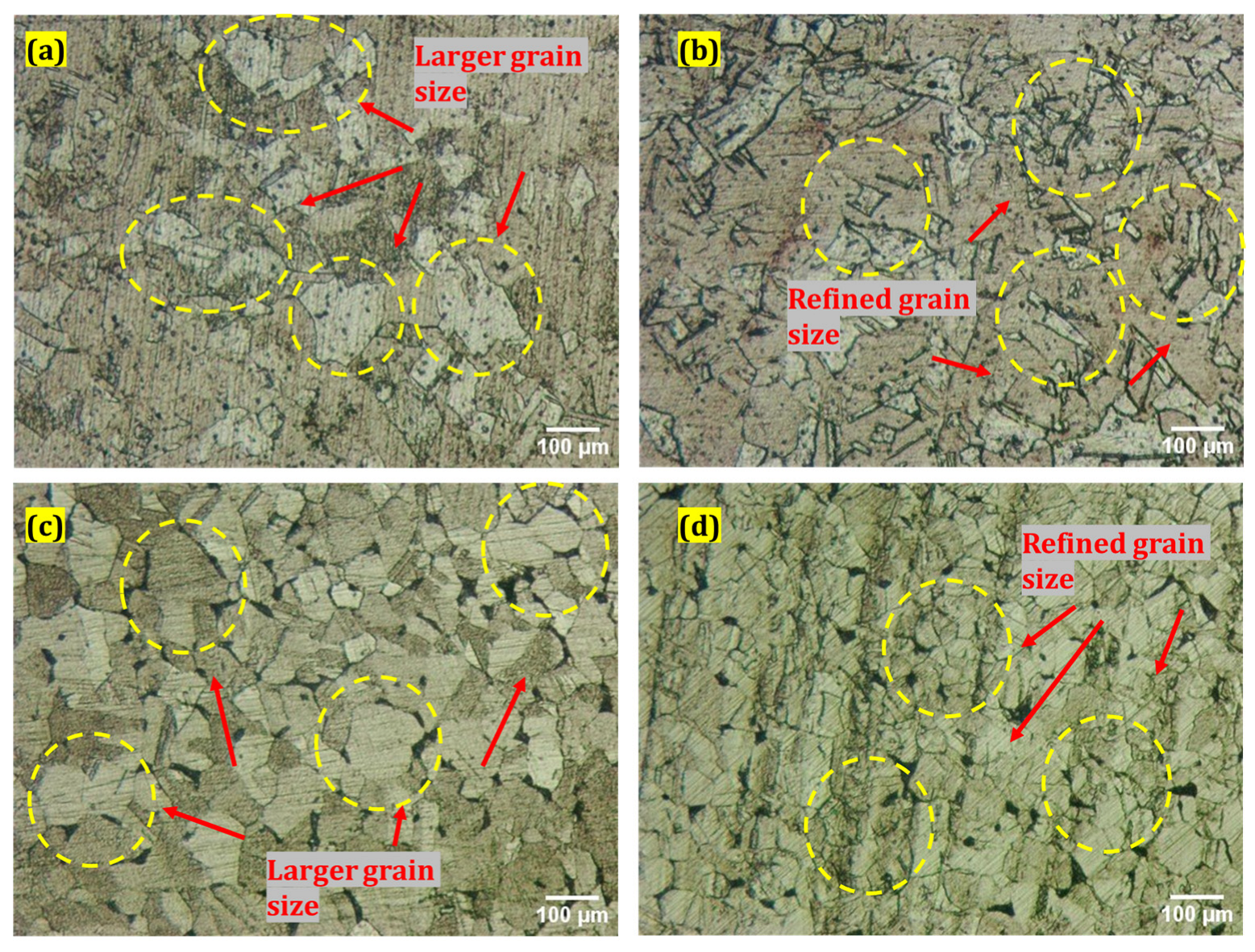

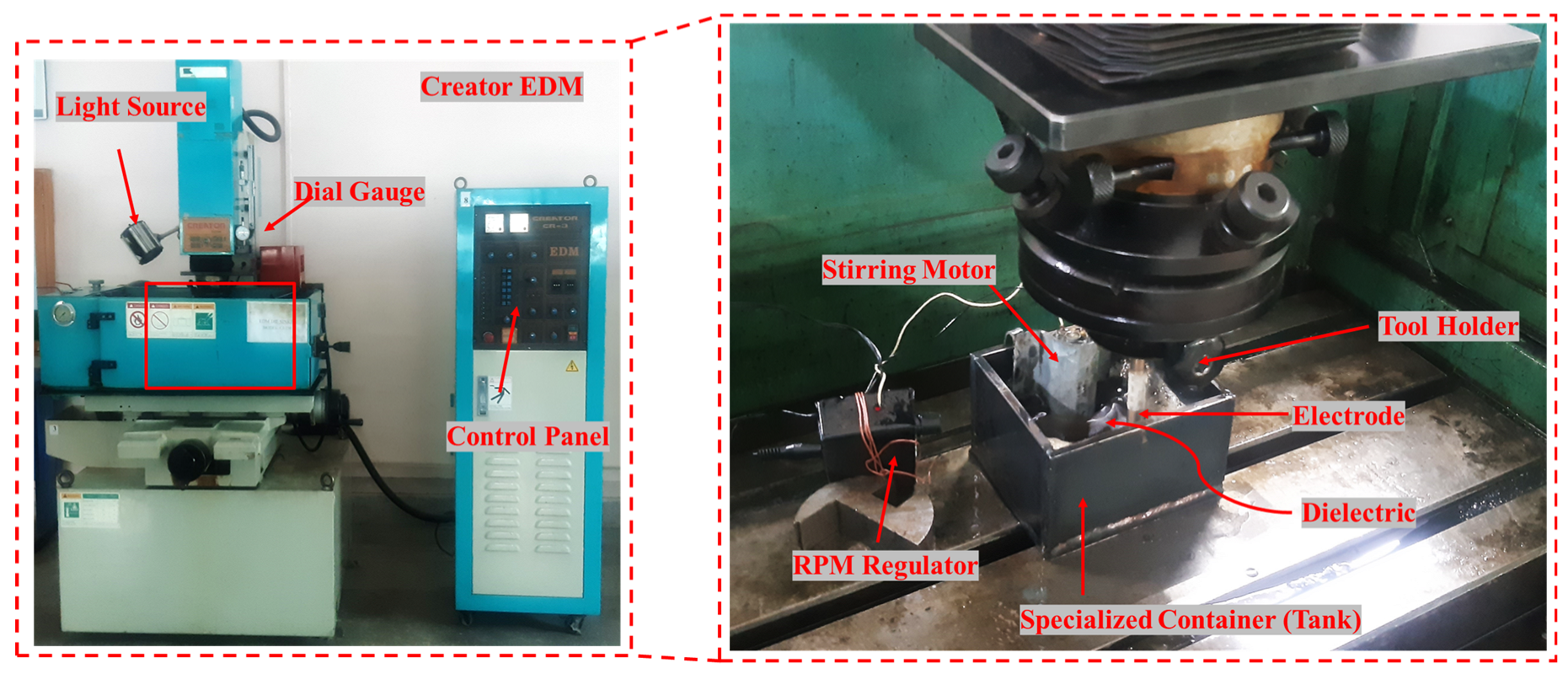

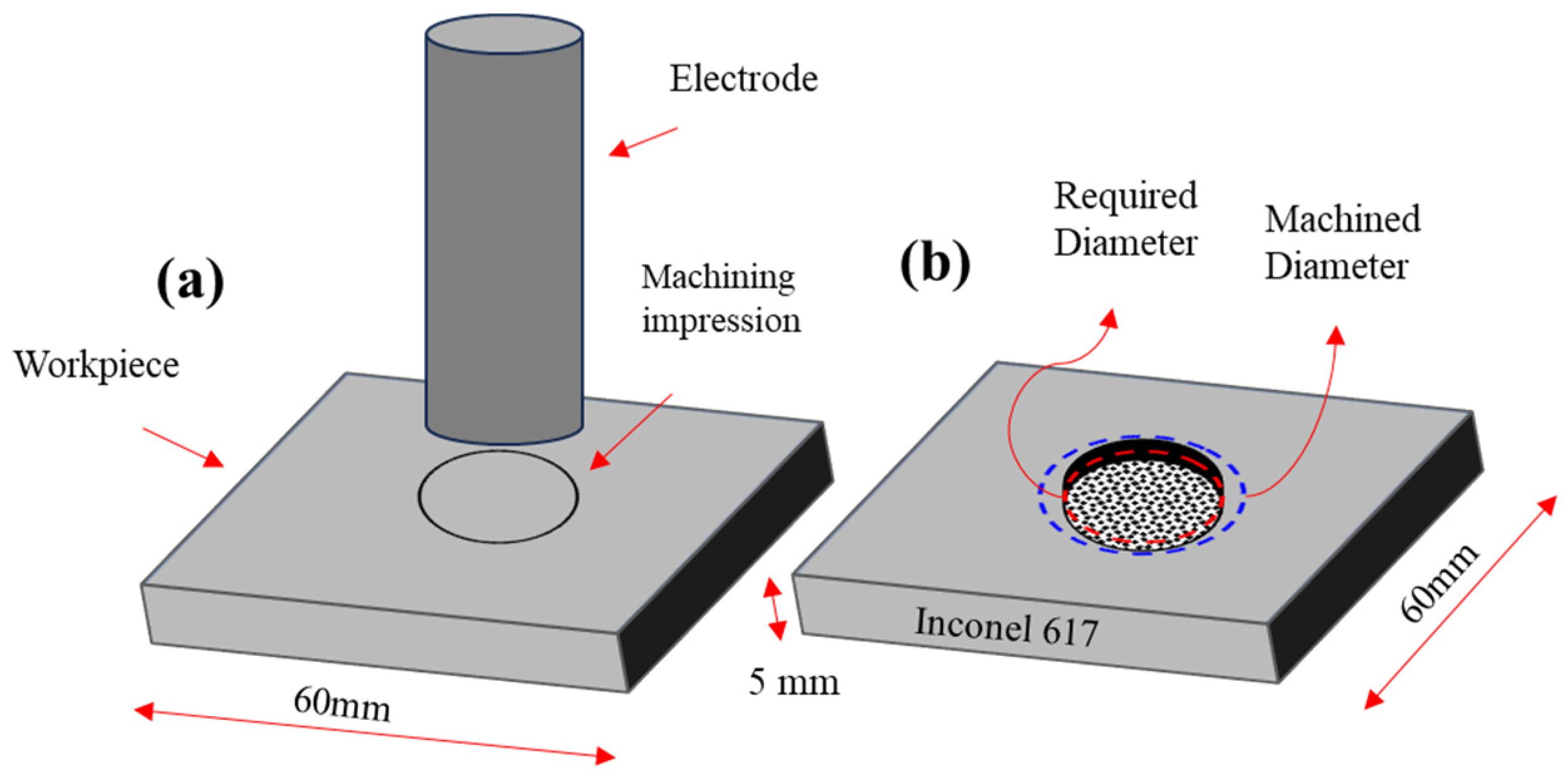

2. Materials and Methods

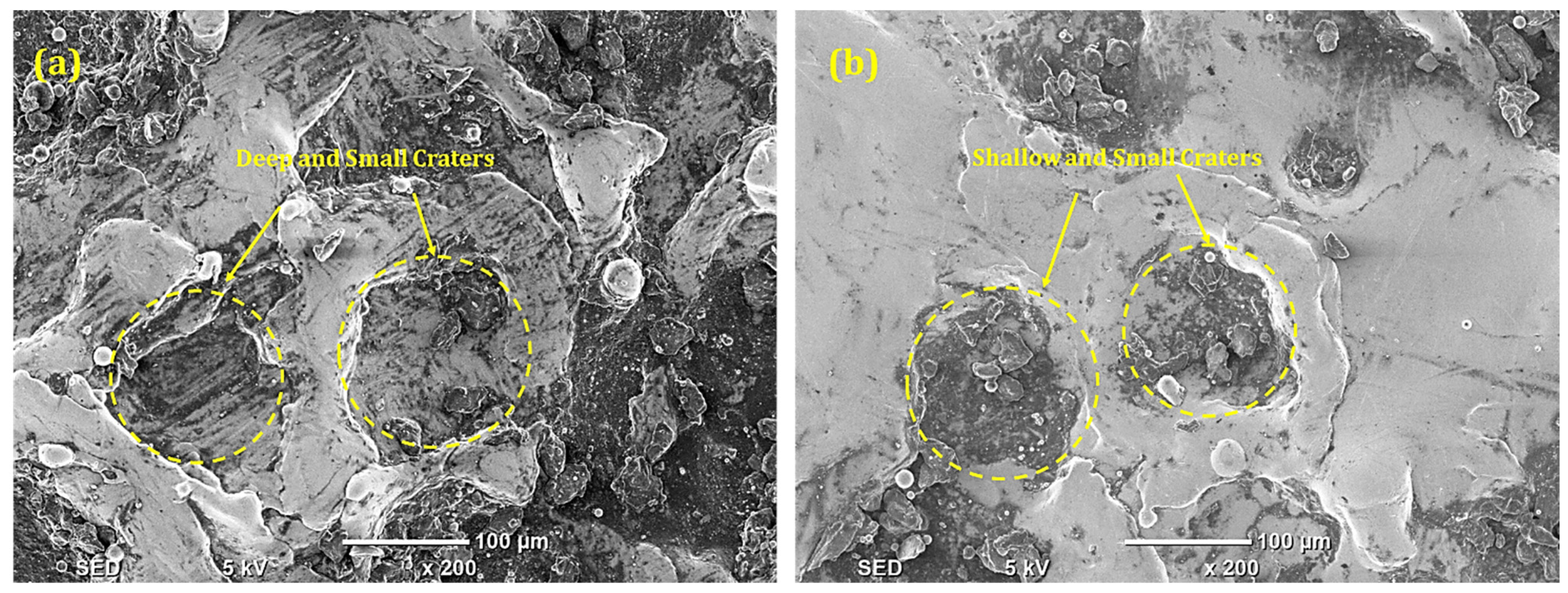

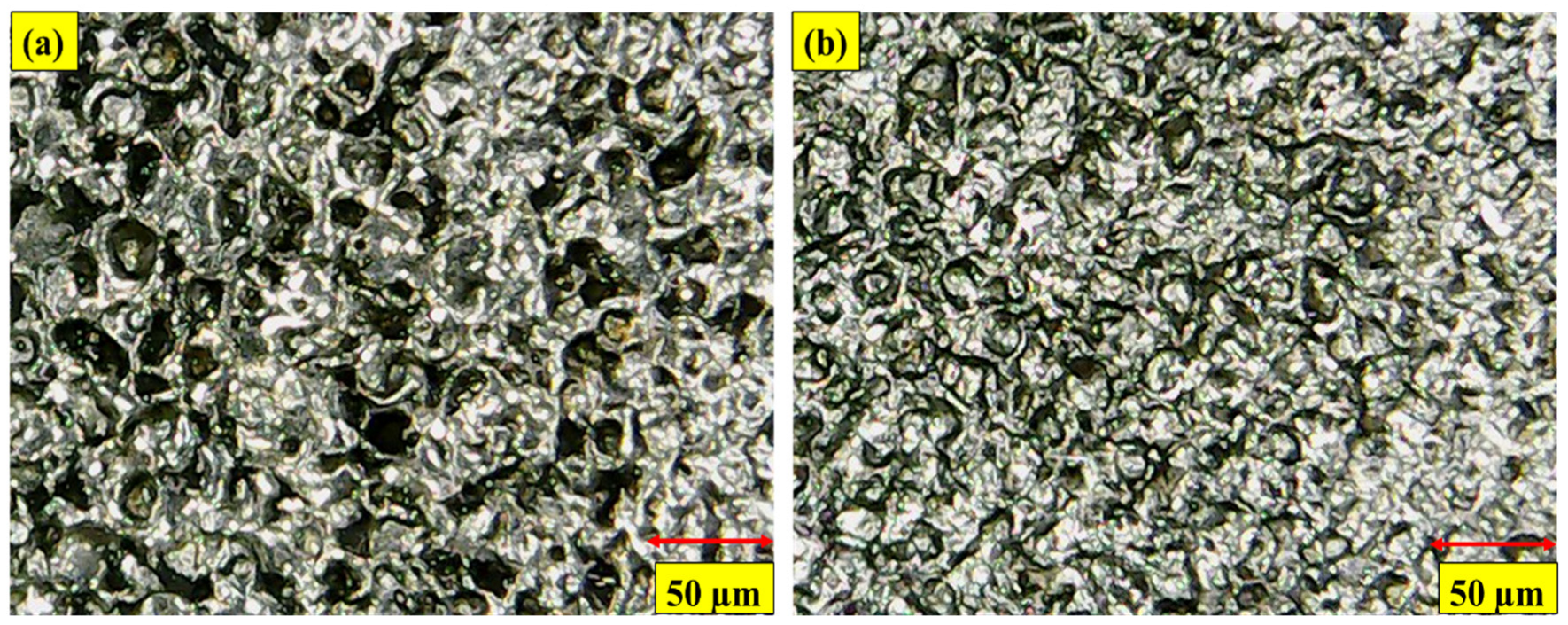

3. Results and Discussion

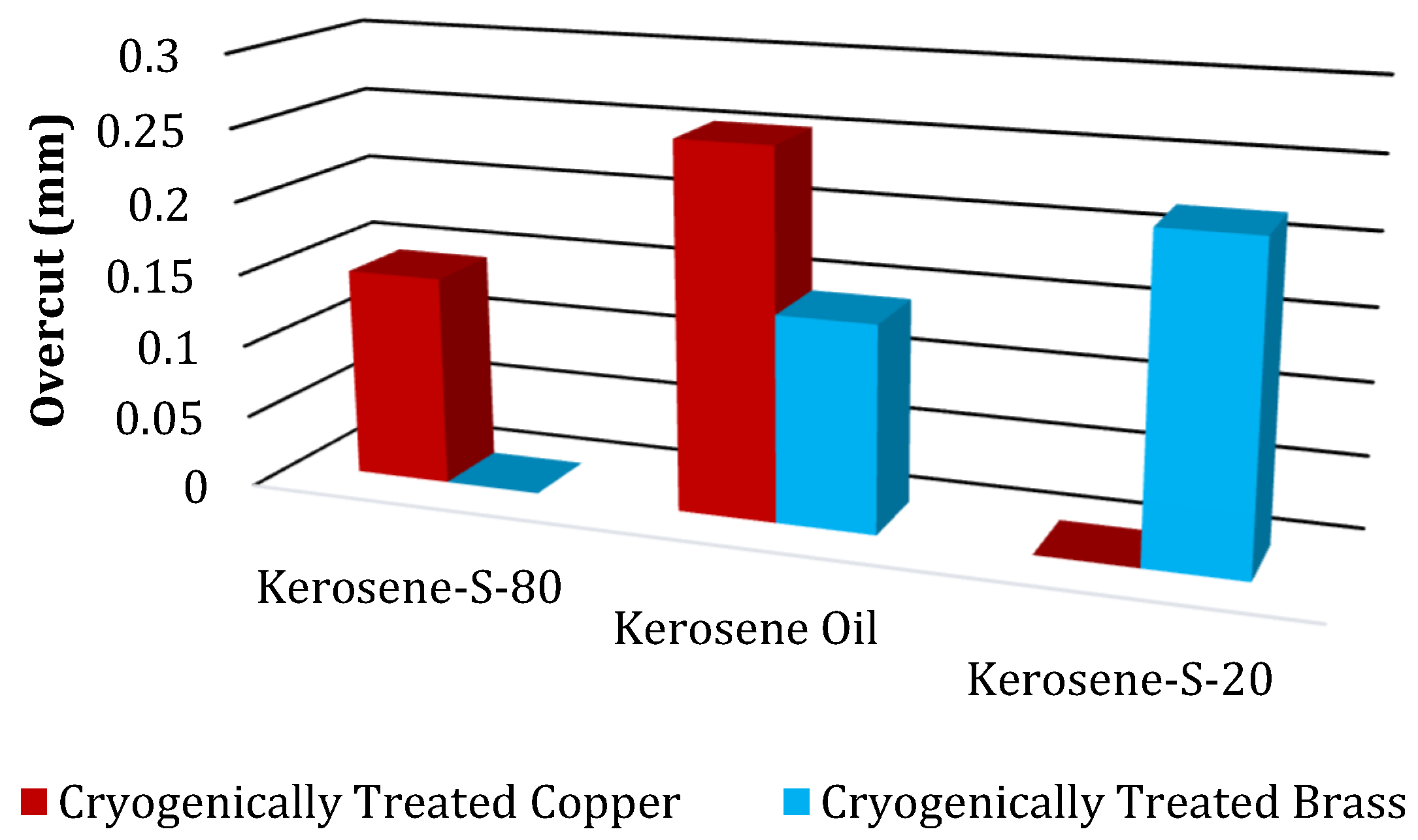

3.1. Experiments

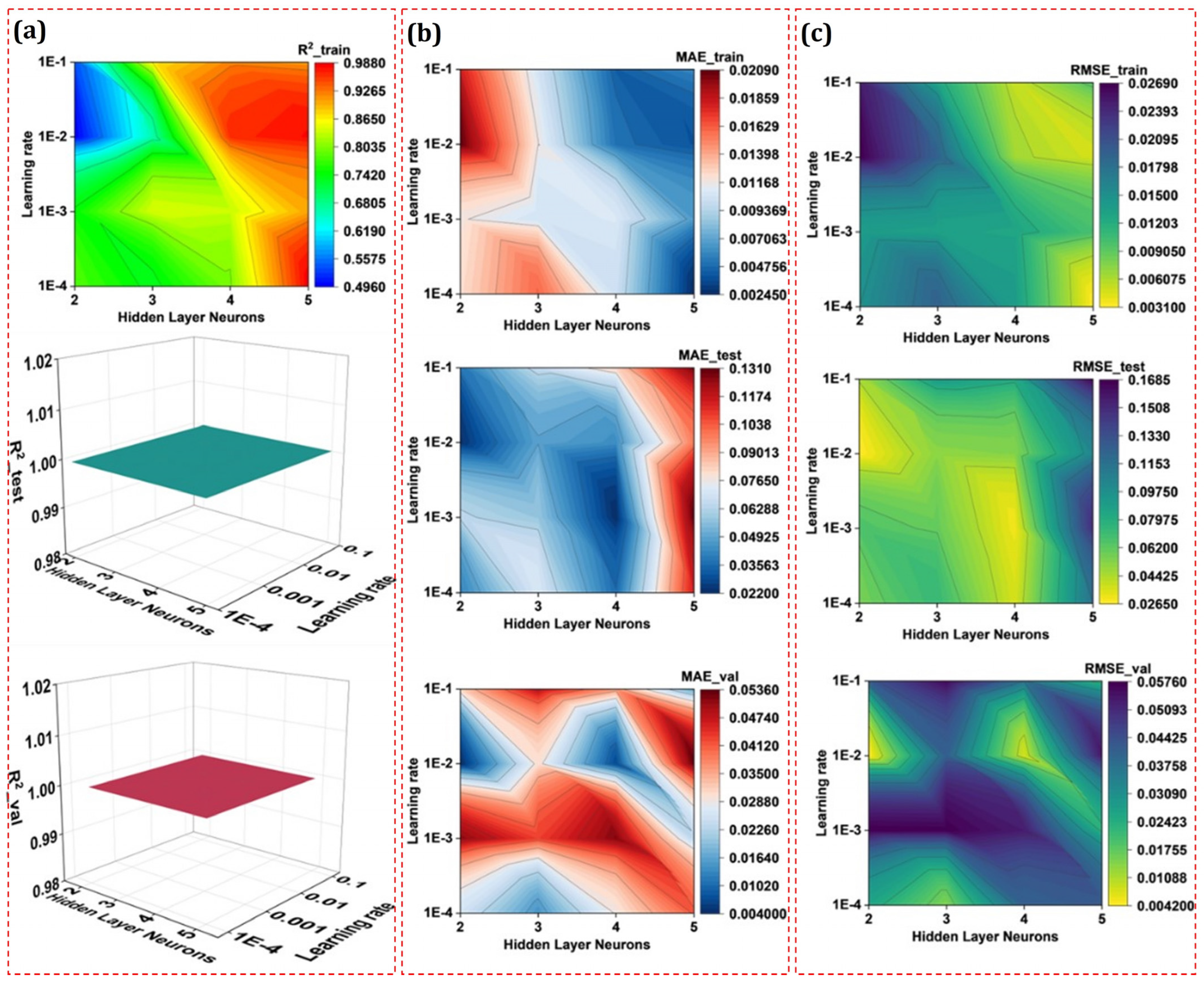

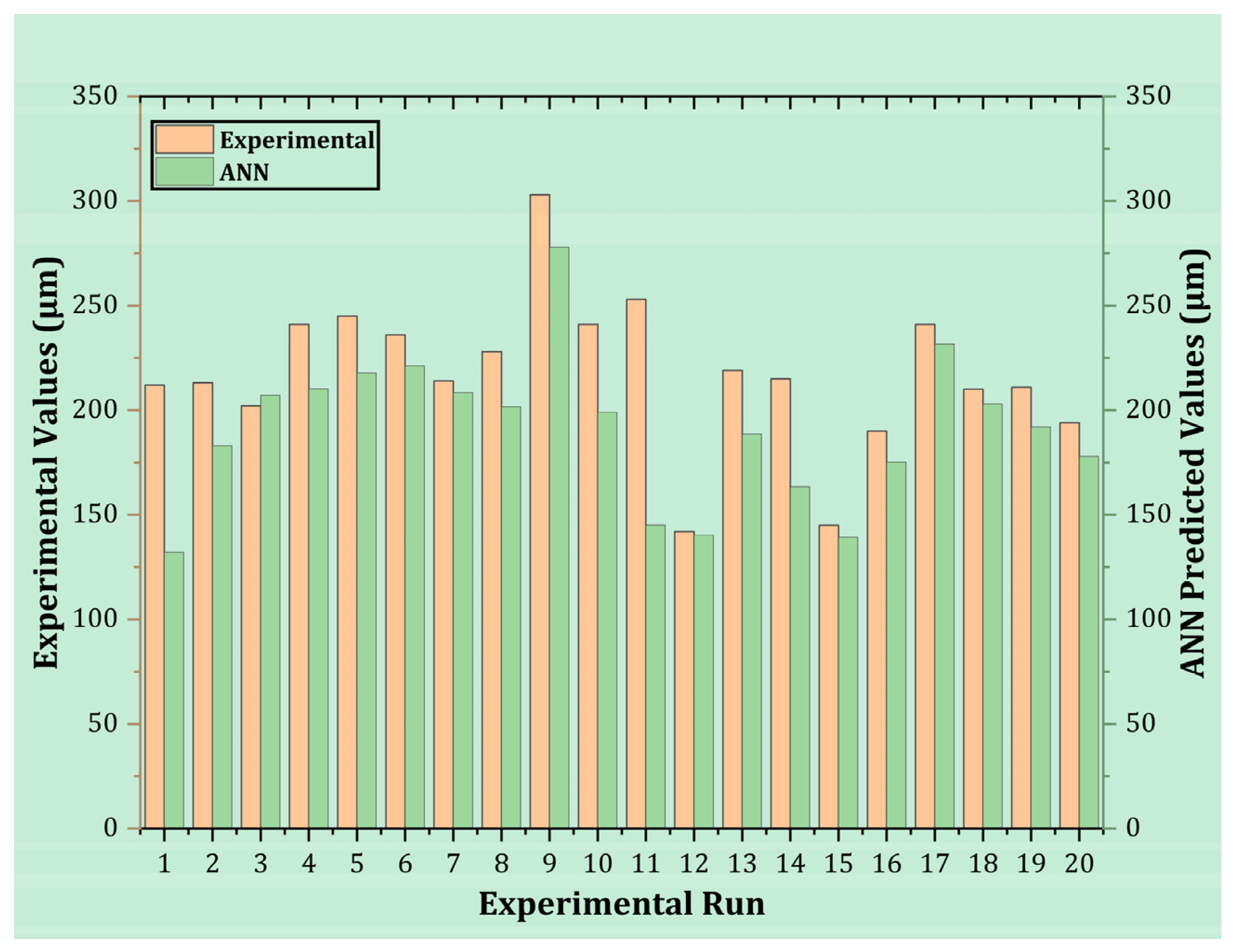

3.2. Development of Artificial Neural Network (ANN) for OC

4. Conclusions

- In various modified dielectrics, the ability of CT electrodes to machine gave greater dimensional accuracy on average by 13.5% compared to NT electrodes;

- CT brass outperformed the treated electrodes and provided the lowest value of OC (0.142 mm). Compared to the average value provided by the total number of CT electrodes, the dimensional accuracy provided by the CT brass is 29.7% better/enhanced;

- A comparison of the machining capabilities of CT electrodes in span and tween-added dielectrics revealed that span-based modified dielectrics provided an 8.7% reduced overcut;

- When using a CT Cu electrode in pure kerosene oil, EDM achieves the lowest OC (0.145 mm) and the highest dimensional accuracy (31.6% better than pure kerosene oil in the NT situations);

- The combination of a NT Cu electrode and the Kerosene-S-20 modified dielectric has yielded the lowest value of OC (0.202 mm). This OC value is 33.3% better than the best OC recorded using a NT Cu electrode and a Kerosene-T-80 modified dielectric;

- It has been shown that tween-added dielectrics against NT electrodes perform 3.0% better than span-based modified dielectrics in machining ability. Tweens perform better than teenagers because their high flash points prevent them from catching fire easily;

- In Kerosene-S-20 and kerosene oil-modified dielectrics, the lowest OC was achieved by proficient NT Cu and brass machining, with 0.202 mm and 0.213 mm, respectively. Kerosene-S-20’s OC value is said to be 4.72% better than kerosene oil’s OC value because of NT Cu;

- The OC phenomenon is observed to possess nonlinear characteristics and is therefore modeled using the ANN approach. Extensive tuning of hyperparameters is carried out; thus, an ANN model with four hidden layer neurons and a learning rate of 0.01 has comparatively better modeling performance. The developed ANN model can accurately predict the OC value in the design input space.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, Y.; Gong, Y.; Wen, X.; Xin, B.; Yin, G.; Meng, F.; Tang, B. Evaluation of Dimensional Accuracy and Surface Integrity of Cylindrical Array Microelectrodes and Cylindrical Array Microholes Machined by EDM. Archiv. Civ. Mech. Eng. 2022, 22, 46. [Google Scholar] [CrossRef]

- Sahu, D.R.; Mandal, A. Critical Analysis of Surface Integrity Parameters and Dimensional Accuracy in Powder-Mixed EDM. Mater. Manuf. Process. 2020, 35, 430–441. [Google Scholar] [CrossRef]

- Kumar, P.; Dewangan, S.; Pandey, C. Analysis of Surface Integrity and Dimensional Accuracy in EDM of P91 Steels. Mater. Today Proc. 2020, 33, 5378–5383. [Google Scholar] [CrossRef]

- Ishfaq, K.; Waseem, M.U.; Sana, M. Investigating Cryogenically Treated Electrodes’ Performance under Modified Dielectric(s) for EDM of Inconel(617). Mater. Manuf. Process. 2022, 37, 1902–1911. [Google Scholar] [CrossRef]

- Li, W.; Guo, Y.B. A Two-Parameter Method to Monitor and Characterize Tool Wear in End Milling Inconel 718. In Proceedings of the ASME 2012 International Manufacturing Science and Engineering Conference, Notre Dame, IN, USA, 4 June 2012; American Society of Mechanical Engineers: Notre Dame, IN, USA; pp. 799–804.

- Guo, Y.B.; Li, W.; Jawahir, I.S. Surface Integrity Characterization and Prediction in Machining of Hardened and Difficult-to-Machine Alloys: A State-of-Art Research Review and Analysis. Mach. Sci. Technol. 2009, 13, 437–470. [Google Scholar] [CrossRef]

- Sidhu, S.S.; Ablyaz, T.R.; Bains, P.S.; Muratov, K.R.; Shlykov, E.S.; Shiryaev, V.V. Parametric Optimization of Electric Discharge Machining of Metal Matrix Composites Using Analytic Hierarchy Process. Micromachines 2021, 12, 1289. [Google Scholar] [CrossRef]

- Shastri, R.K.; Mohanty, C.P.; Dash, S.; Gopal, K.M.P.; Annamalai, A.R.; Jen, C.-P. Reviewing Performance Measures of the Die-Sinking Electrical Discharge Machining Process: Challenges and Future Scopes. Nanomaterials 2022, 12, 384. [Google Scholar] [CrossRef]

- Dilip, D.G.; Panda, S.; Mathew, J. Characterization and Parametric Optimization of Micro-Hole Surfaces in Micro-EDM Drilling on Inconel 718 Superalloy Using Genetic Algorithm. Arab. J. Sci. Eng. 2020, 45, 5057–5074. [Google Scholar] [CrossRef]

- Altin Karataş, M.; Biberci, M.A. Statistical Analysis of WEDM Machining Parameters of Ti-6Al-4V Alloy Using Taguchi-Based Grey Relational Analysis and Artificial Neural Network. Exp. Tech. 2022, 47, 851–870. [Google Scholar] [CrossRef]

- Gangil, M.; Pradhan, M.K. Modeling and Optimization of Electrical Discharge Machining Process Using RSM: A Review. Mater. Today Proc. 2017, 4, 1752–1761. [Google Scholar] [CrossRef]

- Kolli, M.; Kumar, A. Effect of Dielectric Fluid with Surfactant and Graphite Powder on Electrical Discharge Machining of Titanium Alloy Using Taguchi Method. Eng. Sci. Technol. Int. J. 2015, 18, 524–535. [Google Scholar] [CrossRef] [Green Version]

- Fassi, I.; Modica, F. Editorial for the Special Issue on Micro-Electro Discharge Machining: Principles, Recent Advancements and Applications. Micromachines 2021, 12, 554. [Google Scholar] [CrossRef] [PubMed]

- Qudeiri, J.E.A.; Zaiout, A.; Mourad, A.-H.I.; Abidi, M.H.; Elkaseer, A. Principles and Characteristics of Different EDM Processes in Machining Tool and Die Steels. Appli. Sci. 2020, 10, 2082. [Google Scholar] [CrossRef] [Green Version]

- Jafarian, F. Electro Discharge Machining of Inconel 718 Alloy and Process Optimization. Mater. Manuf. Process. 2020, 35, 95–103. [Google Scholar] [CrossRef]

- Singh, K.; Agarwal, A.K.; Yadav, R. Effect of Dielectric Fluids Used on EDM Performance: A Review. IJETER 2017, 5, 7. [Google Scholar]

- Bhattacharyya, B.; Doloi, B. Machining Processes Utilizing Thermal Energy. In Modern Machining Technology; Elsevier: Amsterdam, The Netherlands, 2020; pp. 161–363. ISBN 978-0-12-812894-7. [Google Scholar]

- Joshi, A.Y.; Joshi, A.Y. A Systematic Review on Powder Mixed Electrical Discharge Machining. Heliyon 2019, 5, e02963. [Google Scholar] [CrossRef] [Green Version]

- Zhao, W.S.; Meng, Q.G.; Wang, Z.L. The Application of Research on Powder Mixed EDM in Rough Machining. J. Mater. Process. Technol. 2002, 129, 30–33. [Google Scholar] [CrossRef]

- Kumar, A.; Maheshwari, S.; Sharma, C.; Beri, N. Analysis of Machining Characteristics in Additive Mixed Electric Discharge Machining of Nickel-Based Super Alloy Inconel 718. Mater. Manufac. Process. 2011, 26, 1011–1018. [Google Scholar] [CrossRef]

- Kumar, A.; Maheshwari, S.; Sharma, C.; Beri, N. Research Developments in Additives Mixed Electrical Discharge Machining (AEDM): A State of Art Review. Mater. Manuf. Process. 2010, 25, 1166–1180. [Google Scholar] [CrossRef]

- Jamadar, M.U.M.; Kavade, M.V. Effect of Aluminium powder mixed EDM on machining characteristics of die steel (AISI D3). IJMPE 2014, 2, 120–123. [Google Scholar]

- Dewan, P.R.; Kundu, P.K.; Phipon, R. Powder Mixed Electric Discharge Machining—A Review. In Proceedings of the 2nd International Conference on Mechanical Materials and Renewable Energy (Icmmre 2019), East Sikkim, India, 6–7 December 2019; p. 050075. [Google Scholar]

- Al-Amin, M.; Abdul-Rani, A.M.; Rana, M.; Hastuty, S.; Danish, M.; Rubaiee, S.; Mahfouz, A. bin Evaluation of Modified 316L Surface Properties through HAp Suspended EDM Process for Biomedical Application. Surf. Interfaces 2022, 28, 101600. [Google Scholar] [CrossRef]

- Qazi, M.J.; Schlegel, S.J.; Backus, E.H.G.; Bonn, M.; Bonn, D.; Shahidzadeh, N. Dynamic Surface Tension of Surfactants in the Presence of High Salt Concentrations. Langmuir 2020, 36, 7956–7964. [Google Scholar] [CrossRef] [PubMed]

- Dave, N.; Joshi, T. A Concise Review on Surfactants and Its Significance. Int. J. Appl. Chem. 2017, 13, 663–672. [Google Scholar] [CrossRef]

- Ilani, M.A.; Khoshnevisan, M. Study of Surfactant Effects on Intermolecular Forces (IMF) in Powder-Mixed Electrical Discharge Machining (EDM) of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2021, 116, 1763–1782. [Google Scholar] [CrossRef]

- Bart, J.C.J.; Gucciardi, E.; Cavallaro, S. Formulating Lubricating Oils. In Biolubricants; Elsevier: Amsterdam, The Netherlands, 2013; pp. 351–395. ISBN 978-0-85709-263-2. [Google Scholar]

- Villarrazo, N.; Caneda, S.; Pereira, O.; Rodríguez, A.; López De Lacalle, L.N. The Effects of Lubricooling Ecosustainable Techniques on Tool Wear in Carbon Steel Milling. Materials 2023, 16, 2936. [Google Scholar] [CrossRef]

- Kumar, S.; Khedkar, N.K.; Jagtap, B.; Singh, T.P. The Effects of Cryogenic Treatment on Cutting Tools. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 012104. [Google Scholar] [CrossRef]

- Özdemir, Z. Shallow Cryogenic Treatment (SCT) Effects on the Mechanical Properties of High Cr Cast Iron: Low-Carbon Cast Steel Bimetallic Casting. Inter Met. 2021, 15, 952–961. [Google Scholar] [CrossRef]

- Senthilkumar, D.; Rajendran, I. Influence of Shallow and Deep Cryogenic Treatment on Tribological Behavior of En 19 Steel. J. Iron Steel Res. Int. 2011, 18, 53–59. [Google Scholar] [CrossRef]

- Tiwary, A.P.; Pradhan, B.B.; Bhattacharyya, B. Investigation on the Effect of Dielectrics during Micro-Electro-Discharge Machining of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2018, 95, 861–874. [Google Scholar] [CrossRef]

- Ahmed, N.; Ishfaq, K.; Rafaqat, M.; Pervaiz, S.; Anwar, S.; Salah, B. EDM of Ti-6Al-4V: Electrode and Polarity Selection for Minimum Tool Wear Rate and Overcut. Mater. Manufac. Process. 2019, 34, 769–778. [Google Scholar] [CrossRef]

- Singh, S.; Maheshwari, S.; Pandey, P.C. Some Investigations into the Electric Discharge Machining of Hardened Tool Steel Using Different Electrode Materials. J. Mater. Process. Technol. 2004, 149, 272–277. [Google Scholar] [CrossRef]

- Sivakumar, K.M.; Gandhinathan, R. Establishing Optimum Process Parameters for Machining Titanium Alloys (Ti6Al4V) in Spark Electric Discharge Machining. IJEAT 2013, 2, 201–204. [Google Scholar]

- Singh, B.; Kumar, P.; Arora, G.; Kumar, A. Analysis of Machining Parameters for Dimensional Accuracy in EDM Using Taguchi’s Doe. Int. J. Eng. Res. 2014, 3, 5. [Google Scholar]

- Grewal, G.S.; Dhiman, D.P. Effect of Deep Cryogenic Treatment on Copper Electrode for Non-Traditional Electric Discharge Machining (EDM). Mech. Sci. 2019, 10, 413–427. [Google Scholar] [CrossRef]

- Bhaumik, M.; Maity, K. Effect of Electrode Materials on Different EDM Aspects of Titanium Alloy. Silicon 2019, 11, 187–196. [Google Scholar] [CrossRef]

- Pradhan, B.B.; Masanta, M.; Sarkar, B.R.; Bhattacharyya, B. Investigation of Electro-Discharge Micro-Machining of Titanium Super Alloy. Int. J. Adv. Manuf. Technol. 2009, 41, 1094–1106. [Google Scholar] [CrossRef]

- Kibria, G.; Sarkar, B.R.; Pradhan, B.B.; Bhattacharyya, B. Comparative Study of Different Dielectrics for Micro-EDM Performance during Microhole Machining of Ti-6Al-4V Alloy. Int. J. Adv. Manuf. Technol. 2010, 48, 557–570. [Google Scholar] [CrossRef]

- Singh, P.B.; Phull, G.S.; Puggal, S. Study of Radial Overcut during EDM of H-13 Steel with Cryogenic Cooled Electrode Using Taguchi Method. Int. J. Mech. Eng. Robot. Res. 2015, 4, 9. [Google Scholar]

- Ishfaq, K.; Sana, M.; Rehman, M.; Anwar, S.; Alfaify, A.Y.; Zia, A.W. Role of Biodegradable Dielectrics toward Tool Wear and Dimensional Accuracy in Cu-Mixed Die Sinking EDM of Inconel 600 for Sustainable Machining. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 235. [Google Scholar] [CrossRef]

- Das, A.; Padhan, S.; Ranjan Das, S. Analysis on Hole Overcut during Micro-EDM of Inconel 718. Mater. Today Proc. 2022, 56, 29–35. [Google Scholar] [CrossRef]

- Asif, N.; Saleem, M.Q.; Farooq, M.U. Performance Evaluation of Surfactant Mixed Dielectric and Process Optimization for Electrical Discharge Machining of Titanium Alloy Ti6Al4V. CIRP J. Manuf. Sci. Technol. 2023, 43, 42–56. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Patel, V.; Lacalle, L.N.L.D.; Parikh, D.M. Effect of WEDM Process Parameters on Surface Morphology of Nitinol Shape Memory Alloy. Materials 2020, 13, 4943. [Google Scholar] [CrossRef] [PubMed]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López De Lacalle, L.N. Cryogenic and Minimum Quantity Lubrication for an Eco-Efficiency Turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Pereira, O.; Celaya, A.; Urbikaín, G.; Rodríguez, A.; Fernández-Valdivielso, A.; Lacalle, L.N.L.D. CO2 Cryogenic Milling of Inconel 718: Cutting Forces and Tool Wear. J. Mater. Res. Technol. 2020, 9, 8459–8468. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Valdivielso, A.; Barreiro, J.; Fernández-Abia, A.I.; López-de-Lacalle, L.N. Cryogenic Hard Turning of ASP23 Steel Using Carbon Dioxide. Procedia Eng. 2015, 132, 486–491. [Google Scholar] [CrossRef]

- Sliusarenko, O.; Escudero, G.G.; González, H.; Calleja, A.; Bartoň, M.; Ortega, N.; De Lacalle, L.N.L. Constant Probe Orientation for Fast Contact-Based Inspection of 3D Free-Form Surfaces Using (3+2)-Axis Inspection Machines. Precis. Eng. 2023, 84, 37–44. [Google Scholar] [CrossRef]

- Muhammad Ashraf, W.; Moeen Uddin, G.; Muhammad Arafat, S.; Afghan, S.; Hassan Kamal, A.; Asim, M.; Haider Khan, M.; Waqas Rafique, M.; Naumann, U.; Niazi, S.G.; et al. Optimization of a 660 MWe Supercritical Power Plant Performance—A Case of Industry 4.0 in the Data-Driven Operational Management Part 1. Thermal Efficiency. Energies 2020, 13, 5592. [Google Scholar] [CrossRef]

- Uddin, G.M.; Ziemer, K.S.; Zeid, A.; Kamarthi, S. Monte Carlo Study of the Molecular Beam Epitaxy Process for Manufacturing Magnesium Oxide Nano-Scale Films. IIE Trans. 2015, 47, 125–140. [Google Scholar] [CrossRef]

- Khan, A.A. Electrode Wear and Material Removal Rate during EDM of Aluminum and Mild Steel Using Copper and Brass Electrodes. Int. J. Adv. Manuf. Technol. 2008, 39, 482–487. [Google Scholar] [CrossRef]

- Khan, M.A.R.; Rahman, M.M.; Kadirgama, K. An Experimental Investigation on Surface Finish in Die-Sinking EDM of Ti-5Al-2.5Sn. Int. J. Adv. Manuf. Technol. 2015, 77, 1727–1740. [Google Scholar] [CrossRef]

- Das, S.; Paul, S.; Doloi, B. Feasibility Investigation of Neem Oil as a Dielectric for Electrical Discharge Machining. Int. J. Adv. Manuf. Technol. 2020, 106, 1179–1189. [Google Scholar] [CrossRef]

- Ashraf, W.M.; Uddin, G.M.; Arafat, S.M.; Krzywanski, J.; Xiaonan, W. Strategic-level performance enhancement of a 660 MWe supercritical power plant and emissions reduction by AI approach. Energy Convers. Manag. 2021, 250, 114913. [Google Scholar] [CrossRef]

- Ashraf, W.M.; Uddin, G.M.; Tariq, R.; Ahmed, A.; Farhan, M.; Nazeer, M.A.; Hassan, R.U.; Naeem, A.; Jamil, H.; Krzywanski, J.; et al. Artificial Intelligence Modeling-Based Optimization of an Industrial-Scale Steam Turbine for Moving toward Net-Zero in the Energy Sector. ACS Omega 2023, 8, 1709–21725. [Google Scholar] [CrossRef]

- Krzywanski, J.; Blaszczuk, A.; Czakiert, T.; Rajczyk, R.; Nowak, W. Artificial intelligence treatment of NOX emissions from CFBC in air and oxy-fuel conditions. In Proceedings of the CFB-11: Proceedings of the 11th International Conference on Fluidized Bed Technology, Beijing, China, 14–17 May 2014; pp. 619–624. [Google Scholar]

- Ashraf, W.M.; Uddin, G.M.; Farooq, M.; Riaz, F.; Ahmad, H.A.; Kamal, A.H.; Anwar, S.; El-Sherbeeny, A.M.; Khan, M.H.; Hafeez, N.; et al. Construction of operational data-driven power curve of a generator by industry 4.0 data analytics. Energies 2021, 14, 1227. [Google Scholar]

- Suvarna, M.; Jahirul, M.I.; Aaron-Yeap, W.H.; Augustine, C.V.; Umesh, A.; Rasul, M.G.; Günay, M.E.; Yildirim, R.; Janaun, J. Predicting Biodiesel Properties and Its Optimal Fatty Acid Profile via Explainable Machine Learning. Renew. Energy 2022, 189, 245–258. [Google Scholar] [CrossRef]

- Mondal, N.; Nishant; Ghosh, S.; Mandal, M.C.; Pati, S.; Banik, S. ANN and RSM Based Predictive Model Development and EDM Process Parameters Optimization on AISI 304 Stainless Steel. Mater. Today Proc. 2023, S2214785323004121. [Google Scholar] [CrossRef]

| Element | % Content | Element | % Content | Properties | Values |

|---|---|---|---|---|---|

| C | 0.05–0.15 | Cu | 0.5 | Electrical Resistivity (µ Ωm) | 1.22 |

| S | 0.015 | Co | 10.0–15.0 | Melting Range (°C) | 1332–1380 |

| Cr | 20.0–24.0 | Mo | 8.0–10.0 | Specific Heat (J/kg°C) | 419 |

| Ti | 0.6 | Mn | 1.0 | Density (kg/m3) | 8360 |

| Ni | 44.5 | Al | 0.8–1.5 | - | - |

| Si | 1.0 | B | 0.006 | - | - |

| Fe | 3.0 | - | - | - | - |

| Properties | Chemical Formula | Molecular Weight (g/mol) | Density (g/cm3 at 25 °C) | Flashpoint (°C) | HLB Value |

|---|---|---|---|---|---|

| S-80 | C24H44O6 | 428.60 | 1.068 | 186.2 | 4.6 |

| S-20 | C18H34O6 | 346.46 | 1.032 | >110 | 8.6 |

| T-80 | C64H124O26 | 1309 | 1.08 | 148 | 15 |

| T-20 | C58H114O26 | 1227.54 | 1.095 | >110 | 16.7 |

| Input Variable | Levels | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Type of Dielectric | Pure Kerosene | Kerosene-S-20 | Kerosene-S-80 | Kerosene-T-20 | Kerosene-T-80 |

| Type of Surfactant | S-20 | Span-80 | Tween-20 | Tween-80 | - |

| Electrode Type | Copper | Brass | - | - | - |

| Treatment Type | NT | CT | - | - | - |

| Constant Factors (Units) | Values |

|---|---|

| Surfactant Concentration (Vol %) | 6 |

| Spark Voltage (Volts) | 4 |

| Current (Amperes) | 10 |

| Pulse off Time (µsec) | 26 |

| Pulse on Time (µsec) | 100 |

| Properties | Melting Point (°C) | Electrical Conductivity (S/m) | Density (g/mm3) | Specific Heat Capacity (J/g °C) | Electrical Resistivity (Ω.m) |

|---|---|---|---|---|---|

| Copper | 1083 | 59 × 106 | 8.904 × 10−3 | 0.835 | 1.96 × 10−8 |

| Brass | 990 | 16 × 106 | 8.55 × 10−3 | 0.38 | 4.7 × 10−7 |

| Properties | Kerosene Oil |

|---|---|

| Specific heat (kJ/kg K) | 2.0 |

| Dielectric constant | 2.12 |

| Density (gm/cm3) at 20 °C | 0.8 |

| Flashpoint (°C) | 54 |

| Thermal conductivity (W/mK) | 0.12 |

| Viscosity (cm2/s) | 1.22 |

| Breakdown Voltage (kV) | 48 |

| Sr. No | Modified Dielectric | Electrode Types | OC (mm) | Sr. No | Modified Dielectric | Electrode Types | OC (mm) |

|---|---|---|---|---|---|---|---|

| 1 | Kerosene | NT copper | 0.212 | 11 | Kerosene | CT copper | 0.253 |

| 2 | NT brass | 0.213 | 12 | CT brass | 0.142 | ||

| 3 | Kerosene-S-20 | NT copper | 0.202 | 13 | Kerosene-S-20 | CT copper | 0.219 |

| 4 | NT brass | 0.241 | 14 | CT brass | 0.215 | ||

| 5 | Kerosene-S-80 | NT copper | 0.245 | 15 | Kerosene-S-80 | CT copper | 0.145 |

| 6 | NT brass | 0.236 | 16 | CT brass | 0.19 | ||

| 7 | Kerosene-T-20 | NT copper | 0.214 | 17 | Kerosene-T-20 | CT copper | 0.241 |

| 8 | NT brass | 0.228 | 18 | CT brass | 0.21 | ||

| 9 | Kerosene-T-80 | NT copper | 0.303 | 19 | Kerosene-T-80 | CT copper | 0.211 |

| 10 | NT brass | 0.241 | 20 | CT brass | 0.194 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishfaq, K.; Sana, M.; Waseem, M.U.; Ashraf, W.M.; Anwar, S.; Krzywanski, J. Enhancing EDM Machining Precision through Deep Cryogenically Treated Electrodes and ANN Modelling Approach. Micromachines 2023, 14, 1536. https://doi.org/10.3390/mi14081536

Ishfaq K, Sana M, Waseem MU, Ashraf WM, Anwar S, Krzywanski J. Enhancing EDM Machining Precision through Deep Cryogenically Treated Electrodes and ANN Modelling Approach. Micromachines. 2023; 14(8):1536. https://doi.org/10.3390/mi14081536

Chicago/Turabian StyleIshfaq, Kashif, Muhammad Sana, Muhammad Umair Waseem, Waqar Muhammad Ashraf, Saqib Anwar, and Jaroslaw Krzywanski. 2023. "Enhancing EDM Machining Precision through Deep Cryogenically Treated Electrodes and ANN Modelling Approach" Micromachines 14, no. 8: 1536. https://doi.org/10.3390/mi14081536

APA StyleIshfaq, K., Sana, M., Waseem, M. U., Ashraf, W. M., Anwar, S., & Krzywanski, J. (2023). Enhancing EDM Machining Precision through Deep Cryogenically Treated Electrodes and ANN Modelling Approach. Micromachines, 14(8), 1536. https://doi.org/10.3390/mi14081536