Haptic Feedback Device Using 3D-Printed Flexible, Multilayered Piezoelectric Coating for In-Car Touchscreen Interface

Abstract

1. Introduction

1.1. Principle of Haptic Feedback System and Objective of This Work

- The user interacts with a haptic-enabled device such as a touchscreen by applying pressure or making contact with the surface. This action generates an input signal detected by the machine’s sensors.

- The signal is translated by the machine’s algorithms into a haptic response, such as a vibration or force.

- This response is then outputted by the machine’s actuators, which generate the physical sensation perceived by the user.

- The user’s haptic sensors in the skin detect the physical sensation and transmit information to the brain, which interprets the sensation as a particular texture, shape, or force.

1.2. Materials Used for Haptic Touchscreen Actuators

2. Materials and Process

2.1. Material Selection and Ink Formulation

- Compatible with 3D printing additive manufacturing (AM): easy manipulation (adequate viscosity and dispersion) and good adhesion with the PET substrate.

- Durable: ability to withstand handling, heat, moisture, and other environmental factors.

- Cost-effective materials and printing process.

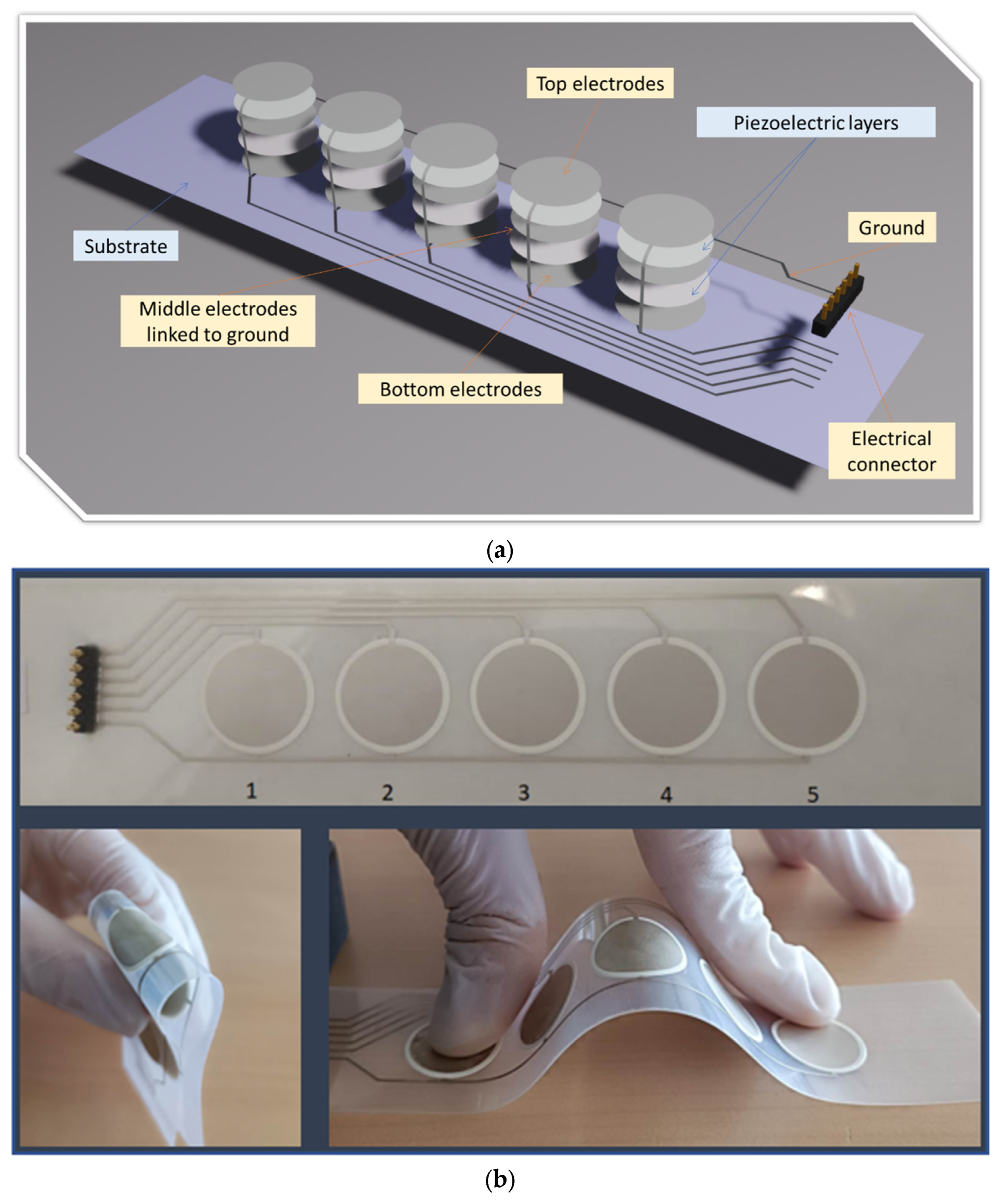

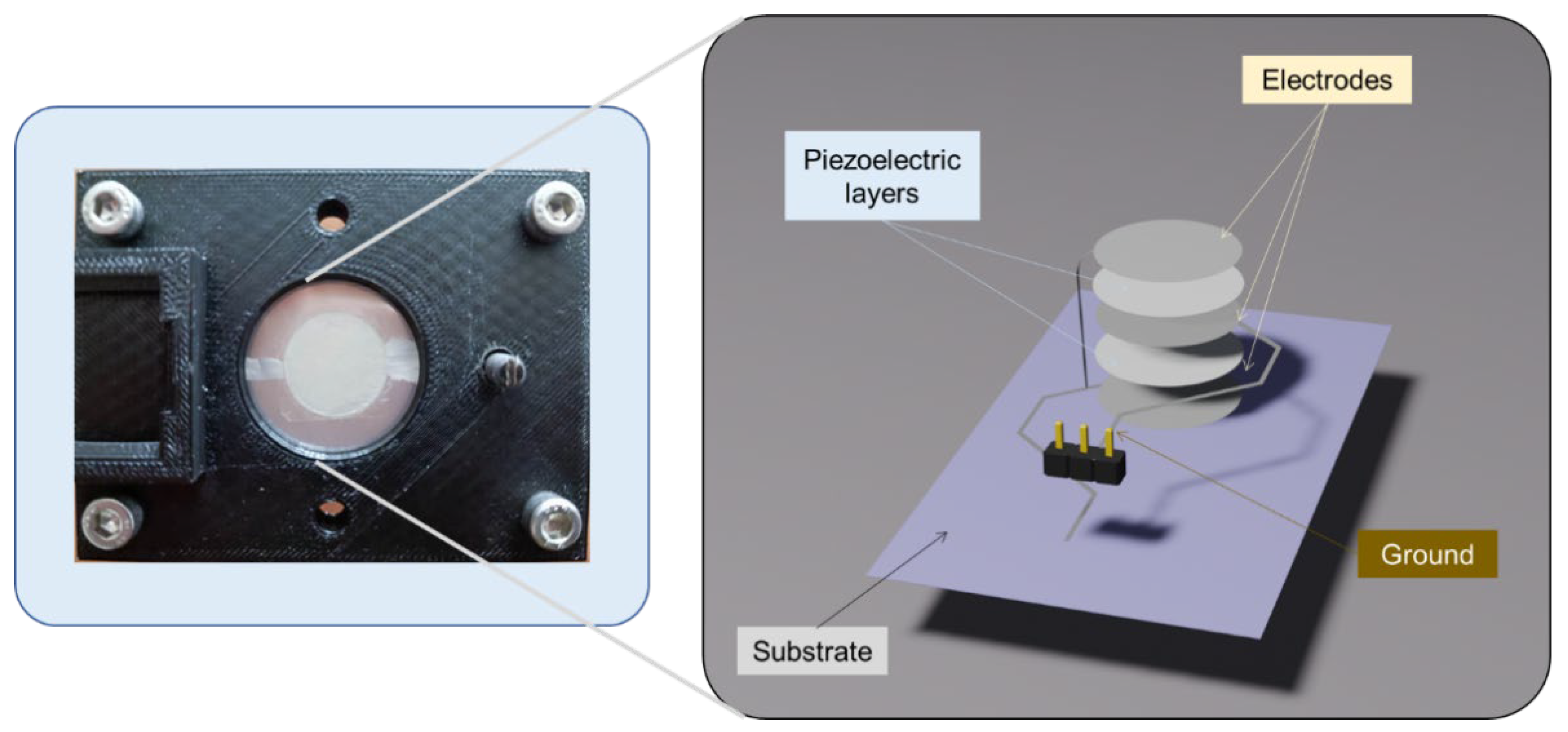

2.2. Fabrication Process Based Screen-Printing Technique

2.3. Poling Procedure

3. Characterization Methods

3.1. Setups for Characterization of Haptic Performance

- Preparation: The piezoelectric actuator is mounted in a test setup, including a power supply, measurement instrument, and any necessary fixtures or support structures.

- Mechanical-to-electrical sensing: A user applies a mechanical force or displacement to the piezoelectric material that results in the generation of an electrical signal, such as voltage or charge (corresponding to red arrows of Figure 3).

- Electrical-to-mechanical actuation: After receiving the trigger mentioned above, an electrical voltage is driven to the piezoelectric element, producing a mechanical motion (such as displacement, strain, or force) that is detected by the user’s fingers (corresponding to green arrows of Figure 3).

- Characterization: The results of the electrical-to-mechanical (actuator) and mechanical-to-electrical (sensor) tests are analyzed to determine the piezoelectric response and validate the haptic performance, such as frequency response, amplitude level, and stability.

- Comparison: The results are compared to the desired specifications and tolerances to determine if the actuator meets the performance criteria of a haptic touchscreen device.

3.1.1. Mechanical-to-Electrical Test Setup

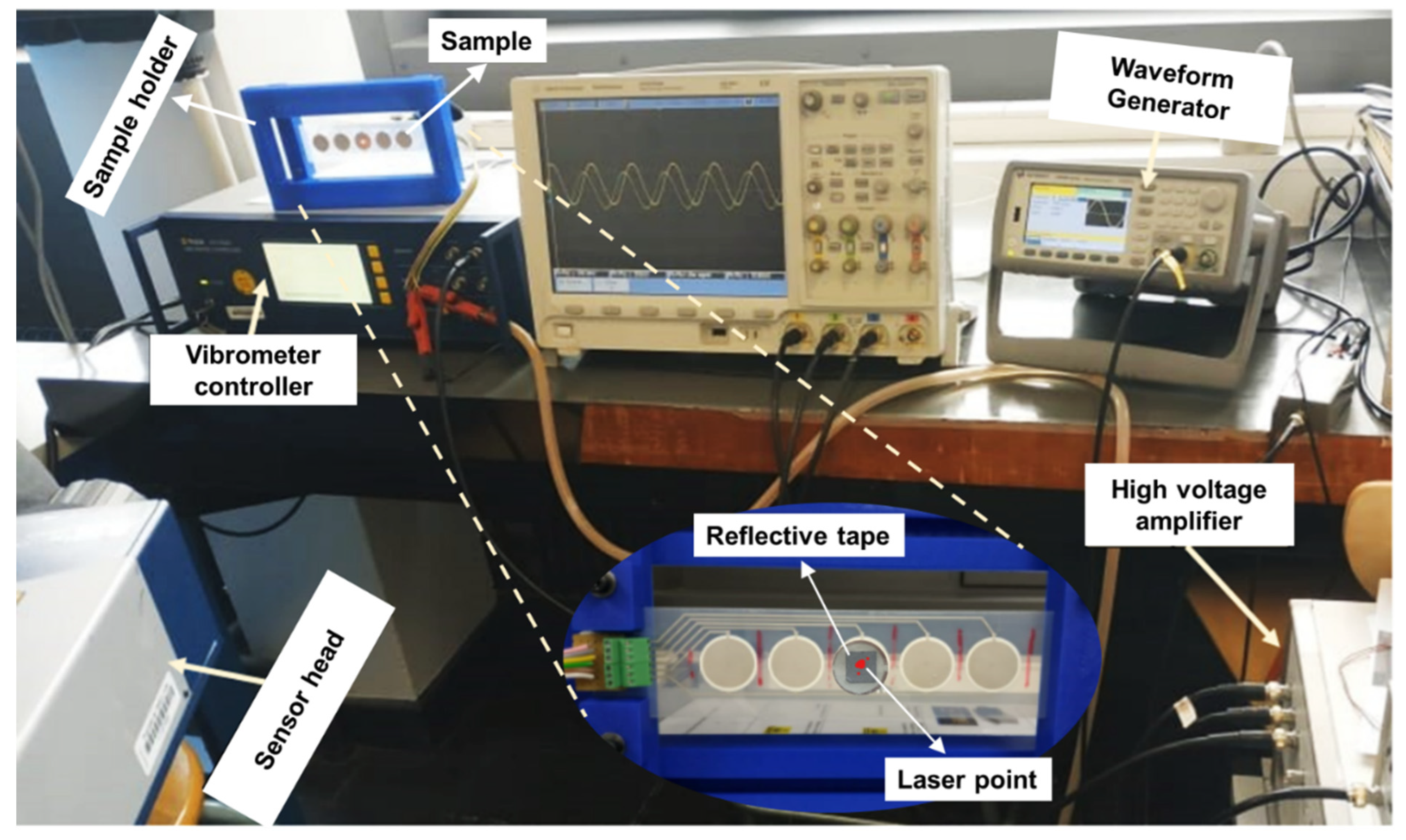

3.1.2. Electrical-to-Mechanical Test Setup

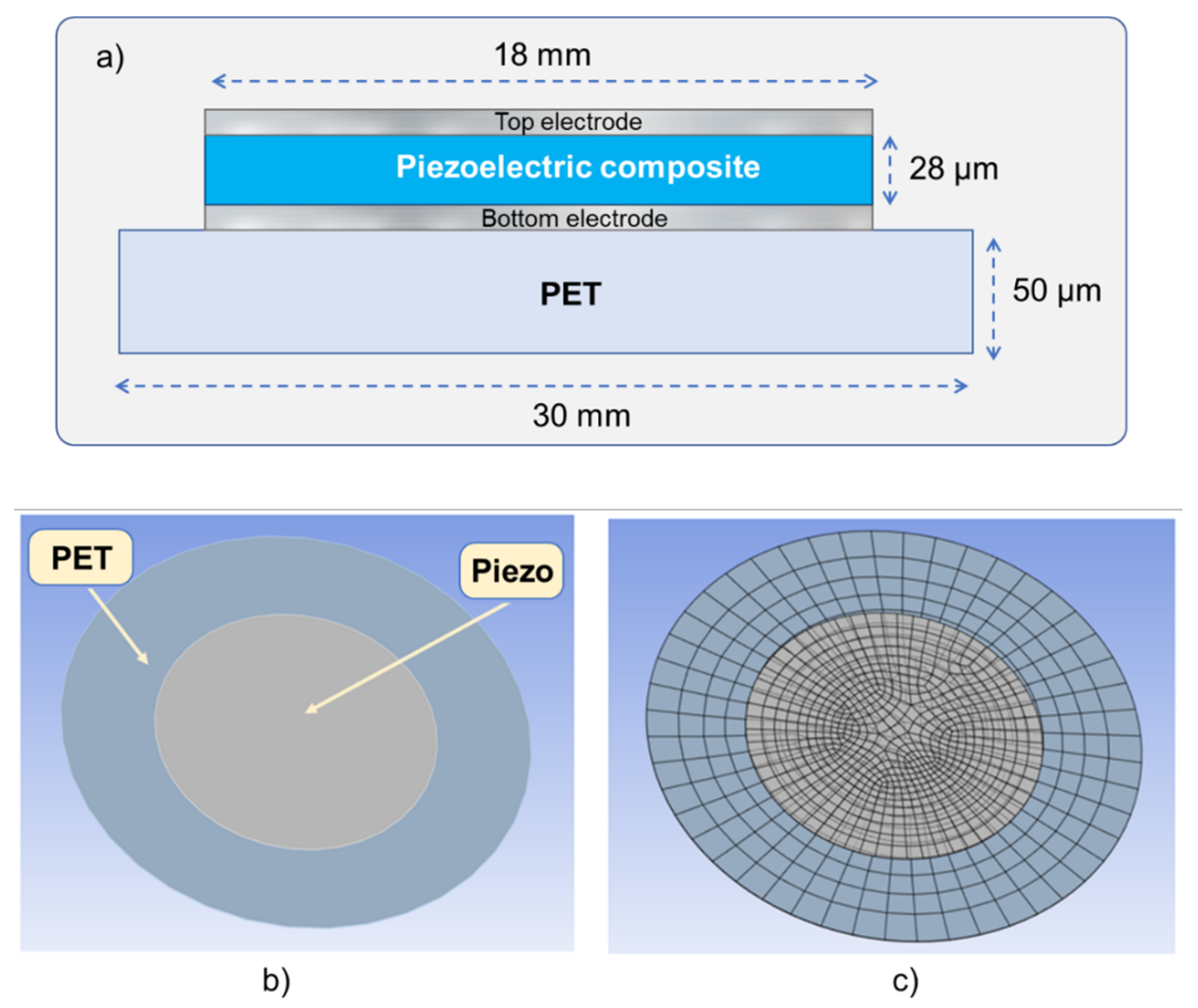

3.2. Simulation Model Used for Design Optimization

- The piezoelectric layer is built from isotropic materials, meaning that electrical and mechanical properties are directionally independent.

- The conductive tracks are not involved in the simulation model.

- The contact surface between the piezoelectric layer and the PET substrate is classified as a bounded contact, whereby they cannot move and rotate with respect to each other (neither sliding nor separating is possible).

- The contact between the PET substrate and the supports is classified as fictional contact, whereby they can slide on the top of each other but cannot be separated or rotated.

4. Results and Discussion

4.1. Optimizations of Smart Piezoelectric Coating-Based FEM

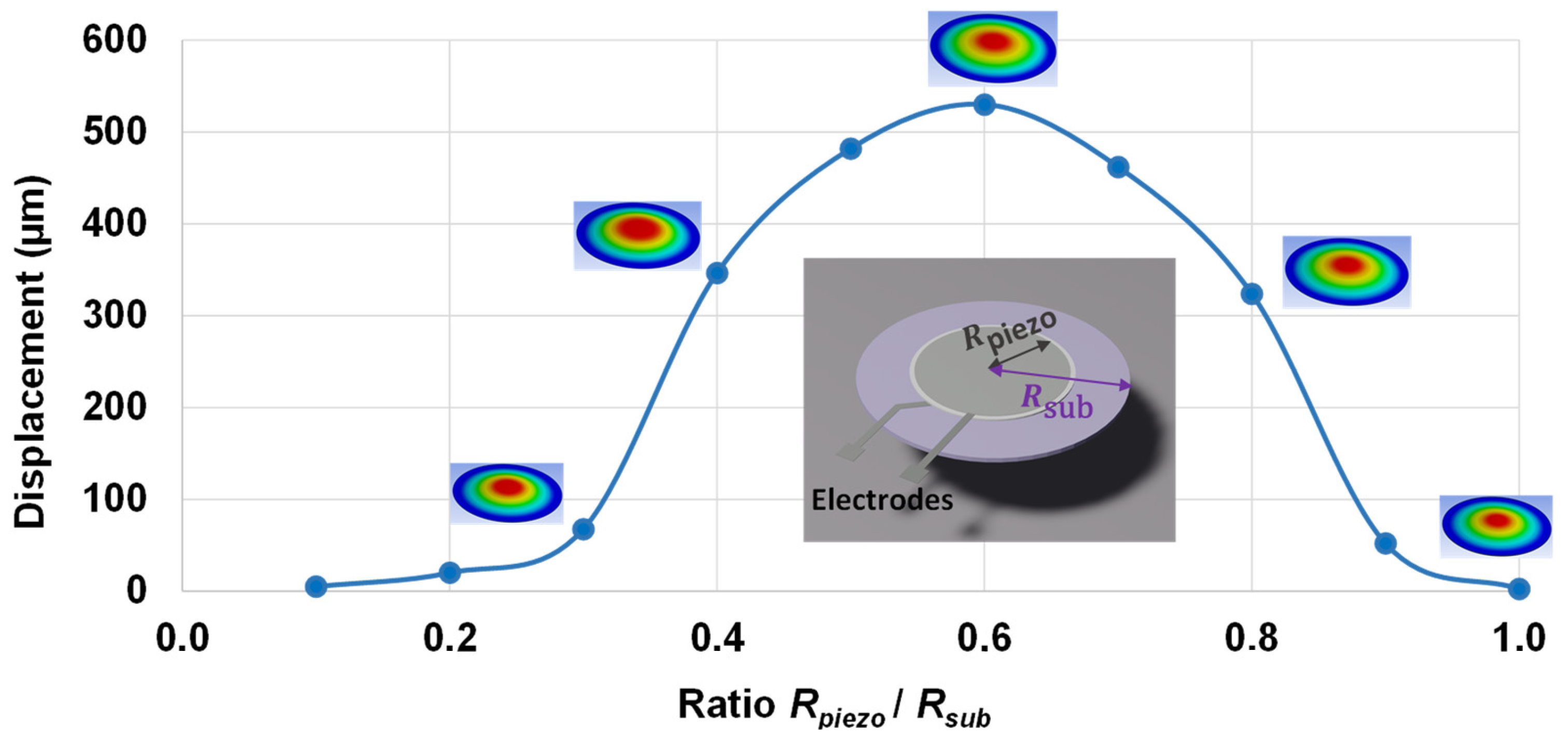

4.1.1. Influence of Radius Ratio

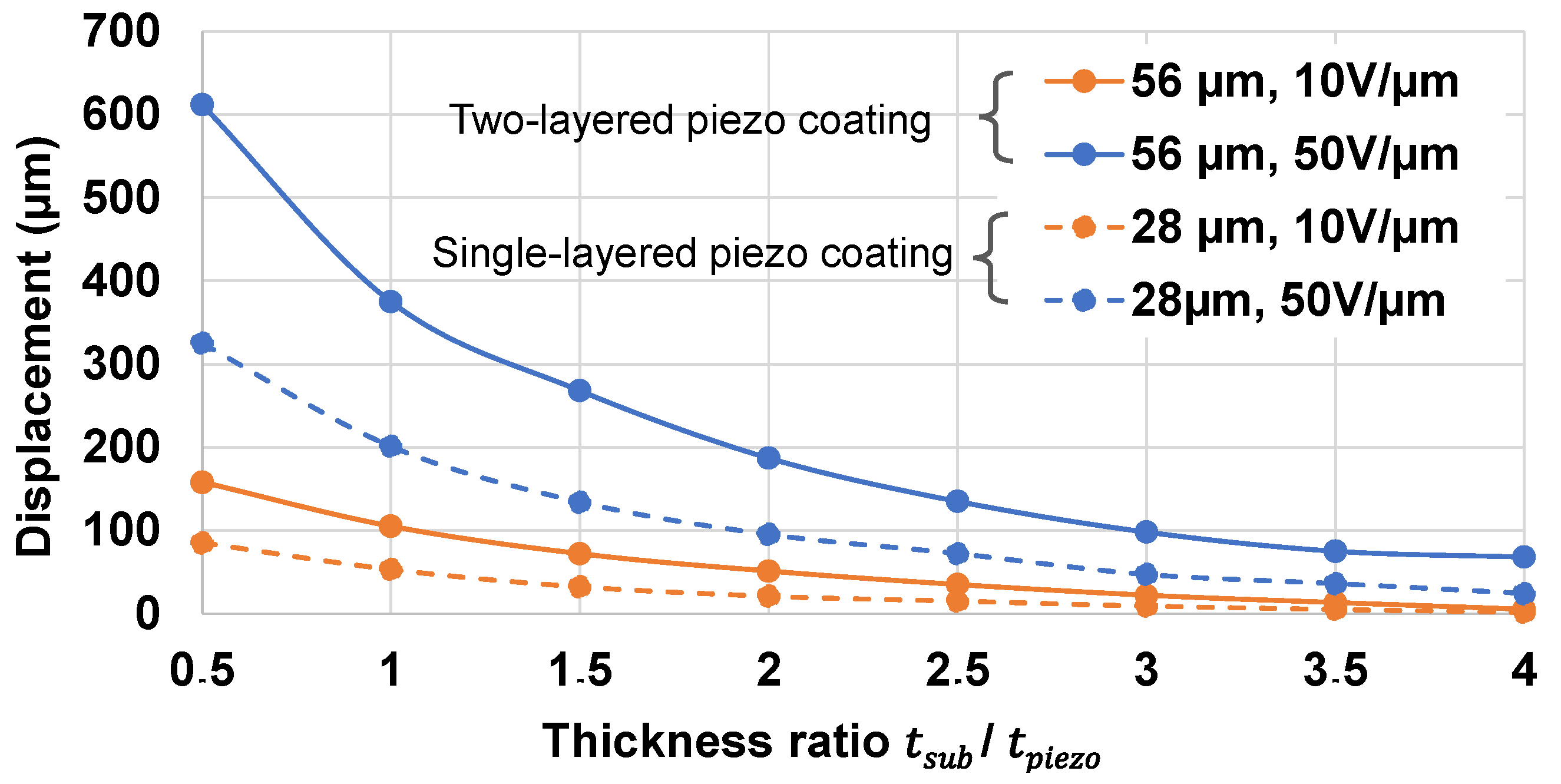

4.1.2. Influence of Thickness Ratio

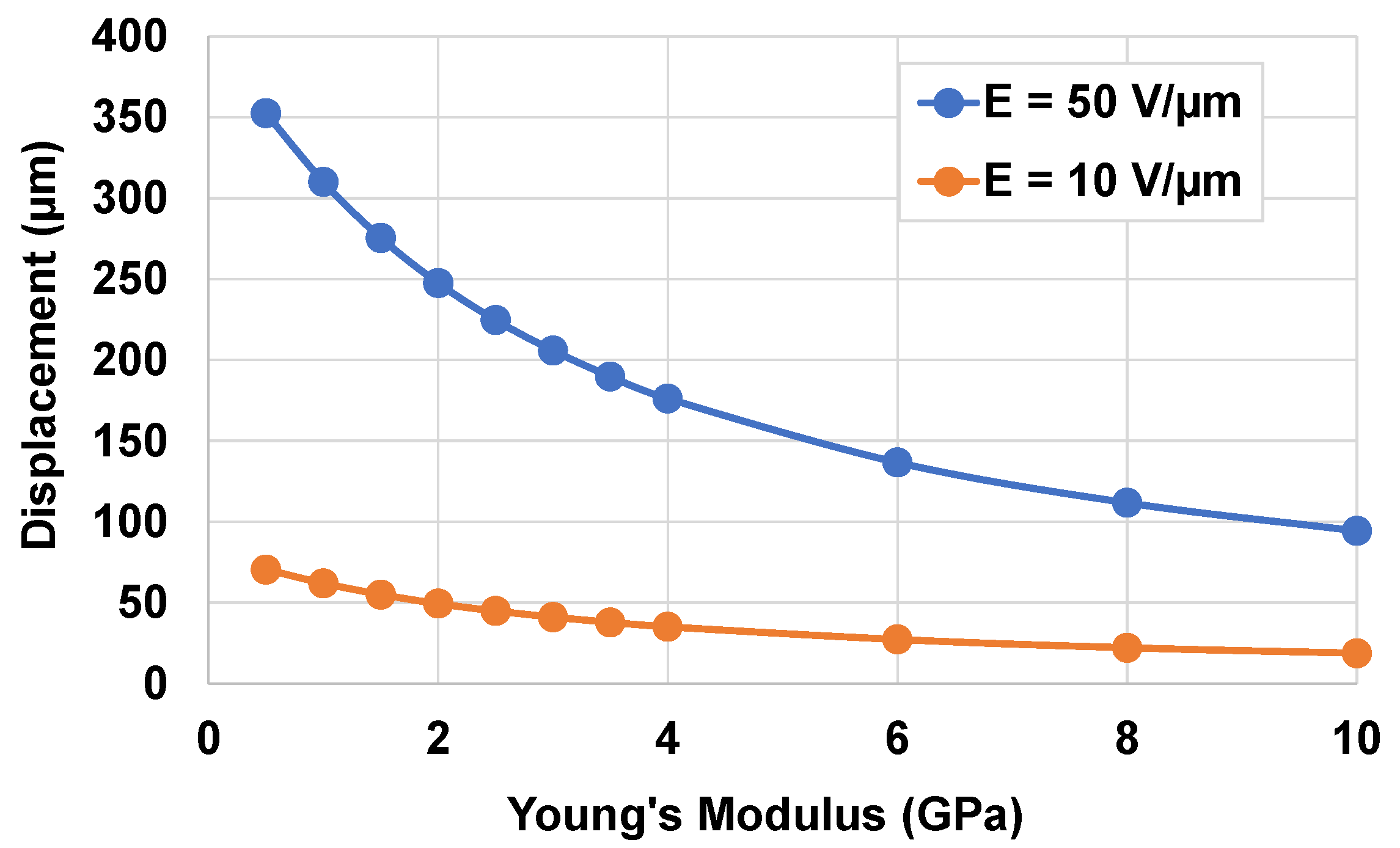

4.1.3. Influence of Young’s Modulus

- Altering the PET substrate thickness (: This is an easy solution but it might not modify the thickness ratio of the structure, which was chosen to be equal to 1.5.

- Using another material of substrate with a different Young’s modulus (denoted ): Materials with a higher are stiffer and more resistant to deformation under load, while those with a lower are more flexible and, thus, more easily stressed.

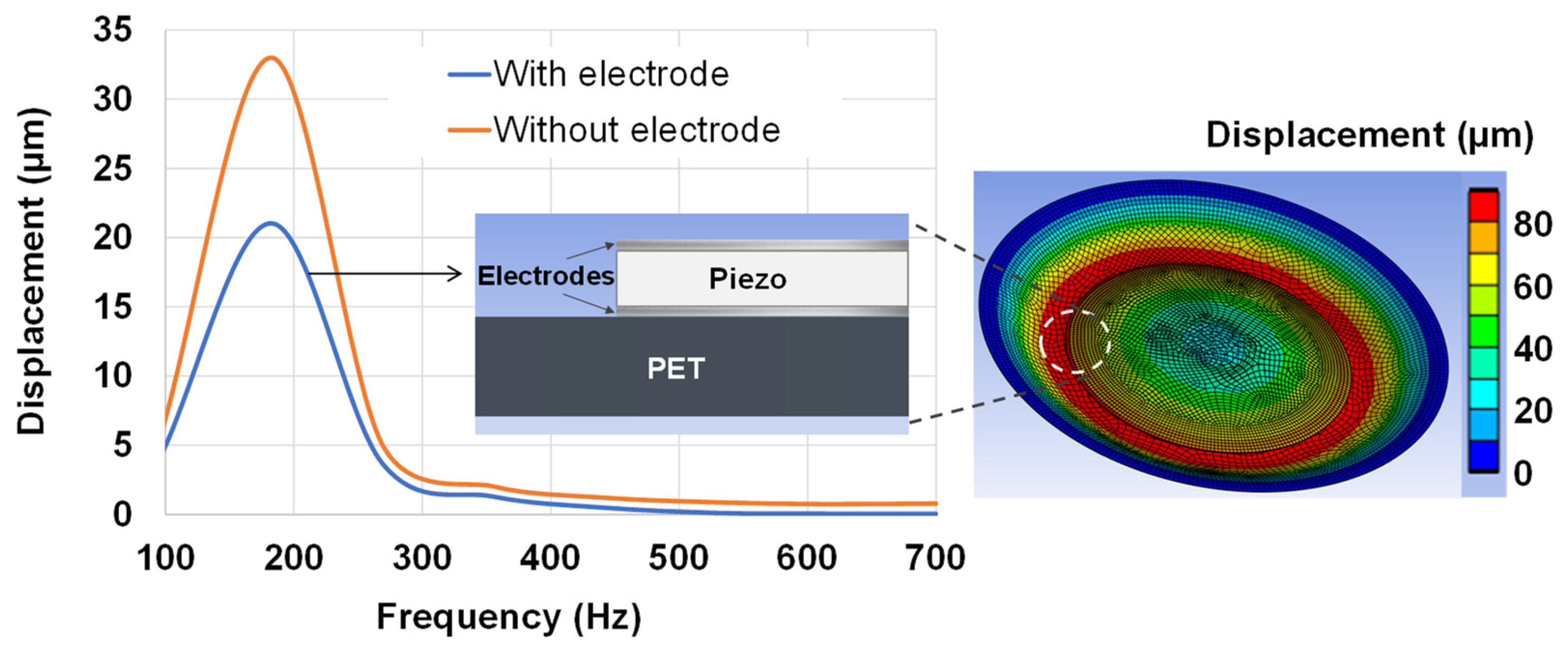

4.1.4. Influence of Electrodes

4.2. Performance of Haptic Device Based on Experimental Results

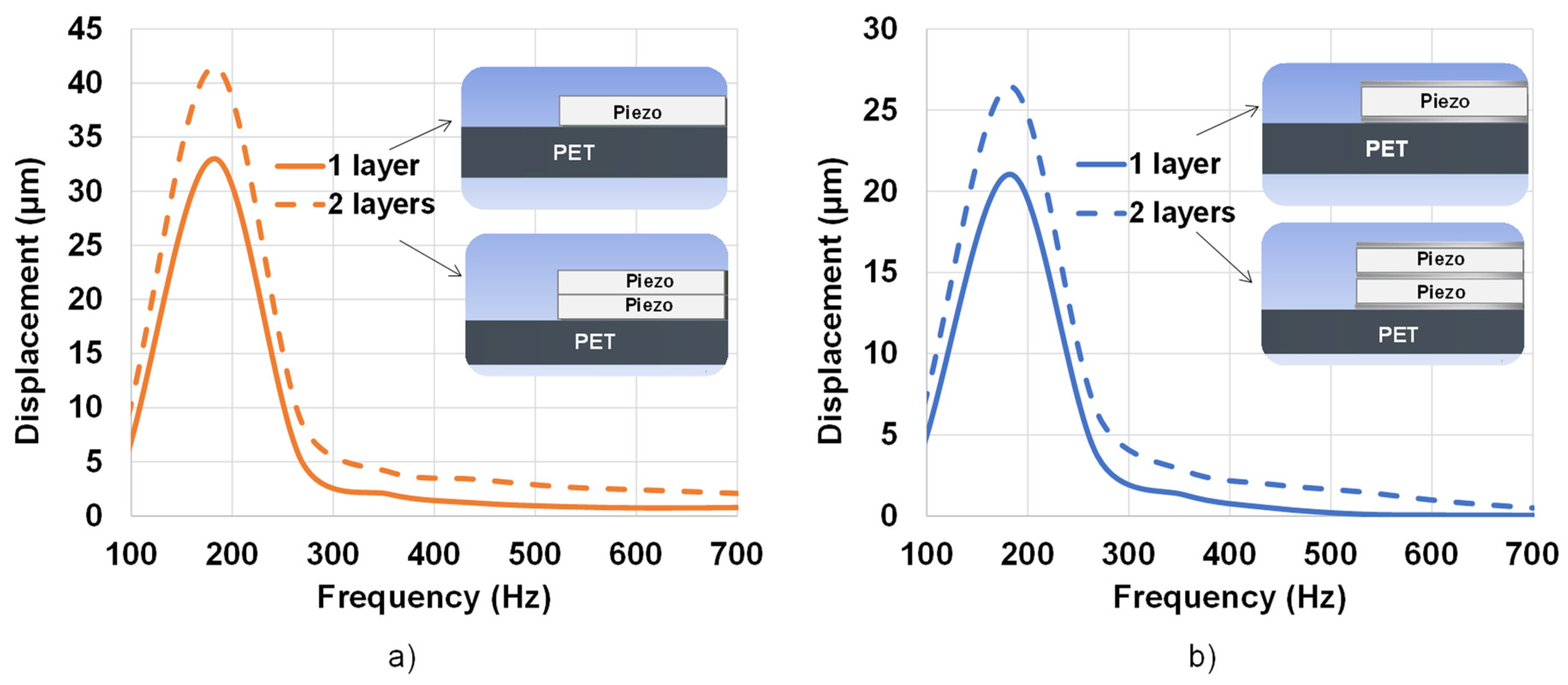

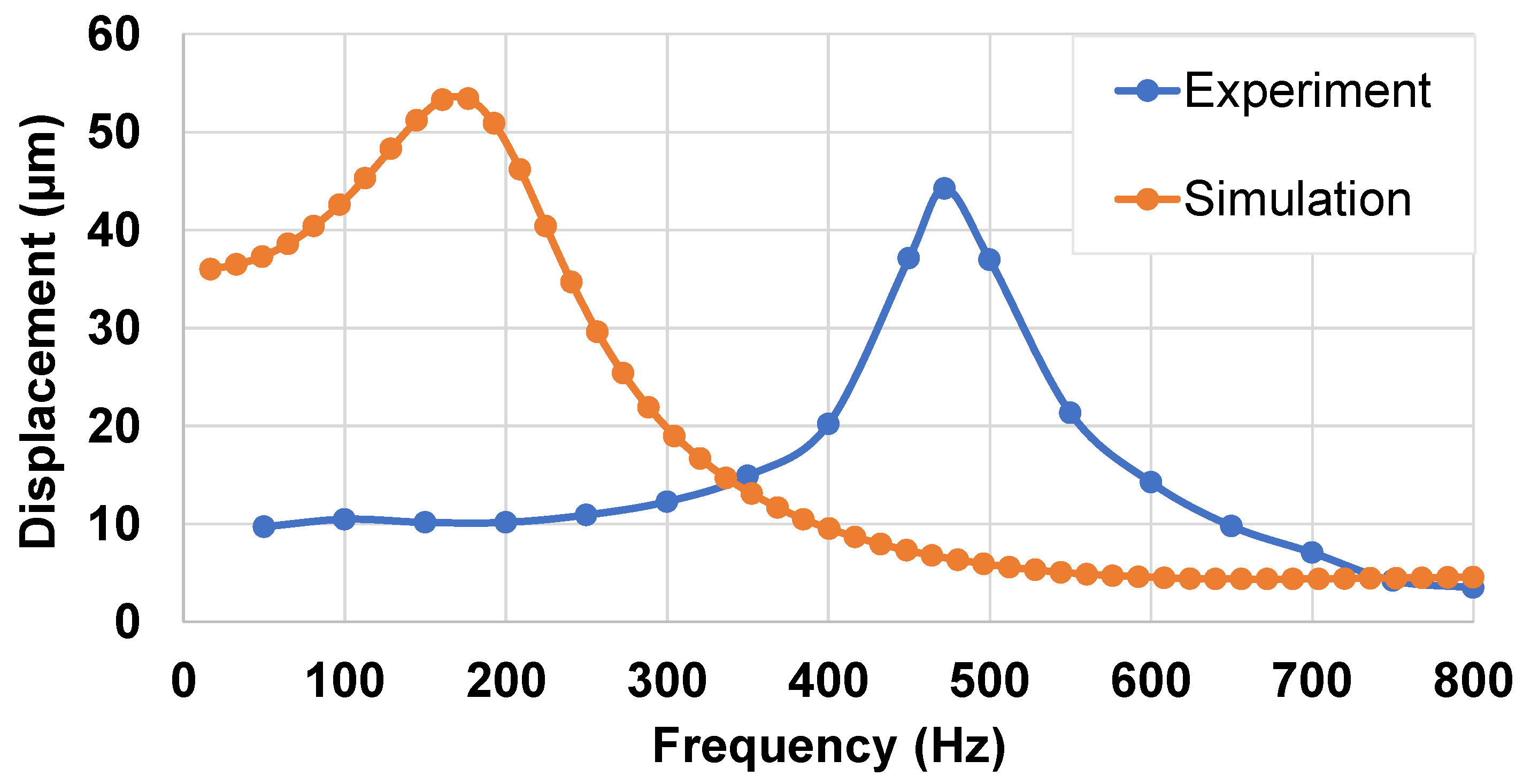

4.2.1. Displacement Spectrum

- In the simulation, the outer radius of the wafer was considered constant as the wafer was supposed to be fixed (i.e., static condition). Inversely to reality, the wafer could move slightly when pressed by a fingertip. In other words, measurements were conducted in a quasi-static environment, which is not similar to the case of the simulation.

- There was a discrepancy between the Young’s modulus of materials (BaTiO3 composite and PET substrate) specified in ANSYS and of the real ones.

- In practice, the wafer may not have been centered exactly on the support, producing some small changes in its geometry and, thus, shifting the resonance frequency to some extent.

- The imperfections in the fabrication process led to variations in the thickness and properties of the different layers.

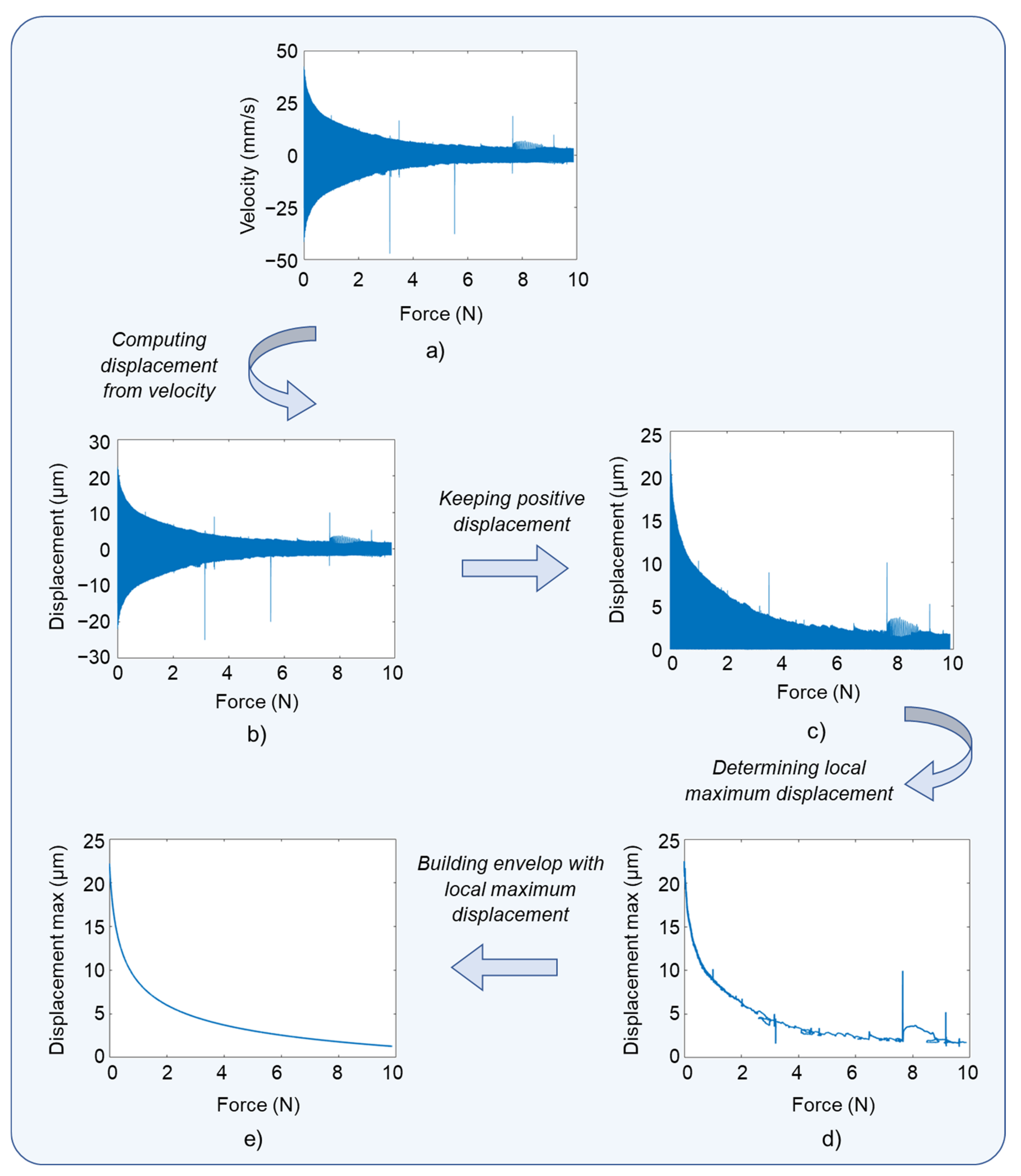

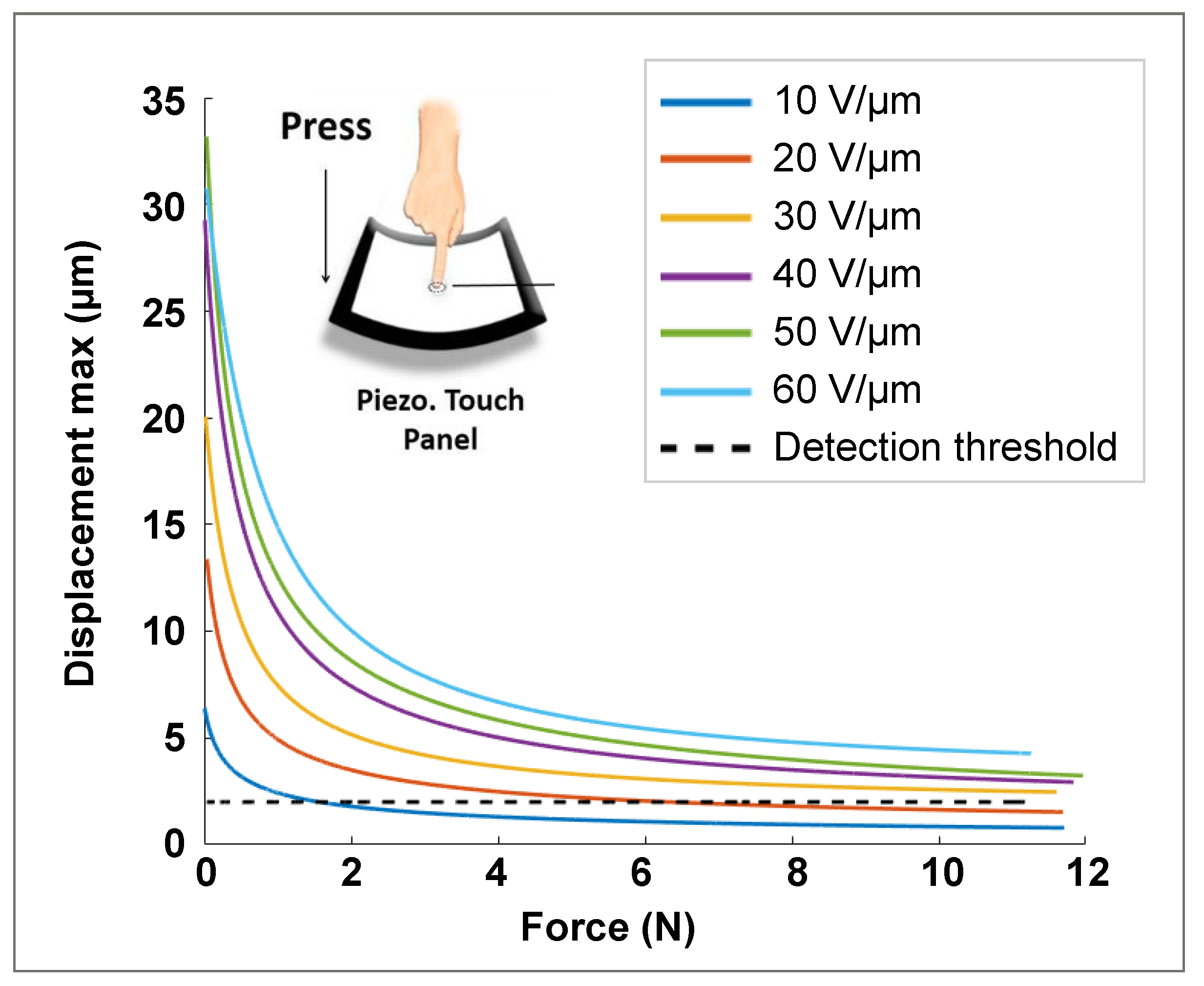

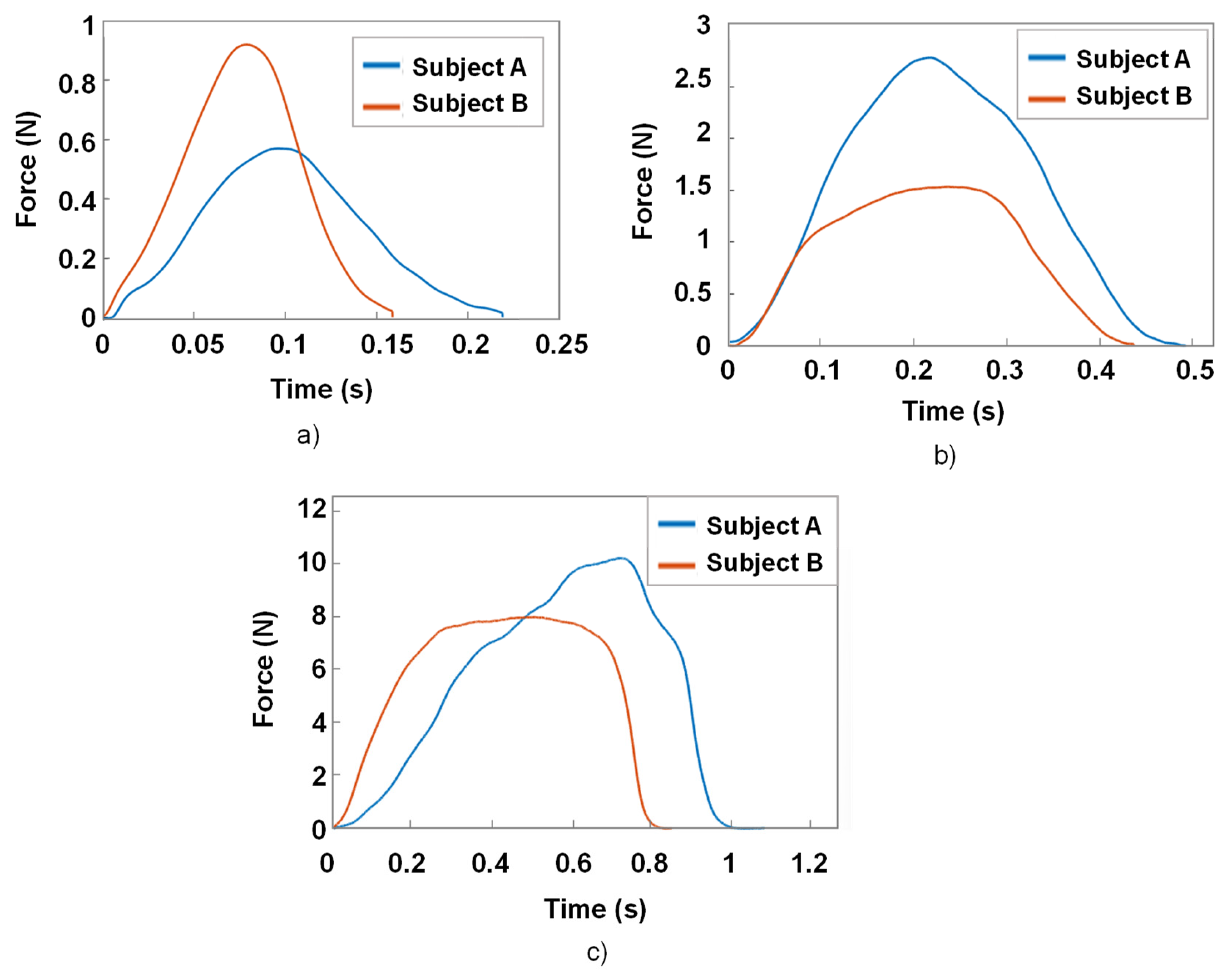

4.2.2. Actuator Mode: Displacement Versus Force

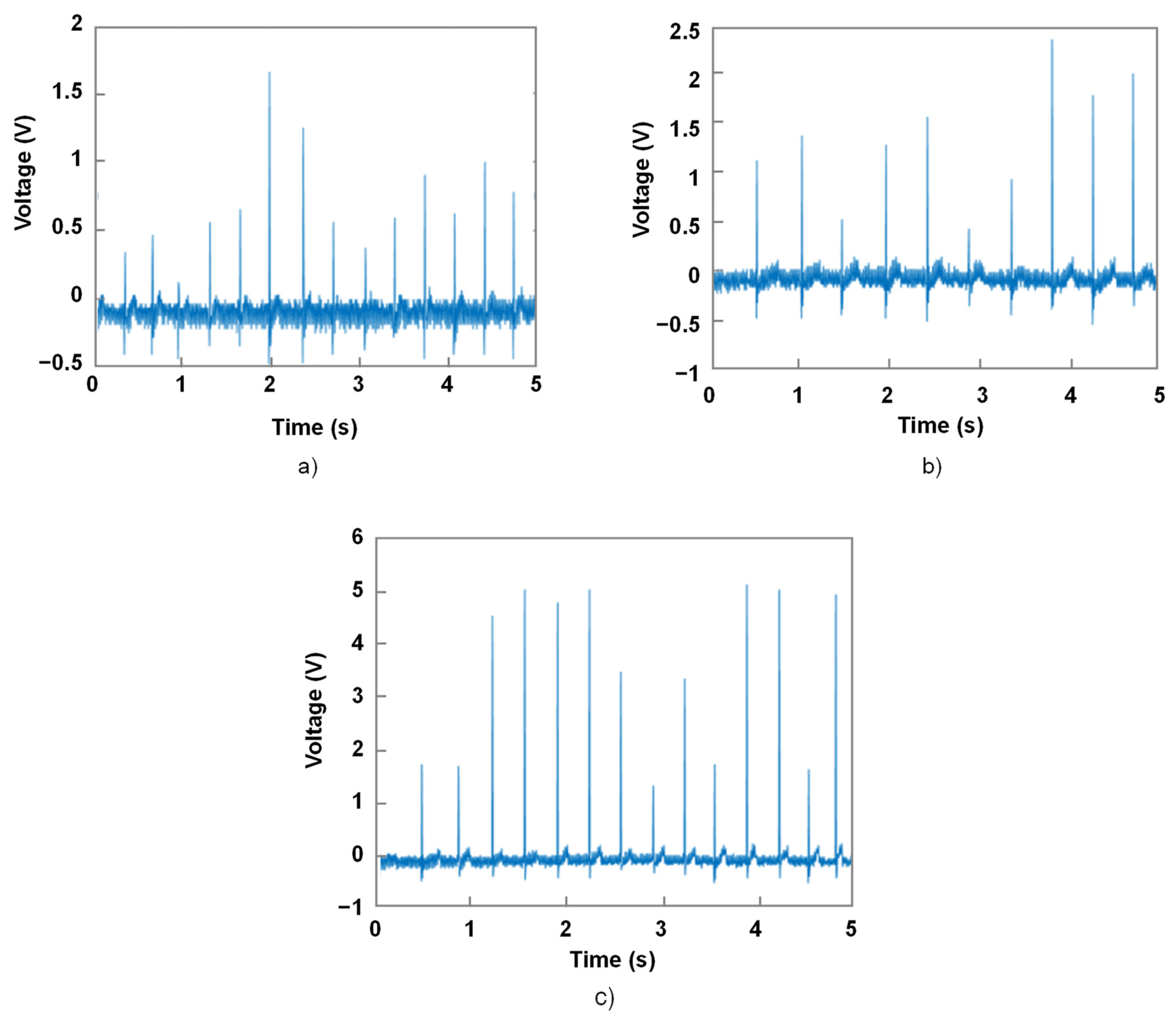

4.2.3. Sensor Mode: Activation of Haptic Response

4.3. Development of Haptic Demonstrator

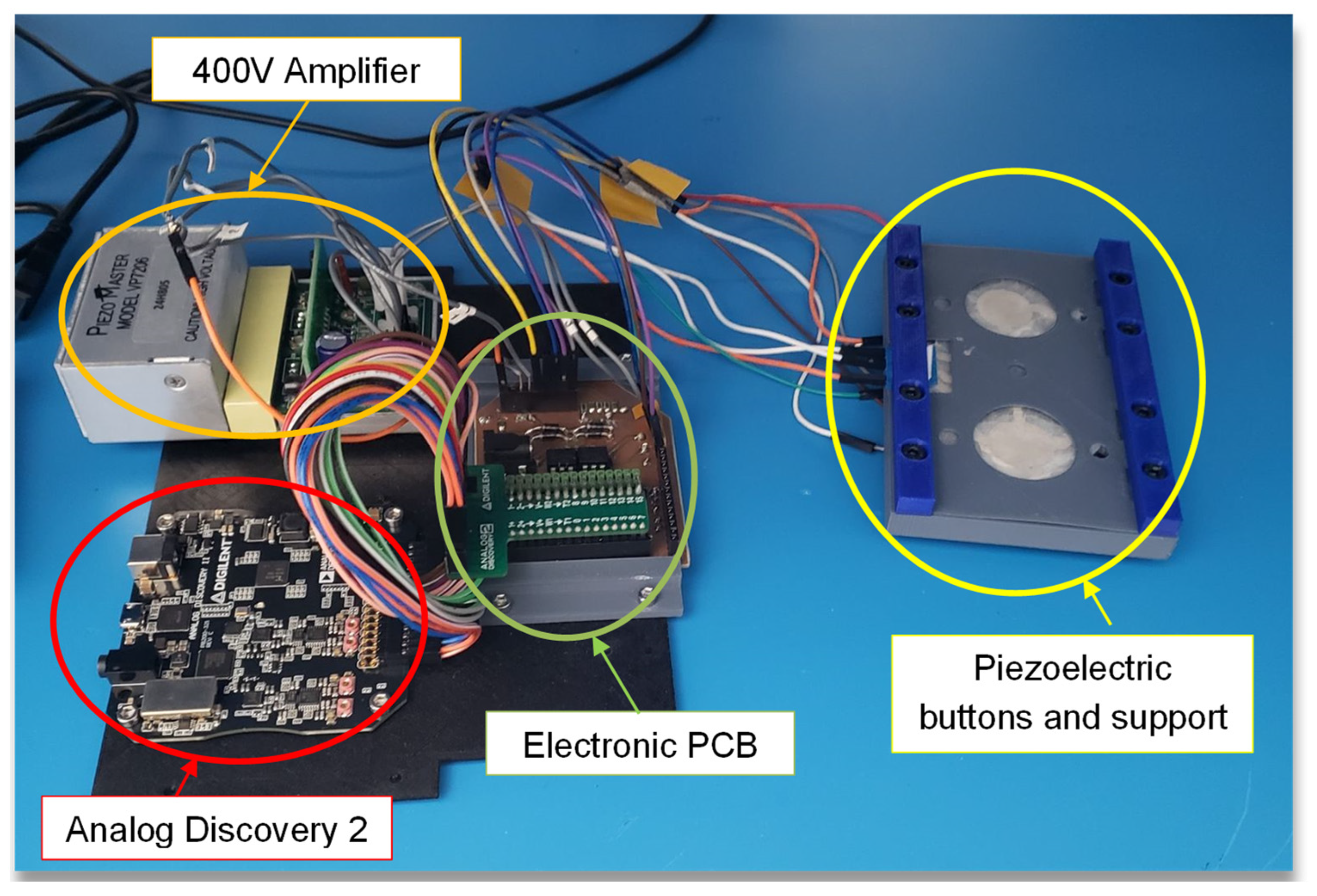

4.3.1. Description of Prototype

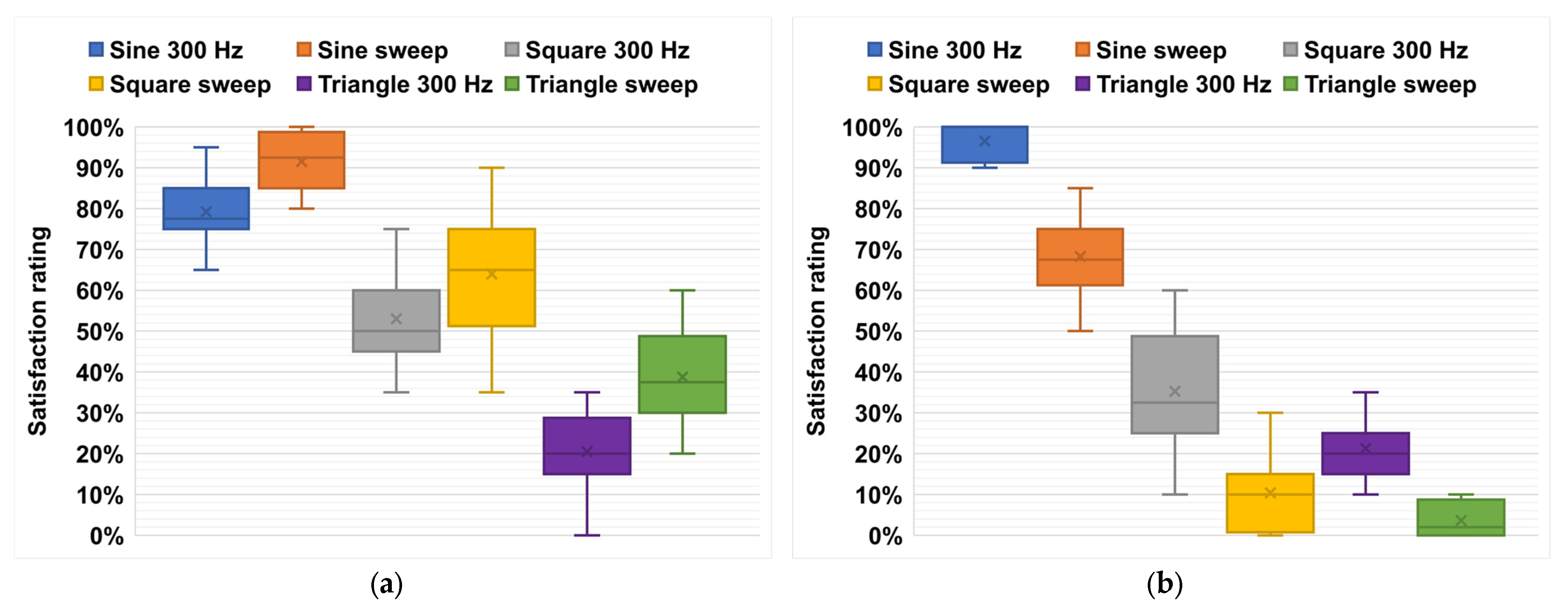

4.3.2. Preliminary Trials

- Haptic perception: How do users perceive the vibrations?

- Audible sound: How loud are the sounds coming from the button?

- Concerning the haptic perception, the sine wave was revealed to be the most preferred by the subjects as opposed to the triangle one, regardless of which frequency was selected for the waveform (fixed at 300 Hz or swept in a range of 100–700 Hz).

- Concerning the audible sound, most subjects found that all the waveforms within the sweep led to more undesirable acoustical noises than those with the fixed frequency (300 Hz). Particularly in the case of the square and triangular signals, the noises became extremely insupportable because of their decomposition into multiples of the fundamental harmonic, in the audible high-frequency range [67].

- By combining the audible and tactile sensations, the sine wave at 300 Hz was demonstrated to be the most appropriate choice in the generation of feedback vibrations (see Figure 19).

- In all cases, the data distributions were almost symmetrical, as the medians (horizonal lines in the whisker box) were close to the mean values (green cross); thus, the skewness was near to zero.

- No observations showed any outliers or extremes values (i.e., falling below or above Q3 + 1.5 IQR), meaning that the highest and lowest occurring values were within this limit interval.

- Finer analysis regarding the data dispersion via led to the following conclusions:

- ✓

- For both perception and audible tests, the dispersion of the data was relatively low in the case of the sine wave, as most subjects appreciated this configuration.

- ✓

- Inversely, very high variation was observed with the other waveforms, especially in the audible tests. Indeed, the value was found to be equal to 74% and 100% for the square and triangle signals, respectively. This is due to the fact that more than 25% the population expressed their absolute unsatisfaction vis-à-vis the acoustical noises (i.e., .

- Improving (or changing) the chemical formulation of the polymer composite so that it can support a higher electrical breakdown level. This solution is somehow time-consuming as several tests need to be conducted to verify whether or not the new matrix exhibits suitable flexibility and is compatible with AM (involving factors such as Young’s modulus, viscosity, adhesion with the substate, and UV-curability).

- Reducing the coating’s thickness, as well as that of the substrate, to maintain an optimized ratio. The decrease in sample thickness, however, should be constrained, as too thin a device might certainly weaken the structure and alter the button stiffness, in turn affecting the sensation of touch.

- Applying a variable electric field in accordance with the variation of the input force. This solution seems to be the most appropriate to achieve the best haptic performance, which should be investigated in future work, but is quite challenging, especially in the case of high-dynamic load.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keetels, M.; Vroomen, J. Perception of Synchrony between the Senses. In The Neural Bases of Multisensory Processes; Murray, M.M., Wallace, M.T., Eds.; Frontiers in Neuroscience; CRC Press/Taylor & Francis: Boca Raton, FL, USA, 2012; ISBN 978-1-4398-1217-4. [Google Scholar]

- Lenay, C.; Canu, S.; Villon, P. Technology and Perception: The Contribution of Sensory Substitutionsystems. In Proceedings of the Second International Conference on Cognitive Technology Humanizing the Information Age, Aizu-Wakamatsu, Japan, 25–28 August 1997; pp. 44–53. [Google Scholar]

- Hamilakis, Y. Archaeology and the Senses: Human Experience, Memory, and Affect; Cambridge University Press: Cambridge, UK, 2014; ISBN 978-0-521-83728-6. [Google Scholar]

- Obrist, M.; Velasco, C.; Vi, C.; Ranasinghe, N.; Israr, A.; Cheok, A.; Spence, C.; Gopalakrishnakone, P. Sensing the Future of HCI: Touch, Taste, and Smell User Interfaces. Interactions 2016, 23, 40–44. [Google Scholar] [CrossRef]

- Sandri, A.; Cecchini, M.P.; Riello, M.; Zanini, A.; Nocini, R.; Fiorio, M.; Tinazzi, M. Pain, Smell, and Taste in Adults: A Narrative Review of Multisensory Perception and Interaction. Pain Ther 2021, 10, 245–268. [Google Scholar] [CrossRef] [PubMed]

- Bartolozzi, C.; Natale, L.; Nori, F.; Metta, G. Robots with a Sense of Touch. Nat. Mater. 2016, 15, 921–925. [Google Scholar] [CrossRef] [PubMed]

- Nghiem, B.T.; Sando, I.C.; Gillespie, R.B.; McLaughlin, B.L.; Gerling, G.J.; Langhals, N.B.; Urbanchek, M.G.; Cederna, P.S. Providing a Sense of Touch to Prosthetic Hands. Plast. Reconstr. Surg. 2015, 135, 1652. [Google Scholar] [CrossRef] [PubMed]

- Paterson, M. The Senses of Touch: Haptics, Affects and Technologies; Berg: Oxford, UK, 2007; ISBN 978-1-84788-344-5. [Google Scholar]

- Yang, T.-H.; Kim, J.R.; Jin, H.; Gil, H.; Koo, J.-H.; Kim, H.J. Recent Advances and Opportunities of Active Materials for Haptic Technologies in Virtual and Augmented Reality. Adv. Funct. Mater. 2021, 31, 2008831. [Google Scholar] [CrossRef]

- Wang, D.; Guo, Y.; Liu, S.; Zhang, Y.; Xu, W.; Xiao, J. Haptic Display for Virtual Reality: Progress and Challenges. Virtual Real. Intell. Hardw. 2019, 1, 136–162. [Google Scholar] [CrossRef]

- Robles-De-La-Torre, G. The Importance of the Sense of Touch in Virtual and Real Environments. IEEE MultiMedia 2006, 13, 24–30. [Google Scholar] [CrossRef]

- Krogmeier, C.; Mousas, C.; Whittinghill, D. Human–Virtual Character Interaction: Toward Understanding the Influence of Haptic Feedback. Comput. Animat. Virtual Worlds 2019, 30, e1883. [Google Scholar] [CrossRef]

- Kvandal, P.; Landsverk, S.A.; Bernjak, A.; Stefanovska, A.; Kvernmo, H.D.; Kirkebøen, K.A. Low-Frequency Oscillations of the Laser Doppler Perfusion Signal in Human Skin. Microvasc. Res. 2006, 72, 120–127. [Google Scholar] [CrossRef]

- Grunwald, M. Human Haptic Perception: Basics and Applications; Springer Science & Business Media: New York, NY, USA, 2008; ISBN 978-3-7643-7612-3. [Google Scholar]

- Kappers, A.M.L.; Bergmann Tiest, W.M. Haptic Perception. WIREs Cogn. Sci. 2013, 4, 357–374. [Google Scholar] [CrossRef]

- Bergmann Tiest, W.M.; Kappers, A.M.L. Cues for Haptic Perception of Compliance. IEEE Trans. Haptics 2009, 2, 189–199. [Google Scholar] [CrossRef]

- Gordon, I.E.; Morison, V. The Haptic Perception of Curvature. Percept. Psychophys. 1982, 31, 446–450. [Google Scholar] [CrossRef] [PubMed]

- Gescheider, G.A.; Bolanowski, S.J.; Pope, J.V.; Verrillo, R.T. A Four-Channel Analysis of the Tactile Sensitivity of the Fingertip: Frequency Selectivity, Spatial Summation, and Temporal Summation. Somatosens. Mot. Res. 2002, 19, 114–124. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, R.F.; Schaible, H.-G. Neuro- und Sinnesphysiologie; Springer: New York, NY, USA, 2006; ISBN 978-3-540-29491-7. [Google Scholar]

- Thetpraphi, K.; Kanlayakan, W.; Chaipo, S.; Moretto, G.; Kuhn, J.; Audigier, D.; Le, M.Q.; Cottinet, P.-J.; Petit, L.; Capsal, J.-F. 3D-Printed Electroactive Polymer Force-Actuator for Large and High Precise Optical Mirror Applications. Addit. Manuf. 2021, 47, 102199. [Google Scholar] [CrossRef]

- Liu, Q.; Le, M.Q.; Richard, C.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Enhanced Pseudo-Piezoelectric Dynamic Force Sensors Based on Inkjet-Printed Electrostrictive Terpolymer. Org. Electron. 2019, 67, 259–271. [Google Scholar] [CrossRef]

- Xiang, Z.; Nguyen, V.-C.; Ducharne, B.; Schiava, N.D.; Capsal, J.-F.; Cottinet, P.-J.; Le, M.-Q. 3D Printing of Flexible Composites via Magnetophoresis: Toward Medical Application Based on Low-Frequency Induction Heating Effect. Macromol. Mater. Eng. 2021, 306, 202100211. [Google Scholar] [CrossRef]

- Grinberg, D.; Siddique, S.; Le, M.-Q.; Liang, R.; Capsal, J.-F.; Cottinet, P.-J. 4D Printing Based Piezoelectric Composite for Medical Applications. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 109–115. [Google Scholar] [CrossRef]

- DeGraff, J.; Liang, R.; Le, M.Q.; Capsal, J.-F.; Ganet, F.; Cottinet, P.-J. Printable Low-Cost and Flexible Carbon Nanotube Buckypaper Motion Sensors. Mater. Des. 2017, 133, 47–53. [Google Scholar] [CrossRef]

- Nguyen, V.-C.; Le, M.-Q.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Extrusion-Based 3D Printing of Stretchable Electronic Coating for Condition Monitoring of Suction Cups. Micromachines 2022, 13, 1606. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Lin, S.; Qu, K.; Xu, J.; Luo, J.; Zhao, X. 3D Printing of Conducting Polymers. Nat. Commun. 2020, 11, 1604. [Google Scholar] [CrossRef]

- Li, J.; Pumera, M. 3D Printing of Functional Microrobots. Chem. Soc. Rev. 2021, 50, 2794–2838. [Google Scholar] [CrossRef]

- Liao, Y.; Tian, Y.; Ma, X.; Zhao, M.; Qian, J.; Wang, X. Screen-Printed High-Performance Flexible Electrothermal Films Based on Three-Dimensional Intercalation Graphene Nanosheets/MWCNT/Carbon Black Composite. ACS Appl. Mater. Interfaces 2020, 12, 48077–48083. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Zheng, S.; Zhang, L.; Shi, X.; He, J.; Chou, X.; Wu, Z.-S. Ink Formulation, Scalable Applications and Challenging Perspectives of Screen Printing for Emerging Printed Microelectronics. J. Energy Chem. 2021, 63, 498–513. [Google Scholar] [CrossRef]

- Ferri, J.; Llinares Llopis, R.; Moreno, J.; Ibañez Civera, J.; Garcia-Breijo, E. A Wearable Textile 3D Gesture Recognition Sensor Based on Screen-Printing Technology. Sensors 2019, 19, 5068. [Google Scholar] [CrossRef]

- Puneeth, S.B.; Goel, S. Novel 3D Printed Microfluidic Paper-Based Analytical Device with Integrated Screen-Printed Electrodes for Automated Viscosity Measurements. IEEE Trans. Electron Devices 2019, 66, 3196–3201. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Trasande, L.; Kannan, K. Occurrence of Polyethylene Terephthalate and Polycarbonate Microplastics in Infant and Adult Feces. Environ. Sci. Technol. Lett. 2021, 8, 989–994. [Google Scholar] [CrossRef]

- Dhaka, V.; Singh, S.; Anil, A.G.; Sunil Kumar Naik, T.S.; Garg, S.; Samuel, J.; Kumar, M.; Ramamurthy, P.C.; Singh, J. Occurrence, Toxicity and Remediation of Polyethylene Terephthalate Plastics. A Review. Environ. Chem. Lett. 2022, 20, 1777–1800. [Google Scholar] [CrossRef] [PubMed]

- Tiso, T.; Narancic, T.; Wei, R.; Pollet, E.; Beagan, N.; Schröder, K.; Honak, A.; Jiang, M.; Kenny, S.T.; Wierckx, N.; et al. Towards Bio-Upcycling of Polyethylene Terephthalate. Metab. Eng. 2021, 66, 167–178. [Google Scholar] [CrossRef]

- Singh, A.K.; Bedi, R.; Kaith, B.S. Composite Materials Based on Recycled Polyethylene Terephthalate and Their Properties—A Comprehensive Review. Compos. Part B Eng. 2021, 219, 108928. [Google Scholar] [CrossRef]

- Nisticò, R. Polyethylene Terephthalate (PET) in the Packaging Industry. Polym. Test. 2020, 90, 106707. [Google Scholar] [CrossRef]

- Priya, S.; Song, H.-C.; Zhou, Y.; Varghese, R.; Chopra, A.; Kim, S.-G.; Kanno, I.; Wu, L.; Ha, D.S.; Ryu, J.; et al. A Review on Piezoelectric Energy Harvesting: Materials, Methods, and Circuits. Energy Harvest. Syst. 2017, 4, 3–39. [Google Scholar] [CrossRef]

- Nguyen, V.-C.; Le, M.-Q.; Bernadet, S.; Hebrard, Y.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Design Rules of Bidirectional Smart Sensor Coating for Condition Monitoring of Bearings. Polymers 2023, 15, 826. [Google Scholar] [CrossRef] [PubMed]

- Pitts, M.J.; Burnett, G.E.; Williams, M.A.; Wellings, T. Does Haptic Feedback Change the Way We View Touchscreens in Cars? In Proceedings of the International Conference on Multimodal Interfaces and the Workshop on Machine Learning for Multimodal Interaction, Beijing, China, 8–12 November 2010; Association for Computing Machinery: New York, NY, USA, 2010; pp. 1–4. [Google Scholar]

- Song, A.; Fu, L. Multi-Dimensional Force Sensor for Haptic Interaction: A Review. Virtual Real. Intell. Hardw. 2019, 1, 121–135. [Google Scholar] [CrossRef]

- Phung, H.; Hoang, P.T.; Jung, H.; Nguyen, T.D.; Nguyen, C.T.; Choi, H.R. Haptic Display Responsive to Touch Driven by Soft Actuator and Soft Sensor. IEEE/ASME Trans. Mechatron. 2021, 26, 2495–2505. [Google Scholar] [CrossRef]

- Vezzoli, E.; Sednaoui, T.; Amberg, M.; Giraud, F.; Lemaire-Semail, B. Texture Rendering Strategies with a High Fidelity—Capacitive Visual-Haptic Friction Control Device. In Proceedings of the Haptics: Perception, Devices, Control, and Applications, London, UK, 4–7 July 2016; Bello, F., Kajimoto, H., Visell, Y., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 251–260. [Google Scholar]

- Parikh, S.P.; Esposito, J.M. Negative Feedback for Small Capacitive Touchscreen Interfaces: A Usability Study for Data Entry Tasks. IEEE Trans. Haptics 2012, 5, 39–47. [Google Scholar] [CrossRef]

- Akther, A.; Castro, J.O.; Shaegh, S.A.M.; Rezk, A.R.; Yeo, L.Y. Miniaturised Acoustofluidic Tactile Haptic Actuator. Soft Matter 2019, 15, 4146–4152. [Google Scholar] [CrossRef]

- Emgin, S.E.; Aghakhani, A.; Sezgin, T.M.; Basdogan, C. HapTable: An Interactive Tabletop Providing Online Haptic Feedback for Touch Gestures. IEEE Trans. Vis. Comput. Graph. 2019, 25, 2749–2762. [Google Scholar] [CrossRef] [PubMed]

- Basdogan, C.; Giraud, F.; Levesque, V.; Choi, S. A Review of Surface Haptics: Enabling Tactile Effects on Touch Surfaces. IEEE Trans. Haptics 2020, 13, 450–470. [Google Scholar] [CrossRef]

- Mullenbach, J.; Johnson, D.; Colgate, J.E.; Peshkin, M.A. ActivePaD Surface Haptic Device. In Proceedings of the 2012 IEEE Haptics Symposium (HAPTICS), Vancouver, BC, Canada, 4–7 March 2012; pp. 407–414. [Google Scholar]

- Woo, J.-H.; Ih, J.-G. Vibration Rendering on a Thin Plate with Actuator Array at the Periphery. J. Sound Vib. 2015, 349, 150–162. [Google Scholar] [CrossRef]

- Bai, M.R.; Tsai, Y.K. Impact Localization Combined with Haptic Feedback for Touch Panel Applications Based on the Time-Reversal Approach. J. Acoust. Soc. Am. 2011, 129, 1297–1305. [Google Scholar] [CrossRef]

- Dhiab, A.B.; Hudin, C. Confinement of Vibrotactile Stimuli in Narrow Plates: Principle and Effect of Finger Loading. IEEE Trans. Haptics 2020, 13, 471–482. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Kuchenbecker, K.J. Vibrotactile Display: Perception, Technology, and Applications. Proc. IEEE 2013, 101, 2093–2104. [Google Scholar] [CrossRef]

- Fimbel, A.; Abensur, T.; Le, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Accurate Electroadhesion Force Measurements of Electrostrictive Polymers: The Case of High Performance Plasticized Terpolymers. Polymers 2022, 14, 24. [Google Scholar] [CrossRef]

- Ghenna, S.; Vezzoli, E.; Giraud-Audine, C.; Giraud, F.; Amberg, M.; Lemaire-Semail, B. Enhancing Variable Friction Tactile Display Using an Ultrasonic Travelling Wave. IEEE Trans. Haptics 2017, 10, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Hudin, C.; Lozada, J.; Hayward, V. Localized Tactile Feedback on a Transparent Surface through Time-Reversal Wave Focusing. IEEE Trans. Haptics 2015, 8, 188–198. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Oh, J.H.; Kwon, J.H.; Lim, K.J. Haptic Actuator Design Using PMN-PT Ceramic. Ferroelectrics 2014, 469, 105–110. [Google Scholar] [CrossRef]

- Damamme, R.; Seveyrat, L.; Borta-Boyon, A.; Nguyen, V.-C.; Le, M.-Q.; Cottinet, P.-J. 3D Printing of Doped Barium-Titanate Using Robocasting—Toward New Generation Lead-Free Piezoceramic Transducers. J. Eur. Ceram. Soc. 2023, 43, 3297–3306. [Google Scholar] [CrossRef]

- Tikka, V.; Laitinen, P. Designing Haptic Feedback for Touch Display: Experimental Study of Perceived Intensity and Integration of Haptic and Audio. In Proceedings of the Haptic and Audio Interaction Design, Glasgow, UK, 31 August–1 September 2006; McGookin, D., Brewster, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 36–44. [Google Scholar]

- Bar-Cohen, Y. Electroactive Polymer (EAP) Actuators as Artificial Muscles: Reality, Potential, and Challenges; SPIE Press: Bellingham, WA, USA, 2004; ISBN 978-0-8194-5297-9. [Google Scholar]

- Carpi, F.; Rossi, D.D.; Kornbluh, R.; Pelrine, R.E.; Sommer-Larsen, P. Dielectric Elastomers as Electromechanical Transducers: Fundamentals, Materials, Devices, Models and Applications of an Emerging Electroactive Polymer Technology; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 978-0-08-055772-4. [Google Scholar]

- Della Schiava, N.; Pedroli, F.; Thetpraphi, K.; Flocchini, A.; Le, M.-Q.; Lermusiaux, P.; Capsal, J.-F.; Cottinet, P.-J. Effect of Beta-Based Sterilization on P(VDF-TrFE-CFE) Terpolymer for Medical Applications. Sci. Rep. 2020, 10, 8805. [Google Scholar] [CrossRef] [PubMed]

- Mistewicz, K.; Nowak, M.; Starczewska, A.; Jesionek, M.; Rzychoń, T.; Wrzalik, R.; Guiseppi-Elie, A. Determination of Electrical Conductivity Type of SbSI Nanowires. Mater. Lett. 2016, 182, 78–80. [Google Scholar] [CrossRef]

- Liu, Y.; Ji, Y.; Yang, Y. Growth, Properties and Applications of Bi0.5Na0.5TiO3 Ferroelectric Nanomaterials. Nanomaterials 2021, 11, 1724. [Google Scholar] [CrossRef]

- Brochu, P.; Pei, Q. Advances in Dielectric Elastomers for Actuators and Artificial Muscles. Macromol. Rapid Commun. 2010, 31, 10–36. [Google Scholar] [CrossRef]

- Ganet, F.; Le, M.Q.; Capsal, J.F.; Lermusiaux, P.; Petit, L.; Millon, A.; Cottinet, P.J. Development of a Smart Guide Wire Using an Electrostrictive Polymer: Option for Steerable Orientation and Force Feedback. Sci. Rep. 2015, 5, 18593. [Google Scholar] [CrossRef]

- Le, M.Q.; Capsal, J.-F.; Galineau, J.; Ganet, F.; Yin, X.; Yang, M.; Chateaux, J.-F.; Renaud, L.; Malhaire, C.; Cottinet, P.-J.; et al. All-Organic Electrostrictive Polymer Composites with Low Driving Electrical Voltages for Micro-Fluidic Pump Applications. Sci. Rep. 2015, 5, 11814. [Google Scholar] [CrossRef] [PubMed]

- Poncet, P.; Casset, F.; Latour, A.; Santos, F.D.D.; Gwoziecki, R.; Fanget, S. Development of Haptic Button Based on Electro Active Polymer Actuator. Procedia Eng. 2016, 168, 1500–1503. [Google Scholar] [CrossRef]

- Schmidt, G.C.; Werner, J.M.; Weissbach, T.; Strutwolf, J.; Eland, R.; Drossel, W.-G.; Hübler, A.C. Printed Multilayer Piezoelectric Transducers on Paper for Haptic Feedback and Dual Touch-Sound Sensation. Sensors 2022, 22, 3796. [Google Scholar] [CrossRef] [PubMed]

- Correia, V.; Mitra, K.Y.; Castro, H.; Rocha, J.G.; Sowade, E.; Baumann, R.R.; Lanceros-Mendez, S. Design and Fabrication of Multilayer Inkjet-Printed Passive Components for Printed Electronics Circuit Development. J. Manuf. Process. 2018, 31, 364–371. [Google Scholar] [CrossRef]

- Zhang, X.; Villafuerte, J.; Consonni, V.; Sarigiannidou, E.; Capsal, J.-F.; Bruhat, A.; Grinberg, D.; Petit, L.; Cottinet, P.-J.; Le, M.-Q. Optimization Strategies Used for Boosting Piezoelectric Response of Biosensor Based on Flexible Micro-ZnO Composites. Biosensors 2022, 12, 245. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Le, M.-Q.; Bordet, M.; Lermusiaux, P.; Della Schiava, N.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Piezoelectric Biosensor for Smart Cardiovascular Grafts Based on NaNbO3 Fibers/PDMS Structured Composite. Mater. Des. 2022, 223, 111195. [Google Scholar] [CrossRef]

- Thetpraphi, K.; Le, M.Q.; Houachtia, A.; Cottinet, P.-J.; Petit, L.; Audigier, D.; Kuhn, J.; Moretto, G.; Capsal, J.-F. Surface Correction Control Based on Plasticized Multilayer P(VDF-TrFE-CFE) Actuator—Live Mirror. Adv. Opt. Mater. 2019, 7, 1900210. [Google Scholar] [CrossRef]

- Xiang, Z.; Le, M.Q.; Cottinet, P.-J.; Griffiths, P.; Baeza, G.P.; Capsal, J.-F.; Lermusiaux, P.; Della Schiava, N.; Ducharne, B. Development of Anisotropic Ferromagnetic Composites for Low-Frequency Induction Heating Technology in Medical Applications. Mater. Today Chem. 2021, 19, 100395. [Google Scholar] [CrossRef]

- Zahhaf, O.; D’Ambrogio, G.; Giunta, A.; Le, M.-Q.; Rival, G.; Cottinet, P.-J.; Capsal, J.-F. Molten-State Dielectrophoretic Alignment of EVA/BaTiO3 Thermoplastic Composites: Enhancement of Piezo-Smart Sensor for Medical Application. Int. J. Mol. Sci. 2022, 23, 15745. [Google Scholar] [CrossRef]

- Diatezo, L.; Le, M.-Q.; Tonellato, C.; Puig, L.; Capsal, J.-F.; Cottinet, P.-J. Development and Optimization of 3D-Printed Flexible Electronic Coatings: A New Generation of Smart Heating Fabrics for Automobile Applications. Micromachines 2023, 14, 762. [Google Scholar] [CrossRef]

- Yin, W.; Zeng, X.; Li, H.; Hou, Y.; Gao, Q. Synthesis, Photopolymerization Kinetics, and Thermal Properties of UV-Curable Waterborne Hyperbranched Polyurethane Acrylate Dispersions. J. Coat. Technol. Res. 2011, 8, 577. [Google Scholar] [CrossRef]

- Nguyen, V.-C.; Le, M.-Q.; Fimbel, A.; Bernadet, S.; Hebrard, Y.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Printing Smart Coating of Piezoelectric Composite for Application in Condition Monitoring of Bearings. Mater. Des. 2022, 215, 110529. [Google Scholar] [CrossRef]

- Dalle Vacche, S.; Oliveira, F.; Leterrier, Y.; Michaud, V.; Damjanovic, D.; Månson, J.-A.E. Effect of Silane Coupling Agent on the Morphology, Structure, and Properties of Poly(Vinylidene Fluoride–Trifluoroethylene)/BaTiO3 Composites. J. Mater. Sci. 2014, 49, 4552–4564. [Google Scholar] [CrossRef]

- Siponkoski, T.; Nelo, M.; Peräntie, J.; Juuti, J.; Jantunen, H. BaTiO3–P(VDF-TrFE) Composite Ink Properties for Printed Decoupling Capacitors. Compos. Part B Eng. 2015, 70, 201–205. [Google Scholar] [CrossRef]

- Capsal, J.-F.; David, C.; Dantras, E.; Lacabanne, C. Piezoelectric Sensing Coating for Real Time Impact Detection and Location on Aircraft Structures. Smart Mater. Struct. 2012, 21, 055021. [Google Scholar] [CrossRef]

- Wu, E.Y.; Vollertsen, R.-P. On the Weibull Shape Factor of Intrinsic Breakdown of Dielectric Films and Its Accurate Experimental Determination. Part I: Theory, Methodology, Experimental Techniques. IEEE Trans. Electron Devices 2002, 49, 2131–2140. [Google Scholar] [CrossRef]

- Pedroli, F.; Flocchini, A.; Marrani, A.; Le, M.-Q.; Sanseau, O.; Cottinet, P.-J.; Capsal, J.-F. Boosted Energy-Storage Efficiency by Controlling Conduction Loss of Multilayered Polymeric Capacitors. Mater. Des. 2020, 192, 108712. [Google Scholar] [CrossRef]

- Holterman, J.; Groen, P. An Introduction to Piezoelectric Materials and Applications; Stichting Applied Piezo: Apeldoorn, The Netherlands, 2013; ISBN 978-90-819361-1-8. [Google Scholar]

- Poncet, P.; Casset, F.; Latour, A.; Domingues Dos Santos, F.; Pawlak, S.; Gwoziecki, R.; Devos, A.; Emery, P.; Fanget, S. Static and Dynamic Studies of Electro-Active Polymer Actuators and Integration in a Demonstrator. Actuators 2017, 6, 18. [Google Scholar] [CrossRef]

- Zhang, X.; Le, M.-Q.; Nguyen, V.-C.; Mogniotte, J.-F.; Capsal, J.-F.; Grinberg, D.; Cottinet, P.-J.; Petit, L. Characterization of Micro-ZnO/PDMS Composite Structured via Dielectrophoresis—Toward Medical Application. Mater. Des. 2021, 109912. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Hebrard, Y.; Le, M.Q.; Cottinet, P.-J.; Capsal, J.-F. Micro-Structuration of Piezoelectric Composites Using Dielectrophoresis: Toward Application in Condition Monitoring of Bearings. Adv. Eng. Mater. 2021, 23, 2000773. [Google Scholar] [CrossRef]

- Shouji, Y.; Sekine, T.; Ito, K.; Ito, N.; Yasuda, T.; Wang, Y.-F.; Takeda, Y.; Kumaki, D.; Santos, F.D.D.; Miyabo, A.; et al. Fast Response, High-Power Tunable Ultrathin Soft Actuator by Functional Piezoelectric Material Composite for Haptic Device Application. Adv. Electron. Mater. 2023, 2201040. [Google Scholar] [CrossRef]

- Pedroli, F.; Marrani, A.; Le, M.-Q.; Froidefond, C.; Cottinet, P.-J.; Capsal, J.-F. Processing Optimization: A Way to Improve the Ionic Conductivity and Dielectric Loss of Electroactive Polymers. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 1164–1173. [Google Scholar] [CrossRef]

- Chen, J.; Teo, E.H.T.; Yao, K. Electromechanical Actuators for Haptic Feedback with Fingertip Contact. Actuators 2023, 12, 104. [Google Scholar] [CrossRef]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric Materials for Energy Harvesting and Sensing Applications: Roadmap for Future Smart Materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef] [PubMed]

- Materials and Stacking Technology. Available online: http://www.piezotechnics.com/piezo-technology/piezoelement/ (accessed on 3 May 2023).

- Carbone, C.; Benwadih, M.; D’Ambrogio, G.; Le, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Influence of Matrix and Surfactant on Piezoelectric and Dielectric Properties of Screen-Printed BaTiO3/PVDF Composites. Polymers 2021, 13, 2166. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Bordet, M.; Le, M.Q.; Della Schiava, N.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Structuring BaTiO3/PDMS Nanocomposite via Dielectrophoresis for Fractional Flow Reserve Measurement. Adv. Eng. Mater. 2021, 10, 2100341. [Google Scholar] [CrossRef]

- Zhang, X.; Le, M.-Q.; Zahhaf, O.; Capsal, J.-F.; Cottinet, P.-J.; Petit, L. Enhancing Dielectric and Piezoelectric Properties of Micro-ZnO/PDMS Composite-Based Dielectrophoresis. Mater. Des. 2020, 192, 108783. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Le, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Dielectrophoresis Structurization of PZT/PDMS Micro-Composite for Elastronic Function: Towards Dielectric and Piezoelectric Enhancement. Materials 2021, 14, 4071. [Google Scholar] [CrossRef]

| Actuator Technology | Electromagnetic | Electrostatic | Electroactive Polymers | Piezoelectric | |||

|---|---|---|---|---|---|---|---|

| ERM | LRA | Dielectric materials | Electrostrictive polymers | Ferroelectric polymers | Ceramic piezoelectric | 0–3 piezoelectric composites | |

| Displacement output | High | High | Low | High | High | Low | High |

| Force output | Low | Low | Low | Average | Average | High | High |

| Required input voltage | Low | Low | High | High | High | Moderate | Moderate |

| Frequency (dynamics) | Low | Low | High | Low | Low | High | High |

| Response time | ~50 ms | ~30 ms | ~1 ms | ~10 ms | ~10 ms | ~0.5 ms | ~10 ms |

| Sensor mode possible? | No | No | No | yes, but pseudo mode | Yes | Yes | Yes |

| Flexibility | Non | Non | Yes | Yes | Yes | Non | Yes |

| Energy consumption | High | Average | Low | Low | Low | Low | Low |

| Economic cost | Moderate | Moderate | Moderate | High | High | High | Moderate |

| Material | Properties | Symbol |

|---|---|---|

| PET substrate | ||

| Density | ρ | 952 kg/m3 |

| Poisson’s ratio | v | 0.34 |

| Young’s modulus | Y | 2.62 GPa |

| Diameter | d | 30 mm |

| Thickness | t | 50 µm |

| Piezoelectric composite | ||

| Density | ρ’ | 3000 kg/m3 |

| Poisson’s ratio | v’ | 0.37 |

| Young’s modulus | Y’ | 7 GPa |

| Diameter | d’ | 18 mm |

| Thickness | t’ | 28 µm |

| Relative permittivity | ε’ | 10.5 |

| Piezoelectric constants | e31 = e33 e15 | 0.016 C/m2 0 C/m2 |

| Symbol | − − − | − − | − | ~ | + | + + | + + + |

|---|---|---|---|---|---|---|---|

| Satisfaction (%) | 0–15 | 15–30 | 30–45 | 45–55 | 55–70 | 70–85 | 85–100 |

| Perception | Nothing | Bad | Disappointed | Average | Nice | Good | Excellent |

| Audible sound | Unsupportable | Loud | Noisy | Ambient | Soft | Low | Quiet |

| Waveform/Frequency | Human Sensibility | Audio-Sound |

|---|---|---|

| Sine/300 Hz | + + | + + + |

| Sine sweep/100–700 Hz | + + + | + |

| Square/300 Hz | ~ | − |

| Square sweep/100–700 Hz | + | − − − |

| Triangle/300 Hz | − − | − − |

| Triangle sweep/100–700 Hz | − | − − − |

| Waveform | Sine/300 Hz | Sine/Sweep 100–700 Hz | Square/300 Hz | Square/Sweep 100–700 Hz | Triangle/300 Hz | Triangle/Sweep 100–700 Hz |

|---|---|---|---|---|---|---|

| Satisfaction rating (%) in haptic perception | ||||||

| Mean | 79.25 | 91.5 | 53 | 64 | 20.5 | 38.75 |

| SD | 6.75 | 6 | 9.3 | 12.6 | 7.55 | 9.25 |

| Min | 65 | 80 | 35 | 35 | 0 | 20 |

| Max | 95 | 100 | 75 | 90 | 35 | 60 |

| Q1 | 75 | 85 | 45 | 53.75 | 15 | 30 |

| Q2 | 77.5 | 92.5 | 50 | 65 | 20 | 37.5 |

| Q3 | 85 | 96.25 | 60 | 75 | 26.25 | 46.25 |

| IQR | 10 | 11.25 | 15 | 21.25 | 11.25 | 16.25 |

| QCD (%) | 6.25 | 6.21 | 14.29 | 16.50 | 27.27 | 21.31 |

| Satisfaction rating (%) in audible sound | ||||||

| Mean | 96.5 | 68.25 | 35.25 | 10.4 | 21.25 | 3.65 |

| SD | 3.85 | 7.75 | 12.775 | 7.26 | 6.125 | 3.58 |

| Min | 90 | 50 | 10 | 0 | 10 | 0 |

| Max | 100 | 85 | 60 | 30 | 35 | 10 |

| Q1 | 93.75 | 63.75 | 25 | 2.25 | 15 | 0 |

| Q2 | 100 | 67.5 | 32.5 | 10 | 20 | 2 |

| Q3 | 100 | 75 | 46.25 | 15 | 25 | 6.25 |

| IQR | 6.25 | 11.25 | 21.25 | 12.75 | 10 | 6.25 |

| QCD (%) | 3.23 | 8.11 | 29.82 | 73.91 | 25.00 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.-C.; Oliva-Torres, V.; Bernadet, S.; Rival, G.; Richard, C.; Capsal, J.-F.; Cottinet, P.-J.; Le, M.-Q. Haptic Feedback Device Using 3D-Printed Flexible, Multilayered Piezoelectric Coating for In-Car Touchscreen Interface. Micromachines 2023, 14, 1553. https://doi.org/10.3390/mi14081553

Nguyen V-C, Oliva-Torres V, Bernadet S, Rival G, Richard C, Capsal J-F, Cottinet P-J, Le M-Q. Haptic Feedback Device Using 3D-Printed Flexible, Multilayered Piezoelectric Coating for In-Car Touchscreen Interface. Micromachines. 2023; 14(8):1553. https://doi.org/10.3390/mi14081553

Chicago/Turabian StyleNguyen, Van-Cuong, Victor Oliva-Torres, Sophie Bernadet, Guilhem Rival, Claude Richard, Jean-Fabien Capsal, Pierre-Jean Cottinet, and Minh-Quyen Le. 2023. "Haptic Feedback Device Using 3D-Printed Flexible, Multilayered Piezoelectric Coating for In-Car Touchscreen Interface" Micromachines 14, no. 8: 1553. https://doi.org/10.3390/mi14081553

APA StyleNguyen, V.-C., Oliva-Torres, V., Bernadet, S., Rival, G., Richard, C., Capsal, J.-F., Cottinet, P.-J., & Le, M.-Q. (2023). Haptic Feedback Device Using 3D-Printed Flexible, Multilayered Piezoelectric Coating for In-Car Touchscreen Interface. Micromachines, 14(8), 1553. https://doi.org/10.3390/mi14081553