Very High-Aspect-Ratio Polymeric Micropillars Made by Two-Photon Polymerization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Photoresist

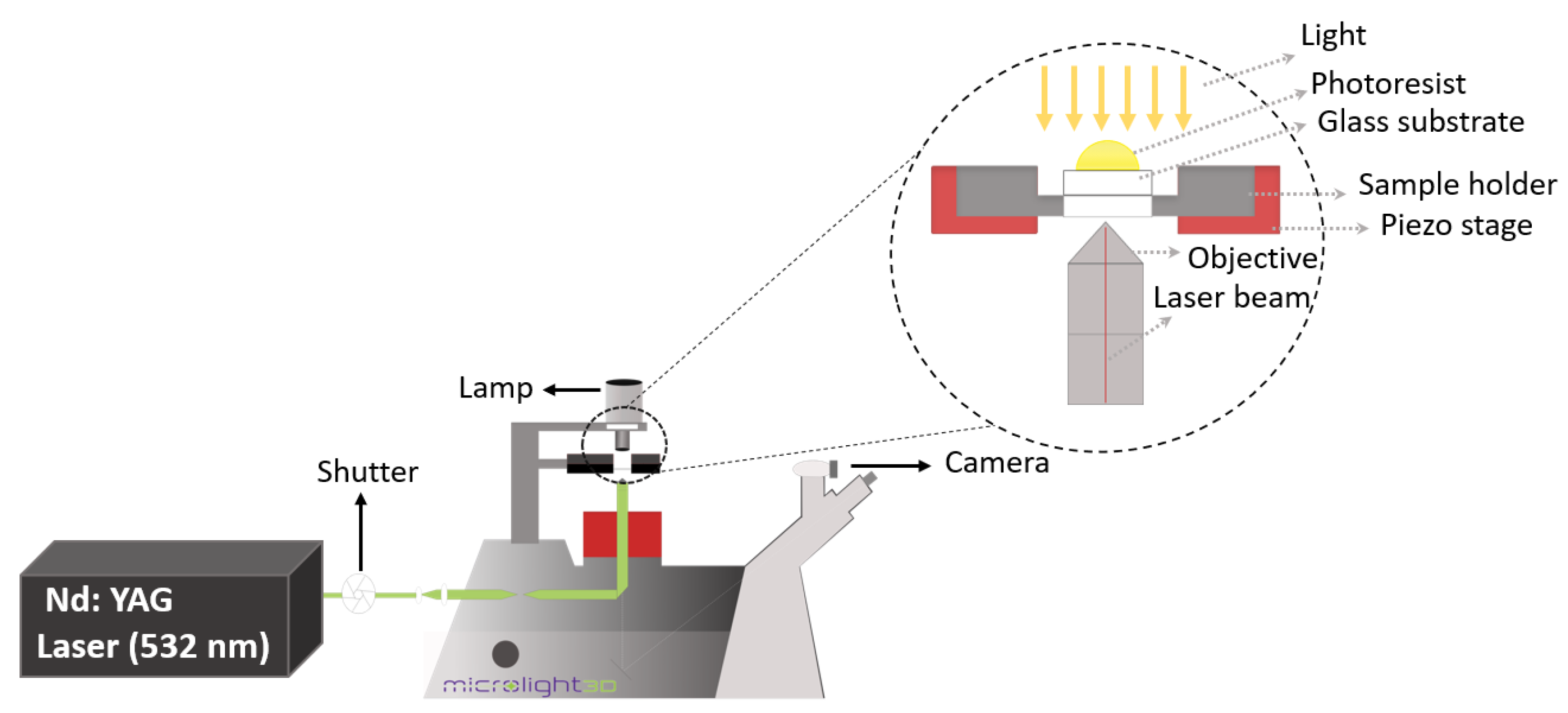

2.3. Two-Photon Polymerization 3D Printer

2.4. Surface Modification on Glass Substrate

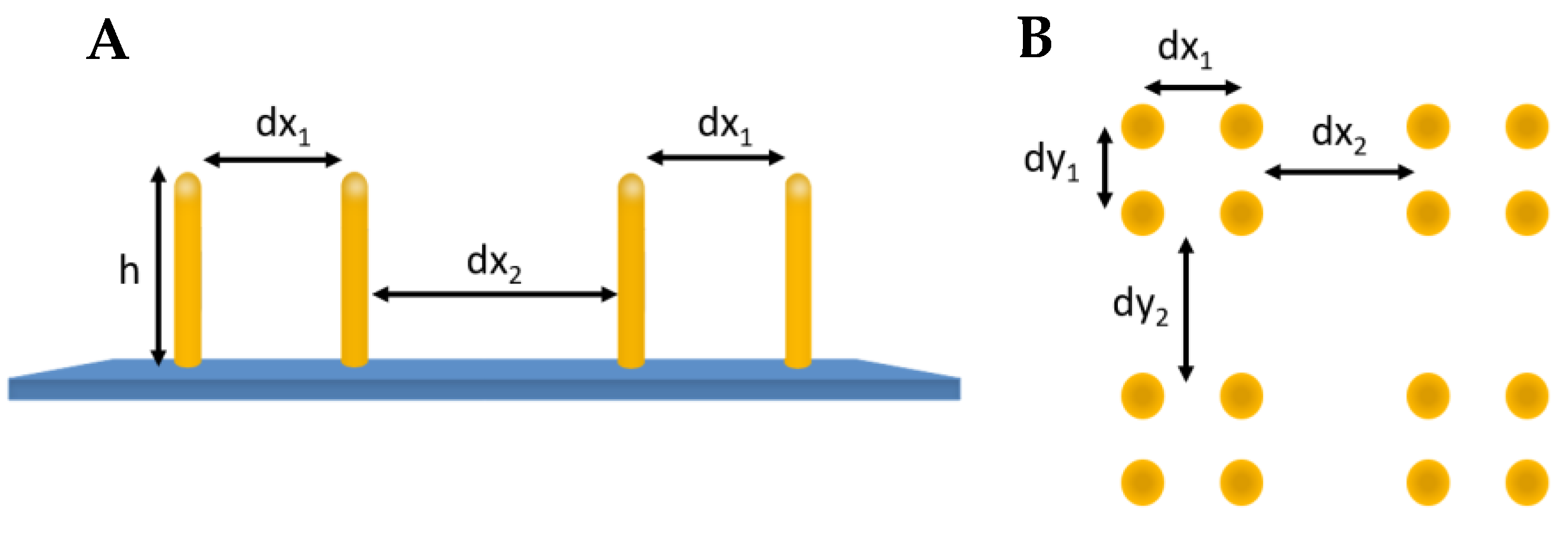

2.5. Fabrication of Microstructures

2.6. Scanning Electron Microscopy

3. Results and Discussion

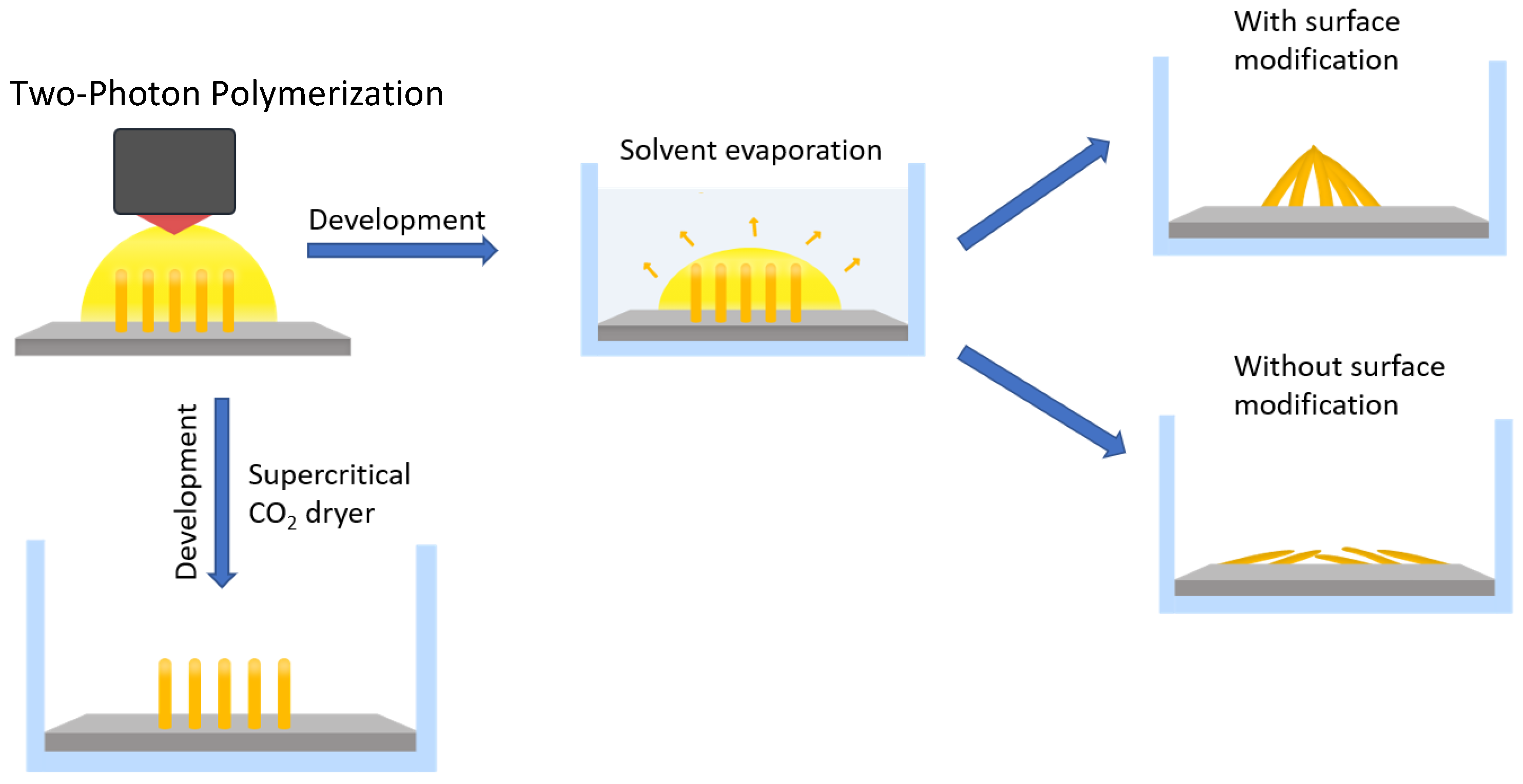

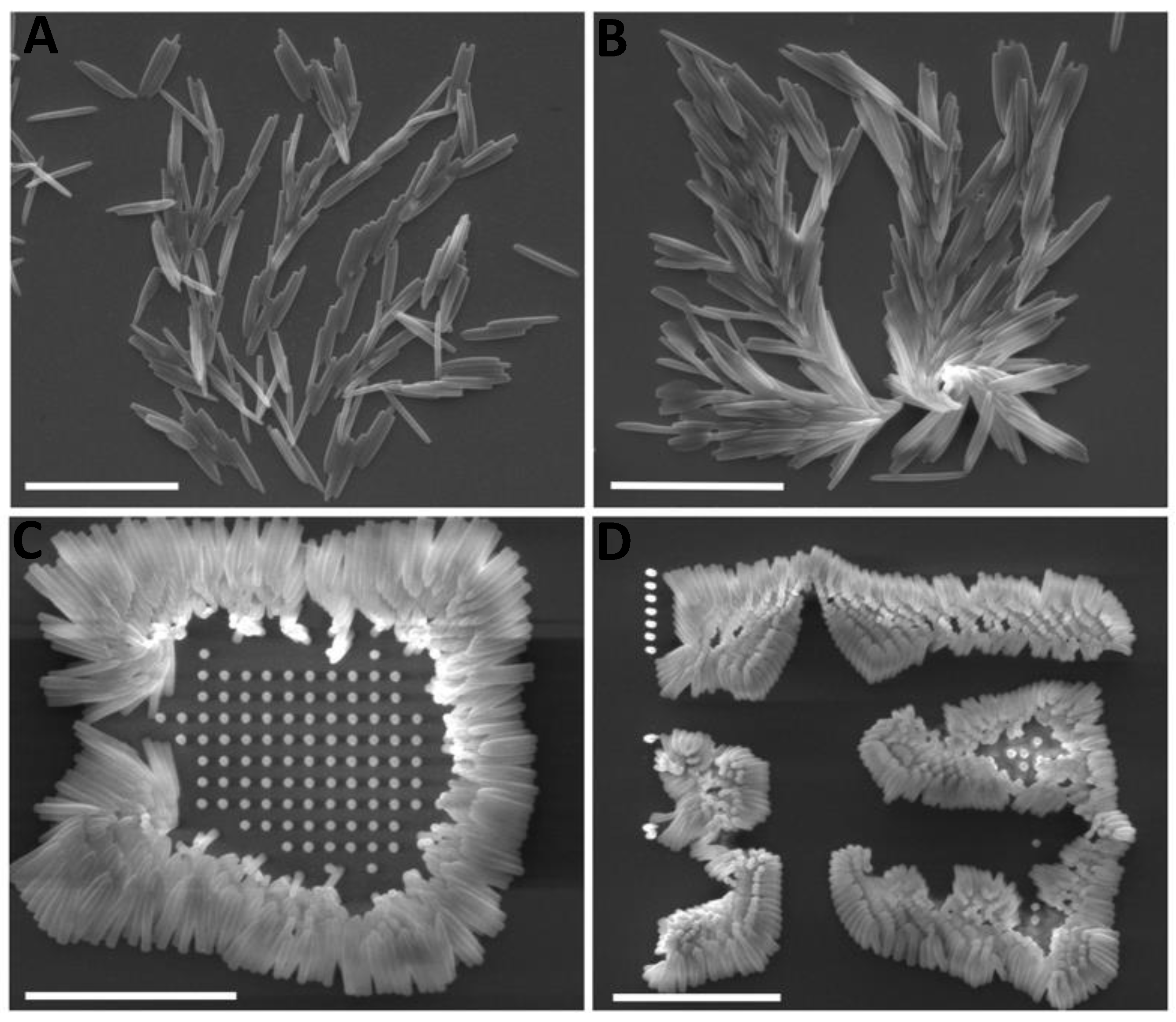

3.1. Surface Modification of the Glass Substrate

3.2. Very HAR Micropillars with Supercritical CO2 Dryer

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McAllister, D.V.; Wang, P.M.; Davis, S.P.; Park, J.-H.; Canatella, P.J.; Allen, M.G.; Prausnitz, M.R. Microfabricated needles for transdermal delivery of macromolecules and nanoparticles: Fabrication methods and transport studies. Proc. Natl. Acad. Sci. USA 2003, 100, 13755. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-H.; Allen, M.G.; Prausnitz, M.R. Biodegradable polymer microneedles: Fabrication, mechanics and transdermal drug delivery. J. Control. Release 2005, 104, 51. [Google Scholar] [CrossRef]

- Rad, Z.F.; Prewett, P.D.; Davies, G.J. High-resolution two-photon polymerization: The most versatile technique for the fabrication of microneedle arrays. Microsyst. Nanoeng. 2021, 7, 71. [Google Scholar]

- Geim, A.K.; Dubonos, S.V.; Grigorieva, I.V.; Novoselov, K.S.; Zhukov, A.A.; Shapoval, S.Y. Microfabricated adhesive mimicking gecko foot-hair. Nat. Mater. 2003, 2, 461. [Google Scholar] [CrossRef]

- Suh, K.; Jon, S. Control over Wettability of Polyethylene Glycol Surfaces Using Capillary Lithography. Langmuir 2005, 21, 6836–6841. [Google Scholar] [CrossRef]

- Jeong, H.E.; Lee, S.H.; Kim, J.K.; Suh, K.Y. Nanoengineered multiscale hierarchical structures with tailored wetting properties. Langmuir 2006, 22, 1640. [Google Scholar] [CrossRef] [PubMed]

- Madou, M.J. Fundamentals of Microfabrication: The Science of Miniaturization, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Kim, K.; Park, S.; Lee, J.-B.; Manohara, H.; Desta, Y.; Murphy, M.; Ahn, C.H. Rapid replication of polymeric and metallic high aspect ratio microstructures using PDMS and LIGA technology. Microsyst. Technol. 2002, 9, 5. [Google Scholar] [CrossRef]

- Cadarso, V.J.; Pfeiffer, K.; Ostrzinski, U.; Bureau, J.B.; Racine, G.A.; Voigt, A.; Gruetzner, G.; Brugger, J. Direct writing laser of high aspect ratio epoxy microstructures. J. Micromech. Microeng. 2011, 21, 017003. [Google Scholar] [CrossRef]

- Wong, T.-S.; Kang, S.H.; Tang, S.K.Y.; Smythe, E.J.; Hatton, B.D.; Grinthal, A.; Aizenberg, J. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 2011, 477, 443. [Google Scholar] [CrossRef]

- Buch-Månson, N.; Spangenberg, A.; Gomez, L.P.C.; Malval, J.-P.; Soppera, O.; Martinez, K.L. Rapid prototyping of polymeric nanopillars by 3D direct laser writing for controlling cell behavior. Sci. Rep. 2017, 7, 9247. [Google Scholar]

- Purtov, J.; Rogin, P.; Verch, A.; Johansen, V.E.; Hensel, R. Nanopillar diffraction gratings by two-photon lithography. Nanomaterials 2019, 9, 1495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, C.; Yang, J.; He, W.; Xiong, M.; Niu, X.; Li, X.; Yu, D.-G. A review on fabrication and application of tunable hybrid micro–nano array surfaces. Adv. Mater. Interfaces 2023, 10, 2202160. [Google Scholar] [CrossRef]

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. In Ceramics Science and Technology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 245–320. [Google Scholar]

- Manz, A.; Becker, H. (Eds.) Microsystem Technology in Chemistry and Life Science; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Higgins, S.G.; Becce, M.; Belessiotis-Richards, A.; Seong, H.; Sero, J.E.; Stevens, M.M. High-aspect-ratio nanostructured surfaces as biological metamaterials. Adv. Mater. 2020, 32, 1903862. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-M.; Yang, S. Directed water shedding on high-aspect-ratio shape memory polymer micropillar arrays. Adv. Mater. 2014, 26, 1283. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-M.; Chiang, C.-L.; Lai, C.-L.; Xie, T.; Yang, S. Buckling-based strong dry adhesives via interlocking. Adv. Funct. Mater. 2013, 23, 3813. [Google Scholar] [CrossRef]

- Shao, G.; Wu, J.; Cai, Z.; Wang, W. Fabrication of elastomeric high-aspect-ratio microstructures using polydimethylsiloxane (PDMS) double casting technique. Sens. Actuators A Phys. 2012, 178, 230. [Google Scholar] [CrossRef]

- Block, I.D.; Chan, L.L.; Cunningham, B.T. Large-area submicron replica molding of porous low-k dielectric films and application to photonic crystal biosensor fabrication. Microelectron. Eng. 2007, 84, 603. [Google Scholar] [CrossRef]

- Shinohara, H.; Goto, H.; Kasahara, T.; Mizuno, J. Fabrication of a polymer high-aspect-ratio pillar array using UV imprinting. Micromachines 2013, 4, 157. [Google Scholar] [CrossRef] [Green Version]

- Shinohara, H.; Tashiro, T.; Ookawa, T.; Nishihara, H. High-throughput UV nanoimprint process using flexible resin mold for high-brightness light-emitting diodes. IEEJ Trans. Sens. Micromachines 2012, 132, 235. [Google Scholar] [CrossRef]

- Shibazaki, T.; Shinohara, H.; Hirasawa, T.; Sakai, N.; Taniguchi, J.; Mizuno, J.; Shoji, S. Anti-sticking curing of fluorinated polymers for improvement of mold releasability. J. Photopolym. Sci. Technol. 2010, 22, 727. [Google Scholar] [CrossRef] [Green Version]

- Copic, D.; Park, S.J.; Tawfick, S.; Volder, M.F.L.D.; Hart, A.J. Fabrication of high-aspect-ratio polymer microstructures and hierarchical textures using carbon nanotube composite master molds. Lab Chip 2011, 11, 1831. [Google Scholar]

- Zhang, Y.; Lo, C.-W.; Taylor, J.A.; Yang, S. Replica molding of high-aspect-ratio polymeric nanopillar arrays with high fidelity. Langmuir 2006, 22, 8595. [Google Scholar]

- Rajput, D.; Costa, L.; Lansford, K.; Terekhov, A.; Hofmeister, W. Solution-cast high-aspect-ratio polymer structures from direct-write templates. ACS Appl. Mater. Interfaces 2013, 5, 1. [Google Scholar] [CrossRef] [PubMed]

- Miranda, I.; Souza, A.; Sousa, P.; Ribeiro, J.; Castanheira, E.M.S.; Lima, R.; Minas, G. Properties and applications of PDMS for biomedical engineering: A review. J. Funct. Biomater. 2022, 13, 2. [Google Scholar] [CrossRef]

- Kotz, F.; Mader, M.; Dellen, N.; Risch, P.; Kick, A.; Helmer, D.; Rapp, B. Fused deposition modeling of microfluidic chips in polymethylmethacrylate. Micromachines 2020, 11, 873. [Google Scholar] [CrossRef] [PubMed]

- Mekaru, H.; Utsumi, Y.; Hattori, T. Quasi-3D microstructure fabrication technique utilizing hard X-ray lithography of synchrotron radiation. Microsyst. Technol. 2002, 9, 36. [Google Scholar]

- Sato, H.; Houshi, Y.; Shoji, S. Three-dimensional micro-structures consisting of high aspect ratio inclined micro-pillars fabricated by simple photolithography. Microsyst. Technol. 2004, 10, 440. [Google Scholar] [CrossRef]

- del Campo, A.; Arzt, E. Fabrication approaches for generating complex micro-and nanopatterns on polymeric surfaces. Chem. Rev. 2008, 108, 911. [Google Scholar] [CrossRef]

- Lorenz, H.; Laudon, M.; Renaud, P. Mechanical characterization of a new high-aspect-ratio near UV-photoresist. Microelectron. Eng. 1998, 41–42, 371. [Google Scholar]

- Lee, J.B.; Choi, K.-H.; Yoo, K. Innovative SU-8 lithography techniques and their applications. Micromachines 2015, 6, 1. [Google Scholar]

- Yoon, Y.-K.; Park, J.-H.; Allen, M.G. Multidirectional UV lithography for complex 3-D MEMS structures. J. Microelectromech. Syst. 2006, 15, 1121. [Google Scholar] [CrossRef]

- Jin, P. Ultrathick SU-8 fabrication for microreciprocating engines. J. Micro Nanolithography MEMS MOEMS 2004, 3, 569. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.; Lee, H.C.; Lee, D.-S.; Jung, H. Drawing lithography: Three-dimensional fabrication of an ultrahigh-aspect-ratio microneedle. Adv. Mater. 2010, 22, 483. [Google Scholar] [CrossRef] [PubMed]

- Teh, W.H.; Dürig, U.; Salis, G.; Harbers, R.; Drechsler, U.; Mahrt, R.F.; Smith, C.G.; Güntherodt, H.-J. SU-8 for real three-dimensional subdiffraction-limit two-photon microfabrication. Appl. Phys. Lett. 2004, 84, 4095. [Google Scholar] [CrossRef]

- Zamfirescu, M.; Jipa, F.; Ulmeanu, M.; Luculescu, C.; Ionita, I.; Dabu, R. High-aspect-ratio structures produced by two-photon photopolymerization. J. Optoelectron. Adv. Mater. 2009, 12, 124–128. [Google Scholar]

- Farsari, M.; Chichkov, B.N. Two-photon fabrication. Nat. Photon 2009, 3, 450. [Google Scholar] [CrossRef]

- Kawata, S.; Sun, H.-B.; Tanaka, T.; Takada, K. Finer features for functional microdevices. Nature 2001, 412, 697. [Google Scholar] [CrossRef]

- Nielsen, A.V.; Beauchamp, M.J.; Nordin, G.P.; Woolley, A.T. 3D Printed Microfluidics. Annu. Rev. Anal. Chem. Palo. Alto. Calif. 2020, 13, 45. [Google Scholar] [CrossRef]

- Baldacchini, T. Three-Dimensional Microfabrication Using Two-Photon Polymerization: Fundamentals, Technology, and Applications; William Andrew: Norwich, NY, USA, 2015. [Google Scholar]

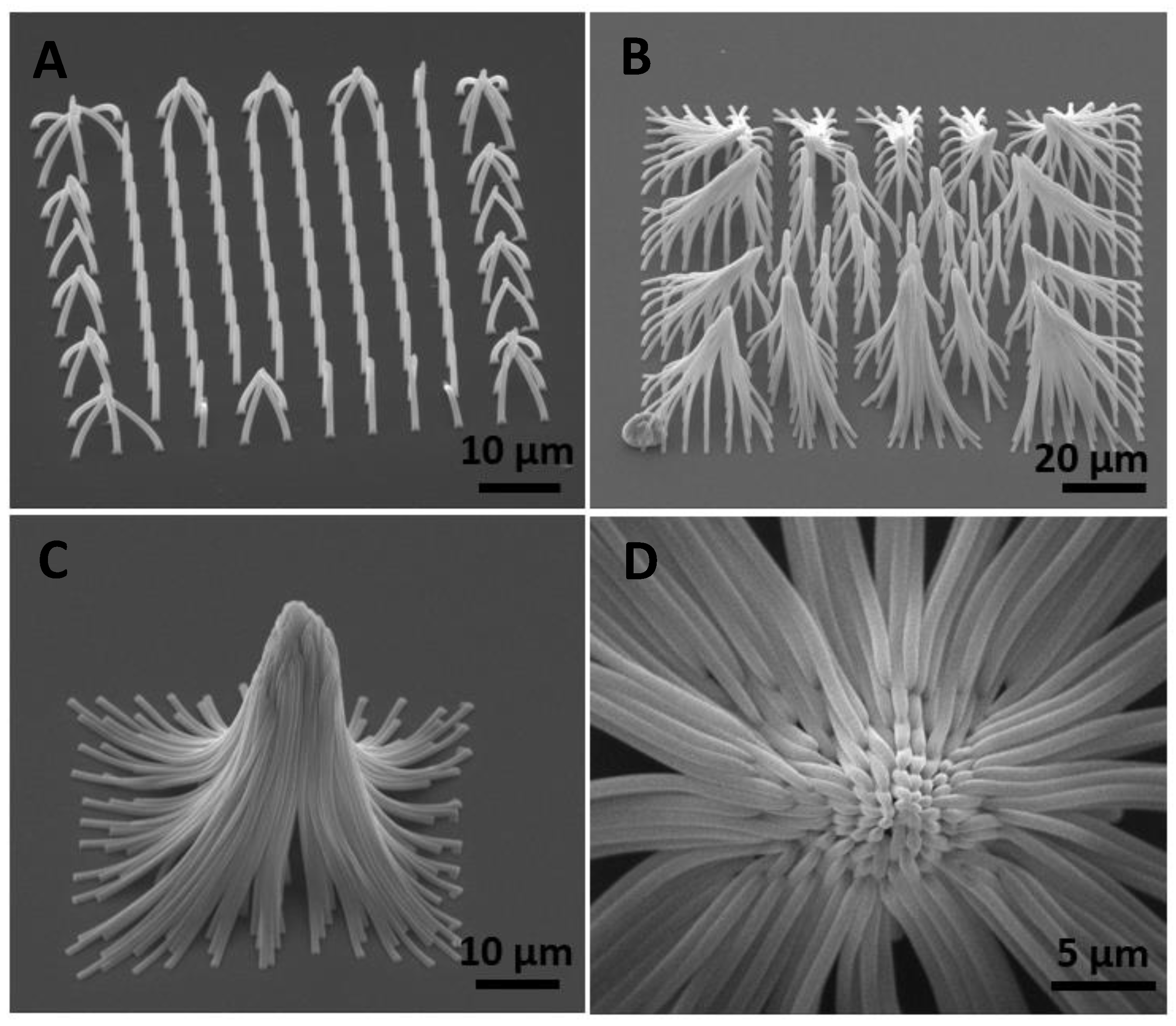

- De Volder, M.; Hart, A.J. Engineering hierarchical nanostructures by elastocapillary self-assembly. Angew. Chem. Int. Ed. 2013, 52, 2412. [Google Scholar] [CrossRef] [Green Version]

- Singh, K.; Lister, J.R.; Vella, D. A fluid-mechanical model of elastocapillary coalescence. J. Fluid Mech. 2014, 745, 621. [Google Scholar] [CrossRef] [Green Version]

- Purtov, J.; Verch, A.; Rogin, P.; Hensel, R. Improved development procedure to enhance the stability of microstructures created by two-photon polymerization. Microelectron. Eng. 2018, 194, 45. [Google Scholar] [CrossRef]

- Lao, Z.; Pan, D.; Yuan, H.; Ni, J.; Ji, S.; Zhu, W.; Hu, Y.; Li, J.; Wu, D.; Chu, J. Mechanical-tunable capillary-force-driven self-assembled hierarchical structures on soft substrate. ACS Nano 2018, 12, 10142. [Google Scholar] [CrossRef] [PubMed]

- Chandra, D.; Yang, S. Stability of high-aspect-ratio micropillar arrays against adhesive and capillary forces. Acc. Chem. Res. 2010, 43, 1080. [Google Scholar] [CrossRef]

- Ghosh, T.; Fritz, E.-C.; Balakrishnan, D.; Zhang, Z.; Vrancken, N.; Anand, U.; Zhang, H.; Loh, N.D.; Xu, X.; Holsteyns, F.; et al. Preventing the Capillary-Induced Collapse of Vertical Nanostructures. ACS Appl. Mater. Interfaces 2022, 14, 5537. [Google Scholar] [CrossRef]

- Xu, X.; Vrancken, N.; Vereecke, G.; Suhard, S.; Pourtois, G.; Holsteyns, F. Some critical issues in pattern collapse prevention and repair. Solid State Phenom. 2016, 255, 147. [Google Scholar] [CrossRef]

- Vrancken, N.; Vereecke, G.; Bal, S.; Sergeant, S.; Doumen, G.; Holsteyns, F.; Terryn, H.; De Gendt, S.; Xu, X. Pattern collapse of high-aspect-ratio silicon nanostructures-A parametric study. Solid State Phenom. 2016, 255, 136. [Google Scholar] [CrossRef]

- Lázár, I.; Fábián, I. A continuous extraction and pumpless supercritical CO2 drying system for laboratory-scale aerogel production. Gels 2016, 2, 26. [Google Scholar] [CrossRef] [Green Version]

- Araujo, J.; Teran, F.; Oliveira, R.; Nour, E.; Montenegro, M.; Campos, J.; Vazoller, R. Comparison of hexamethyldisilazane and critical point drying treatments for SEM analysis of anaerobic biofilms and granular sludge. J. Electron Microsc. 2003, 52, 429. [Google Scholar] [CrossRef]

- Arkles, B. Tailoring surfaces with silanes. Chemtech 1977, 7, 766. [Google Scholar]

- Chandra, D.; Yang, S. Capillary-force-induced clustering of micropillar arrays: Is it caused by isolated capillary bridges or by the lateral capillary meniscus interaction force? Langmuir 2009, 25, 10430. [Google Scholar] [CrossRef]

- Hu, Y.; Lao, Z.; Cumming, B.P.; Wu, D.; Li, J.; Liang, H.; Chu, J.; Huang, W.; Gu, M. Laser printing hierarchical structures with the aid of controlled capillary-driven self-assembly. Proc. Natl. Acad. Sci. USA 2015, 112, 6876. [Google Scholar] [CrossRef] [PubMed]

- Saha, S.K.; Wang, D.; Nguyen, V.H.; Chang, Y.; Oakdale, J.S.; Chen, S.-C. Scalable submicrometer additive manufacturing. Science 2019, 366, 105. [Google Scholar] [CrossRef] [PubMed]

- Park, J.E.; Won, S.; Cho, W.; Kim, J.G.; Jhang, S.; Lee, J.G.; Wie, J.J. Fabrication and applications of stimuli-responsive micro/nanopillar arrays. J. Polym. Sci. 2021, 59, 1491. [Google Scholar] [CrossRef]

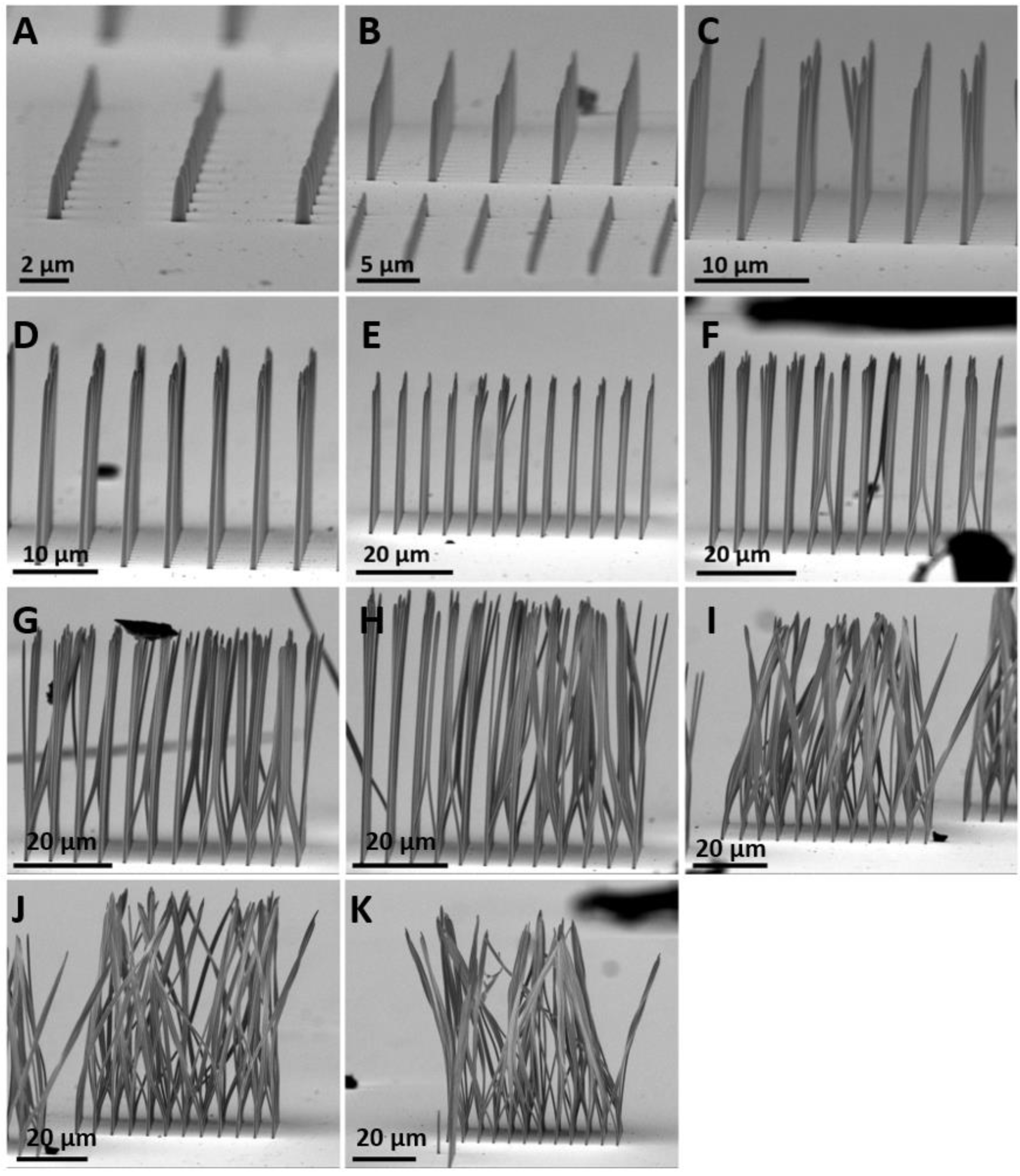

| Sample | Lcorr/µm | Ø/µm | Aspect Ratio |

|---|---|---|---|

| A | 1.90 ± 0.07 | 0.50 ± 0.01 | 3.80 |

| B | 6.75 ± 0.28 | 0.66 ± 0.05 | 10.23 |

| C | 14.29 ± 0.20 | 0.64 ± 0.03 | 22.33 |

| D | 21.75 ± 0.13 | 0.66 ± 0.03 | 33.00 |

| E | 29.22 ± 0.16 | 0.66 ± 0.04 | 44.27 |

| F | 37.51 ± 0.24 | 0.65 ± 0.05 | 57.71 |

| G | 45.12 ± 0.11 | 0.72 ± 0.01 | 62.67 |

| H | 52.99 ± 0.14 | 0.66 ± 0.04 | 80.29 |

| I | 59.04 1 | 0.71 1 | 83.70 |

| J | 57.24 1 | 0.74 1 | 90.09 |

| K | 73.64 1 | 0.73 1 | 101 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamranikia, K.; Dominici, S.; Keller, M.; Kube, N.; Mougin, K.; Spangenberg, A. Very High-Aspect-Ratio Polymeric Micropillars Made by Two-Photon Polymerization. Micromachines 2023, 14, 1602. https://doi.org/10.3390/mi14081602

Kamranikia K, Dominici S, Keller M, Kube N, Mougin K, Spangenberg A. Very High-Aspect-Ratio Polymeric Micropillars Made by Two-Photon Polymerization. Micromachines. 2023; 14(8):1602. https://doi.org/10.3390/mi14081602

Chicago/Turabian StyleKamranikia, Keynaz, Sébastien Dominici, Marc Keller, Niklas Kube, Karine Mougin, and Arnaud Spangenberg. 2023. "Very High-Aspect-Ratio Polymeric Micropillars Made by Two-Photon Polymerization" Micromachines 14, no. 8: 1602. https://doi.org/10.3390/mi14081602

APA StyleKamranikia, K., Dominici, S., Keller, M., Kube, N., Mougin, K., & Spangenberg, A. (2023). Very High-Aspect-Ratio Polymeric Micropillars Made by Two-Photon Polymerization. Micromachines, 14(8), 1602. https://doi.org/10.3390/mi14081602