Study on the Fabrication Process of X-ray Focusing Mirrors

Abstract

:1. Introduction

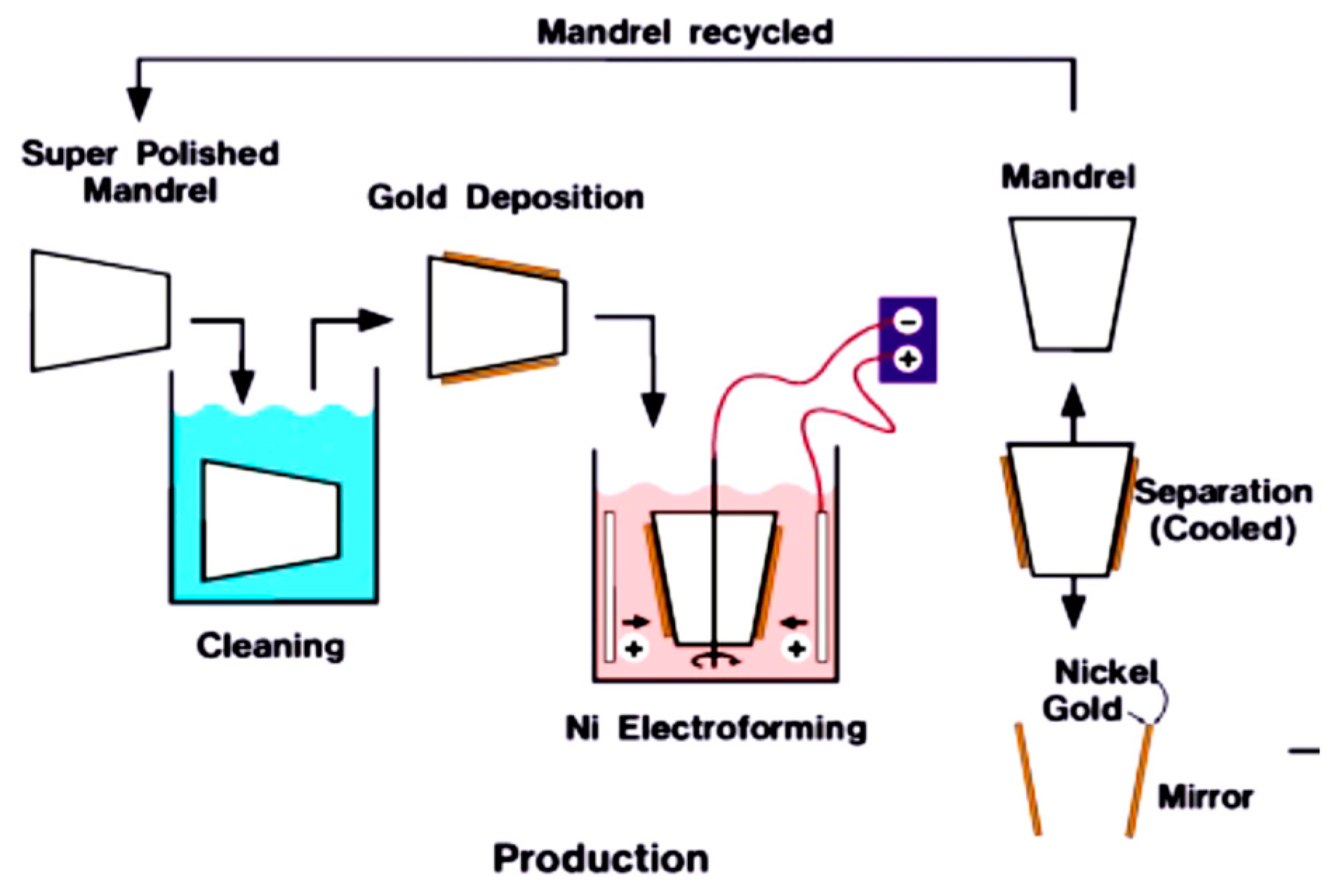

2. Efficient Replication Process Route

2.1. Chemical Plating with Nickel–Phosphorus Alloy

2.2. Ultraprecision Machining of the Mandrel

2.3. Ultra-Smooth Polishing

2.4. Mandrel Coating and Nickel Electroplating

2.5. Demolding

3. Molecular Dynamic Simulation and Tensile Testing Experiment

3.1. Molecular Dynamic Simulation

3.1.1. Calculation Method and Procedure

3.1.2. Calculation Parameter Setting

3.1.3. System Balance Judgment

3.1.4. Interface Energy Analysis

3.1.5. Software and Modules

3.2. Tensile Testing Experiment

3.3. Results and Discussions

4. The Demolding System and Demolding Process

4.1. Demolding System

4.2. Demolding Process

- (a)

- Debug the demolding device and calibrate three mechanical sensors.

- (b)

- Transfer the combination of the mandrel and mirror ready for release to the demolding device; adjust the size of the “step” in front of the demolding claw according to the thickness of different mirrors; then, move it to the lower end of the mirrors, while locking the demolding claw. Attach thermocouples to the upper and lower ends of the mandrel.

- (c)

- Start the vacuum pump until the chamber humidity is lower than 5%, and continue to start the air compressor until the air humidity in the environmental control seal chamber drops to 1%; if the air source of the drying air compressor is not enough to make the internal air humidity lower, at this time, the way of passing high-purity nitrogen is further replaced until the air humidity is close to 0% (monitored by the humidity monitor).

- (d)

- Open the self-pressurized liquid nitrogen tank and begin to continuously inject liquid nitrogen into the mandrel. Notice the gap between the edges of the mirror shell and the mandrel; stop liquid nitrogen as soon as the gap appears.

- (e)

- At last, use the control operation platform to control the vertical sliding table to move upward slowly; always observe that the maximum value of the sensor indicator does not exceed 500 N. When the mirror shell is lifted higher than the mandrel, stop moving the vertical sliding table, remove the mirror shell, and the demolding is completed.

4.3. Demolding Experiment

4.4. Results and Discussions

5. Conclusions

- We explored the optimized process of nickel electroforming replication, and the HPD of the mirror is reduced from 48″ to 25″, which is better than the production target.

- Calculations and experiments based on molecular dynamics demonstrate that the interfacial energy value correlates to the interfacial adsorption strength and binding force.

- The DLC release layer reduces the adhesion force of the film, facilitating the release of mirror shells and decreasing the danger of mirror distortion. The DLC release layer can also protect the mandrel, so that it can be reused.

- To increase demolding efficiency and guarantee mirror quality, force-feedback automatic demolding equipment and a demolding process have been created.

- The fabrication process of the X-ray focusing mirrors will provide key technical support for China’s space X-ray detection and contribute to X-ray astronomy.

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.N.; Feroci, M.; Santangelo, A.; Dong, Y.W.; Feng, H.; Lu, F.J.; Nandra, K.; Wang, Z.S.; Zhang, S.; Bozzo, E.; et al. eXTP: Enhanced X-ray Timing and Polarization mission. In Proceedings of the Space Telescopes and Instrumentation 2016: Ultraviolet to Gamma Ray, Edinburgh, UK, 26 June–1 July 2016; SPIE: Bellingham, WA, USA, 2017; Volume 9905, p. 99051Q. [Google Scholar]

- Zhang, S.; Santangelo, A.; Feroci, M.; Xu, Y.; Lu, F.; Chen, Y.; Feng, H.; Zhang, S.; Brandt, S.; Hernanz, M.; et al. The enhanced X-ray Timing and Polarimetry mission—eXTP. Sci. China Phys. Mech. Astron. 2019, 62, 29502. [Google Scholar] [CrossRef]

- Peres, C.B.; Fabian, A.C.; Edge, A.C.; Allen, S.W.; Johnstone, R.M.; White, D.A. A ROSAT study of the cores of clusters of galaxies—I. Cooling flows in an X-ray flux-limited sample. Mon. Not. R. Astron. Soc. 1998, 298, 416–432. [Google Scholar] [CrossRef]

- Tanaka, Y.; Moue, H.; Holt, S.S. The X-ray astronomy satellite ASCA. Publ. Astron. Soc. Jpn. 1993, 46, 37–41. [Google Scholar]

- Weisskopf, M.C.; Ramsey, B.; O’Dell, S.L.; Tennant, A.; Elsner, R.; Soffita, P.; Bellazzini, R.; Costa, E.; Kolodziejczak, J.; Kaspi, V.; et al. The Imaging X-ray Polarimetry Explorer (IXPE). Results Phys. 2016, 6, 1179–1180. [Google Scholar] [CrossRef]

- Serlemitsos, P.J.; Soong, Y.; Chan, K.W.; Okajima, T.; Lehan, J.P.; Maeda, Y.; Itoh, K.; Mori, H.; Iizuka, R.; Itoh, A.; et al. The X-ray Telescope onboard Suzaku. Publ. Astron. Soc. Jpn. 2007, 59, S9–S21. [Google Scholar] [CrossRef]

- Koglin, J.E.; An, H.; Blaedel, K.L.; Brejnholt, N.F.; Christensen, F.E.; Craig, W.W.; Decker, T.A.; Hailey, C.J.; Hale, L.C.; Harrison, F.A.; et al. NuSTAR hard X-ray optics design and performance. In Proceedings of the Optics for EUV, X-ray, and Gamma-ray Astronomy IV, San Diego, CA, USA, 2–6 August 2009; SPIE: Bellingham, WA, USA, 2019. [Google Scholar]

- Harrison, F.A.; Boggs, S.; Christensen, F.; Craig, W.; Hailey, C.; Stern, D.; Zhang, W.; Angelini, L.; An, H.; Bhalerao, V.; et al. The Nuclear Spectroscopic Telescope Array (NuSTAR). In Proceedings of the Space Telescopes and Instrumentation 2010: Ultraviolet to Gamma ray, 27 June–2 July 2010; SPIE: Bellingham, WA, USA, 2010. [Google Scholar]

- Bavdaz, M.; Rando, N.; Wille, E.; Wallace, K.; Shortt, B.; Collon, M.; van Baren, C.; Pareschi, G.; Christensen, F.; Krumrey, M.; et al. ESA-led ATHENA/IXO optics development status. In Proceedings of the Optics for EUV, X-ray, and Gamma-ray Astronomy V, San Diego, CA, USA, 21–25 August 2011; SPIE: Bellingham, WA, USA, 2011. [Google Scholar]

- Grant, C.E.; Bautz, M.W.; Ford, P.G.; Plucinsky, P.P. Fifteen years of the Advanced CCD Imaging Spectrometer. In Proceedings of the Space Telescopes and Instrumentation 2014: Ultraviolet to Gamma ray, Montréal, QC, Canada, 22–27 June 2014; SPIE: Bellingham, WA, USA, 2014; Volume 9144. [Google Scholar]

- Ravera, L.; Barret, D.; den Herder, J.W.; Piro, L.; Clédassou, R.; Pointecouteau, E.; Peille, P.; Pajot, F.; Arnaud, M.; Pigot, C.; et al. The X-ray integral field unit (X-IFU) for athena. In Proceedings of the Space Telescopes and Instrumentation 2014: Ultraviolet to Gamma ray, Montréal, QC, Canada, 22–27 June 2014; SPIE: Bellingham, WA, USA, 2014. [Google Scholar]

- Gendreau, K.C.; Arzoumanian, Z.; Adkins, P.W.; Albert, C.L.; Anders, J.F.; Aylward, A.T.; Baker, C.L.; Balsamo, E.R.; Bamford, W.A.; Benegalrao, S.S.; et al. The Neutron star Interior Composition Explorer (NICER): Design and development. In Proceedings of the Space Telescopes and Instrumentation 2016: Ultraviolet to Gamma ray, Edinburgh, UK, 26 June–1 July 2016; SPIE: Bellingham, WA, USA, 2016. [Google Scholar]

- Brinkman, A.C.; Behar, E.; Güdel, M.; Audard, M.; Boggende, A.J.F.D.; Branduardi-Raymont, G.; Cottam, J.; Erd, C.; Herder, J.W.D.; Jansen, F.; et al. First light measurements with the XMM-Newton reflection grating spectrometers: Evidence for an inverse first ionisation potential effect and anomalous Ne abundance in the Coronae of HR 1099. Astron. Astrophys. 2001, 365, 75–76. [Google Scholar] [CrossRef]

- Parmar, A.N.; Martin, D.D.; Bavdaz, M.; Favata, F.; Kuulkers, E.; Vacanti, G.; Lammers, U.; Peacock, A.; Taylor, B.G. The low-energy concentrator spectrometer on-board the BeppoSAX X-ray astronomy satellite. Astron. Astrophys. Suppl. Ser. 1997, 122, 309–326. [Google Scholar] [CrossRef]

- Boella, G.; Chiappetti, L.; Conti, G.; Cusumano, G.; Del Sordo, S.; La Rosa, G.; Maccarone, M.C.; Mineo, T.; Molendi, S.; Re, S.; et al. The medium-energy concentrator spectrometer on board the BeppoSAX X-ray astronomy satellite. Astron. Astrophys. Suppl. Ser. 1997, 122, 327–340. [Google Scholar] [CrossRef]

- Garmire, G.P.; Bautz, M.W.; Ford, P.G.; Nousek, J.A.; Ricker, G.R., Jr. Advanced CCD imaging spectrometer (ACIS) instrument on the Chandra X-ray Observatory. In Proceedings of the X-ray and Gamma-ray Telescopes and Instruments for Astronomy, Waikoloa, HW, USA, 22–28 August 2002; SPIE: Bellingham, WA, USA, 2002; Volume 4851, pp. 28–45. [Google Scholar]

- Polletta, M.; Tajer, M.; Maraschi, L.; Trinchieri, G.; Lonsdale, C.J.; Chiappetti, L.; Andreon, S.; Pierre, M.; Le Fevre, O.; Zamorani, G.; et al. Spectral energy distributions of hard X-ray selected active galactic nuclei in the XMM-Newton medium deep survey. Astrophys. J. 2007, 663, 81. [Google Scholar] [CrossRef]

- Citterio, O.; Campana, S.; Conconi, P.; Ghigo, M.; Mazzoleni, F.; Poretti, E.; Conti, G.; Cusumano, G.; Sacco, B.; Braeuninger, H.W.; et al. Characteristics of the flight model optics for the JET-X telescope onboard the Spectrum-X-Gamma satellite. In Proceedings of the Multilayer and Grazing Incidence X-ray/EUV Optics III, Denver, CO, USA, 4–9 August 1996; SPIE: Bellingham, WA, USA, 1996; Volume 2805, pp. 56–66. [Google Scholar]

- Burrows, D.N.; Hill, J.E.; Nousek, J.A.; Kennea, J.A.; Wells, A.; Osborne, J.P.; Abbey, A.F.; Beardmore, A.; Mukerjee, K.; Short, A.D.T.; et al. The Swift X-ray telescope. Space Sci. Rev. 2005, 120, 165–195. [Google Scholar] [CrossRef]

- Vernani, D. Advanced Manufacturing Techniques for X-ray and VHE Gamma-ray Astronomical Mirrors. Ph.D. Thesis, University of Insubria, Varese, Italy, 2011; pp. 42–55. [Google Scholar]

- De Chambure, D.; Laine, R.; van Katwijk, K.; van Casteren, J.F.; Glaude, P. Status of the X-ray mirror production for the ESA XMM spacecraft. In Proceedings of the EUV, X-Ray, and Gamma-ray Instrumentation for Astronomy VII, Denver, CO, USA, 4–9 August 1996; SPIE: Bellingham, WA, USA, 1996; Volume 2808, pp. 362–375. [Google Scholar]

- O’Dell, S.L.; Atkins, C.; Broadway, D.M.; Elsner, R.F.; Gaskin, J.A.; Gubarev, M.V.; Kilaru, K.; Kolodziejczak, J.J.; Ramsey, B.D.; Roche, J.M.; et al. X-ray optics at nasa marshall space flight center. In Proceedings of the EUV and X-ray Optics: Synergy between Laboratory and Space IV, Prague, Czech Republic, 13–16 April 2015; SPIE: Bellingham, WA, USA, 2015; Volume 9510, pp. 7–20. [Google Scholar]

- Romaine, S.; Boike, J.; Bruni, R.; Engelhaupt, D.; Gorenstein, P.; Gubarev, M.; Ramsey, B. Mandrel replication for hard X-ray optics using titanium nitride. In Proceedings of the Optics for EUV, X-ray, and Gamma-ray Astronomy IV, San Diego, CA, USA, 2–6 August 2009; SPIE: Bellingham, WA, USA, 2009; Volume 7437, pp. 325–332. [Google Scholar]

- Romaine, S.; Boike, J.; Bruni, R.; Engelhaupt, D.; Gorenstein, P.; Ramsey, B. Improved release coatings for electroformed X-ray optics. In Proceedings of the Optics for EUV, X-ray, and Gamma-ray Astronomy V, San Diego, CA, USA, 21–25 August 2011; SPIE: Bellingham, WA, USA, 2011; Volume 8147, pp. 323–328. [Google Scholar]

- Dutta, B.N.; Dayal, B. Lattice Constants and Thermal Expansion of Gold up to 878 °C by X-ray Method. Phys. Status Solidi (b) 1963, 3, 473–477. [Google Scholar] [CrossRef]

- Straumanis, M.E.; Aka, E.Z. Precision Determination of Lattice Parameter, Coefficient of Thermal Expansion and Atomic Weight of Carbon in Diamond1. J. Am. Chem. Soc. 1951, 73, 5643–5646. [Google Scholar] [CrossRef]

- Bravais, A. Études Cristallographiques; Gauthier-Villars: Paris, France, 1866. [Google Scholar]

- Friedel, M.G. Etudes sur la loi de Bravais. Bull. Soc. Franc. Miner. 1907, 9, 326. [Google Scholar] [CrossRef]

- Donnay, J.D.H.; Harker, D. A new law of crystal morphology extending the law of Bravais. Am. Mineral. 1937, 22, 446–467. [Google Scholar]

- Sun, H. COMPASS: An ab Initio Forcefield Optimized for Condensed-Phase Applications—Overview with Details on Alkane and Benzene Compounds. J. Phys. Chem. B 1998, 102, 7338–7364. [Google Scholar] [CrossRef]

- Sun, H.; Ren, P.; Fried, J.R. The COMPASS Forcefield: Parameterization and Validation for Polyphosphazenes. Comput. Theor. Polym. Sci. 1998, 8, 229–246. [Google Scholar] [CrossRef]

| Calculating Parameter | Set Result |

|---|---|

| Force field | COMPASS II |

| Charge calculation method | Force field assigned |

| Van der Waals force calculation method | Atom based |

| Van der Waals force cutoff radius (A) | 12.5 |

| Electrostatic force calculation method | Ewald |

| Electrostatic force calculation accuracy (kcal/mol) | 1 × 10−3 |

| Module | Function |

|---|---|

| MS Visualizer | Molecular, cell, interface model construction; model visualization and output |

| Amorphous Cell | The construction of the Au NiP and C cells |

| Morphology | The crystal morphology of the cell was calculated, and the representative crystal face was determined |

| Forcite | Molecular dynamics calculation and result analysis and output |

| Interface Model | Eint (kcal/mol) |

|---|---|

| Au-NiP | −2843 ± 8 |

| C-NiP | −595 ± 2 |

| Au-C | −398 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, Q.; Ding, F.; Chen, Z.; Li, D.; Wang, B. Study on the Fabrication Process of X-ray Focusing Mirrors. Micromachines 2023, 14, 1666. https://doi.org/10.3390/mi14091666

Liao Q, Ding F, Chen Z, Li D, Wang B. Study on the Fabrication Process of X-ray Focusing Mirrors. Micromachines. 2023; 14(9):1666. https://doi.org/10.3390/mi14091666

Chicago/Turabian StyleLiao, Qiuyan, Fei Ding, Zhigao Chen, Duo Li, and Bo Wang. 2023. "Study on the Fabrication Process of X-ray Focusing Mirrors" Micromachines 14, no. 9: 1666. https://doi.org/10.3390/mi14091666

APA StyleLiao, Q., Ding, F., Chen, Z., Li, D., & Wang, B. (2023). Study on the Fabrication Process of X-ray Focusing Mirrors. Micromachines, 14(9), 1666. https://doi.org/10.3390/mi14091666