Analysis of Flow Characteristics between Tandem Flexible Structures Based on PIV: Substantial Applications for the Removal of Microplastics

Abstract

1. Introduction

2. Materials and Methods

2.1. PIV Experiment

2.2. Experimental Model

3. Results and Discussion

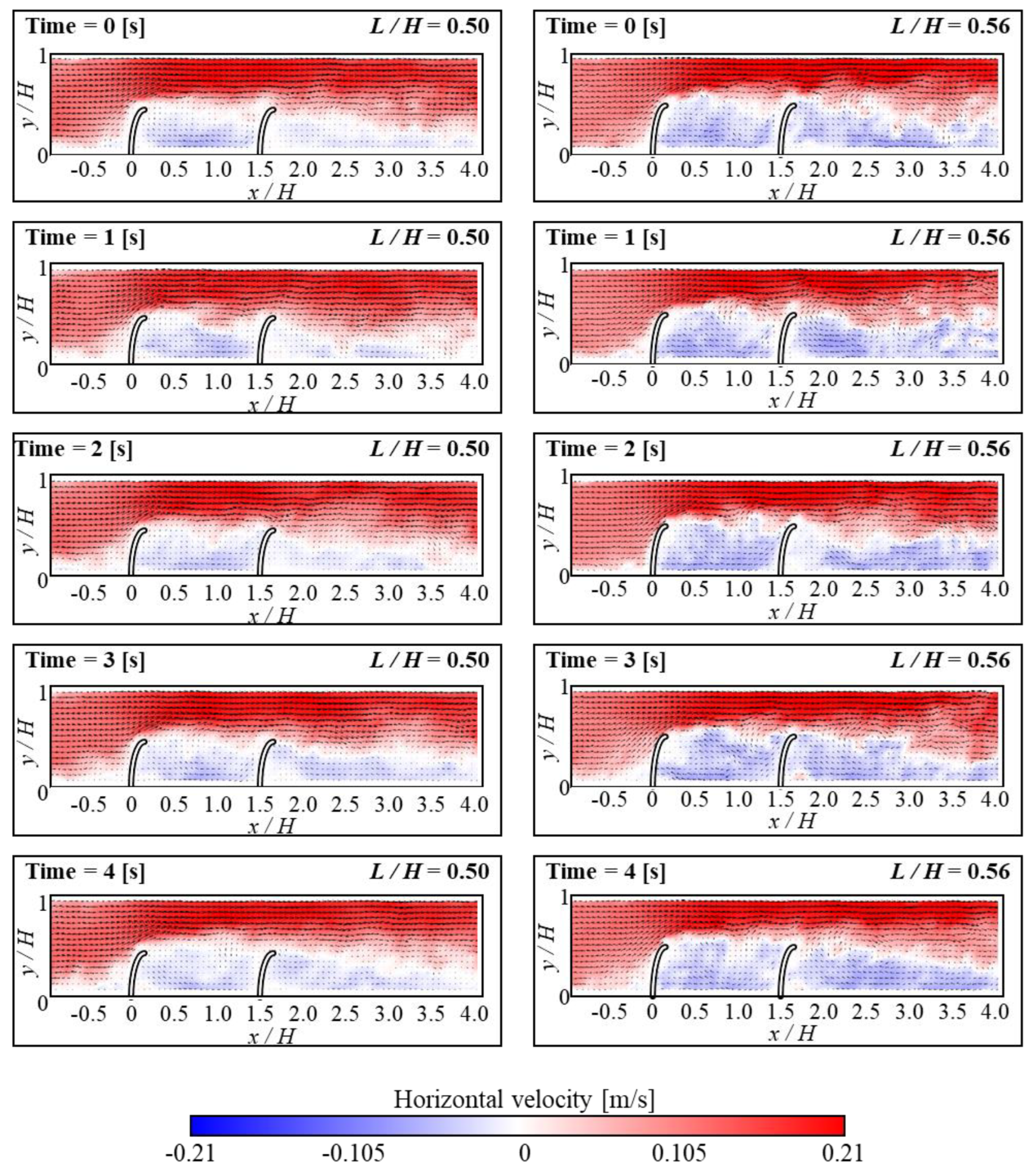

3.1. Effects of Gap Distance of FSs

3.2. Effects of Height of FSs

3.3. Secondary Vortex Stability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zuo, W.; Zhang, Y.; E, J.; Li, J.; Li, Q.; Zhang, G. Performance comparison between single S-channel and double S-channel cold plate for thermal management of a prismatic LiFePO4 battery. Renew. Energy 2022, 192, 46–57. [Google Scholar] [CrossRef]

- Li, F.; Zou, W.; Zhuo, K.; Li, Q.; Huang, Y.; Zhang, G. State-of-charge estimation of lithium-ion battery based on second order resistor-capacitance circuit-PSO-TCN model. Energy 2024, 289, 130025. [Google Scholar] [CrossRef]

- Duis, K.; Coors, A. Microplastics in the Aquatic and Terrestrial Environment: Sources (with a Specific Focus on Personal Care Products), Fate and Effects. Environ. Sci. Eur. 2016, 28, 2. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe. Plastics—The Facts 2020. An Analysis of European Plastics Production, Demand, Conversion and End-of-Life Management; PlasticsEurope: Brussels, Belgium, 2020; pp. 1–80. Available online: https://plasticseurope.org/wp-content/uploads/2022/12/PE-PLASTICS-THE-FACTS_FINAL_DIGITAL.pdf (accessed on 1 October 2022).

- Zhang, S.; Wang, J.; Yan, P.; Hao, X.; Xu, B.; Wang, W.; Aurangzeib, M. Non-Biodegradable Microplastics in Soils: A Brief Review and Challenge. J. Hazard Mater. 2021, 409, 124525. [Google Scholar] [CrossRef] [PubMed]

- Azizi, N.; Nasseri, S.; Nodehi, R.N.; Jaafarzadeh, N.; Pirsaheb, M. Evaluation of Conventional Wastewater Treatment Plants Efficiency to Remove Microplastics in Terms of Abundance, Size, Shape, and Type: A Systematic Review and Meta-Analysis. Mar. Pollut. Bull. 2022, 177, 113462. [Google Scholar] [CrossRef] [PubMed]

- Gigault, J.; Ter Halle, A.; Baudrimont, M.; Pascal, P.-Y.; Gauffre, F.; Phi, T.-L.; El Hadri, H.; Grassl, B.; Reynaud, S. Current Opinion: What Is a Nanoplastic? Environ. Pollut. 2018, 235, 1030–1034. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.C.; Olsen, Y.; Mitchell, R.P.; Davis, A.; Rohewland, S.J.; John, A.W.G.; McGonigle, D.; Russell, A.E. Lost at Sea: Where Is All the Plastic? Science 2004, 304, 838. [Google Scholar] [CrossRef]

- Oliva, J.; Valle-Garcia, L.S.; Garces, L.; Oliva, A.I.; Valadez-Renteria, E.; Hernandez-Bustos, D.A.; Campos-Amador, J.J.; Gomez-Solis, C. Using NIR Irradiation and Magnetic Bismuth Ferrite Microparticles to Accelerate the Removal of Polystyrene Microparticles from the Drinking Water. J. Environ. Manag. 2023, 345, 118784. [Google Scholar] [CrossRef]

- Yang, X.; Man, Y.B.; Wong, M.H.; Owen, R.B.; Chow, K.L. Environmental Health Impacts of Microplastics Exposure on Structural Organization Levels in the Human Body. Sci. Total Environ. 2022, 825, 154025. [Google Scholar] [CrossRef]

- Yang, L.; Qiao, F.; Lei, K.; Li, H.; Kang, Y.; Cui, S.; An, L. Microfiber Release from Different Fabrics during Washing. Environ. Pollut. 2019, 249, 136–143. [Google Scholar] [CrossRef]

- Lo, H.-S.; Xu, X.; Wong, C.-Y.; Cheung, S.-G. Comparisons of Microplastic Pollution between Mudflats and Sandy Beaches in Hong Kong. Environ. Pollut. 2018, 236, 208–217. [Google Scholar] [CrossRef] [PubMed]

- Siegfried, M.; Koelmans, A.A.; Besseling, E.; Kroeze, C. Export of Microplastics from Land to Sea. A Modelling Approach. Water Res. 2017, 127, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Pang, L.-Y.; Sonagara, S.; Oduwole, O.; Gibbins, C.; Nee, T.K. Microplastics—An Emerging Silent Menace to Public Health. Life Sci. Med. Biomed. 2021, 5. [Google Scholar] [CrossRef]

- Eriksen, M.; Lebreton, L.C.M.; Carson, H.S.; Thiel, M.; Moore, C.J.; Borerro, J.C.; Galgani, F.; Ryan, P.G.; Reisser, J. Plastic Pollution in the World’s Oceans: More than 5 Trillion Plastic Pieces Weighing over 250,000 Tons Afloat at Sea. PLoS ONE 2014, 9, e111913. [Google Scholar] [CrossRef] [PubMed]

- Auta, H.S.; Emenike, C.U.; Fauziah, S.H. Distribution and Importance of Microplastics in the Marine Environment: A Review of the Sources, Fate, Effects, and Potential Solutions. Environ. Int. 2017, 102, 165–176. [Google Scholar] [CrossRef]

- Barnes, D.K.A.; Galgani, F.; Thompson, R.C.; Barlaz, M. Accumulation and Fragmentation of Plastic Debris in Global Environments. Philos. Trans. R. Soc. B 2009, 364, 1985–1998. [Google Scholar] [CrossRef]

- Moore, C.J. Synthetic Polymers in the Marine Environment: A Rapidly Increasing, Long-Term Threat. Environ. Res. 2008, 108, 131–139. [Google Scholar] [CrossRef]

- Sol, D.; Laca, A.; Laca, A.; Díaz, M. Wastewater Treatment Approaches to Remove Microplastics. In Polluting Textiles: The Problem with Microfibres; Routledge: London, UK, 2022. [Google Scholar]

- Sol, D.; Laca, A.; Laca, A.; Díaz, M. Microplastics in Wastewater and Drinking Water Treatment Plants: Occurrence and Removal of Microfibres. Appl. Sci. 2021, 11, 10109. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, X.; Ren, H.; Cao, G.; Xie, G.; Xing, D.; Liu, B. Investigation and Fate of Microplastics in Wastewater and Sludge Filter Cake from a Wastewater Treatment Plant in China. Sci. Total Environ. 2020, 746, 141378. [Google Scholar] [CrossRef]

- Kosuth, M.; Mason, S.A.; Wattenberg, E.V. Anthropogenic Contamination of Tap Water, Beer, and Sea Salt. PLoS ONE 2018, 13, e0194970. [Google Scholar] [CrossRef]

- Mason, S.A.; Welch, V.G.; Neratko, J. Synthetic Polymer Contamination in Bottled Water. Front. Chem. 2018, 6, 407. [Google Scholar] [CrossRef] [PubMed]

- Tong, H.; Jiang, Q.; Hu, X.; Zhong, X. Occurrence and Identification of Microplastics in Tap Water from China. Chemosphere 2020, 252, 126493. [Google Scholar] [CrossRef] [PubMed]

- Muhib, M.I.; Uddin, M.K.; Rahman, M.M.; Malafaia, G. Occurrence of Microplastics in Tap and Bottled Water, and Food Packaging: A Narrative Review on Current Knowledge. Sci. Total Environ. 2023, 865, 161274. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.K.; Ravi, S.K.; Sun, W.; Tan, S.C. Transparent Nanofibrous Mesh Self-assembled from Molecular LEGOs for High Efficiency Air Filtration with New Functionalities. Small 2017, 13, 1601924. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, D.; Ji, C.; Zhu, T.; Rao, Z.; Wang, B. Large-eddy simulations of self-excited thermoacoustic instability in a premixed swirling combustor with an outlet nozzle. Physic Fluids 2022, 34, 044112. [Google Scholar] [CrossRef]

- Hassan, N.H.; Zawawi, M.H.; Mustafa, A.M.; Bakri, A.I.; Rozainy, Z.M.R.; Kamaruddin, M.A.; Nasir, W.N.Y.W.M.; Mazlan, M.A.N.; Irfan, A.R. A Review on Applications of Particle Image Velocimetry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 864, 012149. [Google Scholar] [CrossRef]

- Kitagawa, A.; Ota, M.; Watamura, T.; Tonooka, T.; Murai, Y. Microplastic particle trapping through microfluidic devices with different shaped pillars. Chem. Eng. Sci. 2022, 264, 118163. [Google Scholar] [CrossRef]

- Xu, X.; Li, Z.; Nehorai, A. Finite element simulations of hydrodynamic trapping in microfluidic particle-trap array systems. Biomicrofluidics 2013, 7, 054108. [Google Scholar] [CrossRef]

- Ma, C.-J. Experimental Verification of the Particle Blocking Feature of Nasal Hair. Asian J. Atmos. Environ. 2019, 13, 99–105. [Google Scholar] [CrossRef]

- Lee, J.B.; Park, S.G.; Kim, B.; Ryu, J.; Sung, H.J. Heat Transfer Enhancement by Flexible Flags Clamped Vertically in a Poiseuille Channel Flow. Int. J. Heat Mass Transf. 2017, 107, 391–402. [Google Scholar] [CrossRef]

- Sakamoto, H.; Hainu, H.; Obata, Y. Fluctuating Forces Acting on Two Square Prisms in a Tandem Arrangement. J. Wind Eng. Ind. Aerodyn. 1987, 26, 85–103. [Google Scholar] [CrossRef]

- Yen, S.-C.; San, K.C.; Chuang, T.H. Interactions of Tandem Square Cylinders at Low Reynolds Numbers. Exp. Therm. Fluid Sci. 2008, 32, 927–938. [Google Scholar] [CrossRef]

- Luo, S.C.; Chew, Y.T.; Ng, Y.T. Characteristics of Square Cylinder Wake Transition Flows. Phys. Fluids 2003, 15, 2549–2559. [Google Scholar] [CrossRef]

- Jung, S.Y.; Kim, J.J.; Lee, S.J. Effect of Material Stiffness on the Motion and Flow near the Free End of a Finite Cylinder Surface. Exp. Therm. Fluid Sci. 2019, 102, 548–558. [Google Scholar] [CrossRef]

- Jung, S.Y.; Kim, J.J.; Park, H.W.; Lee, S.J. Comparison of Flow Structures behind Rigid and Flexible Finite Cylinders. Int. J. Mech. Sci. 2018, 142, 480–490. [Google Scholar] [CrossRef]

- Ferrante, A.; Elghobashi, S. 3-Physics of two-way coupling in particle-laden homogeneous isotropic turbulence. In Modeling Approaches and Computational Methods for Particle-Laden Turbulent Flows; Academic Press: Cambridge, MA, USA, 2023; pp. 81–109. [Google Scholar] [CrossRef]

- Sumner, D. Two Circular Cylinders in Cross-Flow: A Review. J. Fluids Struct. 2010, 26, 849–899. [Google Scholar] [CrossRef]

- Holton, J.R. An Introduction to Dynamic Meteorology; Academic Press: New York, NY, USA; San Francisco, CA, USA; London, UK, 1979; Volume 23, Chapter 4; pp. iv–xii; 78–100. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Sangtam, B.T.; Seong, H.; Kim, J.J.; Park, H. Analysis of Flow Characteristics between Tandem Flexible Structures Based on PIV: Substantial Applications for the Removal of Microplastics. Micromachines 2024, 15, 100. https://doi.org/10.3390/mi15010100

Lee H, Sangtam BT, Seong H, Kim JJ, Park H. Analysis of Flow Characteristics between Tandem Flexible Structures Based on PIV: Substantial Applications for the Removal of Microplastics. Micromachines. 2024; 15(1):100. https://doi.org/10.3390/mi15010100

Chicago/Turabian StyleLee, Hyeonjin, Bongliba T. Sangtam, Heejoong Seong, Jeong Jae Kim, and Hanwook Park. 2024. "Analysis of Flow Characteristics between Tandem Flexible Structures Based on PIV: Substantial Applications for the Removal of Microplastics" Micromachines 15, no. 1: 100. https://doi.org/10.3390/mi15010100

APA StyleLee, H., Sangtam, B. T., Seong, H., Kim, J. J., & Park, H. (2024). Analysis of Flow Characteristics between Tandem Flexible Structures Based on PIV: Substantial Applications for the Removal of Microplastics. Micromachines, 15(1), 100. https://doi.org/10.3390/mi15010100