Effect of Eccentricity Difference on the Mechanical Response of Microfluidics-Derived Hollow Silica Microspheres during Nanoindentation

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Microfluidic Device

2.2. Materials

2.3. Preparation of the Hollow Silica Microspheres

2.4. Characterization

3. Results and Discussion

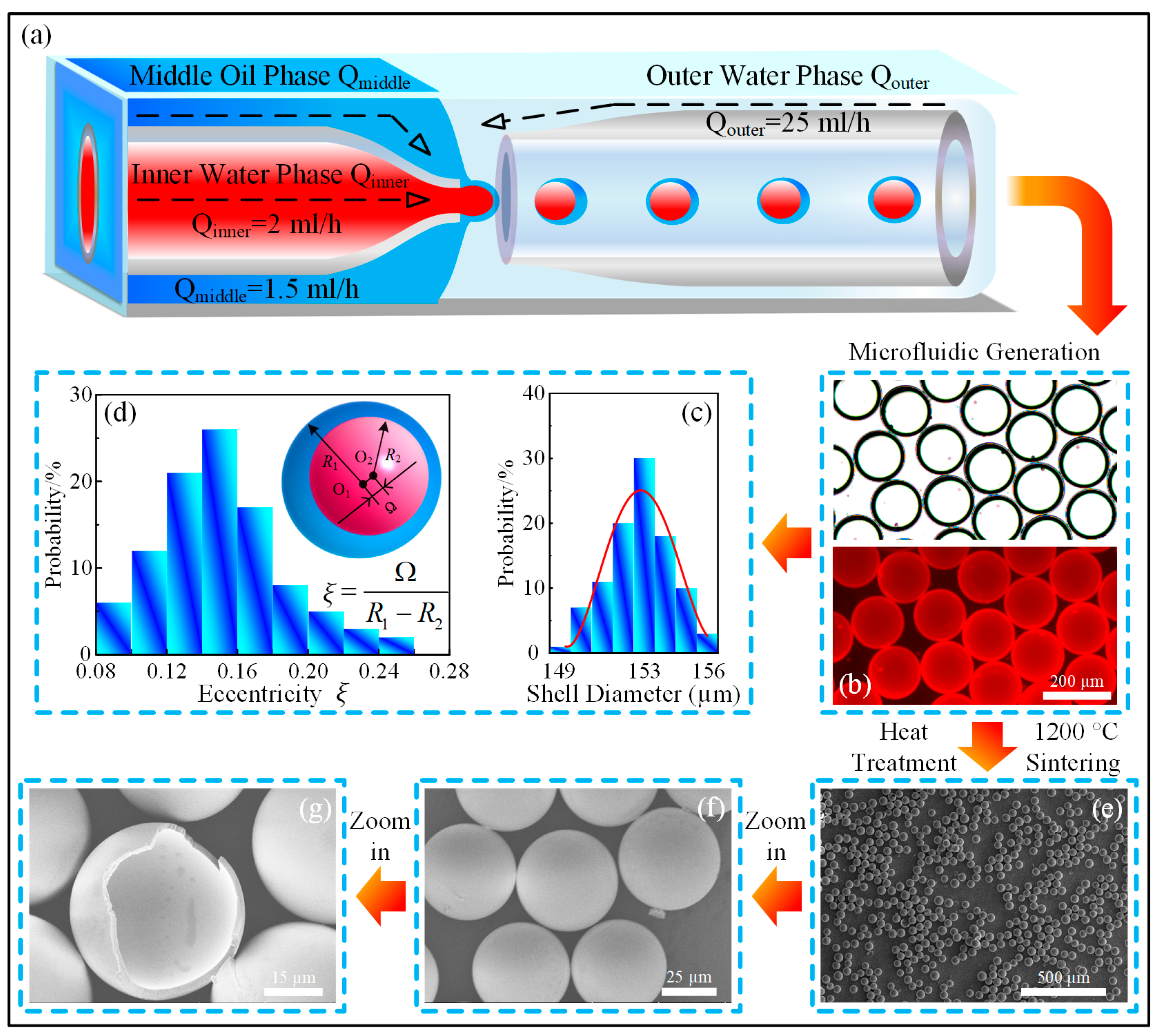

3.1. Microfluidic Fabrication and Characterization of the Hollow Microspheres

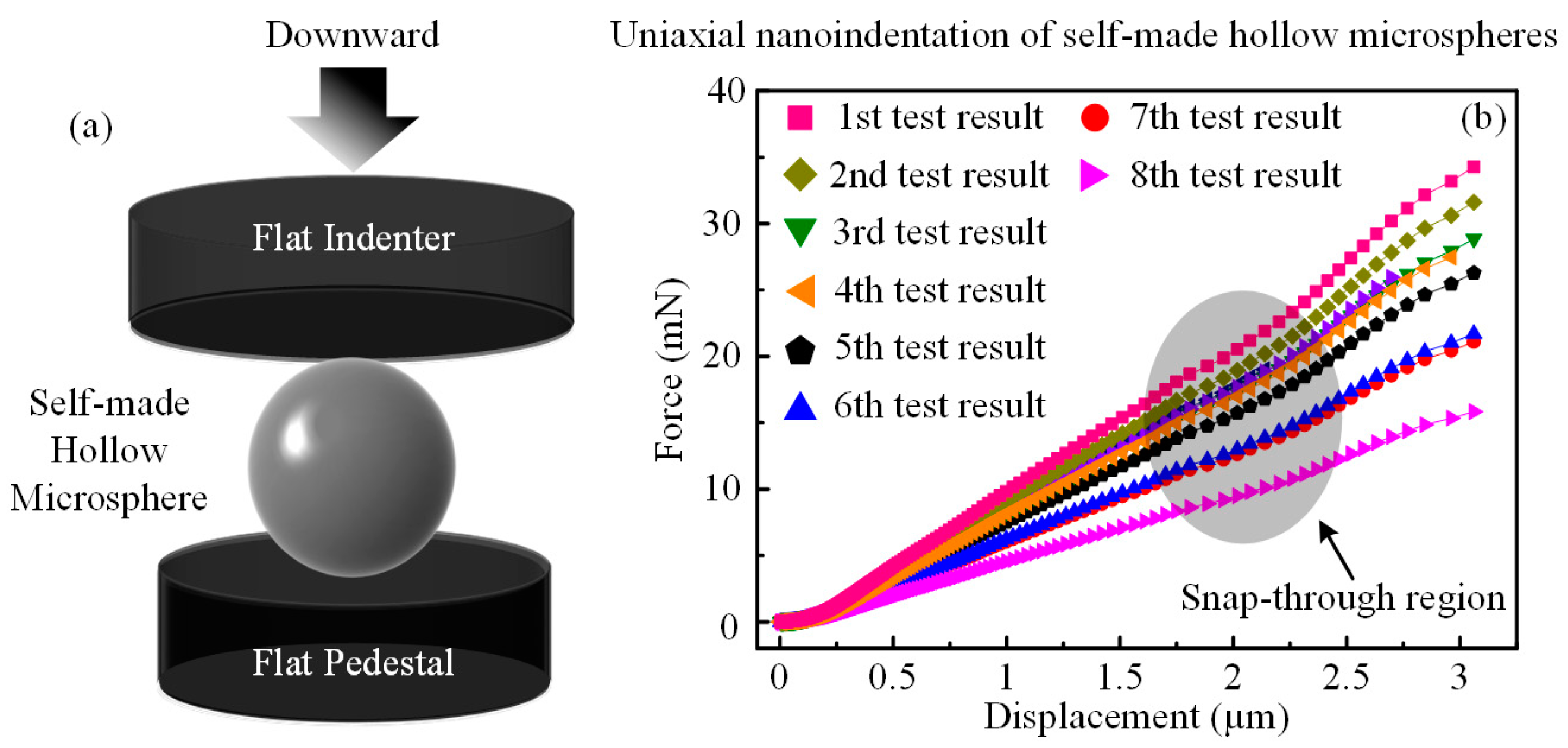

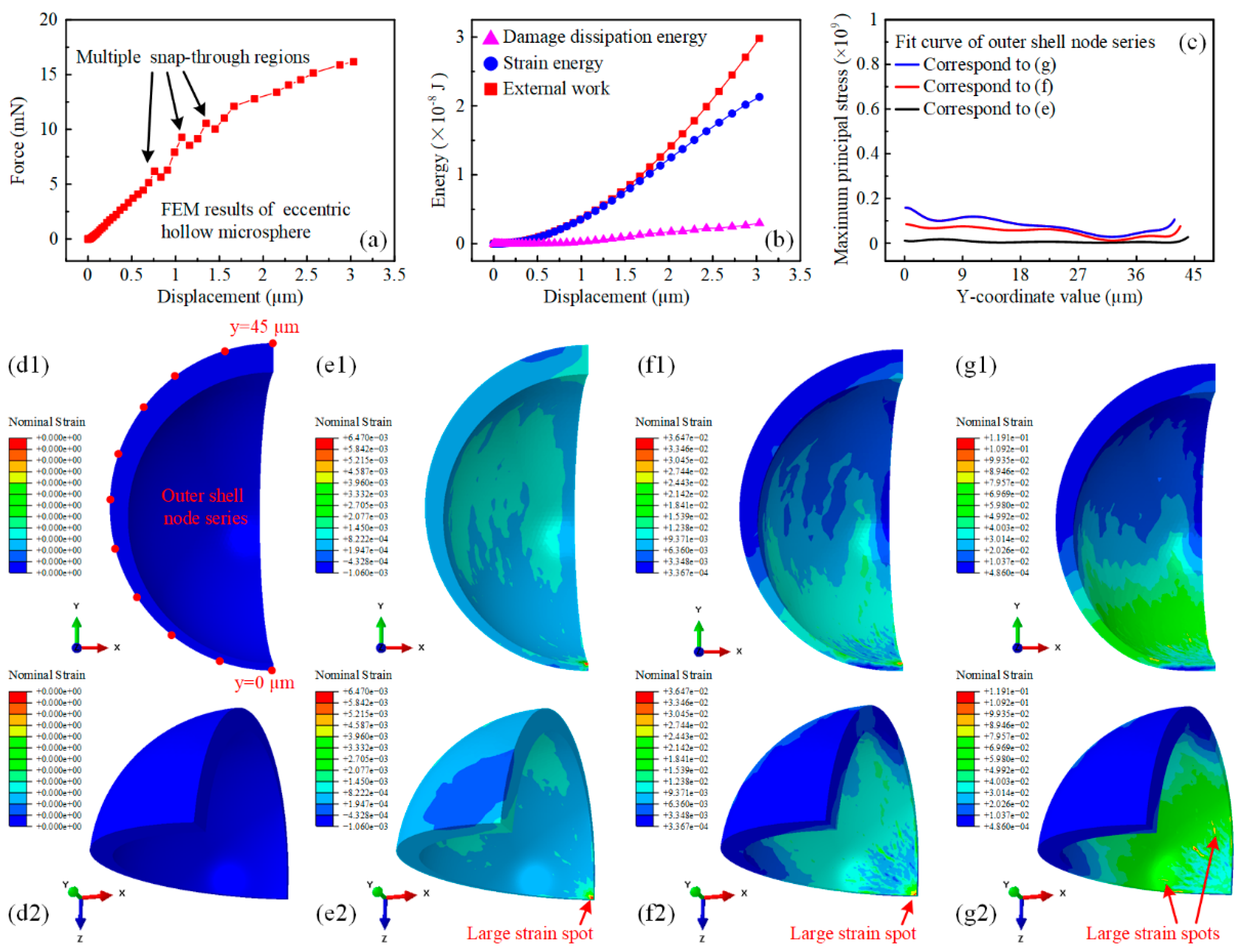

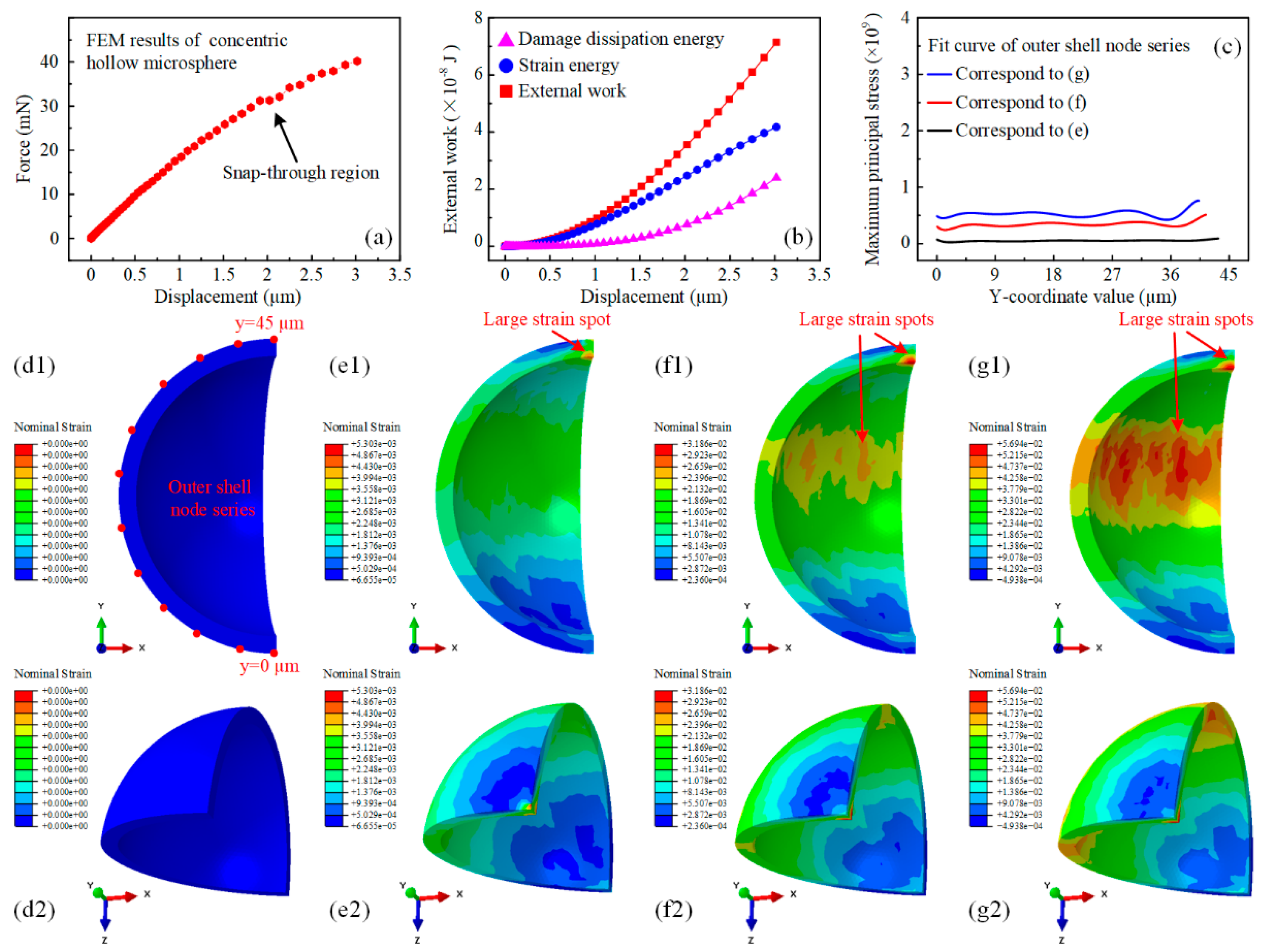

3.2. Simulation-Based Mechanical Response Analysis of Hollow Silica Microspheres with Varying Eccentricities

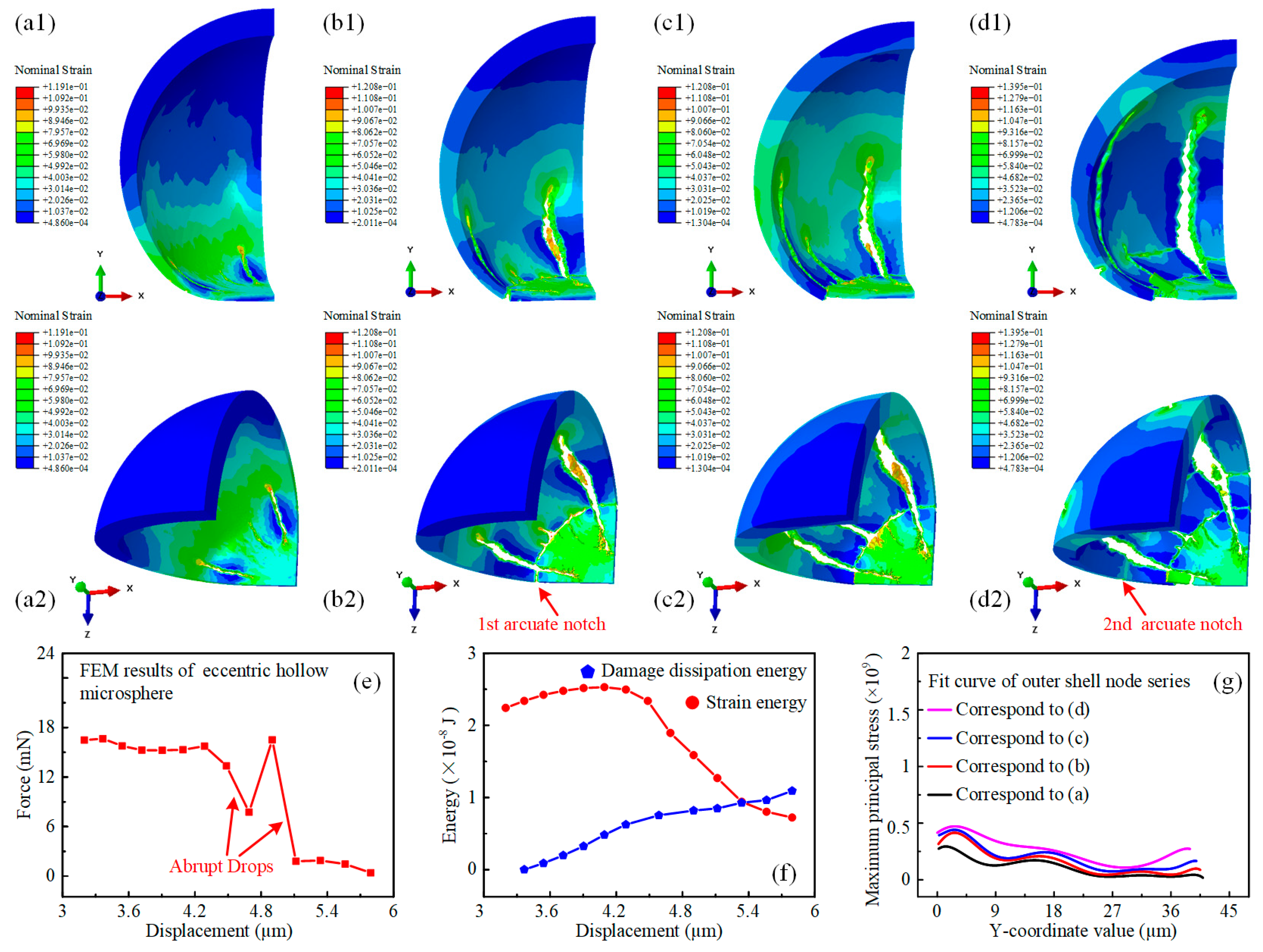

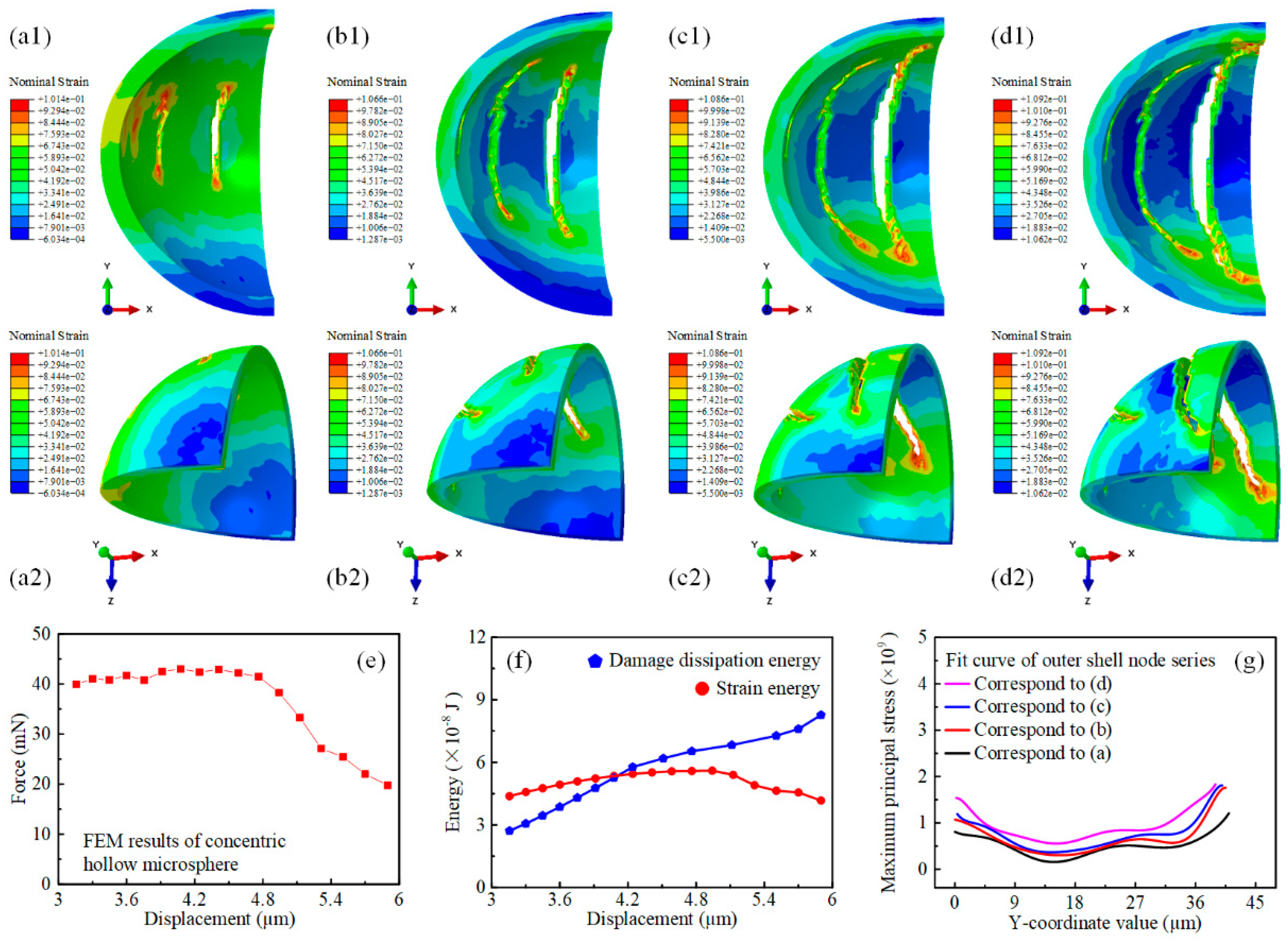

3.3. Simulation-Based Prediction of Damage Evolution Behavior of Hollow Silica Microspheres with Varying Eccentricities

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dhasindrakrishna, K.; Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Progress, current thinking and challenges in geopolymer foam concrete technology. Cem. Concr. Compos. 2021, 116, 103886. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, F.; Liu, M.; Hu, X. Novel sustainable geopolymer based syntactic foams: An eco-friendly alternative to polymer based syntactic foams. Chem. Eng. J. 2017, 313, 74–82. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Li, Z. Utilization of fly ash cenosphere as lightweight filler in cement-based composites—A review. Constr. Build. Mater. 2017, 144, 373–384. [Google Scholar] [CrossRef]

- Wang, H.; Hou, F.; Chang, C. Experimental and computational modeling of thermal conductivity of cementitious syntactic foams filled with hollow glass microspheres. Constr. Build. Mater. 2020, 265, 120739. [Google Scholar] [CrossRef]

- Brugarolas, T.; Gianola, D.S.; Zhang, L.; Campbell, G.M.; Bassani, J.L.; Feng, G.; Lee, D. Tailoring and understanding the mechanical properties of nanoparticle-shelled bubbles. ACS Appl. Mater. Interfaces 2014, 6, 11558–11572. [Google Scholar] [CrossRef] [PubMed]

- Labella, M.; Zeltmann, S.E.; Shunmugasamy, V.C.; Gupta, N.; Rohatgi, P.K. Mechanical and thermal properties of fly ash/vinyl ester syntactic foams. Fuel 2014, 121, 240–249. [Google Scholar] [CrossRef]

- Carolan, D.; Mayall, A.; Dear, J.P.; Fergusson, A.D. Micromechanical modelling of syntactic foam. Compos. Part B 2020, 183, 107701. [Google Scholar] [CrossRef]

- Yabu, H. Fabrication of Nanostructured Composite Microspheres Based on the Self-Assembly of Polymers and Functional Nanomaterials. Part. Part. Syst. Charact. 2019, 36, 1900178. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, G.; Wang, J.; Cui, G.; Wei, X.; Shui, L.; Kempa, K.; Zhou, G.; Wang, X.; Chen, Z. Hierarchical Defective Fe3-xC@C Hollow Microsphere Enables Fast and Long-Lasting Lithium–Sulfur Batteries. Adv. Funct. Mater. 2020, 30, 2001165. [Google Scholar] [CrossRef]

- Mazetyte, R.; Kronfeld, K.P.; Köhler, J.M. Five-Level Structural Hierarchy: Microfluidically Supported Synthesis of Core-Shell Microparticles Containing Nested Set of Dispersed Metal and Polymer Micro and Nanoparticles. Part. Part. Syst. Charact. 2023, 40, 2300030. [Google Scholar] [CrossRef]

- Cai, L.; Bian, F.; Chen, H.; Guo, J.; Wang, Y.; Zhao, Y. Anisotropic Microparticles from Microfluidics. Chem 2021, 7, 93–136. [Google Scholar] [CrossRef]

- Vian, A.; Amstad, E. Mechano-responsive microcapsules with uniform thin shells. Soft Matter 2019, 15, 1290–1296. [Google Scholar] [CrossRef] [PubMed]

- Ling, J.; Wang, B.B.; Li, X.N.; Zhang, R.; Pan, L.F.; Zhang, H.; Hu, Y.T.; Wang, S.B.; Kong, X.D. Multifunctional Iron-Doped Hollow Mesoporous Silica Nanoregulator for Enhanced Tumor Chemodynamic Therapy. Part. Part. Syst. Charact. 2023, 2300054. [Google Scholar] [CrossRef]

- Zhu, K.; Yu, Y.; Cheng, Y.; Tian, C.; Zhao, G.; Zhao, Y. All-Aqueous-Phase Microfluidics for Cell Encapsulation. ACS Appl. Mater. Interfaces 2019, 11, 4826–4832. [Google Scholar] [CrossRef] [PubMed]

- Ceylan, H.; Giltinan, J.; Kozielski, K.; Sitti, M. Mobile microrobots for bioengineering applications. Lab Chip 2017, 17, 1705–1724. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Gao, Y.; Wang, Y.; Fan, R.; Ali, Z.; Yu, J.; Yang, K.; Sun, K.; Li, X.; Lei, Y.; et al. Recent developments on epoxy-based syntactic foams for deep sea exploration. J. Mater. Sci. 2020, 56, 2037–2076. [Google Scholar] [CrossRef]

- Nawafleh, N.; Wright, W.; Dariavach, N.; Celik, E. 3D-printed thermoset syntactic foams with tailorable mechanical performance. J. Mater. Sci. 2020, 55, 16048–16057. [Google Scholar] [CrossRef]

- Yousaf, Z.; Smith, M.; Potluri, P.; Parnell, W. Compression properties of polymeric syntactic foam composites under cyclic loading. Compos. Part B 2020, 186, 107764. [Google Scholar] [CrossRef]

- Yuan, J.; An, Z.; Zhang, J. Effects of hollow microsphere surface property on the mechanical performance of high strength syntactic foams. Compos. Sci. Technol. 2020, 199, 108309. [Google Scholar] [CrossRef]

- Marx, J.; Rabiei, A. Overview of Composite Metal Foams and Their Properties and Performance. Adv. Eng. Mater. 2017, 19, 1600776. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Szlancsik, A.; Kemény, A.; Kincses, D. Compressive mechanical properties of low-cost, aluminium matrix syntactic foams. Compos. Part A 2020, 135, 105923. [Google Scholar] [CrossRef]

- Anirudh, S.; Jayalakshmi, C.G.; Anand, A.; Kandasubramanian, B.; Ismail, S.O. Epoxy/hollow glass microsphere syntactic foams for structural and functional application-A review. Eur. Polym. J. 2022, 171, 111163. [Google Scholar] [CrossRef]

- Garza-Cruz, T.V.; Nakagawa, M. On a hybrid method to characterize the mechanical behavior of thin hollow glass microspheres. Granul. Matter 2012, 14, 309–318. [Google Scholar] [CrossRef]

- Ding, J.; Ye, F.; Liu, Q.; Yang, C.; Gao, Y. Preparation of lightweight hollow glass microsphere ceramics by gel casting. Ceram. Int. 2019, 45, 10126–10132. [Google Scholar] [CrossRef]

- Meng, J.; Liu, T.-W.; Wang, H.-Y.; Dai, L.-H. Ultra-high energy absorption high-entropy alloy syntactic foam. Compos. Part B 2021, 207, 108563. [Google Scholar] [CrossRef]

- Yang, Q.; Cheng, J.; Wei, Y.; Yu, B.; Miao, Z.; Gao, P. Innovative compound casting technology and mechanical properties of steel matrix syntactic foams. J. Alloys Compd. 2021, 853, 156572. [Google Scholar] [CrossRef]

- Abedin, R.; Feng, X.; Pojman, J., Jr.; Ibekwe, S.; Mensah, P.; Warner, I.; Li, G. A Thermoset Shape Memory Polymer-Based Syntactic Foam with Flame Retardancy and 3D Printability. ACS Appl. Polym. Mater 2022, 4, 1183–1195. [Google Scholar] [CrossRef]

- Wu, H.; Chen, J.; Duan, K.; Zhu, M.; Hou, Y.; Zhou, J.; Ren, Y.; Jiang, H.; Fan, R.; Lu, Y. Three Dimensional Printing of Bioinspired Crossed-Lamellar Metamaterials with Superior Toughness for Syntactic Foam Substitution. ACS Appl. Mater. Interfaces 2022, 14, 42504–42512. [Google Scholar] [CrossRef]

- Shahapurkar, K.; Garcia, C.D.; Doddamani, M.; Mohan Kumar, G.C.; Prabhakar, P. Compressive behavior of cenosphere/epoxy syntactic foams in arctic conditions. Compos. Part B 2018, 135, 253–262. [Google Scholar] [CrossRef]

- Sun, Y.; Dou, G.; Wu, K.; Chen, P.; Zhang, T.; Peng, G. Maximum prime vertical strain criterion to predict rupture of core-shell microspheres. Int. J. Mech. Sci. 2023, 244, 108053. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, M.; Tang, W.; Wang, W.; Wang, M. Buckling of spherical shells subjected to external pressure: A comparison of experimental and theoretical data. Thin. Wall. Struct. 2017, 111, 58–64. [Google Scholar] [CrossRef]

- Vogiatzis, C.A.; Tsouknidas, A.; Kountouras, D.T.; Skolianos, S. Aluminum–ceramic cenospheres syntactic foams produced by powder metallurgy route. Mater. Design. 2015, 85, 444–454. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Gupta, N.; Schultz, B.F.; Luong, D.D. The synthesis, compressive properties, and applications of metal matrix syntactic foams. JOM 2011, 63, 36–42. [Google Scholar] [CrossRef]

- Gupta, N.; Ye, R.; Porfiri, M. Comparison of tensile and compressive characteristics of vinyl ester/glass microballoon syntactic foams. Compos. Part B 2010, 41, 236–245. [Google Scholar] [CrossRef]

- Drozhzhin, V.S.; Shpirt, M.Y.; Danilin, L.D.; Kuvaev, M.D.; Pikulin, I.V.; Potemkin, G.A.; Redyushev, S.A. Formation Processes and Main Properties of Hollow Aluminosilicate Microspheres in Fly Ash from Thermal Power Stations. Solid Fuel Chem. 2008, 42, 107–119. [Google Scholar] [CrossRef]

- Solonenko, O.P.; Gulyaev, I.P.; Smirnov, A.V. Thermal Plasma Processes for Production of Hollow Spherical Powders: Theory and Experiment. J. Them. Sci. Technol. 2011, 6, 219–234. [Google Scholar] [CrossRef]

- Bertling, J.; Blömer, J.; Kümmel, R. Hollow Microsperes. Chem. Eng. Technol. 2004, 27, 829–837. [Google Scholar] [CrossRef]

- Wang, X.; Feng, J.; Bai, Y.; Zhang, Q.; Yin, Y. Synthesis, Properties, and Applications of Hollow Micro-/Nanostructures. Chem. Rev. 2016, 116, 10983–11060. [Google Scholar] [CrossRef]

- Li, W.; Zhang, L.; Ge, X.; Xu, B.; Zhang, W.; Qu, L.; Choi, C.H.; Xu, J.; Zhang, A.; Lee, H.; et al. Microfluidic fabrication of microparticles for biomedical applications. Chem. Soc. Rev. 2018, 47, 5646–5683. [Google Scholar] [CrossRef]

- Qi, J.; Lai, X.; Wang, J.; Tang, H.; Ren, H.; Yang, Y.; Jin, Q.; Zhang, L.; Yu, R.; Ma, G.; et al. Multi-shelled hollow micro-/nanostructures. Chem. Soc. Rev. 2015, 44, 6749–6773. [Google Scholar] [CrossRef]

- Huang, C.C.; Huang, W.; Yeh, C.S. Shell-by-shell synthesis of multi-shelled mesoporous silica nanospheres for optical imaging and drug delivery. Biomaterials 2011, 32, 556–564. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.P.; Zeng, H.C. Creation of Interior Space, Architecture of Shell Structure, and Encapsulation of Functional Materials for Mesoporous SiO2Spheres. Chem. Mater. 2011, 23, 4886–4899. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Ma, Y.; Li, M.; Zhao, J.; Xin, H.; Zhang, L.; Yang, Y.; Li, C.; Yang, Q. Engineering the formation of secondary building blocks within hollow interiors. Adv. Mater. 2012, 24, 1424–1428. [Google Scholar] [CrossRef]

- Chen, X.; Hou, L.; Yin, Z.; Wang, K.; Zhang, Z.; Bao, F. NIR light-triggered core-coalescence of double-emulsion drops for micro-reactions. Chem. Eng. J. 2023, 454, 140050. [Google Scholar] [CrossRef]

- Wu, H.; Ren, Y.; Jiang, T.; Chen, J.; Wu, W.; Lu, Y.; Jiang, H. Synthesis of tubular silica fiber via all-aqueous microfluidics for geopolymer regulation. Int. J. Appl. Ceram. Technol. 2022, 19, 2979–2989. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, S.; Liu, L.; Ren, Y.; Xue, C.; Wu, W.; Chen, X.; Jiang, H. Controllable Fabrication of Molecularly Imprinted Microspheres with Nanoporous and Multilayered Structure for Dialysate Regeneration. Nanomaterials 2022, 12, 418. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Wang, L. Microfluidics-Enabled Soft Manufacture of Materials with Tailorable Wettability. Chem. Rev. 2021, 122, 7010–7060. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Ren, Y.; Jiang, T.; Wu, W.; Lu, Y.; Jiang, H. Fabrication of syntactic foam fillers via integrated on/off-chip microfluidic methods for optimized geopolymer composites. Lab Chip 2022, 22, 836–847. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, T.; Han, F.; Cao, L.; Li, M.; Ge, Z.; Sun, H.; Wu, H.; Wu, W.; Zhou, N.; et al. A wearable self-powered microneedle system based on conductive drugs for infected wound healing: A new electrical stimulation delivery strategy. Chem. Eng. J. 2024, 480, 148347. [Google Scholar] [CrossRef]

- Feng, K.; Gao, N.; Zhang, W.; Zhou, K.; Dong, H.; Wang, P.; Tian, L.; He, G.; Li, G. Creation of Nonspherical Microparticles through Osmosis-Driven Arrested Coalescence of Microfluidic Emulsions. Small 2020, 16, e1903884. [Google Scholar] [CrossRef]

- Hou, L.; Liang, Z.; Fan, X.; Yu, J.; Bao, F. Bioinspired self-coiling Janus microfiber actuators for micro-lifter and humidity sensing. Sens. Actuators B 2023, 394, 134344. [Google Scholar] [CrossRef]

- Wu, H.; Jiang, T.; Wu, W.; Zhang, S.; Li, M.; Zhou, J.; Zhu, M.; Chen, J.; Li, Z.; Lu, Y.; et al. Osmosis-induced hydrodynamic centering of W/O/W double emulsion droplets for quasi-concentric microcapsule/microsphere fabrication. Colloid Surf. A 2023, 677, 132428. [Google Scholar] [CrossRef]

- Wu, H.; Ren, Y.; Hou, L.; Jiang, T.; Jiang, H. Fabrication of syntactic foam fillers via manipulation of on-chip quasi concentric nanoparticle-shelled droplet templates. Lab Chip 2020, 20, 4600–4610. [Google Scholar] [CrossRef] [PubMed]

- Liang, S.; Shen, L.; Zhou, C.; Chen, H.; Li, J. Scalable preparation of hollow ZrO2 microspheres through a liquid-liquid phase reunion assisted sol-gel method. Ceram. Int. 2020, 46, 14188–14194. [Google Scholar] [CrossRef]

- Liang, S.; Li, J.; Xu, Q.; Man, J.; Chen, H. Hydrodynamically Formed Uniform Thick Coatings on Microspheres. Small 2018, 14, e1800613. [Google Scholar] [CrossRef]

| Modeled Hollow Microsphere | Physical Parameters of Microsphere |

|---|---|

| Part description: 3D deformable | Young’s Modulus: 76 GPa |

| Materials behavior: brittle cracking | Poisson’s ratio: 0.22 |

| Section type: Solid, homogeneous | Simulated Diameter: 45 μm |

| Element type: Linear tetrahedron C3D10 | Modeled Indenter and Pedestal |

| Through thickness elements: 4 | Part description: 3D analytical rigid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Chen, J.; Jiang, T.; Wu, W.; Li, M.; Zhang, S.; Li, Z.; Ye, H.; Zhu, M.; Zhou, J.; et al. Effect of Eccentricity Difference on the Mechanical Response of Microfluidics-Derived Hollow Silica Microspheres during Nanoindentation. Micromachines 2024, 15, 109. https://doi.org/10.3390/mi15010109

Wu H, Chen J, Jiang T, Wu W, Li M, Zhang S, Li Z, Ye H, Zhu M, Zhou J, et al. Effect of Eccentricity Difference on the Mechanical Response of Microfluidics-Derived Hollow Silica Microspheres during Nanoindentation. Micromachines. 2024; 15(1):109. https://doi.org/10.3390/mi15010109

Chicago/Turabian StyleWu, Hao, Juzheng Chen, Tianyi Jiang, Wenlong Wu, Ming Li, Shanguo Zhang, Ziyong Li, Haitao Ye, Mengya Zhu, Jingzhuo Zhou, and et al. 2024. "Effect of Eccentricity Difference on the Mechanical Response of Microfluidics-Derived Hollow Silica Microspheres during Nanoindentation" Micromachines 15, no. 1: 109. https://doi.org/10.3390/mi15010109

APA StyleWu, H., Chen, J., Jiang, T., Wu, W., Li, M., Zhang, S., Li, Z., Ye, H., Zhu, M., Zhou, J., Lu, Y., & Jiang, H. (2024). Effect of Eccentricity Difference on the Mechanical Response of Microfluidics-Derived Hollow Silica Microspheres during Nanoindentation. Micromachines, 15(1), 109. https://doi.org/10.3390/mi15010109