Non-Contact Current Sensing System Based on the Giant Magnetoimpedance Effect of CoFeNiSiB Amorphous Ribbon Meanders

Abstract

:1. Introduction

2. Design and Construction of Current Sensing System

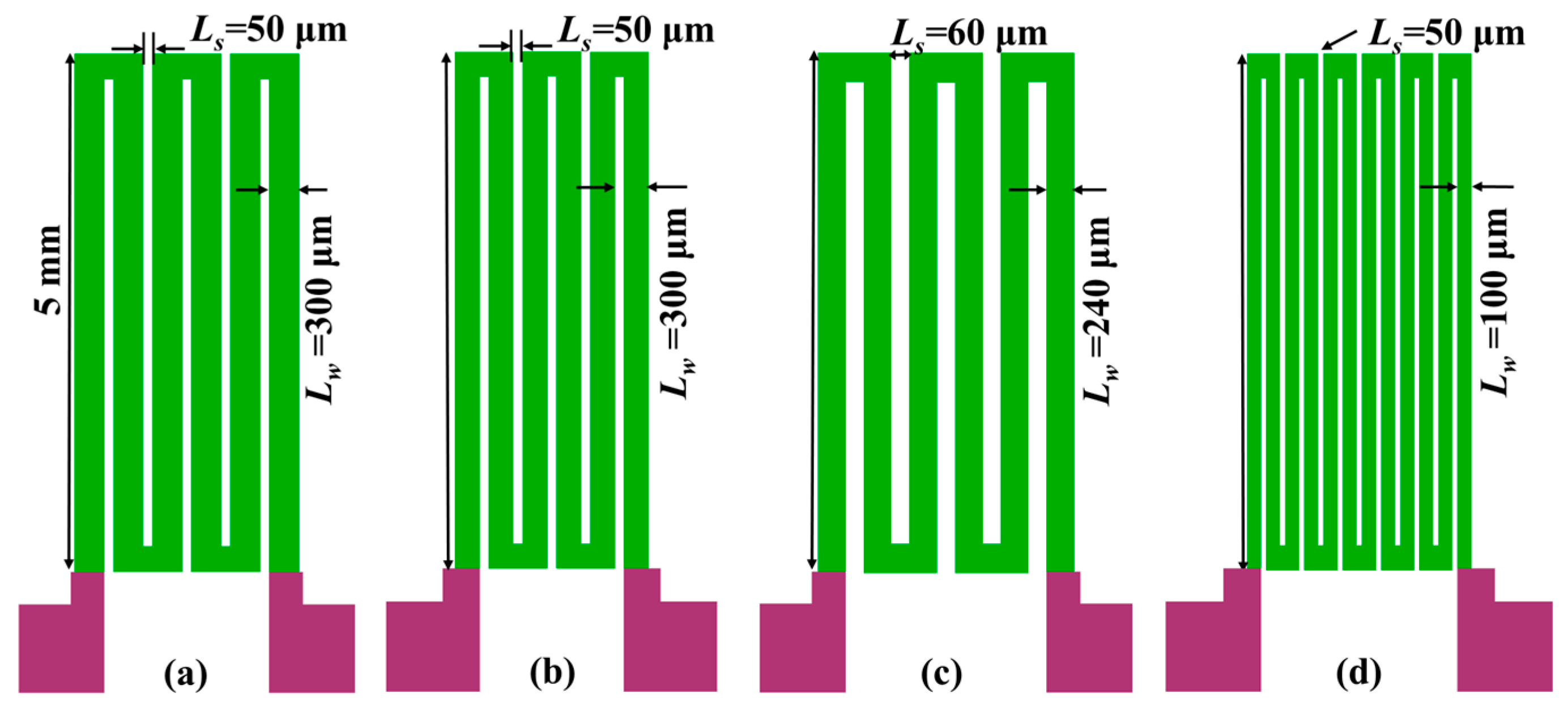

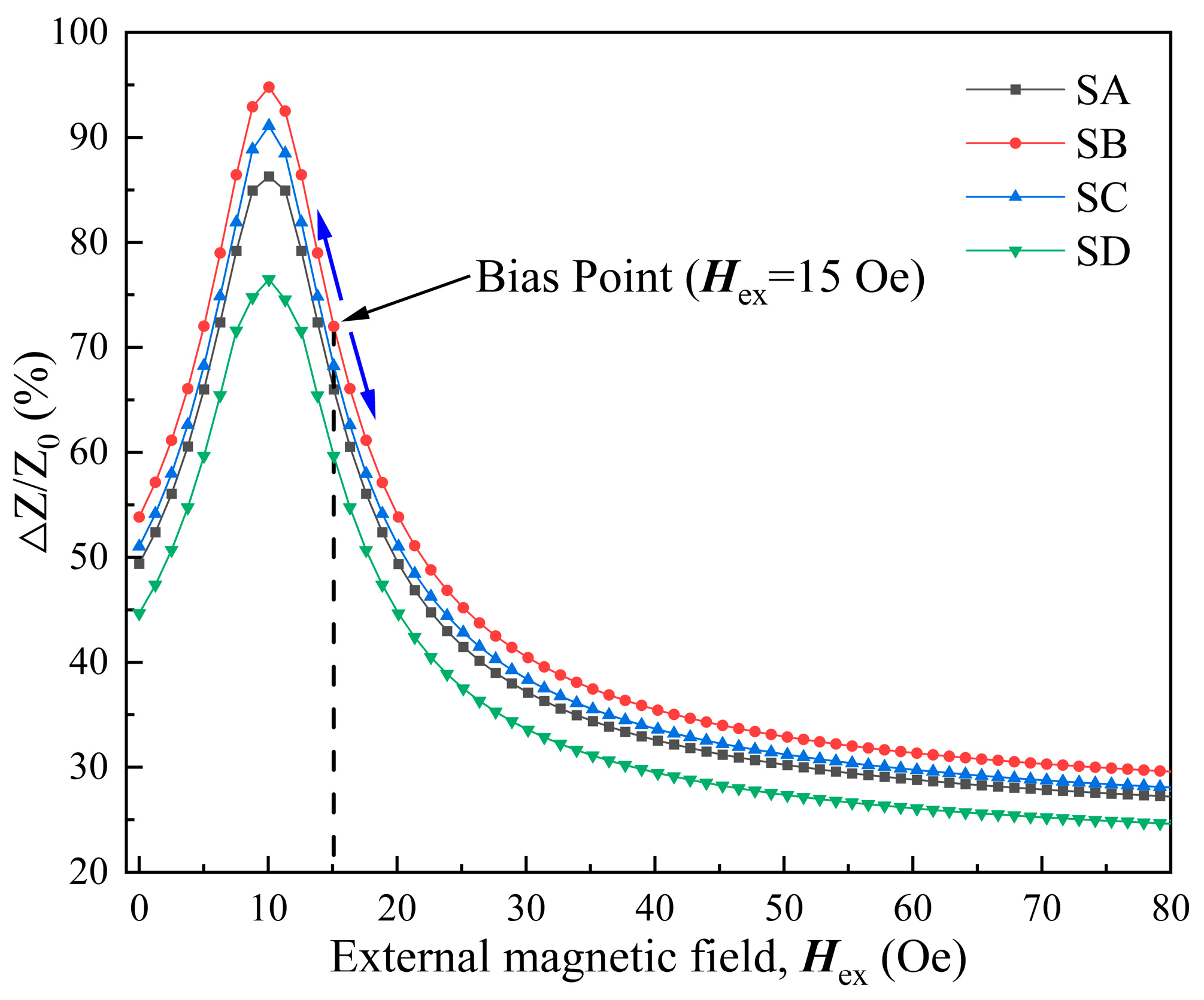

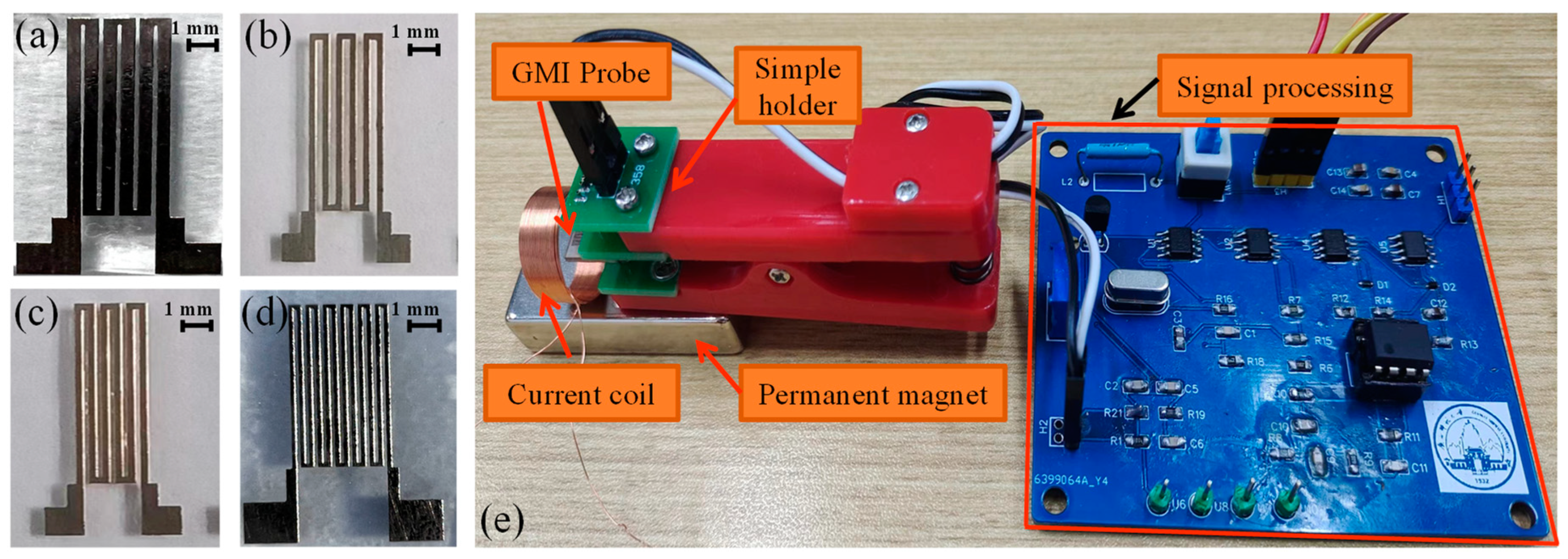

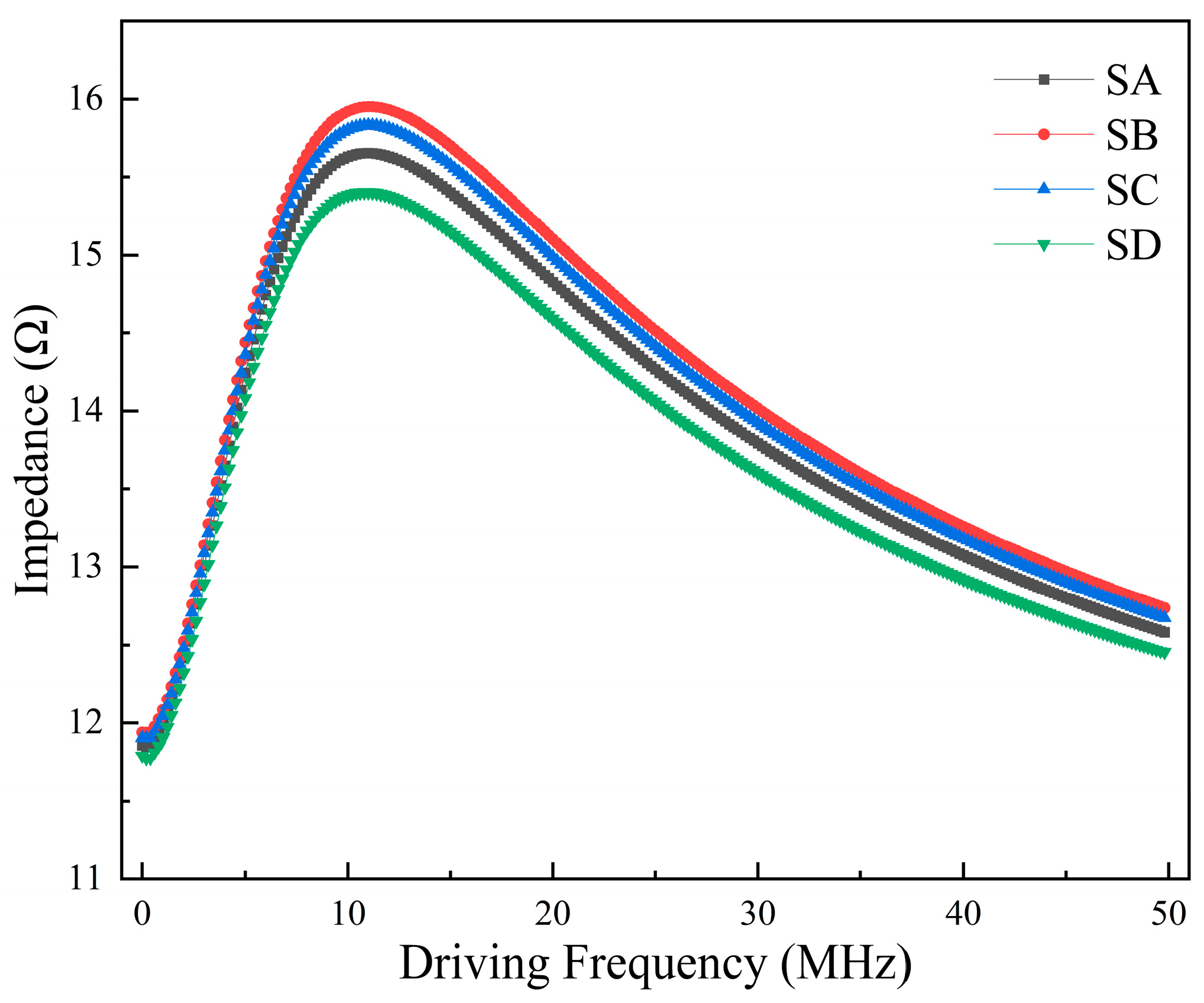

2.1. Fabrication and Characteristics of Meander GMI Probes

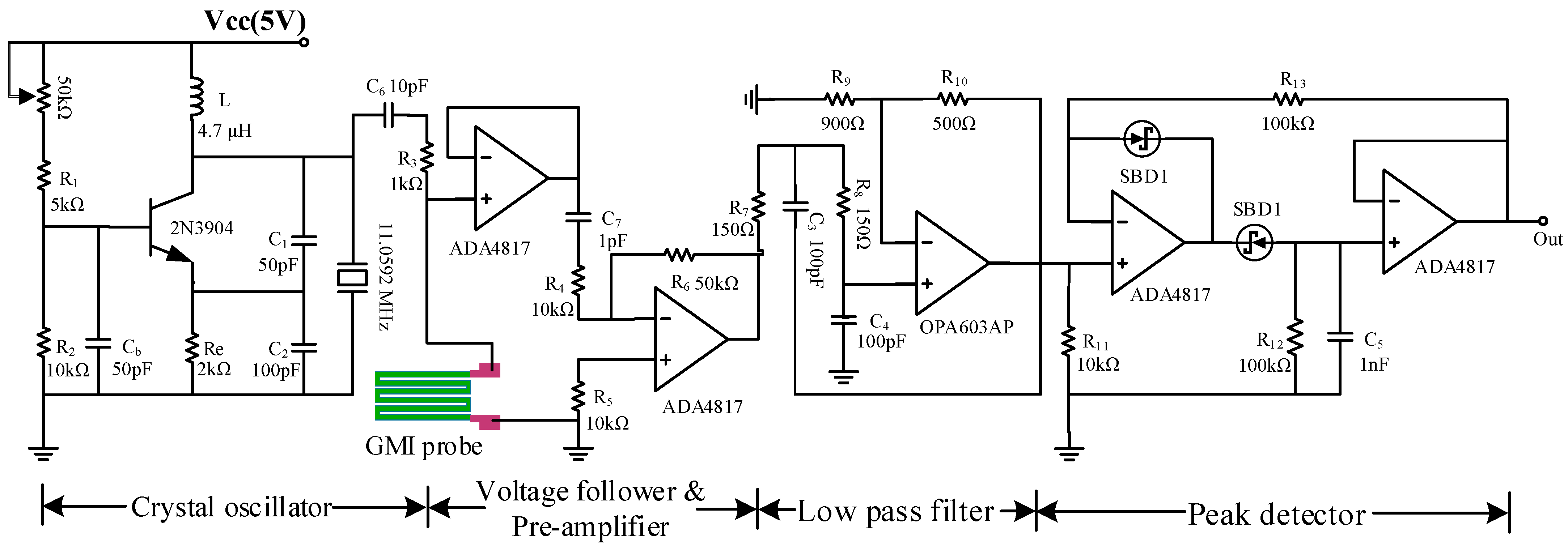

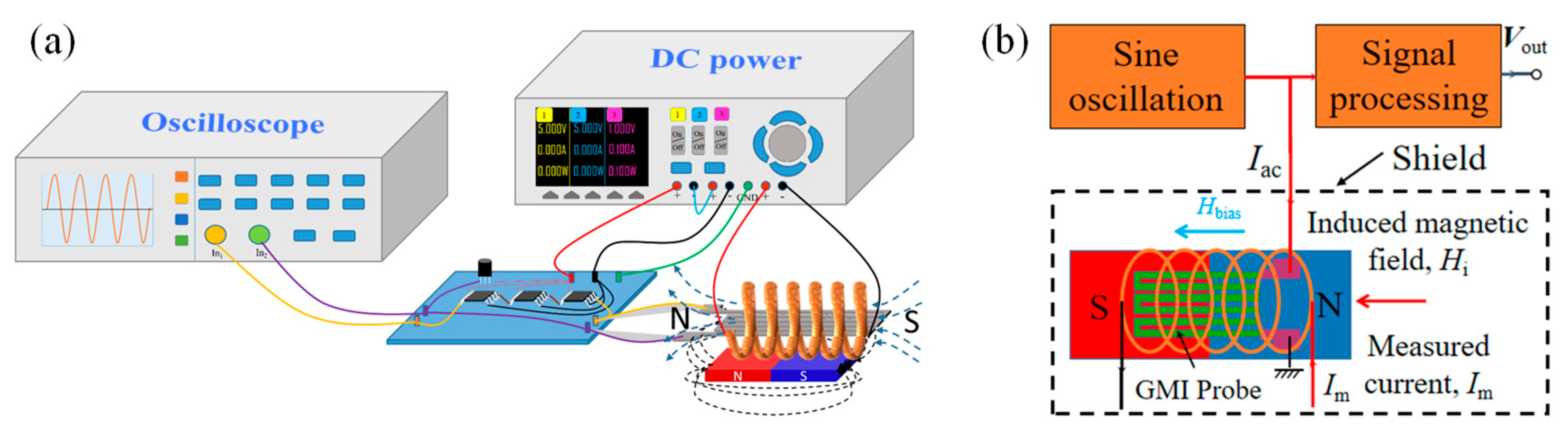

2.2. Construction of Current Sensing System

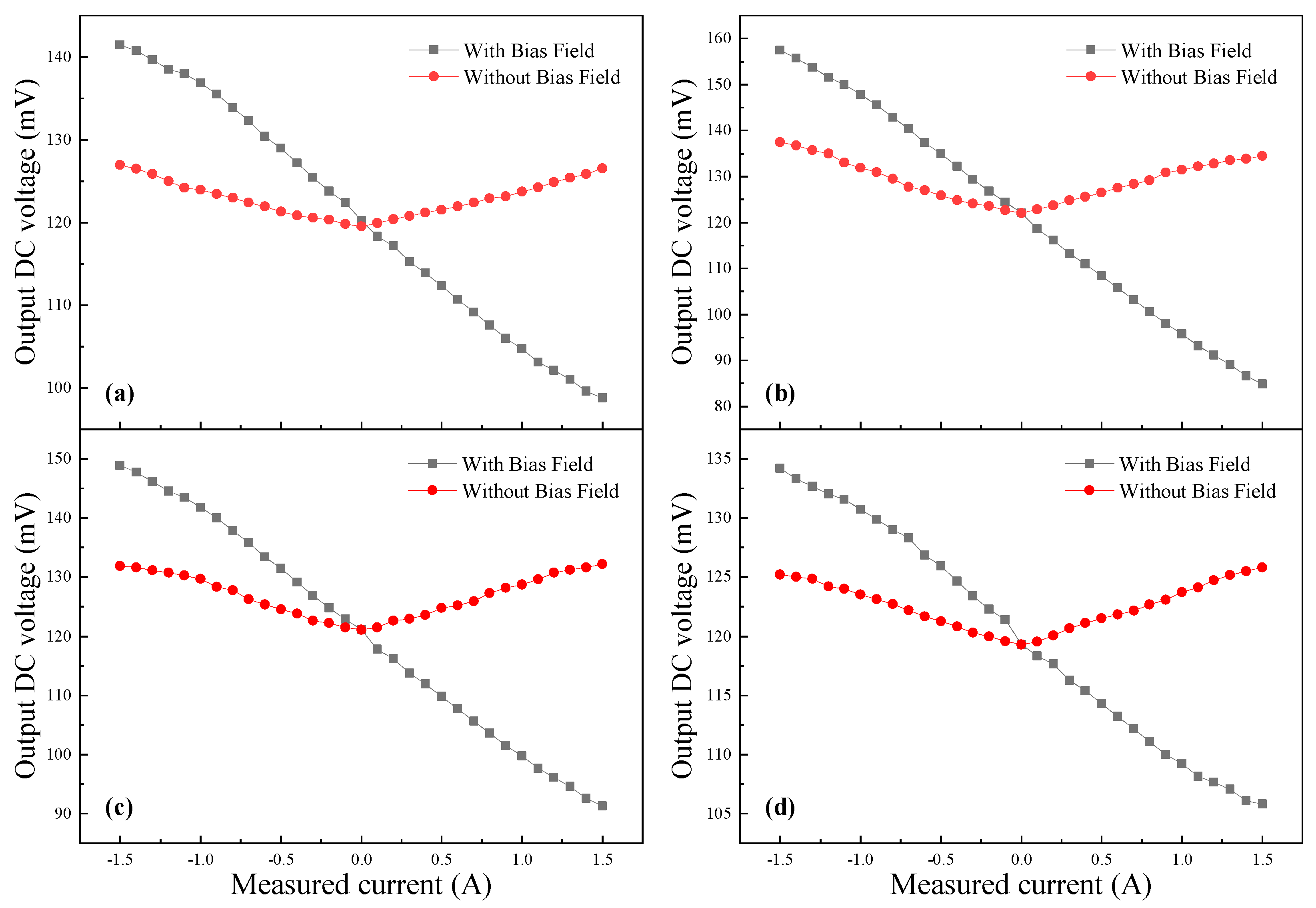

3. Results and Discussion

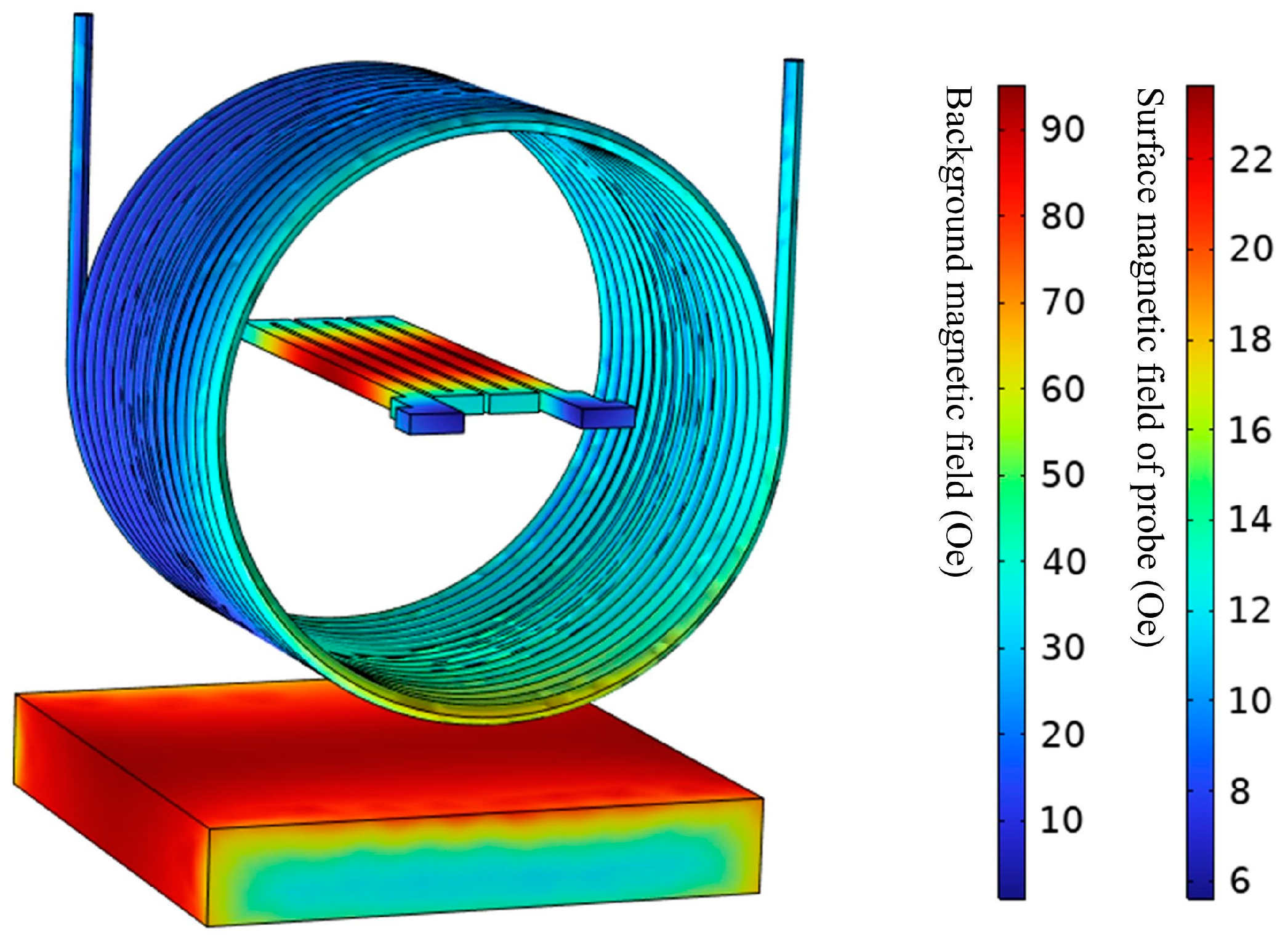

3.1. Theory and Simulation

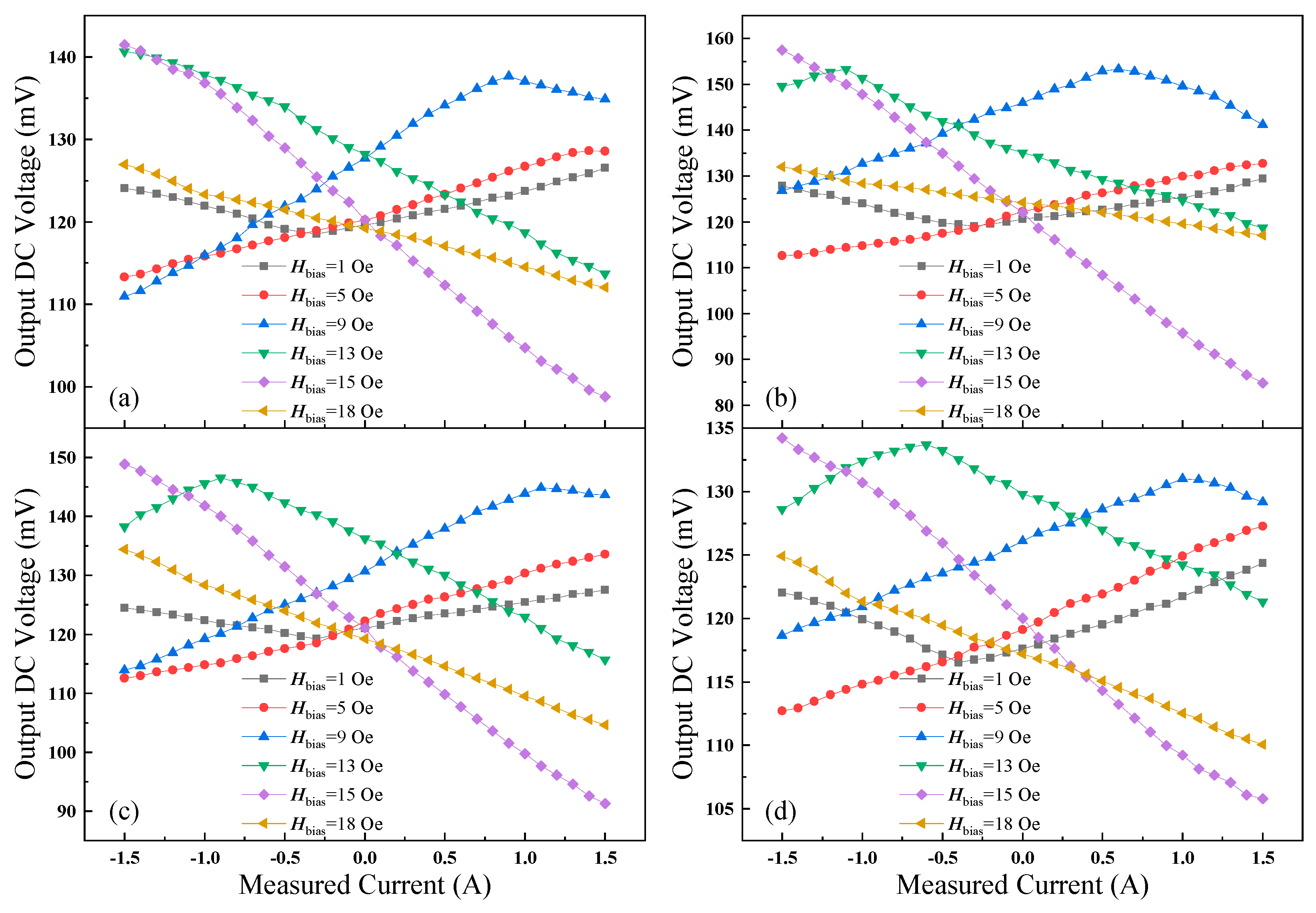

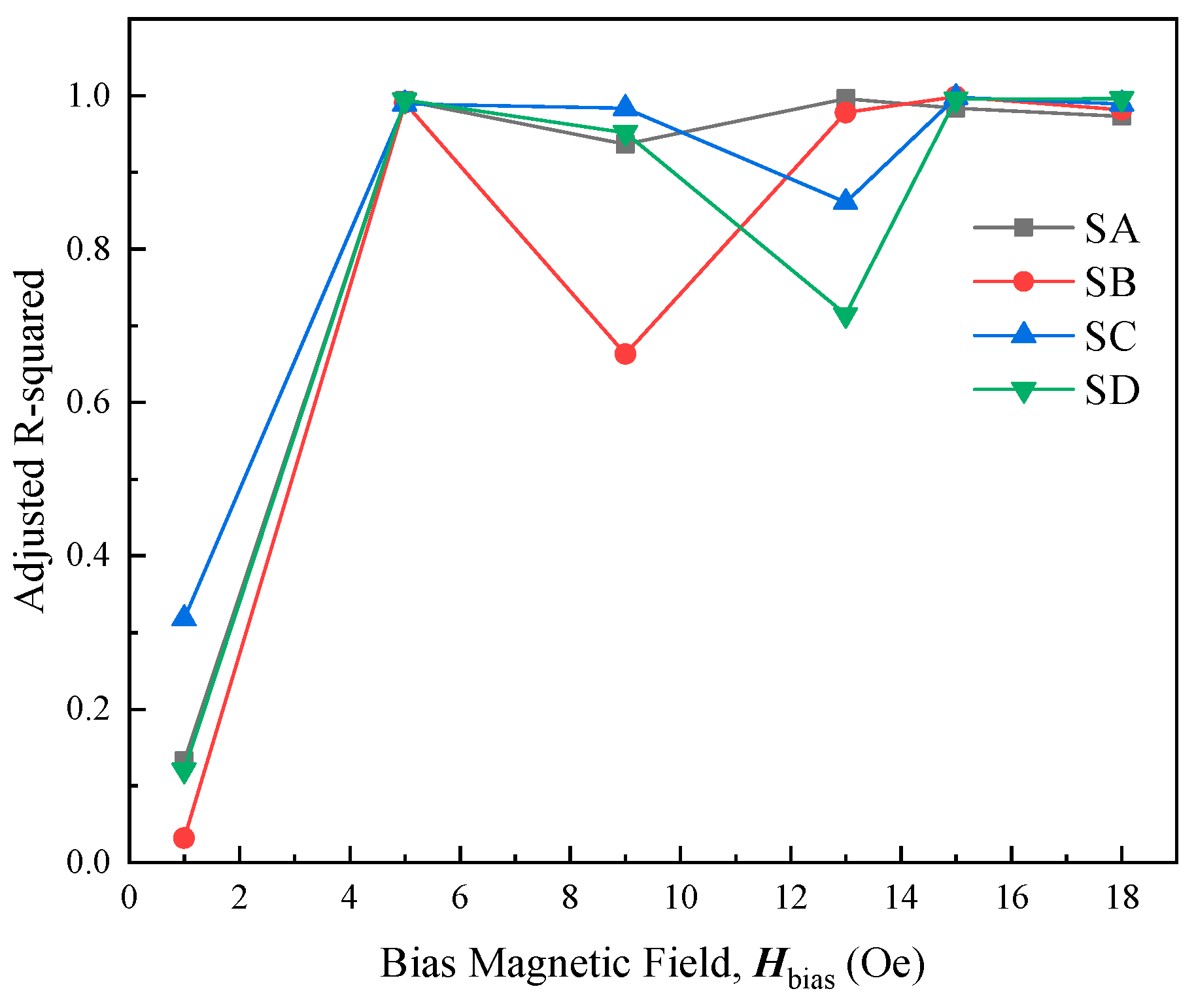

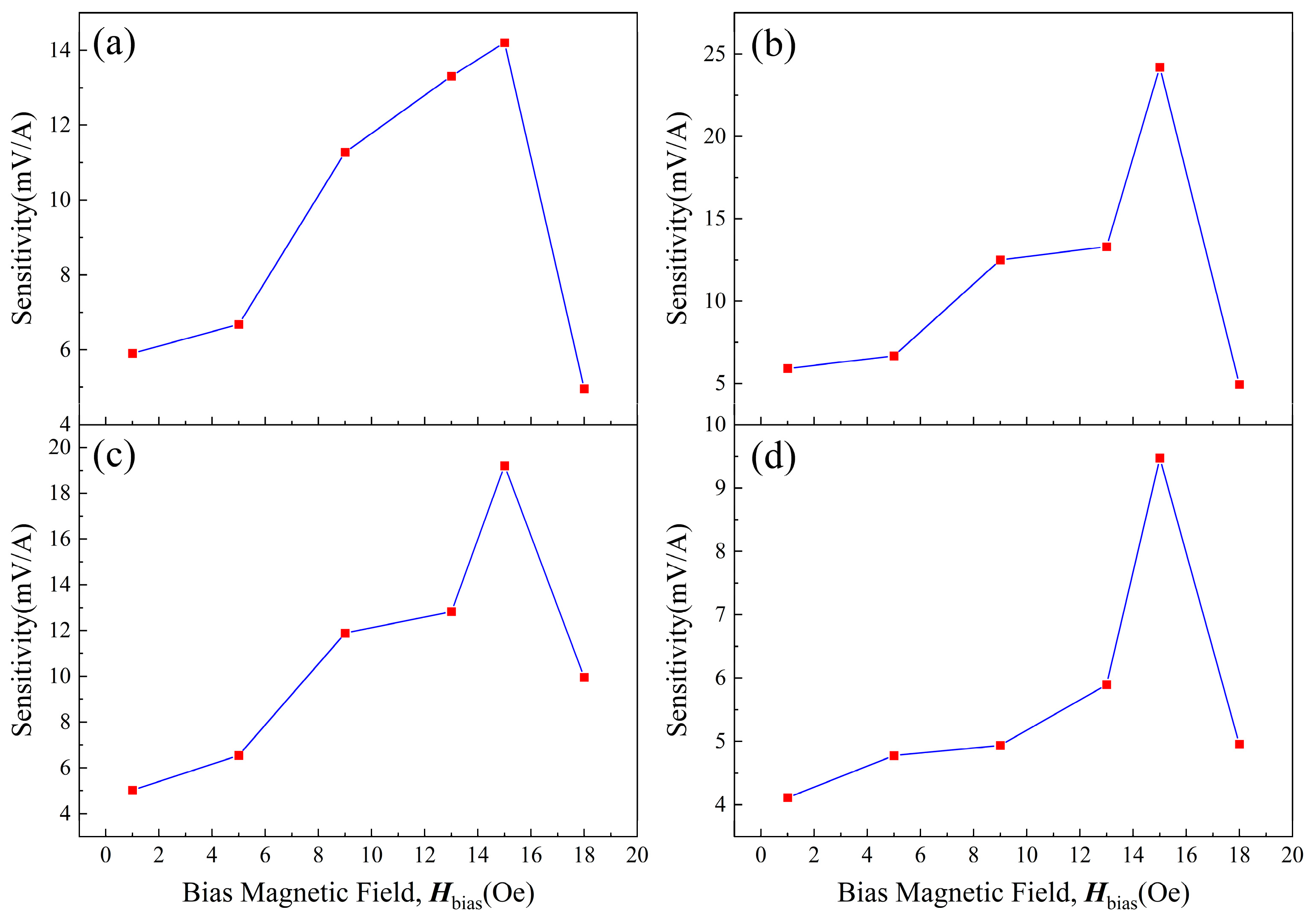

3.2. Experimental Section

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Peng, H.-X.; Qin, F.; Phan, M.-H. Ferromagnetic Microwire Composites; Engineering Materials and Processes; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-29274-8. [Google Scholar]

- Corte-Leon, P.; Zhukova, V.; Chizhik, A.; Blanco, J.M.; Ipatov, M.; Gonzalez-Legarreta, L.; Zhukov, A. Magnetic Microwires with Unique Combination of Magnetic Properties Suitable for Various Magnetic Sensor Applications. Sensors 2020, 20, 7203. [Google Scholar] [CrossRef]

- Mardani, R. Fabrication of FM/NM/FM Hetero-Structure Multilayers and Investigation on Structural and Magnetic Properties: Application in GMI Magnetic Sensors. J. Supercond. Nov. Magn. 2020, 33, 503–509. [Google Scholar] [CrossRef]

- Crescentini, M.; Ramilli, R.; Gibiino, G.P.; Marchesi, M.; Canegallo, R.; Romani, A.; Tartagni, M.; Traverso, P.A. The X-Hall Sensor: Toward Integrated Broadband Current Sensing. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Crescentini, M.; Syeda, S.F.; Gibiino, G.P. Hall-Effect Current Sensors: Principles of Operation and Implementation Techniques. IEEE Sens. J. 2022, 22, 10137–10151. [Google Scholar] [CrossRef]

- Dewi, S.D.T.; Panatarani, C.; Joni, I.M. Design and Development of DC High Current Sensor Using Hall-Effect Method. In AIP Conference Proceedings; AIP Publishing: Jatinangor, Indonesia, 2016; p. 030006. [Google Scholar]

- Girgin, A.; Bilmez, M.; Amin, H.Y.; Karalar, T.C. A Silicon Hall Sensor SoC for Current Sensors. Microelectron. J. 2019, 90, 12–18. [Google Scholar] [CrossRef]

- Borole, U.P.; Barshilia, H.C.; Ananda, C.M.; Chowdhury, P. Design, Development, and Performance Evaluation of GMR-Based Current Sensor for Industrial and Aerospace Applications. IEEE Sens. J. 2023, 23, 12687–12694. [Google Scholar] [CrossRef]

- Mușuroi, C.; Oproiu, M.; Volmer, M.; Firastrau, I. High Sensitivity Differential Giant Magnetoresistance (GMR) Based Sensor for Non-Contacting DC/AC Current Measurement. Sensors 2020, 20, 323. [Google Scholar] [CrossRef]

- Mușuroi, C.; Oproiu, M.; Volmer, M.; Neamtu, J.; Avram, M.; Helerea, E. Low Field Optimization of a Non-Contacting High-Sensitivity GMR-Based DC/AC Current Sensor. Sensors 2021, 21, 2564. [Google Scholar] [CrossRef]

- Asfour, A.; Nabias, J.; Traore, P.S.; Yonnet, J.-P. Practical Use of the GMI Effect to Make a Current Sensor. IEEE Trans. Magn. 2019, 55, 1–10. [Google Scholar] [CrossRef]

- Kondalkar, V.V.; Li, X.; Park, I.; Yang, S.S.; Lee, K. Development of Chipless, Wireless Current Sensor System Based on Giant Magnetoimpedance Magnetic Sensor and Surface Acoustic Wave Transponder. Sci. Rep. 2018, 8, 2401. [Google Scholar] [CrossRef]

- Nabias, J.; Asfour, A.; Yonnet, J.-P. Use of Magnetic Circuits for Toroidal GMI Current Sensors. IEEE Sens. J. 2019, 19, 4866–4873. [Google Scholar] [CrossRef]

- Panina, L.V.; Mohri, K. Magneto-Impedance Effect in Amorphous Wires. Appl. Phys. Lett. 1994, 65, 1189–1191. [Google Scholar] [CrossRef]

- Panina, L.V.; Mohri, K. Mechanism of the Magneto-Impedance Effect in Negative Magnetostrictive Amorphous Wires. IEEE Transl. J. Magn. Jpn. 1994, 5, 34–39. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, X.; Li, S. Research Progress of Giant Magneto-Impedance (GMI) Sensors. In Proceedings of the 2017 2nd International Conference on Frontiers of Sensors Technologies (ICFST), Shenzhen, China, 14–16 April 2017; pp. 73–77. [Google Scholar]

- Chen, J.; Li, J.; Xu, L. Highly Integrated MEMS Magnetic Sensor Based on GMI Effect of Amorphous Wire. Micromachines 2019, 10, 237. [Google Scholar] [CrossRef]

- Asfour, A.; Yonnet, J.-P.; Zidi, M. A High Dynamic Range GMI Current Sensor. J. Sens. Technol. 2012, 2, 165–171. [Google Scholar] [CrossRef]

- Fisher, B.; Panina, L.V.; Fry, N.; Mapps, D.J. High Performance Current Sensor Utilizing Pulse Magneto-Impedance in Co-Based Amorphous Wires. IEEE Trans. Magn. 2013, 49, 89–92. [Google Scholar] [CrossRef]

- Kashiwagi, Y.; Kondo, T.; Mitsui, K.; Mohri, K. 300 A Current Sensor Using Amorphous Wire Core (Invertor Control of AC Motors). IEEE Trans. Magn. 1990, 26, 1566–1568. [Google Scholar] [CrossRef]

- Yoshida, Y.; Tayaoka, A.; Takaoka, E. Precise Current Sensor by Means of Small-Angle Magnetization Rotation Using Amorphous Wire and Its Industrial Application. IEEE Trans. Magn. 1993, 29, 3180–3182. [Google Scholar] [CrossRef]

- Sun, Y.; Jia, Y.; Zhang, Y.; Cheng, L.; Liang, Y.; Wang, W. Enhanced Sensitivity of FeGa Thin-Film Coated SAW Current Sensor. Appl. Sci. 2021, 11, 11726. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, W.; Cheng, L.; Jia, Y.; Liang, Y.; Zhang, Y. Enhanced Sensitivity of Surface Acoustic Wave (SAW) Current Sensor Based on TbDyFe Thin Film. In Proceedings of the 2021 IEEE International Ultrasonics Symposium (IUS), Xi’an, China, 12–16 September 2021; pp. 1–4. [Google Scholar]

- Yamashita, T.; Maeda, R.; Itoh, T. Thin Film Based Flexible Current Sensor Using a Micropatterned Cu Coil. In Proceedings of the 2017 Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP), Bordeaux, France, 29 May–1 June 2017; pp. 1–4. [Google Scholar]

- Ou, Z.; Lu, C.; Yang, A.; Zhou, H.; Cao, Z.; Zhu, R.; Gao, H. Self-Biased Magnetoelectric Current Sensor Based on SrFe12O19/FeCuNbSiB/PZT Composite. Sens. Actuators A Phys. 2019, 290, 8–13. [Google Scholar] [CrossRef]

- Han, B.; Zhang, T.; Huang, D.; Yue, X.; Zhou, Y.; Bi, M. Giant Magnetoimpedance Current Sensor with Spiral Structure Double-Probe. IEEE Trans. Magn. 2009, 45, 1999–2002. [Google Scholar] [CrossRef]

- Han, B.; Zhang, T.; Zhang, K.; Yao, B.; Yue, X.; Huang, D.; Ren, H.; Tang, X. Giant Magnetoimpedance Current Sensor with Array-Structure Double Probes. IEEE Trans. Magn. 2008, 44, 605–608. [Google Scholar] [CrossRef]

- Kondalkar, V.V.; Li, X.; Yang, S.S.; Lee, K. Highly Efficient Current Sensor Built on a Chip Based on Nanocrystalline NiFe/Cu/NiFe Thin Film. J. Ind. Eng. Chem. 2017, 53, 416–424. [Google Scholar] [CrossRef]

- Feng, Z.; Zhi, S.; Wei, M.; Zhou, Y.; Liu, C.; Lei, C. An Integrated Three-Dimensional Micro-Solenoid Giant Magnetoimpedance Sensing System Based on MEMS Technology. Sens. Actuators A Phys. 2019, 299, 111640. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Y.; Wang, B.; He, Y.; Li, H.; Liu, M.; Rao, J.; Wu, Z.; Xie, S.; Luo, J. A Giant Magnetoimpedance-Based Separable-Type Method for Supersensitive Detection of 10 Magnetic Beads at High Frequency. Sens. Actuators A Phys. 2019, 300, 111656. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, Y.; Lei, C.; Luo, J.; Xie, S.; Pu, H. Magnetic Impedance Biosensor: A Review. Biosens. Bioelectron. 2017, 90, 418–435. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Golubeva, E.V.; Volchkov, S.O.; Shcherbinin, S.V. Magnetic Properties and Giant Magnetic Impedance of Amorphous CoFeNISiB Ribbons in the Form of Micromeanders. Inorg. Mater. Appl. Res. 2020, 11, 849–854. [Google Scholar] [CrossRef]

- Yang, Z.; Chlenova, A.A.; Golubeva, E.V.; Volchkov, S.O.; Guo, P.; Shcherbinin, S.V.; Kurlyandskaya, G.V. Magne-toimpedance Effect in the Ribbon-Based Patterned Soft Ferromagnetic Meander-Shaped Elements for Sensor Application. Sensors 2019, 19, 2468. [Google Scholar] [CrossRef]

- Kikuchi, H.; Tanii, M.; Umezaki, T. Effects of Parallel and Meander Configuration on Thin-Film Magnetoimpedance Element. AIP Adv. 2020, 10, 015334. [Google Scholar] [CrossRef]

- Wang, T.; Wang, B.; Chen, Y. Fabrication of Soft Ferromagnetic Multilayer-structure Sensor for Measurement of Microampere Direct Currents. Electron. Lett. 2019, 55, 901–903. [Google Scholar] [CrossRef]

- Zhu, Z.; Xia, X.; Streiter, R.; Ruan, G.; Otto, T.; Wolf, H.; Gessner, T. Closed-Form Formulae for Frequency-Dependent 3-D Interconnect Inductance. Microelectron. Eng. 2001, 56, 359–370. [Google Scholar] [CrossRef]

- Greenhouse, H. Design of Planar Rectangular Microelectronic Inductors. IEEE Trans. Parts Hybrids Packag. 1974, 10, 101–109. [Google Scholar] [CrossRef]

- Stojanović, G.; Živanov, L.; Damnjanović, M. Novel Efficient Methods for Inductance Calculation of Meander Inductor. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2006, 25, 916–928. [Google Scholar] [CrossRef]

- Tang, X.-L.; Zhang, H.W.; Su, H.; Shi, Y.; Jiang, X.D. Study of the Impact of Winding Form and Film Thickness on Thin-Film Inductors. Microelectron. Eng. 2005, 81, 212–216. [Google Scholar] [CrossRef]

- Khan, M.A.; Sun, J.; Li, B.; Przybysz, A.; Kosel, J. Magnetic Sensors-A Review and Recent Technologies. Eng. Res. Express 2021, 3, 022005. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.; Lei, J.; Wang, Q.; Chen, J.; Li, H.; Wu, Z.; Cui, Z.; Liu, M.; Rao, J. Influences of Anisotropic Equivalent Field and Magnetic Damping Coefficient on Giant Magnetoimpedance Effect of Cylindrical Alloy Fibers: Theoretical Magnetoimpedance Calculations. Metals 2022, 12, 1532. [Google Scholar] [CrossRef]

- Qin, W.; Xu, F.; Peng, K.; Gao, W.L.; Jiang, X.L.; Ni, G.; Tang, S.L.; Du, Y.W. Effect of the Slight Surface Oxidation of Ribbons on the Dynamic Magnetization of Nanocrystalline Soft Magnetic Ribbons. J. Non-Cryst. Solids 2003, 316, 398–402. [Google Scholar] [CrossRef]

- Algueta-Miguel, J.M.; Beato-López, J.J.; López-Martín, A.J. Analog Lock-in Amplifier Design Using Subsampling for Accuracy Enhancement in GMI Sensor Applications. Sensors 2022, 23, 57. [Google Scholar] [CrossRef]

- Dehmel, G. Magnetic Field Sensors: Induction Coil (Search Coil) Sensors. In Sensors; Boll, R., Overshott, K.J., Eds.; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2008; pp. 205–253. ISBN 978-3-527-62016-6. [Google Scholar]

- Devkota, J.; Luong, T.; Liu, J.S.; Shen, H.; Qin, F.X.; Sun, J.F.; Mukherjee, P.; Srikanth, H.; Phan, M.H. A Soft Ferromagnetic Multiwire-Based Inductance Coil Sensor for Sensing Applications. J. Appl. Phys. 2014, 116, 234504. [Google Scholar] [CrossRef]

- Yu, G.; Bu, X.; Xiang, C.; Xu, H. Design of a GMI Magnetic Sensor Based on Longitudinal Excitation. Sens. Actuators A Phys. 2010, 161, 72–77. [Google Scholar] [CrossRef]

- Rodriguez-Sotelo, D.; Rodriguez-Licea, M.A.; Araujo-Vargas, I.; Prado-Olivarez, J.; Barranco-Gutiérrez, A.-I.; Perez-Pinal, F.J. Power Losses Models for Magnetic Cores: A Review. Micromachines 2022, 13, 418. [Google Scholar] [CrossRef] [PubMed]

- Graham, C.D., Jr. Physical Origin of Losses in Conducting Ferromagnetic Materials (Invited). J. Appl. Phys. 1982, 53, 8276–8280. [Google Scholar] [CrossRef]

- Ménard, D.; Britel, M.; Ciureanu, P.; Yelon, A. Giant Magnetoimpedance in a Cylindrical Magnetic Conductor. J. Appl. Phys. 1998, 84, 2805–2814. [Google Scholar] [CrossRef]

- Ripka, P.; Billingsley, S.W. Fluxgate: Tuned vs. Untuned Output. IEEE Trans. Magn. 1998, 34, 1303–1305. [Google Scholar] [CrossRef]

| Magnetic & Physical Properties | ||

|---|---|---|

| Hebei King Do | Metglas | |

| Saturation Induction (T) | >0.55 | 0.5 |

| Curie Temperature (°C) | 205 | 200 |

| Maximum Permeability (µ) | >1,200,000 | 1,000,000 |

| Coercive Force (A/m) | <2.0 | 2 |

| Density (g/cm3) | 8.5 | 7.59 |

| Crystallization Temperature (°C) | 550 | 550 |

| SA | SB | SC | SD | |

|---|---|---|---|---|

| Ls (μm) | 50 | 50 | 60 | 50 |

| Lw (μm) | 300 | 100 | 240 | 100 |

| Turn | 3 | 3 | 3 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Wang, Z.; Liu, M.; Sun, X. Non-Contact Current Sensing System Based on the Giant Magnetoimpedance Effect of CoFeNiSiB Amorphous Ribbon Meanders. Micromachines 2024, 15, 161. https://doi.org/10.3390/mi15010161

Yang Z, Wang Z, Liu M, Sun X. Non-Contact Current Sensing System Based on the Giant Magnetoimpedance Effect of CoFeNiSiB Amorphous Ribbon Meanders. Micromachines. 2024; 15(1):161. https://doi.org/10.3390/mi15010161

Chicago/Turabian StyleYang, Zhen, Zhenbao Wang, Mengyu Liu, and Xuecheng Sun. 2024. "Non-Contact Current Sensing System Based on the Giant Magnetoimpedance Effect of CoFeNiSiB Amorphous Ribbon Meanders" Micromachines 15, no. 1: 161. https://doi.org/10.3390/mi15010161

APA StyleYang, Z., Wang, Z., Liu, M., & Sun, X. (2024). Non-Contact Current Sensing System Based on the Giant Magnetoimpedance Effect of CoFeNiSiB Amorphous Ribbon Meanders. Micromachines, 15(1), 161. https://doi.org/10.3390/mi15010161