Inert-Atmosphere Microfabrication Technology for 2D Materials and Heterostructures

Abstract

:1. Introduction

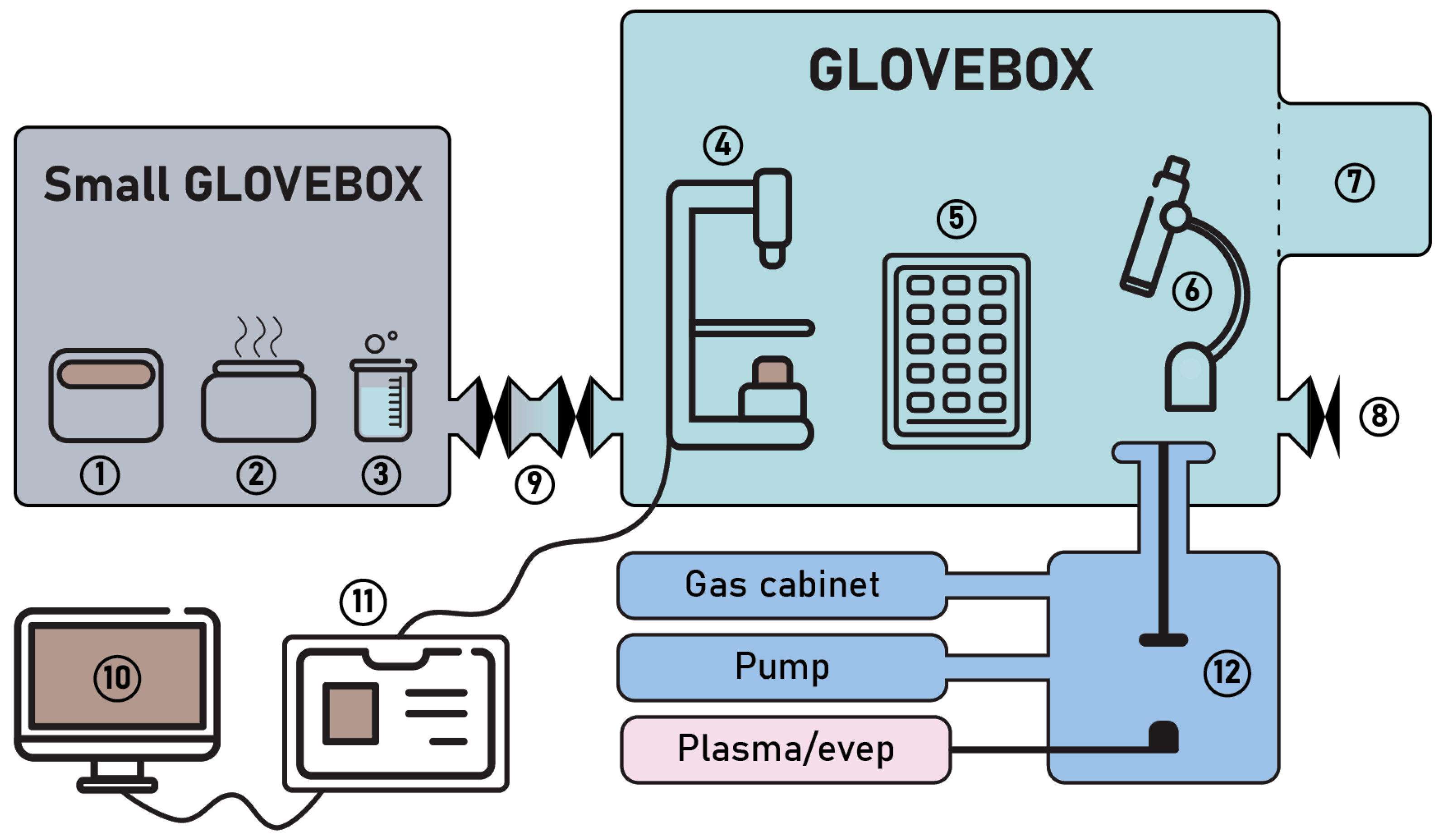

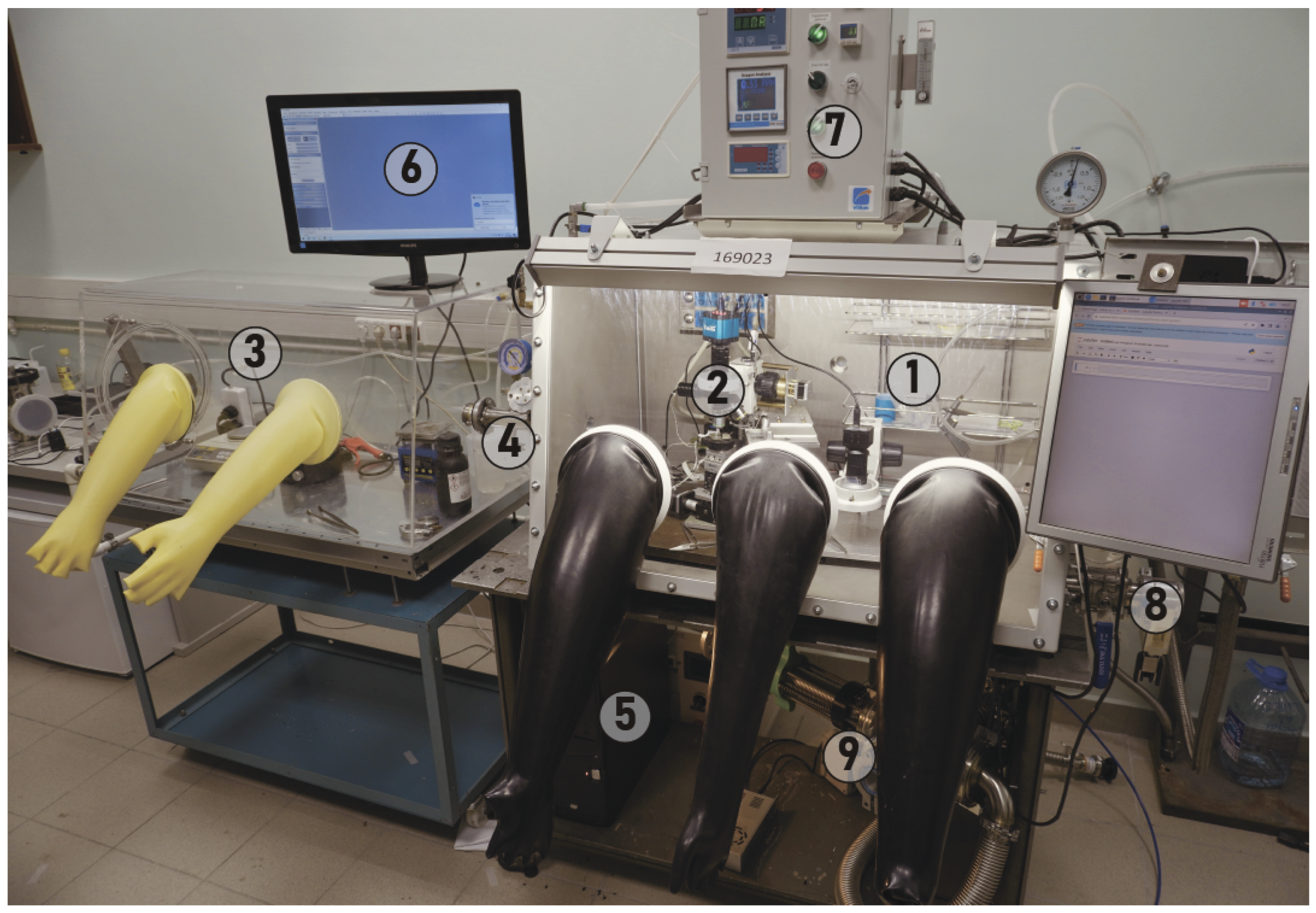

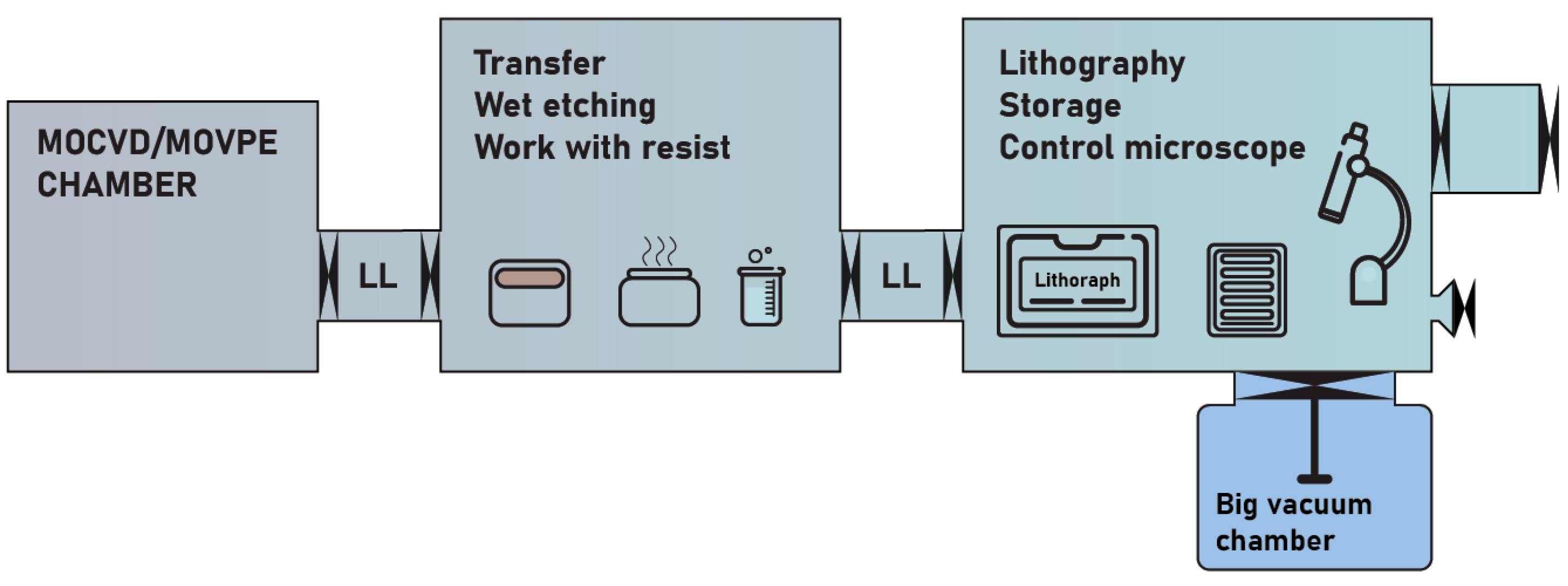

2. Overview of the Technology

2.1. Glovebox

2.2. Wet Process (Small) Glovebox

- compact size of the hot plate to avoid overheating;

- compact size of the spin-coater;

- AC mains inside;

- home-made KF40 load lock to pass the samples to/from the main glovebox. The samples are transferred in Petri dishes;

- USB cable is fed through the wall to connect the USB temperature/moisture monitor;

- chemicals (acetone, isopropanol, photoresist, water, wet etching) are stored in the closed bottles;

- the glovebox is equipped with tweezers, pipettes, etc.

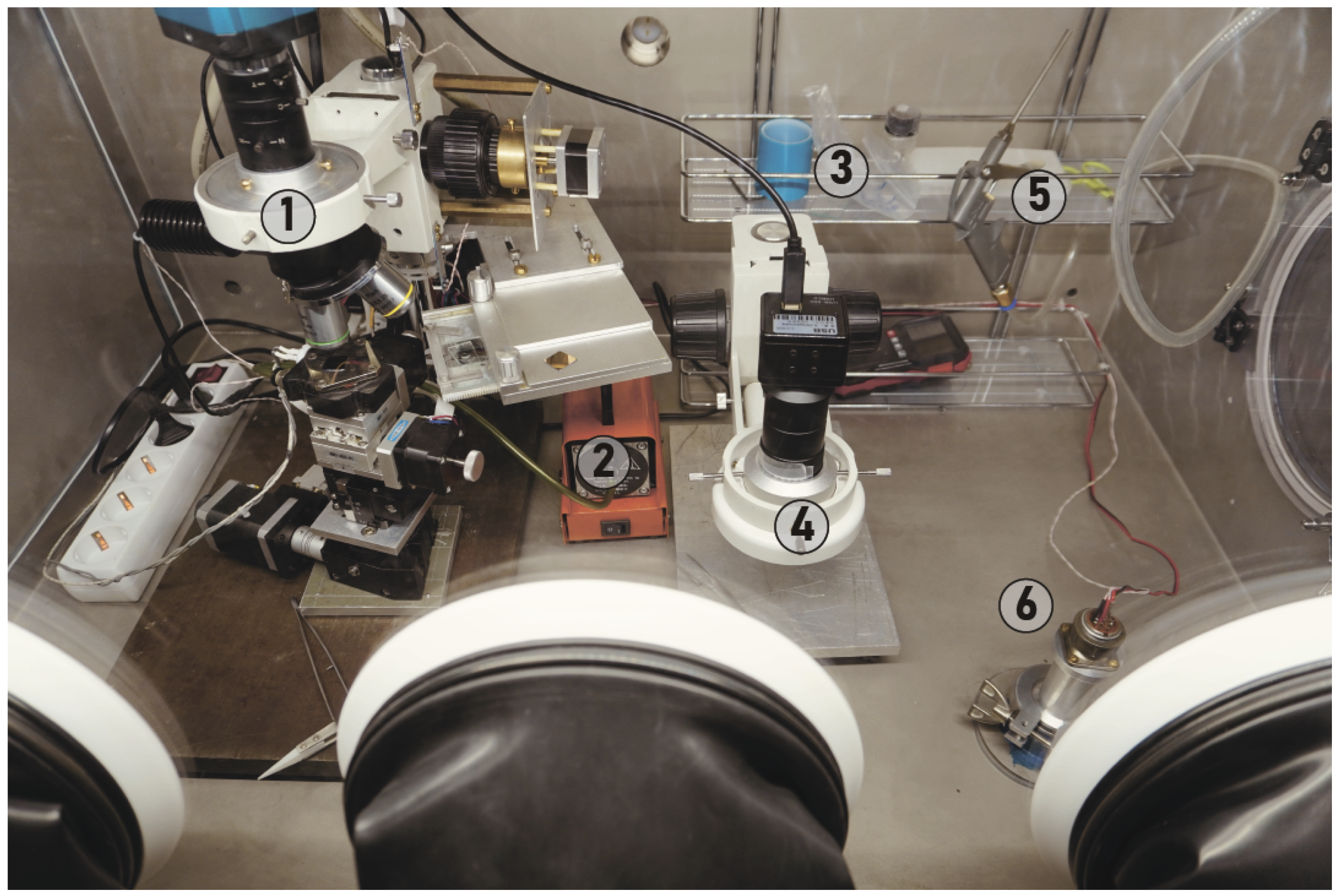

2.3. Transfer Lithography Machine

- Transfer machine to assemble heterostructures out of separate layers;

- Small mask aligner to make lithographical operations.

2.4. Vacuum Processes

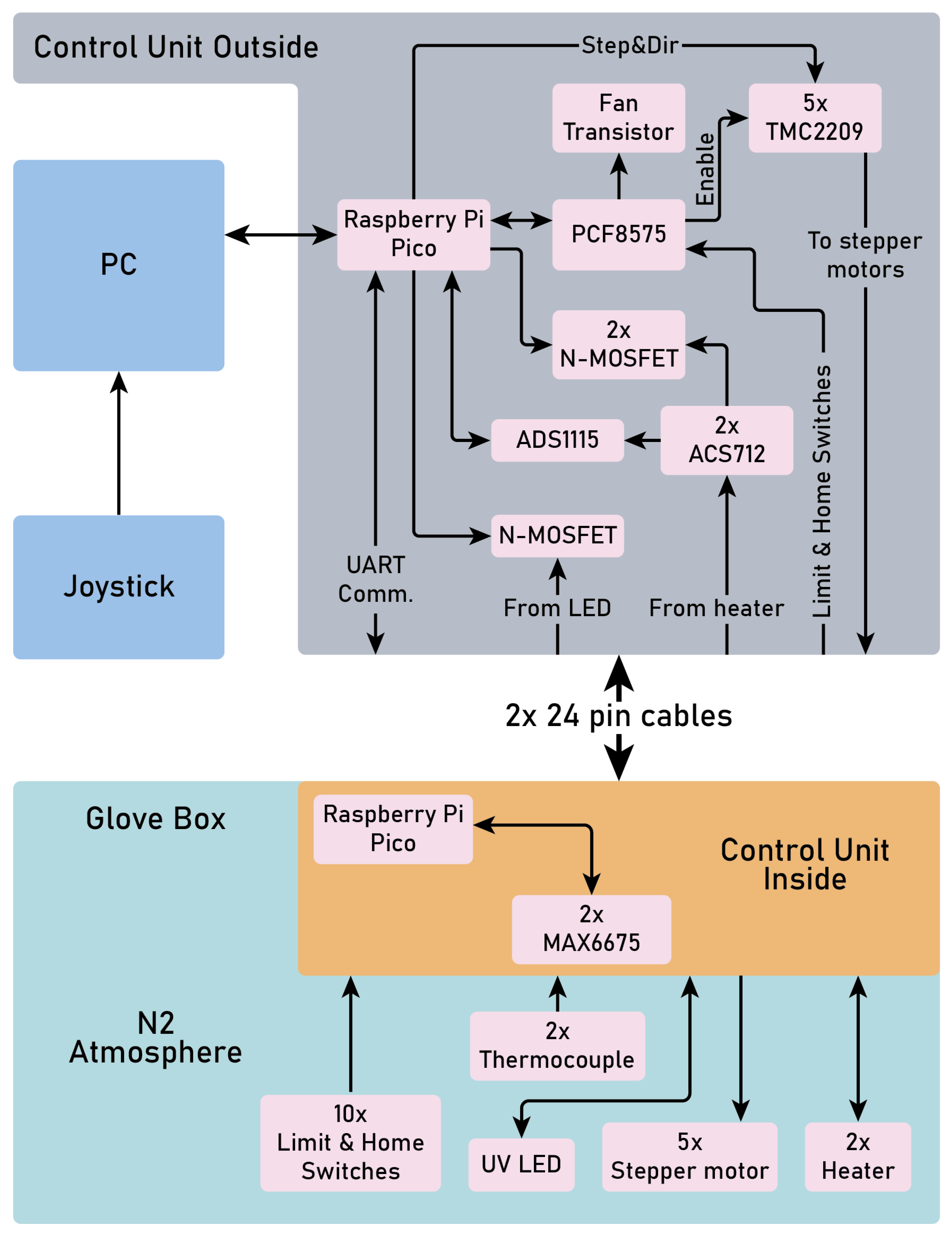

2.5. Automation

- A computer for users to control the setup with a joystick or keyboard/mouse;

- Outside control unit, located near the PC;

- Inside control unit, located in the glovebox.

3. Cost Effectiveness

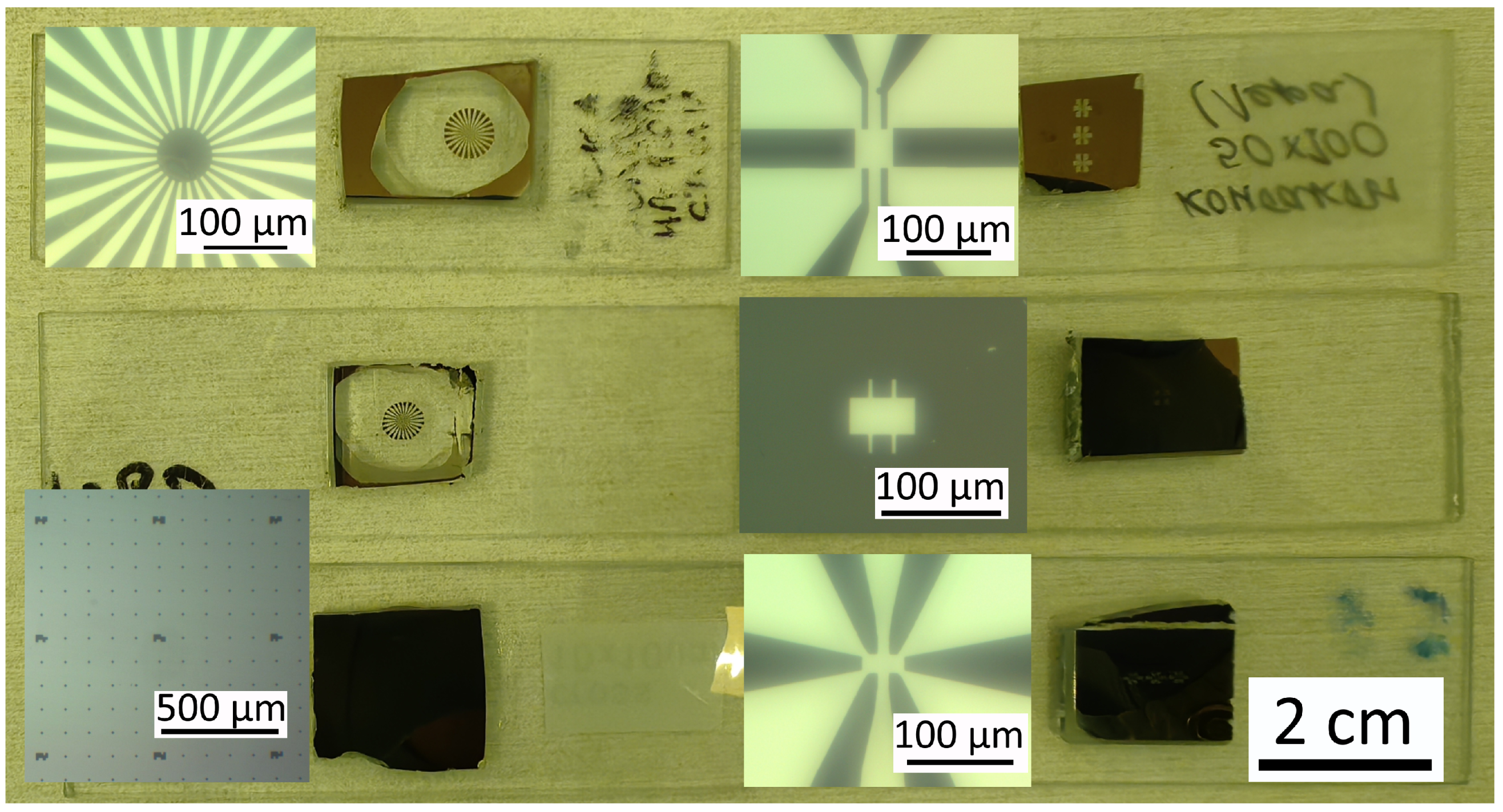

4. Examples of Operation

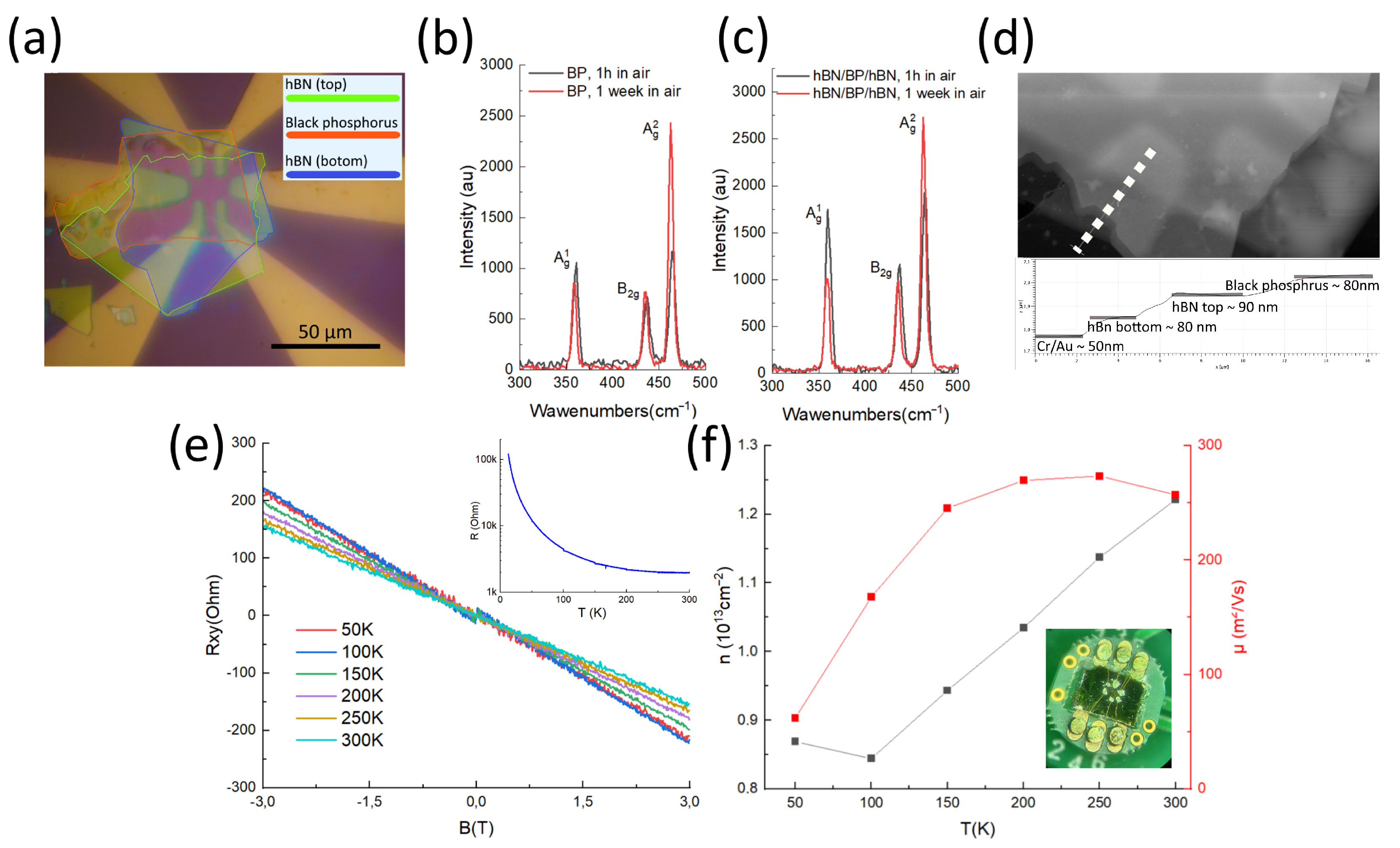

4.1. hBN-Packed Black Phosphorous Flake

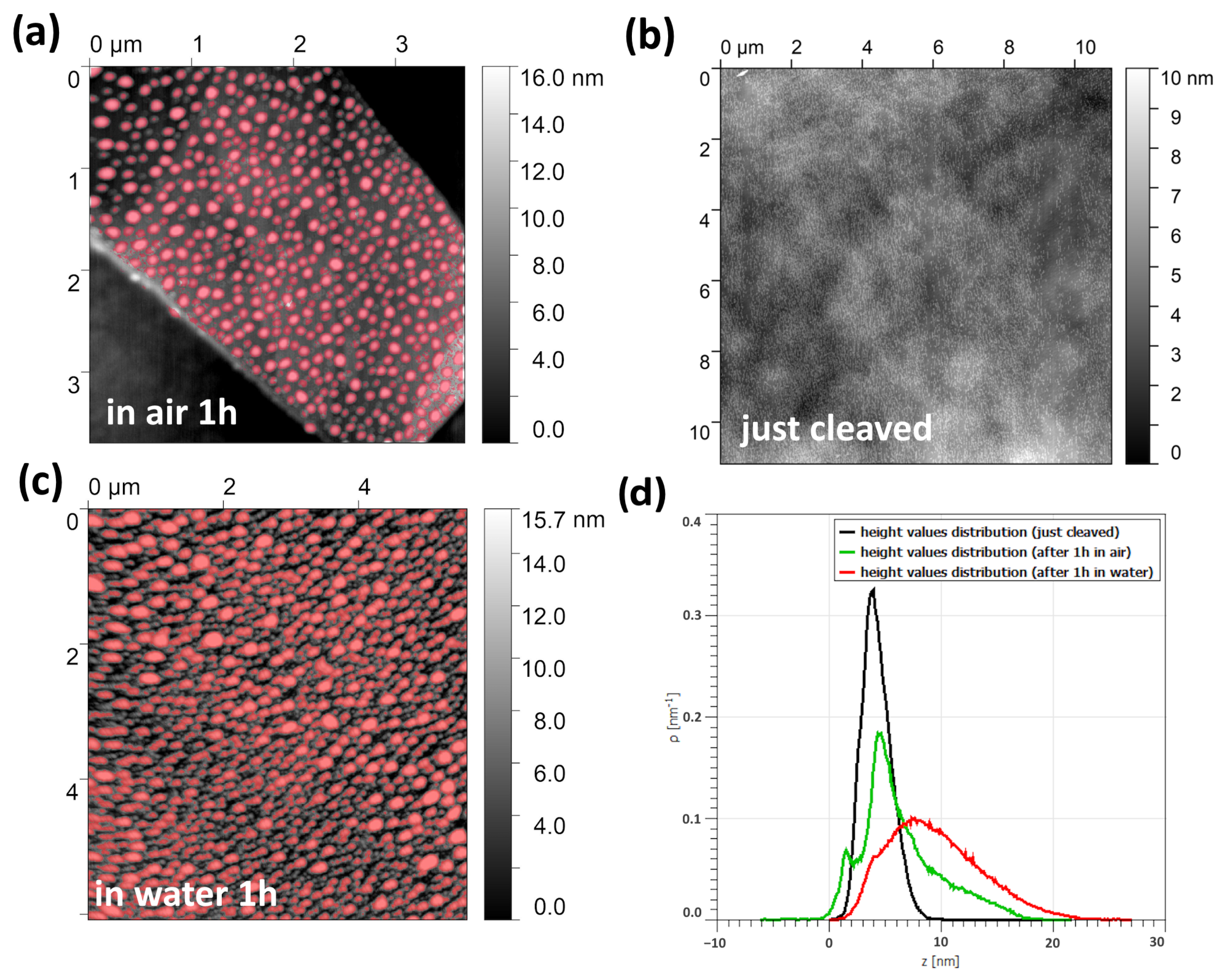

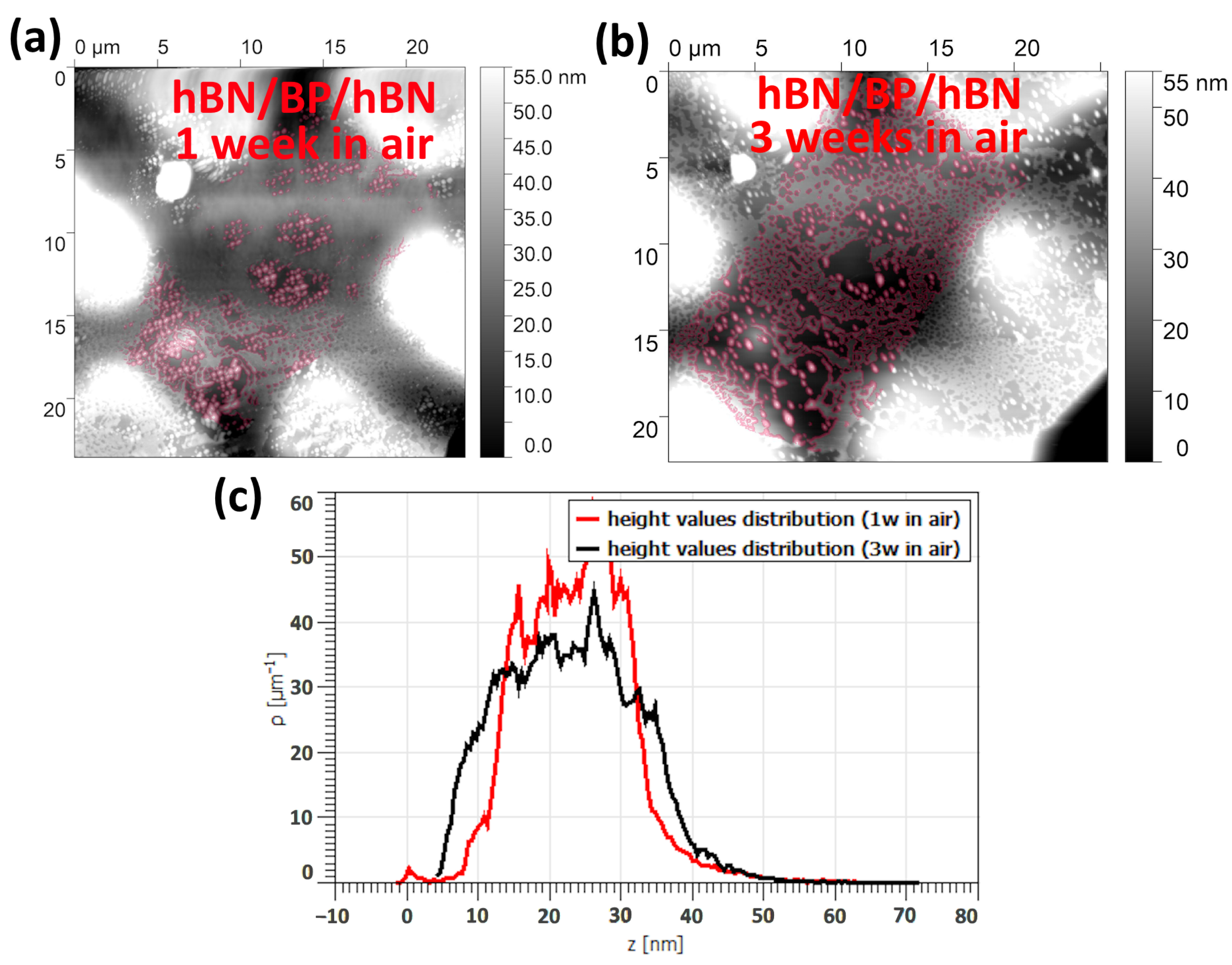

4.2. Black Phosphorous Degradation

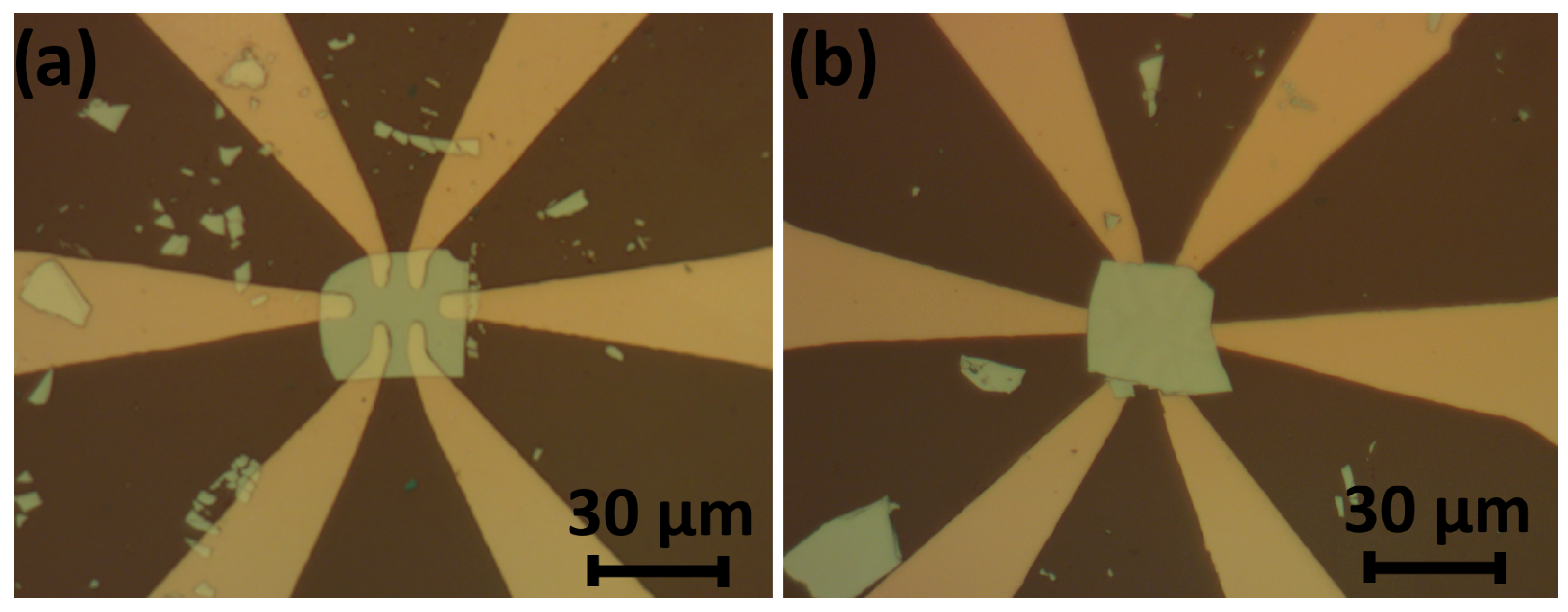

4.3. Contacts to Bismuth Chalcogenides

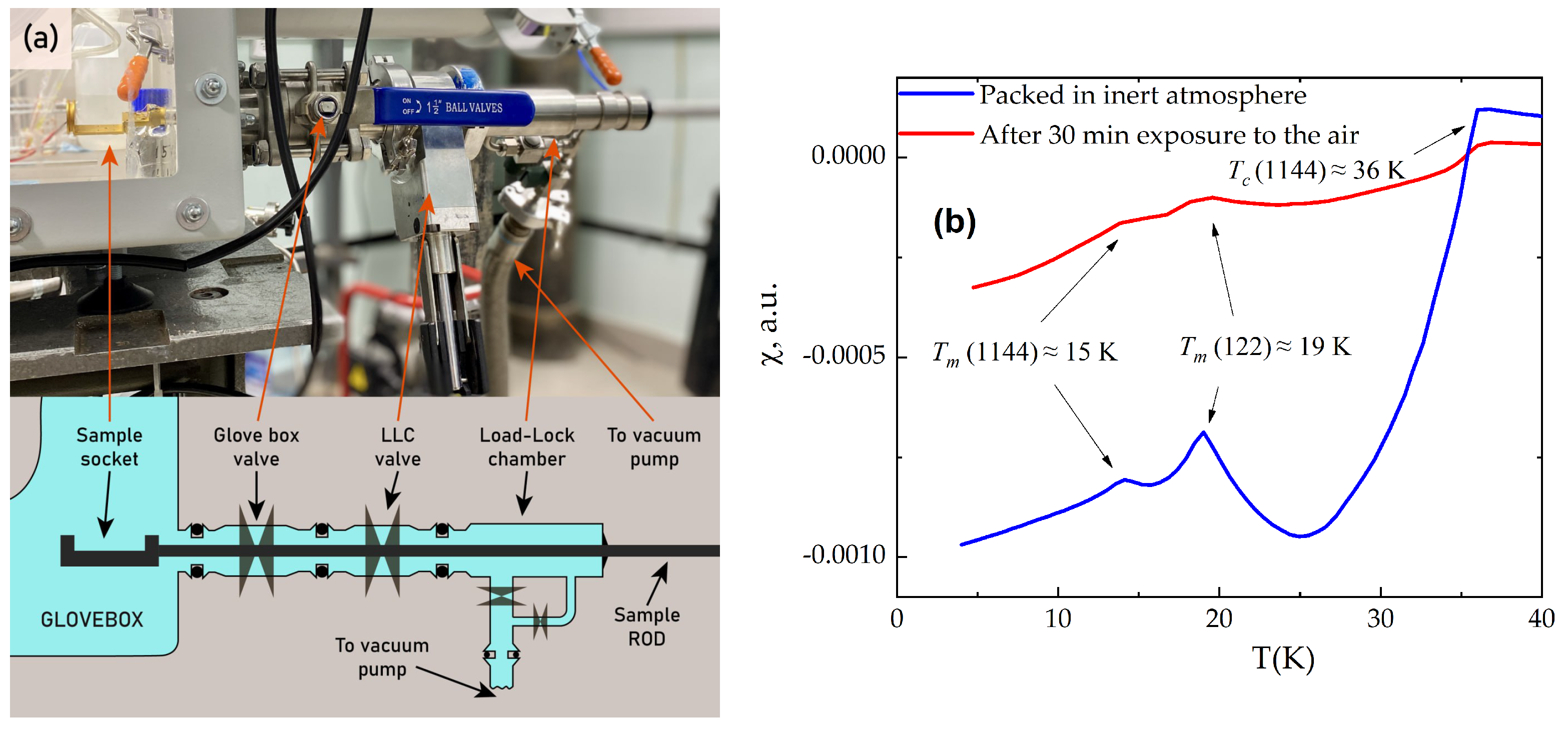

4.4. (1144) Iron-Based Superconductors and Inert-Atmosphere Transfer to Cryostat

5. Discussion: Further Development

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geim, A.K.; Grigorieva, I.V. Van derWaals Heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.; Mishchenko, A.; Carvalho, A.; Castro Neto, A.H. 2D materials and van der Waals heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef] [PubMed]

- Ryu, B.; Wang, L.; Pu, H.; Chan, M.K.Y.; Chen, J. Understanding, discovery, and synthesis of 2D materials enabled by machine learning. Chem. Soc. Rev. 2022, 51, 1899–1925. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Jia, C.; Huang, Y.; Duan, X. Van der Waals Heterostructures by Design: From 1D and 2D to 3D. Matter 2001, 4, 552–581. [Google Scholar] [CrossRef]

- Castellanos-Gomez, A.; Duan, X.; Fei, Z.; Gutierrez, H.R.; Huang, Y.; Huang, X.; Quereda, J.; Qian, Q.; Sutter, E.; Sutter, P. Van der Waals heterostructures. Nat. Rev. Methods Prim. 2022, 2, 58. [Google Scholar] [CrossRef]

- Chaves, A.; Azadani, J.; Alsalman, H.; Costa, D.; Frisenda, R.; Chaves, A.; Song, S.; Kim, Y.; He, D.; Zhou, J.; et al. Bandgap engineering of two-dimensional semiconductor materials. Npj 2D Mater. Appl. 2020, 4, 29. [Google Scholar] [CrossRef]

- Wang, X.; Sun, Y.; Liu, K. Chemical and structural stability of 2D layered materials. 2D Mater. 2019, 6, 042001. [Google Scholar] [CrossRef]

- Cao, Y.; Mishchenko, A.; Yu, G.L.; Khestanova, E.; Rooney, A.P.; Prestat, E.; Kretinin, A.V.; Blake, P.; Shalom, M.B.; Woods, C.; et al. Quality Heterostructures from Two-Dimensional Crystals Unstable in Air by Their Assembly in Inert Atmosphere. Nano Lett. 2015, 15, 4914–4921. [Google Scholar] [CrossRef]

- Gant, P.; Carrascoso, F.; Zhao, Q.; Ryu, Y.K.; Seitz, M.; Prins, F.; Frisenda, R.; Castellanos-Gomez, A. A system for the deterministic transfer of 2D materials under inert environmental conditions. 2D Mater. 2020, 7, 025034. [Google Scholar] [CrossRef]

- Masubuchi, S.; Morimoto, M.; Morikawa, S.; Onodera, M.; Asakawa, Y.; Watanabe, K.; Taniguchi, T.; Machida, T. Autonomous robotic searching and assembly of two-dimensional crystals to build van der Waals superlattices. Nat. Commun. 2018, 9, 1413. [Google Scholar] [CrossRef]

- Buapan, K.; Somphonsane, R.; Chiawchan, T.; Ramamoorthy, H. Versatile, Low-Cost, and Portable 2D Material Transfer Setup with a Facile and Highly Efficient DIY Inert-Atmosphere Glove Compartment Option. ACS Omega 2021, 28, 17952–17964. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Luo, M.; Shi, G.; Tian, N.; Huang, Z.; Yang, F.; Ma, L.; Wang, N.Z.; Shi, Q.; Xu, K.; et al. An ultra-high vacuum system for fabricating clean two-dimensional material devices. Rev. Sci. Instrum. 2023, 94, 013903. [Google Scholar] [CrossRef] [PubMed]

- Masubuchi, S.; Sakano, M.; Tanaka, Y.; Wakafuji, Y.; Yamamoto, T.; Okazaki, S.; Watanabe, K.; Taniguchi, T.; Li, J.; Ejima, H.; et al. Dry pick-and-flip assembly of van der Waals heterostructures for microfocus angle-resolved photoemission spectroscopy. Sci. Rep. 2022, 12, 10936. [Google Scholar] [CrossRef] [PubMed]

- Frisenda, R.; Navarro-Moratalla, E.; Gant, P.; De Lara, D.P.; Jarillo-Herrero, P.; Gorbachev, R.V.; Castellanos-Gomez, A. Recent progress in the assembly of nanodevices and van der Waals heterostructures by deterministic placement of 2D materials. Chem. Soc. Rev. 2018, 47, 53–68. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.-W.; Hu, Z.; Liu, Z.-B.; Tian, J.-G. Stacking of 2D Materials. Adv. Funct. Mater. 2021, 31, 2007810. [Google Scholar] [CrossRef]

- Gray, M.J.; Kumar, N.; O’Connor, R.; Hoek, M.; Sheridan, E.; Doyle, M.C.; Romanelli, M.L.; Osterhoudt, G.B.; Wang, Y.; Plisson, V.; et al. A cleanroom in a glovebox. Rev. Sci. Instrum. 2020, 91, 073909. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Liao, M.; Guo, Y.; Tang, J.; Cai, Y.; Chen, H.; Wang, Q.; Jia, Q.; Lu, Y.; Zhao, Y.; et al. Scratching lithography for wafer-scale MoS2 monolayers. 2D Mater. 2020, 7, 045028. [Google Scholar] [CrossRef]

- Rao, Q.; Gao, G.; Wang, X.; Xue, H.; Ki, D.-K. Scratching lithography, manipulation, and soldering of 2D materials using microneedle probes. arXiv 2023, arXiv:2308.05968. [Google Scholar]

- Jung, Y.; Choi, M.S.; Nipane, A.; Borah, A.; Kim, B.; Zangiabadi, A.; Taniguchi, T.; Watanabe, K.; Yoo, W.J.; Hone, J.; et al. Transferred via contacts as a platform for ideal two-dimensional transistors. Nat. Electron. 2019, 2, 187–194. [Google Scholar] [CrossRef]

- Satterthwaite, P.; Zhu, W.; Jastrzebska-Perfect, P.; Tang, M.; Spector, S.; Gao, H.; Kitadai, H.; Lu, A.; Tan, Q.; Tang, S.; et al. Van der Waals device integration beyond the limits of van der Waals forces using adhesive matrix transfer. Nat. Electron. 2023. [Google Scholar] [CrossRef]

- Pugachev, M.; Duleba, A.; Galiullin, A.; Kuntsevich, A. Micromask Lithography for Cheap and Fast 2D Materials Microstructures Fabrication. Micromachines 2021, 12, 850. [Google Scholar] [CrossRef] [PubMed]

- Gogotsi, Y.; Anasori, B. The Rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef] [PubMed]

- Botana, A.S.; Norman, M.R. Electronic structure and magnetism of transition metal dihalides: Bulk to monolayer. Phys. Rev. Mater. 2019, 3, 044001. [Google Scholar] [CrossRef]

- Mogulkoc, A.; Modarresi, M.; Rudenko, A.N. Two-dimensional chromium pnictides CrX (X = P, As, Sb): Half-metallic ferromagnets with high Curie temperature. Phys. Rev. B 2020, 102, 024441. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, Y.; Peng, J.; Tang, J.; Zheng, K.; Liang, Z. 2D Ruddlesden–Popper Perovskites for Optoelectronics. Adv. Mater. 2018, 11, 1703487. [Google Scholar] [CrossRef] [PubMed]

- Jain, A.; Bharadwaj, P.; Heeg, S.; Parzefall, M.; Taniguchi, T.; Watanabe, K.; Novotny, L. Minimizing residues and strain in 2D materials transferred from PDMS. Nanotechnology 2018, 29, 265203. [Google Scholar] [CrossRef]

- Zhao, Q.; Wang, T.; Ryu, Y.K.; Frisenda, R.; Castellanos-Gomez, A. An inexpensive system for the deterministic transfer of 2D materials. J. Phys. Mater. 2020, 3, 016001. [Google Scholar] [CrossRef]

- Martanov, S.G.; Zhurbina, N.K.; Pugachev, M.V.; Duleba, A.I.; Akmaev, M.A.; Belykh, V.V.; Kuntsevich, A.Y. Making van der Waals Heterostructures Assembly Accessible to Everyone. Nanomaterials 2020, 10, 2305. [Google Scholar] [CrossRef]

- Luo, W.; Zemlyanov, D.; Milligan, C.; Du, Y.; Yang, L.; Wu, Y.; Ye, P. Surface chemistry of black phosphorus under a controlled oxidative environment. Nanotechnology 2016, 27, 434002. [Google Scholar] [CrossRef]

- Favron, A.; Gaufrès, E.; Fossard, F.; Phaneuf-L’Heureux, A.; Tang, N.; Lévesque, P.; Loiseau, A.; Leonelli, R.; Francoeur, S.; Martel, R. Photooxidation and quantum confinement effects in exfoliated black phosphorus. Nat. Mater. 2015, 14, 826–832. [Google Scholar] [CrossRef]

- Kuntz, K.; Wells, R.; Hu, J.; Yang, T.; Dong, B.; Guo, H.; Woomer, A.; Druffel, D.; Alabanza, A.; Tománek, D.; et al. Control of Surface and Edge Oxidation on Phosphorene. Acs Appl. Mater. Interfaces 2017, 9, 9126–9135. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, H.B.; Pimenta, M.A.; de Matos, C.J.S. Raman spectroscopy in black phosphorus. J. Raman Spectrosc. 2018, 49, 76–90. Available online: https://api.semanticscholar.org/CorpusID:103401669 (accessed on 30 December 2023). [CrossRef]

- Perello, D.; Chae, S.; Song, S.; Lee, Y. High-performance n-type black phosphorus transistors with type control via thickness and contact-metal engineering. Nat. Commun. 2015, 6, 7809. [Google Scholar] [CrossRef] [PubMed]

- Radisavljevic, B.; Kis, A. Mobility engineering and a metal–insulator transition in monolayer MoS2. Nat. Mater. 2013, 12, 815–820. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Viscardi, L.; Faella, E.; Giubileo, F.; Intonti, K.; Pelella, A.; Sleziona, S.; Kharsah, O.; Schleberger, M.; Di Bartolomeo, A. Temperature dependent black phosphorus transistor and memory. Nano Express 2023, 4, 014001. [Google Scholar] [CrossRef]

- Li, L.; Yu, Y.; Ye, G.J.; Ge, Q.; Ou, X.; Wu, H.; Feng, D.; Chen, X.H.; Zhang, Y. Black phosphorus field-effect transistors. Nat. Nanotechnol. 2014, 9, 372–377. [Google Scholar] [CrossRef]

- Kuzmichev, S.A.; Pervakov, K.S.; Vlasenko, V.A.; Degtyarenko, A.Y.; Gavrilkin, S.Y.; Kuzmicheva, T.E. Andreev Spectroscopy of EuCsFe4As4 Stoichiometric Superconducting Pnictide. JETP Lett. 2022, 116, 723. [Google Scholar] [CrossRef]

- Degtyarenko, A.Y.; Vlasenko, V.A.; Kuzmicheva, T.E.; Pervakov, K.S.; Gavrilkin, S.Y.; Tsvetkov, A.Y.; Kuzmichev, S.A. Anisotropy of the Critical Current and Abrikosov Vortex Pinning in Magnetic Superconductor EuCsFe4As4. JETP Lett. 2023, 181, 1. [Google Scholar] [CrossRef]

- Degtyarenko, A.Y.; Karateev, I.A.; Ovcharov, A.V.; Vlasenko, V.A.; Pervakov, K.S. Synthesis and HRTEM Investigation of EuRbFe4As4 Superconductor. Nanomaterials 2022, 12, 3801. [Google Scholar] [CrossRef]

- Pizzocchero, F.; Gammelgaard, L.; Jessen, B.S.; Caridad, J.M.; Wang, L.; Hone, J.; Bøggild, P.; Booth, T.J. The hot pick-up technique for batch assembly of van der Waals heterostructures. Nat. Commun. 2016, 7, 11894. [Google Scholar] [CrossRef]

- Welch, K.; Doha, M.; Uttley, Z.; Fereidouni, A.; Omolewu, A.; Santos, J.; El-Shenawee, M.; Churchill, H. Comparison of Hall Mobility and Carrier Density of Thin Black Phosphorus Exfoliated from Bulk Crystals Provided by Various Vendors. In Proceedings of the 2022 IEEE USNC-URSI Radio Science Meeting (Joint With AP-S Symposium), Denver, CO, USA, 10–15 July 2022. [Google Scholar]

- Mannix, A.; Ye, A.; Sung, S.; Ray, A.; Mujid, F.; Park, C.; Lee, M.; Kang, J.; Shreiner, R.; High, A.; et al. Robotic four-dimensional pixel assembly of van der Waals solids. Nat. Nanotechnol. 2022, 17, 361–366. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.; Wu, J.; Zhang, Y.; Qu, Y.; Jia, B.; Chen, Z.; Moss, D.J. Fabrication Technologies for the On-Chip Integration of 2D Materials. Small Methods 2022, 6, 2101435. [Google Scholar] [CrossRef] [PubMed]

- Joe, D.J.; Park, E.; Kim, D.H.; Doh, I.; Song, H.-C.; Kwak, J.Y. Graphene and Two-Dimensional Materials-Based Flexible Electronics for Wearable Biomedical Sensors. Electronics 2023, 12, 45. [Google Scholar] [CrossRef]

- Yang, D.; Wang, H.; Luo, S.; Wang, C.; Zhang, S.; Guo, S. Paper-Cut Flexible Multifunctional Electronics Using MoS2 Nanosheet. Nanomaterials 2019, 9, 922. [Google Scholar] [CrossRef] [PubMed]

- Hywel, M.; Rout, C.S.; Late, D.J. Fundamentals and Sensing Applications of 2D Materials; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar]

- Rehman, A.; Park, S.-J. State of the art two-dimensional materials-based photodetectors: Prospects, challenges and future outlook. J. Ind. Eng. Chem. 2020, 89, 28–46. [Google Scholar] [CrossRef]

- Schram, T.; Sutar, S.; Radu, I.; Asselberghs, I. Challenges of Wafer-Scale Integration of 2D Semiconductors for High-Performance Transistor Circuits. Adv. Mater. 2022, 34, 2109796. [Google Scholar] [CrossRef]

- Ko, H.; Choi, S.; Kim, J.; Kim, Y.; Kim, Y.; Adofo, L.; Jung, M.; Kim, Y.; Jeong, M.; Kim, K.; et al. Toward non-gas-permeable hBN film growth on smooth Fe surface. 2D Mater. 2021, 8, 034003. [Google Scholar] [CrossRef]

- Xu, X.; Guo, T.; Kim, H.; Hota, M.K.; Alsaadi, R.S.; Lanza, M.; Zhang, X.H.N. Alshareef Growth of 2D Materials at the Wafer Scale. Adv. Mater. 2022, 34, 2108258. [Google Scholar] [CrossRef]

- Baojun Sun, B.; Pang, J.; Cheng, Q.; Zhang, S.; Li, Y.; Zhang, C.; Sun, D.; Ibarlucea, B.; Li, Y.; Chen, D. Synthesis of Wafer-Scale Graphene with Chemical Vapor Deposition for Electronic Device Applications. Adv. Mater. Technol. 2021, 6, 2000744. [Google Scholar]

- Park, J.-H.; Park, J.C.; Yun, S.J.; Kim, H.; Luong, D.H.; Kim, S.M.; Choi, S.H.; Yang, W.; Kong, J.; Kim, K.K.; et al. Large-area monolayer hexagonal boron nitride on Pt foil. ACS Nano 2014, 8, 8520–8528. [Google Scholar] [CrossRef]

- Watson, A.J.; Lu, W.; Guimarães, M.H.D.; Stöhr, M. Transfer of large-scale two-dimensional semiconductors: Challenges and developments. 2D Mater. 2021, 8, 032001. [Google Scholar] [CrossRef]

- Han, H.; Lu, A.; Lu, L.; Huang, J.; Hsu, C.; Lin, Y.; Chiu, M.; Suenaga, K.; Chu, C.; Kuo, K.; et al. Photoluminescence Enhancement and Structure Repairing of Monolayer MoSe2 by Hydrohalic Acid Treatment. ACS Nano 2016, 10, 1454–1461. [Google Scholar] [CrossRef] [PubMed]

| Block | Component | Our Solution | Our Costs, USD | Recommended Solution | Recommended Cost, USD |

|---|---|---|---|---|---|

| Glovebox | Glovebox | https://vilitek.com/ | 14,000 | Aliexpress | 6000 |

| Microscope | Data | Data | Aliexpress | 100 | |

| Table | Local supplier | 200 | The same | 200 | |

| Scroll pump | Edwards NXDS 10 | 5000 | Baosi | 3500 | |

| Gas tanks, reducers, etc. | Local suppliers | 500 | The same | 500 | |

| Small glovebox | Glovebox | Aliexpress | 1000 | Example | 2000 |

| Table | local supplier | 100 | The same | 100 | |

| Hot Plate | Aliexpress | 65 | Aliexpress | 20 | |

| Spin-coater | Aliexpress | 1600 | Instras | 700 | |

| ]Vacuum part | ISO100 Chamber | Aliexpress | 1000 | The same | 1000 |

| Turbopump | Used from eBay | 2000 | Pfeiffer | 7500 | |

| Vacuum furniture | Flanges, feedthroughs, o-rings, clamps, hoses, valves | 1000 | The same | 1000 | |

| Vacuum gauge | Thyracont | 1500 | The same | 1500 | |

| Thermal evaporation | Aliexpress | 700 | The same | 700 | |

| Plasma generator 500 W | Used from eBay | 1500 | Aliexpress | 6500 | |

| Transfer lithography | Microscope | Home-made from Aliexpress components | 400 | The same | 400 |

| XYZ stage | Motorized, used | 1000 | Manual, Aliexpress | 150 | |

| Mask holder | Aliexpress | 100 | The same | 100 | |

| Automation (Raspberry Pi, controllers, AC/DC adapters) | Aliexpress | 500 | Manual system | 100 | |

| Computer | PC with monitor | 1100 | The same | 1100 | |

| Total | ∼33,000 | ∼ 32,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duleba, A.; Pugachev, M.; Blumenau, M.; Martanov, S.; Naumov, M.; Shupletsov, A.; Kuntsevich, A. Inert-Atmosphere Microfabrication Technology for 2D Materials and Heterostructures. Micromachines 2024, 15, 94. https://doi.org/10.3390/mi15010094

Duleba A, Pugachev M, Blumenau M, Martanov S, Naumov M, Shupletsov A, Kuntsevich A. Inert-Atmosphere Microfabrication Technology for 2D Materials and Heterostructures. Micromachines. 2024; 15(1):94. https://doi.org/10.3390/mi15010094

Chicago/Turabian StyleDuleba, Aliaksandr, Mikhail Pugachev, Mark Blumenau, Sergey Martanov, Mark Naumov, Aleksey Shupletsov, and Aleksandr Kuntsevich. 2024. "Inert-Atmosphere Microfabrication Technology for 2D Materials and Heterostructures" Micromachines 15, no. 1: 94. https://doi.org/10.3390/mi15010094

APA StyleDuleba, A., Pugachev, M., Blumenau, M., Martanov, S., Naumov, M., Shupletsov, A., & Kuntsevich, A. (2024). Inert-Atmosphere Microfabrication Technology for 2D Materials and Heterostructures. Micromachines, 15(1), 94. https://doi.org/10.3390/mi15010094