CMOS-Compatible High-Performance Silicon Nanowire Array Natural Light Electronic Detection System

Abstract

:1. Introduction

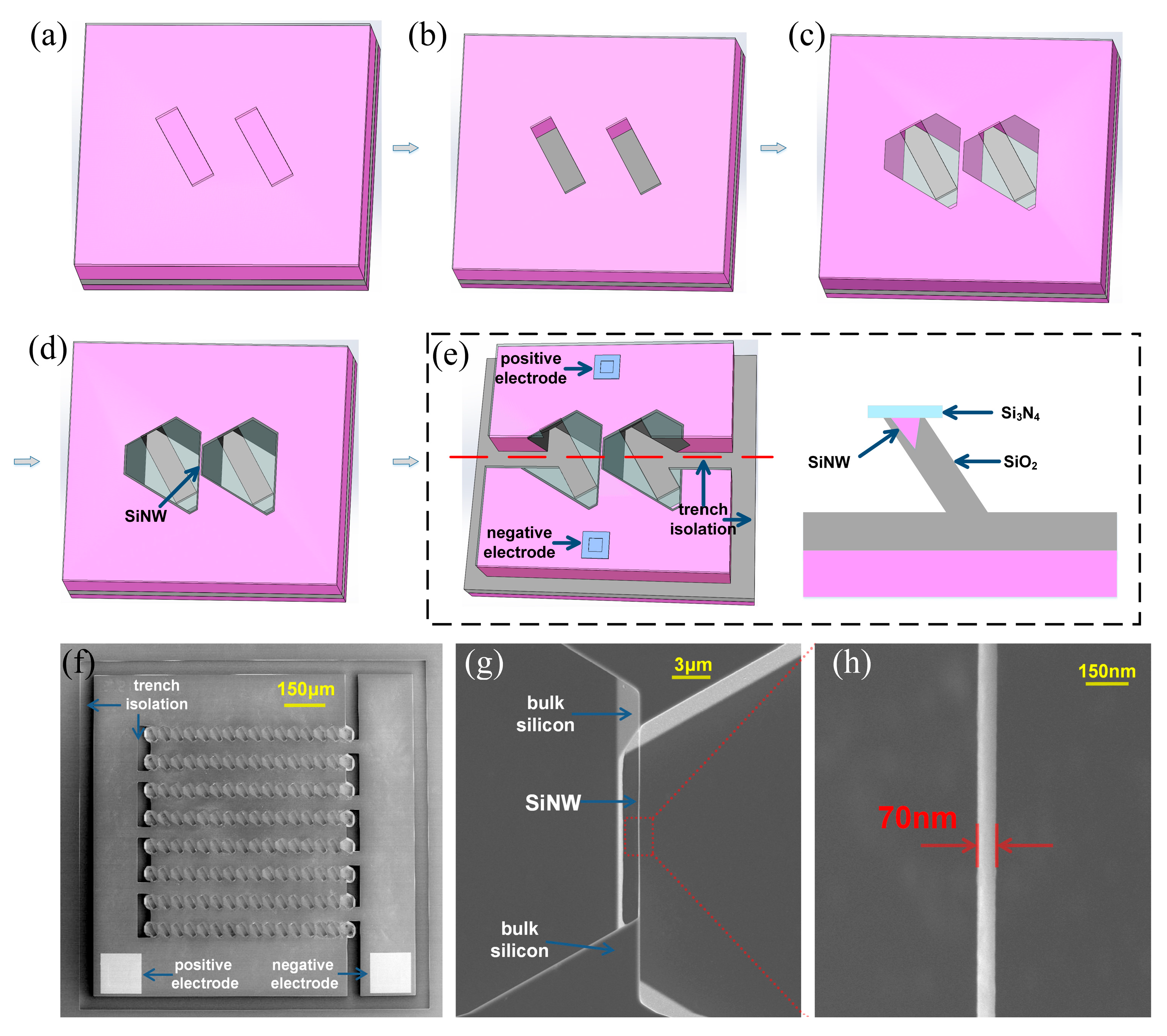

2. Materials and Methods

3. Results

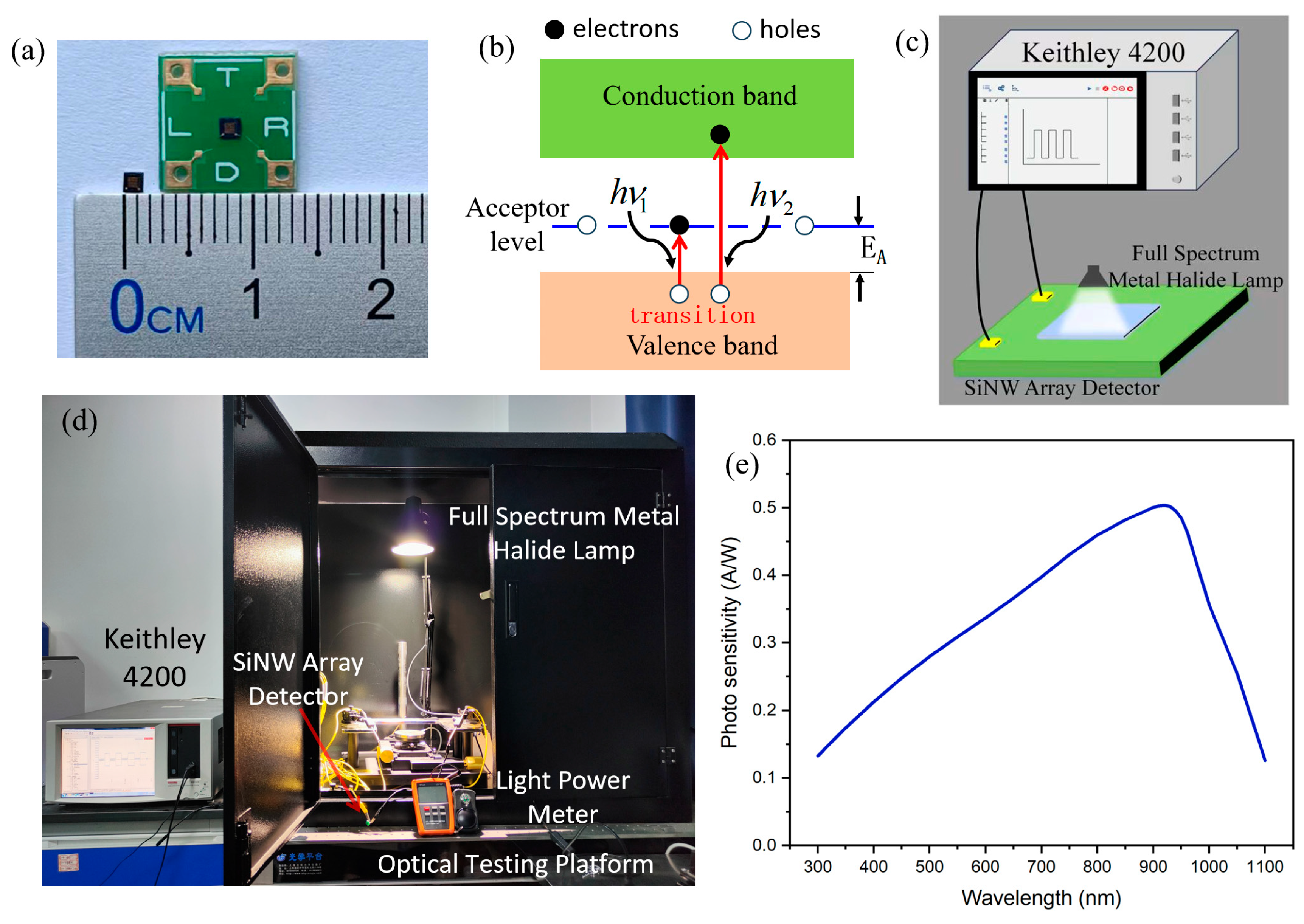

3.1. The Construction of Optical Testing System

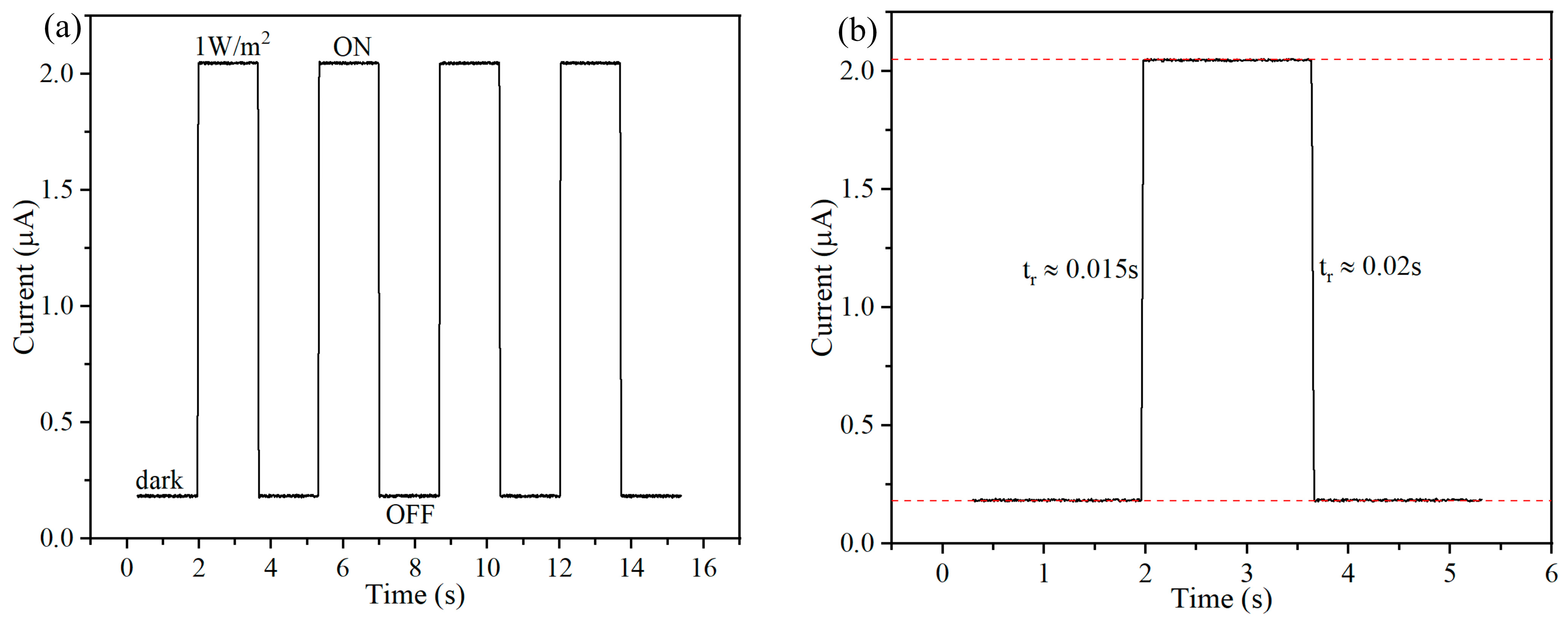

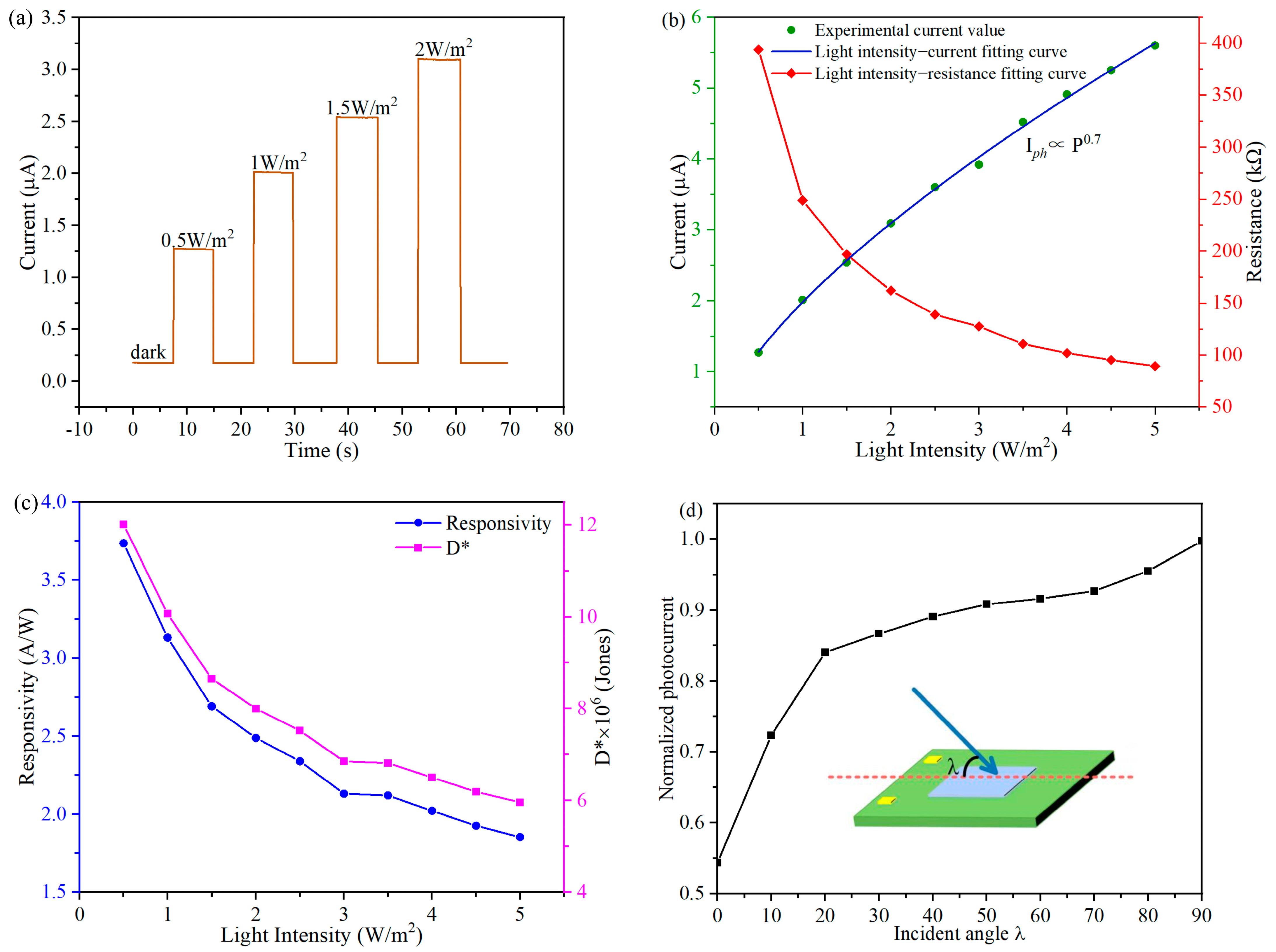

3.2. The Optoelectronic Testing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, S.H.; Wu, P.C. Exploring plasmonic gradient metasurfaces for enhanced optical sensing in the visible spectrum. Nanophotonics 2024, 13, 1099–1108. [Google Scholar] [CrossRef]

- Kong, L.; Zhao, Y.; Dong, L.; Jian, Y.; Jin, X.; Li, B.; Feng, Y.; Liu, M.; Liu, X.; Wu, H. Non-contact detection of oxygen saturation based on visible light imaging device using ambient light. Opt. Express 2013, 21, 17464–17471. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.X.; Li, H.Y.; Guo, X. Flexible and transparent sensors for ultra-low NO2 detection at room temperature under visible light illumination. J. Mater. Chem. A 2020, 8, 14482–14490. [Google Scholar] [CrossRef]

- Minotto, A.; Haigh, P.A.; Łukasiewicz, Ł.G.; Lunedei, E.; Gryko, D.T.; Darwazeh, I.; Cacialli, F. Visible light communication with efficient far-red/near-infrared polymer light-emitting diodes. Light Sci. Appl. 2020, 9, 70. [Google Scholar] [CrossRef]

- Hao, P.; Jiang, W.; Li, M.; Li, M.; Liu, Q.; Yang, L.; Tan, Y.; Wang, Y.; Wang, D. Fully Flexible Yarn-Based Phototransistors for UV–Visible Light Detection. ACS Photonics 2023, 11, 128–138. [Google Scholar] [CrossRef]

- Chierici, A.; Ciolini, R.; Nascimento, D.S.; d’Errico, F. A novel silicon PIN photodiode device for radiation exposure monitoring in dental CBCT. Radiat. Meas. 2024, 177, 107258. [Google Scholar] [CrossRef]

- Zel, G.; Demirezen, S. Investigation of hybrid CuPc-doped ZnO/p-silicon photodiodes for photonic and electronic applications. J. Mater. Sci. Mater. Electron. 2024, 35, 946. [Google Scholar]

- Kannichankandy, D.; Pataniya, P.M.; Zankat, C.K.; Tannarana, M.; Pathak, V.M.; Solanki, G.K.; Patel, K.D. Paper based organic–inorganic hybrid photodetector for visible light detection. Appl. Surf. Sci. 2020, 524, 146589. [Google Scholar] [CrossRef]

- Jo, M.S.; Song, H.J.; Kim, B.J.; Shin, Y.K.; Kim, S.H.; Tian, X.; Kim, S.M.; Seo, M.H.; Yoon, J.B. Aligned CuO nanowire array for a high performance visible light photodetector. Sci. Rep. 2022, 12, 2284. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, G.; Liang, B.; Yu, G.; Huang, H.; Chen, D.; Shen, G. Fabrication of high-quality ZnTe nanowires toward high-performance rigid/flexible visible-light photodetectors. Opt. Express 2013, 21, 7799–7810. [Google Scholar] [CrossRef]

- Nedev, N.; Arias, A.; Curiel, M.; Nedev, R.; Mateos, D.; Manolov, E.; Nesheva, D.; Valdez, B.; Herrera, R.; Sanchez, A. Visible light sensor based on metal-oxide-semiconductor structure. Key Eng. Mater. 2014, 605, 384–387. [Google Scholar] [CrossRef]

- Ouyang, W.; Teng, F.; He, J.H.; Fang, X. Enhancing the photoelectric performance of photodetectors based on metal oxide semiconductors by charge-carrier engineering. Adv. Funct. Mater. 2019, 29, 1807672. [Google Scholar] [CrossRef]

- Yoo, H.; Kim, W.G.; Kang, B.H.; Kim, H.T.; Park, J.W.; Choi, D.H.; Kim, T.S.; Lim, J.H.; Kim, H.J. High photosensitive indium–gallium–zinc oxide thin-film phototransistor with a selenium cap** layer for visible-light detection. ACS Appl. Mater. Interfaces 2020, 12, 10673–10680. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Zhang, M.; Ding, J.; Liu, A.; Huang, F.; Sheng, M. Advances in colloidal quantum dot-based photodetectors. J. Mater. Chem. C 2022, 10, 7404–7422. [Google Scholar] [CrossRef]

- Ma, D.D.; Lee, C.S.; Au, F.C.; Tong, S.Y.; Lee, S.T. Small-diameter silicon nanowire surfaces. Science 2003, 299, 1874–1877. [Google Scholar] [CrossRef] [PubMed]

- De Smet, L.C.; Ullien, D.; Mescher, M.; Sudhölter, E.J. Organic surface modification of silicon nanowire-based sensor devices. In Nanowires—Implementations and Applications; IntechOpen: London, UK, 2021; pp. 267–288. [Google Scholar]

- Maculan, G.; Sheikh, A.D.; Abdelhady, A.L.; Saidaminov, M.I.; Haque, M.A.; Murali, B.; Alarousu, E.; Mohammed, O.F.; Wu, T.; Bakr, O.M. CH3NH3PbCl3 single crystals: Inverse temperature crystallization and visible-blind UV-photodetector. J. Phys. Chem. Lett. 2015, 6, 3781–3786. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Gargas, D.; Hwang, Y.J.; Yang, P. Single crystalline mesoporous silicon nanowires. Nano Lett. 2009, 9, 3550–3554. [Google Scholar] [CrossRef]

- Mihalache, I.; Radoi, A.; Pascu, R.; Romanitan, C.; Vasile, E.; Kusko, M. Engineering graphene quantum dots for enhanced ultraviolet and visible light p-Si nanowire-based photodetector. ACS Appl. Mater. Interfaces 2017, 9, 29234–29247. [Google Scholar] [CrossRef] [PubMed]

- Xie, C.; Lu, X.; Liang, Y.; Chen, H.; Wang, L.; Wu, C.; Wu, D.; Yang, W.; Luo, L. Patterned growth of β-Ga2O3 thin films for solar-blind deep-ultraviolet photodetectors array and optical imaging application. J. Mater. Sci. Technol. 2021, 72, 189–196. [Google Scholar] [CrossRef]

- Wang, L.; Jie, J.; Shao, Z.; Zhang, Q.; Zhang, X.; Wang, Y.; Sun, Z.; Lee, S.T. MoS2/Si heterojunction with vertically standing layered structure for ultrafast, high-detectivity, self-driven visible–near infrared photodetectors. Adv. Funct. Mater. 2015, 25, 2910–2919. [Google Scholar] [CrossRef]

- Wu, E.; Wu, D.; Jia, C.; Wang, Y.; Yuan, H.; Zeng, L.; Xu, T.; Shi, Z.; Tian, Y.; Li, X. In situ fabrication of 2D WS2/Si type-II heterojunction for self-powered broadband photodetector with response up to mid-infrared. ACS Photonics 2019, 6, 565–572. [Google Scholar] [CrossRef]

- Zeng, L.H.; Wang, M.Z.; Hu, H.; Nie, B.; Yu, Y.Q.; Wu, C.Y.; Wang, L.; Hu, J.G.; Xie, C.; Liang, F.X.; et al. Monolayer graphene/germanium Schottky junction as high-performance self-driven infrared light photodetector. ACS Appl. Mater. Interfaces 2013, 5, 9362–9366. [Google Scholar] [CrossRef] [PubMed]

- Xie, C.; Lu, X.T.; Tong, X.W.; Zhang, Z.X.; Liang, F.X.; Liang, L.; Luo, L.B.; Wu, Y.C. Recent progress in solar-blind deep-ultraviolet photodetectors based on inorganic ultrawide bandgap semiconductors. Adv. Funct. Mater. 2019, 29, 1806006. [Google Scholar] [CrossRef]

- Chinnamuthu, P.; Mondal, A.; Dhar, J.C.; Singh, N.K. Visible light detection using glancing angle deposited TiO2 nanowire arrays. Jpn. J. Appl. Phys. 2015, 54, 06FJ01. [Google Scholar] [CrossRef]

- Zhai, T.; Fang, X.; Liao, M.; Xu, X.; Li, L.; Liu, B.; Koide, Y.; Ma, Y.; Yao, J.; Bando, Y.; et al. Fabrication of high-quality In2Se3 nanowire arrays toward high-performance visible-light photodetectors. ACS Nano 2010, 4, 1596–1602. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xu, C.; Li, Y.; Wu, F.; Zhang, K.; Miao, Y.; Sun, S. Sensor nanoarchitectonics with free-standing C60 super-long nanowire for sensitivity-enhanced all-optical visible light detecting. Opt. Laser Technol. 2022, 149, 107821. [Google Scholar] [CrossRef]

- Zhuo, S.; Zhang, J.; Shi, Y.; Huang, Y.; Zhang, B. Self-template-directed synthesis of porous perovskite nanowires at room temperature for high-performance visible-light photodetectors. Angew. Chem. 2015, 127, 5785–5788. [Google Scholar] [CrossRef]

- Khan, M.T.; Ashraf, I.M.; Abdel-Wahab, F.; Sanaa, M.F.; Al-Juman, M.A.; Almohammedi, A.; Shkir, M.; AlFaify, S. High performance visible light photodetector based on TlInSSe single crystal for optoelectronic devices. Phys. Scr. 2019, 94, 105816. [Google Scholar] [CrossRef]

- Chao, J.; Xing, S.; Zhang, J.; Qin, C.; Duan, D.; Wu, X.; Shen, Q. Synthesis of Sb2S3 nanowall arrays for high performance visible light photodetectors. Mater. Res. Bull. 2014, 57, 300–305. [Google Scholar] [CrossRef]

| Material (s) | Bias (V) | Responsivity (A/W) | tr/td (s) | D* (Jones) | Ref. |

|---|---|---|---|---|---|

| SiNWs | 0.5 | 3.74 | ~0.015/~0.02 | 3.7 × 1011 | This Work |

| TiO2 NWs | 10 | ~3.5 | 2.5/2 | - | [25] |

| In2Se3 NWs | 3 | ~89 | <0.3/<0.3 | - | [26] |

| C60 NWs | - | - | 0.06/0.05 | - | [27] |

| Porous perovskite NWs | 1 | - | 0.12/0.08 | - | [28] |

| TllnSSe single crystal | 20 | 0.61 | 0.31/0.3 | 6.24 × 1011 | [29] |

| Sb2S3 nanowall arrays | 0.5 | - | 0.52/1.11 | - | [30] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Zeng, J.; Liu, M.; Zheng, C.; Wang, X.; Liu, C.; Yang, X. CMOS-Compatible High-Performance Silicon Nanowire Array Natural Light Electronic Detection System. Micromachines 2024, 15, 1201. https://doi.org/10.3390/mi15101201

Chen X, Zeng J, Liu M, Zheng C, Wang X, Liu C, Yang X. CMOS-Compatible High-Performance Silicon Nanowire Array Natural Light Electronic Detection System. Micromachines. 2024; 15(10):1201. https://doi.org/10.3390/mi15101201

Chicago/Turabian StyleChen, Xin, Jiaye Zeng, Mingbin Liu, Chilin Zheng, Xiaoyuan Wang, Chaoran Liu, and Xun Yang. 2024. "CMOS-Compatible High-Performance Silicon Nanowire Array Natural Light Electronic Detection System" Micromachines 15, no. 10: 1201. https://doi.org/10.3390/mi15101201

APA StyleChen, X., Zeng, J., Liu, M., Zheng, C., Wang, X., Liu, C., & Yang, X. (2024). CMOS-Compatible High-Performance Silicon Nanowire Array Natural Light Electronic Detection System. Micromachines, 15(10), 1201. https://doi.org/10.3390/mi15101201