Investigation on the Machinability of Polycrystalline ZnS by Micro-Laser-Assisted Diamond Cutting

Abstract

1. Introduction

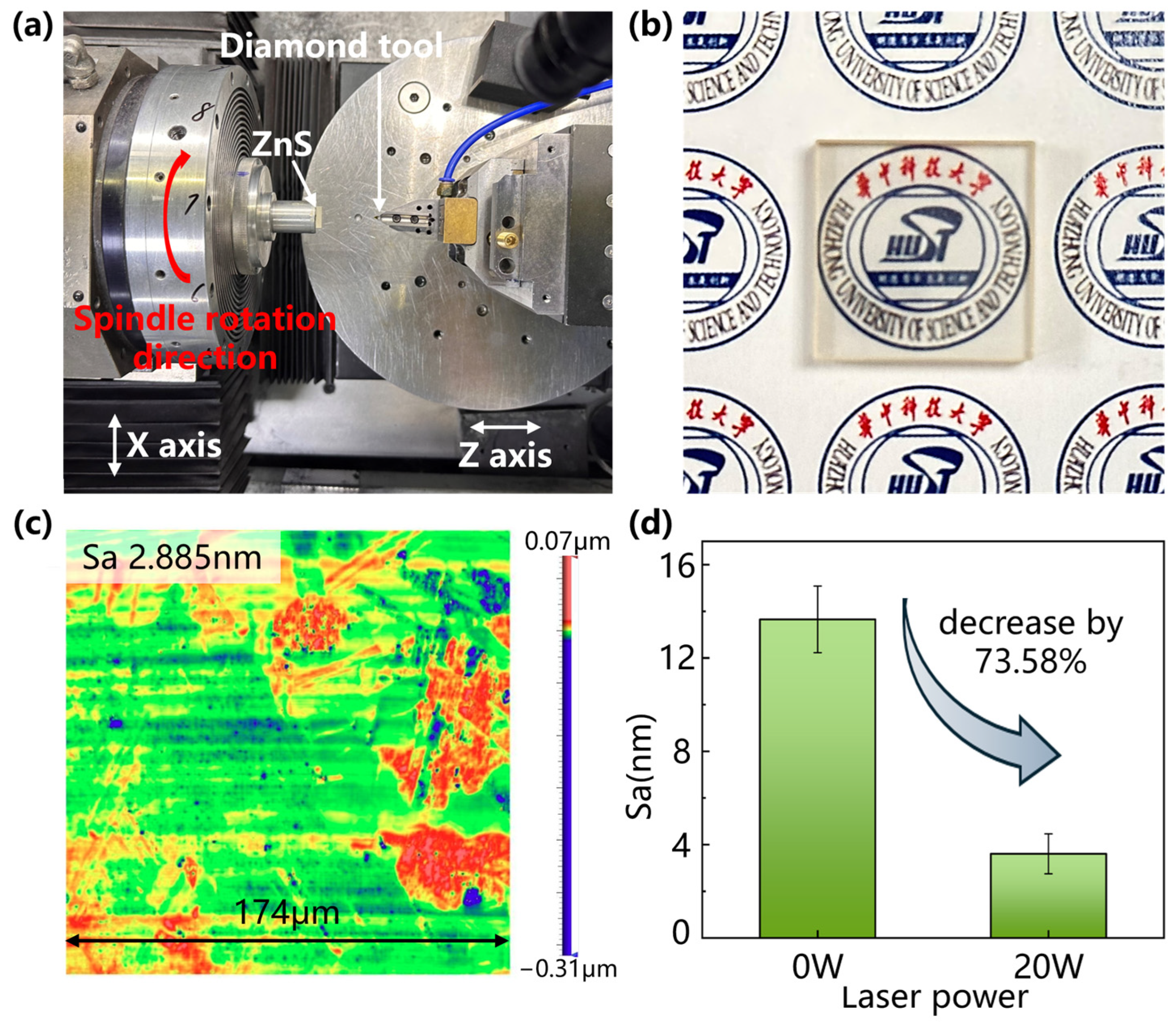

2. Materials and Methods

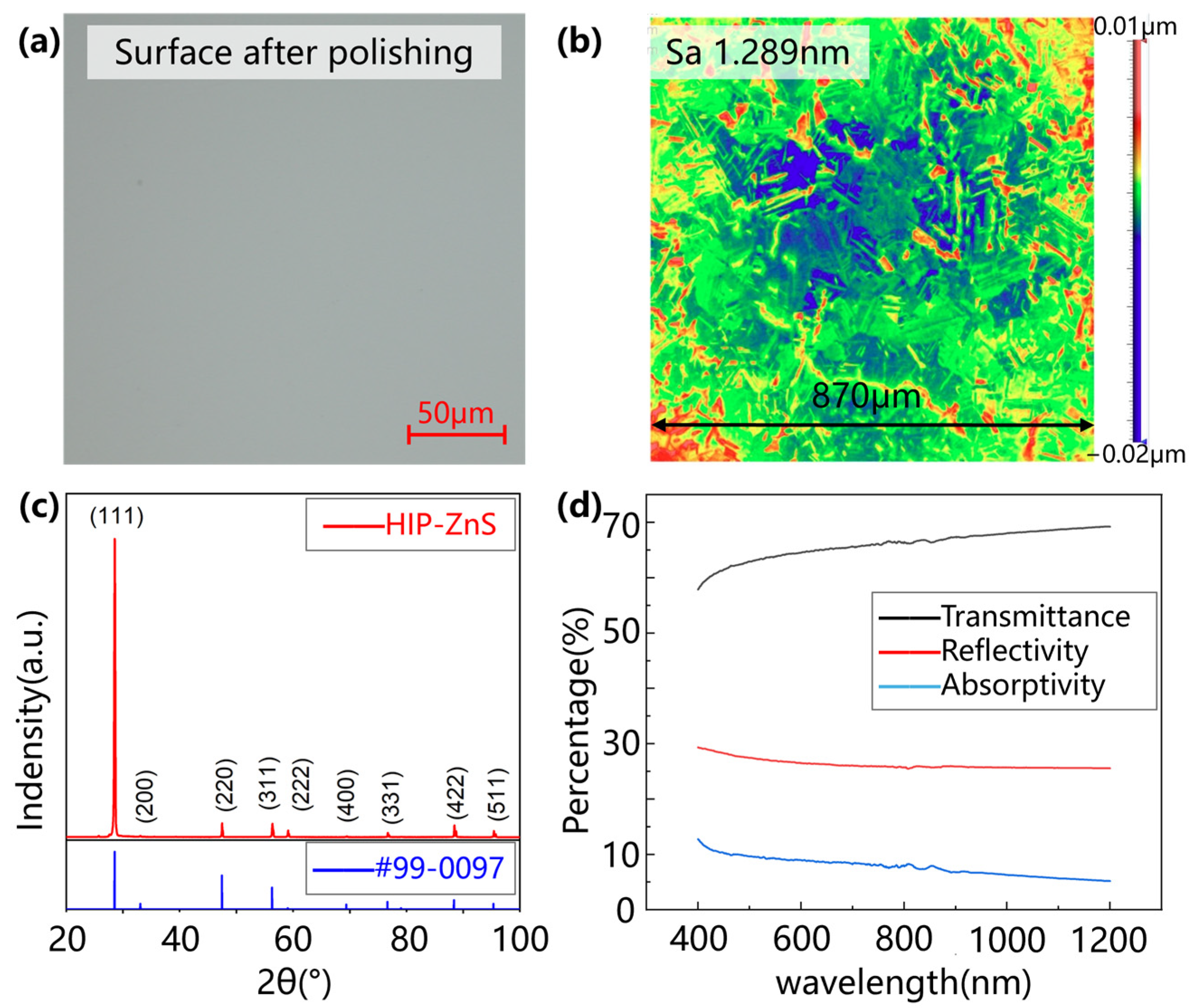

2.1. Materials

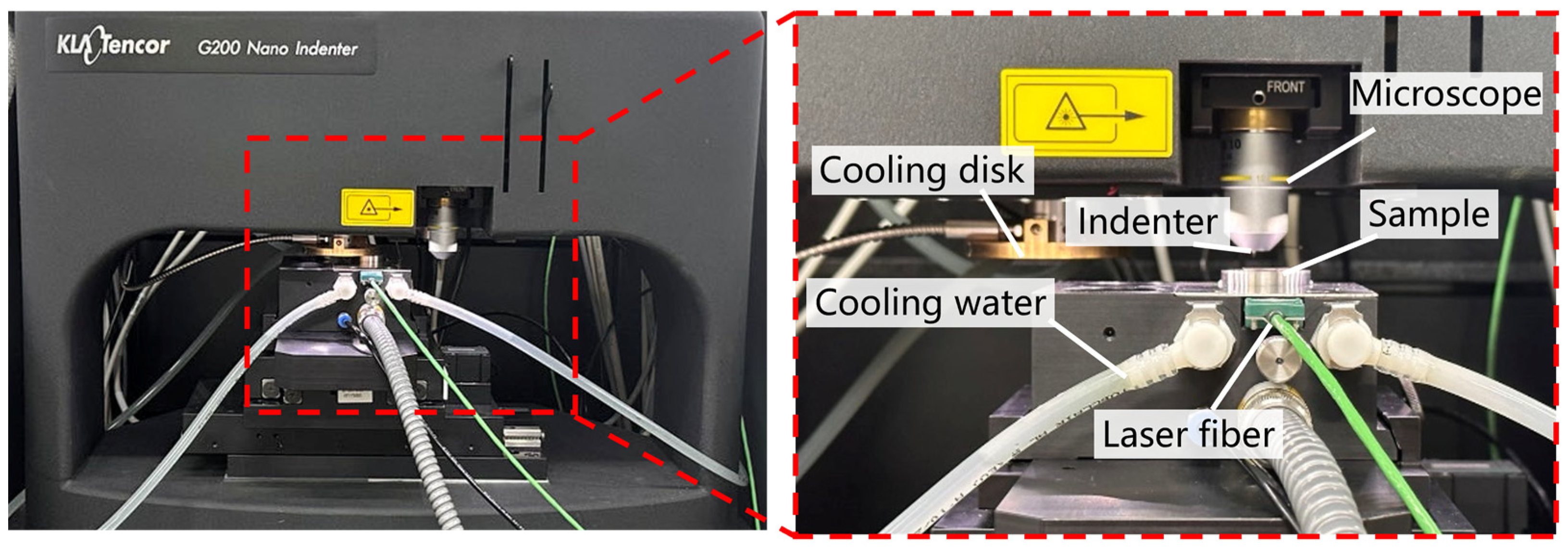

2.2. High-Temperature Nanoindentation

2.3. Grooving Experiments

2.4. Surface Characterization

3. Results and Discussions

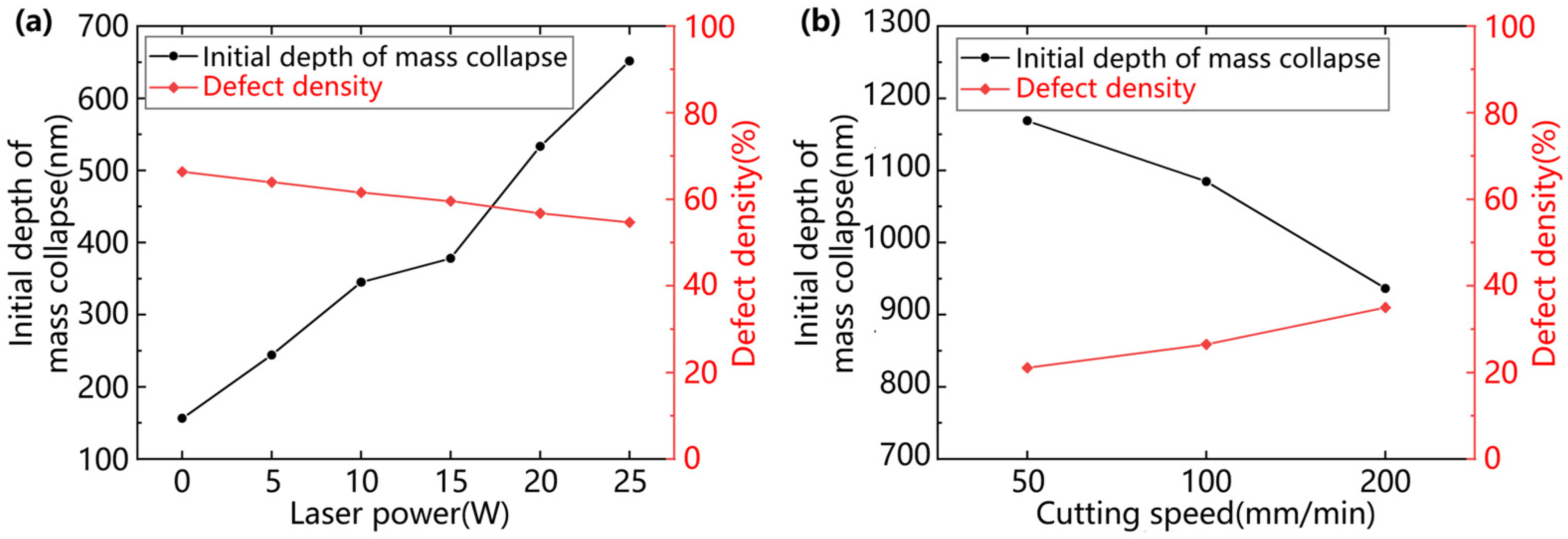

3.1. Temperature Response of Material Properties

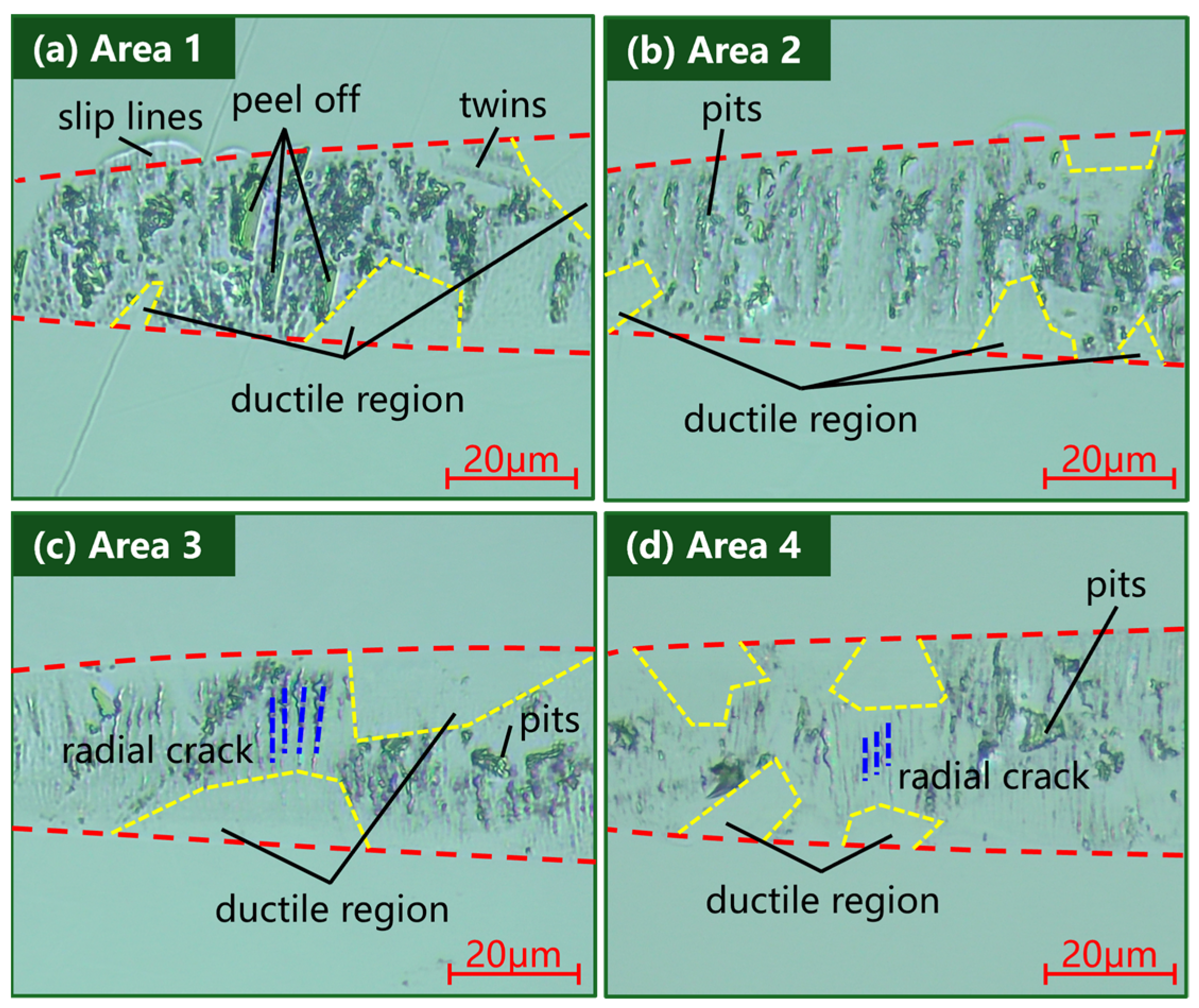

3.2. Material Cutting Removal Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Huang, W.; Hu, X. Light scattering to investigate the surface quality of silicon substrates. In Proceedings of the Annual Conference of the Chinese-Society-for-Optical-Engineering on Applied Optics and Photonics, China (AOPC), Beijing, China, 5–7 May 2015. [Google Scholar]

- Sun, H.; Tan, W.; Ruan, Y.; Bai, L.; Xu, J. Surface roughness classification using light scattering matrix and deep learning. Sci. China-Technol. Sci. 2024, 67, 520–535. [Google Scholar] [CrossRef]

- Ramavath, P.; Biswas, P.; Johnson, R.; Reddy, G.J.; Laxminarayana, P. Hot Isostatic Pressing of ZnS Powder and CVD ZnS Ceramics: Comparative Evaluation of Physico-chemical, Microstructural and Transmission Properties. Trans. Indian Ceram. Soc. 2014, 73, 299–302. [Google Scholar] [CrossRef]

- Ramavath, P.; Mahender, V.; Hareesh, U.S.; Johnson, R.; Kumari, S.; Prasad, N.E. Fracture behaviour of chemical vapour deposited and hot isostatically pressed zinc sulphide ceramics. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2011, 528, 5030–5035. [Google Scholar] [CrossRef]

- Geng, R.; Xie, Q.; Yang, X.; Zhang, R.; Zhang, W.; Qiu, H.; You, J.; Jiao, S. Experimental study of the feasibility of micro-laser-assisted machining in polycrystal ZnSe ceramics. In Proceedings of the Eighth Symposium on Novel Photoelectronic Detection Technology and Applications, Kunming, China, 9–11 November 2021; pp. 3350–3360. [Google Scholar]

- Li, W.; Tong, Y.; Lian, W.; Liu, D.; Zhang, H. Experiment study on the cutting property of hot press Zinc Sulfide by single point diamond turning. In Proceedings of the 7th International Symposium on Advanced Optical Manufacturing and Testing Technologies (AOMATT)—Advanced Optical Manufacturing Technologies, Harbin, China, 26–29 April 2014. [Google Scholar]

- Zhang, Y.; Sun, J.; Han, Y.; Xiao, Q.; Zhang, L. Study of stress-assisted nano-cutting mechanism of gallium arsenide. Appl. Surf. Sci. 2024, 672, 160813. [Google Scholar] [CrossRef]

- Arif, M.; Zhang, X.; Rahman, M.; Kumar, S. A predictive model of the critical undeformed chip thickness for ductile-brittle transition in nano-machining of brittle materials. Int. J. Mach. Tools Manuf. 2013, 64, 114–122. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Zhao, C. On a Novel Modulation Cutting Process for Potassium Dihydrogen Phosphate with an Increased Brittle-Ductile Transition Cutting Depth. Machines 2023, 11, 961. [Google Scholar] [CrossRef]

- Yao, T.; Yang, X.; Kang, J.; Guo, Y.; Cheng, B.; Qin, Y.; Wang, Y.; Xie, Q.; Du, G. Ductile-brittle transition and ductile-regime removal mechanisms in micro-and nanoscale machining of ZnS crystals. Infrared Phys. Technol. 2024, 138, 105096. [Google Scholar] [CrossRef]

- Navare, J.; Kang, D.; Zaytsev, D.; Bodlapati, C.; Ravindra, D.; Shahinian, H. Experimental investigation on the effect of crystal orientation of diamond tooling on micro laser assisted diamond turning of zinc sulfide. In Proceedings of the 48th SME North American Manufacturing Research Conference (NAMRC), Cincinnati, OH, USA, 22–26 June 2020; pp. 606–610. [Google Scholar]

- Zong, W.J.; Cao, Z.M.; He, C.L.; Xue, C.X. Theoretical modelling and FE simulation on the oblique diamond turning of ZnS crystal. Int. J. Mach. Tools Manuf. 2016, 100, 55–71. [Google Scholar] [CrossRef]

- Salzman, S.; Romanofsky, H.J.; Giannechini, L.J.; Jacobs, S.D.; Lambropoulos, J.C. Magnetorheological finishing of chemical-vapor deposited zinc sulfide via chemically and mechanically modified fluids. Appl. Opt. 2016, 55, 1481–1489. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, X.; Li, M.; Kang, J.; Zhang, W.; Xie, Q. Cutting Surface Quality and Cutting Conditions Optimization of Zinc Sulfide Crystal. Chin. J. Rare Met. 2023, 47, 315–321. [Google Scholar]

- Chen, J.; Gong, Q.; Song, G.; Zhou, W.; Zhang, T.; An, Q.; Chen, M. Transition of material removal mechanism in cutting of unidirectional SiCf/SiC composites. Int. J. Adv. Manuf. Technol. 2024, 133, 391–408. [Google Scholar] [CrossRef]

- Mohammadi, H.; Ravindra, D.; Kode, S.K.; Patten, J.A. Experimental work on micro laser-assisted diamond turning of silicon (111). J. Manuf. Process. 2015, 19, 125–128. [Google Scholar] [CrossRef]

- Shahinian, H.; Di, K.; Navare, J.; Bodlapati, C.; Zaytsev, D.; Ravindra, D. Ultraprecision laser-assisted diamond machining of single crystal Ge. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2020, 65, 149–155. [Google Scholar] [CrossRef]

- Bodlapati, C.; Navare, J.; Zaytsev, D.; Kang, D.; Mohammadi, H.; Ravindra, D.; Arlt, M.; Shahinian, H. Effect of laser-assisted diamond turning (micro-LAM) on non-optimally oriented calcium fluoride crystal. In Proceedings of the 34th ASPE Annual Meeting, Pittsburgh, PA, USA, 28 October–1 November 2019. [Google Scholar]

- Wang, L.; Wu, M.; Chen, H.; Hang, W.; Wang, X.; Han, Y.; Chen, H.; Chen, P.; Beri, T.H.; Luo, L. Damage evolution and plastic deformation mechanism of passivation layer during shear rheological polishing of polycrystalline tungsten. J. Mater. Res. Technol. 2024, 28, 1584–1596. [Google Scholar] [CrossRef]

- Chen, H.; Wang, L.; Peng, F.; Xu, Q.; Xiong, Y.; Zhao, S.; Tokunaga, K.; Wu, Z.; Ma, Y.; Chen, P. Hydrogen retention and affecting factors in rolled tungsten: Thermal desorption spectra and molecular dynamics simulations. Int. J. Hydrogen Energy 2023, 48, 30522–30531. [Google Scholar] [CrossRef]

- You, K.; Fang, F.; Yan, G.; Zhang, Y. Experimental Investigation on Laser Assisted Diamond Turning of Binderless Tungsten Carbide by In-Process Heating. Micromachines 2020, 11, 1104. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, Y.; Chen, X.; Shen, Z.; Zhang, J.; Xiao, J.; Xu, J. Investigation of the material removal process in in-situ laser-assisted diamond cutting of reaction-bonded silicon carbide. J. Eur. Ceram. Soc. 2023, 43, 2354–2365. [Google Scholar] [CrossRef]

- Fan, M.; Zhou, X.; Song, J. Experimental investigation on cutting force and machining parameters optimization in in-situ laser-assisted machining of glass-ceramic. Opt. Laser Technol. 2024, 169, 110109. [Google Scholar] [CrossRef]

- Song, H.; Dan, J.; Li, J.; Du, J.; Xiao, J.; Xu, J. Experimental study on the cutting force during laser-assisted machining of fused silica based on the Taguchi method and response surface methodology. J. Manuf. Process. 2019, 38, 9–20. [Google Scholar] [CrossRef]

- He, Y.; Xiao, G.; Liu, Z.; Ni, Y.; Liu, S. Subsurface damage in laser-assisted machining titanium alloys. Int. J. Mech. Sci. 2023, 258, 108576. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, Q.; Dong, J.; Wang, Z.; Yu, T. Experimental investigation and numerical analysis for machinability of alumina ceramic by laser-assisted grinding. Precis. Eng. 2021, 72, 798–806. [Google Scholar] [CrossRef]

- Pu, Y.; Zhao, Y.; Zhang, H.; Zhao, G.; Meng, J.; Song, P. Study on the three-dimensional topography of the machined surface in laser-assisted machining of Si3N4 ceramics under different material removal modes. Ceram. Int. 2020, 46, 5695–5705. [Google Scholar] [CrossRef]

- Kong, X.; Hu, G.; Hou, N.; Liu, N.; Wang, M. Numerical and experimental investigations on the laser assisted machining of the TC6 titanium alloy. J. Manuf. Process. 2023, 96, 68–79. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, L.; Wu, Z. Effect of anisotropy of potassium dihydrogen phosphate crystals on its deformation mechanisms subjected to nanoindentation. ACS Appl. Mater. Interfaces 2021, 13, 41351–41360. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Zhang, L.; Wu, Z. Subsurface damage minimization of KDP crystals. Appl. Surf. Sci. 2022, 604, 154592. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, L.; Wu, Z. An investigation on the nano-abrasion wear mechanisms of KDP crystals. Wear 2021, 476, 203692. [Google Scholar] [CrossRef]

- Liu, Q.; Liao, Z.; Axinte, D. Temperature effect on the material removal mechanism of soft-brittle crystals at nano/micron scale. Int. J. Mach. Tools Manuf. 2020, 159, 103620. [Google Scholar] [CrossRef]

| Experimental Parameters | Data |

|---|---|

| Workpiece material | HIP-ZnS |

| Tool material | Single-crystal diamond |

| Tool nose radius | 0.5 mm |

| Rake angle | −35° |

| Clearance angle | 10° |

| Cutting speeds | 500 mm/min, 200 mm/min, 100 mm/min, 50 mm/min |

| Slope ratio | 1:1000 |

| Laser power | 5 W, 10 W, 15 W, 20 W, 25 W |

| Experimental Parameters | Data |

|---|---|

| Workpiece material | HIP-ZnS |

| Tool material | Single-crystal diamond |

| Tool nose radius | 0.5 mm |

| Rake angle | −35° |

| Clearance angle | 10° |

| Cutting speeds | 500 mm/min |

| Feed rate | 4 μm/rev |

| Depth of cutting | 4 μm |

| Laser power | 0 W, 20 W |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Wang, X.; Qin, L.; Zhao, H.; Zhu, D.; Ma, S.; Zhang, J.; Xiao, J. Investigation on the Machinability of Polycrystalline ZnS by Micro-Laser-Assisted Diamond Cutting. Micromachines 2024, 15, 1275. https://doi.org/10.3390/mi15101275

Luo H, Wang X, Qin L, Zhao H, Zhu D, Ma S, Zhang J, Xiao J. Investigation on the Machinability of Polycrystalline ZnS by Micro-Laser-Assisted Diamond Cutting. Micromachines. 2024; 15(10):1275. https://doi.org/10.3390/mi15101275

Chicago/Turabian StyleLuo, Haoqi, Xue Wang, Lin Qin, Hongxin Zhao, Deqing Zhu, Shanyi Ma, Jianguo Zhang, and Junfeng Xiao. 2024. "Investigation on the Machinability of Polycrystalline ZnS by Micro-Laser-Assisted Diamond Cutting" Micromachines 15, no. 10: 1275. https://doi.org/10.3390/mi15101275

APA StyleLuo, H., Wang, X., Qin, L., Zhao, H., Zhu, D., Ma, S., Zhang, J., & Xiao, J. (2024). Investigation on the Machinability of Polycrystalline ZnS by Micro-Laser-Assisted Diamond Cutting. Micromachines, 15(10), 1275. https://doi.org/10.3390/mi15101275