Buckling Behavior Analysis of Kirigami Structure Under Tension

Abstract

1. Introduction

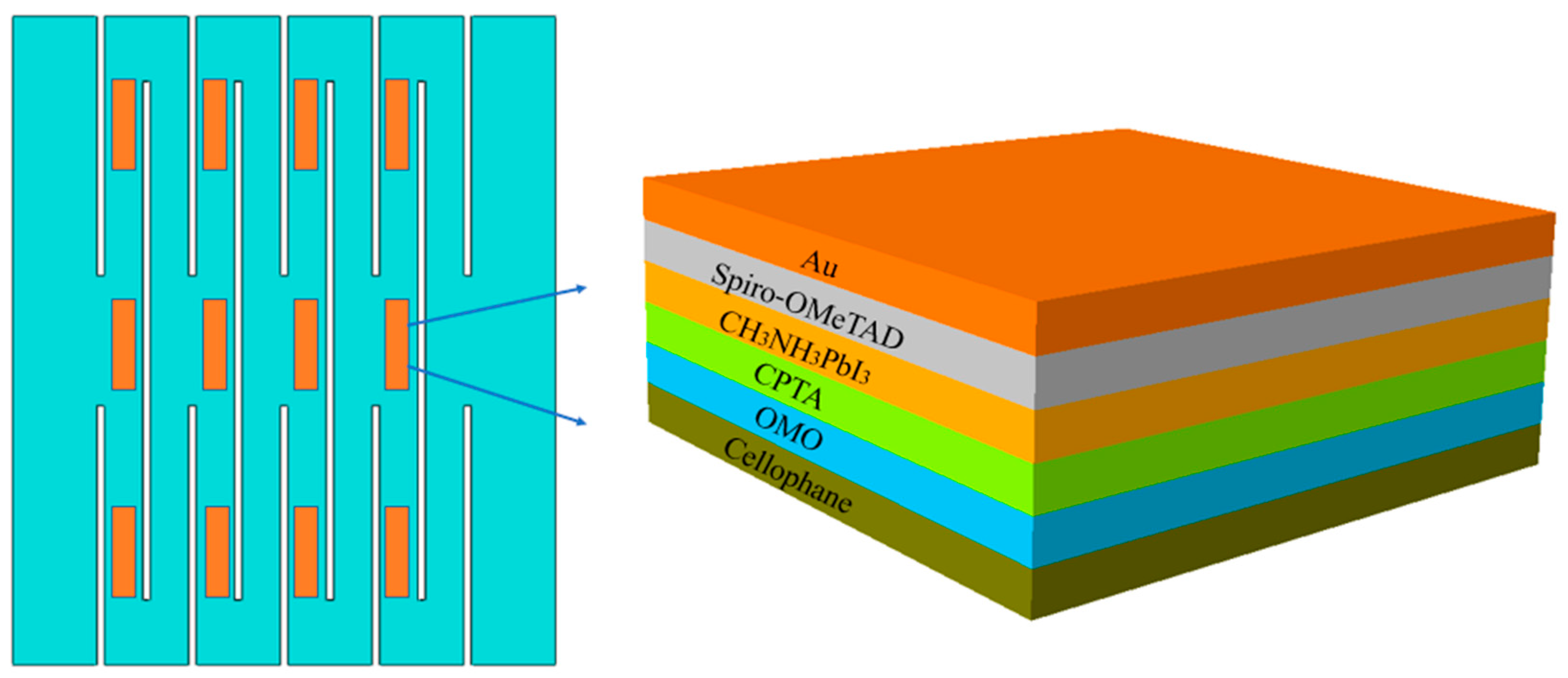

2. Materials and Methods

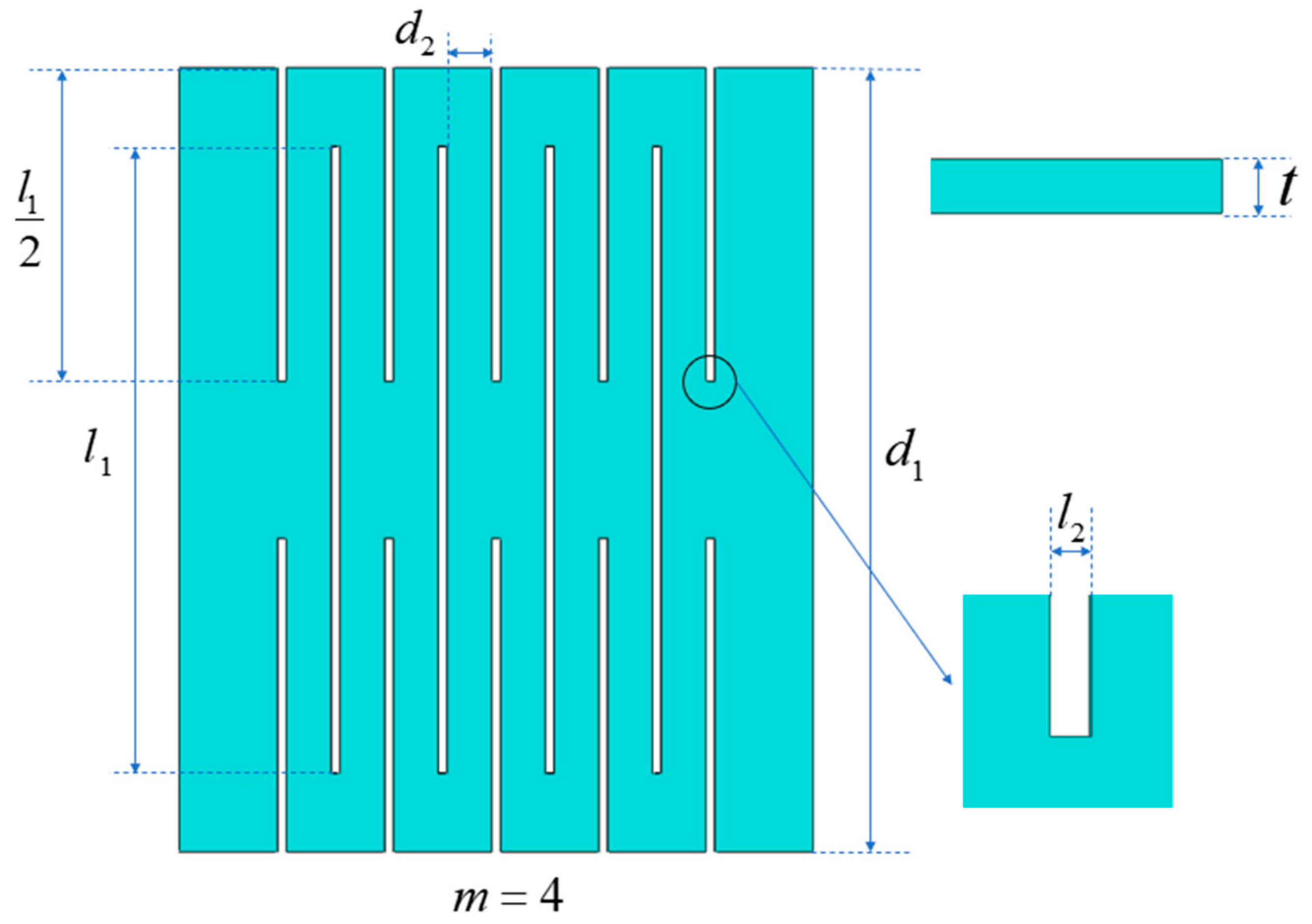

2.1. Kirigami Structure

2.2. Theory Analysis

2.3. Simulation Analysis

3. Results

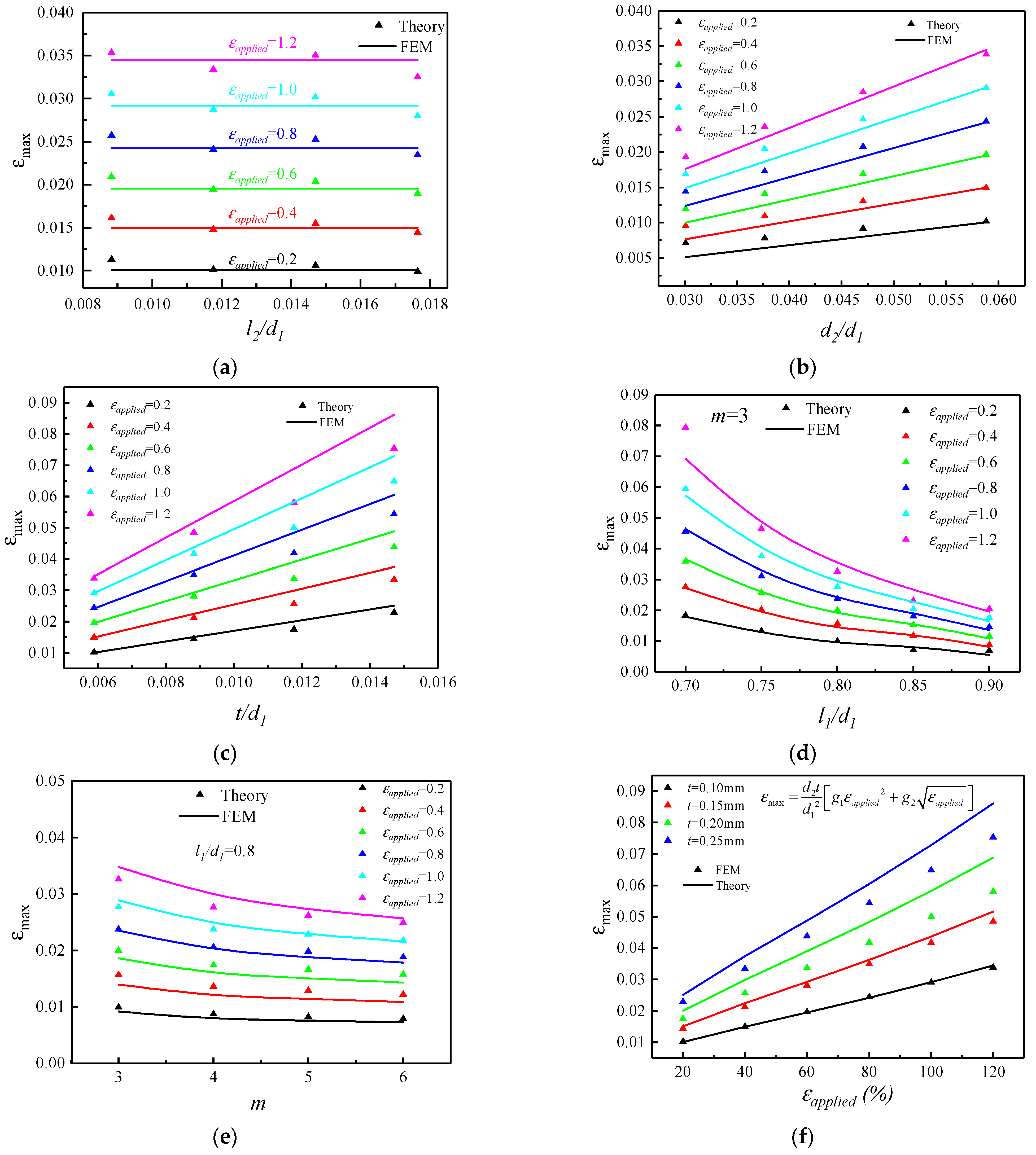

3.1. Maximum Strain Versus Geometric Parameters

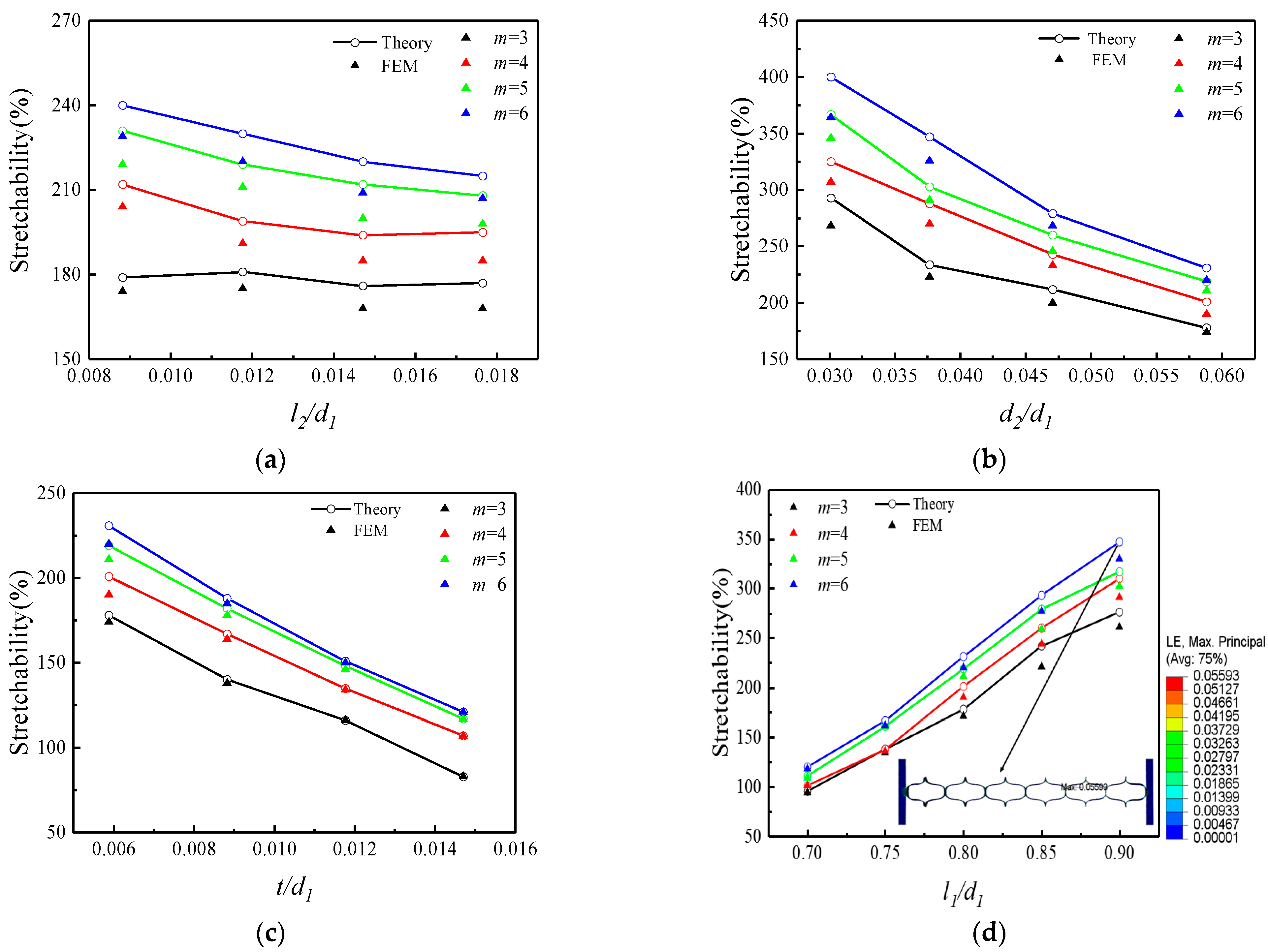

3.2. Elastic Stretchability Versus Geometric Parameters

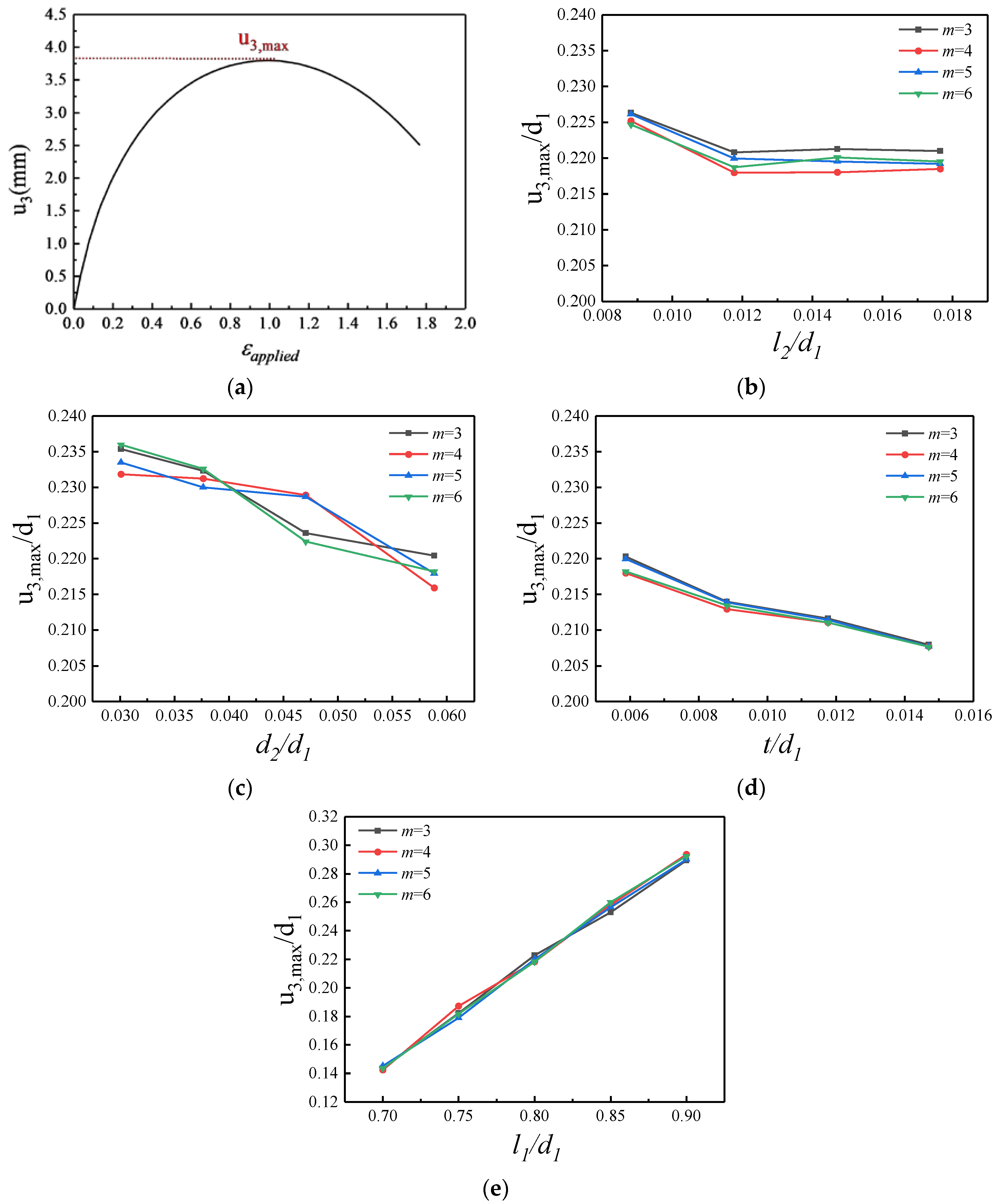

3.3. Maximum Out-of-Plane Displacement Versus Geometric Parameters

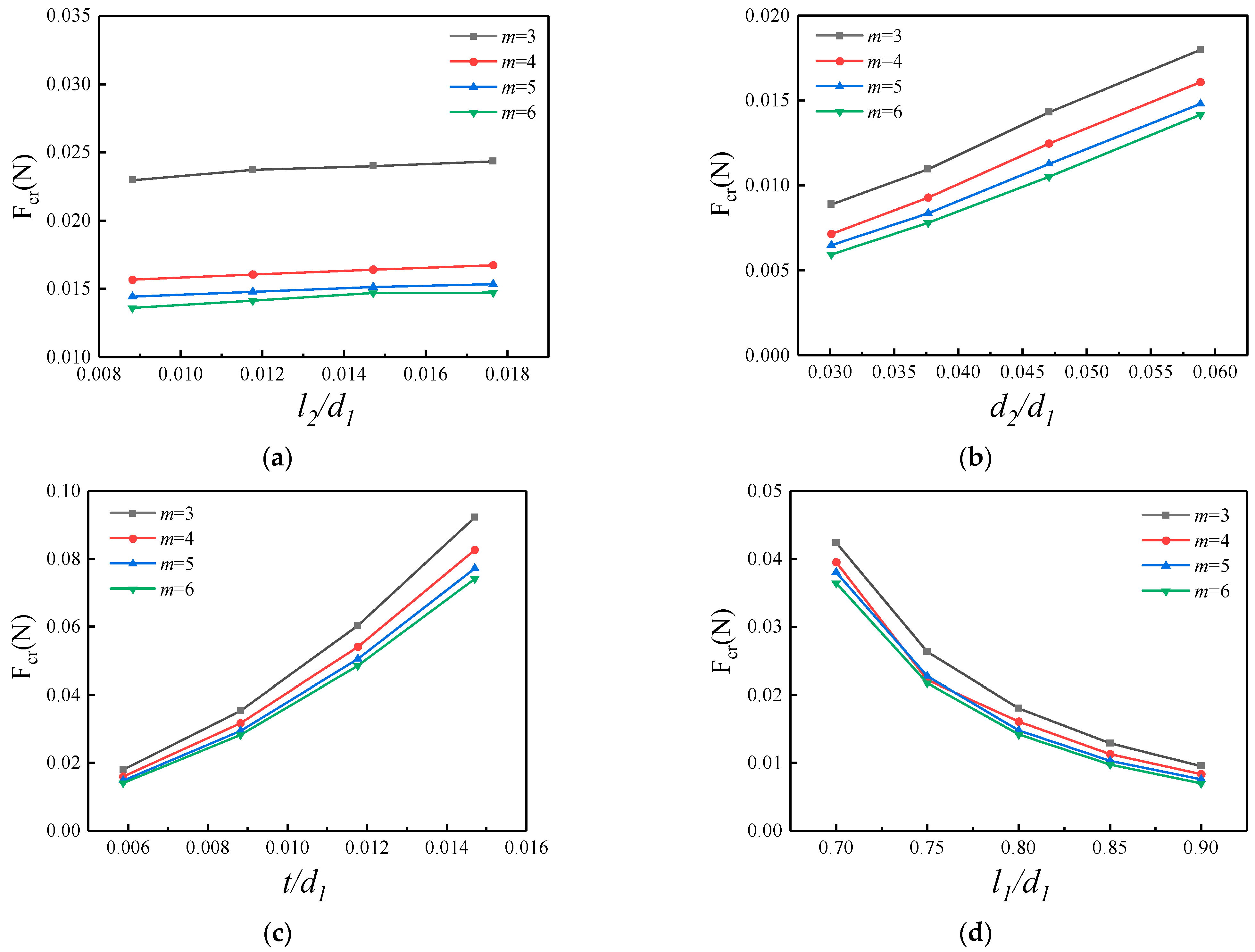

3.4. Critical Buckling Load Versus Geometric Parameters

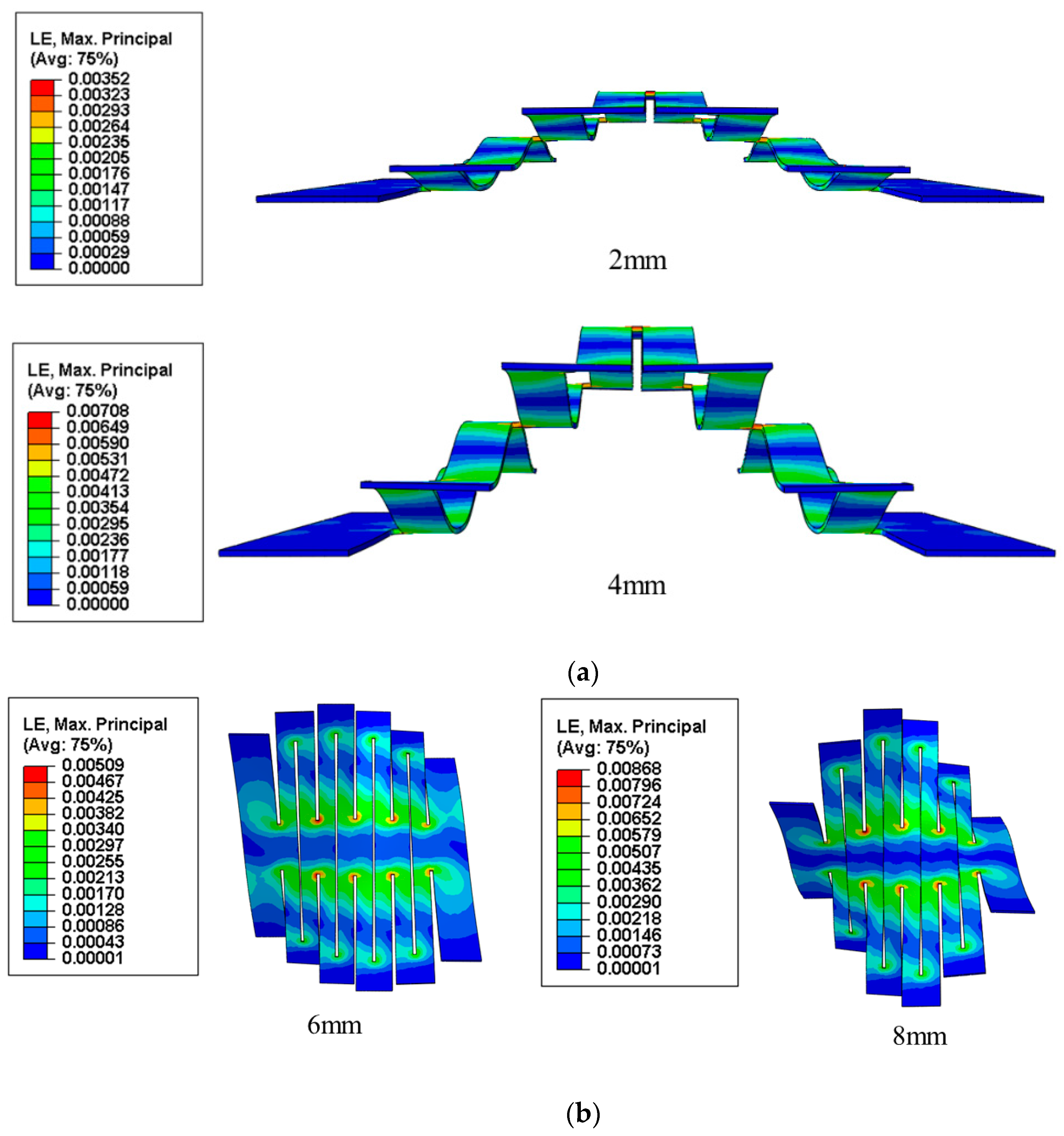

3.5. Deformation of Kirigami Structures Under Bending and Torsion

3.6. Conclusions

- (1)

- It can be concluded from the results of the study of the maximum strain that the effect of the cut width on the maximum strain of the structure is very small and negligible, and the maximum strain basically doesn’t change with it; when the cut spacing and the thickness of the substrate are increased, the maximum strain in the structure increases approximately linearly with it; cut length has a large effect on the maximum strain of the structure, and the maximum strain decreases with the increase, and the two are no longer in a linear relationship; the effect of the number of cuts on the maximum strain of the structure is relatively small, and the maximum strain decreases with the increase in the number of units, and the relationship is also no longer linear. In addition, as the applied strain increases, the maximum strain in the structure also increases.

- (2)

- From the results of the structural elastic stretchability study, it can be concluded that cut width has a small effect on the structural stretchability, and the stretchability decreases by a small amount when it increases; cut spacing and thickness of the substrate have a large effect on the structural elastic stretchability, and the stretchability decreases by a large amount when its value increases; cut length has the most significant effect on the structural stretchability, and the ductility increases by a very significant amount when its value increases; In addition, the increase in the number of cuts also improves the stretchability of the structure.

- (3)

- From the results of the maximum out-of-plane displacement, it can be concluded that, except for cut length , cut width , cut spacing , and thickness of the substrate have less effect on the maximum out-of-plane displacement. In addition, the change in the number of cells hardly affects the maximum out-of-plane displacement. The above findings can provide some theoretical guidance for the size design of flexible electronic devices and the packaging strategy of the devices.

- (4)

- From the results of the critical buckling load study, it can be concluded that the critical load of structural buckling is basically unaffected by cut width ; with the increase in the cut spacing and thickness of the substrate , the critical buckling load also increases, and the increase in the thickness of the substrate has a more obvious effect on the critical buckling load compared with cut spacing ; the critical buckling load decreases with the increase in cut length , and the magnitude of the decrease is relatively obvious. Finally, for a fixed geometric parameter, the critical buckling load decreases with the increase in the number of cells, and this effect decreases with the increase in the number of cells.

- (5)

- The kirigami structures can withstand certain bending and torsion loads in addition to large tensile loads.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, H.; Wang, W.; Yang, Y.; Wang, Y.; Li, P.; Huang, J.; Li, J.; Lu, Y.; Li, Z.; Wang, Z.; et al. Kirigami-Based Highly Stretchable Thin Film Solar Cells That Are Mechanically Stable for More than 1000 Cycles. ACS Nano 2020, 14, 1560–1568. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Yeh, M.H.; Lai, Y.C.; Zi, Y.; Wu, C.; Wen, Z.; Hu, C.; Wang, Z.L. All-in-One Shape-Adaptive Self-Charging Power Package for Wearable Electronics. ACS Nano 2016, 10, 10580–10588. [Google Scholar] [CrossRef]

- Lee, H.; Choi, T.K.; Lee, Y.B.; Cho, H.R.; Ghaffari, R.; Wang, L.; Choi, H.J.; Chung, T.D.; Lu, N.; Hyeon, T.; et al. A graphene-based electrochemical device with thermoresponsive microneedles for diabetes monitoring and therapy. Nat. Nanotechnol. 2016, 11, 566–572. [Google Scholar] [CrossRef]

- Sadri, B.; Goswami, D.; Sala de Medeiros, M.; Pal, A.; Castro, B.; Kuang, S.; Martinez, R.V. Wearable and Implantable Epidermal Paper-Based Electronics. ACS Appl. Mater. Interfaces 2018, 10, 31061–31068. [Google Scholar] [CrossRef]

- Zhou, W.; Yao, S.; Wang, H.; Du, Q.; Ma, Y.; Zhu, Y. Gas-Permeable, Ultrathin, Stretchable Epidermal Electronics with Porous Electrodes. ACS Nano 2020, 14, 5798–5805. [Google Scholar] [CrossRef]

- Kim, K.; Kim, B.; Lee, C.H. Printing Flexible and Hybrid Electronics for Human Skin and Eye-Interfaced Health Monitoring Systems. Adv. Mater. 2020, 32, 1902051. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.J.; Choi, C.; Kim, D.H.; Song, Y.M. Bioinspired Artificial Eyes: Optic Components, Digital Cameras, and Visual Prostheses. Adv. Funct. Mater. 2018, 28, 1705202. [Google Scholar] [CrossRef]

- Kim, J.; Shim, H.J.; Yang, J.; Choi, M.K.; Kim, D.C.; Kim, J.; Hyeon, T.; Kim, D.H. Ultrathin Quantum Dot Display Integrated with Wearable Electronics. Adv. Mater. 2017, 29, 1700217. [Google Scholar] [CrossRef]

- Lu, D.; Liu, T.L.; Chang, J.K.; Peng, D.; Zhang, Y.; Shin, J.; Hang, T.; Bai, W.; Yang, Q.; Rogers, J.A. Transient Light-Emitting Diodes Constructed from Semiconductors and Transparent Conductors that Biodegrade Under Physiological Conditions. Adv. Mater. 2019, 31, 1902739. [Google Scholar] [CrossRef]

- Xu, K.; Lu, Y.; Honda, S.; Arie, T.; Akita, S.; Takei, K. Highly stable kirigami-structured stretchable strain sensors for perdurable wearable electronics. J. Mater. Chem. C 2019, 7, 9609–9617. [Google Scholar] [CrossRef]

- Sun, R.; Zhang, B.; Yang, L.; Zhang, W.; Farrow, I.; Scarpa, F.; Rossiter, J. Kirigami stretchable strain sensors with enhanced piezoelectricity induced by topological electrodes. Appl. Phys. Lett. 2018, 112, 251904. [Google Scholar] [CrossRef]

- Kim, D.H.; Xiao, J.; Song, J.; Huang, Y.; Rogers, J.A. Stretchable, Curvilinear Electronics Based on Inorganic Materials. Adv. Mater. 2010, 22, 2108–2124. [Google Scholar] [CrossRef]

- Song, Z.; Ma, T.; Tang, R.; Cheng, Q.; Wang, X.; Krishnaraju, D.; Panat, R.; Chan, C.K.; Yu, H.; Jiang, H. Origami lithium-ion batteries. Nat. Commun. 2014, 5, 3140. [Google Scholar] [CrossRef] [PubMed]

- Mao, Z.; Kobayashi, R.; Nabae, H.; Suzumori, K. Multimodal Strain Sensing System for Shape Recognition of Tensegrity Structures by Combining Traditional Regression and Deep Learning Approaches. IEEE Robot. Autom. Lett. 2024, 9, 10050–10056. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, Y.; Hu, F.; He, M.; Mao, Z.; Huang, X.; Ding, J. Predictive modeling of flexible EHD pumps using Kolmogorov–Arnold Networks. Biomim. Intell. Robot. 2024, 4, 100184. [Google Scholar] [CrossRef]

- Zhang, W.; Zhuang, X.; Youn, S.-K.; Guo, X. Kirigami pattern design for buckling induced assembly 3D structures via topology optimization. Extrem. Mech. Lett. 2023, 65, 102099. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, Z.; Nan, K.; Xiao, D.; Liu, Y.; Luan, H.; Fu, H.; Wang, X.; Yang, Q.; Wang, J.; et al. A mechanically driven form of Kirigami as a route to 3D mesostructures in micro/nanomembranes. Proc. Natl. Acad. Sci. USA 2015, 112, 11757–11764. [Google Scholar] [CrossRef]

- Tang, R.; Fu, H. Mechanics of Buckled Kirigami Membranes for Stretchable Interconnects in Island-Bridge Structures. J. Appl. Mech. 2020, 87, 051002. [Google Scholar] [CrossRef]

- Su, Y.; Wu, J.; Fan, Z.; Hwang, K.C.; Song, J.; Huang, Y.; Rogers, J.A. Postbuckling analysis and its application to stretchable electronics. J. Mech. Phys. Solids 2012, 60, 487–508. [Google Scholar] [CrossRef]

- Lyu, J.; Hammig, M.D.; Liu, L.; Xu, L.; Chi, H.; Uher, C.; Li, T.; Kotov, N.A. Stretchable conductors by kirigami patterning of aramid-silver nanocomposites with zero conductance gradient. Appl. Phys. Lett. 2017, 111, 161901. [Google Scholar] [CrossRef]

- Shyu, T.C.; Damasceno, P.F.; Dodd, P.M.; Lamoureux, A.; Xu, L.; Shlian, M.; Shtein, M.; Glotzer, S.C.; Kotov, N.A. A kirigami approach to engineering elasticity in nanocomposites through patterned defects. Nat. Mater. 2015, 14, 785–789. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, P.; Li, Z.; Zhang, X.; Yu, Q. Buckling Behavior Analysis of Kirigami Structure Under Tension. Micromachines 2024, 15, 1398. https://doi.org/10.3390/mi15111398

Dai P, Li Z, Zhang X, Yu Q. Buckling Behavior Analysis of Kirigami Structure Under Tension. Micromachines. 2024; 15(11):1398. https://doi.org/10.3390/mi15111398

Chicago/Turabian StyleDai, Pengzhong, Ziqi Li, Xiaoyang Zhang, and Qingmin Yu. 2024. "Buckling Behavior Analysis of Kirigami Structure Under Tension" Micromachines 15, no. 11: 1398. https://doi.org/10.3390/mi15111398

APA StyleDai, P., Li, Z., Zhang, X., & Yu, Q. (2024). Buckling Behavior Analysis of Kirigami Structure Under Tension. Micromachines, 15(11), 1398. https://doi.org/10.3390/mi15111398