The Development of the Stress-Free Polishing System Based on the Positioning Error Analysis for the Deterministic Polishing of Jet Electrochemical Machining

Abstract

:1. Introduction

2. Mechanism

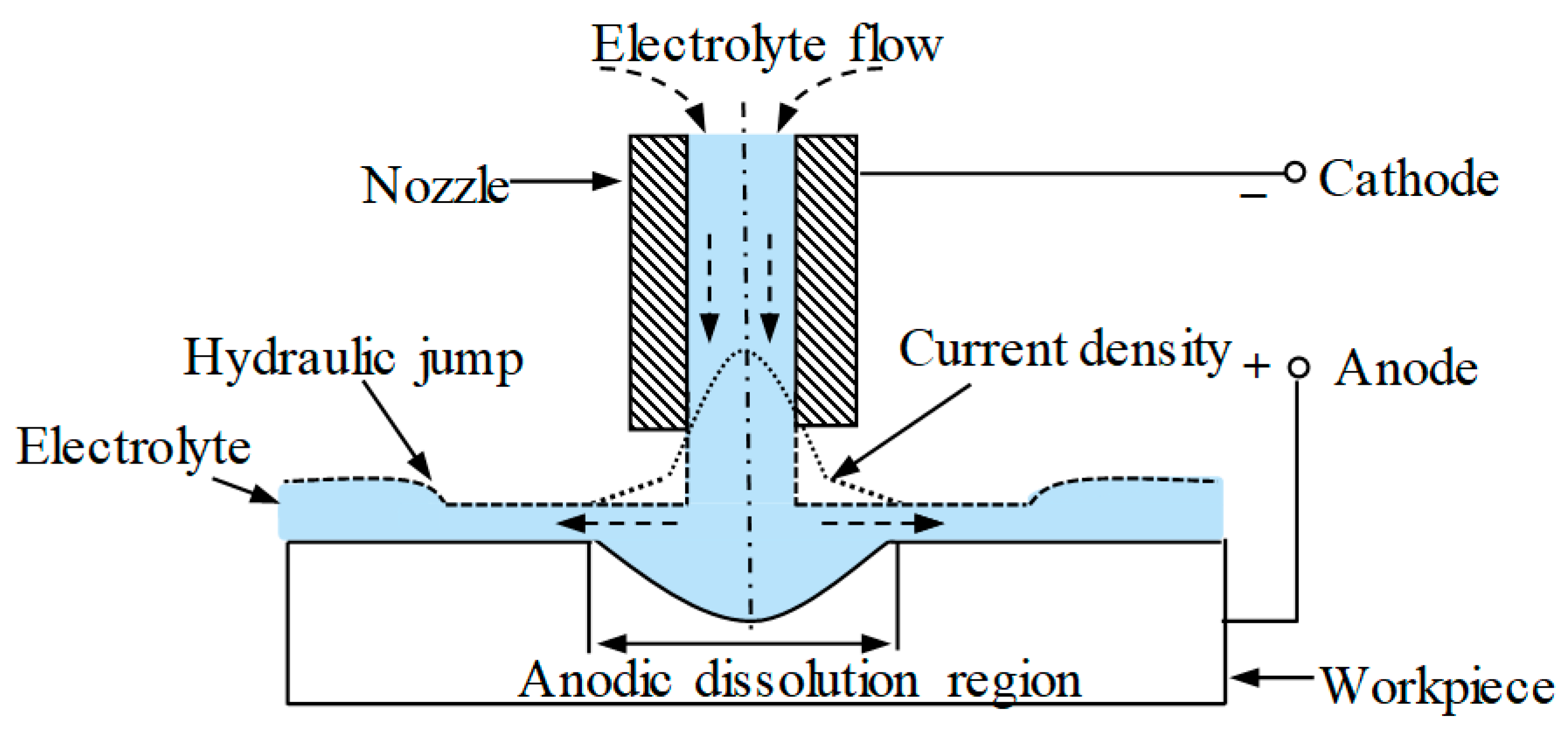

2.1. The Mechanism of Jet-ECM

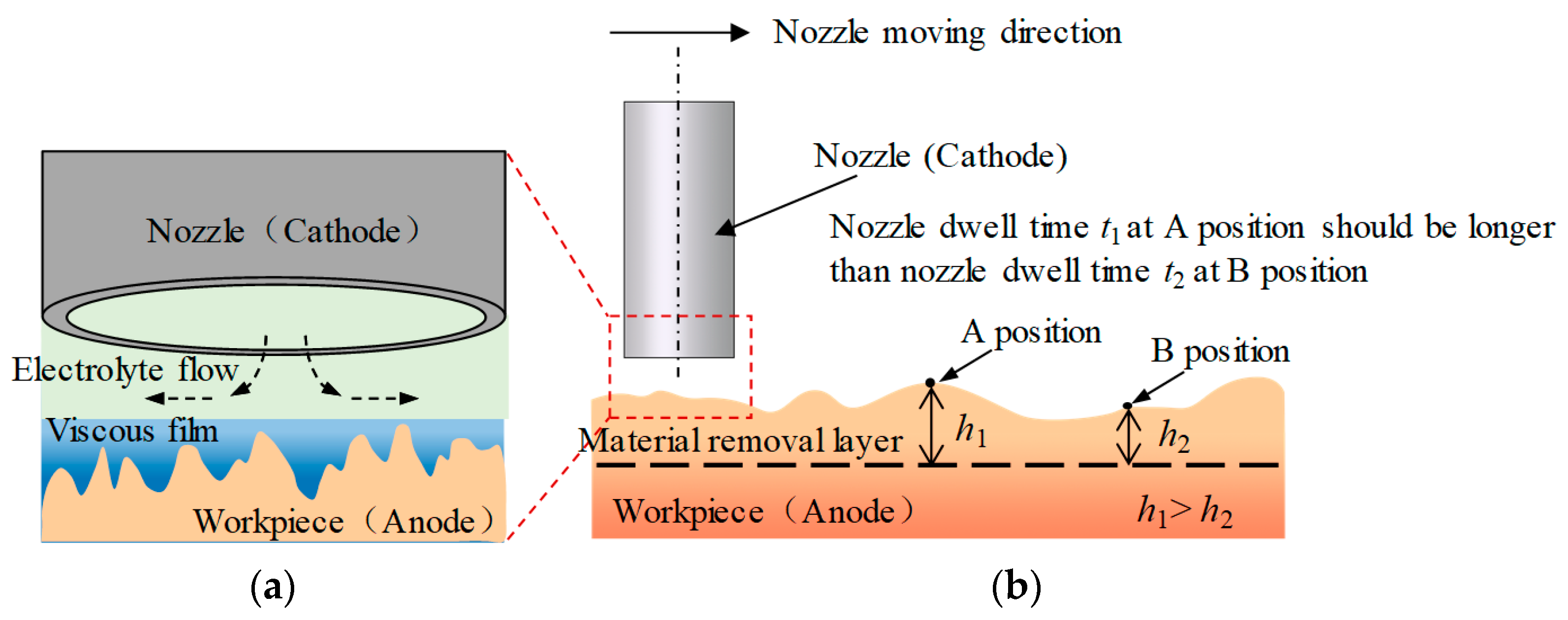

2.2. The Mechanism of Deterministic Polishing Based on Jet-ECM

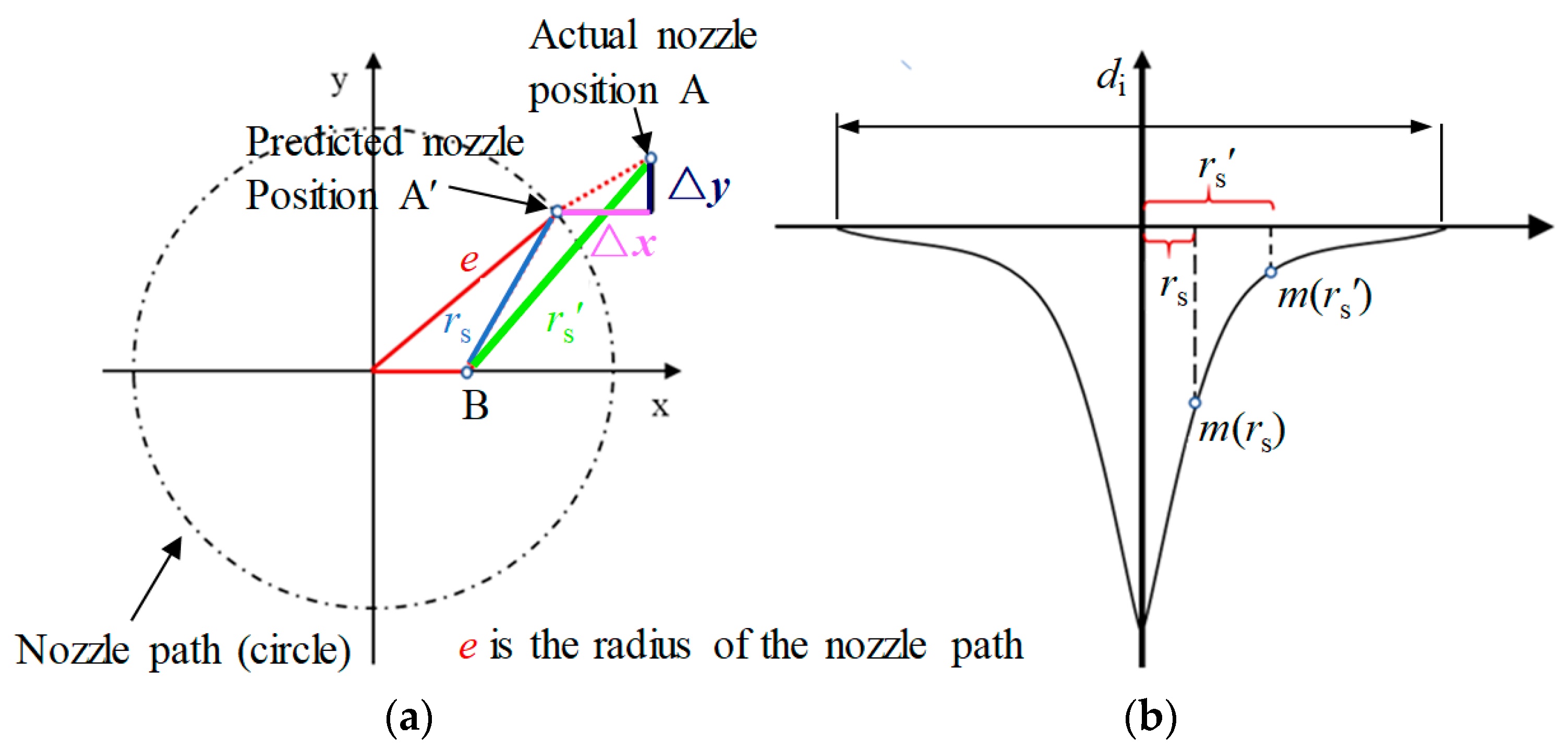

2.3. The Influence of Nozzle Positioning Errors on Deterministic Polishing Based on Jet-ECM

3. Experiments

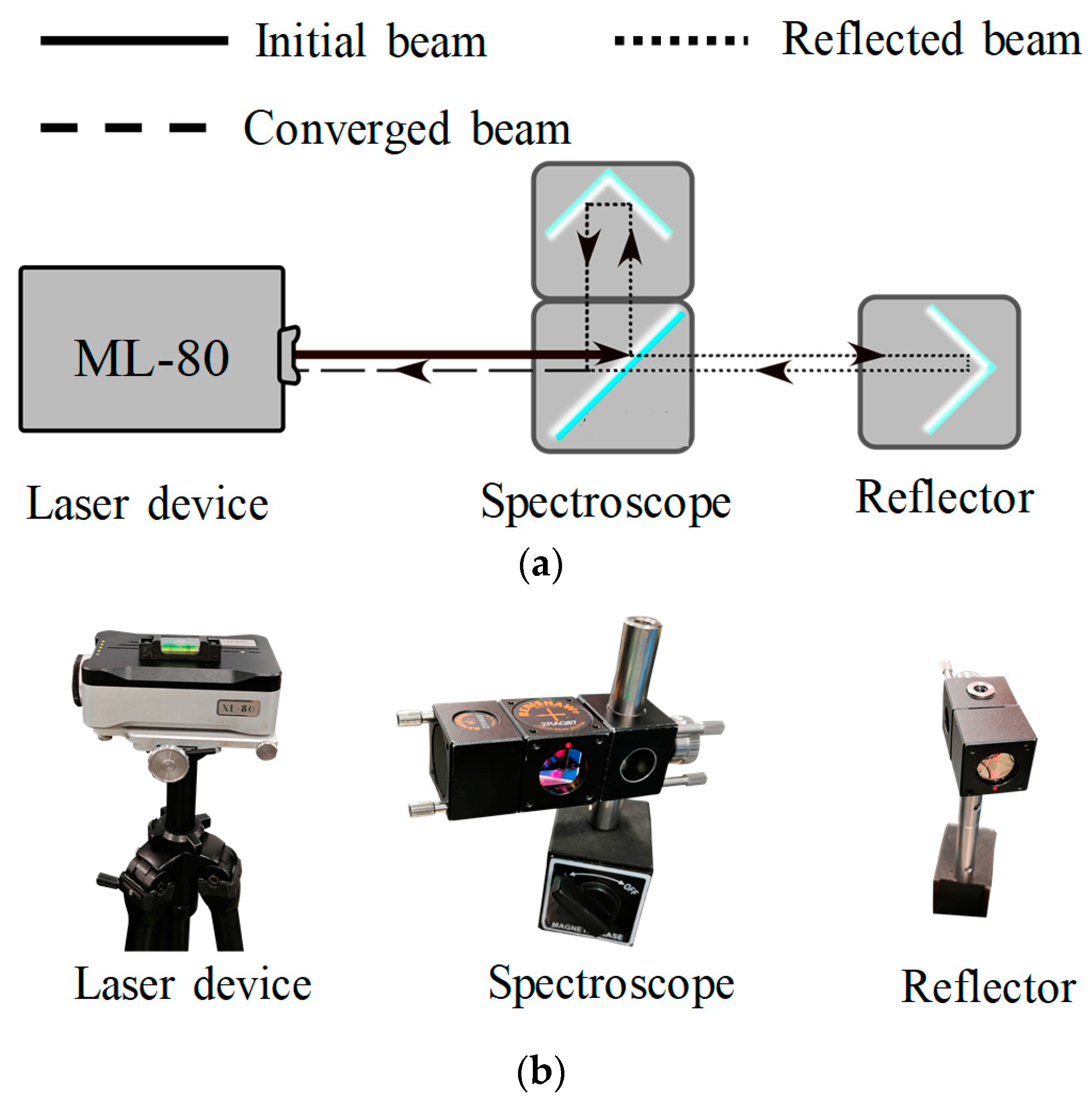

3.1. Experimental Device Design

3.1.1. Mechanical Devices

3.1.2. Motion Control System

3.1.3. Accessory Devices

3.2. Experimental Parameters

4. Results and Discussion

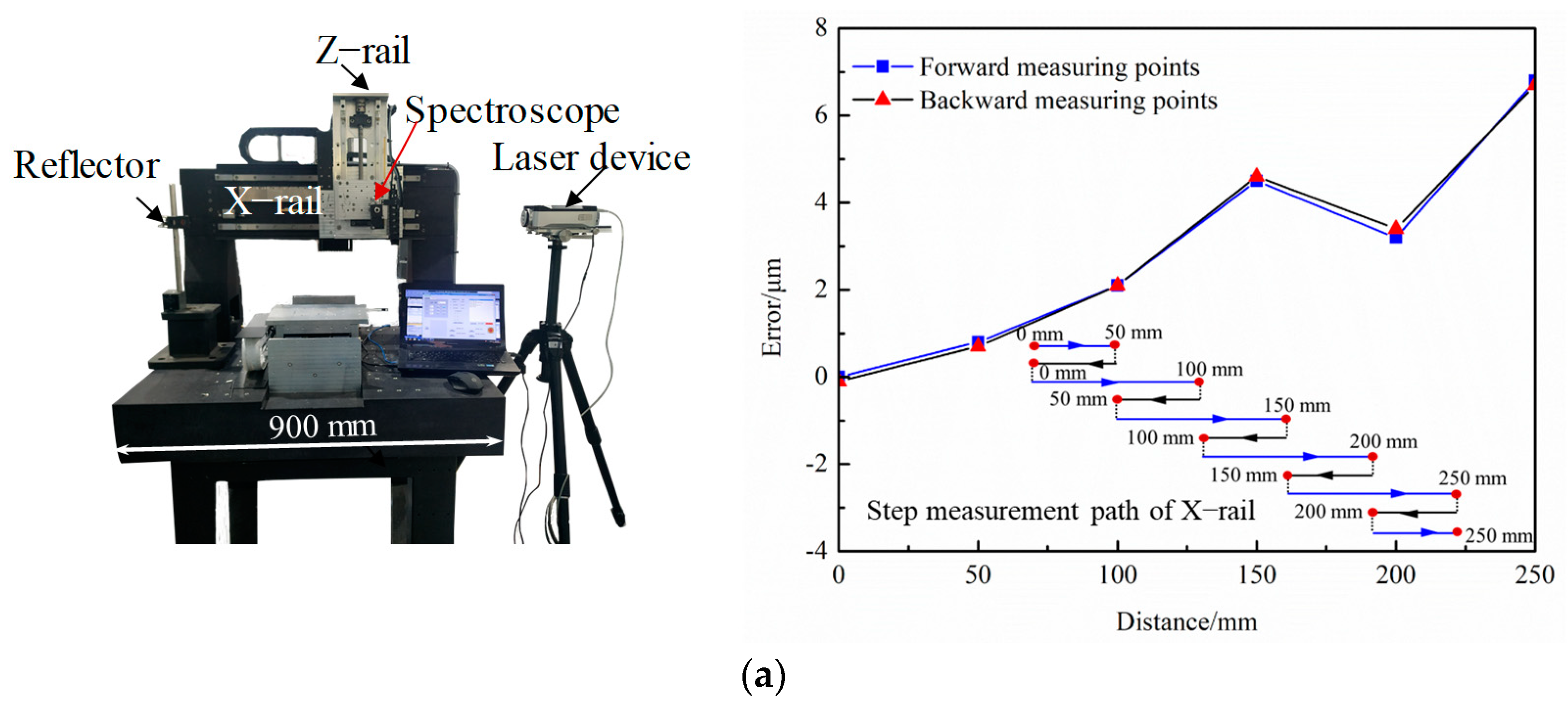

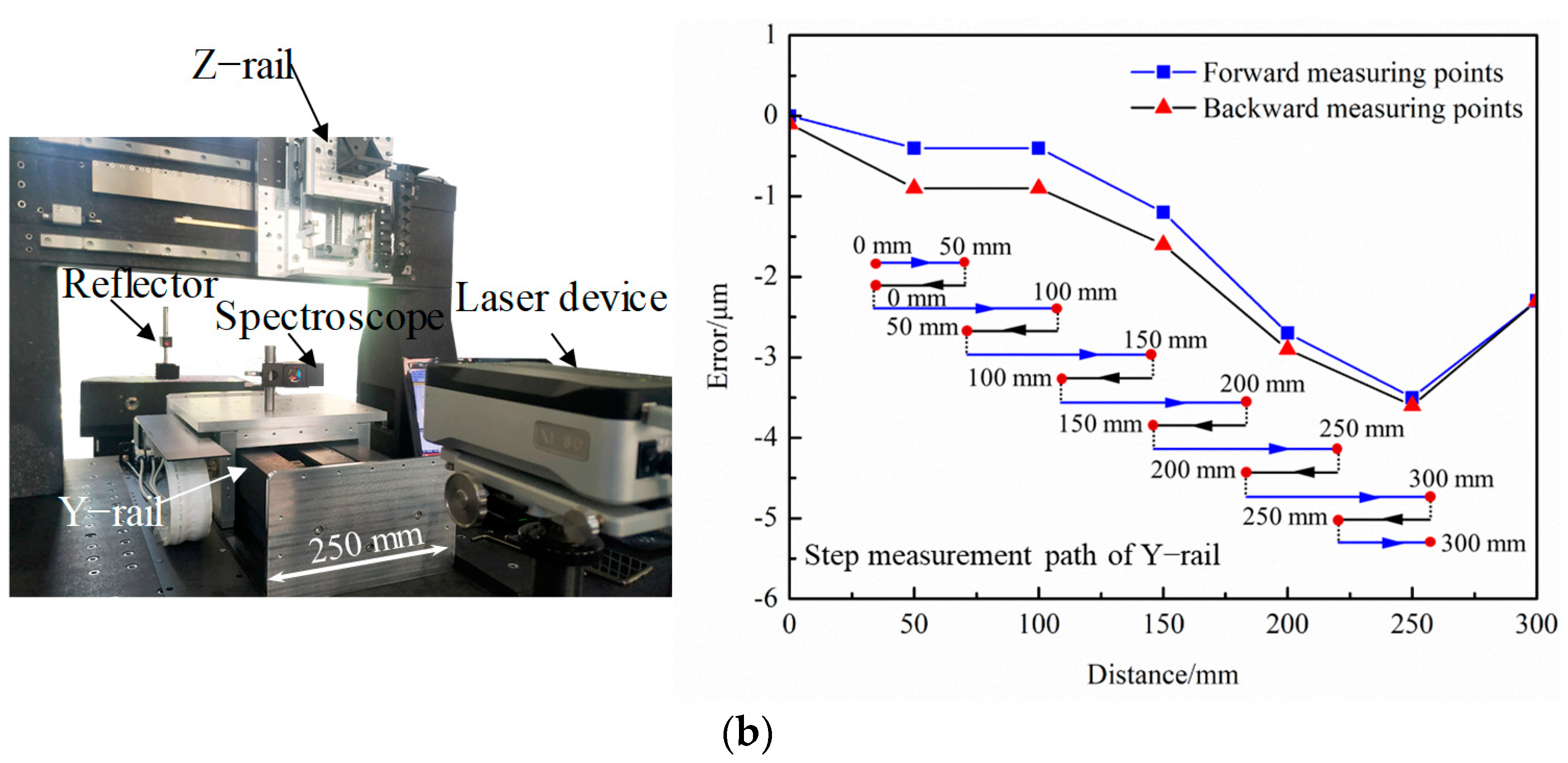

4.1. The Positioning Accuracy of the Assembled Device

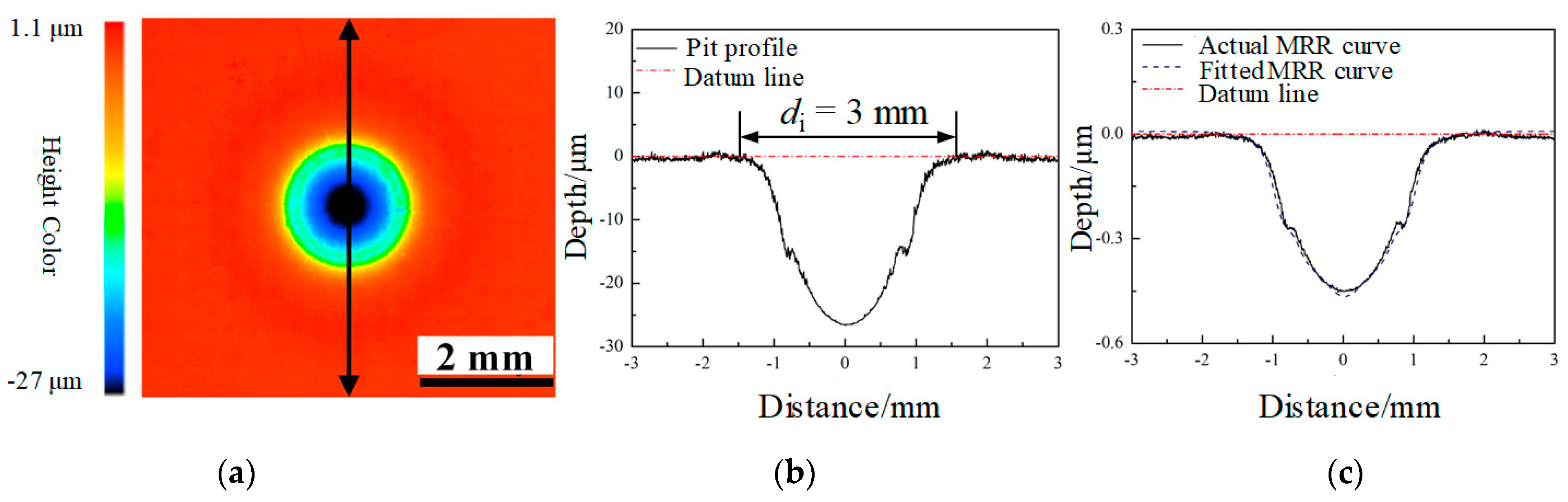

4.2. The MRR Function of Jet-ECM

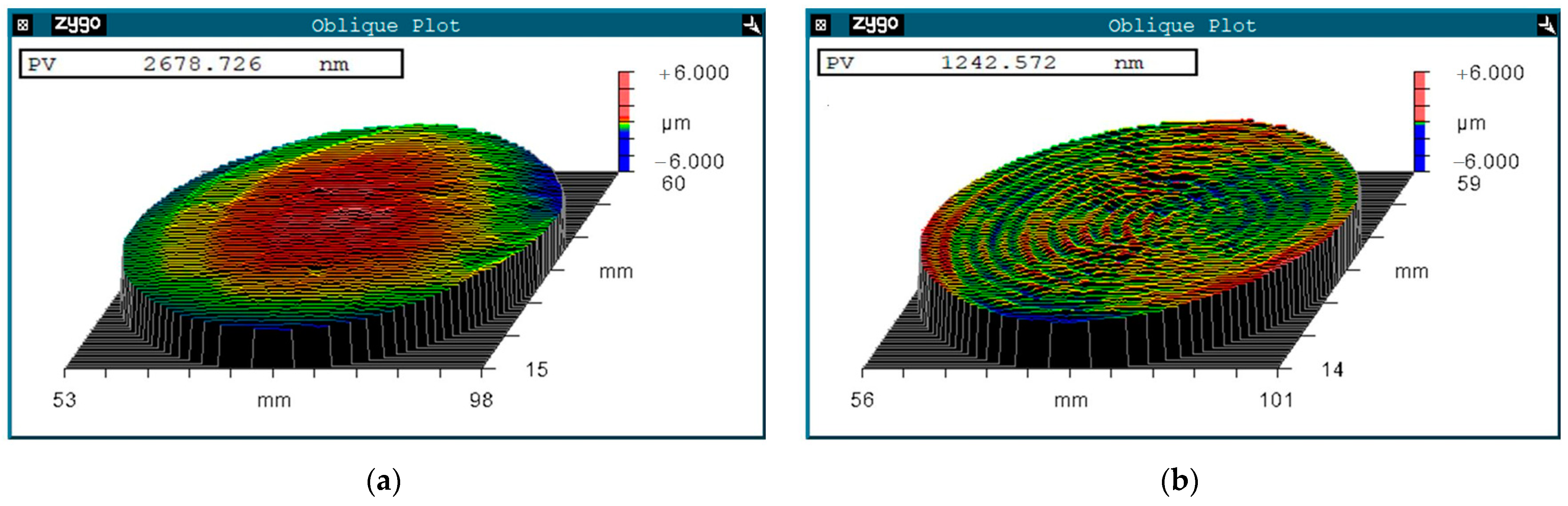

4.3. The Polishing Results of the Stress-Free Deterministic Polishing Based on Jet-ECM

5. Conclusions

- (1)

- The stress-free deterministic polishing based on Jet-ECM combines electrochemical dissolution, nozzle path planning, and nozzle speed control to achieve the flattening of the workpiece. Through this method, the PV value of the surface can be effectively reduced, which indicates that surface shape accuracy was improved. Also, it can provide an important supplement to the deterministic processing.

- (2)

- When the actual nozzle position deviates from the predicted position, the material removal amounts distribution of the workpiece is changed, resulting in machining errors. In Jet-ECM, the MRR is Gaussian-type. It can be concluded from the mathematical model that the requirements of the machine device accuracy are related to the shape of the material removal. The larger the MRR diameter di, the lower the machine device accuracy requirement is needed. As the diameter of the MRR decreases, the requirements for positioning accuracy increase. When the di is 3 mm, the nozzle positioning errors in the X and Y directions are required to be less than 110 μm. Based on the principle of precision distribution, the positioning accuracy of the machine device should be superior to 27 μm, respectively.

- (3)

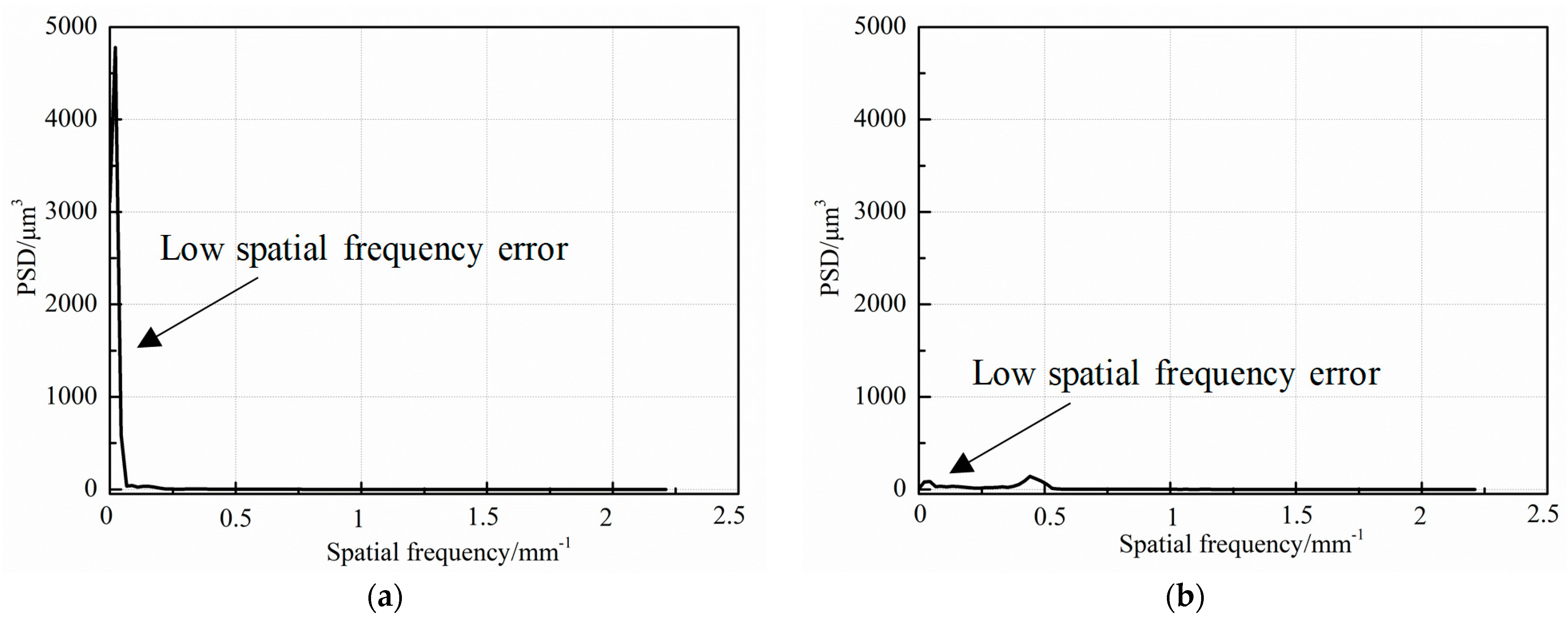

- The specific device for the stress-free deterministic polishing based on Jet-ECM was designed. The positioning errors of the X-rail and Y-rail of the machine device are 6.9 μm and 3.6 μm. The specific device was used for stress-free deterministic polishing based on Jet-ECM. After processing for 34 min, the PV value of the surface was reduced from 2.67 μm to 1.24 μm. According to the PSD analysis, the low frequency spatial errors of the surface height distribution were significantly eliminated after polishing, which means the surface shape accuracy was significantly improved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Explanation |

| rs | The distance between an arbitrary predicted nozzle position A and a random location B on the workpiece surface |

| rs′ | The distance between the actual nozzle position A′ and a random location B on the workpiece surface |

| m(rs) | A mathematical function to describe the line profile of the Jet-ECM MRR |

| Δx | Nozzle positioning error in X direction |

| Δy | Nozzle positioning error in Y direction |

| ε | The deviation between the theoretical MRR and actual MRR |

| kw | The deviation rate |

| d | The eigenvalue of the Gaussian function |

| di | The diameter of the pit machined by Jet-ECM |

| rz | The distance from a random point to the symmetry axis |

| ei | The distance between the nozzle center and the workpiece symmetric center which represents the nozzle revolution radius during the deterministic polishing |

| ωi | Nozzle moving speed during the deterministic polishing |

| ni | Nozzle revolution numbers in ei |

| PV | The surface peak and valley value |

| CMP | Chemical mechanical polishing |

| CCOS | Computer-controlled optical surfacing |

| Jet-ECM | Jet electrochemical machining |

| MRR | The material removal rate |

| PSD | The power spectral density |

References

- Geis, M.W.; Efremow, N.N.; Rathman, D.D. Summary Abstract: Device applications of diamonds. J. Vac. Sci. Technol. A 1988, 6, 1953–1954. [Google Scholar] [CrossRef]

- Holmes, S.; Klugman, A.; Kraatz, P. Copper Mirror Surfaces for High Power Infrared Lasers. Appl. Opt. 1973, 12, 1743–1745. [Google Scholar] [CrossRef] [PubMed]

- Pan, B.; Kang, R.; Guo, J.; Fu, H.; Du, D.; Kong, J. Precision fabrication of thin copper substrate by double-sided lapping and chemical mechanical polishing. J. Manuf. Process. 2019, 44, 47–54. [Google Scholar] [CrossRef]

- Cho, Y.C.; Lee, S.; Ajmal, M.; Kim, W.-K.; Cho, C.R.; Jeong, S.-Y.; Park, J.H.; Park, S.E.; Park, S.; Pak, H.-K.; et al. Copper better than silver: Electrical resistivity of the grain-free single-crystal copper wire. Cryst. Growth Des. 2010, 10, 2780–2784. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, P.; Yan, Y.; Zhang, B.; Kang, R.; Guo, D. Chemical–mechanical wear of monocrystalline silicon by a single pad asperity. Int. J. Mach. Tools Manuf. 2017, 120, 61–71. [Google Scholar] [CrossRef]

- Liu, Z.; Jin, Z.; Wu, D.; Guo, J. Investigation on Material Removal Uniformity in Electrochemical Mechanical Polishing by Polishing Pad with Holes. ECS J. Solid State Sci. Technol. 2019, 8, P3047–P3052. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, S.; Jeong, H. Effect of polishing pad with holes in electro-chemical mechanical planarization. Microelectron. Eng. 2008, 85, 2236–2242. [Google Scholar] [CrossRef]

- Lin, B.; Li, K.L.; Cao, Z.-C.; Huang, T. Modeling of pad surface topography and material removal characteristics for computer-controlled optical surfacing process. J. Mater. Process. Technol. 2019, 265, 210–218. [Google Scholar] [CrossRef]

- Jones, R.A. Computer simulation of smoothing during computer-controlled optical polishing. Appl. Opt. 1995, 34, 1162–1169. [Google Scholar] [CrossRef] [PubMed]

- Schinhaerl, M.; Rascher, R.; Stamp, R.; Smith, L.; Smith, G.; Sperber, P.; Pitschke, E. Utilisation of time-variant influence functions in the computer controlled polishing. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2008, 32, 47–54. [Google Scholar] [CrossRef]

- Raghu, A.; Melkote, S.N. Analysis of the effects of fixture clamping sequence on part location errors. Int. J. Mach. Tools Manuf. 2004, 44, 373–382. [Google Scholar] [CrossRef]

- Ju, K.; Duan, C.Z.; Kong, J.X.; Chen, Y.; Sun, Y.W.; Wu, S.L. Prediction of clamping deformation in vacuum fixture–workpiece system for low-rigidity thin-walled precision parts using finite element method. Int. J. Adv. Manuf. Technol. 2020, 109, 1895–1916. [Google Scholar] [CrossRef]

- Kawanaka, T.; Kunieda, M. Mirror-like finishing by electrolyte jet machining. CIRP Ann.-Manuf. Technol. 2015, 64, 237–240. [Google Scholar] [CrossRef]

- Zhang, X.; Song, X.; Ming, P.; Li, X.; Zeng, Y.; Cai, J. The Effect of Electrolytic Jet Orientation on Machining Characteristics in Jet Electrochemical Machining. Micromachines 2019, 10, 404. [Google Scholar] [CrossRef]

- Natsu, W.; Ikeda, T.; Kunieda, M. Generating complicated surface with electrolyte jet machining. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2007, 31, 33–39. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, N. Obtaining high surface quality in electrolyte jet machining TB6 titanium alloy via enhanced product transport. J. Mater. Process. Technol. 2020, 276, 116381. [Google Scholar] [CrossRef]

- Liu, W.; Luo, Z.; Kunieda, M. Electrolyte jet machining of Ti1023 titanium alloy using NaCl ethylene glycol-based electrolyte. J. Mater. Process. Technol. 2020, 283, 116731. [Google Scholar] [CrossRef]

- Wang, K.; Yan, Y.; Zhou, P.; Zhang, C.; Kang, R.; Guo, D. Preparation of flat and smooth copper surface by jet electrochemical machining and electrochemical polishing. J. Electrochem. Soc. 2020, 167, 163501. [Google Scholar] [CrossRef]

- Zhou, P.; Wang, K.; Yan, Y.; Kang, R.K.; Guo, D.M. Jet Electrochemical Machining device and Method for a High Flatness Metal Surface. China Patent CN201910544025.0, 14 July 2020. (In Chinese). [Google Scholar]

- Liang, F.; Zhao, J.; Ji, S.; Lu, L. Deterministic polishing of freeform optical surface by iterative intersection tool path in an off-axial three-mirror anastigmat imaging system. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 816–826. [Google Scholar] [CrossRef]

- Sun, Z.; Dai, Y.; Hu, H.; Guan, C.; Tie, G.; Chen, X. Design of Compound Machine Tool for Ultra-Precision Shaft Parts. In Proceedings of the 8th Asia Conference on Mechanical and Materials Engineering (ACMME), Singapore, 11–14 June 2020; Volume 319. [Google Scholar] [CrossRef]

- Saxena, K.K.; Qian, J.; Reynaerts, D. Development and investigations on a hybrid tooling concept for coaxial and concurrent application of electrochemical and laser micromachining processes. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2020, 65, 171–184. [Google Scholar] [CrossRef]

- Liu, W.; Kunieda, M.; Luo, Z. Three-dimensional simulation and experimental investigation of electrolyte jet machining with the inclined nozzle. J. Mater. Process. Technol. 2021, 297, 117244. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, P.; Yan, Y.; Zhang, C.; Guo, D.M. The Localization and Roughness Analysis of Jet Electrochemical Machining on Copper Surface. J. Mech. Eng. 2022, 58, 258–266. (In Chinese) [Google Scholar] [CrossRef]

- Mitchell-Smith, J.; Speidel, A.; Clare, A.T. Transitory electrochemical masking for precision jet processing techniques. J. Manuf. Process. 2018, 31, 273–285. [Google Scholar] [CrossRef]

- Kozak, J.; Rajurkar, K.P.; Balkrishna, R. Study of electrochemical jet machining process. J. Manuf. Sci. Eng.-Trans. ASME 1996, 118, 490–498. [Google Scholar] [CrossRef]

- Wu, M.; Liu, J.; He, J.; Chen, X.; Guo, Z. Fabrication of surface microstructures by mask electrolyte jet machining. Int. J. Mach. Tools Manuf. 2020, 148, 103471. [Google Scholar] [CrossRef]

- Xu, M.J. Research on Ion Beam Figuring and Intrinsic Characteristic Evolution of High Power Laser Optics. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2017. (In Chinese). [Google Scholar]

- Feng, Y.; Yan, Y.; Zhou, P.; Guo, D. High precision material removal of copper surface by jet electrochemical machining. In Proceedings of the 3rd International Conference on Material Engineering and Advanced Manufacturing Technology, Shanghai, China, 26–28 April 2019. [Google Scholar] [CrossRef]

- Zhou, L. Study on Theory and Technology in Ion Beam Figuring for Optical Surfaces. Ph.D. Thesis, National University of De-fense Technology, Changsha, China, 2008. (In Chinese). [Google Scholar]

- Takacs, P.Z. Standardization of methods for extracting statistics from surface profile measurements. In Proceedings of the Conference on Instrumentation, Metrology, and Standards for Nanomanufacturing, Optics, and Semiconductors VIII, San Diego, CA, USA, 17–22 August 2014. [Google Scholar] [CrossRef]

| Composition | Value |

|---|---|

| Phosphoric acid/mL | 425 |

| Ethanol/mL | 45 |

| Lactic acid/mL | 30 |

| Benzotriazole/g | 3 |

| Ammonium acetate/g | 1.5 |

| Parameters | Value |

|---|---|

| Voltage/V | 6.5 |

| Frequency/kHz | 10 |

| Duty ratio/% | 50 |

| Gap/mm | 0.6 |

| Electrolyte temperature/°C | 35 |

| Ring Groove Serial Numbers | Revolution Radius ei (mm) | Nozzle Moving Speed ωi (rad/s) | Revolution Numbers ni |

|---|---|---|---|

| 1 | e1 = 1 | 4π/12 | 2 |

| 2 | e2 = 2 | 4π/18 | 2 |

| 3 | e3 = 3 | 4π/35 | 2 |

| 4 | e4 = 4 | 4π/35 | 2 |

| 5 | e5 = 5 | 4π/59 | 2 |

| 6 | e6 = 6 | 4π/47 | 2 |

| 7 | e7 = 7 | 4π/85 | 2 |

| 8 | e8 = 8 | 4π/60 | 2 |

| 9 | e9 = 9 | 4π/105 | 2 |

| 10 | e10 = 10 | 4π/75 | 2 |

| 11 | e11 = 11 | 4π/115 | 2 |

| 12 | e12 = 12 | 4π/90 | 2 |

| 13 | e13 = 13 | 4π/130 | 2 |

| 14 | e14 = 14 | 4π/95 | 2 |

| 15 | e15 = 15 | 4π/140 | 2 |

| 16 | e16 = 16 | 4π/95 | 2 |

| 17 | e17 = 17 | 4π/145 | 2 |

| 18 | e18 = 18 | 4π/100 | 2 |

| 19 | e19 = 19 | 4π/140 | 2 |

| 20 | e20 = 20 | 4π/85 | 2 |

| 21 | e21 = 21 | 4π/135 | 2 |

| 22 | e22 = 22 | 4π/80 | 2 |

| 23 | e23 = 23 | 4π/120 | 2 |

| 24 | e24 = 24 | 4π/45 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Wang, H.; Zhang, Y.; Shi, H.; Shi, J. The Development of the Stress-Free Polishing System Based on the Positioning Error Analysis for the Deterministic Polishing of Jet Electrochemical Machining. Micromachines 2024, 15, 393. https://doi.org/10.3390/mi15030393

Wang K, Wang H, Zhang Y, Shi H, Shi J. The Development of the Stress-Free Polishing System Based on the Positioning Error Analysis for the Deterministic Polishing of Jet Electrochemical Machining. Micromachines. 2024; 15(3):393. https://doi.org/10.3390/mi15030393

Chicago/Turabian StyleWang, Ke, Hongding Wang, Yanlong Zhang, Huirong Shi, and Jiahao Shi. 2024. "The Development of the Stress-Free Polishing System Based on the Positioning Error Analysis for the Deterministic Polishing of Jet Electrochemical Machining" Micromachines 15, no. 3: 393. https://doi.org/10.3390/mi15030393

APA StyleWang, K., Wang, H., Zhang, Y., Shi, H., & Shi, J. (2024). The Development of the Stress-Free Polishing System Based on the Positioning Error Analysis for the Deterministic Polishing of Jet Electrochemical Machining. Micromachines, 15(3), 393. https://doi.org/10.3390/mi15030393