Machine Learning Classification of Self-Organized Surface Structures in Ultrashort-Pulse Laser Processing Based on Light Microscopic Images

Abstract

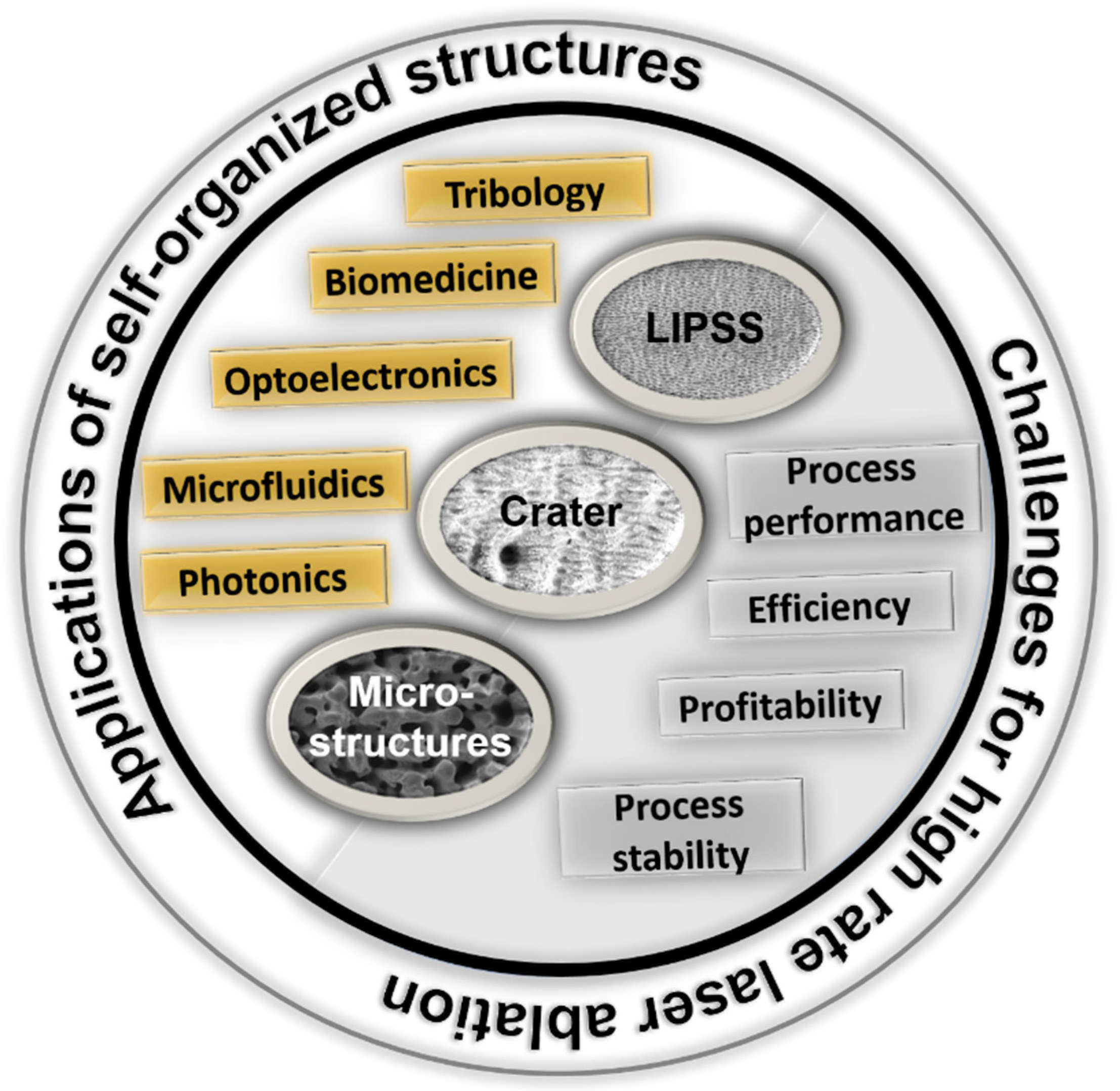

:1. Introduction

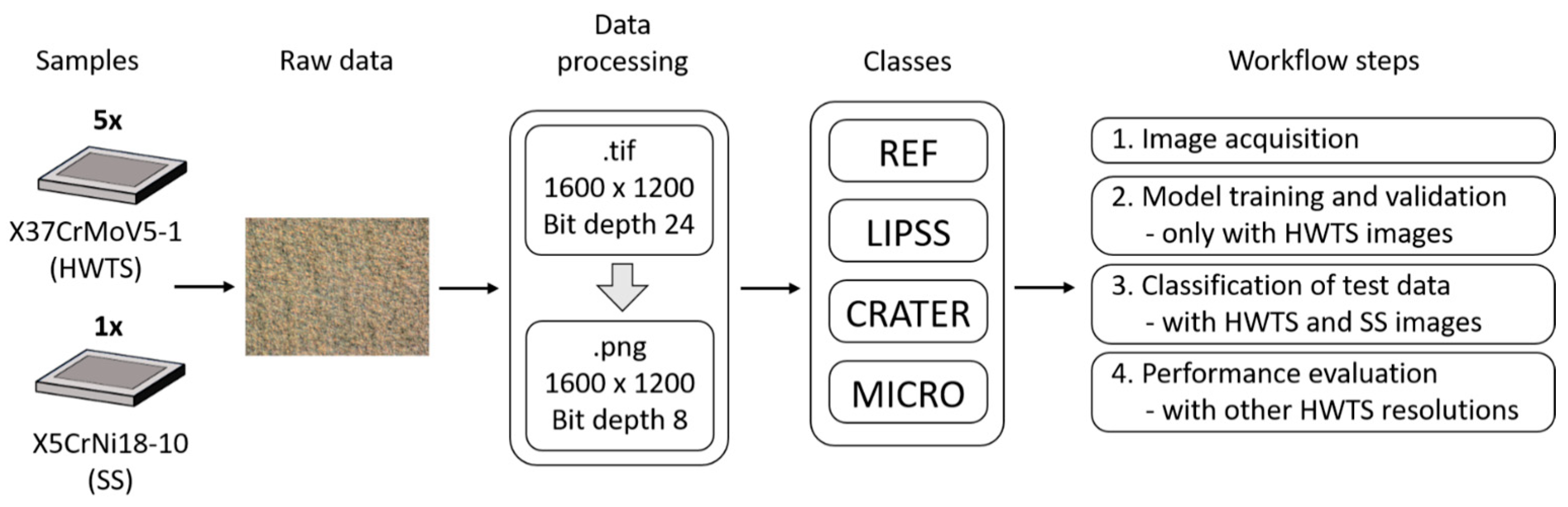

2. Materials and Methods

2.1. Preparation Samples

2.2. Laser Treatment

2.3. Machine Learning for Image Recognition and Data Classification

2.3.1. Microscopy, Data Generation, and Data Preprocessing

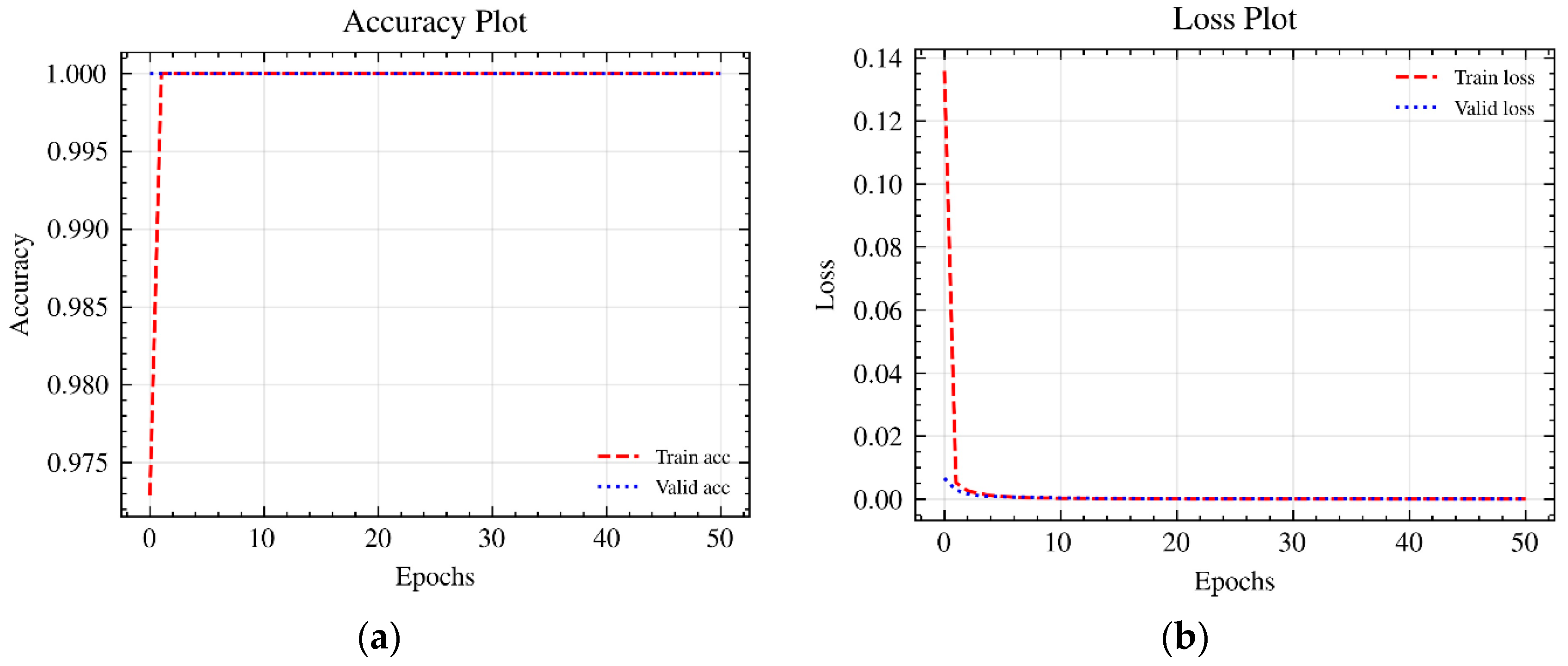

2.3.2. Machine Learning Development and Hyperparameter Tuning

- Epochs: This specifies how many times each individual image in the training dataset is input to the ML model at least once [46] (i.e., for epochs = 50, the ML model goes through the entire training dataset 50 times during training). More epochs generally allow for better prediction accuracy but increase the risk of overfitting the ML model to the training data [45,46].

- Batch size: This is the size of a set of images used for a training iteration [46] (i.e., for a batch size of 16 and a training dataset of 160 images, the data are divided into 160/16 = 10 batches and entered into the model). Once all stacks are entered, an epoch is completed.

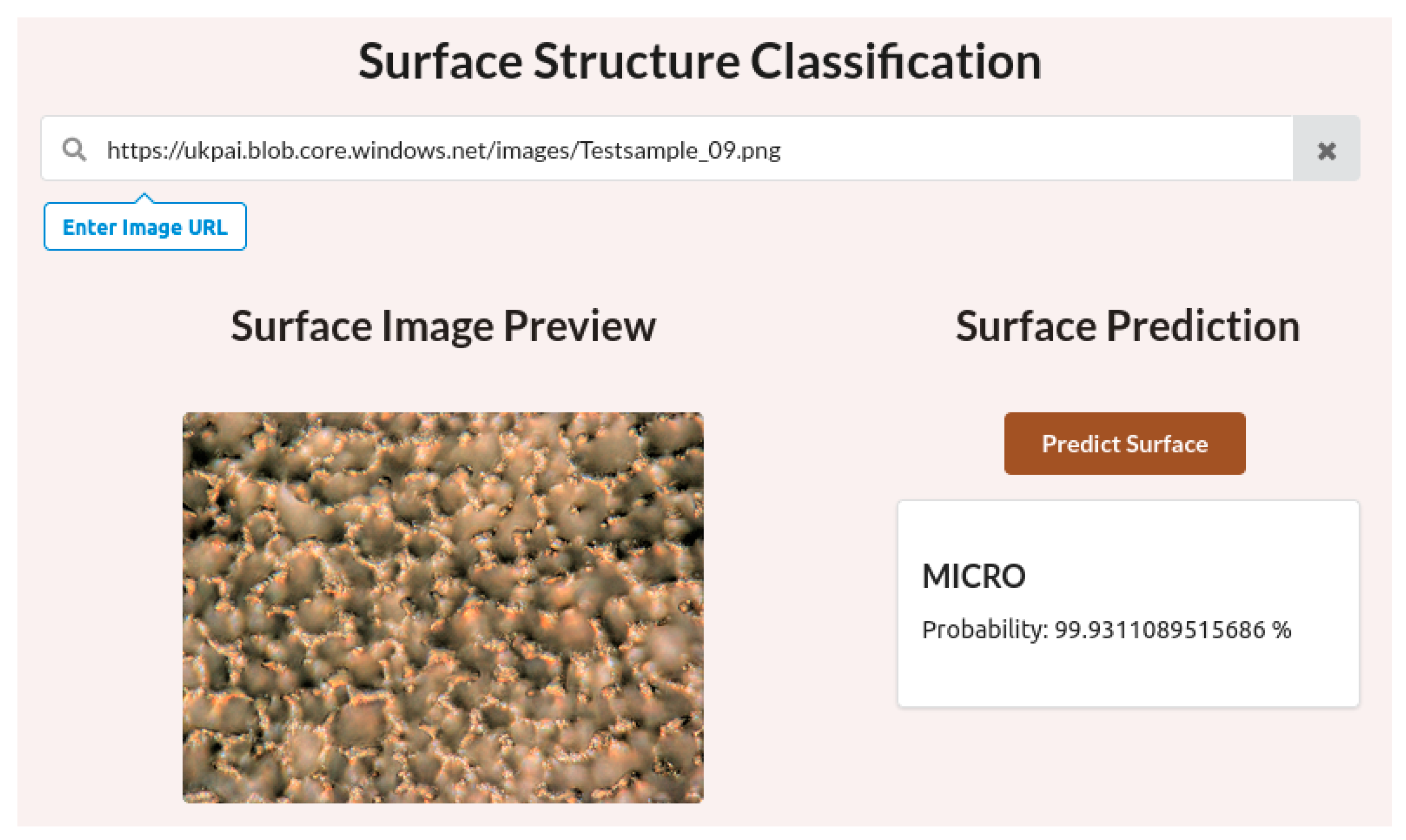

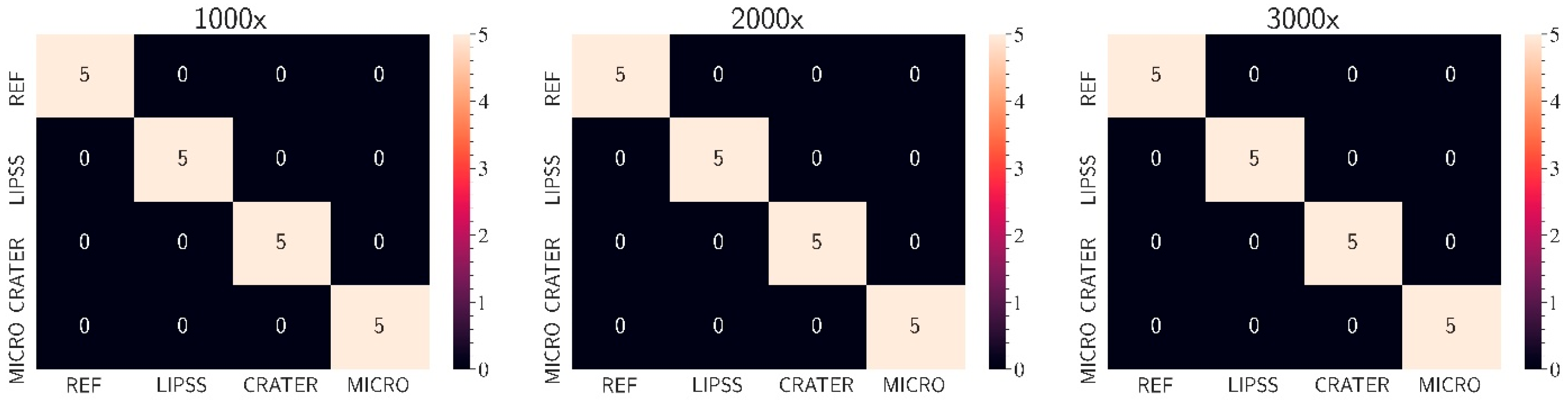

2.4. Application Development and Performance Evaluation

3. Results and Discussion

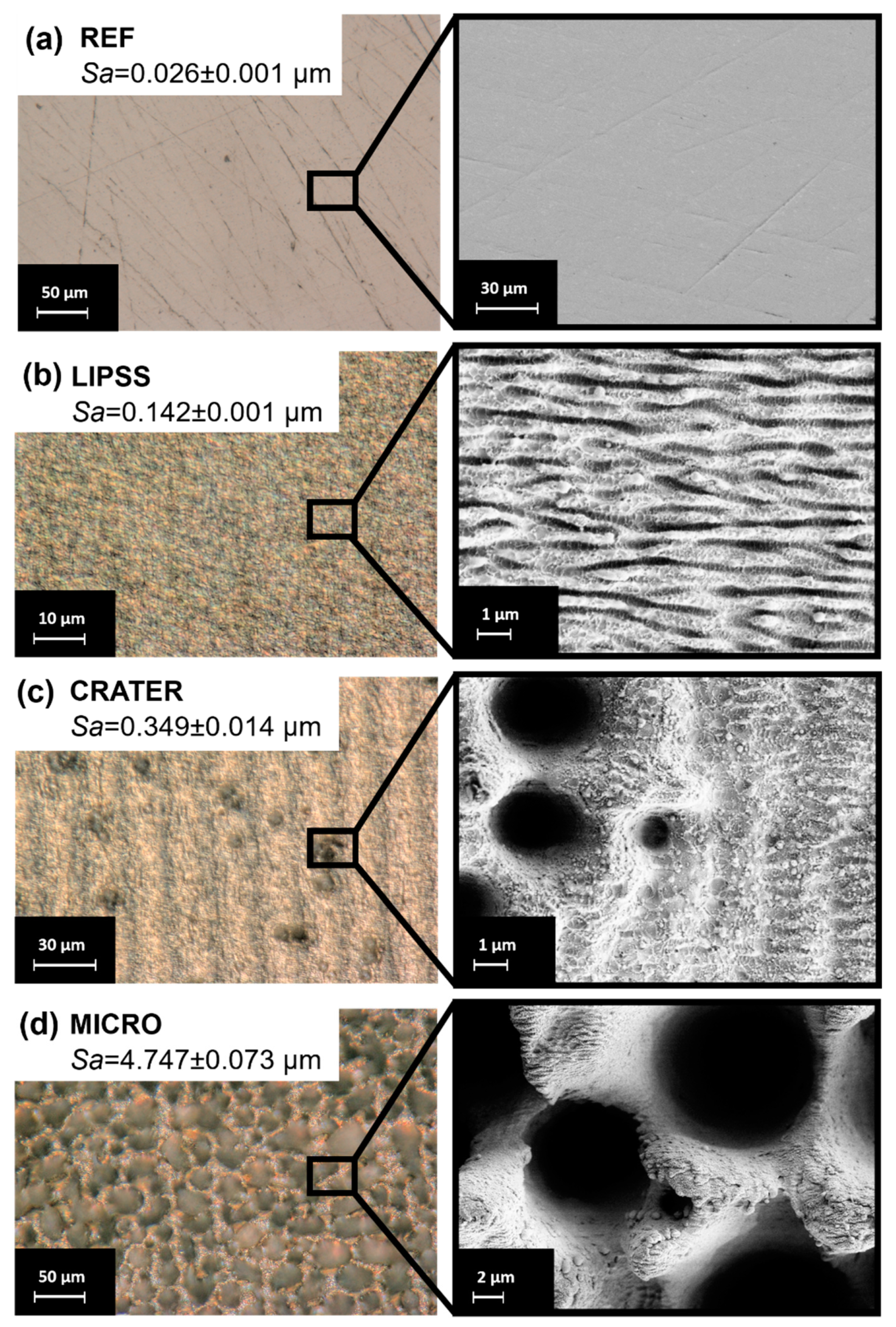

3.1. Surface Structure Types

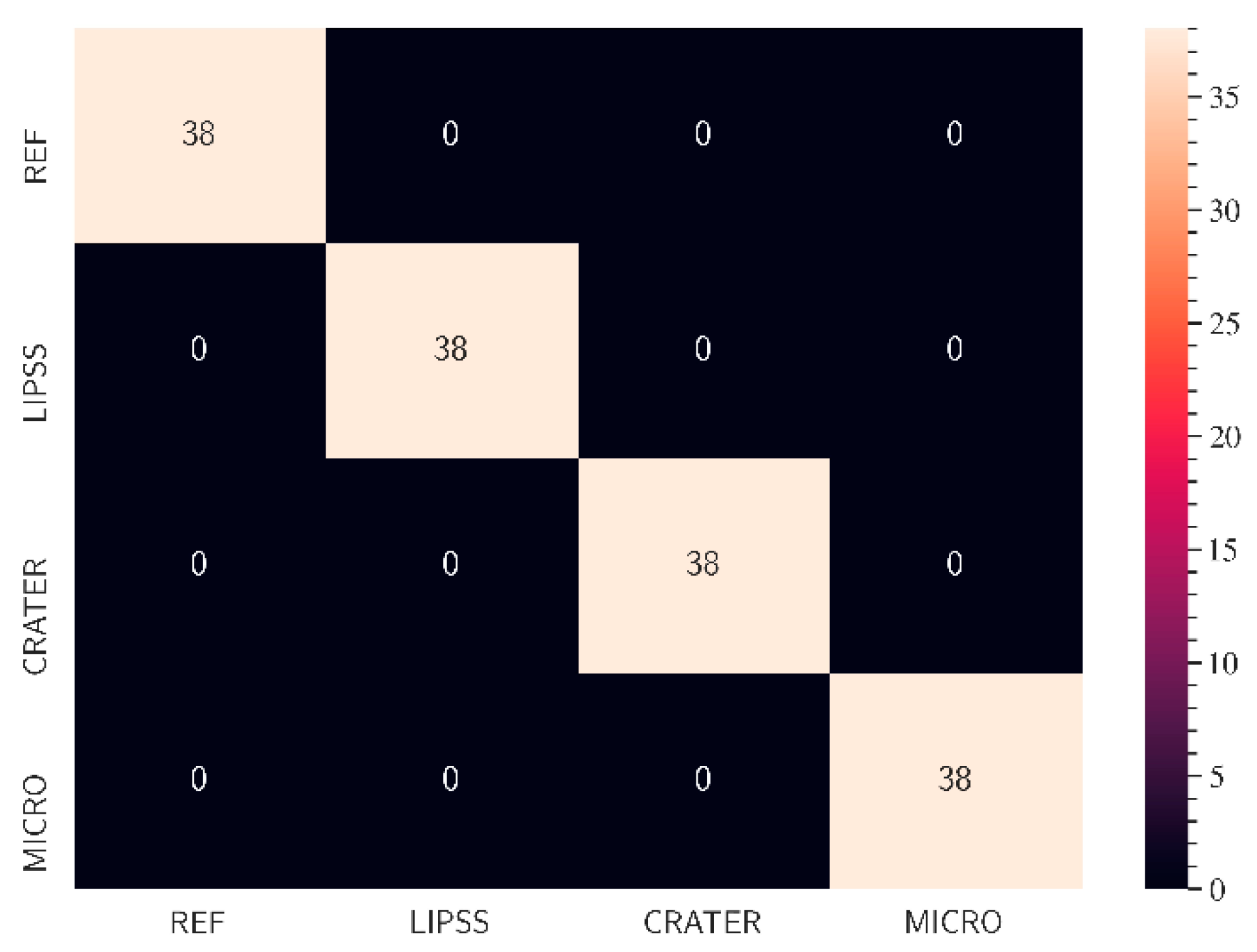

3.2. Machine Learning Model Implementation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Weber, R.; Graf, T. The challenges of productive materials processing with ultrafast lasers. Adv. Opt. Technol. 2021, 10, 239–245. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast lasers—Reliable tools for advanced materials processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Schnell, G.; Lund, H.; Bartling, S.; Polley, C.; Riaz, A.; Senz, V.; Springer, A.; Seitz, H. Heat accumulation during femtosecond laser treatment at high repetition rate—A morphological, chemical and crystallographic characterization of self-organized structures on Ti6Al4V. Appl. Surf. Sci. 2021, 570, 151115. [Google Scholar] [CrossRef]

- Faisal, N.; Zindani, D.; Kumar, K.; Bhowmik, S. Laser Micromachining of Engineering Materials—A Review. In Micro and Nano Machining of Engineering Materials; Kumar, K., Zindani, D., Kumari, N., Davim, J.P., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 121–136. ISBN 978-3-319-99899-2. [Google Scholar]

- Gattass, R.R.; Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photonics 2008, 2, 219–225. [Google Scholar] [CrossRef]

- Anisimov, S.I.; Luk’yanchuk, B.S. Selected problems of laser ablation theory. Phys. Usp. 2002, 45, 293–324. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Rode, A.V.; Luther-Davies, B.; Tikhonchuk, V.T. Ablation of solids by femtosecond lasers: Ablation mechanism and ablation thresholds for metals and dielectrics. Phys. Plasmas 2002, 9, 949–957. [Google Scholar] [CrossRef]

- Rethfeld, B.; Sokolowski-Tinten, K.; von der Linde, D.; Anisimov, S.I. Timescales in the response of materials to femtosecond laser excitation. Appl. Phys. A Mater. Sci. Process. 2004, 79, 767–769. [Google Scholar] [CrossRef]

- Zhigilei, L.V.; Lin, Z.; Ivanov, D.S. Atomistic Modeling of Short Pulse Laser Ablation of Metals: Connections between Melting, Spallation, and Phase Explosion. J. Phys. Chem. C 2009, 113, 11892–11906. [Google Scholar] [CrossRef]

- Povarnitsyn, M.E.; Itina, T.E.; Sentis, M.; Khishchenko, K.V.; Levashov, P.R. Material decomposition mechanisms in femtosecond laser interactions with metals. Phys. Rev. B 2007, 75, 235414. [Google Scholar] [CrossRef]

- Upadhyay, A.K.; Inogamov, N.A.; Rethfeld, B.; Urbassek, H.M. Ablation by ultrashort laser pulses: Atomistic and thermodynamic analysis of the processes at the ablation threshold. Phys. Rev. B 2008, 78, 045437. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev. 2013, 7, 385–407. [Google Scholar] [CrossRef]

- Jaeggi, B.; Remund, S.; Streubel, R.; Goekce, B.; Barcikowski, S.; Neuenschwander, B. Laser Micromachining of Metals with Ultra-Short Pulses: Factors Limiting the Scale-Up Process. JLMN 2017, 12, 267–273. [Google Scholar]

- Bonse, J.; Kirner, S.V.; Krüger, J. Laser-Induced Periodic Surface Structures (LIPSS). In Handbook of Laser Micro- and Nano-Engineering; Sugioka, K., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–59. ISBN 978-3-319-69537-2. [Google Scholar]

- Schnell, G.; Duenow, U.; Seitz, H. Effect of Laser Pulse Overlap and Scanning Line Overlap on Femtosecond Laser-Structured Ti6Al4V Surfaces. Materials 2020, 13, 969. [Google Scholar] [CrossRef]

- JJ Nivas, J.; Allahyari, E.; Gesuele, F.; Maddalena, P.; Fittipaldi, R.; Vecchione, A.; Bruzzese, R.; Amoruso, S. Influence of ambient pressure on surface structures generated by ultrashort laser pulse irradiation. Appl. Phys. A Mater. Sci. Process. 2018, 124, 198. [Google Scholar] [CrossRef]

- Fuentes-Edfuf, Y.; Sánchez-Gil, J.A.; Garcia-Pardo, M.; Serna, R.; Tsibidis, G.D.; Giannini, V.; Solis, J.; Siegel, J. Tuning the period of femtosecond laser induced surface structures in steel: From angled incidence to quill writing. Appl. Surf. Sci. 2019, 493, 948–955. [Google Scholar] [CrossRef]

- Bonse, J.; Koter, R.; Hartelt, M.; Spaltmann, D.; Pentzien, S.; Höhm, S.; Rosenfeld, A.; Krüger, J. Tribological performance of femtosecond laser-induced periodic surface structures on titanium and a high toughness bearing steel. Appl. Surf. Sci. 2015, 336, 21–27. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Enhanced absorptance of gold following multipulse femtosecond laser ablation. Phys. Rev. B 2005, 72, 195422. [Google Scholar] [CrossRef]

- Iyengar, V.V.; Nayak, B.K.; Gupta, M.C. Ultralow reflectance metal surfaces by ultrafast laser texturing. Appl. Opt. 2010, 49, 5983. [Google Scholar] [CrossRef]

- Paivasaari, K.; Kaakkunen, J.J.J.; Kuittinen, M.; Jaaskelainen, T. Enhanced optical absorptance of metals using interferometric femtosecond ablation. Opt. Express 2007, 15, 13838–13843. [Google Scholar] [CrossRef]

- Kaakkunen, J.J.J.; Paivasaari, K.; Kuittinen, M.; Jaaskelainen, T. Morphology studies of the metal surfaces with enhanced absorption fabricated using interferometric femtosecond ablation. Appl. Phys. A Mater. Sci. Process. 2009, 94, 215–220. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, J.; Liang, C.; Wang, H. Ultra-broadband enhanced absorption of metal surfaces structured by femtosecond laser pulses. Opt. Express 2008, 16, 11259–11265. [Google Scholar] [CrossRef]

- Zuhlke, C.A.; Alexander, D.R.; Bruce, J.C.; Ianno, N.J.; Kamler, C.A.; Yang, W. Self assembled nanoparticle aggregates from line focused femtosecond laser ablation. Opt. Express 2010, 18, 4329–4339. [Google Scholar] [CrossRef] [PubMed]

- Carey, J.E.; Crouch, C.H.; Shen, M.; Mazur, E. Visible and near-infrared responsivity of femtosecond-laser microstructured silicon photodiodes. Opt. Lett. 2005, 30, 1773–1775. [Google Scholar] [CrossRef]

- Huang, Z.; Carey, J.E.; Liu, M.; Guo, X.; Mazur, E.; Campbell, J.C. Microstructured silicon photodetector. Appl. Phys. Lett. 2006, 89, 033506. [Google Scholar] [CrossRef]

- Sanz, M.; Rebollar, E.; Ganeev, R.A.; Castillejo, M. Nanosecond laser-induced periodic surface structures on wide band-gap semiconductors. Appl. Surf. Sci. 2013, 278, 325–329. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Colorizing metals with femtosecond laser pulses. Appl. Phys. Lett. 2008, 92, 041914. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Spectral and polarization responses of femtosecond laser-induced periodic surface structures on metals. J. Appl. Phys. 2008, 103, 043513. [Google Scholar] [CrossRef]

- Fadeeva, E.; Schlie, S.; Koch, J.; Chichkov, B.N. Selective Cell Control by Surface Structuring for Orthopedic Applications. J. Adhes. Sci. Technol. 2010, 24, 2257–2270. [Google Scholar] [CrossRef]

- Stratakis, E.; Ranella, A.; Fotakis, C. Biomimetic micro/nanostructured functional surfaces for microfluidic and tissue engineering applications. Biomicrofluidics 2011, 5, 13411. [Google Scholar] [CrossRef]

- Papadopoulou, E.L.; Samara, A.; Barberoglou, M.; Manousaki, A.; Pagakis, S.N.; Anastasiadou, E.; Fotakis, C.; Stratakis, E. Silicon scaffolds promoting three-dimensional neuronal web of cytoplasmic processes. Tissue Eng. Part C Methods 2010, 16, 497–502. [Google Scholar] [CrossRef] [PubMed]

- Ranella, A.; Barberoglou, M.; Bakogianni, S.; Fotakis, C.; Stratakis, E. Tuning cell adhesion by controlling the roughness and wettability of 3D micro/nano silicon structures. Acta Biomater. 2010, 6, 2711–2720. [Google Scholar] [CrossRef]

- Schnell, G.; Staehlke, S.; Duenow, U.; Nebe, J.B.; Seitz, H. Femtosecond Laser Nano/Micro Textured Ti6Al4V Surfaces-Effect on Wetting and MG-63 Cell Adhesion. Materials 2019, 12, 2210. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, J.; Liang, C.; Wang, H.; Zhu, X.; Zhang, N. Surface microstructuring of Ti plates by femtosecond lasers in liquid ambiences: A new approach to improving biocompatibility. Opt. Express 2009, 17, 21124–21133. [Google Scholar] [CrossRef]

- Bonse, J.; Gräf, S. Ten Open Questions about Laser-Induced Periodic Surface Structures. Nanomaterials 2021, 11, 3326. [Google Scholar] [CrossRef]

- Xie, Y.; Heath, D.J.; Grant-Jacob, J.A.; Mackay, B.S.; McDonnell, M.D.T.; Praeger, M.; Eason, R.W.; Mills, B. Deep learning for the monitoring and process control of femtosecond laser machining. J. Phys. Photonics 2019, 1, 35002. [Google Scholar] [CrossRef]

- Mills, B.; Heath, D.J.; Grant-Jacob, J.A.; Xie, Y.; Eason, R.W. Image-based monitoring of femtosecond laser machining via a neural network. J. Phys. Photonics 2019, 1, 15008. [Google Scholar] [CrossRef]

- Na, H.; Yoo, J.; Ki, H. Prediction of surface morphology and reflection spectrum of laser-induced periodic surface structures using deep learning. J. Manuf. Process. 2022, 84, 1274–1283. [Google Scholar] [CrossRef]

- Wang, B.; Wang, P.; Song, J.; Lam, Y.C.; Song, H.; Wang, Y.; Liu, S. A hybrid machine learning approach to determine the optimal processing window in femtosecond laser-induced periodic nanostructures. J. Mater. Process. Technol. 2022, 308, 117716. [Google Scholar] [CrossRef]

- DIN—Deutsches Institut für Normung e. V. DIN EN ISO 4957:2018-11: Werkzeugstähle; Beuth Verlag GmbH: Berlin, Germany, 2018. [Google Scholar]

- DIN—Deutsches Institut für Normung e. V. DIN EN 10088-2:2014-12: Nichtrostende Stähle—Teil 2: Technische Lieferbedingungen für Blech und Band aus Korrosionsbeständigen Stählen für Allgemeine Verwendung; Beuth Verlag GmbH: Berlin, Germany, 2024. [Google Scholar]

- DIN—Deutsches Institut für Normung e. V. DIN EN 10088-3:2024-04: Nichtrostende Stähle—Teil 3: Technische Lieferbedingungen für Halbzeug, Stäbe, Walzdraht, Gezogenen Draht, Profile und Blankstahlerzeugnisse aus Korrosionsbeständigen Stählen für Allgemeine Verwendung; Beuth Verlag GmbH: Berlin, Germany, 2024. [Google Scholar]

- Carney, M.; Webster, B.; Alvarado, I.; Phillips, K.; Howell, N.; Griffith, J.; Jongejan, J.; Pitaru, A.; Chen, A. Teachable Machine: Approachable Web-Based Tool for Exploring Machine Learning Classification. In Extended Abstracts of the 2020 CHI Conference on Human Factors in Computing Systems, Proceedings of the CHI’20: CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 25–30 April 2020; Bernhaupt, R., Mueller, F., Verweij, D., Andres, J., McGrenere, J., Cockburn, A., Avellino, I., Goguey, A., Bjørn, P., Zhao, S., et al., Eds.; ACM: New York, NY, USA, 2020; pp. 1–8. ISBN 9781450368193. [Google Scholar]

- Hutter, F.; Kotthoff, L.; Vanschoren, J. Automated Machine Learning; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-05317-8. [Google Scholar]

- Teachable Machine. Available online: https://teachablemachine.withgoogle.com/ (accessed on 21 September 2023).

- Rashid, T. Make Your Own Neural Network; CreateSpace Independent Publishing Platform S.l.: North Charleston, SC, USA, 2016; ISBN 978-1530826605. [Google Scholar]

- Johnson, J.M.; Khoshgoftaar, T.M. Survey on deep learning with class imbalance. J. Big Data 2019, 6, 27. [Google Scholar] [CrossRef]

- Grandini, M.; Bagli, E.; Visani, G. Metrics for Multi-Class Classification: An Overview. arXiv 2020, arXiv:2008.05756. [Google Scholar]

- Team, K. Keras: Deep Learning for Humans. Available online: https://keras.io/ (accessed on 21 September 2023).

- Westphal, E.; Seitz, H. A machine learning method for defect detection and visualization in selective laser sintering based on convolutional neural networks. Addit. Manuf. 2021, 41, 101965. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Griepentrog, M.; Spaltmann, D.; Krüger, J. Femtosecond Laser Texturing of Surfaces for Tribological Applications. Materials 2018, 11, 801. [Google Scholar] [CrossRef]

- Heitz, J.; Arenholz, E.; Buerle, D.; Sauerbrey, R.; Phillips, H.M. Femtosecond excimer-laser-induced structure formation on polymers. Appl. Phys. A 1994, 59, 289–293. [Google Scholar] [CrossRef]

- Zuhlke, C.A.; Anderson, T.P.; Alexander, D.R. Formation of multiscale surface structures on nickel via above surface growth and below surface growth mechanisms using femtosecond laser pulses. Opt. Express 2013, 21, 8460–8473. [Google Scholar] [CrossRef]

- Mannion, P.; Magee, J.; Coyne, E.; O’Connor, G.; Glynn, T. The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 2004, 233, 275–287. [Google Scholar] [CrossRef]

- Selvaraju, R.R.; Cogswell, M.; Das, A.; Vedantam, R.; Parikh, D.; Batra, D. Grad-CAM: Visual Explanations from Deep Networks via Gradient-Based Localization. Int. J. Comput. Vis. 2020, 128, 336–359. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. arXiv 2015, arXiv:1506.02640. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLO9000: Better, Faster, Stronger. arXiv 2016, arXiv:1612.08242. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLOv3: An Incremental Improvement. arXiv 2018, arXiv:1804.02767. [Google Scholar]

| Predicted Class | ||||||

| Classes | REF | LIPSS | CRATER | MICRO | total | |

| True Class | REF | TP | TN | TN | TN | FN |

| LIPSS | TN | TP | TN | TN | FN | |

| CRATER | TN | TN | TP | TN | FN | |

| MICRO | TN | TN | TN | TP | FN | |

| total | FP | FP | FP | FP | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thomas, R.; Westphal, E.; Schnell, G.; Seitz, H. Machine Learning Classification of Self-Organized Surface Structures in Ultrashort-Pulse Laser Processing Based on Light Microscopic Images. Micromachines 2024, 15, 491. https://doi.org/10.3390/mi15040491

Thomas R, Westphal E, Schnell G, Seitz H. Machine Learning Classification of Self-Organized Surface Structures in Ultrashort-Pulse Laser Processing Based on Light Microscopic Images. Micromachines. 2024; 15(4):491. https://doi.org/10.3390/mi15040491

Chicago/Turabian StyleThomas, Robert, Erik Westphal, Georg Schnell, and Hermann Seitz. 2024. "Machine Learning Classification of Self-Organized Surface Structures in Ultrashort-Pulse Laser Processing Based on Light Microscopic Images" Micromachines 15, no. 4: 491. https://doi.org/10.3390/mi15040491

APA StyleThomas, R., Westphal, E., Schnell, G., & Seitz, H. (2024). Machine Learning Classification of Self-Organized Surface Structures in Ultrashort-Pulse Laser Processing Based on Light Microscopic Images. Micromachines, 15(4), 491. https://doi.org/10.3390/mi15040491