Enhancing the Carrier Mobility and Bias Stability in Metal–Oxide Thin Film Transistors with Bilayer InSnO/a-InGaZnO Heterojunction Structure

Abstract

:1. Introduction

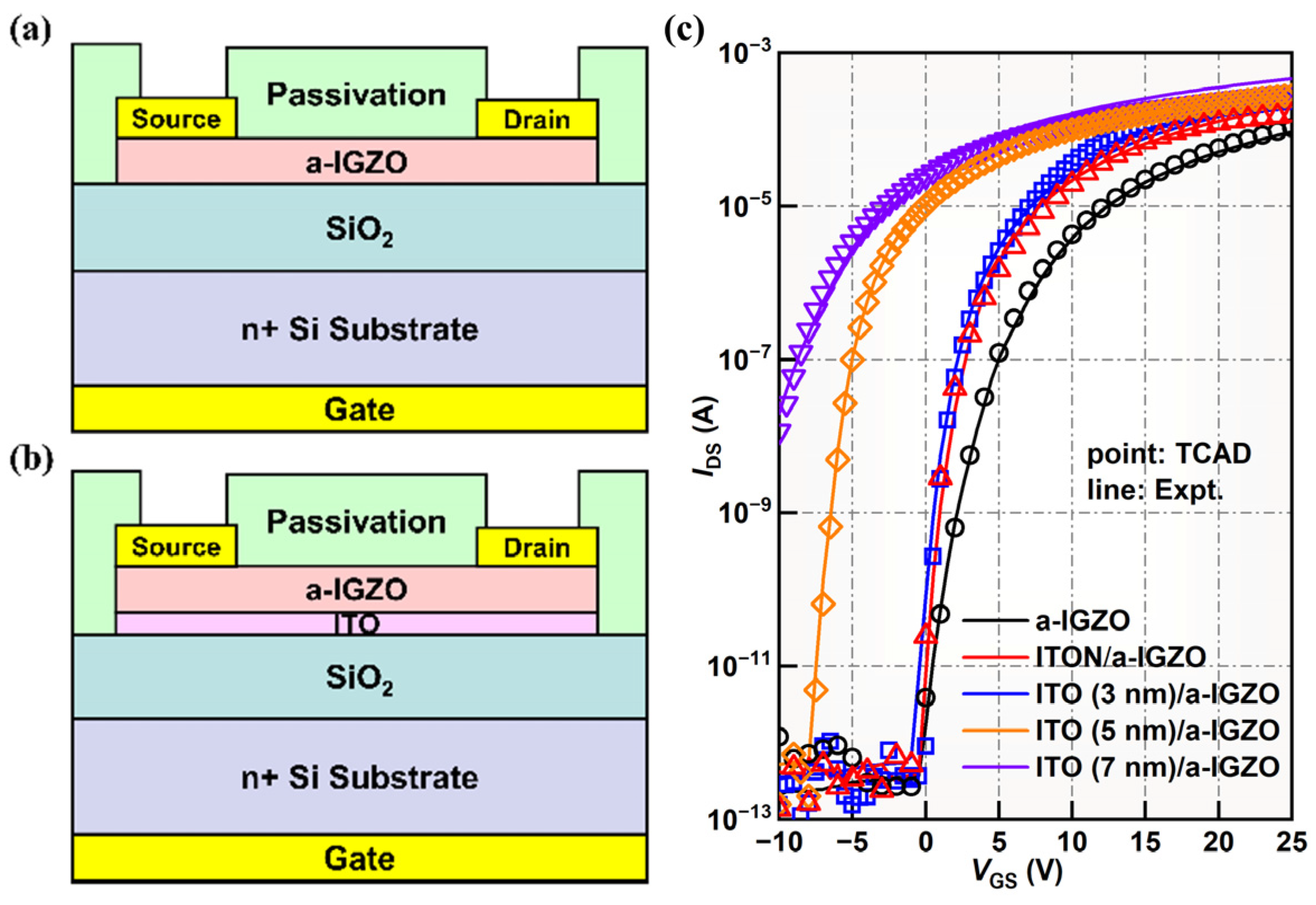

2. Device Fabrication and Simulation

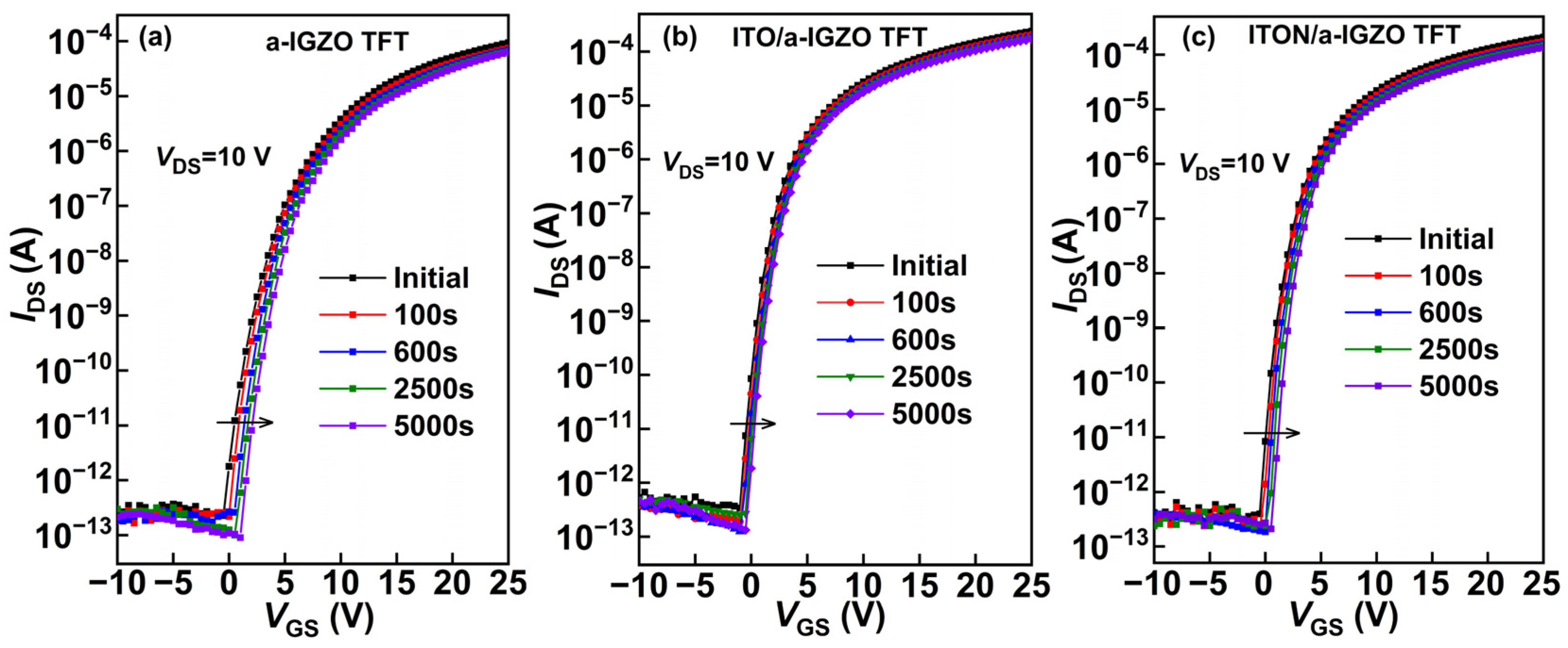

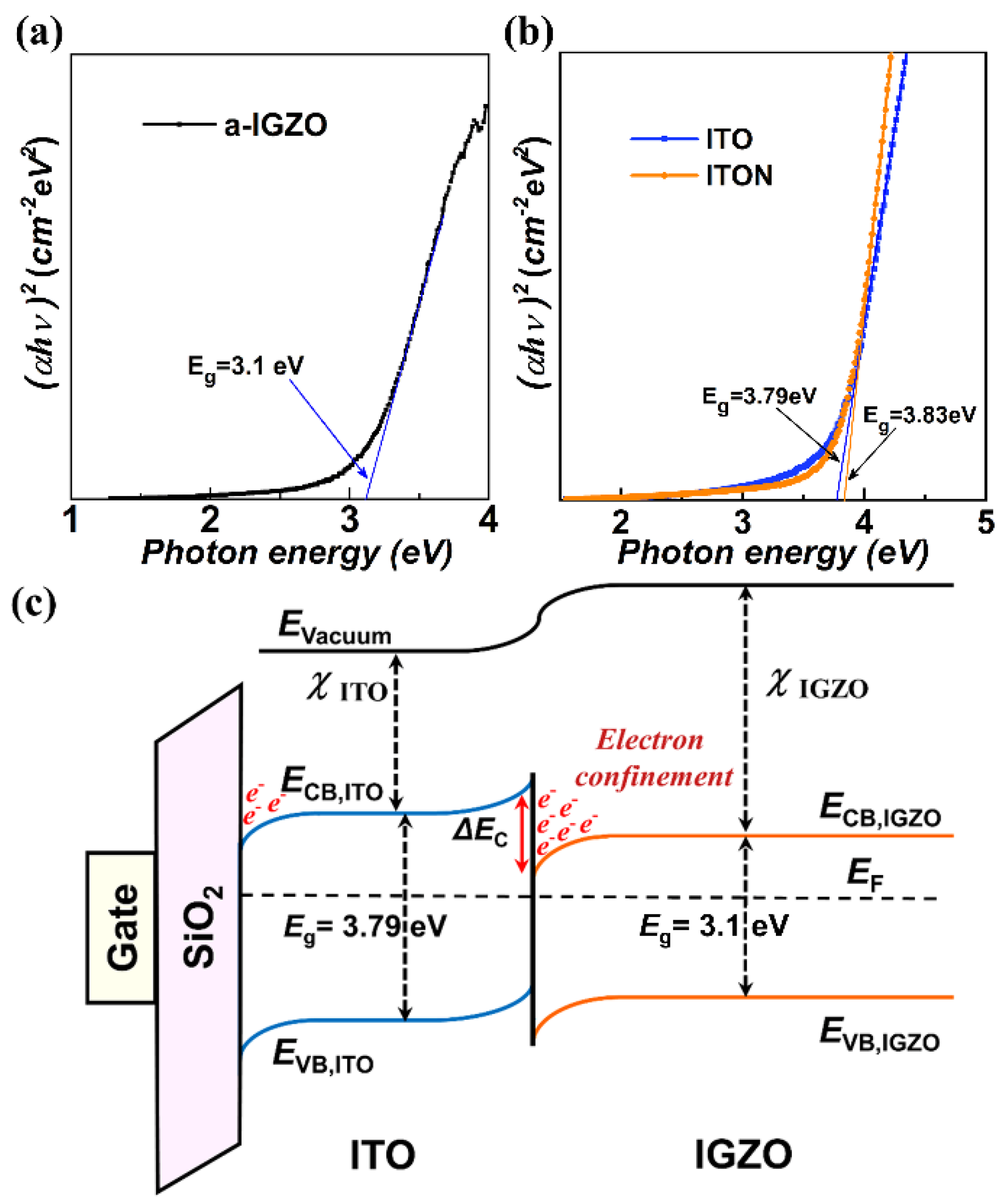

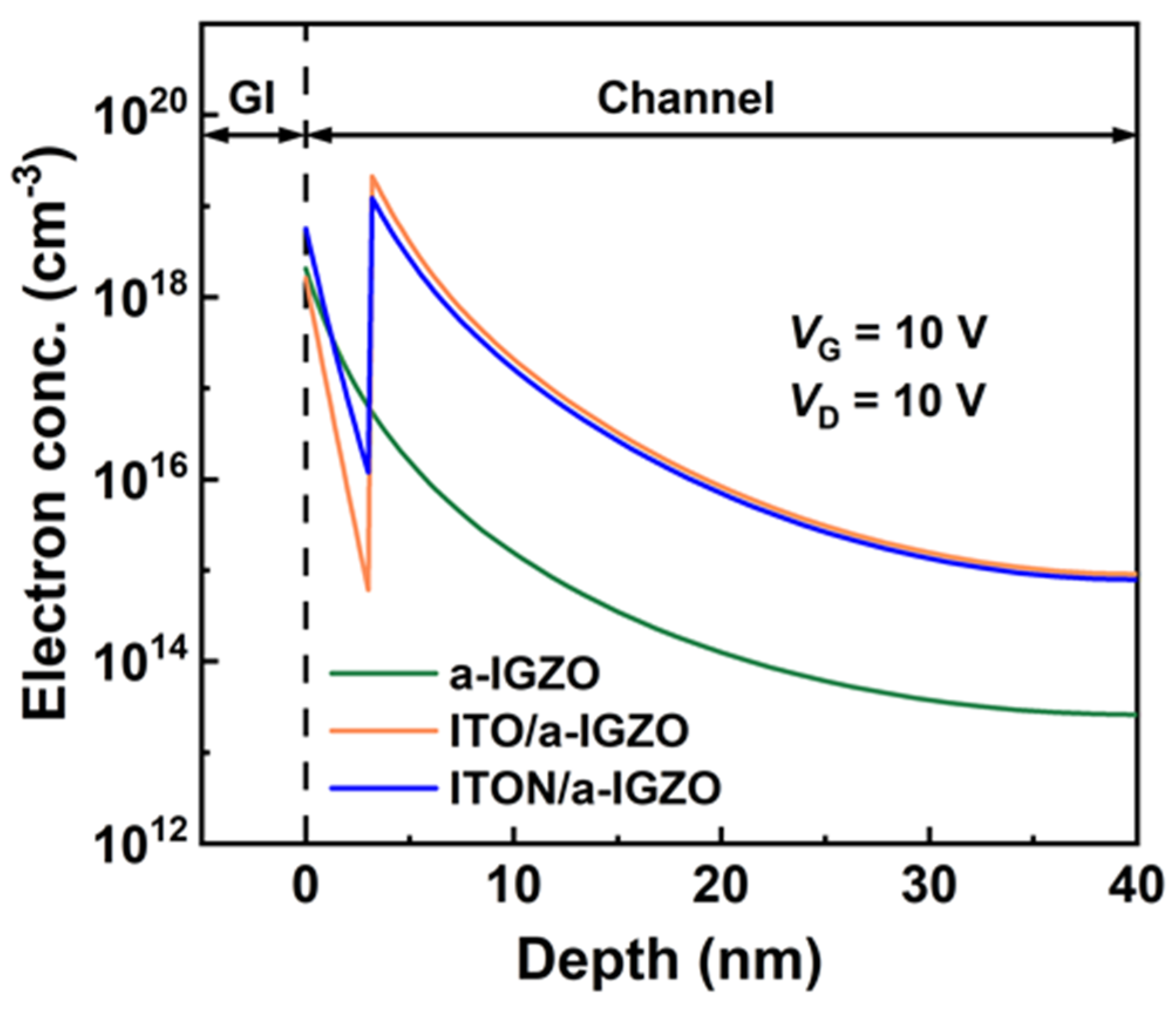

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kamiya, T.; Nomura, K.; Hosono, H. Present status of amorphous In-Ga-Zn-O thin-film transistors. Sci. Technol. Adv. Mater. 2010, 11, 044305. [Google Scholar] [CrossRef] [PubMed]

- Myny, K. The development of flexible integrated circuits based on thin-film transistors. Nat. Electron. 2018, 1, 30–39. [Google Scholar] [CrossRef]

- Zhu, Y.; He, Y.; Jiang, S.; Zhu, L.; Chen, C.; Wan, Q. Indium–gallium–zinc–oxide thin-film transistors: Materials, devices, and applications. J. Semicond. 2021, 42, 031101. [Google Scholar] [CrossRef]

- Geng, D.; Wang, K.; Li, L.; Myny, K.; Nathan, A.; Jang, J.; Kuo, Y.; Liu, M. Thin-film transistors for large-area electronics. Nat. Electron. 2023, 6, 963–972. [Google Scholar] [CrossRef]

- Chang, T.C.; Tsao, Y.C.; Chen, P.H.; Tai, M.C.; Huang, S.P.; Su, W.C.; Chen, G.F. Flexible low-temperature polycrystalline silicon thin-film transistors. Mater. Today Adv. 2020, 5, 100040. [Google Scholar] [CrossRef]

- Chen, Y.; Kim, H.; Lee, J.; Lee, S.; Do, Y.; Choi, M.; Jang, J. An 18.6-μm-Pitch Gate Driver Using a-IGZO TFTs for Ultrahigh-Definition AR/VR Displays. IEEE Trans. Electron Devices 2020, 67, 4929–4933. [Google Scholar] [CrossRef]

- Zulqarnain, M.; Cantatore, E. Analog and Mixed Signal Circuit Design Techniques in Flexible Unipolar a-IGZO TFT Technology: Challenges and Recent Trends. IEEE Open J. Circuits Syst. 2021, 2, 743–756. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, W.; Wilson, J.; Ma, X.; Brownless, J.; Li, Y.; Yang, J.; Yuan, Y.; Ma, P.; Xin, Q. 8.4: Invited Paper: Oxide devices for displays and low power electronics. SID Symp. Dig. Tech. Pap. 2019, 50, 81–84. [Google Scholar] [CrossRef]

- Meng, W.; Xu, F.; Yu, Z.; Tao, T.; Shao, L.; Liu, L.; Li, T.; Wen, K.; Wang, J.; He, L. Three-dimensional monolithic micro-LED display driven by atomically thin transistor matrix. Nat. Nanotechnol. 2021, 16, 1231–1236. [Google Scholar] [CrossRef]

- Wolfgang, K.; Daniel, F.U.; Christian, E. Origin of subgap states in amorphous In-Ga-Zn-O. J. Appl. Phys. 2013, 28, 114. [Google Scholar] [CrossRef]

- Vemuri, R.N.; Mathews, W.P. Investigation of defect generation and annihilation in IGZO TFTs during practical stress conditions: Illumination and electrical bias. J. Appl. Phys. 2013, 46, 4. [Google Scholar] [CrossRef]

- Seul, H.J.; Cho, J.H.; Hur, J.S.; Cho, M.H.; Cho, M.H.; Ryu, M.T.; Jeong, J.K. Improvement in carrier mobility through band-gap engineering in atomic-layer-deposited In-Ga-Zn-O stacks. J. Alloys Compd. 2022, 903, 163876. [Google Scholar] [CrossRef]

- Cho, M.H.; Choi, C.H.; Jeong, J.K. Comparative Study of Atomic Layer Deposited Indium-Based Oxide Transistors with a Fermi Energy Level-Engineered Heterojunction Structure Channel through a Cation Combinatorial Approach. ACS Appl. Mater. Interfaces 2022, 14, 18646–18661. [Google Scholar] [CrossRef]

- Tai, A.-H.; Yen, C.-C.; Chen, T.-L.; Chou, C.-H.; Liu, C.W. Mobility Enhancement of Back-Channel-Etch Amorphous InGaZnO TFT by Double Layers With Quantum Well Structures. IEEE Trans. Electron Devices 2019, 66, 4188–4192. [Google Scholar] [CrossRef]

- Faber, H.; Das, S.; Lin, Y.-H.; Pliatsikas, N.; Zhao, K.; Kehagias, T. Heterojunction oxide thin-film transistors with unprecedented electron mobility grown from solution. Sci. Adv. 2017, 3, e1602640. [Google Scholar] [CrossRef]

- Wang, P.; Yang, H.; Li, J.; Zhang, X.; Wang, L.; Xiao, J.; Zhao, B.; Zhang, S.; Lu, L. Synergistically Enhanced Performance and Reliability of Abrupt Metal-Oxide Heterojunction Transistor. Adv. Electron. Mater. 2022, 9, 2200807. [Google Scholar] [CrossRef]

- Hyeon, J.S.; Min, J.K.; Hyun, J.Y. Atomic Layer Deposition Process-Enabled Carrier Mobility Boosting in Field-Effect Transistors through a Nanoscale ZnO/IGO Heterojunction. ACS Appl. Mater. Interfaces 2020, 12, 33887–33898. [Google Scholar] [CrossRef]

- He, P.; Ding, C.; Zou, X.; Li, G.; Hu, W.; Ma, C.; Flandre, D.; Iñíguez, B.; Liao, L.; Lan, L. Enhanced stability and mobility of solution-processed oxide thin-film transistors with bilayer terbium-incorporated indium oxide channel. Appl. Phys. Lett. 2022, 121, 193301. [Google Scholar] [CrossRef]

- Park, C.-Y.; Jeon, S.-P.; Park, J.B.; Park, H.-B.; Kim, D.-H.; Yang, S.H.; Kim, G.; Jo, J.-W.; Oh, M.S.; Kim, M.; et al. High-performance ITO/a-IGZO heterostructure TFTs enabled by thickness-dependent carrier concentration and band alignment manipulation. Ceram. Int. 2023, 49, 5905–5914. [Google Scholar] [CrossRef]

- Chiu, H.-C.; Wang, H.-C.; Luo, Y.-C.; Huang, F.-H.; Kao, H.-L.; Hsueh, K.-P. Band offsets and electrical stability characterization of Zr-doped ZnO thin-film transistors with a Gd2O3 gate insulator. Microelectron. Eng. 2014, 118, 20–24. [Google Scholar] [CrossRef]

- Deng, K.; Wang, X.; Huang, S.; Jiang, Q.; Yin, H.; Fan, J.; Jing, G.; Wang, Y.; Luan, T.; Wei, K. Effective suppression of deep interface states and dielectric trapping in SiNx/GaN metal-insulator-semiconductor structures by a SiOxNy interfacial layer grown by plasma-enhanced atomic layer deposition. Appl. Surf. Sci. 2023, 607, 154937. [Google Scholar] [CrossRef]

- Stewart, K.A.; Gouliouk, V.; McGlone, J.M.; Wager, J.F. Side-by-Side Comparison of Single- and Dual-Active Layer Oxide TFTs: Experiment and TCAD Simulation. IEEE Trans. Electron Devices 2017, 64, 4131–4136. [Google Scholar] [CrossRef]

- Hsu, C.-C.; Chen, H.-P.; Ting, W.-C. Correlation Between Carrier Concentration Distribution, I–V and C–V Characteristics of a-InGaZnO TFTs. J. Disp. Technol. 2016, 12, 328–337. [Google Scholar] [CrossRef]

- Krausmann, J.; Sanctis, S.; Engstler, J.; Luysberg, M.; Bruns, M.; Schneider, J.J. Charge Transport in Low-Temperature Processed Thin-Film Transistors Based on Indium Oxide/Zinc Oxide Heterostructures. ACS Appl. Mater. Interfaces 2018, 10, 20661–20671. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Yuan, Y.; Yin, X.; Yan, S.; Xin, Q.; Song, A. High-Performance Thin-Film Transistors With Sputtered IGZO/Ga2O3 Heterojunction. IEEE Trans. Electron Devices 2022, 69, 6783–6788. [Google Scholar] [CrossRef]

- Tian, L.; Cheng, G.; Wang, H.; Wu, Y.; Zheng, R.; Ding, P. Effect of nitrogen doping on the structural, optical and electrical properties of indium tin oxide films prepared by magnetron sputtering for gallium nitride light emitting diodes. Superlattices Microstruct. 2017, 101, 261–270. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, C.; Yang, Z.; Yao, J.; Wang, H.; Ding, G. Effect of nitrogen doping temperature on the resistance stability of ITO thin films. J. Alloys Compd. 2019, 778, 90–96. [Google Scholar] [CrossRef]

- Suresh, A.; Muth, J.F. Bias stress stability of indium gallium zinc oxide channel based transparent thin film transistors. Appl. Phys. Lett. 2008, 92, 033502. [Google Scholar] [CrossRef]

- Kim, H.; Kim, S.; Yoo, J.; Oh, C.; Kim, B.; Hwang, H.; Park, J.; Choi, P.; Song, J.; Im, K.; et al. Conduction band offset-dependent induced threshold voltage shifts in a-InGaZnO TFTs under positive bias illumination stress. AIP Adv. 2021, 11, 035312. [Google Scholar] [CrossRef]

- Carey, P.H.; Ren, F.; Hays, D.C.; Gila, B.P.; Pearton, S.J.; Jang, S.; Kuramata, A. Valence and conduction band offsets in AZO/Ga2O3 heterostructures. Vacuum 2017, 141, 103–108. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Qian, L.X.; Liu, X.Z. Determination of the Band Alignment of a-IGZO/a-IGMO Heterojunction for High-Electron Mobility Transistor Application. Phys. Status Solidi (RRL)-Rapid Res. Lett. 2017, 11, 1700251. [Google Scholar] [CrossRef]

- He, G.; Chen, X.F.; Lv, J.G.; Fang, Z.B.; Liu, Y.M.; Zhu, K.R.; Sun, Z.Q.; Liu, M. Band offsets in HfTiO/InGaZnO4 heterojunction determined by X-ray photoelectron spectroscopy. J. Alloys Compd. 2015, 642, 172–176. [Google Scholar] [CrossRef]

- Kim, H.; Gilmore, C.M.; Piqué, A.; Horwitz, J.S.; Mattoussi, H.; Murata, H.; Kafafi, Z.H.; Chrisey, D.B. Electrical, optical, and structural properties of indium–tin–oxide thin films for organic light-emitting devices. J. Appl. Phys. 1999, 86, 6451–6461. [Google Scholar] [CrossRef]

- Chuang, C.; Fung, T.; Mullins, B.G.; Nomura, K.; Kamiya, T.; Shieh, H.D. P-13: Photosensitivity of amorphous IGZO TFTs for active-matrix flat-panel displays. SID Symp. Dig. Tech. Pap. 2008, 39, 1215–1218. [Google Scholar] [CrossRef]

- Wu, K.-R.; Yeh, C.-W.; Hung, C.-H.; Cheng, L.-H.; Chung, C.-Y. Photoelectrochemical properties of nitrogen-doped indium tin oxide thin films prepared by reactive DC magnetron sputtering. Thin Solid Film. 2009, 518, 1581–1584. [Google Scholar] [CrossRef]

- Avelar-Muñoz, F.; Berumen, J.A.; Aguilar-Frutis, M.A.; Araiza, J.J.; Ortega, J.J. Enhancement on carrier mobility in amorphous indium tin oxynitride (ITON) thin films. J. Alloys Compd. 2020, 835, 155353. [Google Scholar] [CrossRef]

- Thirumoorthi, M.; Thomas Joseph Prakash, J. Structure, optical and electrical properties of indium tin oxide ultra thin films prepared by jet nebulizer spray pyrolysis technique. J. Asian Ceram. Soc. 2018, 4, 124–132. [Google Scholar] [CrossRef]

- Cai, W.; Li, M.; Lu, S.; Qian, Q.; Zang, Z. Heterojunction Channel Engineering in Performance Enhancement of Solution-Processed Oxide Thin-Film Transistors. IEEE Trans. Electron Devices 2023, 70, 3085–3091. [Google Scholar] [CrossRef]

- Khim, D.; Lin, Y.H.; Anthopoulos, T.D. Impact of Layer Configuration and Doping on Electron Transport and Bias Stability in Heterojunction and Superlattice Metal Oxide Transistors. Adv. Funct. Mater. 2019, 29, 1902591. [Google Scholar] [CrossRef]

- Park, J.W.; Kang, B.H.; Kim, H.J. A Review of Low-Temperature Solution-Processed Metal Oxide Thin-Film Transistors for Flexible Electronics. Adv. Funct. Mater. 2019, 30, 1904632. [Google Scholar] [CrossRef]

- Sun, Q.-J.; Wu, J.; Zhang, M.; Yuan, Y.; Gao, X.; Wang, S.-D.; Tang, Z.; Kuo, C.-C.; Yan, Y. Enhanced Electrical Performance and Bias-Stress Stability of Solution-Processed Bilayer Metal Oxide Thin-Film Transistors. Phys. Status Solidi (A) 2022, 219, 2200311. [Google Scholar] [CrossRef]

| Channel Structure | Vth (V) | μFE (cm2 V−1s−1) | SS (V dec−1) | Ion/off |

|---|---|---|---|---|

| a-IGZO ITO/a-IGZO (ITO 3 nm) | 4.8 2.8 | 6.8 12.4 | 0.7 0.46 | >108 >108 |

| ITO/a-IGZO (ITO 5 nm) | −4.9 | 13.2 | 0.55 | >108 |

| ITON/a-IGZO (ITON 3 nm) | 3.2 | 11.2 | 0.41 | >108 |

| Sample | Metal ECL | Peak (Bulk) | Peak (Interface) | Peak Shift | VBM |

|---|---|---|---|---|---|

| a-IGZO | Zn 2p3/2 | 1021.55 | 1021.67 | 0.12 | 2.34 |

| ITO | In 3d5/2 | 444.3 | 444.55 | 0.25 | 2.02 |

| ITON | In 3d5/2 | 444.42 | 444.67 | 0.25 | 1.88 |

| Parameters | a-IGZO | ITO | ITON | Description |

|---|---|---|---|---|

| NTA (eV−1cm−3) | 2.45 × 1020 | 1 × 1020 | 2.5 × 1020 | Accept-like tail states at EC |

| WTA (eV) | 0.05 | 0.02 | 0.1 | Conduction-band-tail slope |

| NGA (eV−1cm−3) | 3.2 × 1017 | - | - | Peak of Oi states |

| WGA (meV) | 0.44 | - | - | Characteristic decay energy |

| EGA (eV) | 0.8 | - | - | Peak energy |

| NTD (eV−1cm−3) | 1 × 1019 | 4 × 1020 | 1.5 × 1020 | Donor-like tail states at EV |

| WTD (eV) | 0.2 | 0.11 | 0.11 | Valence-band-tail slope |

| NGD (eV−1cm−3) | 6 × 1017 | - | - | Peak of Gaussian donor-like states |

| WGD (eV) | 0.3 | - | - | Characteristic decay energy |

| EGD (eV) | 2.9 | - | - | Peak energy |

| Eg (eV) | 3.1 | 3.79 | 3.83 | Optical band gap |

| ΔEC (eV) | - | 0.5 (ITO/a-IGZO) | 0.4 (ITON/a-IGZO) | Conduction band offset |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Chen, C.; Sun, F.; Chen, X.; Xu, W.; Li, L. Enhancing the Carrier Mobility and Bias Stability in Metal–Oxide Thin Film Transistors with Bilayer InSnO/a-InGaZnO Heterojunction Structure. Micromachines 2024, 15, 512. https://doi.org/10.3390/mi15040512

Huang X, Chen C, Sun F, Chen X, Xu W, Li L. Enhancing the Carrier Mobility and Bias Stability in Metal–Oxide Thin Film Transistors with Bilayer InSnO/a-InGaZnO Heterojunction Structure. Micromachines. 2024; 15(4):512. https://doi.org/10.3390/mi15040512

Chicago/Turabian StyleHuang, Xiaoming, Chen Chen, Fei Sun, Xinlei Chen, Weizong Xu, and Lin Li. 2024. "Enhancing the Carrier Mobility and Bias Stability in Metal–Oxide Thin Film Transistors with Bilayer InSnO/a-InGaZnO Heterojunction Structure" Micromachines 15, no. 4: 512. https://doi.org/10.3390/mi15040512