Surface Topography in Cutting-Speed-Direction Ultrasonic-Assisted Turning

Abstract

1. Introduction

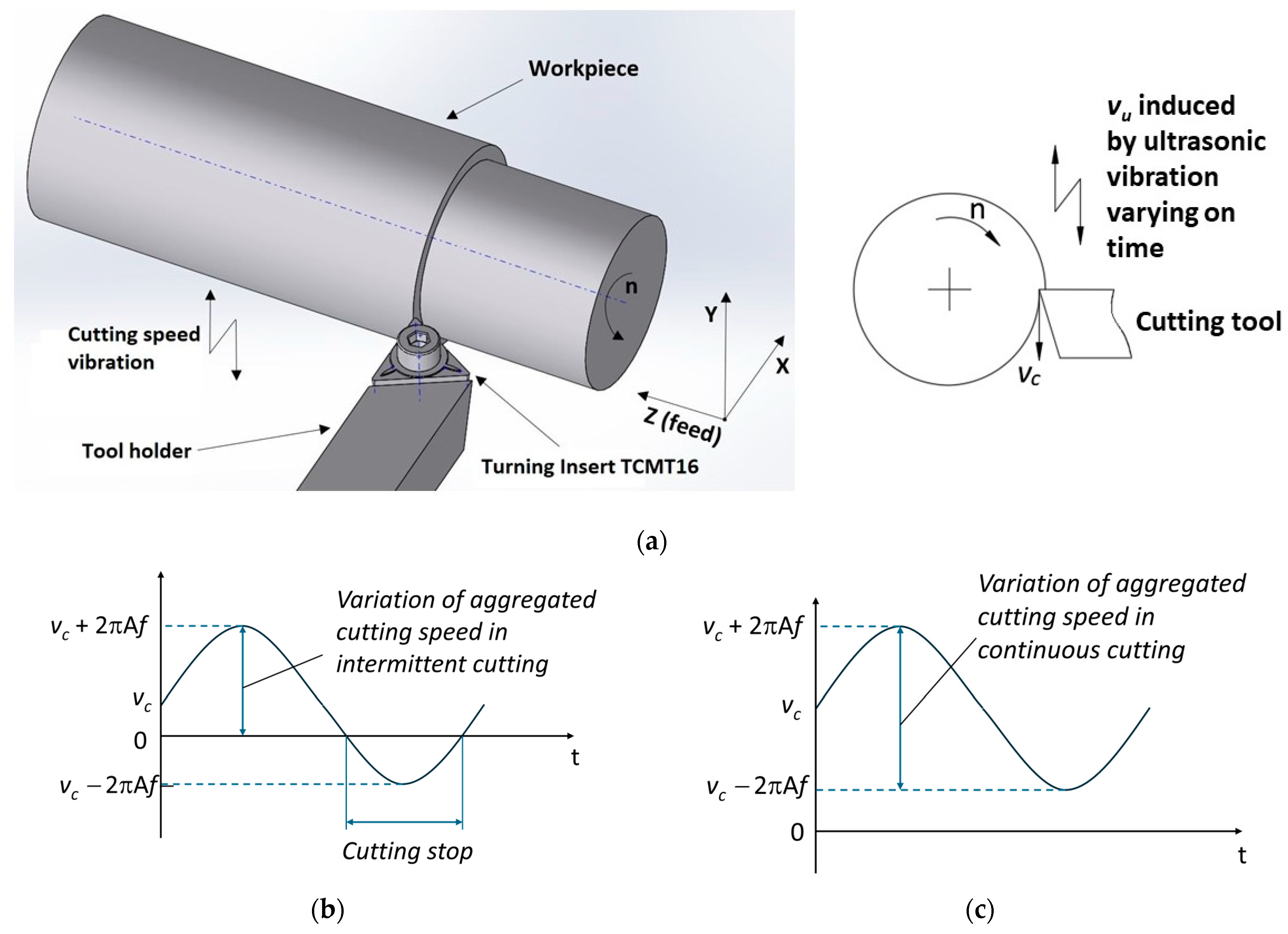

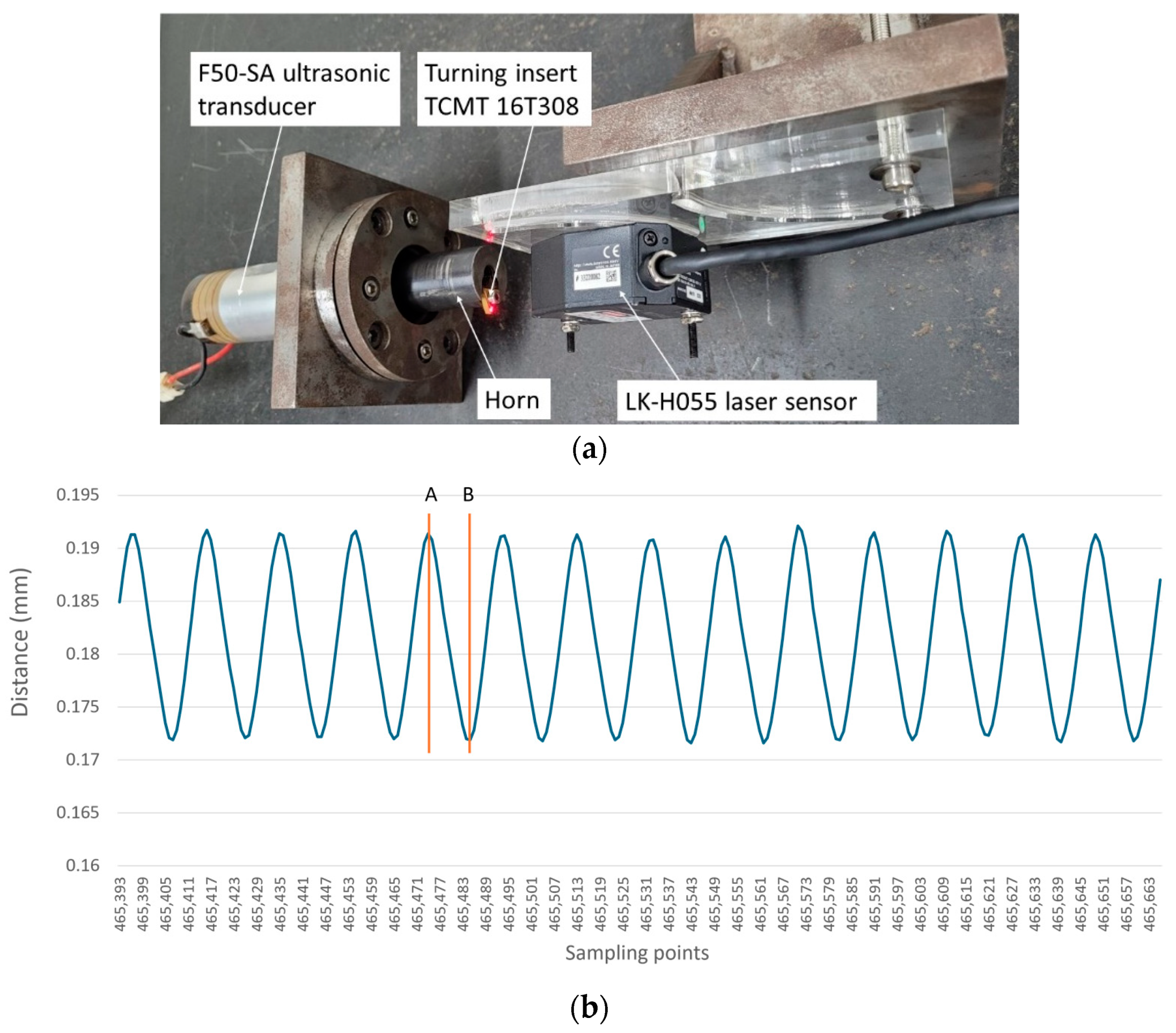

2. Model of Intermittent Cutting in CUAT

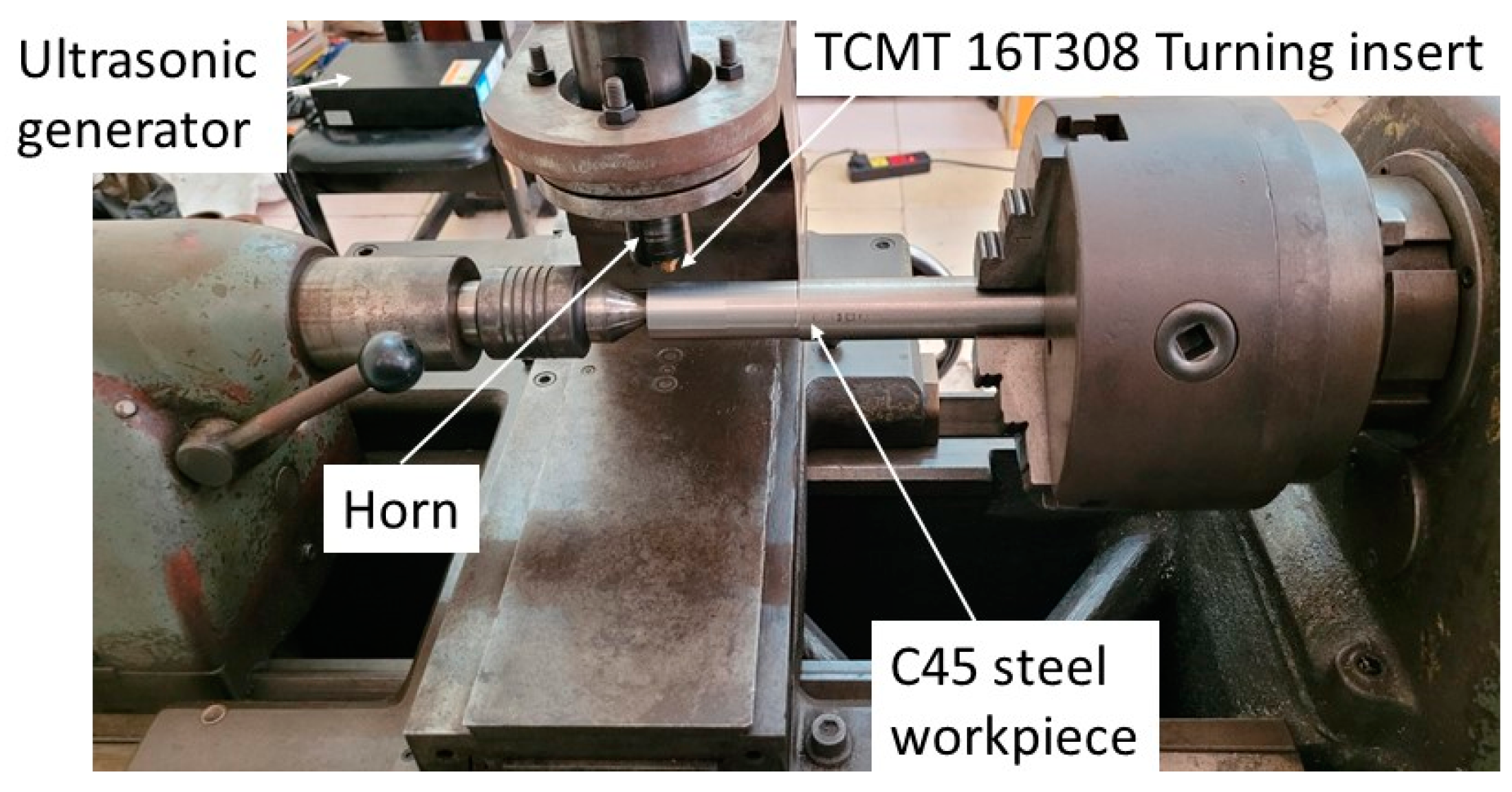

3. Experimental Setup

4. Results and Discussion

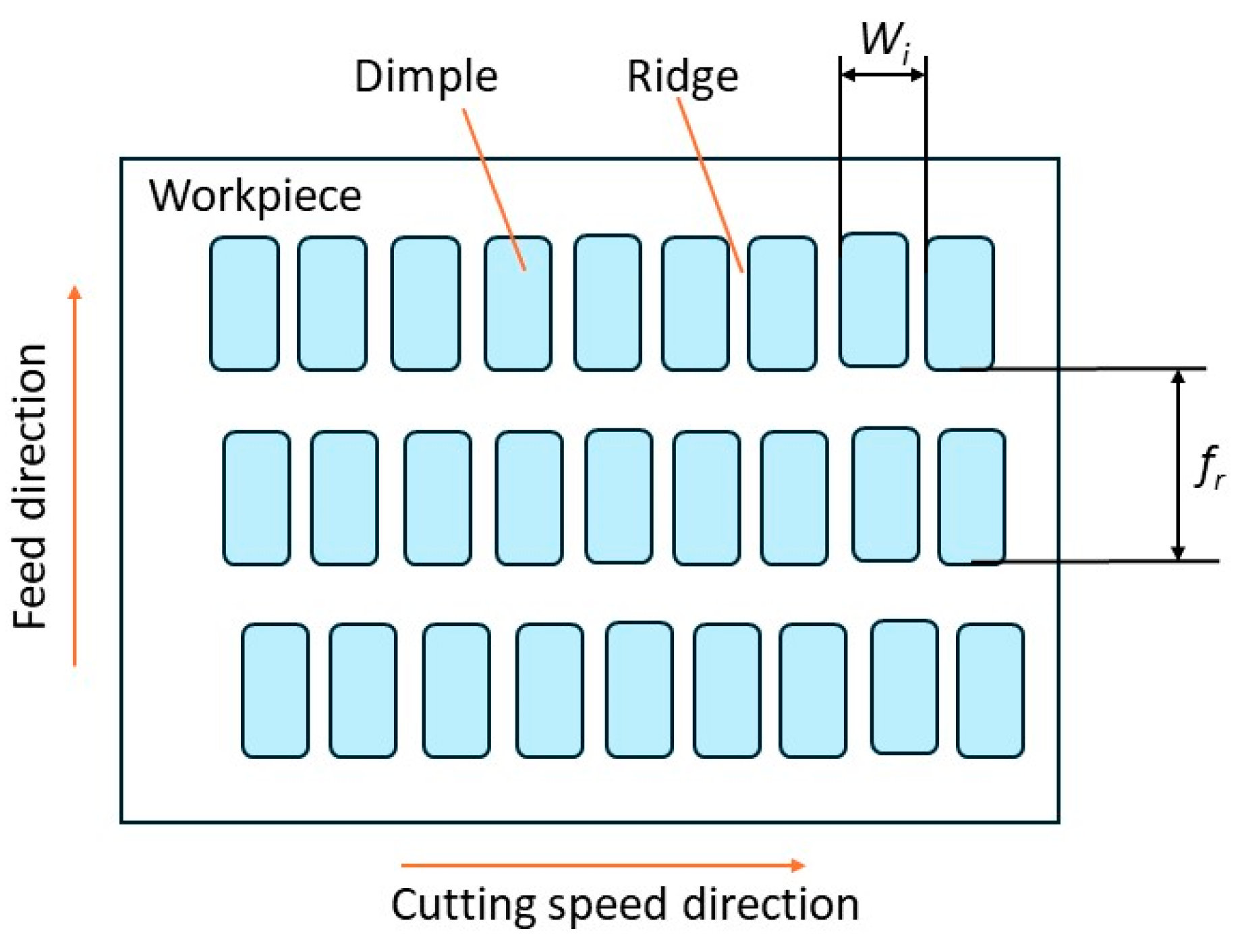

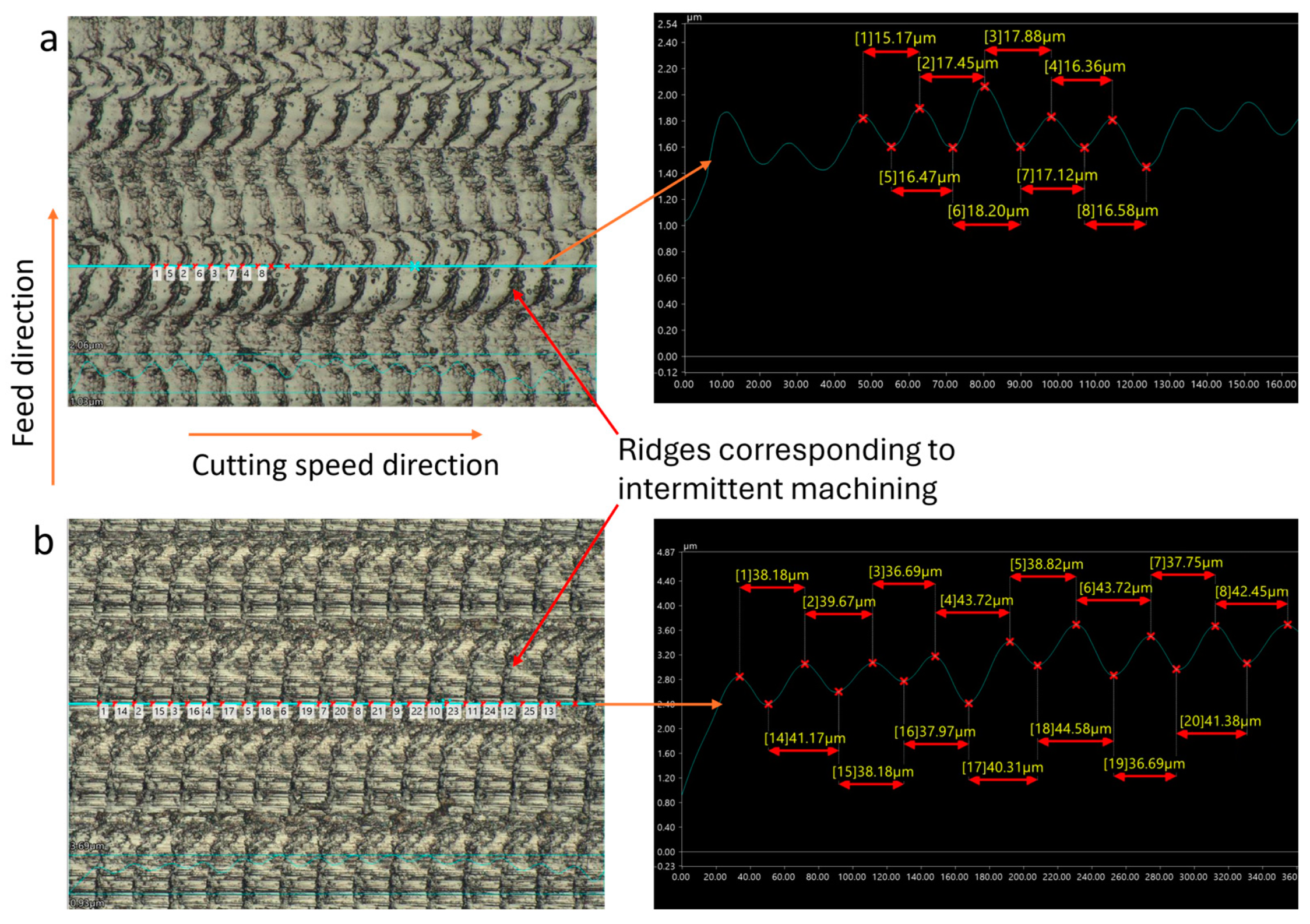

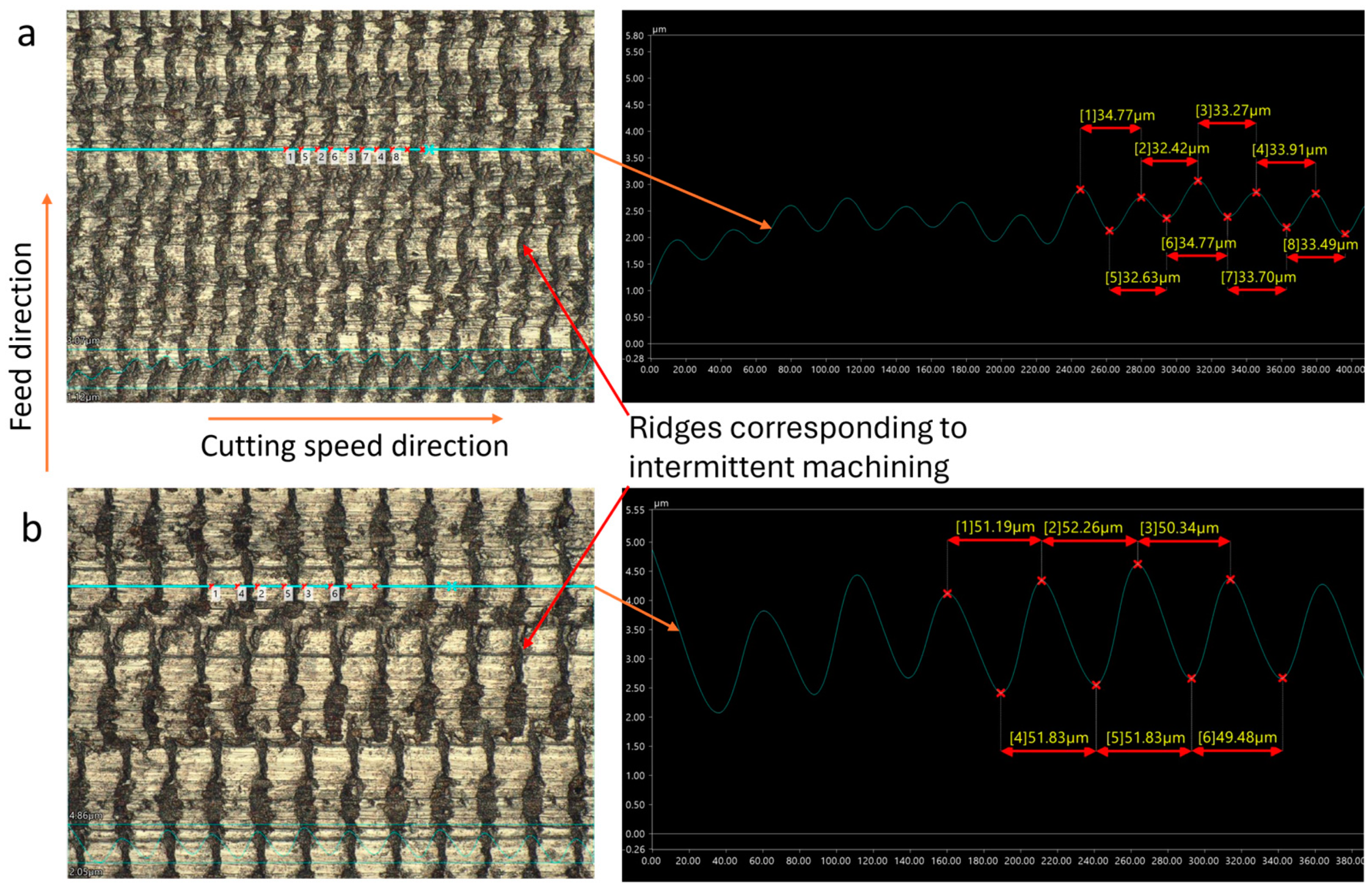

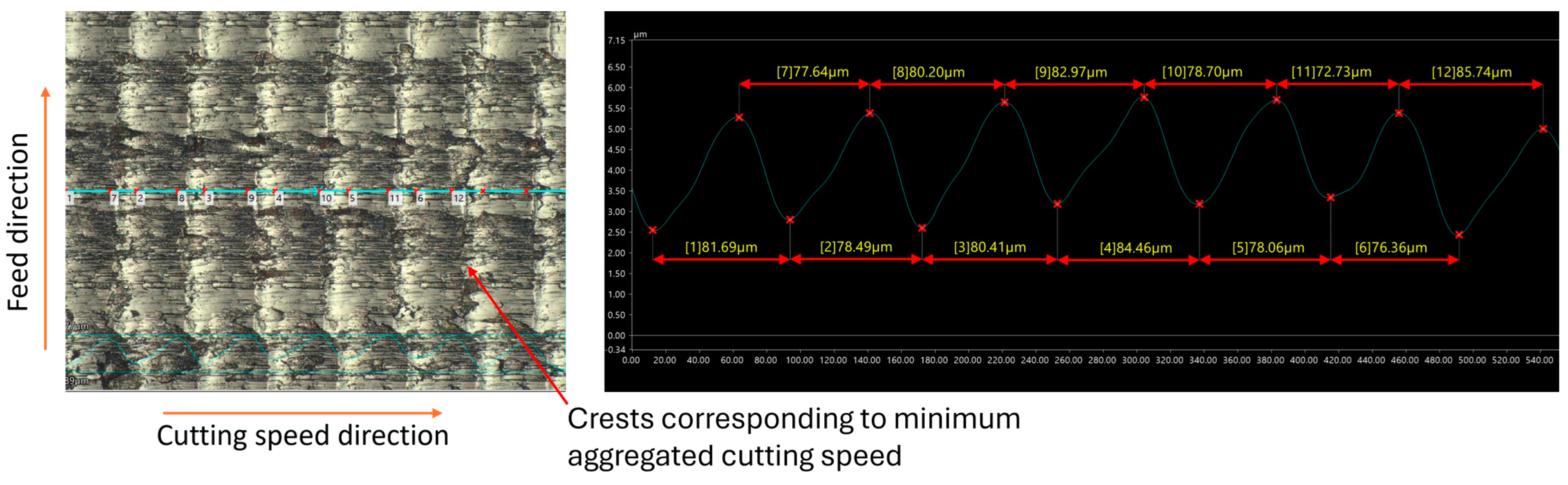

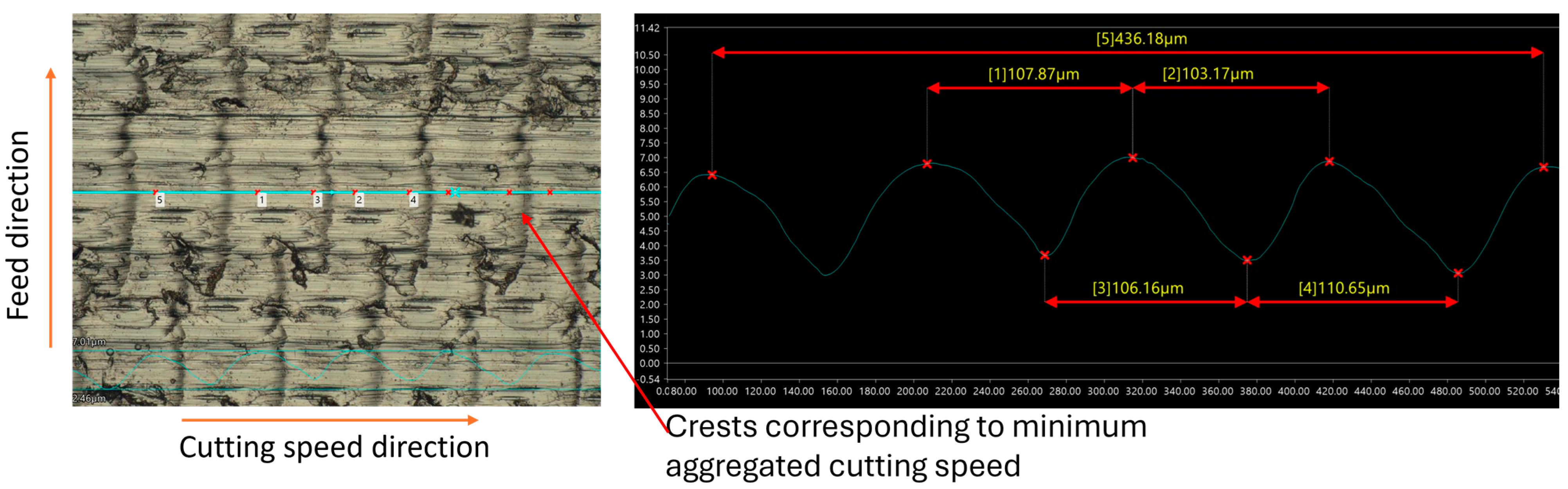

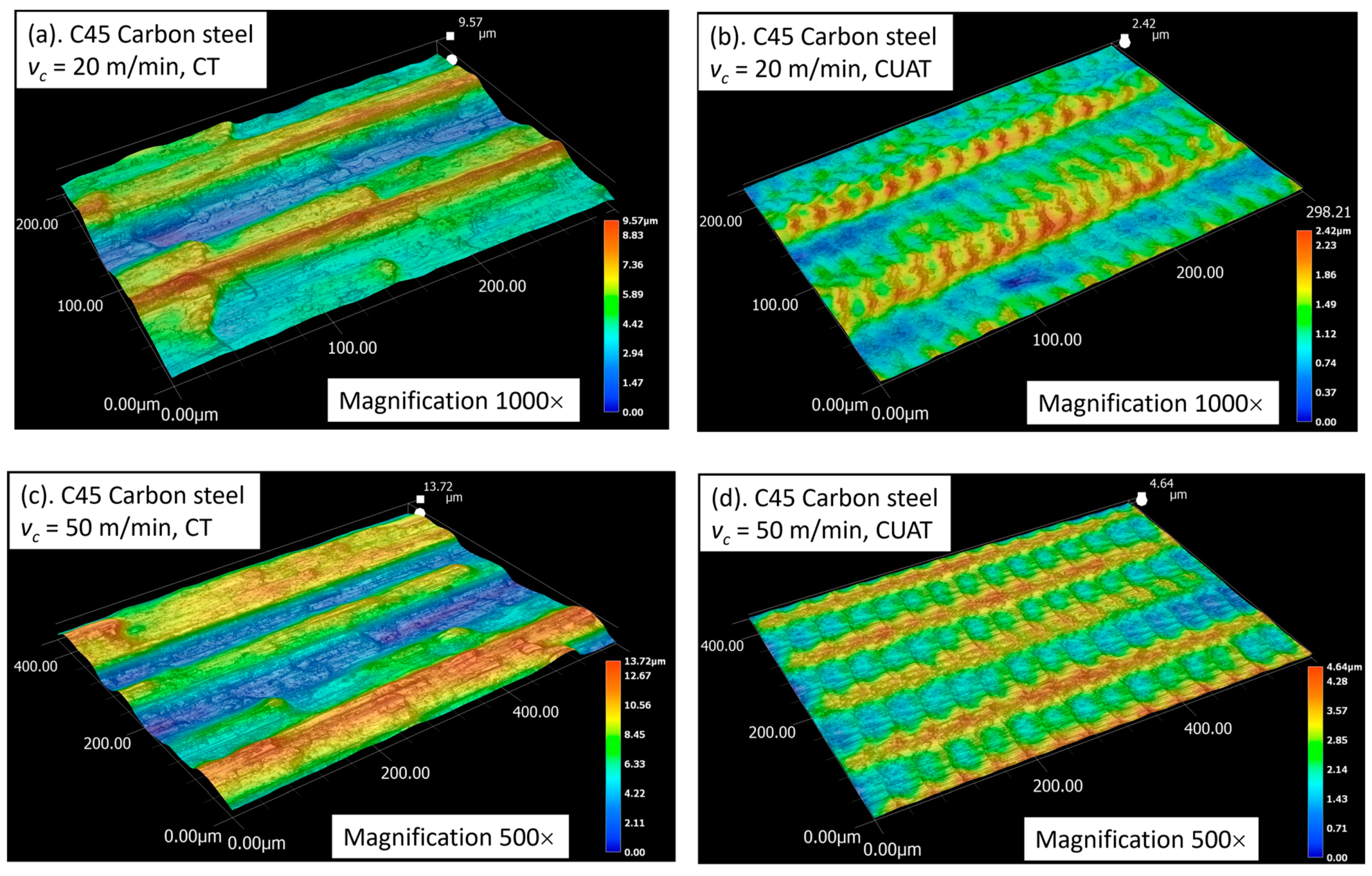

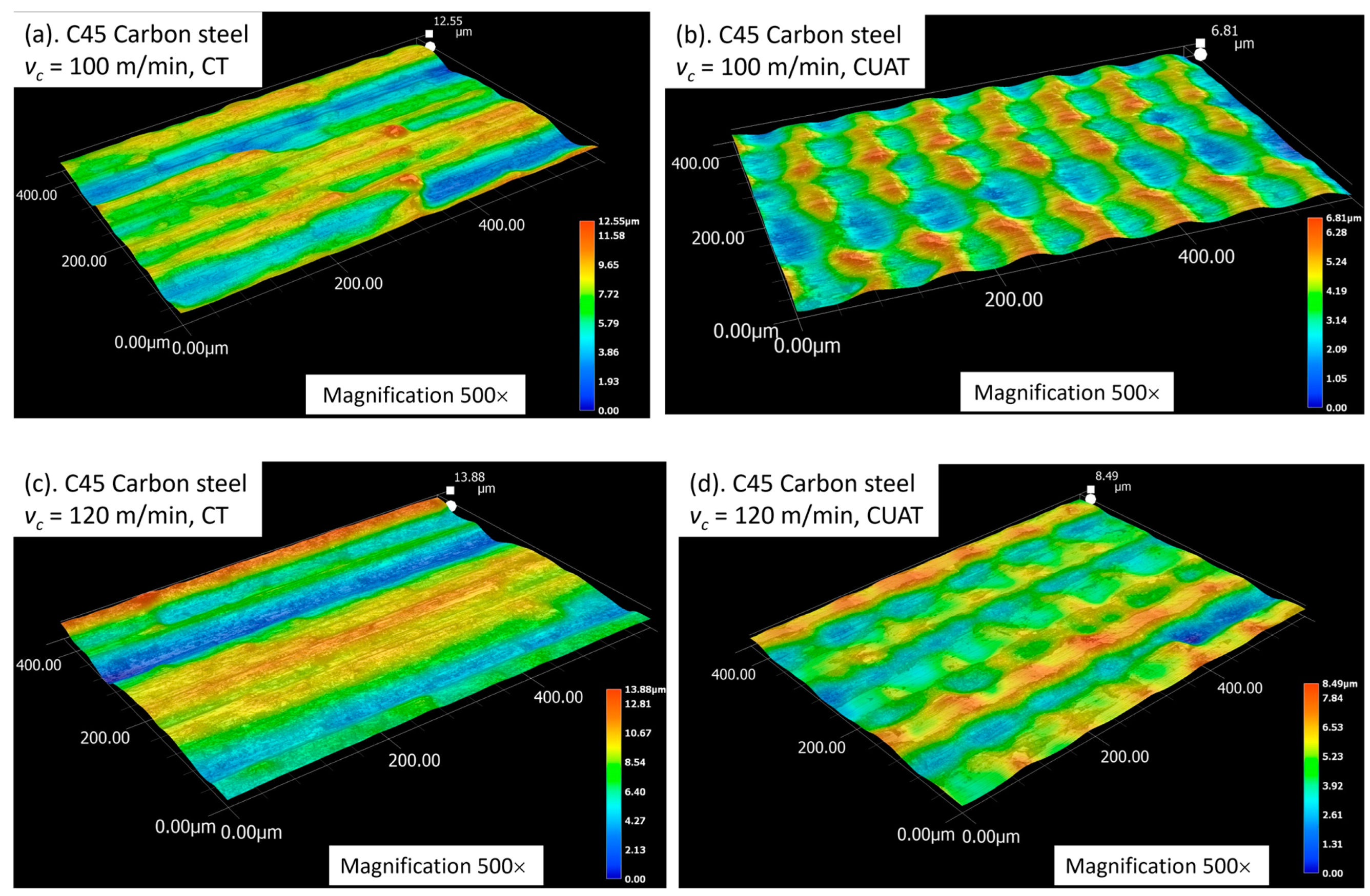

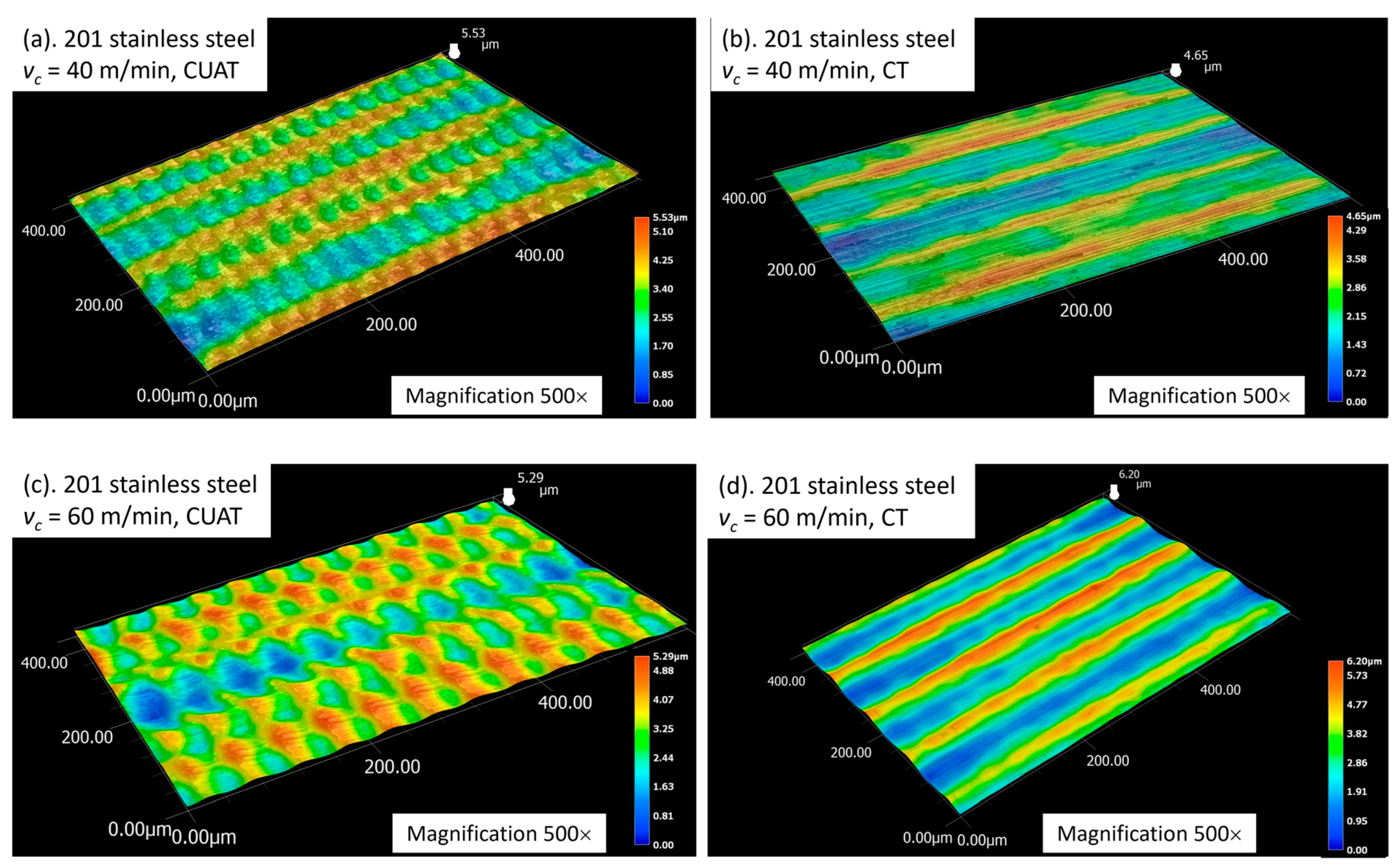

4.1. Surface Topography

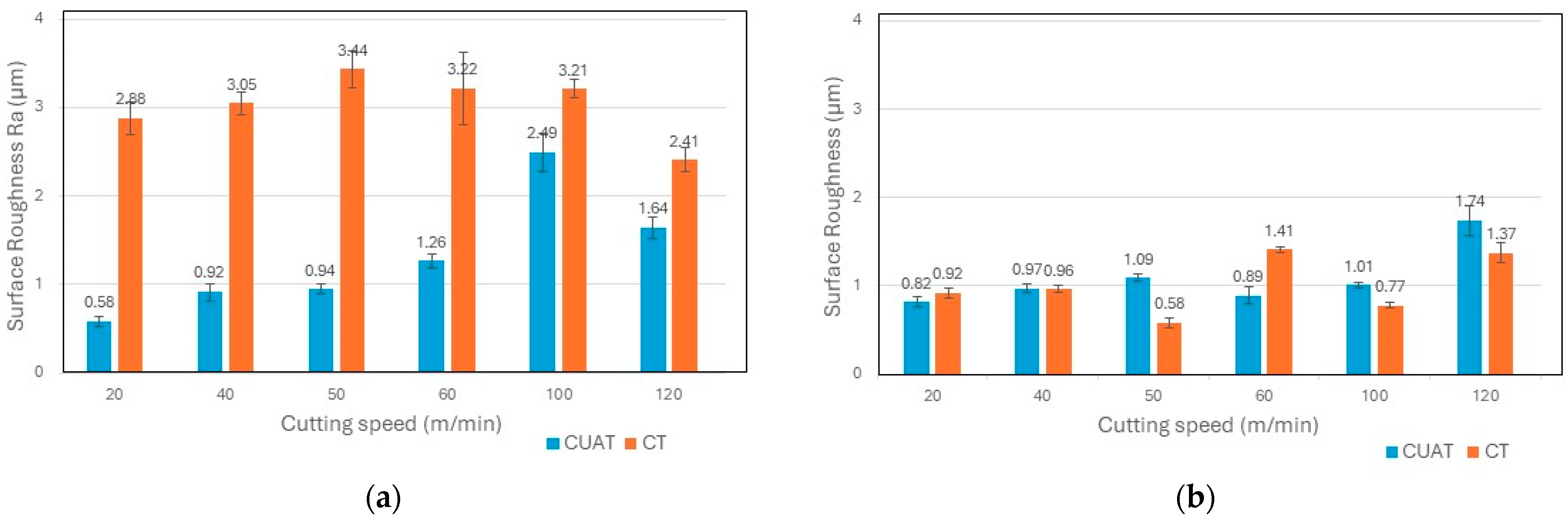

4.2. Surface Roughness

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Ultrasonic vibration amplitude (µm) |

| f | Frequency of ultrasonic vibration (Hz) |

| fr | Feed rate in Conventional Turning (CT) (mm/rev) |

| CUAT | Cutting speed direction Ultrasonic-assisted Turning |

| Cutting speed in Conventional Turning (m/min) | |

| Speed of ultrasonic vibration (m/min) | |

| Aggregated cutting speed in CUAT (m/min) | |

| n | Spindle speed of lathe (rev/min) |

References

- Ağar, S.; Tosun, N. Ultrasonic assisted turning of AISI 52100 steel using nanoparticle-MQL method. Surf. Topogr. Metrol. Prop. 2021, 9, 015024. [Google Scholar] [CrossRef]

- Soleimanimehr, H. Analysis of the cutting ratio and investigating its influence on the workpiece’s diametrical error in ultrasonic vibration assisted turning. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 235, 640–649. [Google Scholar] [CrossRef]

- Chen, J.; Ming, W.; An, Q.; Chen, M. Mechanism and feasibility of ultrasonic-assisted milling to improve the machined surface quality of 2D Cf/SiC composites. Ceram. Int. 2020, 46, 15122–15136. [Google Scholar] [CrossRef]

- Feng, Y.; Hsu, F.-C.; Lu, Y.-T.; Lin, Y.-F.; Lin, C.-T.; Lin, C.-F.; Lu, Y.-C.; Lu, X.; Liang, S.Y. Surface roughness prediction in ultrasonic vibration-assisted milling. J. Adv. Mech. Des. Syst. Manuf. 2020, 14, JAMDSM0063. [Google Scholar] [CrossRef]

- Feng, Y.; Hsu, F.C.; Lu, Y.T.; Lin, Y.F.; Lin, C.T.; Lin, C.F.; Lu, Y.C.; Liang, S.Y. Force prediction in ultrasonic vibration-assisted milling. Mach. Sci. Technol. 2021, 25, 307–330. [Google Scholar] [CrossRef]

- Moghaddas, M.A.; Graff, K.F. On the effect of load on vibration amplitude in ultrasonic-assisted drilling. Int. J. Adv. Manuf. Technol. 2020, 106, 3081–3094. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, Y.; Gao, K.; Zhang, C.; Lv, X.; Xie, X. Simulation and experimental investigations of ultrasonic-assisted drilling with Micro-PDC bit. Geoenergy Sci. Eng. 2023, 223, 211480. [Google Scholar] [CrossRef]

- Naskar, A.; Choudhary, A.; Paul, S. Surface generation in ultrasonic-assisted high-speed superabrasive grinding under minimum quantity cooling lubrication with various fluids. Tribol. Int. 2021, 156, 106815. [Google Scholar] [CrossRef]

- Cao, Y.; Ding, W.; Zhao, B.; Wen, X.; Li, S.; Wang, J. Effect of intermittent cutting behavior on the ultrasonic vibration-assisted grinding performance of Inconel 718 nickel-based superalloy. Precis. Eng. 2022, 78, 248–260. [Google Scholar] [CrossRef]

- Kumar, J. Ultrasonic Machining—A Comprehensive Review. Mach. Sci. Technol. 2013, 17, 325–379. [Google Scholar] [CrossRef]

- Razav, H.; Mirbagheri, M. Design and fabrication of a novel vibrational system for ultrasonic assisted oblique turning process. J. Mech. Sci. Technol. 2016, 30, 827–835. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K.; Outeiro, J.; Khanna, N. Surface integrity in ultrasonic-assisted turning of Ti6Al4V using sustainable cutting fluid. Procedia CIRP 2022, 108, 55–60. [Google Scholar] [CrossRef]

- Xu, Y.; Gao, F.; Zou, P.; Zhang, Q.; Fan, F. Theoretical and experimental investigations of surface roughness, surface topography, and chip shape in ultrasonic vibration-assisted turning of Inconel 718. J. Mech. Sci. Technol. 2020, 34, 3791–3806. [Google Scholar] [CrossRef]

- Zou, L.; Huang, Y.; Zhou, M.; Duan, L. Investigation on diamond tool wear in ultrasonic vibration-assisted turning die steels. Mater. Manuf. Process. 2017, 32, 1505–1511. [Google Scholar] [CrossRef]

- Liu, C.; Wang, W.; Xiong, Y.; Huang, B.; Li, L. Experimental investigation on tool wear in ultrasonic vibration-assisted turning of SiCf/SiC ceramic matrix composite. Int. J. Adv. Manuf. Technol. 2023, 125, 3081–3101. [Google Scholar] [CrossRef]

- Sharma, V.; Pandey, P.M. Experimental investigations and statistical modeling of surface roughness during ultrasonic-assisted turning with self-lubricating cutting inserts. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2017, 232, 709–722. [Google Scholar] [CrossRef]

- Agrawal, C.; Khanna, N.; Gupta, M.K.; Kaynak, Y. Sustainability assessment of in-house developed environment-friendly hybrid techniques for turning Ti-6Al-4V. Sustain. Mater. Technol. 2020, 26, e00220. [Google Scholar] [CrossRef]

- Du, P.; Liu, Y.; Chen, W.; Hu, W.; Zhang, J.; Deng, J. A 2D Ultrasonic-Assisted Turning Tool with Function of In Situ Vibration Amplitude Self-Sensing. IEEE Trans. Ind. Electron. 2023. early access. [Google Scholar] [CrossRef]

- Tan, R.; Zhao, X.; Zou, X.; Li, Z.; Hu, Z.; Zhang, W.; Sun, T. Design and Implementation of a Novel Single-Driven Ultrasonic Elliptical Vibration Assisted Cutting Device. Micromachines 2018, 9, 535. [Google Scholar] [CrossRef]

- Lotfi, M.; Amini, S.; Aghayar, Z.; Sajjady, S.A.; Farid, A.A. Effect of 3D elliptical ultrasonic assisted boring on surface integrity. Measurement 2020, 163, 108008. [Google Scholar] [CrossRef]

- Duan, J.; Zou, P.; Wang, A.; Wei, S.; Fang, R. Research on three-dimensional ultrasonic vibration-assisted turning cutting force. J. Manuf. Process. 2023, 91, 167–187. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K.; Khanna, N. Novel use of ultrasonic-assisted turning in conjunction with cryogenic and lubrication techniques to analyze the machinability of Inconel 718. J. Manuf. Process. 2022, 81, 962–975. [Google Scholar] [CrossRef]

- Sharma, V.; Pandey, P.M. Optimization of machining and vibration parameters for residual stresses minimization in ultrasonic assisted turning of 4340 hardened steel. Ultrasonics 2016, 70, 172–182. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Li, L.; Huang, W. Theoretical and Simulation Analysis on Fabrication of Micro-Textured Surface under Intermittent Cutting Condition by One-Dimensional Ultrasonic Vibration-Assisted Turning. Machines 2022, 10, 166. [Google Scholar] [CrossRef]

- Liu, X.; Wu, D.; Zhang, J. Fabrication of micro-textured surface using feed-direction ultrasonic vibration-assisted turning. Int. J. Adv. Manuf. Technol. 2018, 97, 3849–3857. [Google Scholar] [CrossRef]

- Schubert, A.; Nestler, A.; Pinternagel, S.; Zeidler, H. Influence of ultrasonic vibration assistance on the surface integrity in turning of the aluminium alloy AA2017. Mater. Sci. Eng. Technol. 2011, 42, 658–665. [Google Scholar] [CrossRef]

- Guo, P.; Ehmann, K.F. An analysis of the surface generation mechanics of the elliptical vibration texturing process. Int. J. Mach. Tools Manuf. 2013, 64, 85–95. [Google Scholar] [CrossRef]

- Lotfi, M.; Amini, S.; Akbari, J. Surface integrity and microstructure changes in 3D elliptical ultrasonic assisted turning of Ti–6Al–4V: FEM and experimental examination. Tribol. Int. 2020, 151, 106492. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K.; Bertolini, R.; Krolczyk, G.M.; Khanna, N. Sustainable cooling strategies to reduce tool wear, power consumption and surface roughness during ultrasonic assisted turning of Ti-6Al-4V. Tribol. Int. 2022, 169, 107494. [Google Scholar] [CrossRef]

- Liu, X.; Wu, D.; Zhang, J.; Hu, X.; Cui, P. Analysis of surface texturing in radial ultrasonic vibration-assisted turning. J. Mater. Process. Technol. 2019, 267, 186–195. [Google Scholar] [CrossRef]

- Puga, H.; Grilo, J.; Carneiro, V.H. Ultrasonic Assisted Turning of Al alloys. Influence of Material Processing to Improve Surface Roughness. Surfaces 2019, 2, 326–335. [Google Scholar] [CrossRef]

- Bai, W.; Bisht, A.; Roy, A.; Suwas, S.; Sun, R.; Silberschmidt, V.V. Improvements of machinability of aerospace-grade Inconel alloys with ultrasonically assisted hybrid machining. Int. J. Adv. Manuf. Technol. 2019, 101, 1143–1156. [Google Scholar] [CrossRef]

| Workpiece | Material | C45 carbon steel; 201 stainless steel |

| Diameter (mm) | 21.8; 23.9; 27.6; 28.9; 29.3 | |

| Turning insert | Material | Tungsten carbide |

| Rake angle | Positive | |

| Clearance angle (°) | 7 | |

| Nose radius (mm) | 0.8 | |

| Vibration conditions | Amplitude (µm) | 9.8 |

| Frequency (kHz) | 20 | |

| Cutting conditions | Spindle speed (rev/min) | 285; 550; 700; 1100; 1600 |

| Feed rate (mm/rev) | 0.1 | |

| Depth of cut (mm) | 0.15 |

| Cutting Speed (m/min) | 20 | 40 | 50 | 60 | 100 | 120 |

| WiTheory (µm) | 16.67 | 33.33 | 41.67 | 50 | 83.33 | 100 |

| WiMeasurement for C45 steel (µm) | 17.01 | 33.11 | 40.53 | 50.65 | 80.68 | 107.45 |

| Deviation standard (µm) | 1.24 | 1.00 | 1.58 | 1.49 | 2.53 | 3.70 |

| WiMeasurement for 201 stainless steel (µm) | 16.77 | 34.09 | 39.33 | 51.49 | 77.14 | 107.39 |

| Deviation standard (µm) | 1.67 | 0.67 | 2.79 | 0.75 | 2.52 | 2.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.-T.; Vu, T.-T.; Nguyen, T.-D. Surface Topography in Cutting-Speed-Direction Ultrasonic-Assisted Turning. Micromachines 2024, 15, 668. https://doi.org/10.3390/mi15060668

Nguyen T-T, Vu T-T, Nguyen T-D. Surface Topography in Cutting-Speed-Direction Ultrasonic-Assisted Turning. Micromachines. 2024; 15(6):668. https://doi.org/10.3390/mi15060668

Chicago/Turabian StyleNguyen, Thanh-Trung, Toan-Thang Vu, and Thanh-Dong Nguyen. 2024. "Surface Topography in Cutting-Speed-Direction Ultrasonic-Assisted Turning" Micromachines 15, no. 6: 668. https://doi.org/10.3390/mi15060668

APA StyleNguyen, T.-T., Vu, T.-T., & Nguyen, T.-D. (2024). Surface Topography in Cutting-Speed-Direction Ultrasonic-Assisted Turning. Micromachines, 15(6), 668. https://doi.org/10.3390/mi15060668