IGBT Gate Boost Drive Technology for Promoting the Overload Capacity of Traction Converter

Abstract

1. Introduction

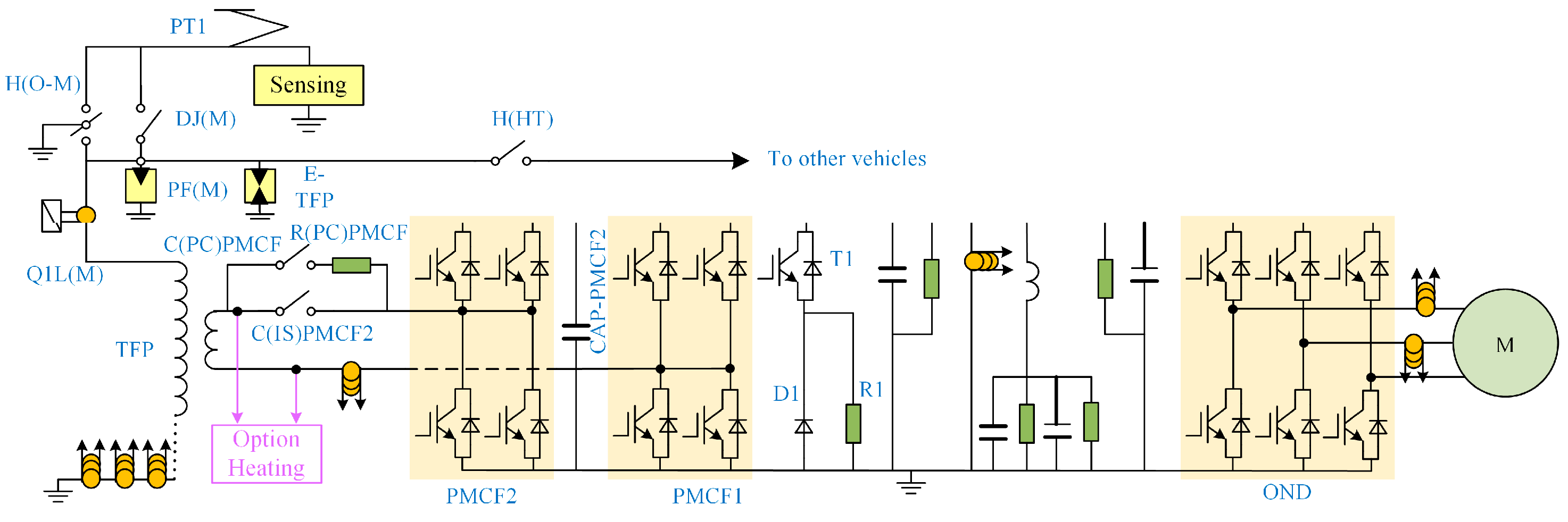

2. Characteristics of Traction Inverter

2.1. Analysis of Traction Converter System

2.2. Overload Condition of Traction Inverter

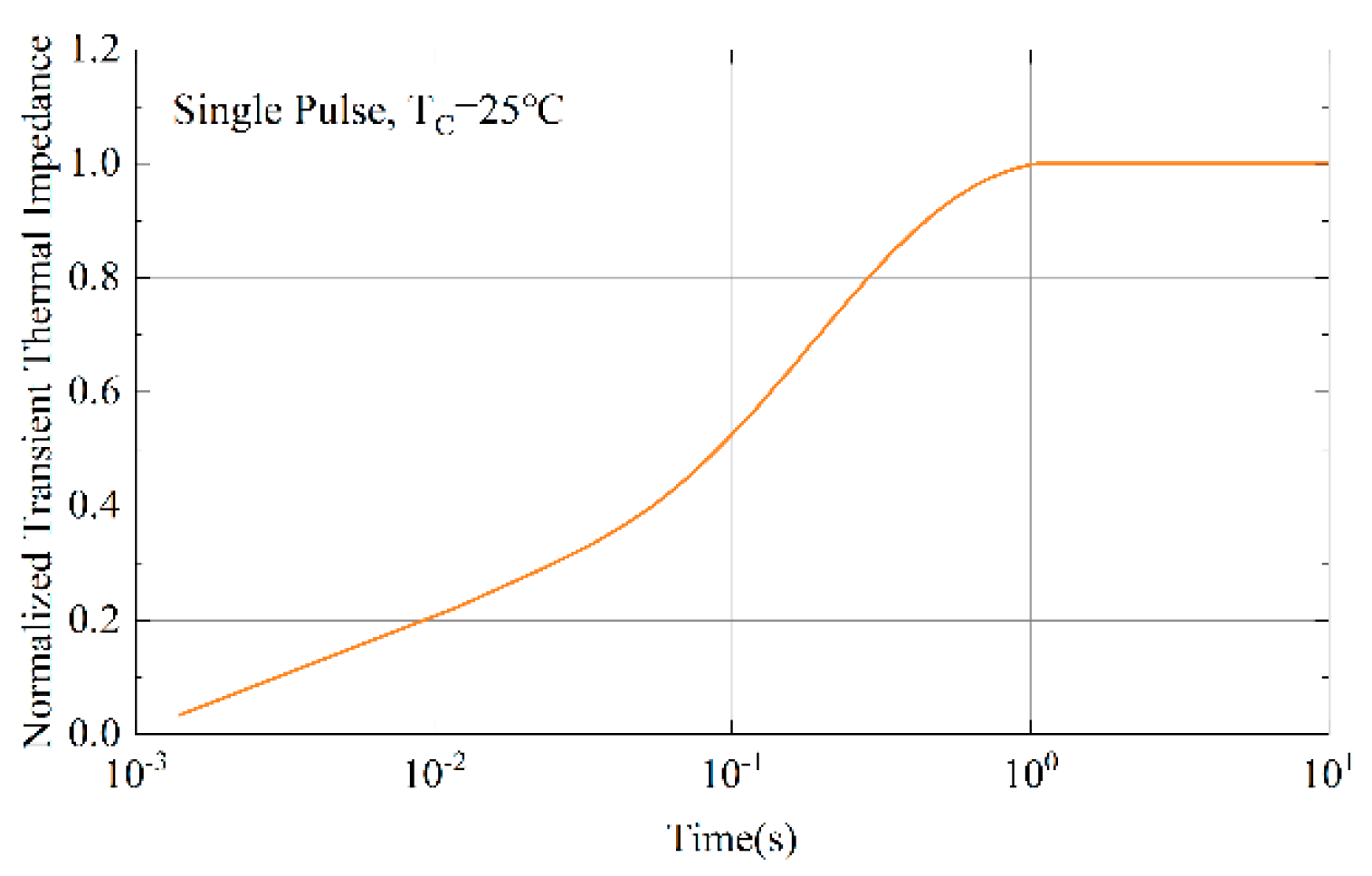

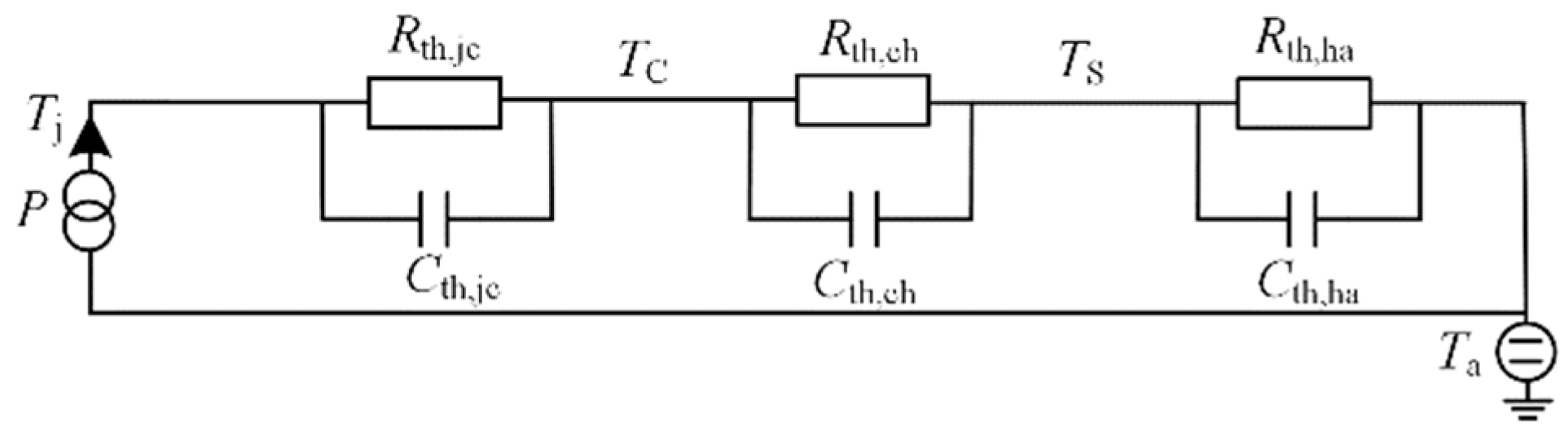

3. Analysis of IGBT Temperature Rise and Working Characteristics

3.1. Analysis of IGBT Temperature Rise

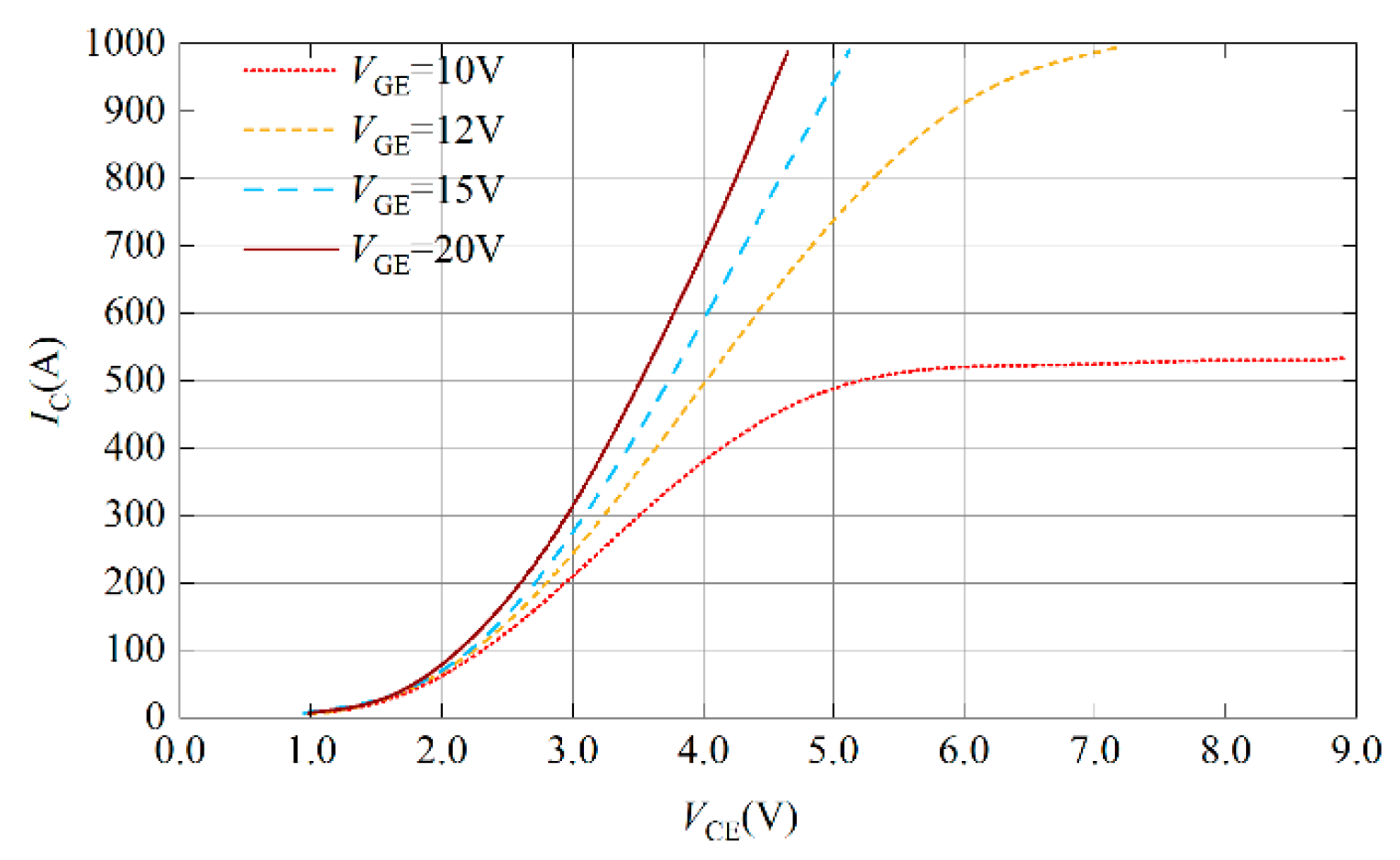

3.2. Analysis of IGBT Working Characteristics

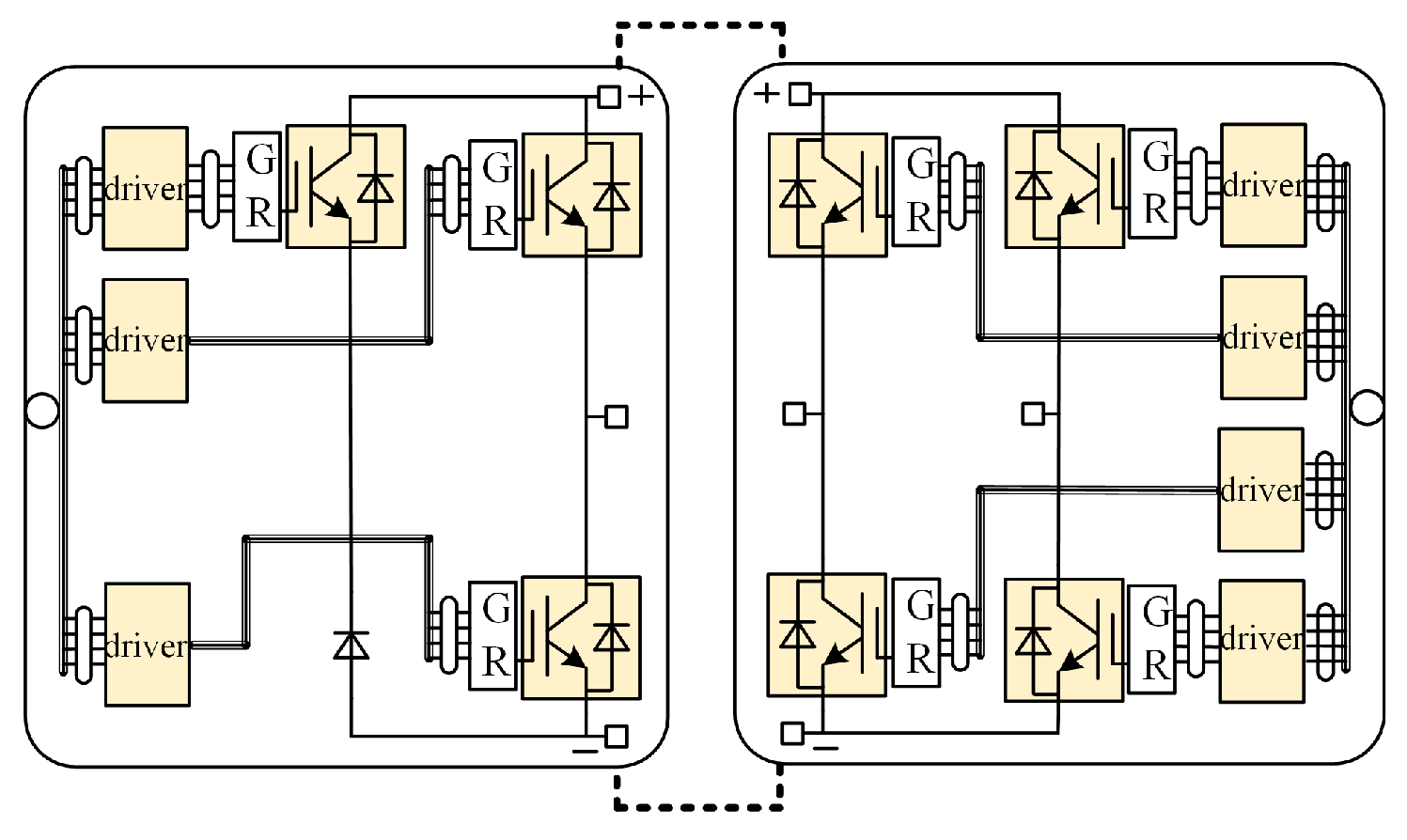

4. Application of Gate-Voltage-Boosting Technology in IGBT Driver Circuit

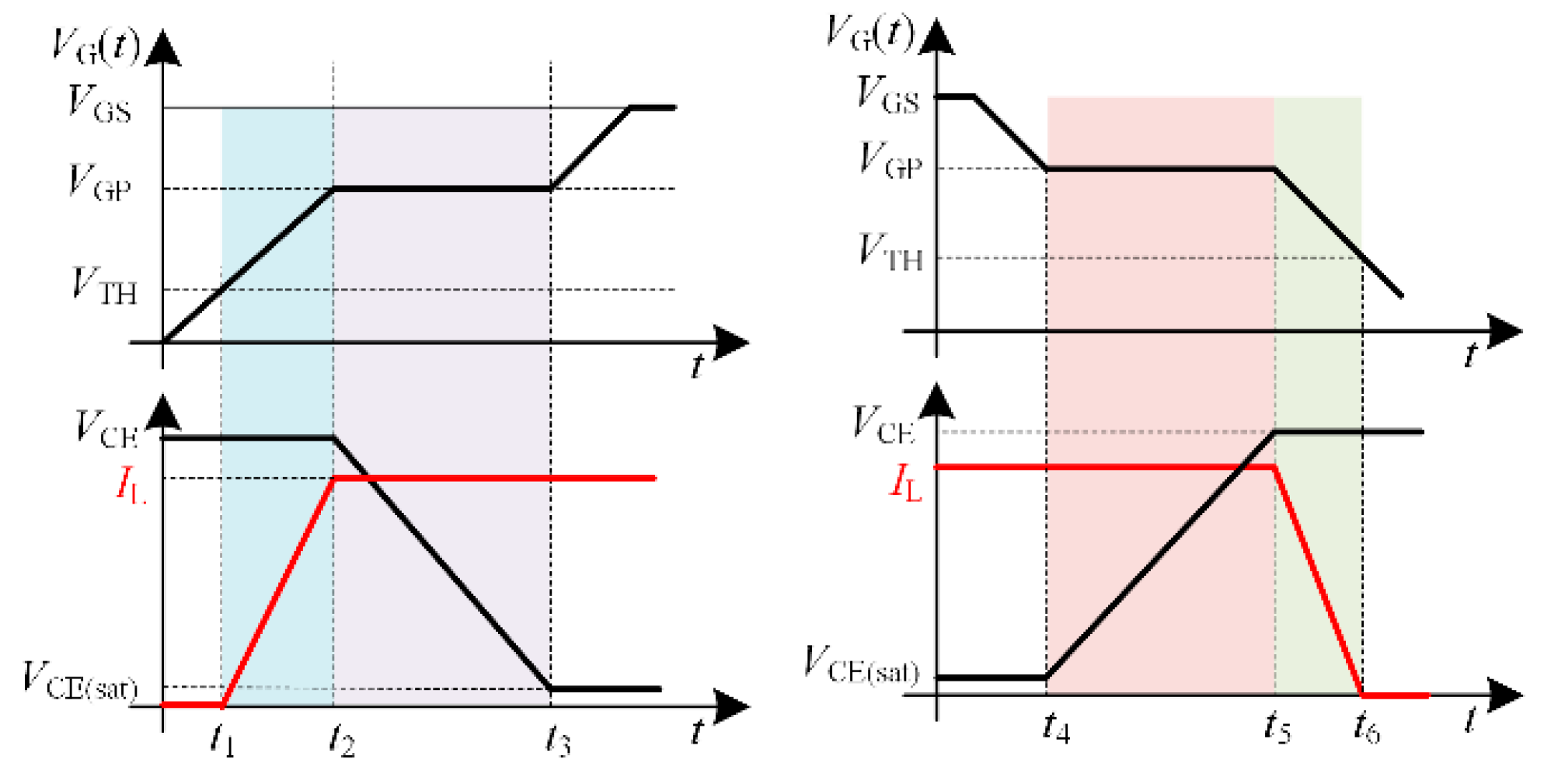

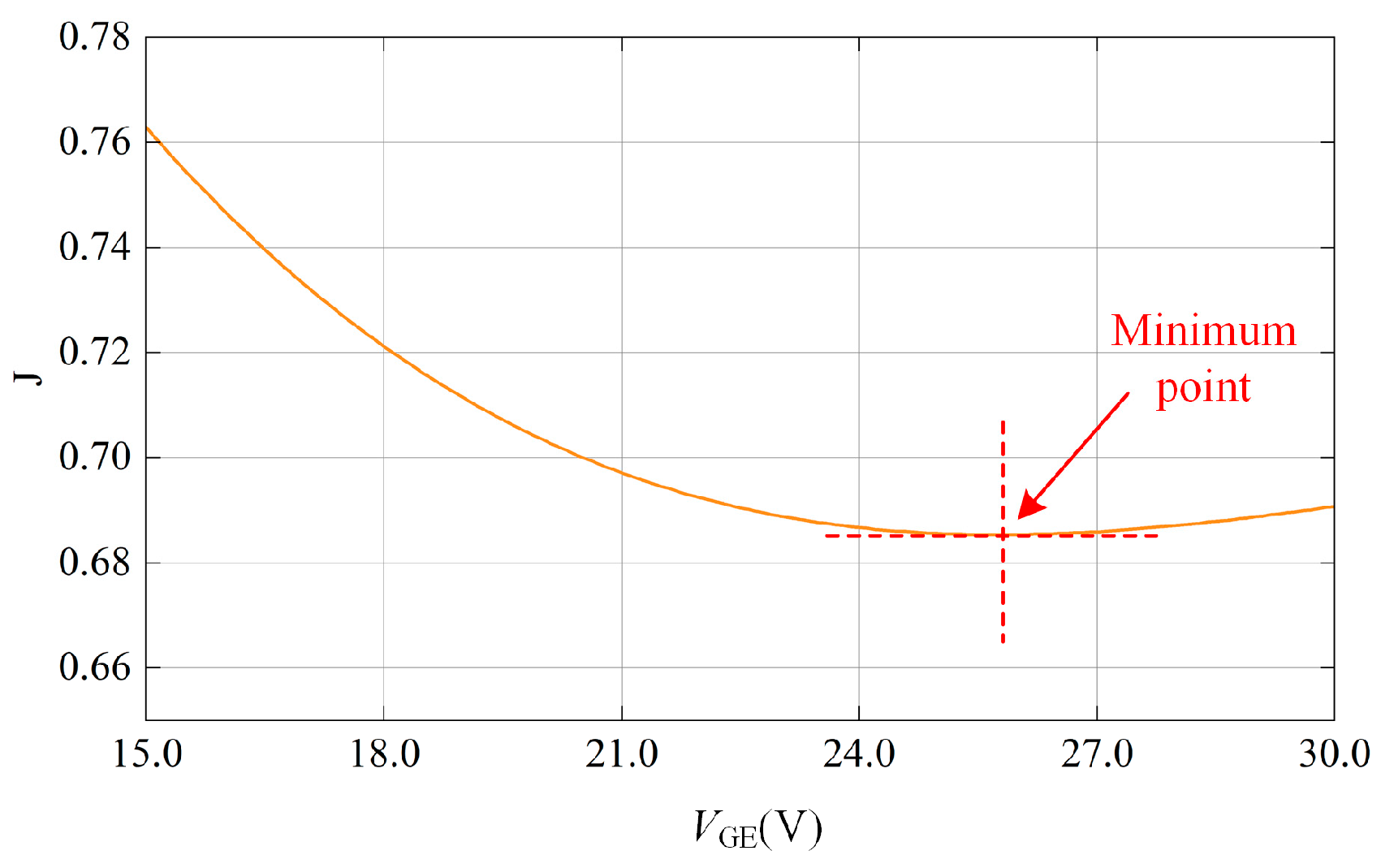

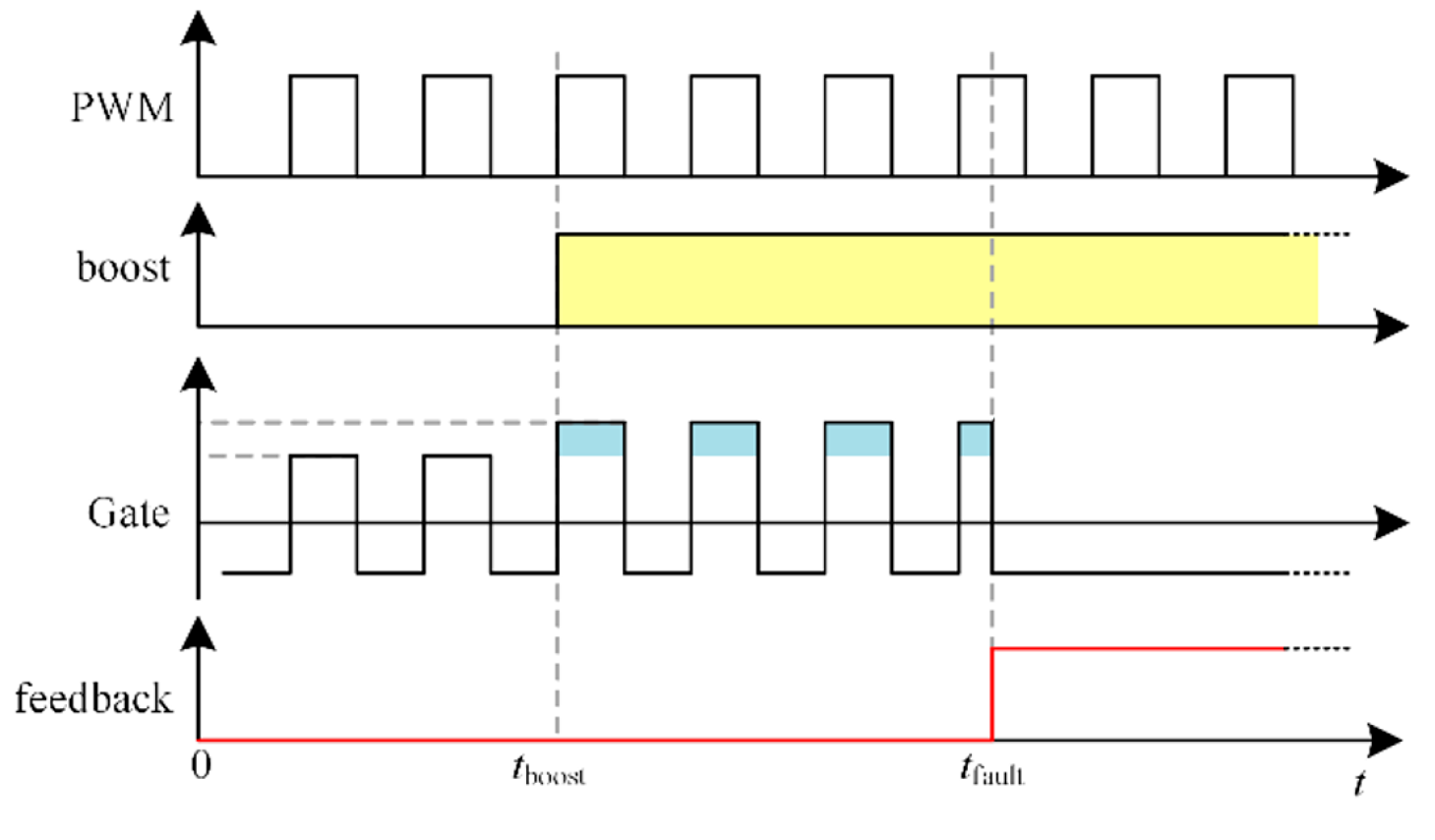

4.1. Principle of Gate-Voltage-Boosting Technology

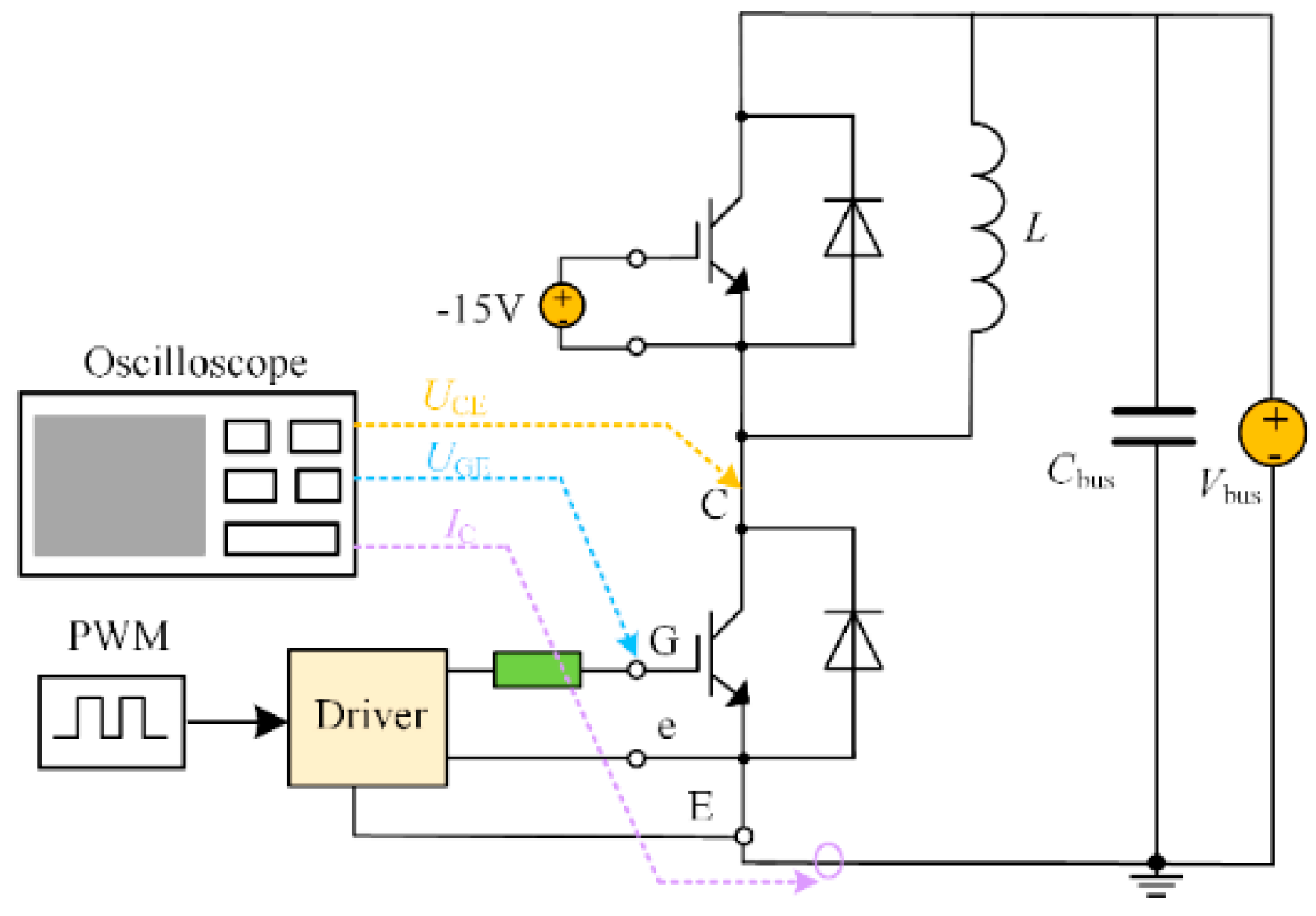

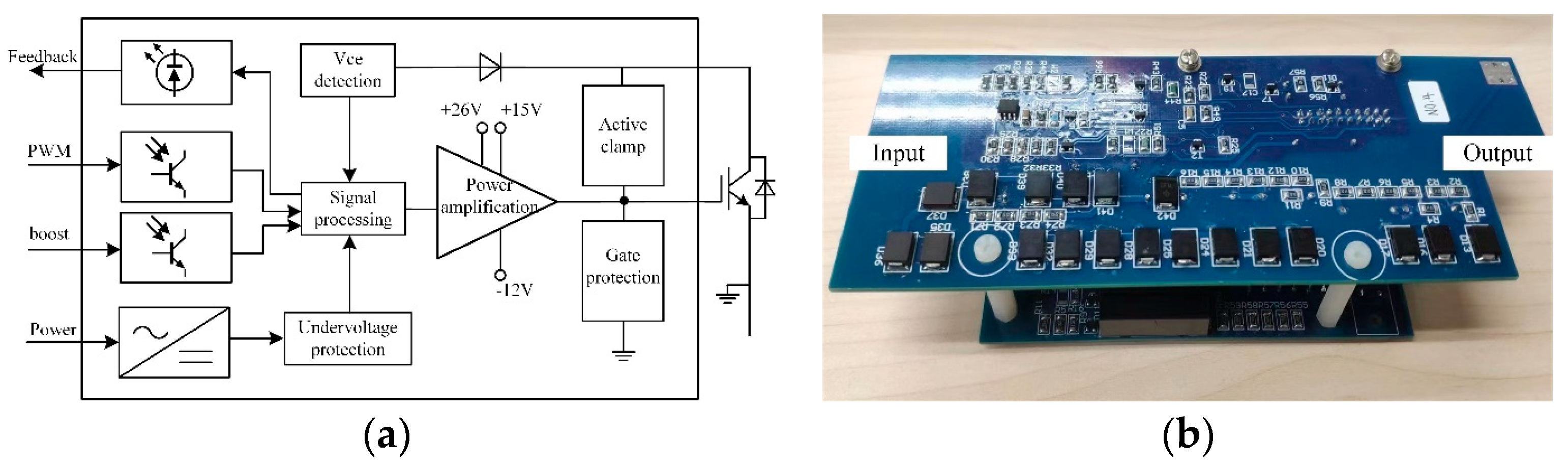

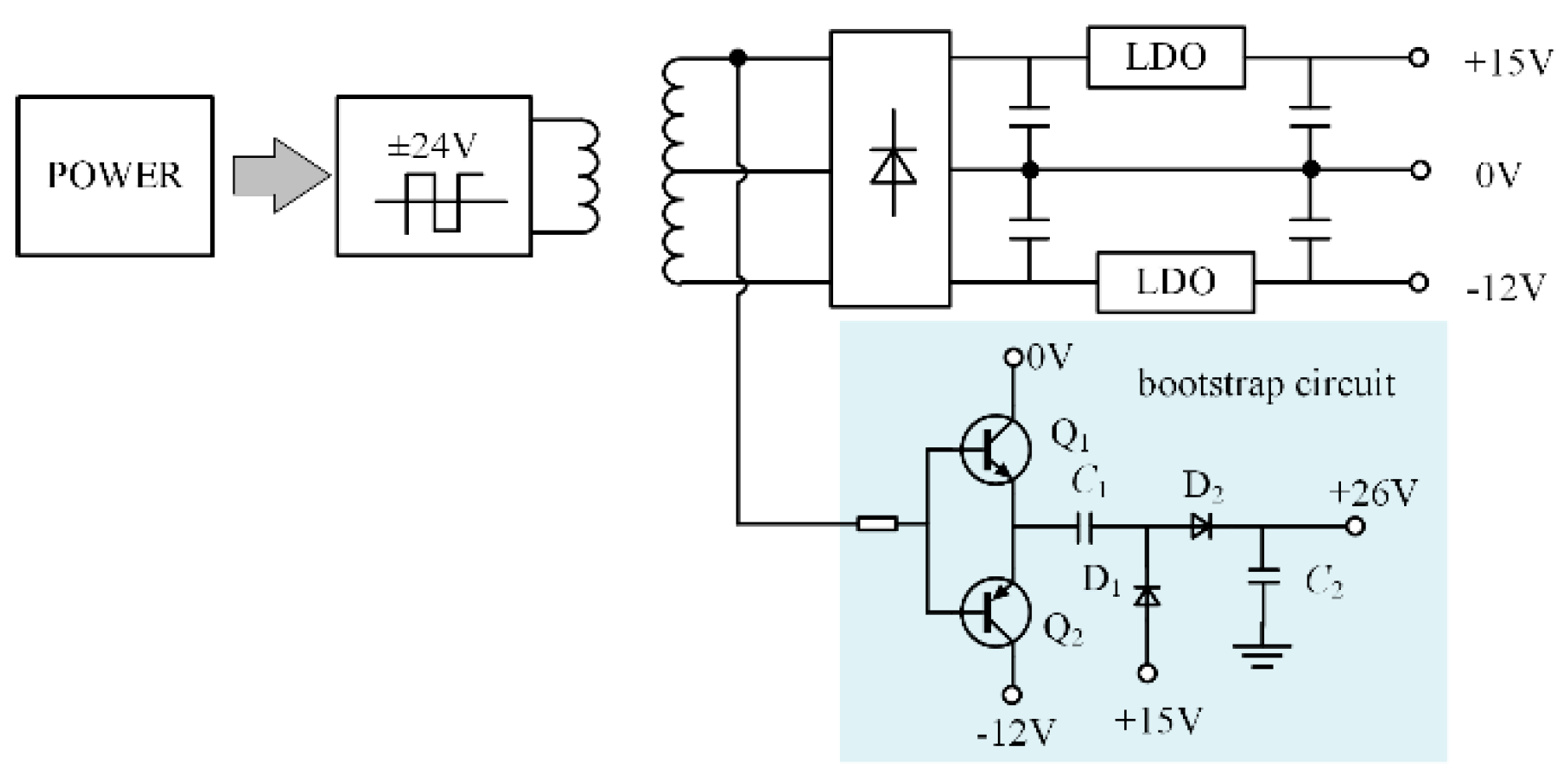

4.2. IGBT Driver Circuit Using Gate-Voltage-Boosting Technology

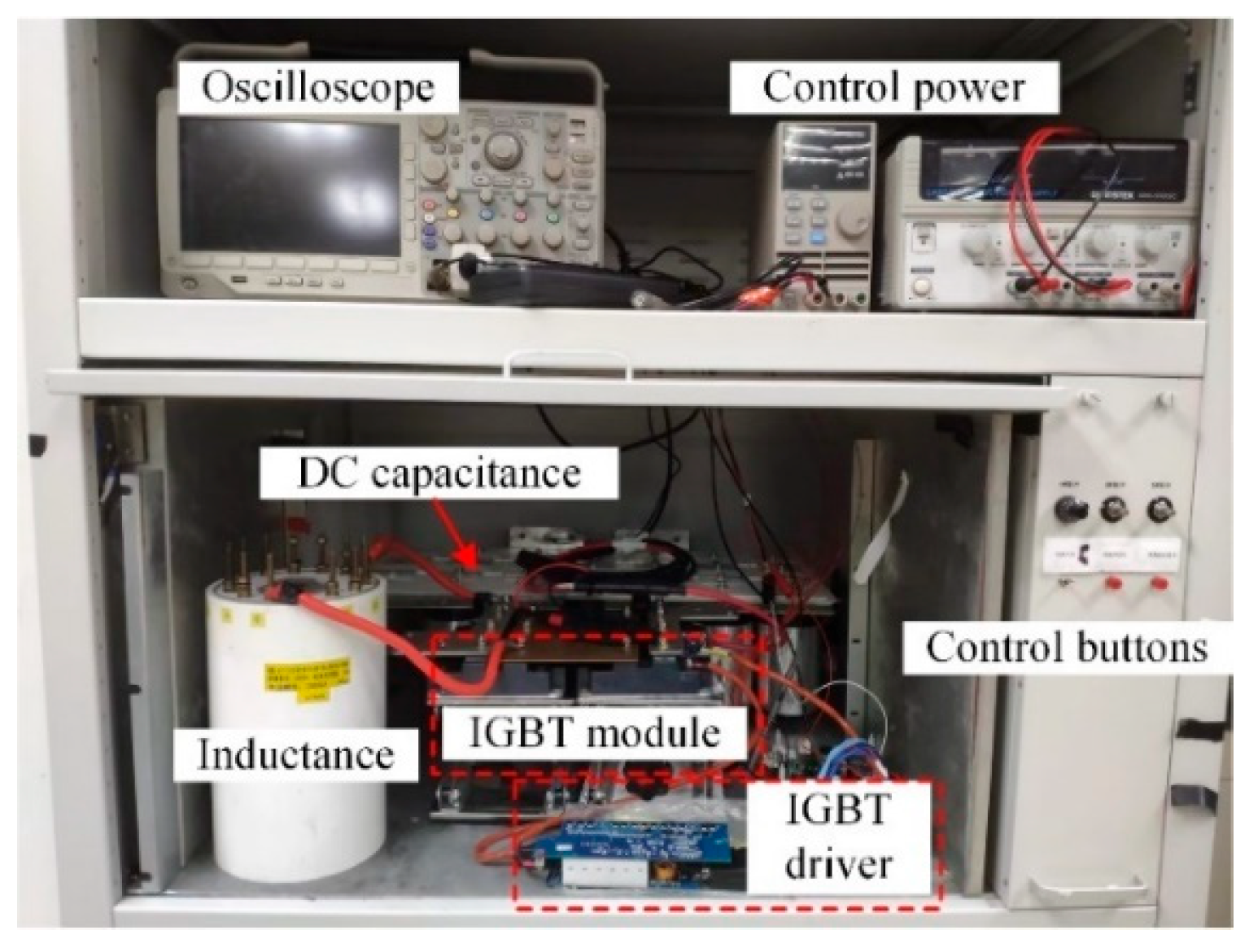

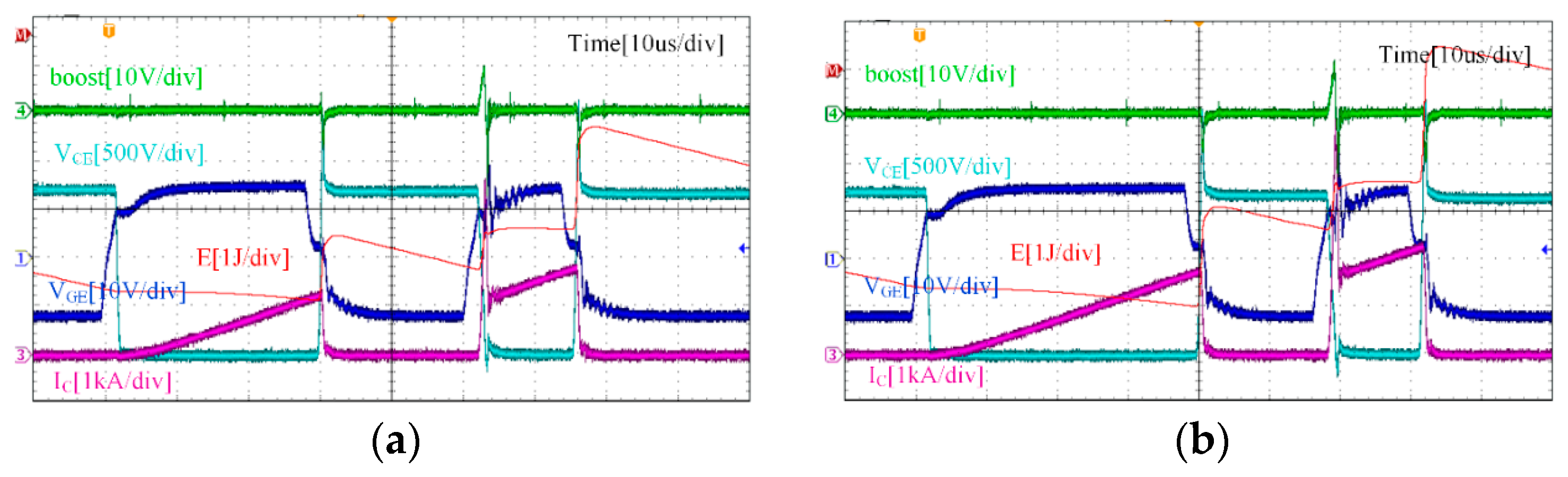

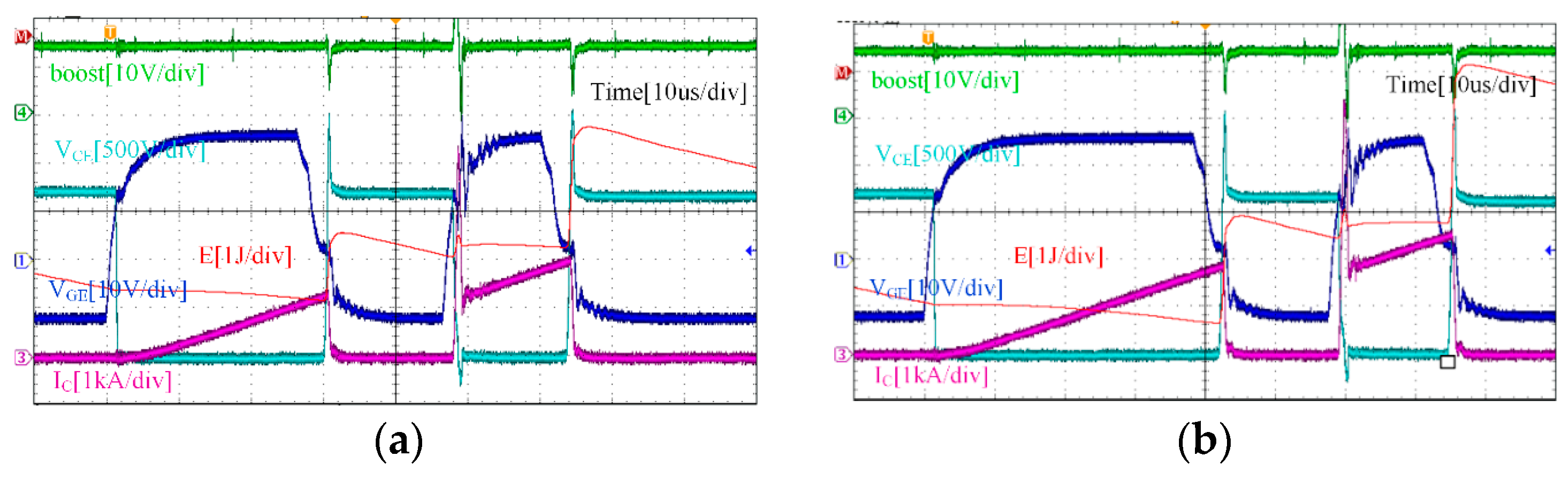

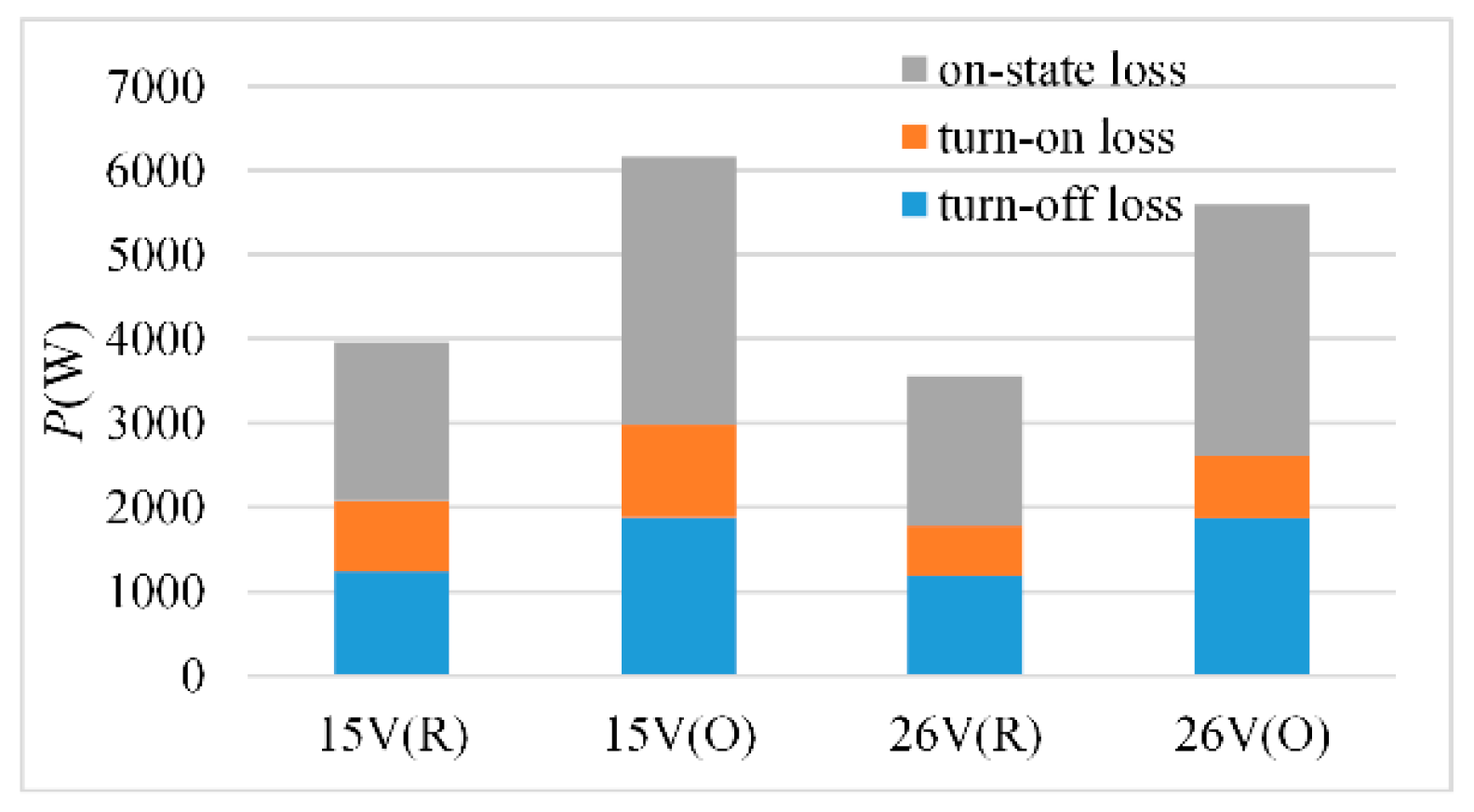

5. Experimental Verification

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, X.; Chang, W.; Zheng, T. Study of the protection and driving characteristics for high voltage high power IGBT modules used in traction converter. In Proceedings of the IEEE 10th Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015. [Google Scholar]

- Huang, X.; Du, T.; Wang, F.; Chen, C.; Sun, H. Research on high power density traction converter for hybrid EMUs. J. China Railw. Soc. 2022, 44, 34–41. [Google Scholar]

- Shen, L.; Chen, J.; Kaung, Y.; Han, W.; Liu, Z. Mission profiles-based lifetime prediction for IGBT modules applied to CRH3 traction converter. Trans. China Electrotech. Soc. 2022, 37, 172–180. [Google Scholar]

- Wang, X.; Wang, Y.; Castellazzi, A. Reduced active and passive thermal cycling degradation by dynamic active cooling of power modules. In Proceedings of the IEEE 27th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Hong Kong, China, 10–14 May 2015. [Google Scholar]

- Wang, X.; Castellazzi, A.; Zanchetta, P. Temperature control for reduced thermal cycling of power devices. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013. [Google Scholar]

- Du, X.; Li, G.; Li, T.; Sun, P.; Zhou, L. A hybrid modulation method for improving the lifetime of power modules in the wind power converter. Proc. CSEE 2015, 35, 5013–5022. [Google Scholar]

- Murdock, D.A.; Ramos, J.E.; Connors, J.J. Active thermal control of power electronics modules. In Proceedings of the 38th IAS Annual Meeting on Conference Record of the Industry Applications Conference, Salt Lake City, UT, USA, 12–16 October 2003. [Google Scholar]

- Lin, S.; Fang, X.; Li, B.; Lin, F.; Yang, Z. Reliability-oriented control strategy of traction converters in urban rail transit trains. Trans. China Electrotech. Soc. 2021, 36, 704–712. [Google Scholar]

- Lin, S.; Fang, X.; Lin, F.; Yang, Z. Mission profiles-based lifetime prediction for IGBT modules in traction inverter application. China Saf. Sci. J. 2019, 29, 52–57. [Google Scholar]

- Tian, Z. Mission-Profile Based Lifetime Assessment of IGBTs in High-Speed Traction Converter System. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2018. [Google Scholar]

- Hu, L.; Xiao, M.; Lou, X. Open-loop hierarchical control technology of High-power IGBT digital active gate drive. Trans. China Electrotech. Soc. 2018, 33, 2365–2375. [Google Scholar]

- Byongjo, H.; Park, J.; Kim, J. The Active Gate Driver for Switching Loss Reduction of Inverter. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020. [Google Scholar]

- Schmitt, G.; Kennel, R.; Holtz, M. Voltage gradient limitation of IGBTS by optimized gate-current profiles. In Proceedings of the IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008. [Google Scholar]

- Wang, Z.; Shi, X.; Tolbert, L.M.; Wang, F.; Blalock, B.J. A di/dt Feedback-Based Active Gate Driver for Smart Switching and Fast Overcurrent Protection of IGBT Modules. IEEE Trans. Power Electron. 2014, 35, 3720–3732. [Google Scholar] [CrossRef]

- Wu, X. Study on Control Method of HXD2 Electric Locomotion Converter. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2018. [Google Scholar]

- Han, C.; Ning, J.; Chen, Y.; Gao, R. Analysis of traction force of HXD3 locomotive and its division of three lines and three areas. Chin. Railw. 2014, 10, 59–63. [Google Scholar]

- Feng, X. Electric traction AC drive and its control system. High. Educ. Press 2009, 13, 11–34. [Google Scholar]

- Du, T. Research on IGBT Loss Heat Characteristics and Electrical Withstand Characteristics Based on Converter Operating Conditions. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2021. [Google Scholar]

- Wang, L. The Research on the Water-Cooled Heatsink of Traction Converter. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2015. [Google Scholar]

- Shahjalal, M.; Lu, H.; Bailey, C. Electro-thermal modelling of multichip power modules for high power converter application. In Proceedings of the International Conference on Electronic Packaging Technology, Harbin, China, 16–19 August 2017. [Google Scholar]

- Chen, M.; Sun, H.; Jin, J.; Rong, C.; Wang, Z. Research and application on new generation of traction IGBT module technology. Electr. Drive Locomot. 2021, 5, 77–86. [Google Scholar]

| Parameters | Traction | Cruise |

|---|---|---|

| ICP (A) | 1592.5 | 112.9 |

| M | 0.9 | 0.9 |

| η | 90% | 90% |

| cos φ | 0.896 | 0.896 |

| fsw (HZ) | 800 | 800 |

| Vdc (V) | 1800 | 1800 |

| Parameters | Traction | Cruise | ||

|---|---|---|---|---|

| IGBT | Diode | IGBT | Diode | |

| On-state loss (W) | 1553.1 | 248.7 | 33.0 | 6.8 |

| Switching loss (W) | 993.3 | 287.5 | 265.8 | 67.4 |

| Total loss (W) | 2546.4 | 536.2 | 298.8 | 74.2 |

| Total (W) | 3082.6 | 373 | ||

| Parameters | Traction | Cruise |

|---|---|---|

| Rth,jc_IGBT (K/kW) | 8.5 | |

| Rth,jc_Diode (K/kW) | 17 | |

| Rth,ch (K/kW) | 6 | |

| Rth,ha (K/kW) | 2 | |

| Ta (°C) | 30 | |

| TjI (°C) | 72.0 | 34.9 |

| TjD (°C) | 43.4 | 31.9 |

| Parameters | Value |

|---|---|

| Vbus (V) | 3600 |

| Cbus (F) | 0.006 |

| L (H) | 0.0006 |

| f (Hz) | 800 |

| Parameters | Value | |||

|---|---|---|---|---|

| condition | 15(R) | 15(O) | 26(R) | 26(O) |

| Eon (J) | 1.06 | 1.37 | 0.73 | 0.91 |

| Eoff (J) | 1.54 | 2.35 | 1.49 | 2.34 |

| VCE(sat) (V) | 3.14 | 3.54 | 2.98 | 3.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Dong, X.; Wu, L.; Wang, X.; Ma, M.; Huang, X.; Jin, Y.; Zhu, P. IGBT Gate Boost Drive Technology for Promoting the Overload Capacity of Traction Converter. Micromachines 2024, 15, 738. https://doi.org/10.3390/mi15060738

Zhang Y, Dong X, Wu L, Wang X, Ma M, Huang X, Jin Y, Zhu P. IGBT Gate Boost Drive Technology for Promoting the Overload Capacity of Traction Converter. Micromachines. 2024; 15(6):738. https://doi.org/10.3390/mi15060738

Chicago/Turabian StyleZhang, Yunxin, Xiaodong Dong, Linxia Wu, Xiaoyu Wang, Ming Ma, Xianjin Huang, Yong Jin, and Pengze Zhu. 2024. "IGBT Gate Boost Drive Technology for Promoting the Overload Capacity of Traction Converter" Micromachines 15, no. 6: 738. https://doi.org/10.3390/mi15060738

APA StyleZhang, Y., Dong, X., Wu, L., Wang, X., Ma, M., Huang, X., Jin, Y., & Zhu, P. (2024). IGBT Gate Boost Drive Technology for Promoting the Overload Capacity of Traction Converter. Micromachines, 15(6), 738. https://doi.org/10.3390/mi15060738