Study on Effect of Surface Micro-Texture of Cemented Carbide on Tribological Properties of Bovine Cortical Bone

Abstract

:1. Introduction

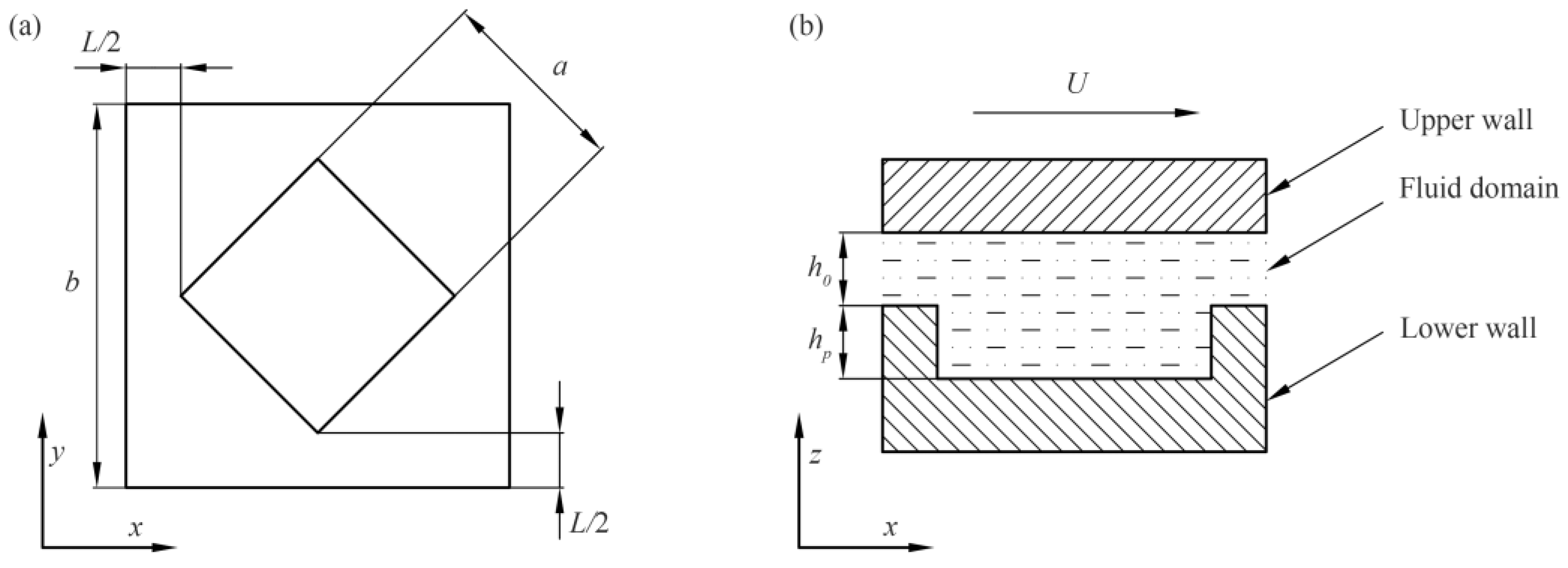

2. Simulation Study of Dynamic Pressure Lubrication Properties of Rhombus Texture

2.1. Modeling Texture Geometry

2.2. Mathematical Modeling of Fluid Dynamic Pressure

- (1)

- Fluid dynamic viscosity is constant. The effect of inertial forces is neglected.

- (2)

- There is no relative sliding between the fluid and the wall. The upper wall moves at the same velocity as the fluid layer in contact with it.

- (3)

- The fluid is a Newtonian fluid and the shear stress is proportional to the velocity.

- (4)

- There is no fluid penetration in the film thickness direction, implying that the velocity in the z-direction is zero.

2.3. Boundary Condition Setting and Lubrication Performance Parameter Calculation

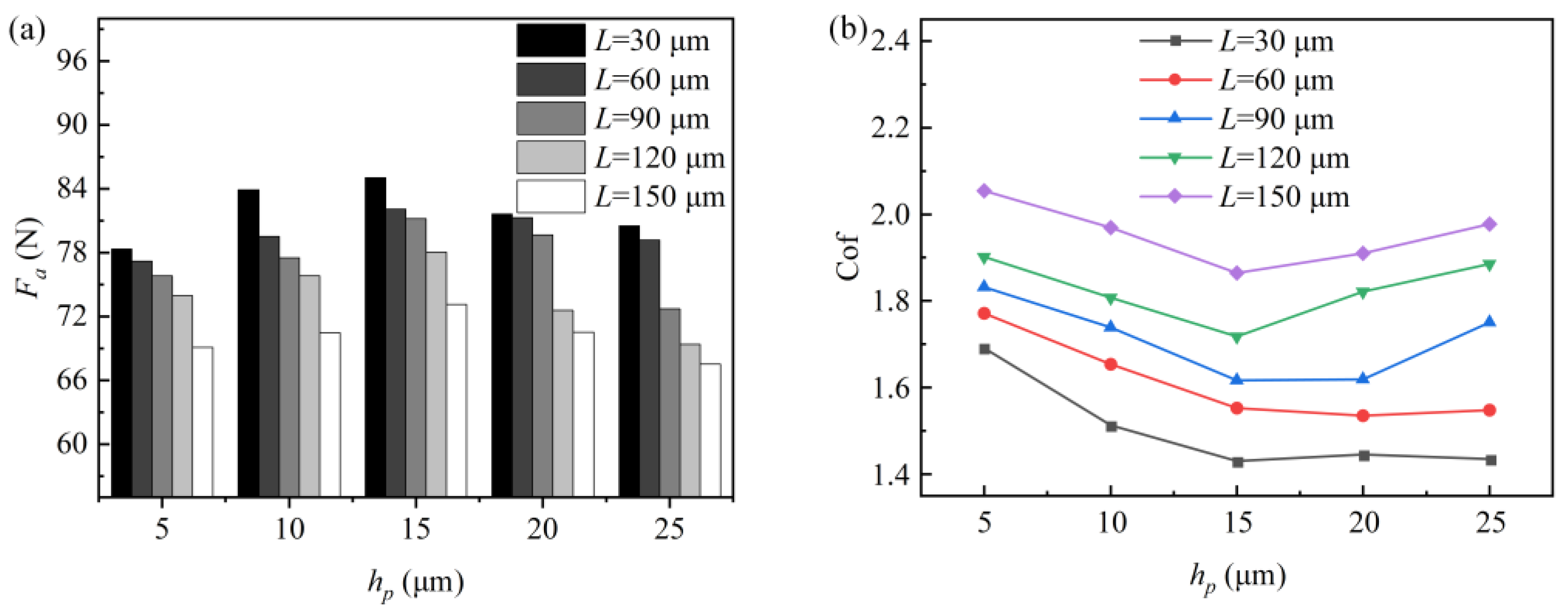

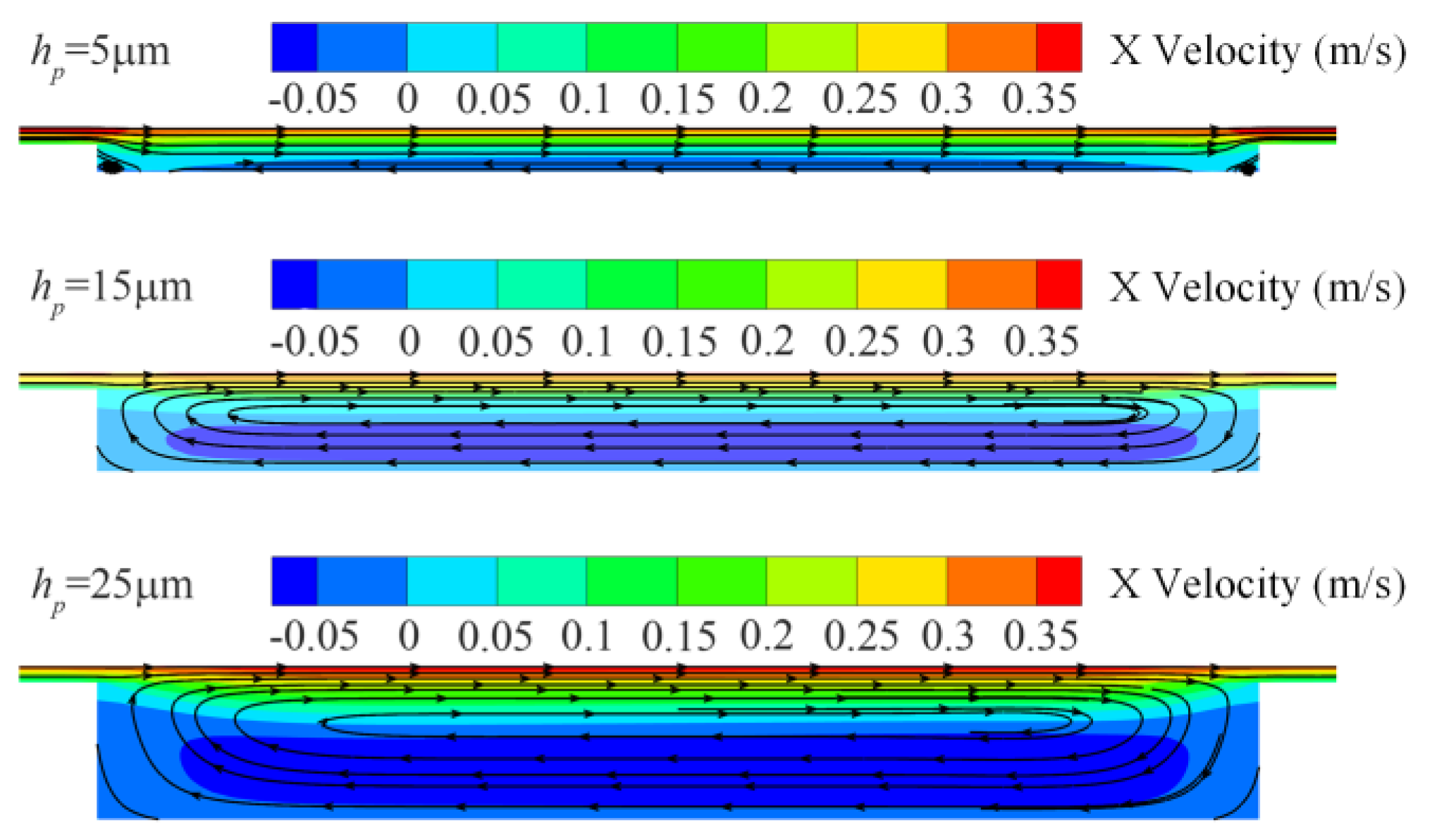

2.4. Effect of Texture Depth on Dynamic Pressure Lubrication Properties

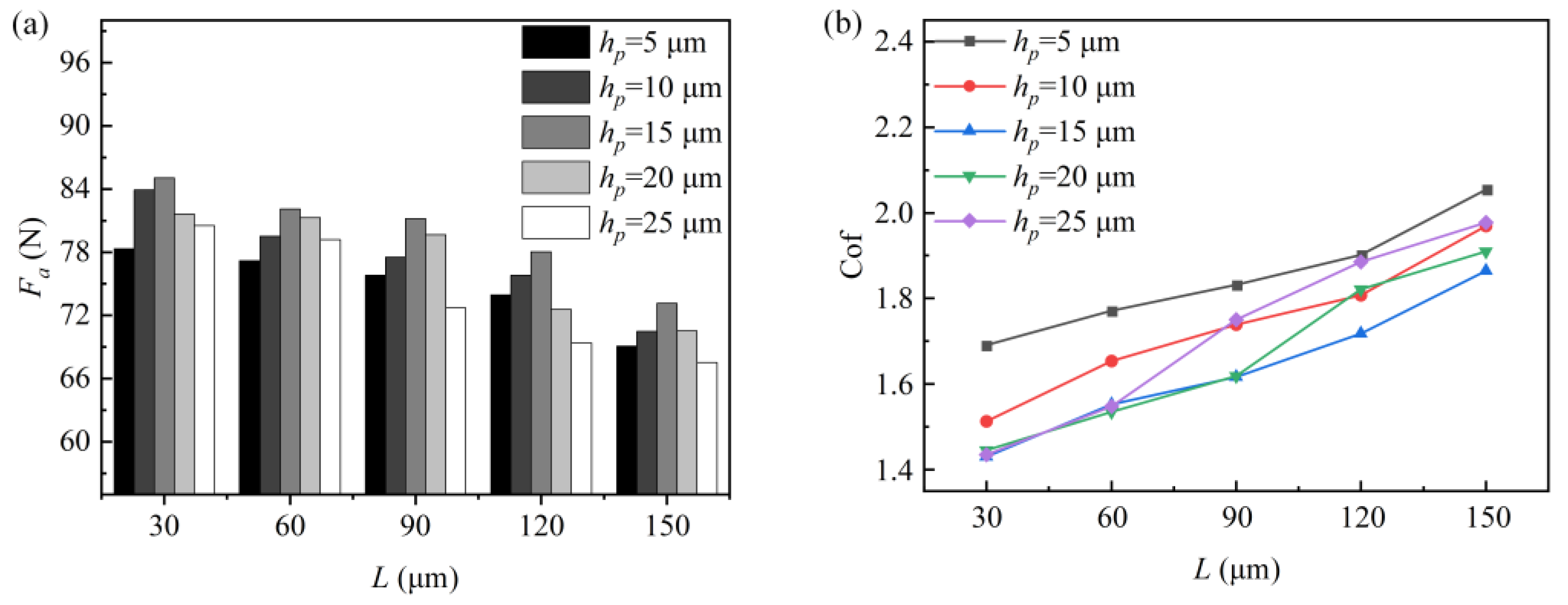

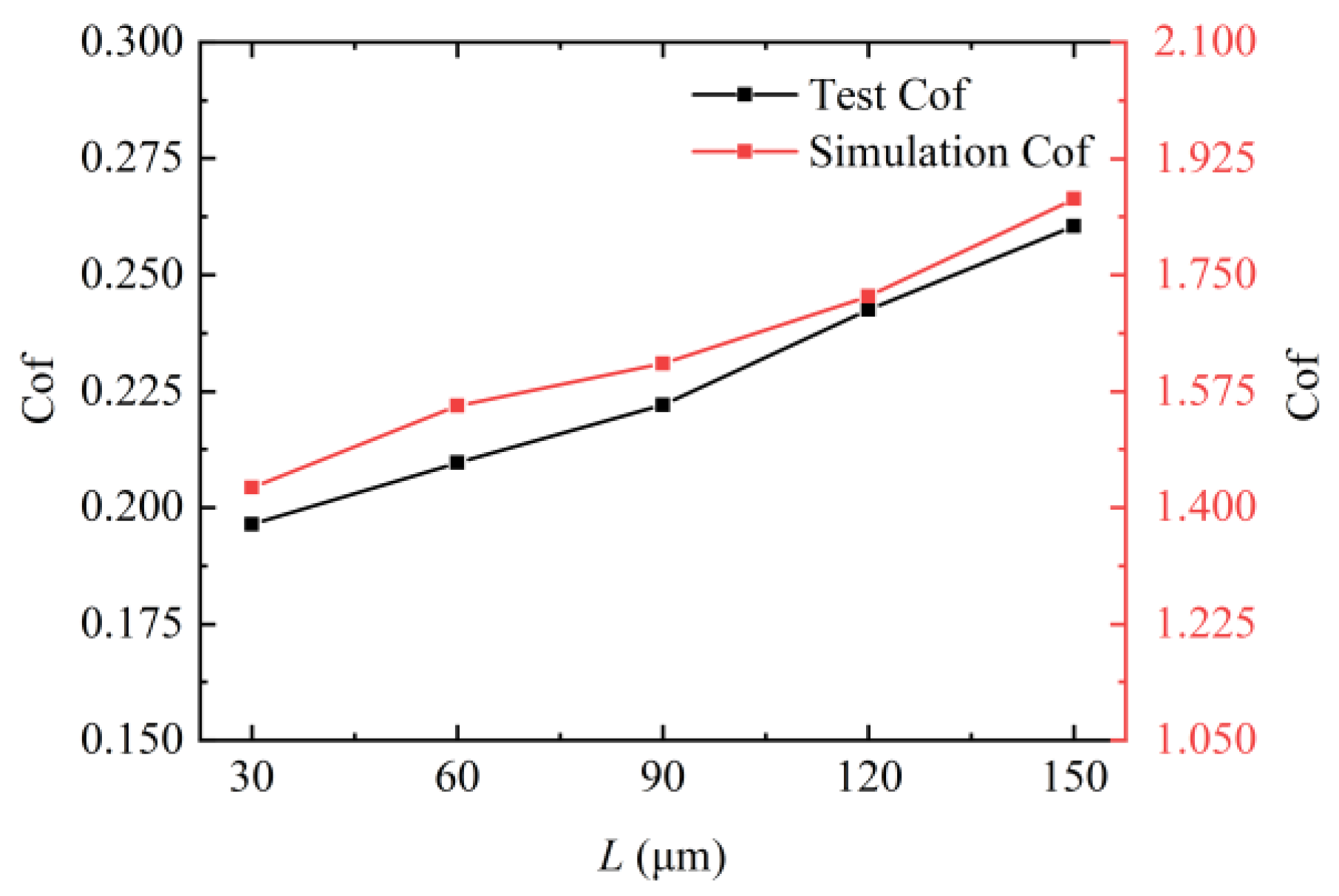

2.5. Effect of Texture Pitch on Dynamic Pressure Lubrication Properties

3. Experimental System and Method

3.1. Experimental Equipment

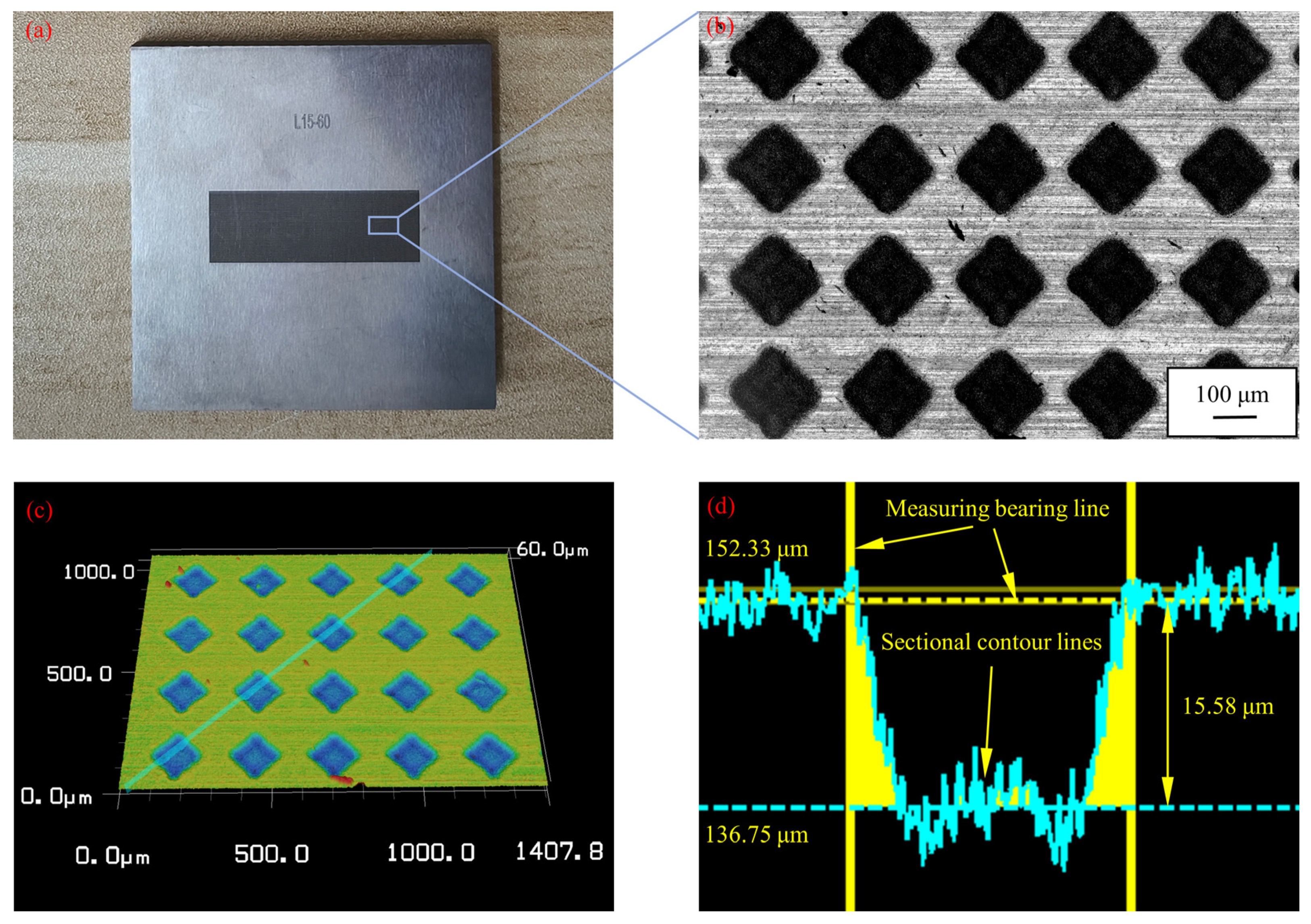

3.2. Sample Preparation

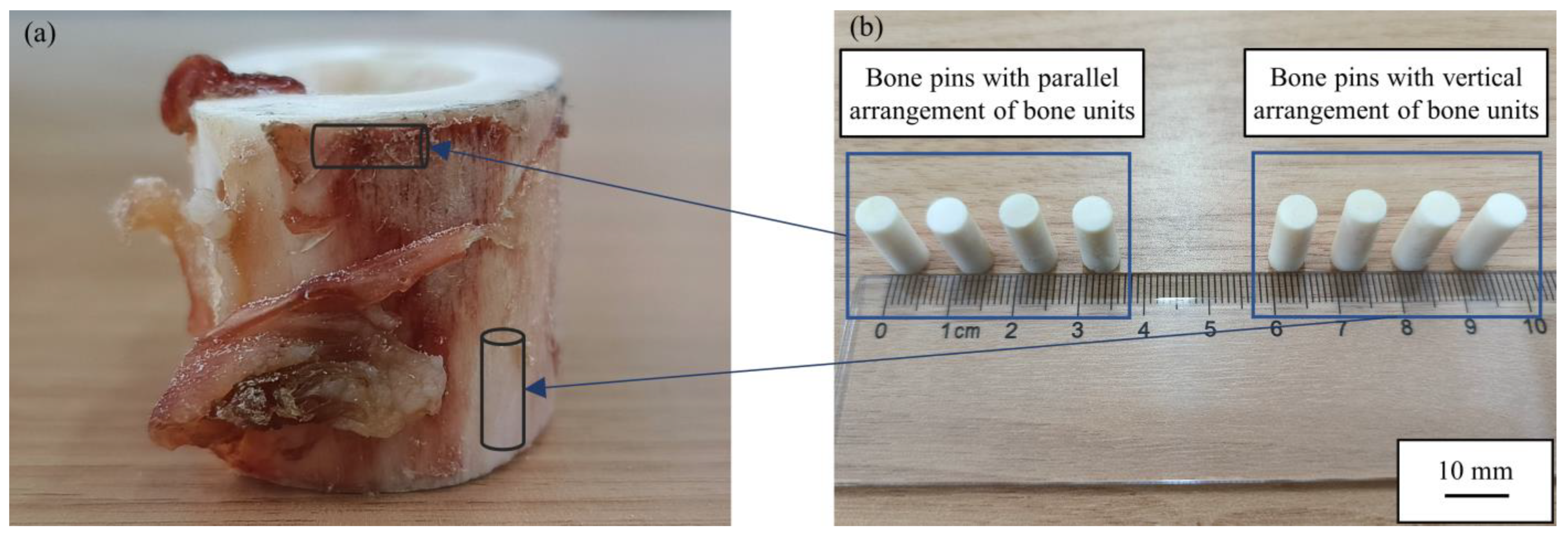

3.3. Experimental Methods

4. Experimental Results and Discussion

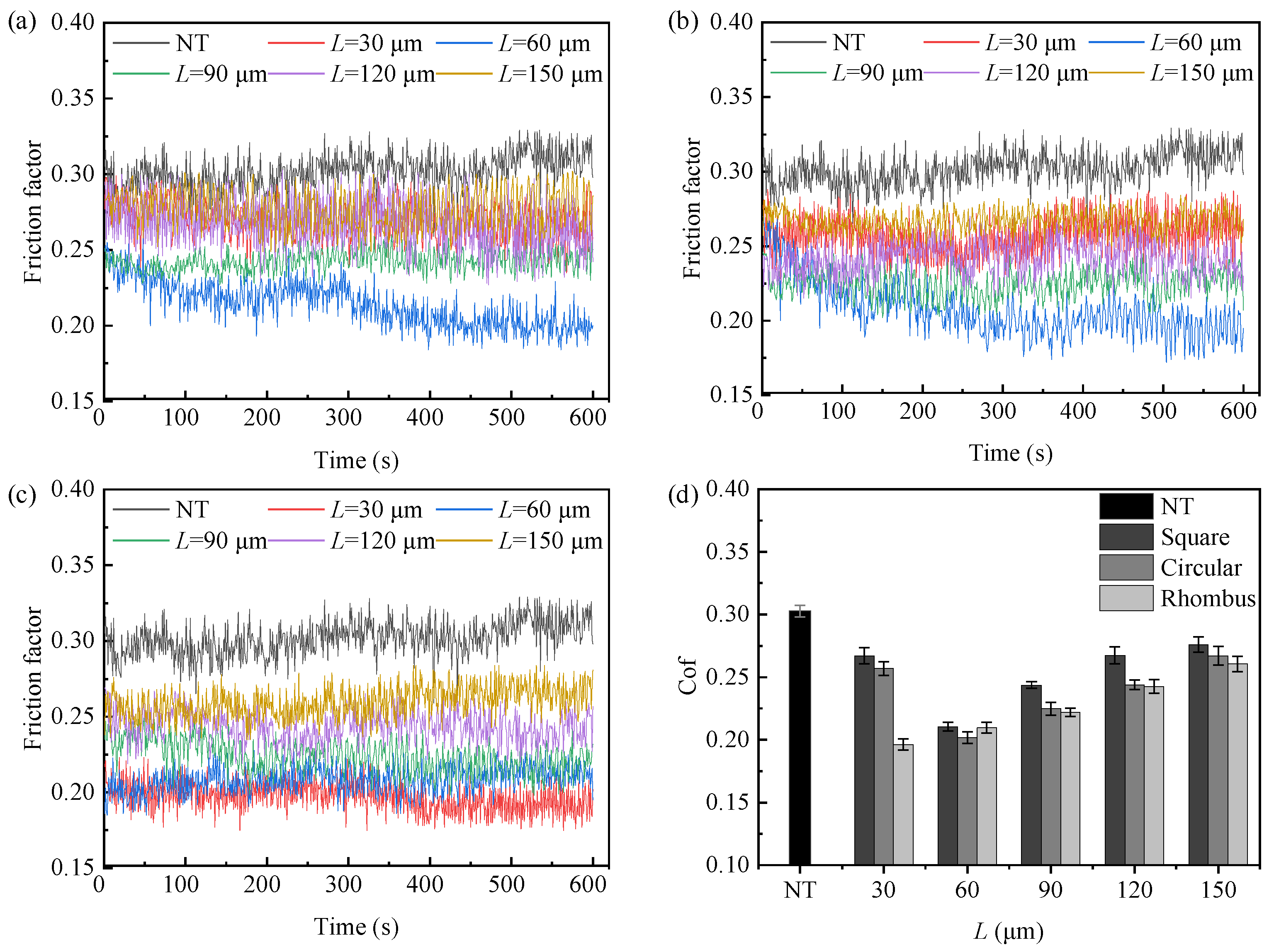

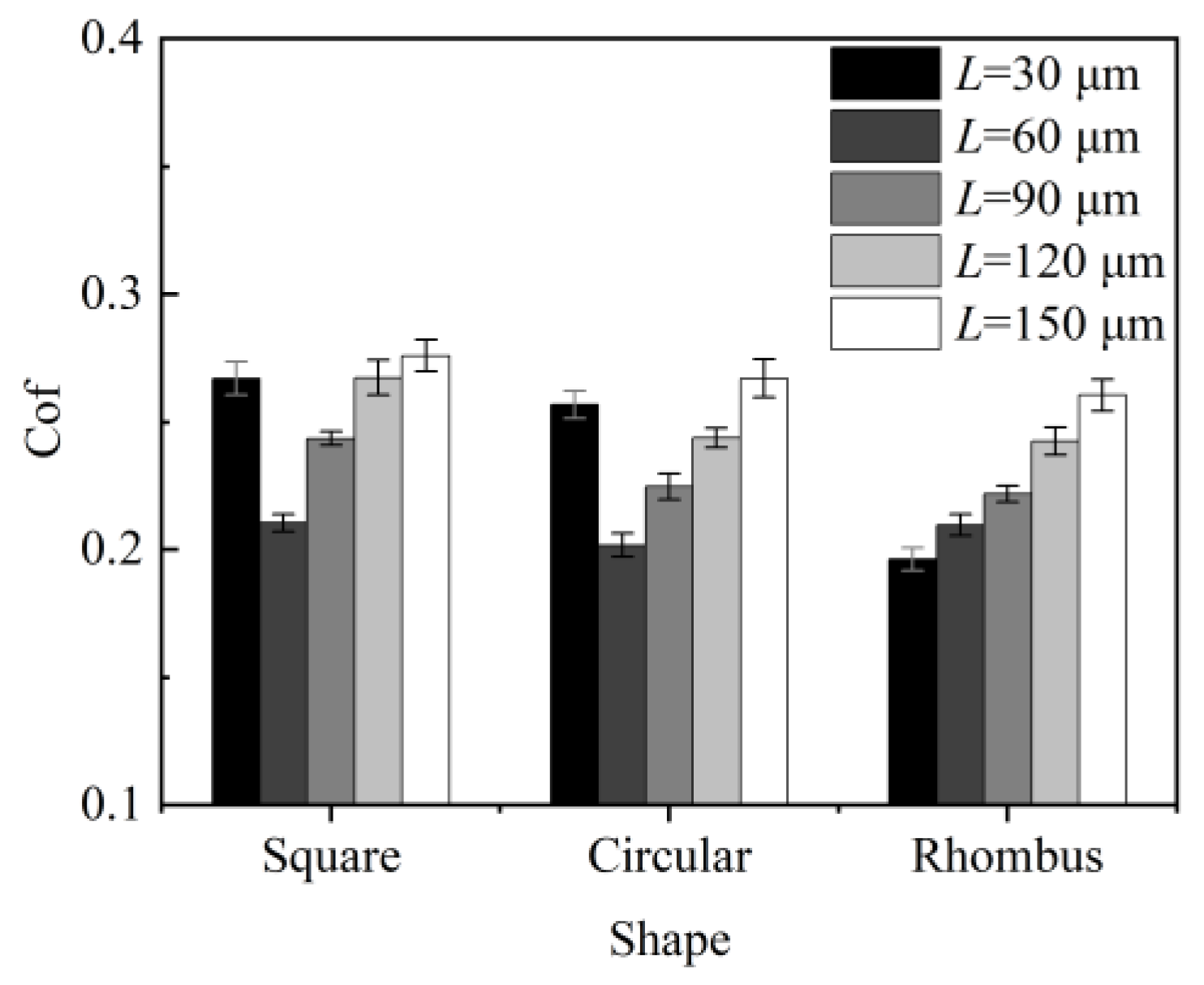

4.1. Effect of Texture Pitch on the Coefficient of Friction

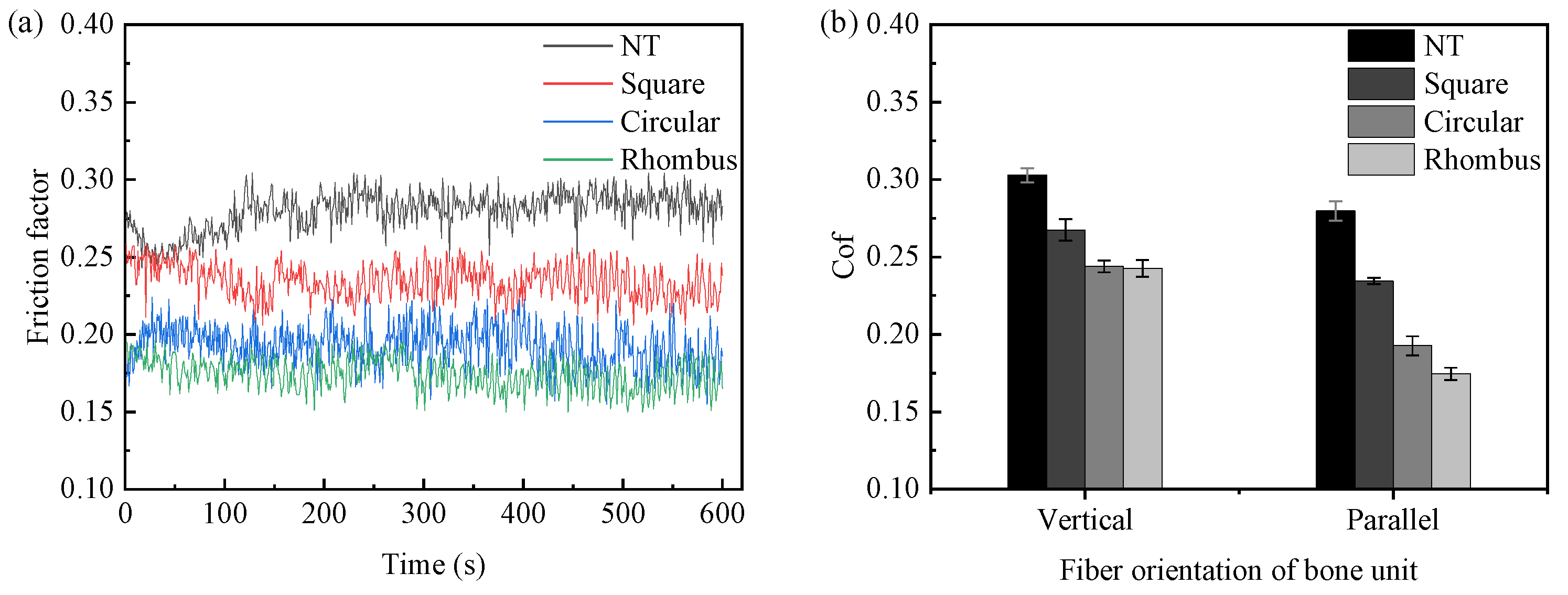

4.2. Effect of Texture Shape on the Coefficient of Friction

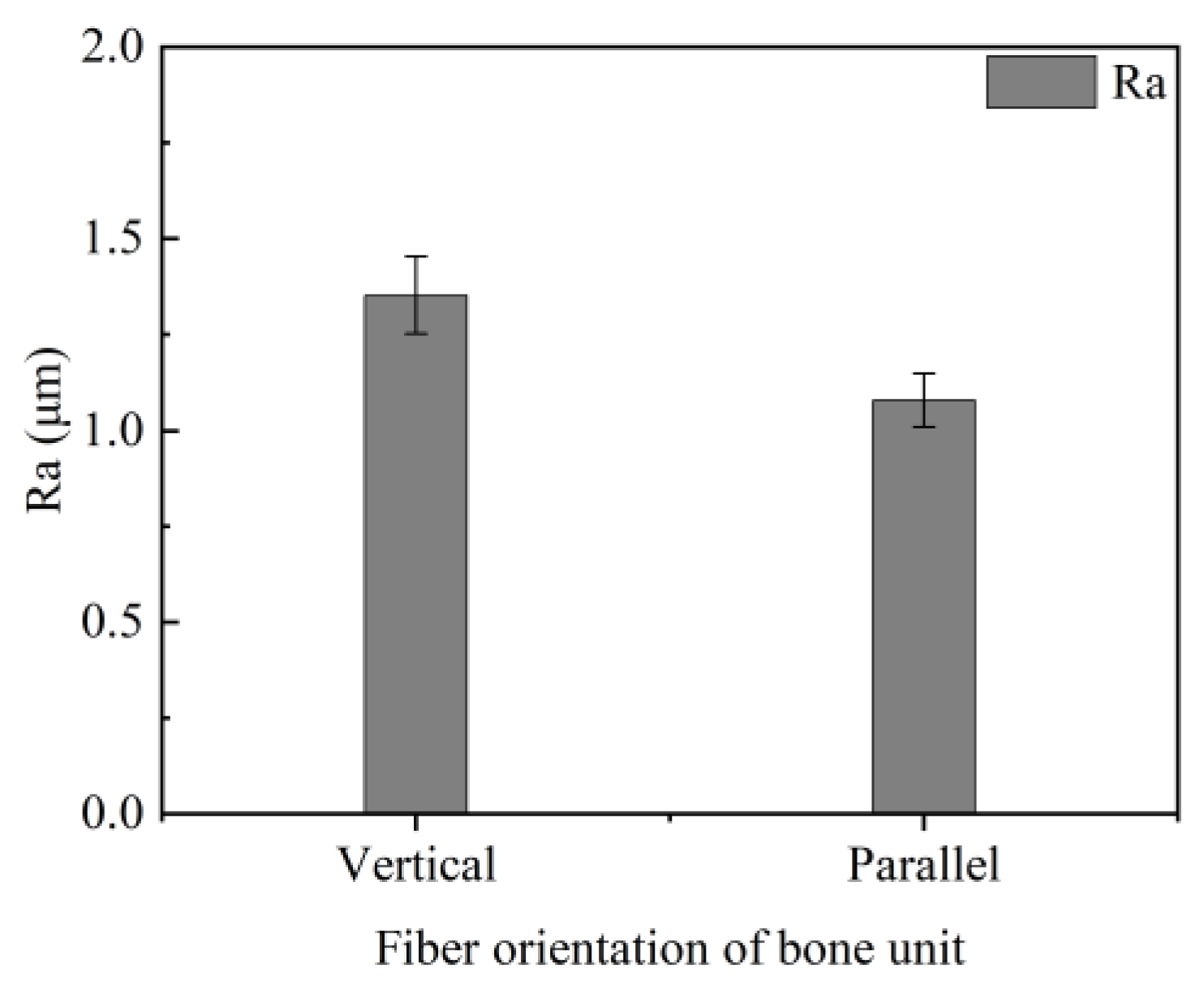

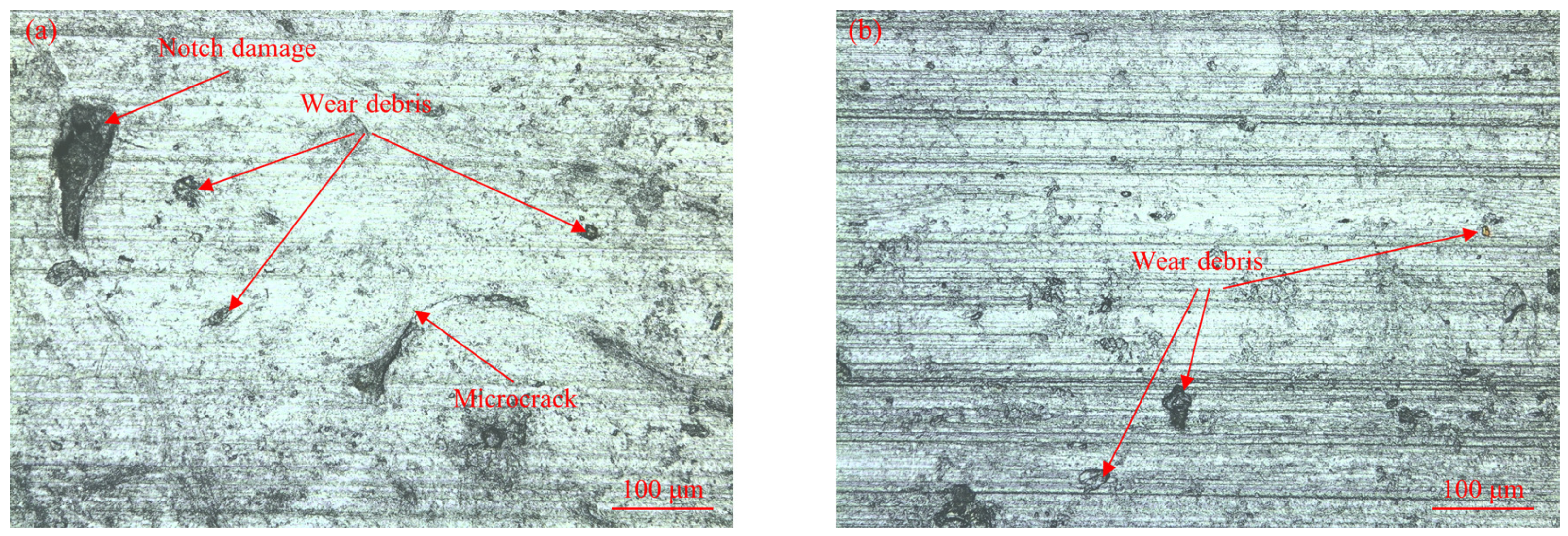

4.3. Effect of Bone Unit Arrangement on the Coefficient of Friction

5. Conclusions

- (1)

- The bearing capacity showed a tendency of increasing and then decreasing with an increase in the texture depth. The maximum bearing capacity and a relatively low friction coefficient were observed at a texture depth of 15 μm. In this case, the wedge effect caused by the increased texture depth counteracted the negative effect of vortex increase. Increasing the texture pitch weakened the pressurization effect of the converging wedge on the entire upper wall, resulting in a lower bearing capacity and higher friction coefficient. Consequently, a texture depth of 15 μm was identified as optimal.

- (2)

- With an increase in the pitch, the contact area of the friction pair increased. This weakened the dynamic pressure lubrication performance and reduced the ability to capture abrasive debris, leading to an increase in the friction coefficient of the diamond texture. The square- and circular-textured samples were affected by laser processing defects, which increased the contact surface roughness at a pitch of 30 μm. A recasting layer produced a plowing effect on bone needles, resulting in increased friction and higher friction coefficients. The smallest friction coefficient was observed at a pitch of 60 μm. Compared to the other textures, the rhombus texture exhibited the largest convergence wedge and the best dynamic pressure lubrication. The rhombus-shaped textured sample with a pitch of 30 μm reduced the coefficient of friction by 34.77% compared to the non-textured sample, demonstrating the best friction reduction effect.

- (3)

- Regardless of the bone unit arrangement, micro-textures reduced friction. However, the tribological properties of the bone pins differed between the two bone cell arrangements. The vertical arrangement had a greater roughness on the contact surface of the bone pins with cemented carbide compared to the parallel arrangement. This increased roughness accelerated the wear of the bone pins and made the surface of the bone pins more susceptible to microcracks under load. Consequently, bone pins with vertically aligned bone units exhibited a higher coefficient of friction.

- (4)

- Appropriate texture parameters can significantly reduce the friction coefficient between cemented carbide and bone contact surfaces. Reducing the contact friction coefficient can inhibit the frictional heat generation from chips and reduce the cutting force. In turn, the purpose of reducing thermal damage to bone cells and microcracks on the bone surface can be achieved. The results of this experiment provide valuable guidance for designing the surface microstructures of surgical instruments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tian, H.; Dang, X.; Meng, D.; Tian, B.; Li, J. Influence of drilling parameters on bone drilling force and temperature by FE simulation and parameters optimization based Taguchi method. Alex. Eng. J. 2023, 75, 115–126. [Google Scholar] [CrossRef]

- Lian, Y.; Chen, X.; Xie, C.; Long, Y.; Lin, F.; Zhou, W.; Chu, X. Cooling and Crack Suppression of Bone Material Drilling Based on Microtextured Bit Modeled on Dung Beetle. Chin. J. Mech. Eng. 2023, 36, 37. [Google Scholar] [CrossRef]

- Huang, Y.; Zhong, L.; Wang, G.; Wei, G.; Peng, S. Research status and progress of surface texture lubrication and friction reduction. Surf. Technol. 2021, 50, 217–232. [Google Scholar]

- Hamilton, D.B.; Walowit, J.A.; Allen, C.M. A Theory of Lubrication by Microirregularities. J. Basic Eng. 1966, 88, 177–185. [Google Scholar] [CrossRef]

- Etsion, I.; Burstein, L. A Model for Mechanical Seals with Regular Microsurface Structure. Tribol. Trans. 1996, 39, 677–683. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G. A Laser Surface Textured Hydrostatic Mechanical Seal. Tribol. Trans. 2002, 45, 430–434. [Google Scholar] [CrossRef]

- Li, P.; Zhang, F.; Zhang, H.; Wang, T.; Wang, Q.; Qiao, W. Lubrication performance of kite-shaped microtexture under hydrodynamic lubrication. Tribol. Int. 2023, 179, 108144. [Google Scholar] [CrossRef]

- Arif, M.; Kango, S.; Shukla, D.K. Investigating the effect of different slip zone locations on the lubrication performance of textured journal bearings. Ind. Lubr. Tribol. 2021, 73, 872–881. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, F.; Jiang, F.; Zhang, Y.; Liu, G. Investigation of tribological performance of micro-groove textured cemented carbide surfaces. Surf. Eng. 2020, 36, 1190–1199. [Google Scholar] [CrossRef]

- Zheng, G.; Lai, F.; Lin, Y.; Yu, J.; Ren, Z. Study on the Friction-Reducing Mechanisms of Surface Texture Cemented Carbide under Dry Sliding. J. Mater. Eng. Perform. 2023, 32, 2074–2083. [Google Scholar] [CrossRef]

- Pratap, T.; Patra, K. Tribological performances of symmetrically micro-textured Ti-6Al-4V alloy for hip joint. Int. J. Mech. Sci. 2020, 182, 105736. [Google Scholar] [CrossRef]

- Pratap, T.; Patra, K. Mechanical micro-texturing of Ti-6Al-4V surfaces for improved wettability and bio-tribological performances. Surf. Coat. Technol. 2018, 349, 71–81. [Google Scholar] [CrossRef]

- Hou, Q.; Yang, X.; Li, D.; Cheng, J.; Wang, S.; Xiao, J.; Li, W. Tribological performance of hydrophobic and micro/nano triangle textured rake face of cutting tools. Appl. Surf. Sci. 2022, 571, 151250. [Google Scholar] [CrossRef]

- Cheng, H.; Zhou, F.; Fei, Z. Dry Friction Properties of Friction Subsets and Angle Related to Surface Texture of Cemented Carbide by Femtosecond Laser Surface Texturing. Coatings 2023, 13, 741. [Google Scholar] [CrossRef]

- Chen, J.; Zheng, Q.; Hu, Y. Effect of dimple micro-texture on friction properties of 4Cr13 stainless steel/cortical friction pair. Tool Eng. 2019, 53, 31–35. [Google Scholar]

- Yin, H.; Yang, J.; Gu, Q. Numerical study on the hydrodynamic lubrication performance improvement of bio-inspired peregrine falcon wing-shaped microtexture. Tribol. Int. 2024, 191, 109049. [Google Scholar] [CrossRef]

- Liu, W.; Ni, H.; Chen, H.; Wang, P. Numerical simulation and experimental investigation on tribological performance of micro-dimples textured surface under hydrodynamic lubrication. Int. J. Mech. Sci. 2019, 163, 105095. [Google Scholar] [CrossRef]

- Chen, K.; Yang, X.; Zhang, Y.; Yang, H.; Lv, G.; Gao, Y. Research progress of improving surface friction properties by surface texture technology. Int. J. Adv. Manuf. Technol. 2021, 116, 2797–2821. [Google Scholar] [CrossRef]

- Liao, Z.; Axinte, D.; Gao, D. On modelling of cutting force and temperature in bone milling. J. Mater. Process. Technol. 2019, 266, 627–638. [Google Scholar] [CrossRef]

- Chen, Q.-S.; Dai, L.; Liu, Y.; Shi, Q.-X. A cortical bone milling force model based on orthogonal cutting distribution method. Adv. Manuf. 2020, 8, 204–215. [Google Scholar] [CrossRef]

- Jing, X.; Zhai, Q.; Zhang, D.; Zheng, S.; Jaffery, S.H.I.; Wang, F. Wettability and frictional properties on zirconia surfaces irradiated by femtosecond laser. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 654, 130198. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, H.; Zhou, W. Surface incubation effect of carbide yg6 induced by femtosecond laser. Acta Photonica Sin. 2019, 48, 614002. [Google Scholar] [CrossRef]

- Cui, Z.; Guo, Z.; Yuan, C. Influence of different rhombic surface textures on the tribological performance of water-lubricated bearings. Mater. Express 2020, 10, 1452–1462. [Google Scholar] [CrossRef]

- Shang, P.; Zhang, H.; Liu, X.; Yang, Z.; Liu, B.; Liu, T. Cutting-Force Modeling Study on Vibration-Assisted Micro-Milling of Bone Materials. Micromachines 2023, 14, 1422. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Z. The effect of micro-pits texture on the coefficient of friction between wood and cemented carbide. Sci. Silvae Sin. 2019, 55, 136–143. [Google Scholar]

| Experiment Number | Texture Pitch (μm) | Texture Depth (μm) |

|---|---|---|

| 1 | 30 | 5 |

| 2 | 30 | 10 |

| 3 | 30 | 15 |

| 4 | 30 | 20 |

| 5 | 30 | 25 |

| 6 | 60 | 5 |

| 7 | 60 | 10 |

| 8 | 60 | 15 |

| 9 | 60 | 20 |

| 10 | 60 | 25 |

| 11 | 90 | 5 |

| 12 | 90 | 10 |

| 13 | 90 | 15 |

| 14 | 90 | 20 |

| 15 | 90 | 25 |

| 16 | 120 | 5 |

| 17 | 120 | 10 |

| 18 | 120 | 15 |

| 19 | 120 | 20 |

| 20 | 120 | 25 |

| 21 | 150 | 5 |

| 22 | 150 | 10 |

| 23 | 150 | 15 |

| 24 | 150 | 20 |

| 25 | 150 | 25 |

| Parameter | Numerical Value |

|---|---|

| Laser type | femtosecond pulsed fiber laser |

| Laser model | HR-Femto-IR-200-35, Huaray, Wuhan, China |

| Laser spot size (μm) | 35 |

| Pulse width (fs) | 317 |

| Repeat frequency rate (khz) | 175 |

| Wavelength (nm) | 1030 |

| Parameter | Numerical Value |

|---|---|

| Single pulse energy (μJ) | 15.43 |

| Scanning speed (mm/s) | 400 |

| Scan times | 3 |

| Experiment Number | Texture Shape | Texture Pitch (μm) | Arrangement of Bone Units |

|---|---|---|---|

| 1 | NT | 0 | Vertical-arranged |

| 2 | Square | 30 | Vertical-arranged |

| 3 | Square | 60 | Vertical-arranged |

| 4 | Square | 90 | Vertical-arranged |

| 5 | Square | 120 | Vertical-arranged |

| 6 | Square | 150 | Vertical-arranged |

| 7 | Circular | 30 | Vertical-arranged |

| 8 | Circular | 60 | Vertical-arranged |

| 9 | Circular | 90 | Vertical-arranged |

| 10 | Circular | 120 | Vertical-arranged |

| 11 | Circular | 150 | Vertical-arranged |

| 12 | Rhombus | 30 | Vertical-arranged |

| 13 | Rhombus | 60 | Vertical-arranged |

| 14 | Rhombus | 90 | Vertical-arranged |

| 15 | Rhombus | 120 | Vertical-arranged |

| 16 | Rhombus | 150 | Vertical-arranged |

| 17 | NT | 0 | Parallel-arranged |

| 18 | Square | 120 | Parallel-arranged |

| 19 | Circular | 120 | Parallel-arranged |

| 20 | Rhombus | 120 | Parallel-arranged |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, P.; Liu, B.; Guo, C.; Cui, P.; Hou, Z.; Jin, F.; Zhang, J.; Guo, S.; Huang, Y.; Zhang, W. Study on Effect of Surface Micro-Texture of Cemented Carbide on Tribological Properties of Bovine Cortical Bone. Micromachines 2024, 15, 994. https://doi.org/10.3390/mi15080994

Shang P, Liu B, Guo C, Cui P, Hou Z, Jin F, Zhang J, Guo S, Huang Y, Zhang W. Study on Effect of Surface Micro-Texture of Cemented Carbide on Tribological Properties of Bovine Cortical Bone. Micromachines. 2024; 15(8):994. https://doi.org/10.3390/mi15080994

Chicago/Turabian StyleShang, Peng, Bingfeng Liu, Chunhai Guo, Peijuan Cui, Zhanlin Hou, Fengbin Jin, Jianjun Zhang, Shijie Guo, Yuping Huang, and Wenwu Zhang. 2024. "Study on Effect of Surface Micro-Texture of Cemented Carbide on Tribological Properties of Bovine Cortical Bone" Micromachines 15, no. 8: 994. https://doi.org/10.3390/mi15080994