An Integrated Solution to FIB-Induced Hydride Artifacts in Pure Zirconium

Abstract

:1. Introduction

2. Experiment

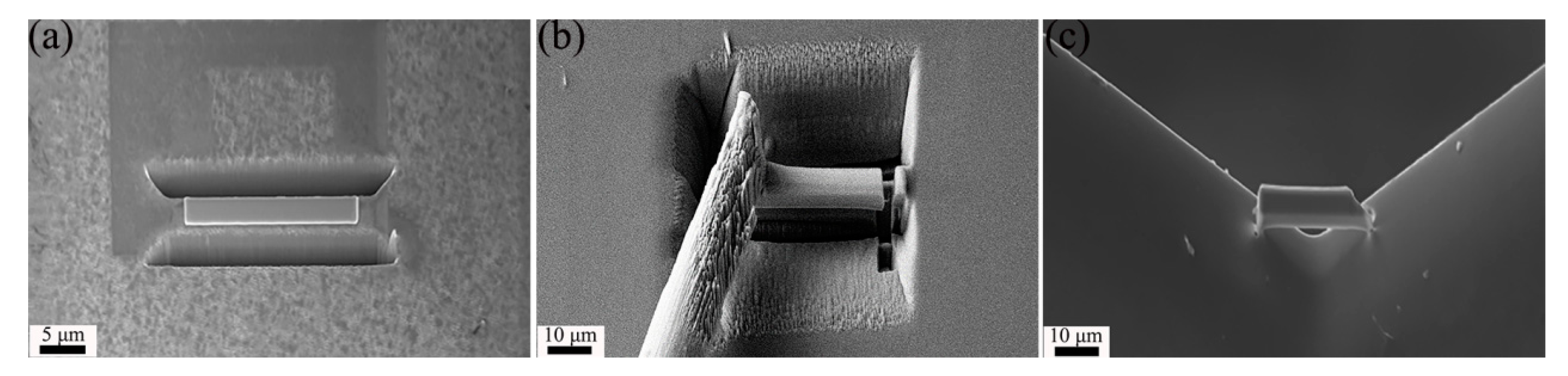

2.1. TEM Sample Preparation Process

- (a)

- Platinum Deposition: A 15 μm × 2 μm × 2 μm layer of platinum is deposited on the sample surface to protect the selected area for preparation. Ion beam-induced deposition uses a focused ion beam to bombard the surface of a sample, inducing the precursor gases of the deposited platinum to decompose and deposit in selected regions of interest on the surface of the sample to form a deposition layer. The ion beam-induced deposition layer has the task of protecting the material surface against scattering ion bombardment in nanofabrication.

- (b)

- Coarse Milling: The thickness of the sample preparation area is reduced to 2 μm using a large beam (30 kV, 20 nA). The purpose of the rough cut is to initially obtain a thin slice of the sample from the in situ characterization area. The process is to use a larger beam current to process a trapezoidal or rectangular groove above and below the sample deposition protection zone, and the processing frame extends 1~4 μm on each side of the protection zone, with a depth of 5~8 μm and a width of about two times the depth.

- (c)

- Fine Milling: The thickness of the sample preparation area is further reduced to 1 μm using a smaller beam (30 kV, 2–4 nA). The purpose of the fine cut is to further thin the samples to be extracted in the future and to eliminate the curtain effect caused by the large beam current thinning in the coarse cut stage. At this stage, the thinning will be reciprocated with smaller beam currents on the top and bottom of the sample deposition protection zone in order to minimize stress.

- (d)

- U-Cut: A U-shaped separation is made between the sample slice and the matrix, leaving a tiny connection. The purpose of the U-cut stage is to pre-separate the matrix from the lamina that will be extracted in the future. At this stage, a smaller beam is used to complete the processing of the asymmetric U-shaped processing frame from left to right on the side of the sample lamina, with a slightly shorter U-shaped edge on the right side to preserve the connection to the matrix.

- (e)

- Lift-Out: The sample slice is extracted from the matrix using nano-manipulators.

- (f)

- Welding: The sample slice is welded to a copper holder. Although, as a recognized preparation step, the welding step occurs after the lift-out step, the welding behavior in the typical technological route of the FIB nanofabrication of TEM in situ characterization samples is actually performed two times, once between the sample lamina and the tip of the nano-manipulator W needle and once between the sample lamina and the TEM-specific carrier mesh (holder).

- (g)

- Separation: The sample slice is separated from the nano-manipulator.

- (h)

- Final Thinning: The sample slice is thinned further until its thickness is less than 100 nm. The purpose of final thinning is to thin the sample lamina to the thickness required for transmission electron microscopy characterization. In order to avoid the deformation of the sample and reduce stress, double-sided thinning is used, i.e., the sample lamina is thinned alternately on both sides of the sample lamina with a smaller beam current back and forth.

- (i)

- Cleaning: Amorphous damage on the sample surface is removed using a small beam current at low voltage (e.g., 5 kV, 120 pA).

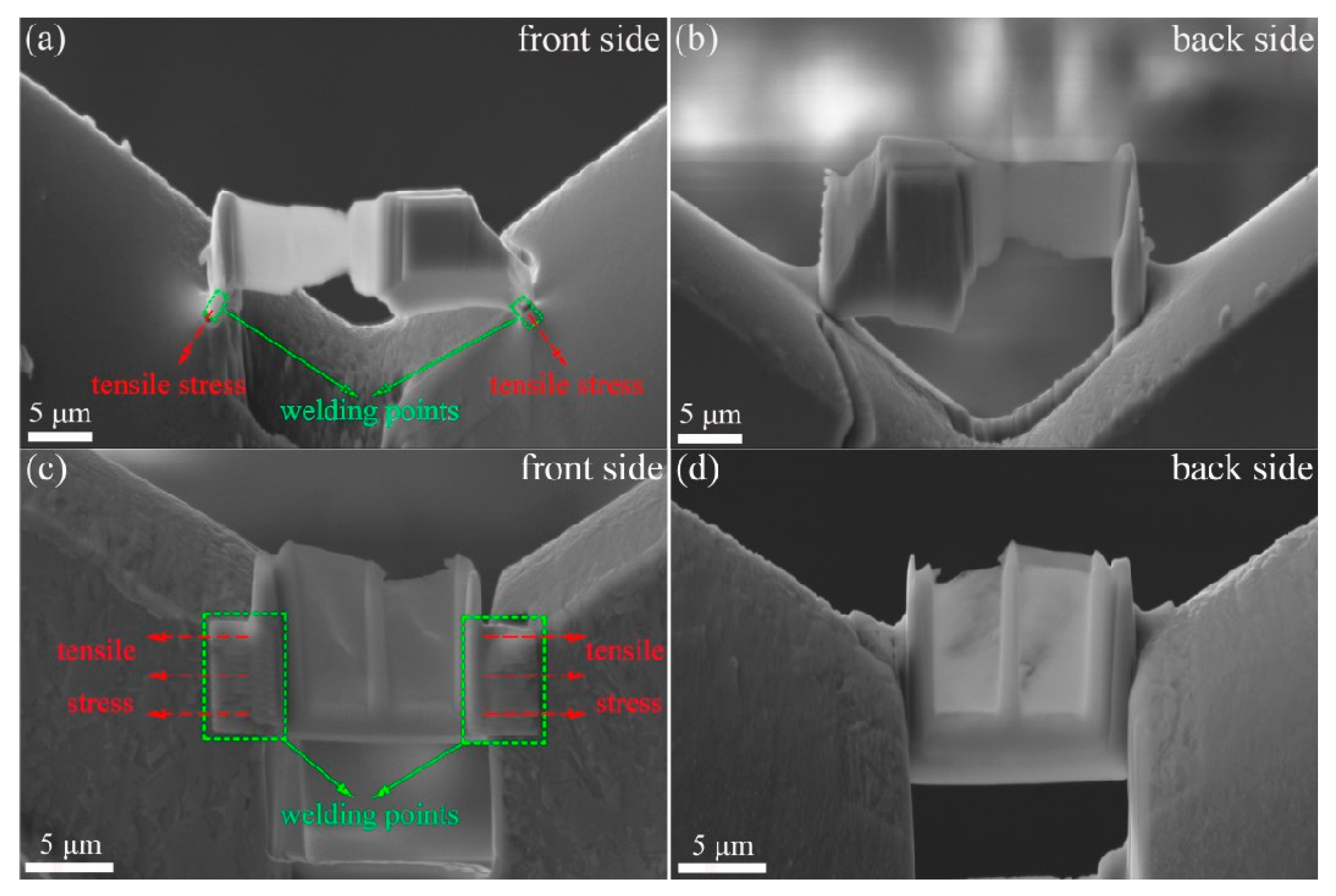

2.2. Point Welding

2.3. Graded Voltage Thinning

3. Results and Discussion

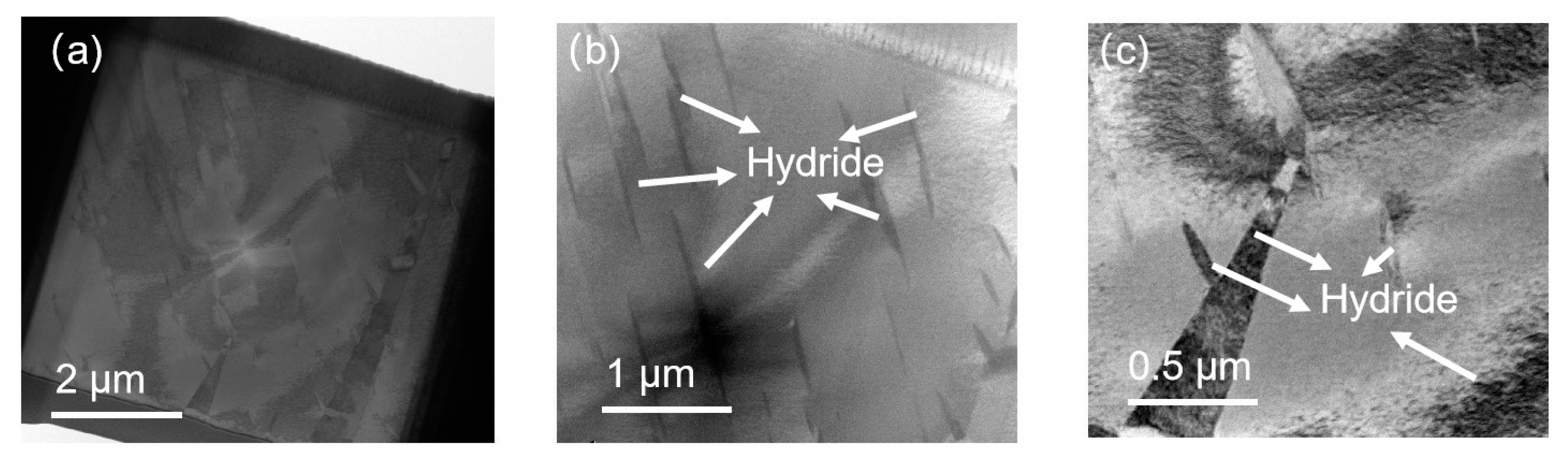

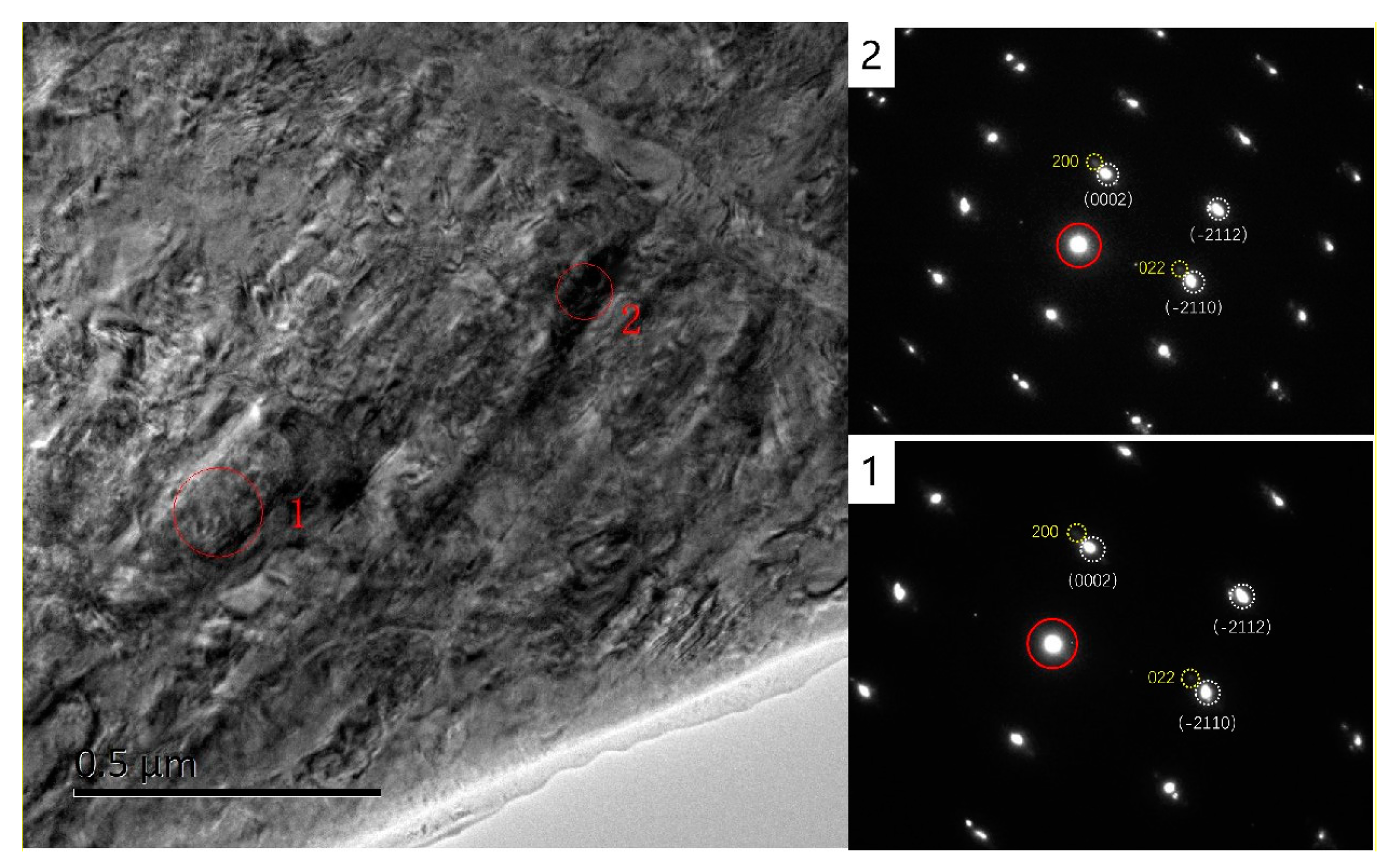

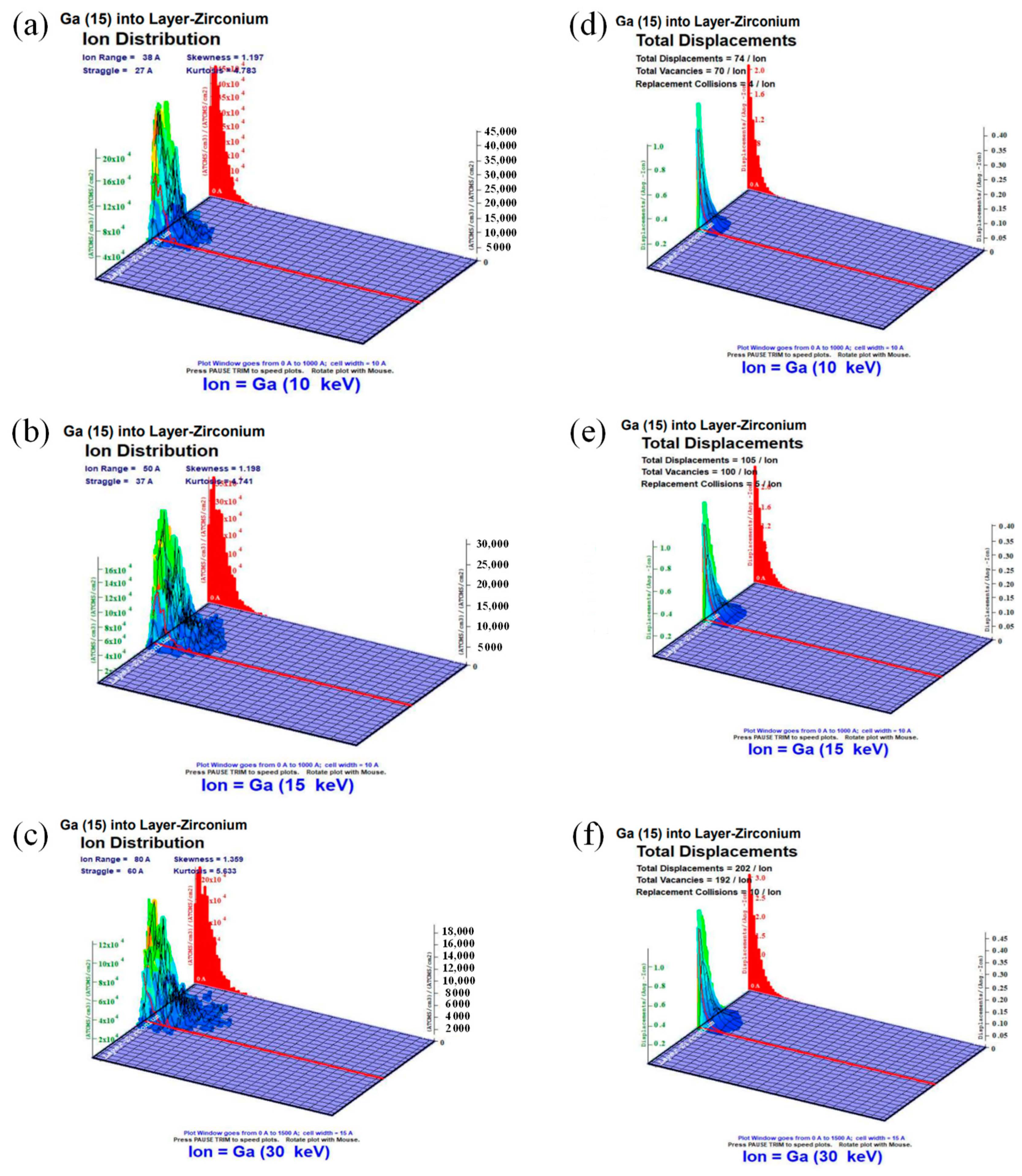

3.1. Mechanism of Hydride Introduction

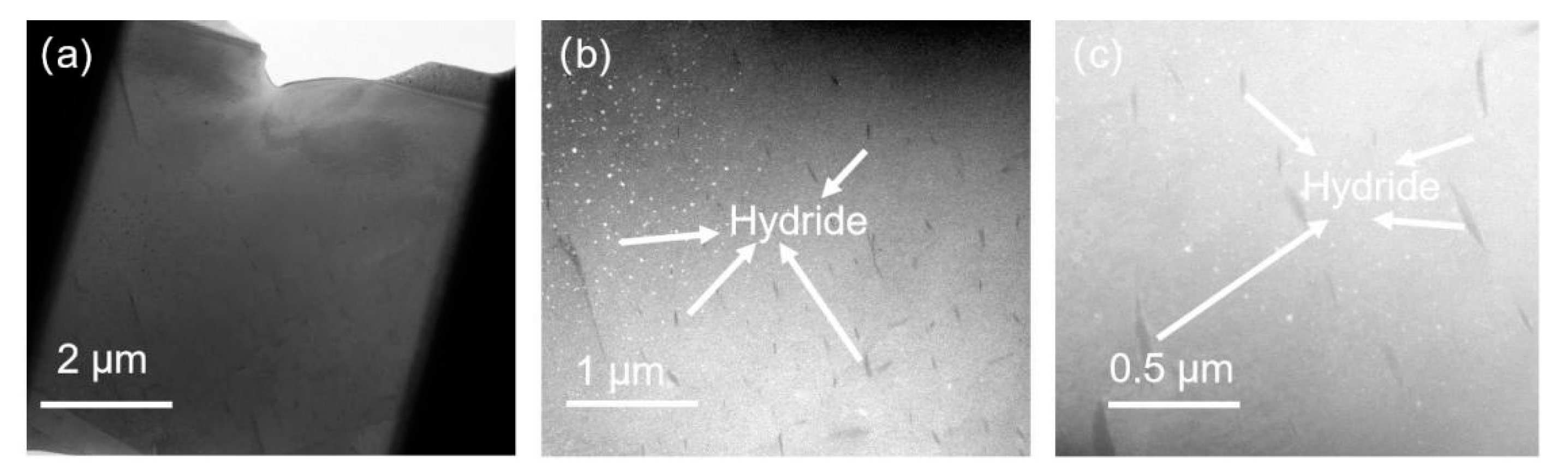

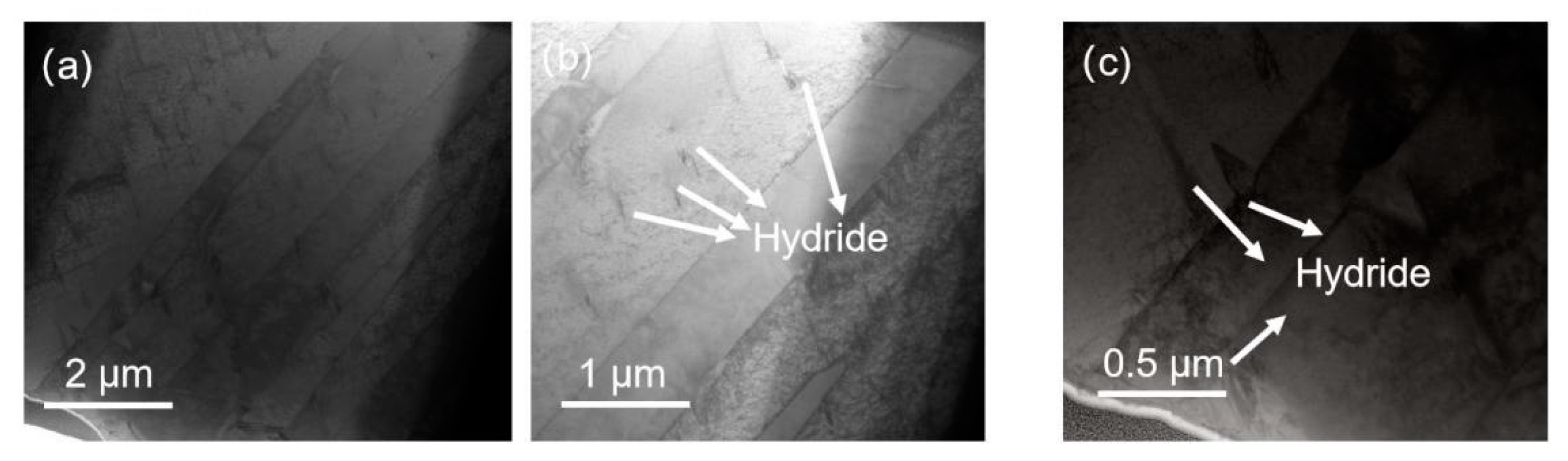

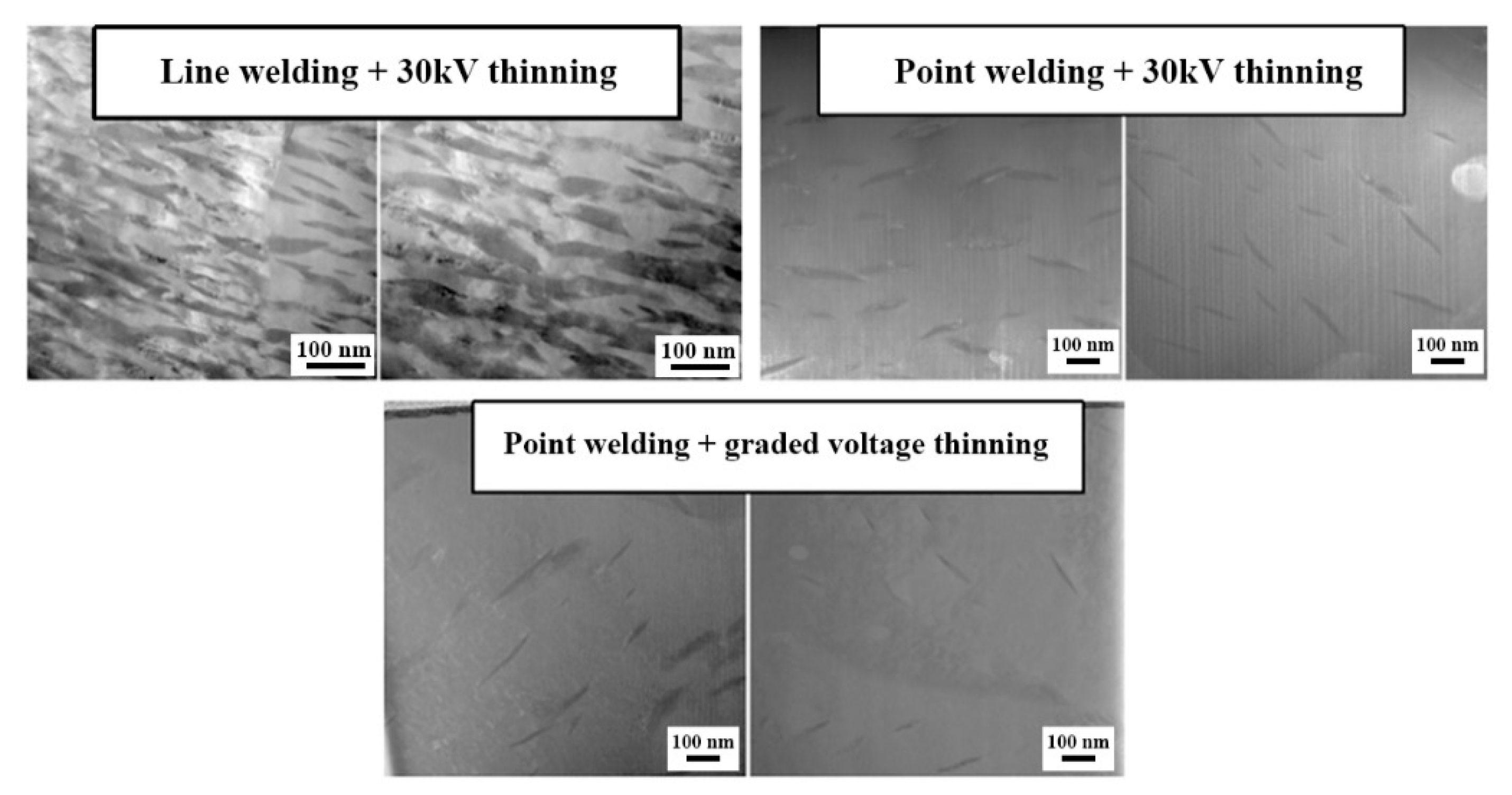

3.2. Solution to FIB-Induced Artifact Hydrides

- (1)

- Point welding

- (2)

- Graded voltage thinning

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Motta, A.T.; Couet, A.; Comstock, R.J. Corrosion of Zirconium Alloys Used for Nuclear Fuel Cladding. Annu. Rev. Mater. Res. 2015, 45, 311–343. [Google Scholar] [CrossRef]

- Ells, C.E. Hydride Precipitates in Zirconium Alloys (A Review). J. Nucl. Mater. 1968, 28, 129–151. [Google Scholar] [CrossRef]

- Pierron, O.N.; Koss, D.A.; Motta, A.T.; Chan, K.S. The Influence of Hydride Blisters on the Fracture of Zircaloy-4. J. Nucl. Mater. 2003, 322, 21–35. [Google Scholar] [CrossRef]

- Cox, B. A Mechanism for the Hydrogen Uptake Process in Zirconium Alloys. J. Nucl. Mater. 1999, 264, 283–294. [Google Scholar] [CrossRef]

- Colas, K.B.; Motta, A.T.; Almer, J.D.; Daymond, M.R.; Kerr, M.; Banchik, A.D.; Vizcaino, P.; Santisteban, J.R. In Situ Study of Hydride Precipitation Kinetics and Re-Orientation in Zircaloy Using Synchrotron Radiation. Acta Mater. 2010, 58, 6575–6583. [Google Scholar] [CrossRef]

- Abromeit, C. Aspects of Simulation of Neutron Damage by Ion Irradiation. J. Nucl. Mater. 1994, 216, 78–96. [Google Scholar] [CrossRef]

- Hanlon, S.M.; Persaud, S.Y.; Long, F.; Korinek, A.; Daymond, M.R. A Solution to FIB Induced Artefact Hydrides in Zr Alloys. J. Nucl. Mater. 2019, 515, 122–134. [Google Scholar] [CrossRef]

- Abolhassani, S.; Gasser, P. Preparation of TEM Samples of Metal–Oxide Interface by the Focused Ion Beam Technique. J. Microsc. 2006, 223, 73–82. [Google Scholar] [CrossRef]

- Chang, Y.; Lu, W.; Guénolé, J.; Stephenson, L.T.; Szczpaniak, A.; Kontis, P.; Ackerman, A.K.; Dear, F.F.; Mouton, I.; Zhong, X.; et al. Ti and Its Alloys as Examples of Cryogenic Focused Ion Beam Milling of Environmentally-Sensitive Materials. Nat. Commun. 2019, 10, 942. [Google Scholar] [CrossRef]

- Chang, Y.; Breen, A.J.; Tarzimoghadam, Z.; Kürnsteiner, P.; Gardner, H.; Ackerman, A.; Radecka, A.; Bagot, P.A.J.; Lu, W.; Li, T.; et al. Characterizing Solute Hydrogen and Hydrides in Pure and Alloyed Titanium at the Atomic Scale. Acta Mater. 2018, 150, 273–280. [Google Scholar] [CrossRef]

- Shen, H.H.; Zu, X.T.; Chen, B.; Huang, C.Q.; Sun, K. Direct Observation of Hydrogenation and Dehydrogenation of a Zirconium Alloy. J. Alloys Compd. 2016, 659, 23–30. [Google Scholar] [CrossRef]

- Ding, R.; Jones, I.P. In Situ Hydride Formation in Titanium during Focused Ion Milling. J. Electron. Microsc. 2011, 60, 1–9. [Google Scholar] [CrossRef]

- Van Dorp, W.F.; Hagen, C.W. A Critical Literature Review of Focused Electron Beam Induced Deposition. J. Appl. Phys. 2008, 104, 081301. [Google Scholar] [CrossRef]

- Qiao, Y.; Zhao, Y.; Zhang, Z.; Liu, B.; Li, F.; Tong, H.; Wu, J.; Zhou, Z.; Xu, Z.; Zhang, Y. Single-Wedge Lift-Out for Atom Probe Tomography Al/Ni Multilayers Specimen Preparation Based on Dual-Beam-FIB. Micromachines 2021, 13, 35. [Google Scholar] [CrossRef]

- Langford, R.M.; Clinton, C. In Situ Lift-out Using a FIB-SEM System. Micron 2004, 35, 607–611. [Google Scholar] [CrossRef]

- Langford, R.M.; Rogers, M. In Situ Lift-out: Steps to Improve Yield and a Comparison with Other FIB TEM Sample Preparation Techniques. Micron 2008, 39, 1325–1330. [Google Scholar] [CrossRef]

- Wnuk, J.D.; Gorham, J.M.; Rosenberg, S.G.; Van Dorp, W.F.; Madey, T.E.; Hagen, C.W.; Fairbrother, D.H. Electron Induced Surface Reactions of the Organometallic Precursor Trimethyl(Methylcyclopentadienyl)Platinum(IV). J. Phys. Chem. C 2009, 113, 2487–2496. [Google Scholar] [CrossRef]

- Qiao, Y.; Li, J.W.; Liu, G.; Zhang, Y.; Chen, L.X.; Shi, W.; Yan, Q.F.; Zhang, H.L. Applications of FIB technique in the preparation of HRTEM samples for diamond/M(M = Cu, Al, AlN) composite materials. J. Chin. Electron. Microsc. Soc. 2016, 35, 53–57. [Google Scholar] [CrossRef]

- Giannuzzi, L.A.; Geurts, R.; Ringnalda, J. 2 keV Ga+ FIB Milling for Reducing Amorphous Damage in Silicon. MAM 2005, 11, 828–829. [Google Scholar] [CrossRef]

- Huang, Y.; Cockayne, D.J.H.; Marsh, C.; Titchmarsh, J.M.; Petford-Long, A.K. Self-Organized Amorphous Material in Silicon (001) by Focused Ion Beam (FIB) System. Appl. Surf. Sci. 2005, 252, 1954–1958. [Google Scholar] [CrossRef]

- Xiao, Y.J.; Fang, F.Z.; Xu, Z.W.; Wu, W.; Shen, X.C. The Study of Ga+ FIB Implanting Crystal Silicon and Subsequent Annealing. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2013, 307, 253–256. [Google Scholar] [CrossRef]

- Rubanov, S. TEM Study of the Damage Formation During FIB Milling of Single Crystal Diamond. In Proceedings of the 16th AINSE Conference on Nuclear and Complementary Techniques of Analysis, Sydney, Australia, 25–27 November 2009. [Google Scholar]

- Rubanov, S.; Munroe, P.R. FIB-induced Damage in Silicon. J. Microsc. 2004, 214, 213–221. [Google Scholar] [CrossRef]

- Giannuzzi, L.A.; Stevie, F.A. (Eds.) Introduction to Focused Ion Beams: Instrumentation, Theory, Techniques and Practice; Springer: Boston, MA, USA, 2005; ISBN 978-0-387-23116-7. [Google Scholar]

- Vivek, A.; Presley, M.; Flores, K.M.; Hutchinson, N.H.; Daehn, G.S. Solid State Impact Welding of BMG and Copper by Vaporizing Foil Actuator Welding. Mater. Sci. Eng. A 2015, 634, 14–19. [Google Scholar] [CrossRef]

- Makin, M.J. Electron Displacement Damage in Copper and Aluminium in a High Voltage Electron Microscope. Philos. Mag. 1968, 18, 637–653. [Google Scholar] [CrossRef]

| Sample Thickness H/nm | Ion Beam Voltage U/kV | Ion Beam Current I/pA |

|---|---|---|

| 1000 | 30 | 750 |

| 200 | 16 | 230–120 |

| 100 | 12 | 92 |

| 50 | 8 | 61 |

| Sample Thickness H/nm | Ion Beam Voltage U/kV | Ion Beam Current I/pA |

|---|---|---|

| 1000 | 30 | 240–120 |

| 200 | 15 | 250 |

| 100 | 15 | 120 |

| 50 | 10 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, Y.; Xu, Z.; Li, S.; Wang, F.; Huang, Y. An Integrated Solution to FIB-Induced Hydride Artifacts in Pure Zirconium. Micromachines 2024, 15, 999. https://doi.org/10.3390/mi15080999

Qiao Y, Xu Z, Li S, Wang F, Huang Y. An Integrated Solution to FIB-Induced Hydride Artifacts in Pure Zirconium. Micromachines. 2024; 15(8):999. https://doi.org/10.3390/mi15080999

Chicago/Turabian StyleQiao, Yi, Zongwei Xu, Shilei Li, Fu Wang, and Yubo Huang. 2024. "An Integrated Solution to FIB-Induced Hydride Artifacts in Pure Zirconium" Micromachines 15, no. 8: 999. https://doi.org/10.3390/mi15080999