Application of Metal Halide Perovskite in Internet of Things

Abstract

:1. Introduction

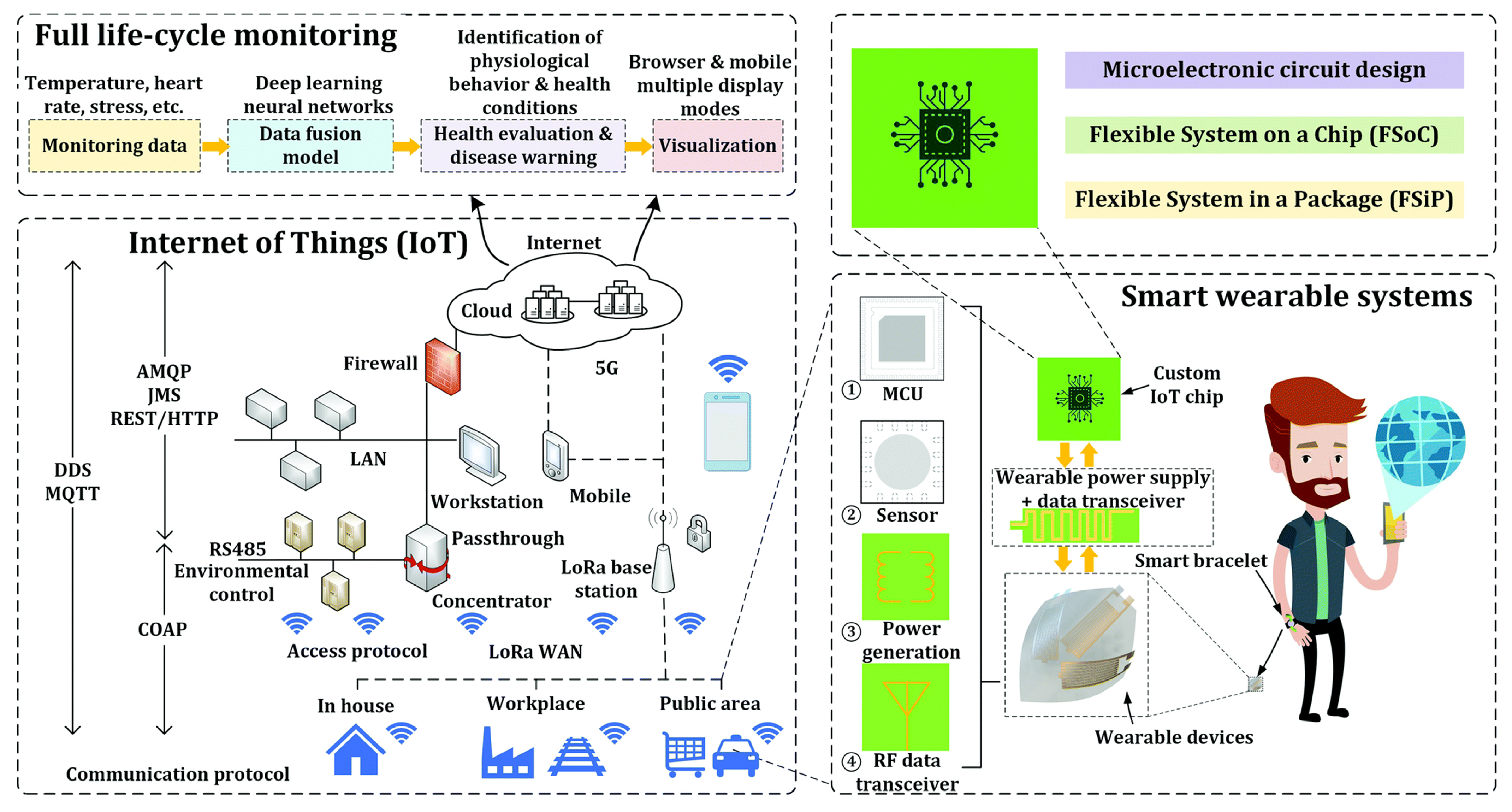

1.1. Basic Concepts of IoT

1.2. Three-Layer Architecture of IoT

- The perception layer covers various physical devices and sensors to gather physical data from the environment, serving as the source for IoT object identification and information collection.

- The network layer comprises various networks and computing platforms, functioning as the central hub of the entire IoT system. Data collected from the perception layer undergo further processing in this part.

- The application layer provides specific services to end users, acting as the interface between the IoT and users. This layer employs a variety of intelligent technologies to analyze and process data received from perception layers, which is closely integrated with industry requirements.

1.3. Development Status and Trend of Perception Layer

2. General Properties of Perovskites

2.1. Concepts

2.2. Structure and Composition

2.3. Properties

3. Perovskite Sensors

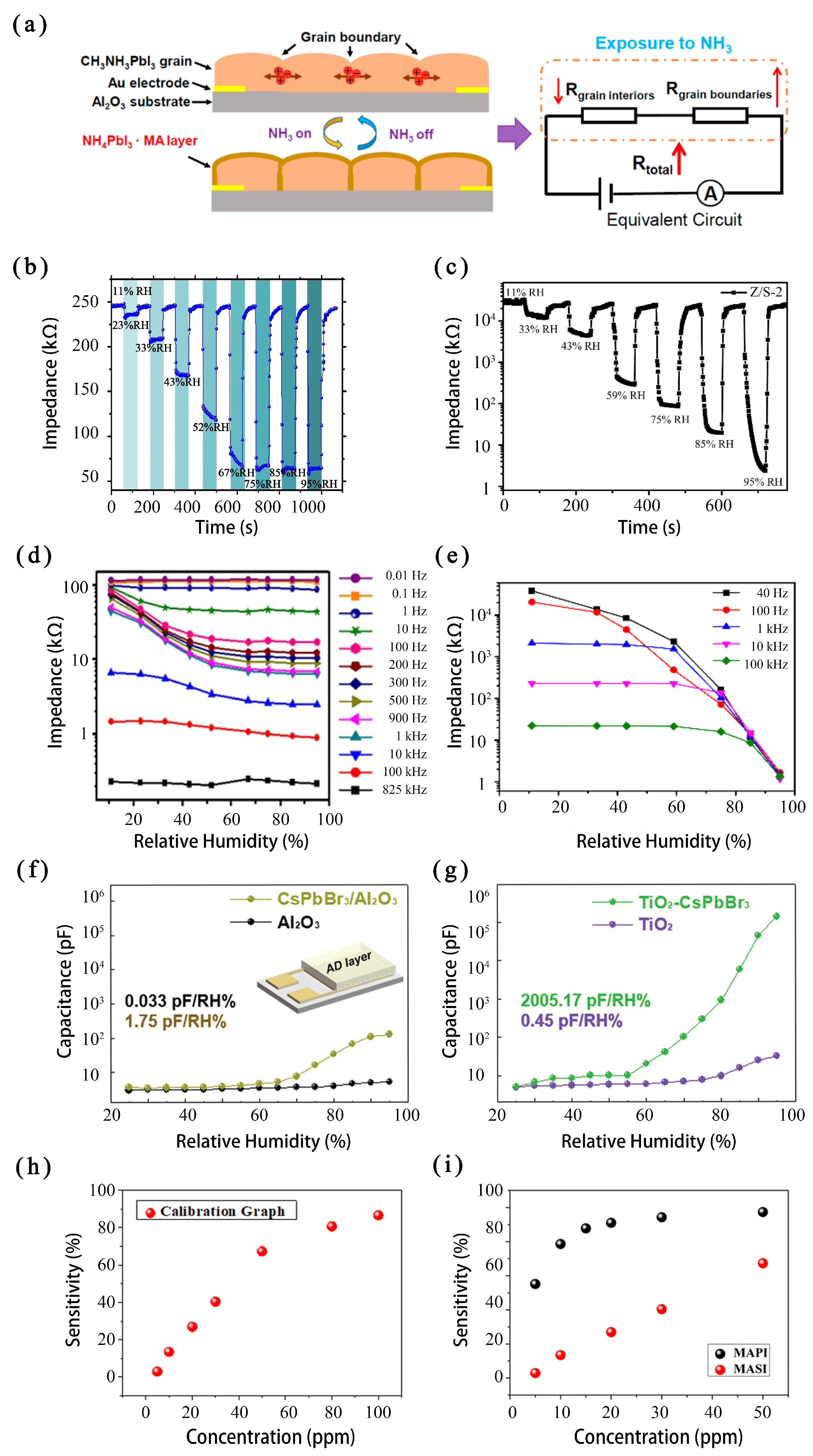

3.1. Gas and Humidity Sensor

3.2. Photodetector

3.3. Optical Conversion Sensor

3.4. Nanogenerator

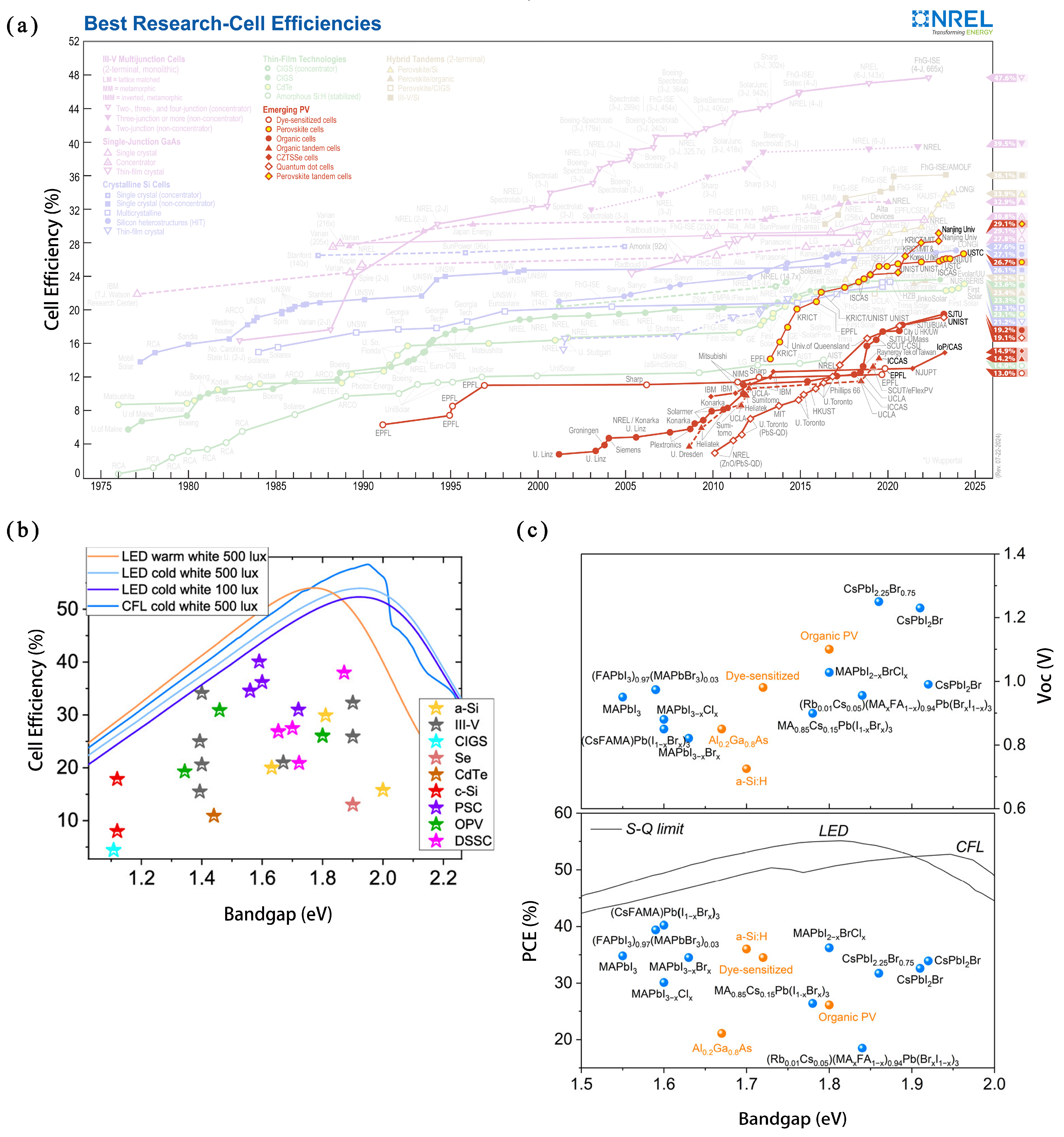

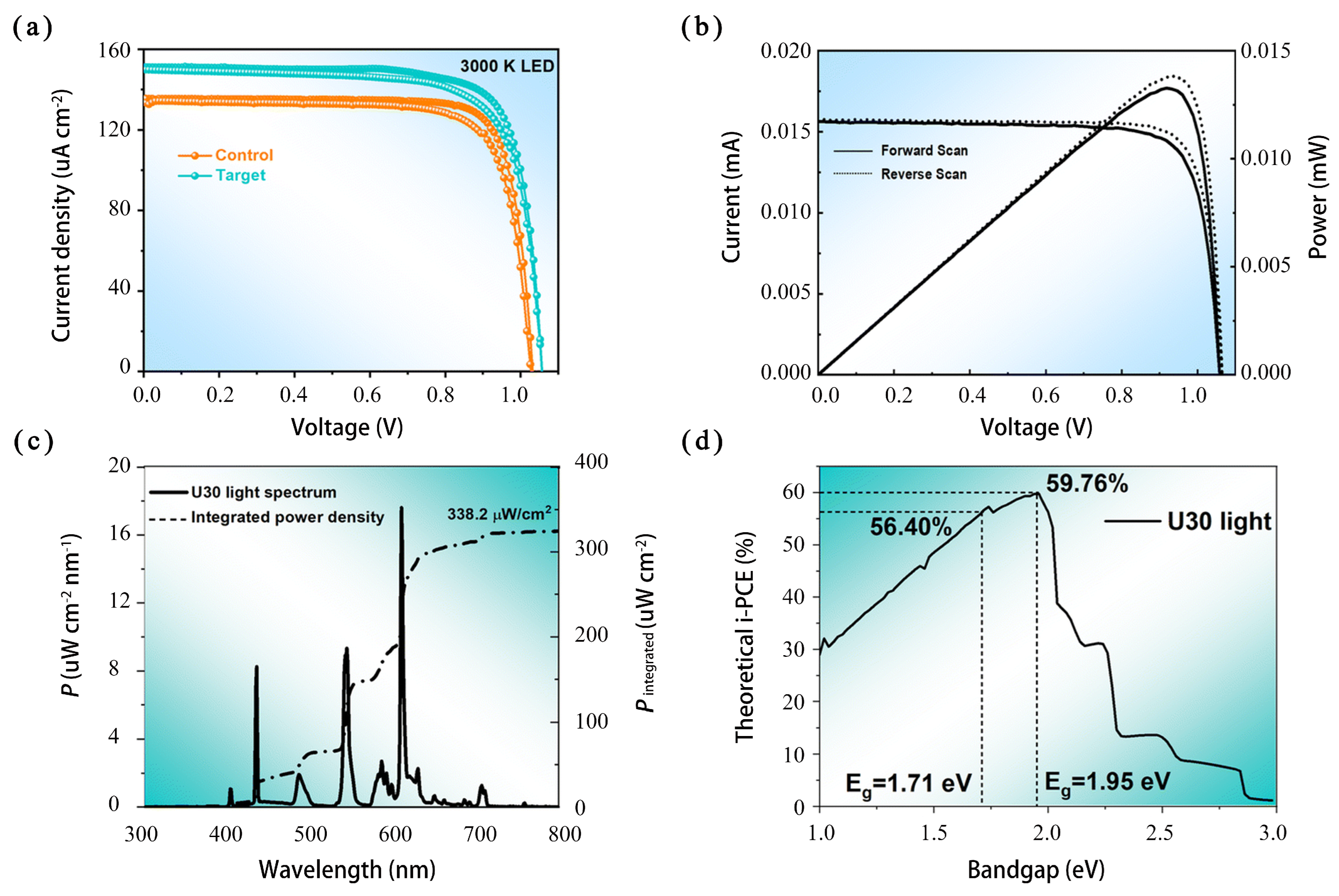

4. Perovskite Solar Cells and Indoor Photovoltaics

4.1. Research Progress

4.2. Advantages

4.2.1. Excellent Photoelectric Property

4.2.2. Low Cost and Simple Preparation Process

4.2.3. Excellent Mechanical Properties

4.3. Applications of PSCs in IoT Field

5. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Ashton, K. That ‘internet of things’ thing. RFID J. 2009, 22, 97–114. [Google Scholar]

- Li, C.; Wang, J.; Wang, S.; Zhang, Y. A review of IoT applications in healthcare. Neurocomputing 2024, 565, 127017. [Google Scholar] [CrossRef]

- Sokienah, Y. Exploring the integration of IoT systems in interior design and the built environment: A systematic review. Heliyon 2023, 9, e22869. [Google Scholar] [CrossRef] [PubMed]

- Taj, S.; Imran, A.S.; Kastrati, Z.; Daudpota, S.M.; Memon, R.A.; Ahmed, J. IoT-based supply chain management: A systematic literature review. Internet Things 2023, 24, 100982. [Google Scholar] [CrossRef]

- Shi, X.; An, X.; Zhao, Q.; Liu, H.; Xia, L.; Sun, X.; Guo, Y. State-of-the-Art Internet of Things in Protected Agriculture. Sensors 2019, 19, 1833. [Google Scholar] [CrossRef]

- Shaikh, F.K.; Karim, S.; Zeadally, S.; Nebhen, J. Recent Trends in Internet-of-Things-Enabled Sensor Technologies for Smart Agriculture. IEEE Internet Things J. 2022, 9, 23583–23598. [Google Scholar] [CrossRef]

- Al-Kahtani, M.S.; Khan, F.; Taekeun, W. Application of Internet of Things and Sensors in Healthcare. Sensors 2022, 22, 5738. [Google Scholar] [CrossRef]

- Li, K.; Cui, Y.; Li, W.; Lv, T.; Yuan, X.; Li, S.; Ni, W.; Simsek, M.; Dressler, F. When Internet of Things Meets Metaverse: Convergence of Physical and Cyber Worlds. IEEE Internet Things J. 2023, 10, 4148–4173. [Google Scholar] [CrossRef]

- Majid, M.; Habib, S.; Javed, A.R.; Rizwan, M.; Srivastava, G.; Gadekallu, T.R.; Lin, J.C. Applications of Wireless Sensor Networks and Internet of Things Frameworks in the Industry Revolution 4.0: A Systematic Literature Review. Sensors 2022, 22, 2087. [Google Scholar] [CrossRef]

- Al-Qaseemi, S.A.; Almulhim, H.A.; Almulhim, M.F.; Chaudhry, S.R. IoT architecture challenges and issues: Lack of standardization. In Proceedings of the 2016 Future Technologies Conference (FTC), San Francisco, CA, USA, 6–7 December 2016. [Google Scholar]

- He, S.; Shi, K.; Liu, C.; Guo, B.; Chen, J.; Shi, Z. Collaborative Sensing in Internet of Things: A Comprehensive Survey. IEEE Commun. Surv. Tutor. 2022, 24, 1435–1474. [Google Scholar] [CrossRef]

- Aldin, H.N.S.; Ghods, M.R.; Nayebipour, F.; Torshiz, M.N. A comprehensive review of energy harvesting and routing strategies for IoT sensors sustainability and communication technology. Sens. Int. 2024, 5, 100258. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, X.; Zhu, M.; Sun, Z.; Zhang, Z.; He, T.; Lee, C. Triboelectric Nanogenerator Enabled Wearable Sensors and Electronics for Sustainable Internet of Things Integrated Green Earth. Adv. Energy Mater. 2022, 13, 2203040. [Google Scholar] [CrossRef]

- Kim, H.; Nguyen, D.C.; Luu, T.T.; Ding, Z.; Lin, Z.H.; Choi, D. Recent Advances in Functional Fiber-Based Wearable Triboelectric Nanogenerators. Nanomaterials 2023, 13, 2718. [Google Scholar] [CrossRef] [PubMed]

- Jamshed, M.A.; Ali, K.; Abbasi, Q.H.; Imran, M.A.; Ur-Rehman, M. Challenges, Applications, and Future of Wireless Sensors in Internet of Things: A Review. IEEE Sens. J. 2022, 22, 5482–5494. [Google Scholar] [CrossRef]

- Wang, K.L.; Lu, H.; Li, M.; Chen, C.H.; Bo Zhang, D.; Chen, J.; Wu, J.J.; Zhou, Y.H.; Wang, X.Q.; Su, Z.H.; et al. Ion-Dipole Interaction Enabling Highly Efficient CsPbI3 Perovskite Indoor Photovoltaics. Adv. Mater. 2023, 35, e2210106. [Google Scholar] [CrossRef]

- Mularso, K.T.; Jeong, J.Y.; Han, G.S.; Jung, H.S. Recent Strategies for High-Performing Indoor Perovskite Photovoltaics. Nanomaterials 2023, 13, 259. [Google Scholar] [CrossRef]

- Guo, F.; Sun, X.; Liu, B.; Yang, Z.; Wei, J.; Xu, D. Enhanced Lifetime and Photostability with Low-Temperature Mesoporous ZnTiO3/Compact SnO2 Electrodes in Perovskite Solar Cells. Angew. Chem. Int. Ed. 2019, 58, 18460–18465. [Google Scholar] [CrossRef]

- Wei, J.; Guo, F.; Liu, B.; Sun, X.; Wang, X.; Yang, Z.; Xu, K.; Lei, M.; Zhao, Y.; Xu, D. UV-Inert ZnTiO3 Electron Selective Layer for Photostable Perovskite Solar Cells. Adv. Energy Mater. 2019, 9, 1901620. [Google Scholar] [CrossRef]

- Wei, J.; Wang, Q.; Huo, J.; Gao, F.; Gan, Z.; Zhao, Q.; Li, H. Mechanisms and Suppression of Photoinduced Degradation in Perovskite Solar Cells. Adv. Energy Mater. 2020, 11, 2002326. [Google Scholar] [CrossRef]

- Sun, X.; Li, D.; Zhao, L.; Zhang, Y.; Hu, Q.; Russell, T.P.; Liu, F.; Wei, J.; Li, H. (111)-Dominated Perovskite Films by Antisolvent Engineering. Adv. Mater. 2023, 35, e2301115. [Google Scholar] [CrossRef]

- Li, D.; Sun, X.; Zhang, Y.; Guan, Z.; Yue, Y.; Wang, Q.; Zhao, L.; Liu, F.; Wei, J.; Li, H. Uniaxial-Oriented Perovskite Films with Controllable Orientation. Adv. Sci. 2024, 11, e2401184. [Google Scholar] [CrossRef] [PubMed]

- Shao, X.; Shi, Y.; Wang, H.; Sun, X.; Yang, L.; Li, X.; Wang, M. A Review on Advances in the Gas-Sensitive Properties of Perovskite Materials. J. Electron. Mater. 2023, 52, 5795–5809. [Google Scholar] [CrossRef]

- Perumal Veeramalai, C.; Feng, S.; Zhang, X.; Pammi, S.V.N.; Pecunia, V.; Li, C. Lead–halide perovskites for next-generation self-powered photodetectors: A comprehensive review. Photonics Res. 2021, 9, 968. [Google Scholar] [CrossRef]

- Yao, X.; Ding, Y.-L.; Zhang, X.-D.; Zhao, Y. A review of the perovskite solar cells. Acta Phys. 2015, 64, 1903713. [Google Scholar]

- Zhou, Y.; Lu, F.; Fang, T.; Gu, D.; Feng, X.; Song, T.; Liu, W. A brief review on metal halide perovskite photocatalysts: History, applications and prospects. J. Alloys Compd. 2022, 911, 165062. [Google Scholar] [CrossRef]

- Stoeckel, M.A.; Gobbi, M.; Bonacchi, S.; Liscio, F.; Ferlauto, L.; Orgiu, E.; Samori, P. Reversible, Fast, and Wide-Range Oxygen Sensor Based on Nanostructured Organometal Halide Perovskite. Adv. Mater. 2017, 29, 100258. [Google Scholar] [CrossRef]

- Kim, J.; John, A.T.; Li, H.; Huang, C.Y.; Chi, Y.; Anandan, P.R.; Murugappan, K.; Tang, J.; Lin, C.H.; Hu, L.; et al. High-Performance Optoelectronic Gas Sensing Based on All-Inorganic Mixed-Halide Perovskite Nanocrystals with Halide Engineering. Small Methods 2024, 8, e2300417. [Google Scholar] [CrossRef]

- Ilin, A.S.; Forsh, P.A.; Martyshov, M.N.; Kazanskii, A.G.; Forsh, E.A.; Kashkarov, P.K. Humidity Sensing Properties of Organometallic Perovskite CH3NH3PbI3. Chem. Sel. 2020, 5, 6705–6708. [Google Scholar] [CrossRef]

- Dai, X.; Xu, K.; Wei, F. Recent progress in perovskite solar cells: The perovskite layer. Beilstein J. Nanotechnol. 2020, 11, 51–60. [Google Scholar] [CrossRef]

- Brenner, T.M.; Egger, D.A.; Kronik, L.; Hodes, G.; Cahen, D. Hybrid organic—Inorganic perovskites: Low-cost semiconductors with intriguing charge-transport properties. Nat. Rev. Mater. 2016, 1, 15007. [Google Scholar] [CrossRef]

- Yettapu, G.R.; Talukdar, D.; Sarkar, S.; Swarnkar, A.; Nag, A.; Ghosh, P.; Mandal, P. Terahertz Conductivity within Colloidal CsPbBr3 Perovskite Nanocrystals: Remarkably High Carrier Mobilities and Large Diffusion Lengths. Nano Lett. 2016, 16, 4838–4848. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Singh, S.; Singh, V.N.; Gupta, G.; Gupta, B.K. Probing reversible photoluminescence alteration in CH3NH3PbBr3 colloidal quantum dots for luminescence-based gas sensing application. J. Colloid Interface Sci. 2019, 554, 668–673. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Hao, M.; Song, Y.; Dang, S.; Liu, X.; Dong, Q. Dynamic Passivation in Perovskite Quantum Dots for Specific Ammonia Detection at Room Temperature. Adv. Small. 2020, 16, e1904462. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Zhu, K. Optical bleaching of perovskite (CH3NH3)PbI3 through room-temperature phase transformation induced by ammonia. Chem. Commun. 2014, 50, 1605–1607. [Google Scholar] [CrossRef]

- Eriksson, J.; Khranovskyy, V.; Söderlind, F.; Käll, P.-O.; Yakimova, R.; Spetz, A.L. ZnO nanoparticles or ZnO films: A comparison of the gas sensing capabilities. Sens. Actuators B 2009, 137, 94–102. [Google Scholar] [CrossRef]

- Ochoa-Munoz, Y.H.; Mejia De Gutierrez, R.; Rodriguez-Paez, J.E.; Gracia, I.; Vallejos, S. Gas Sensors Based on Porous Ceramic Bodies of MSnO3 Perovskites (M = Ba, Ca, Zn): Formation and Sensing Properties towards Ethanol, Acetone, and Toluene Vapours. Molecules 2022, 27, 2889. [Google Scholar] [CrossRef]

- Xue, S.; Cao, S.; Huang, Z.; Yang, D.; Zhang, G. Improving Gas-Sensing Performance Based on MOS Nanomaterials: A Review. Materials 2021, 14, 4263. [Google Scholar] [CrossRef] [PubMed]

- Ye, W.; Cao, Q.; Cheng, X.-F.; Yu, C.; He, J.-H.; Lu, J.-M. A lead-free Cs2PdBr6 perovskite-based humidity sensor for artificial fruit waxing detection. J. Mater. Chem. A 2020, 8, 17675–17682. [Google Scholar] [CrossRef]

- Li, G.; Zhang, Y.; Lin, J.; Xu, X.; Liu, S.; Fang, J.; Jing, C.; Chu, J. Anomalous NH3-Induced Resistance Enhancement in Halide Perovskite MAPbI3 Film and Gas Sensing Performance. J. Phys. Chem. Lett. 2021, 12, 11339–11345. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, J.; Sun, X.; Wu, Y.; Wang, L.; Meng, G.; Kuang, D.; Guo, X.; Qu, W.; Du, B.; et al. An excellent impedance-type humidity sensor based on halide perovskite CsPbBr3 nanoparticles for human respiration monitoring. Sens. Actuators B 2021, 337, 129772. [Google Scholar] [CrossRef]

- Li, F.; Li, P.; Zhang, H. Preparation and Research of a High-Performance ZnO/SnO2 Humidity Sensor. Sensors 2021, 22, 293. [Google Scholar] [CrossRef] [PubMed]

- Cho, M.Y.; Kim, S.; Kim, I.S.; Kim, E.S.; Wang, Z.J.; Kim, N.Y.; Kim, S.W.; Oh, J.M. Perovskite-Induced Ultrasensitive and Highly Stable Humidity Sensor Systems Prepared by Aerosol Deposition at Room Temperature. Adv. Funct. Mater. 2019, 30, 1907449. [Google Scholar] [CrossRef]

- Maity, A.; Mitra, S.; Ghosh, B. Textile Based Lead-Free Halide Perovskite CH3NH3SnI3 Ammonia Gas Sensor Working at Room Temperature. ACS Appl. Electron. Mater. 2024, 6, 2677–2682. [Google Scholar] [CrossRef]

- Cho, M.Y.; Kim, I.S.; Kim, S.H.; Park, C.; Kim, N.Y.; Kim, S.W.; Kim, S.; Oh, J.M. Unique Noncontact Monitoring of Human Respiration and Sweat Evaporation Using a CsPb2Br5-Based Sensor. ACS Appl. Mater. Interfaces 2021, 13, 5602–5613. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Wang, Z.; Chen, T.; Tang, M.; Zhang, J.; Jian, J.; Wang, Y.; Zhou, K.; Zhang, X. Methylamine Gas Sensor Based on Fluorescent Perovskite Nanocrystal Nanofibers Incorporating Aggregation-Induced Emission Materials. ACS Appl. Nano Mater. 2024, 7, 17329–17338. [Google Scholar] [CrossRef]

- Shiek, S.S.; ManToxicologyi, M.S.; Kabekkodu, S.P.; Dsouza, H.S. Health repercussions of environmental exposure to lead: Methylation perspective. Toxicology 2021, 461, 152927. [Google Scholar] [CrossRef]

- Wang, F.; Mei, J.; Wang, Y.; Zhang, L.; Zhao, H.; Zhao, D. Fast Photoconductive Responses in Organometal Halide Perovskite Photodetectors. ACS Appl. Mater. Interfaces 2016, 8, 2840–2846. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Xu, Y.; Pan, Y.; Li, Y.; Chen, J.; Li, Q.; Zhang, X.; Zhu, Z.; Zhao, Z.; et al. Electrically Modulated Near-Infrared/Visible Light Dual-Mode Perovskite Photodetectors. ACS Appl. Mater. Interfaces 2022, 14, 25824–25833. [Google Scholar] [CrossRef]

- Azamat, A.K.; Parkhomenko, H.P.; Kiani, M.S.; Ng, A.; Jumabekov, A.N. Self-Powered Printed Flexible Bifacial Perovskite Photodetector. ACS Appl. Opt. Mater. 2023, 2, 149–157. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; Huang, L.; Sun, W. Research Progress of High-Sensitivity Perovskite Photodetectors: A Review of Photodetectors: Noise, Structure, and Materials. ACS Appl. Electron. Mater. 2022, 4, 1485–1505. [Google Scholar] [CrossRef]

- Wu, W.; Lu, H.; Han, X.; Wang, C.; Xu, Z.; Han, S.T.; Pan, C. Recent Progress on Wavelength-Selective Perovskite Photodetectors for Image Sensing. Small Methods 2023, 7, e2201499. [Google Scholar] [CrossRef] [PubMed]

- Zheng, D.; Pauporté, T. Advances in Optical Imaging and Optical Communications Based on High-Quality Halide Perovskite Photodetectors. Adv. Funct. Mater. 2023, 34, 2311205. [Google Scholar] [CrossRef]

- Pal, S.; Ghorai, A.; Mahato, S.; Ray, S.K. Piezo-Phototronic Effect-Induced Self-Powered Broadband Photodetectors using Environmentally Stable α-CsPbI3 Perovskite Nanocrystals. Adv. Opt. Mater. 2023, 11, 2300233. [Google Scholar] [CrossRef]

- Tang, Y.; Jin, P.; Wang, Y.; Li, D.; Chen, Y.; Ran, P.; Fan, W.; Liang, K.; Ren, H.; Xu, X.; et al. Enabling low-drift flexible perovskite photodetectors by electrical modulation for wearable health monitoring and weak light imaging. Nat. Commun. 2023, 14, 4961. [Google Scholar] [CrossRef]

- Bu, H.; He, C.; Xu, Y.; Xing, L.; Liu, X.; Ren, S.; Yi, S.; Chen, L.; Wu, H.; Zhang, G.; et al. Emerging New-Generation Detecting and Sensing of Metal Halide Perovskites. Adv. Electron. Mater. 2022, 8, 2101204. [Google Scholar] [CrossRef]

- Algadi, H.; Ren, J.; Alqarni, A. A high-performance self-powered photodetector based on solution-processed nitrogen-doped graphene quantum dots/all-inorganic perovskite heterostructures. Adv. Compos. Hybrid Mater. 2023, 6, 98. [Google Scholar] [CrossRef]

- Miao, Y.; Wu, J.; Qi, X.; Yang, L.; Wang, X.; Zheng, F.; Zhao, F.; Shafique, S.; Zhu, Y.; Hu, Z. Gradient 2D–3D Ruddlesden-Popper perovskite film for high-performance self-powered photodetectors. Nano Energy 2023, 113, 108605. [Google Scholar] [CrossRef]

- Chen, M.; An, J.; Hu, Y.; Chen, R.; Lyu, Y.; Hu, N.; Luo, M.; Yuan, M.; Liu, Y. Swelling-shrinking modified hyperstatic hydrophilic perovskite polymer fluorescent beads for Fe(III) detection. Sens. Actuators B 2020, 325, 128809. [Google Scholar] [CrossRef]

- Wang, W.; Deng, P.; Liu, X.; Ma, Y.; Yan, Y. A CsPbBr3 quantum dots/ultra-thin BN fluorescence sensor for stability and highly sensitive detection of tetracycline. Microchem. J. 2021, 162, 105876. [Google Scholar] [CrossRef]

- Xiang, X.; Ouyang, H.; Li, J.; Fu, Z. Humidity-sensitive CsPbBr3 perovskite based photoluminescent sensor for detecting Water content in herbal medicines. Sens. Actuators B 2021, 346, 130547. [Google Scholar] [CrossRef]

- Wang, Z.L. The new field of nanopiezotronics. Mater. Today 2007, 10, 20–28. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wang, A.C. On the origin of contact-electrification. Mater. Today 2019, 30, 34–51. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, D.; Zhao, J.; Liu, G.; Bu, T.; Zhang, C.; Wang, Z.L. Tribovoltaic Effect on Metal–Semiconductor Interface for Direct-Current Low-Impedance Triboelectric Nanogenerators. Adv. Energy Mater. 2020, 10, 1903713. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Ding, R.; Wong, M.C.; Hao, J. Recent advances in hybrid perovskite nanogenerators. EcoMat 2020, 2, e12057. [Google Scholar] [CrossRef]

- Wu, Y.; Huang, L.B.; Pan, C. Halide perovskite-based tribovoltaic effects for self-powered sensors. Sci. Bull 2023, 68, 1849–1852. [Google Scholar] [CrossRef]

- Sultana, A.; Ghosh, S.K.; Alam, M.M.; Sadhukhan, P.; Roy, K.; Xie, M.; Bowen, C.R.; Sarkar, S.; Das, S.; Middya, T.R.; et al. Methylammonium Lead Iodide Incorporated Poly(vinylidene fluoride) Nanofibers for Flexible Piezoelectric-Pyroelectric Nanogenerator. ACS Appl. Mater. Interfaces 2019, 11, 27279–27287. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Jeon, S.; Kim, D.; Lee, D.-M.; Kim, D.; Kim, S.-W. High performance direct current-generating triboelectric nanogenerators based on tribovoltaic p-n junction with ChCl-passivated CsFAMA perovskite. Nano Energy 2023, 106, 108066. [Google Scholar] [CrossRef]

- Best Research-Cell Efficiencies. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 15 August 2024).

- Szabó, G.; Park, N.-G.; De Angelis, F.; Kamat, P.V. Are Perovskite Solar Cells Reaching the Efficiency and Voltage Limits? ACS Energy Lett. 2023, 8, 3829–3831. [Google Scholar] [CrossRef]

- Müller, D.; Jiang, E.; Rivas-Lazaro, P.; Baretzky, C.; Loukeris, G.; Bogati, S.; Paetel, S.; Irvine, S.J.C.; Oklobia, O.; Jones, S.; et al. Indoor Photovoltaics for the Internet-of-Things—A Comparison of State-of-the-Art Devices from Different Photovoltaic Technologies. ACS Appl. Energy Mater. 2023, 6, 10404–10414. [Google Scholar] [CrossRef]

- Guo, Z.; Jena, A.K.; Miyasaka, T. Halide Perovskites for Indoor Photovoltaics: The Next Possibility. ACS Energy Lett. 2022, 8, 90–95. [Google Scholar] [CrossRef]

- Dong, C.; Li, M.; Zhang, Y.; Wang, K.L.; Yuan, S.; Igbari, F.; Yang, Y.; Gao, X.; Wang, Z.K.; Liao, L.S. Lead Oxalate-Induced Nucleation Retardation for High-Performance Indoor and Outdoor Perovskite Photovoltaics. ACS Appl. Mater. Interfaces 2020, 12, 836–843. [Google Scholar] [CrossRef] [PubMed]

- Jena, A.K.; Kulkarni, A.; Miyasaka, T. Halide Perovskite Photovoltaics: Background, Status, and Future Prospects. Chem. Rev. 2019, 119, 3036–3103. [Google Scholar] [CrossRef] [PubMed]

- Ghorai, A.; Midya, A.; Ray, S.K. Surfactant-Induced Anion Exchange and Morphological Evolution for Composition-Controlled Caesium Lead Halide Perovskites with Tunable Optical Properties. ACS Omega 2019, 4, 12948–12954. [Google Scholar] [CrossRef]

- Bati, A.S.R.; Zhong, Y.L.; Burn, P.L.; Nazeeruddin, M.K.; Shaw, P.E.; Batmunkh, M. Next-generation applications for integrated perovskite solar cells. Commun. Mater. 2023, 4, 2. [Google Scholar] [CrossRef]

- Penpong, K.; Seriwatanachai, C.; Naikaew, A.; Phuphathanaphong, N.; Thant, K.K.S.; Srathongsian, L.; Sukwiboon, T.; Inna, A.; Sahasithiwat, S.; Pakawatpanurut, P.; et al. Robust perovskite formation via vacuum thermal annealing for indoor perovskite solar cells. Sci. Rep. 2023, 13, 10933. [Google Scholar] [CrossRef]

- Das, A.; Ghorai, A.; Saha, K.; Chatterjee, A.; Jeong, U. Various approaches to synthesize water-stable halide PeNCs. J. Mater. Chem. A 2023, 11, 6796–6813. [Google Scholar] [CrossRef]

- Ghorai, A.; Mahato, S.; Singh, S.; Bose, S.; Roy, B.; Jeong, U.; Kumar Ray, S. Ligand-Mediated Revival of Degraded alpha-CsPbI3 to Stable Highly Luminescent Perovskite. Angew. Chem. Int. Ed. 2023, 62, e202302852. [Google Scholar] [CrossRef]

- Mahato, S.; Ghorai, A.; Srivastava, S.K.; Modak, M.; Singh, S.; Ray, S.K. Highly Air-Stable Single-Crystalline β-CsPbI3 Nanorods: A Platform for Inverted Perovskite Solar Cells. Adv. Energy Mater. 2020, 10, 2001305. [Google Scholar] [CrossRef]

- Ghorai, A.; Mahato, S.; Srivastava, S.K.; Ray, S.K. Atomic Insights of Stable, Monodispersed CsPbI3−xBrx (x = 0, 1, 2, 3) Nanocrystals Synthesized by Modified Ligand Cell. Adv. Funct. Mater. 2022, 32, 2202087. [Google Scholar] [CrossRef]

- Sun, C.; Jiang, Y.; Zhang, L.; Wei, K.; Yuan, M. Toward the Controlled Synthesis of Lead Halide Perovskite Nanocrystals. ACS Nano 2023, 17, 17600–17609. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.A.; Khan, N.Z.; Sohail, M.; Runowski, M.; Xu, X.; Agathopoulos, S. Recent developments of lead-free halide-perovskite nanocrystals: Synthesis strategies, stability, challenges, and potential in optoelectronic applications. Mater. Today Phys. 2023, 34, 101079. [Google Scholar] [CrossRef]

- Shohag, M.a.S.; Eze, V.O.; Braga Carani, L.; Okoli, O.I. Fully Integrated Mechanoluminescent Devices with Nanometer-Thick Perovskite Film as Self-Powered Flexible Sensor for Dynamic Pressure Sensing. ACS Appl. Nano Mater. 2020, 3, 6749–6756. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Q.; Zhao, J.; Xu, Y.; Wang, H.; Zhou, X.; Yang, S.; Ci, Z.; Jin, Z. Low-Trap-Density CsPbX3 Film for High-Efficiency Indoor Photovoltaics. ACS Appl. Mater. Interfaces 2022, 14, 11528–11537. [Google Scholar] [CrossRef] [PubMed]

- Valluvar Oli, A.; Li, Z.; Chen, Y.; Ivaturi, A. Near-Ultraviolet Indoor Black Light-Harvesting Perovskite Solar Cells. ACS Appl. Energy Mater. 2022, 5, 14669–14679. [Google Scholar] [CrossRef]

- Dayneko, S.V.; Pahlevani, M.; Welch, G.C. Indoor Photovoltaics: Photoactive Material Selection, Greener Ink Formulations, and Slot-Die Coated Active Layers. ACS Appl. Mater. Interfaces 2019, 11, 46017–46025. [Google Scholar] [CrossRef]

- Venkatesan, S.; Lin, W.H.; Teng, H.; Lee, Y.L. High-Efficiency Bifacial Dye-Sensitized Solar Cells for Application under Indoor Light Conditions. ACS Appl. Mater. Interfaces 2019, 11, 42780–42789. [Google Scholar] [CrossRef]

- Wang, H.; Dewi, H.A.; Koh, T.M.; Bruno, A.; Mhaisalkar, S.; Mathews, N. Bifacial, Color-Tunable Semitransparent Perovskite Solar Cells for Building-Integrated Photovoltaics. ACS Appl. Mater. Interfaces 2020, 12, 484–493. [Google Scholar] [CrossRef]

- Park, S.Y.; Li, Y.; Kim, J.; Lee, T.H.; Walker, B.; Woo, H.Y.; Kim, J.Y. Alkoxybenzothiadiazole-Based Fullerene and Nonfullerene Polymer Solar Cells with High Shunt Resistance for Indoor Photovoltaic Applications. ACS Appl. Mater. Interfaces 2018, 10, 3885–3894. [Google Scholar] [CrossRef]

- Polyzoidis, C.; Rogdakis, K.; Kymakis, E. Indoor Perovskite Photovoltaics for the Internet of Things—Challenges and Opportunities toward Market Uptake. Adv. Energy Mater. 2021, 11, 2101854. [Google Scholar] [CrossRef]

- Ma, Q.; Wang, Y.; Liu, L.; Yang, P.; He, W.; Zhang, X.; Zheng, J.; Ma, M.; Wan, M.; Yang, Y.; et al. One-step dual-additive passivated wide-bandgap perovskites to realize 44.72%-efficient indoor photovoltaics. Energy Environ. Sci. 2024, 17, 1637–1644. [Google Scholar] [CrossRef]

- Wojciechowski, K.; Forgács, D. Commercial Applications of Indoor Photovoltaics Based on Flexible Perovskite Solar Cells. ACS Energy Lett. 2022, 7, 3729–3733. [Google Scholar] [CrossRef]

- Kim, S.; Oh, H.; Kang, G.; Han, I.K.; Jeong, I.; Park, M. High-Power and Flexible Indoor Solar Cells via Controlled Growth of Perovskite Using a Greener Antisolvent. ACS Appl. Energy Mater. 2020, 3, 6995–7003. [Google Scholar] [CrossRef]

- Gao, M.; Wang, P.; Jiang, L.; Wang, B.; Yao, Y.; Liu, S.; Chu, D.; Cheng, W.; Lu, Y. Power generation for wearable systems. Energy Environ. Sci. 2021, 14, 2114–2157. [Google Scholar] [CrossRef]

- Christians, J.A.; Habisreutinger, S.N.; Berry, J.J.; Luther, J.M. Stability in Perovskite Photovoltaics: A Paradigm for Newfangled Technologies. ACS Energy Lett. 2018, 3, 2136–2143. [Google Scholar] [CrossRef]

- Pitchaiya, S.; Eswaramoorthy, N.; Madurai Ramakrishnan, V.; Natarajan, M.; Velauthapillai, D. Bio-Inspired Graphitic Carbon-Based Large-Area (10 × 10 cm2) Perovskite Solar Cells: Stability Assessments under Indoor, Outdoor, and Water-Soaked Conditions. ACS Appl. Mater. Interfaces 2022, 14, 43050–43066. [Google Scholar] [CrossRef]

- Boyd, C.C.; Cheacharoen, R.; Leijtens, T.; Mcgehee, M.D. Understanding Degradation Mechanisms and Improving Stability of Perovskite Photovoltaics. Chem. Rev. 2019, 119, 3418–3451. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Su, Z.; Canil, L.; Hughes, D.; Aldamasy, M.H.; Dagar, J.; Trofimov, S.; Wang, L.; Zuo, W.; Jeronimo-Rendon, J.J.; et al. Highly efficient p-i-n perovskite solar cells that endure temperature variations. Science 2023, 379, 399–403. [Google Scholar] [CrossRef]

- Ravi, V.K.; Mondal, B.; Nawale, V.V.; Nag, A. Don’t Let the Lead Out: New Material Chemistry Approaches for Sustainable Lead Halide Perovskite Solar Cells. ACS Omega 2020, 5, 29631–29641. [Google Scholar] [CrossRef]

- Jin, X.; Yang, Y.; Zhao, T.; Wu, X.; Liu, B.; Han, M.; Chen, W.; Chen, T.; Hu, J.-S.; Jiang, Y. Mitigating Potential Lead Leakage Risk of Perovskite Solar Cells by Device Architecture Engineering from Exterior to Interior. ACS Energy Lett. 2022, 7, 3618–3636. [Google Scholar] [CrossRef]

- Horvath, E.; Kollar, M.; Andricevic, P.; Rossi, L.; Mettan, X.; Forro, L. Fighting Health Hazards in Lead Halide Perovskite Optoelectronic Devices with Transparent Phosphate Salts. ACS Appl. Mater. Interfaces 2021, 13, 33995–34002. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, Z.; Lin, H.; Bai, H.; Huang, Y.; Guan, Z.; Liu, F.; Wei, J. Application of Metal Halide Perovskite in Internet of Things. Micromachines 2024, 15, 1152. https://doi.org/10.3390/mi15091152

Chai Z, Lin H, Bai H, Huang Y, Guan Z, Liu F, Wei J. Application of Metal Halide Perovskite in Internet of Things. Micromachines. 2024; 15(9):1152. https://doi.org/10.3390/mi15091152

Chicago/Turabian StyleChai, Zhihao, Hui Lin, Hang Bai, Yixiang Huang, Zhen Guan, Fangze Liu, and Jing Wei. 2024. "Application of Metal Halide Perovskite in Internet of Things" Micromachines 15, no. 9: 1152. https://doi.org/10.3390/mi15091152

APA StyleChai, Z., Lin, H., Bai, H., Huang, Y., Guan, Z., Liu, F., & Wei, J. (2024). Application of Metal Halide Perovskite in Internet of Things. Micromachines, 15(9), 1152. https://doi.org/10.3390/mi15091152