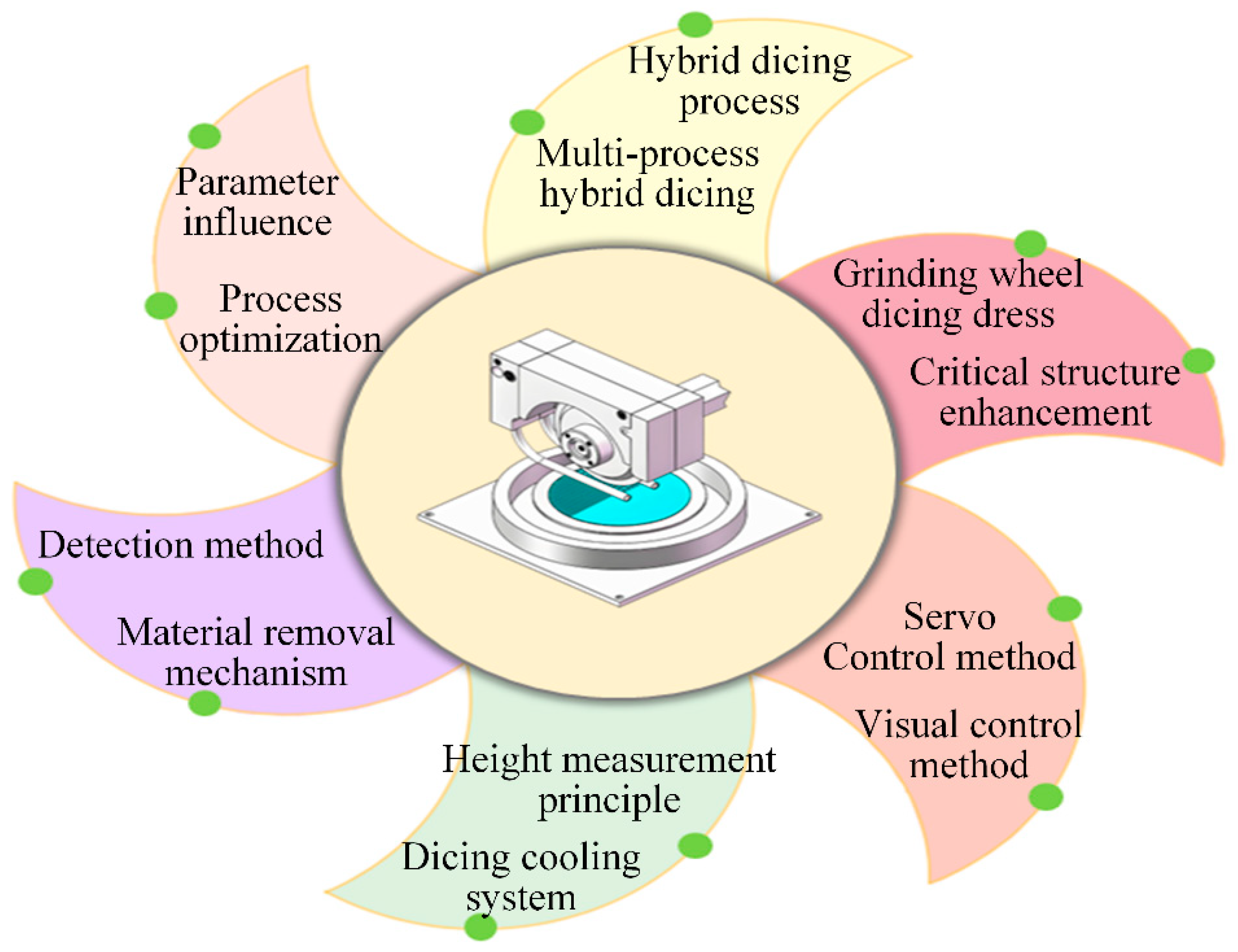

Recent Advances in Precision Diamond Wheel Dicing Technology

Abstract

1. Introduction

2. Semiconductor Dicing Processes

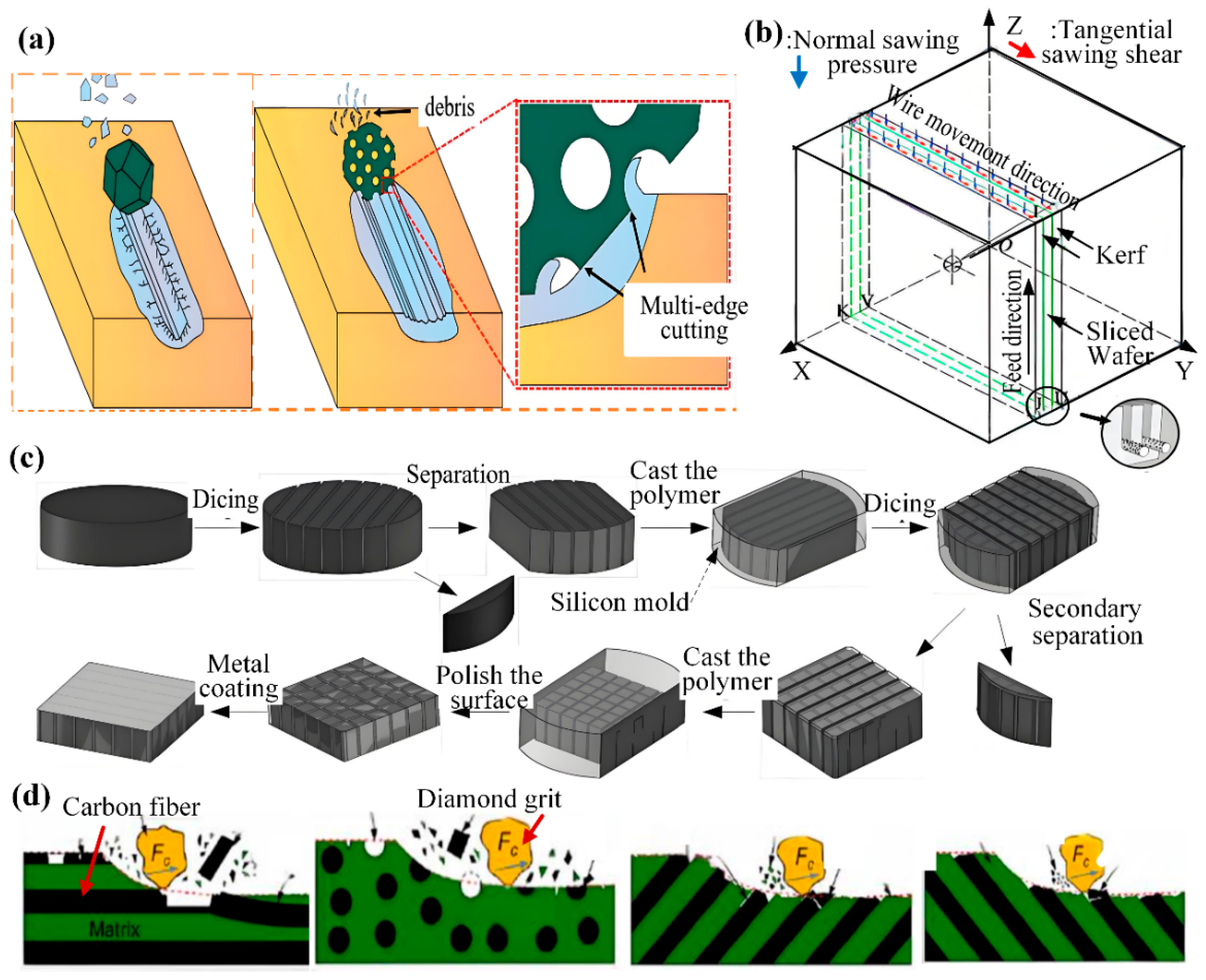

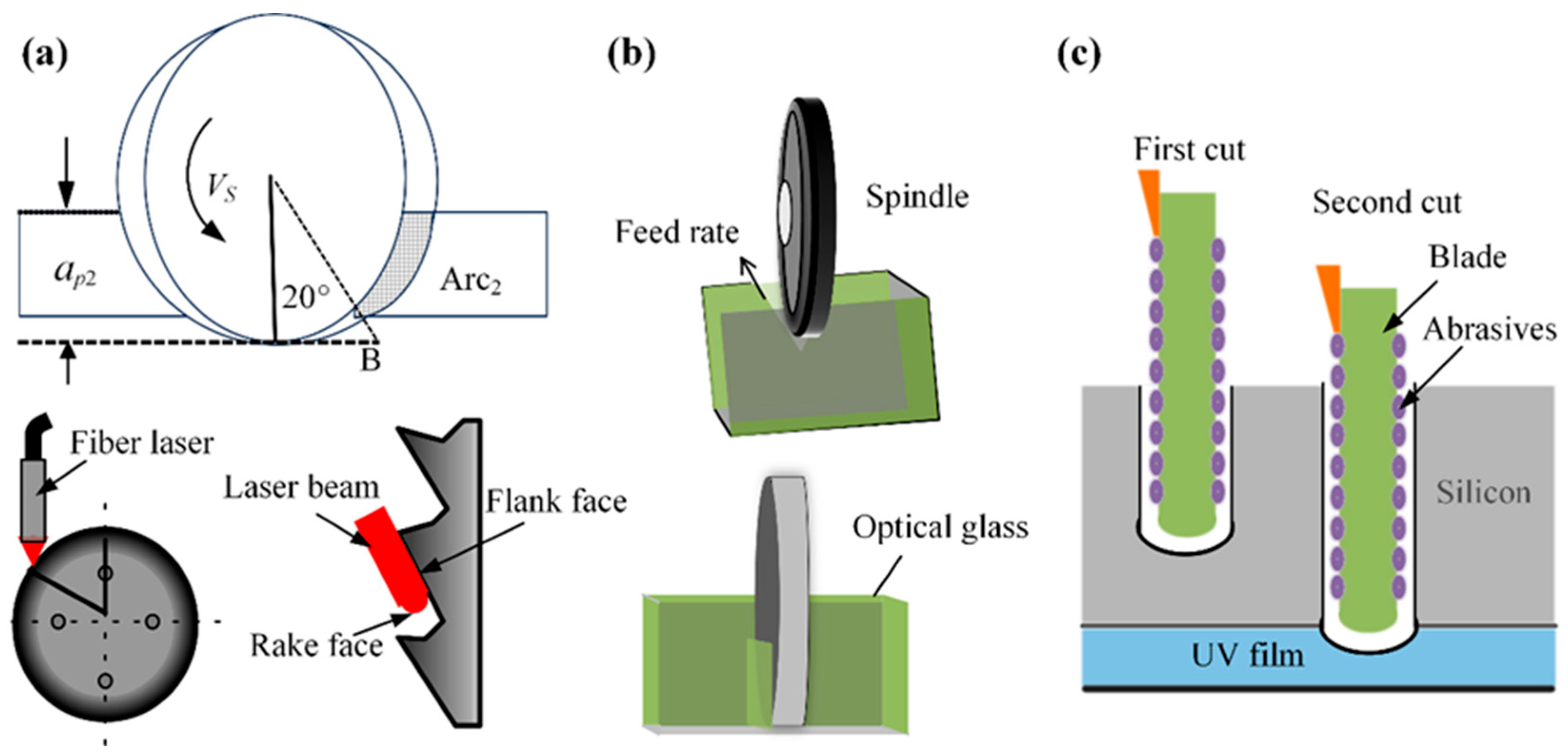

2.1. Multi-Mode Dicing Processes

2.2. Composite Dicing Process

3. Preparation of Ultra-Thin Dicing Blades

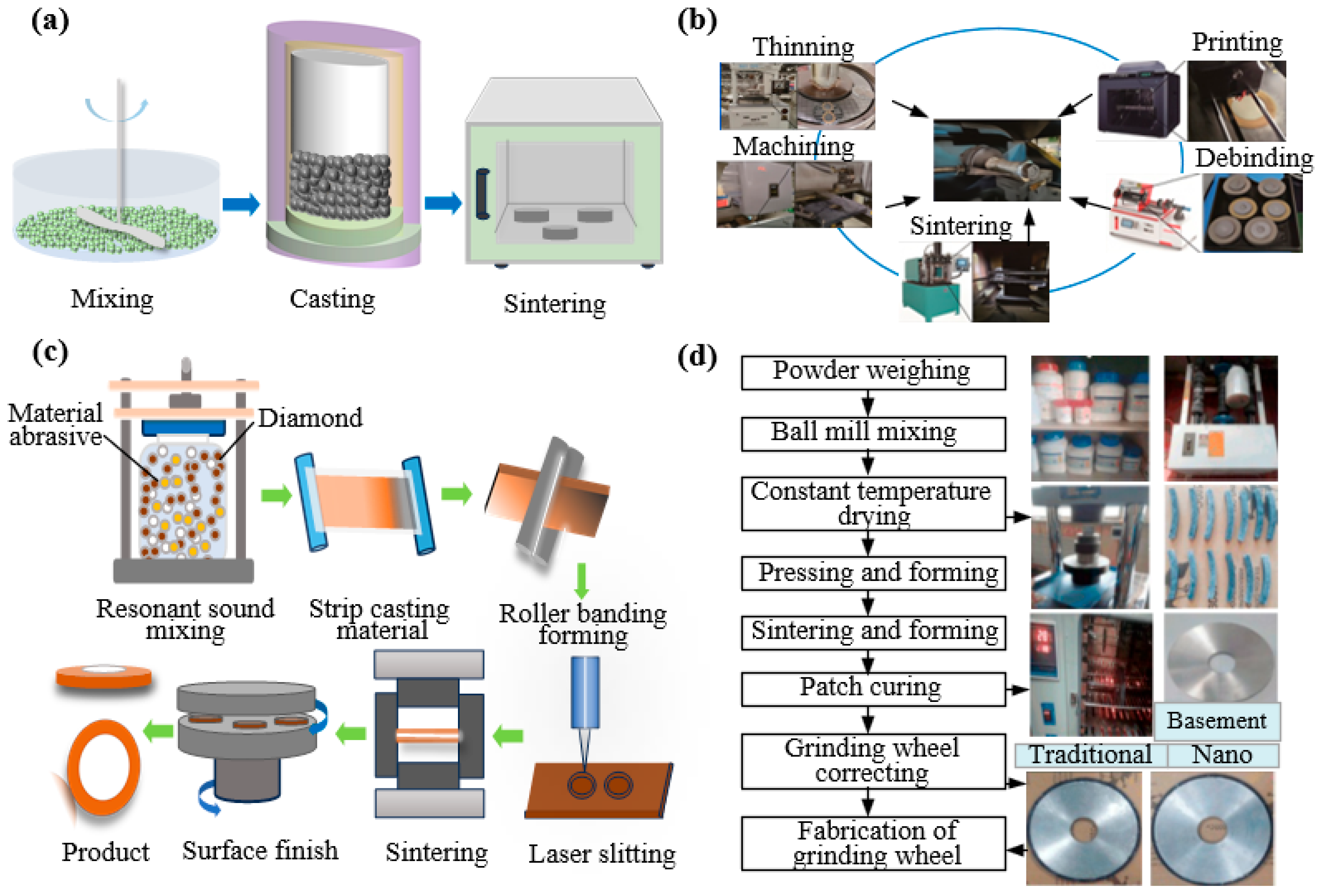

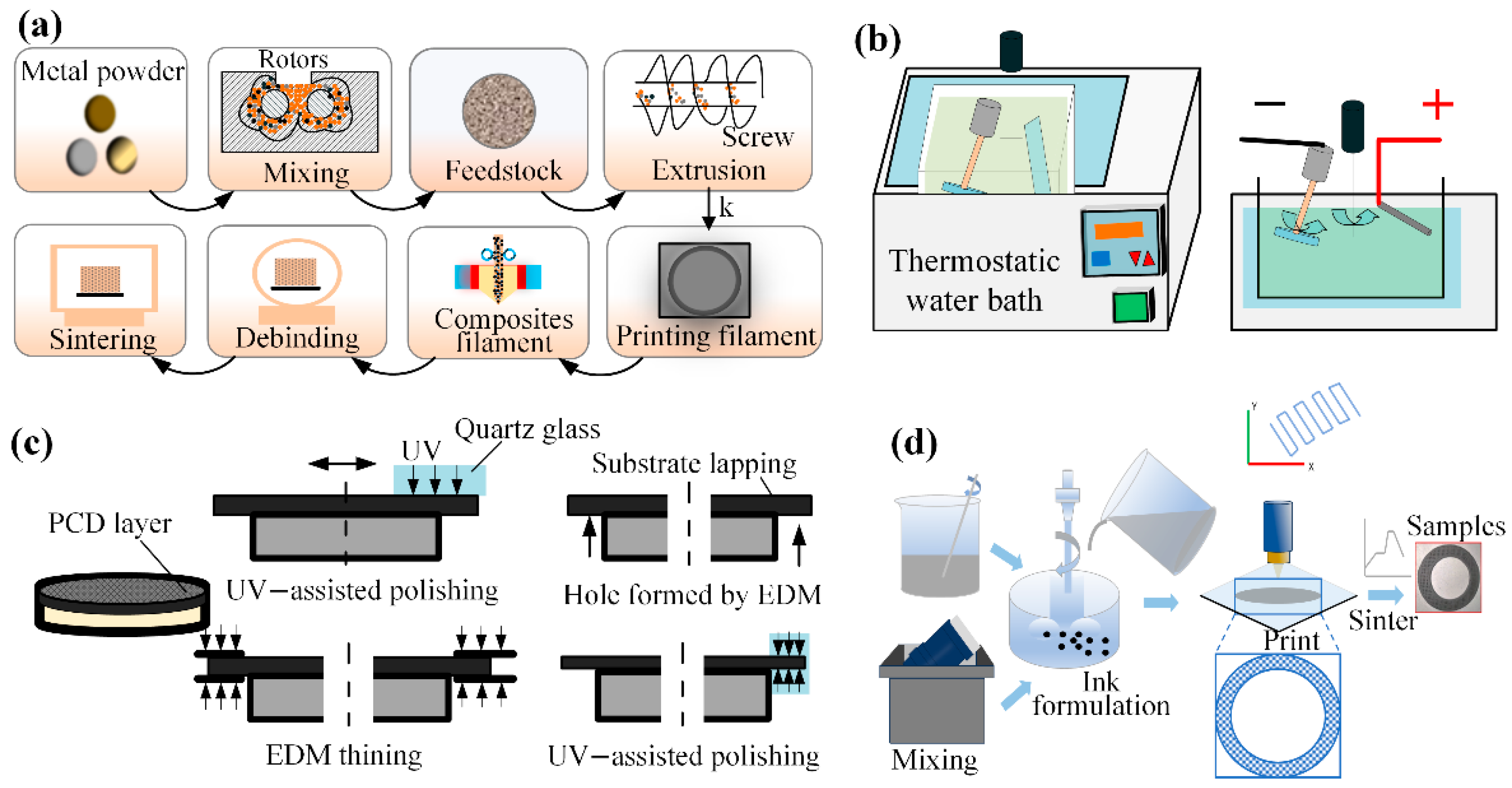

3.1. Preparation of Dicing Blades by Sintering

3.2. Hybrid Fabrication Methodology

3.3. Tool Wear

3.4. Grinding Wheel Dicing Trimming

4. Dicing Control Method

4.1. Vision System Control

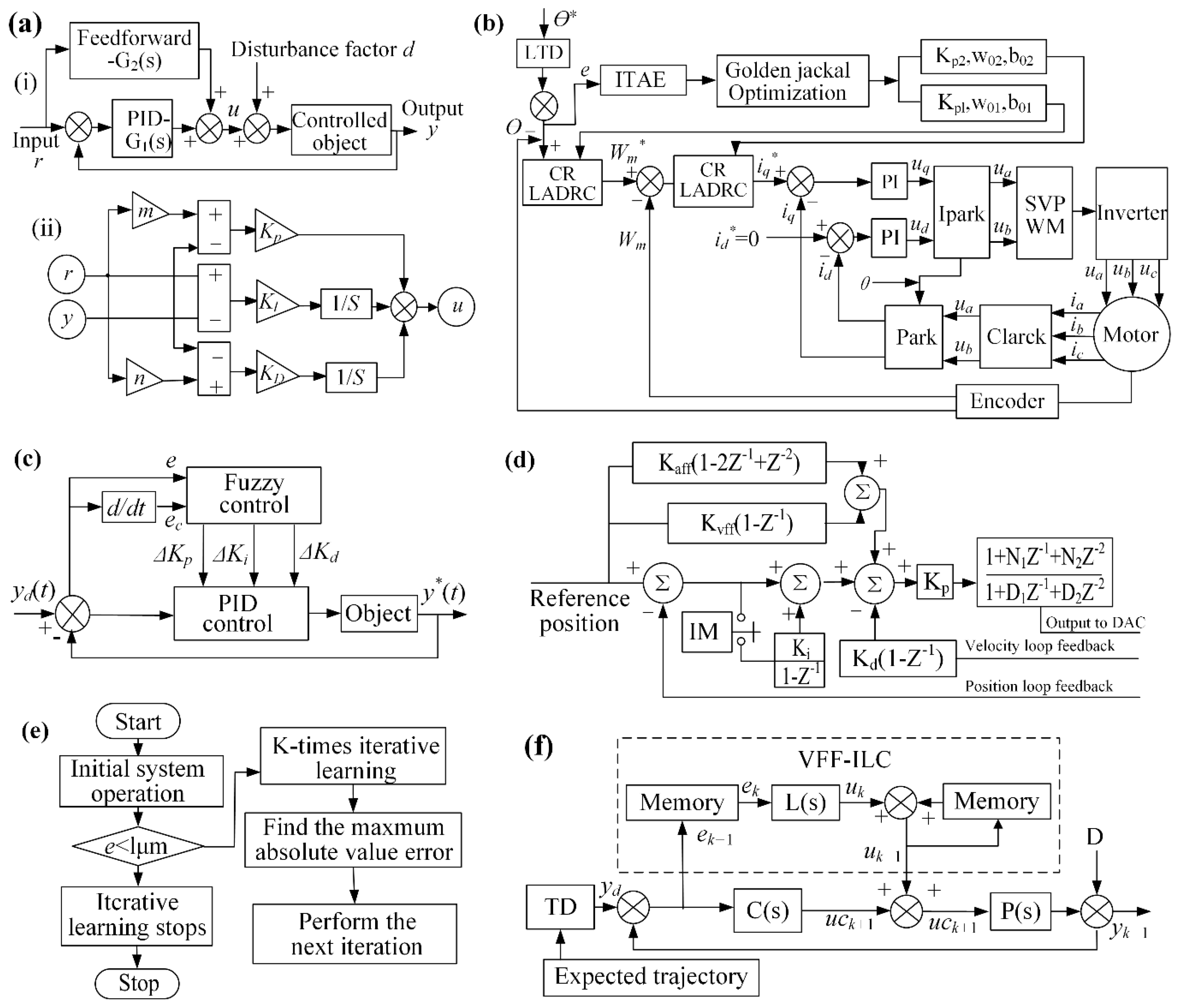

4.2. Servo Control System

5. Key Component Optimization

5.1. Spindle Precision

5.2. Tool Wear Height Measurement

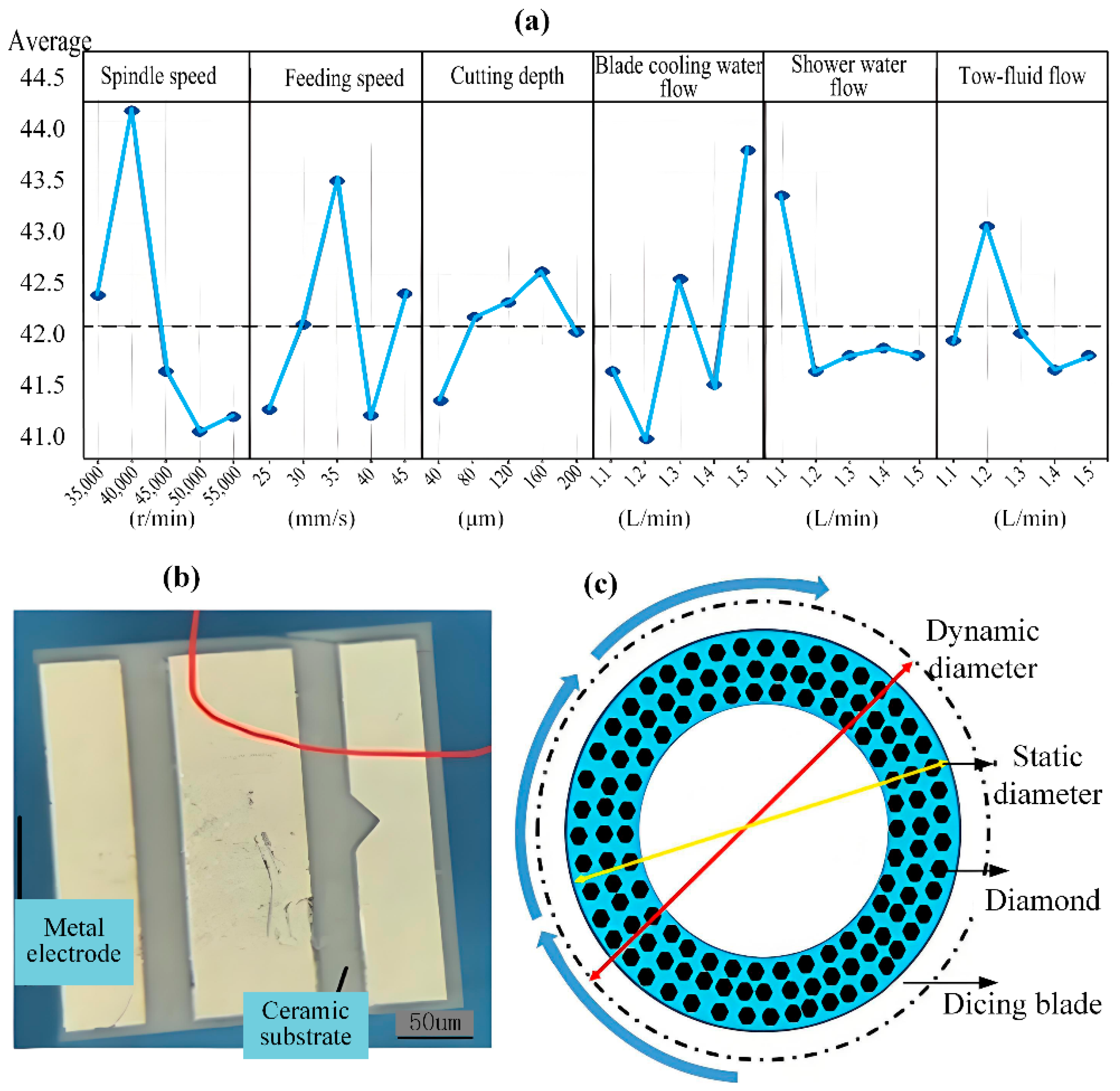

5.3. Grinding Wheel Structural Optimization

6. Experimental Analysis

6.1. Material Removal Mechanism and Simulation

6.2. Process Parameter Influence and Optimization

7. Prospects and Recommendations

- Rational Design of Dicing Processes. High-quality dicing processes minimize edge chipping and preserve workpiece integrity during grinding wheel operations. While single-process methods have inherent limitations, multi-mode and composite dicing techniques combine complementary advantages to reduce dicing-induced damage. Current diamond grinding wheel dicing predominantly employs a wheel-laser hybrid approach, which not only overcomes laser depth inaccuracies but also facilitates precision machining of complex geometries. Future integration of wheel dicing with plasma cutting and electrolytic systems, combined with optimized process design, will streamline operations and improve workpiece quality.

- Process parameter optimization is evolving from singular core parameter adjustments into a comprehensive systems engineering approach that integrates tool characteristics, workpiece properties, and cutting mechanisms. Next-generation intelligent dicing systems will leverage advanced algorithms to develop digital models that capture the complex interrelationships among abrasive composition, bond matrix properties, composite workpiece behavior, and material removal physics. Leveraging this foundational understanding, these systems will perform intelligent decision-making through dynamic analysis and synthesis of multidimensional factors, autonomously generating optimal parameter combinations tailored to specific processing conditions. This paradigm shift fundamentally advances cutting precision, surface integrity, and process consistency to unprecedented levels.

- Dual improvement of cutting accuracy and efficiency. The growing demand for dicing precision in photoelectric semiconductors is driving diamond grinding wheel processes toward higher accuracy and efficiency. By reasonably designing the structure of grinding wheel, the shape and thickness of dicing edge and the working parameters of dicing, ultra-thin cutting of the workpiece can be achieved. This enables the formation of narrower kerfs and suppresses edge chipping, leading to higher levels of dicing accuracy and efficiency. From a materials perspective, significant advances can be made by developing novel bond materials and innovative abrasive grains. A synergistic design with advanced bond systems facilitates control of the material removal process at the atomic scale. This approach enhances the grinding wheel’s strength and toughness, while adjustments to the formulation ratio regulate diamond abrasive concentration, thereby improving the wheel’s overall toughness and wear resistance.

- Develop a system simulation model for sustainable and environmentally friendly operations. Improper parameter settings by operators during diamond wheel dicing can cause system failures and reduce process efficiency. Integrating a real-time virtual dicing simulation model into the dicing machine allows for preemptive identification and correction of such issues. By simulating the process in advance, optimal parameters can be established, thereby reducing material loss and enhancing dicing stability and reliability. Furthermore, in wheel dicing operations, precise temperature control and extended wheel service life remain critical customer-valued performance factors, necessitating an efficient and rational cooling and waterproofing system. This can be accomplished through several approaches: configuring periodic coolant filtration; deploying high-velocity spray pipes or vortex-tube bidirectional drying for the worktable and blades or optimizing coolant formulations to improve cooling performance.

- Efficient combination of intelligence and automation. Advances in modern technology, especially in networking and data processing, are creating new opportunities for photoelectric material dicing. Intelligent and automated system software can be integrated to apply deep learning. This would enable real-time monitoring of abnormal conditions in the grinding machine’s operation. Such a system could automatically adjust dicing parameters to optimal levels, monitor grinding wheel wear, and compensate for it. This allows for the timely correction of improper operations, thereby reducing damage and scrap.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.Y.; Zhou, D.Y.; Gong, S.H. Uncalibrated visual positioning using adaptive Kalman Filter with dual rate structure for wafer chip in LED packaging. Measurement 2022, 191, 110829. [Google Scholar] [CrossRef]

- Kang, R.K. Introduction to processing technology of large-sized monocrystalline silicon Wafers. Diam. Abras. Eng. 2020, 40, 1–4. [Google Scholar]

- Wang, C.N.; Hsueh, M.H.; Lai, C.J.; Chung, C.C.; Chung, W.C.; Wang, S.H. Improve chip side wall crack issue in nanometer packing process of semiconductor. IEEE. Trans. Comp. Pack. Man. 2021, 11, 2. [Google Scholar] [CrossRef]

- Shen, J.Y.; Lu, L.; Gong, Y.Y.; Xu, X.P. Study on the influence of variation of contact arc zone on the single-pass sawing of sapphire wafer. Int. J. Precis. Eng. Manuf. 2018, 19, 1265–1271. [Google Scholar] [CrossRef]

- Fujita, T.; Izumi, Y.; Watanabe, J.J. Ultrafine ductile-mode dicing technology for SiC substrate with metal film using PCD blade. J. Adv. Mech. Des. Syst. Manuf. 2019, 13, JAMDSM0073. [Google Scholar] [CrossRef]

- Chen, S.L.; Tsai, C.Z.; Wu, E.; Shih, I.G.; Chen, Y.N. Study on the effects of wafer thinning and dicing on chip strength. IEEE Trans. Adv. Packag. 2006, 29, 149–157. [Google Scholar] [CrossRef]

- Yin, S.H.; Yang, H.L.; Chen, F.J.; Geng, J.X.; Zhang, J.J. Experimental research on step cut process of silicon wafer. Surf. Technol. 2018, 47, 1–7. [Google Scholar]

- Lee, S.M. Adoption of hybrid dicing technique to minimize sawing-induced damage during semiconductor wafer separation. Mater. Trans. 2017, 58, 530–534. [Google Scholar] [CrossRef]

- Li, Y.L.; Gao, A.M.; Zhang, Y.L. Study on multiple dicing technology for silicon wafer. Equip. Electron. Prod. Manuf. 2018, 47, 25–28+68. [Google Scholar]

- Qu, M.N.; Zhang, Y.; Huang, C.Z. Interface failure behavior and mechanisms of 4H-SiC wafer with alloy backside layer caused by different dicing technologies. J. Manuf. Process. 2024, 120, 1115–1123. [Google Scholar] [CrossRef]

- Wang, D.D.; Shao, Q.; Diao, Y.Y.; Bing, J.L.; Zhao, F.; Gong, Y.G.; Wang, B.; Xu, B.C.; Sun, R.F.; Li, D.F. Effect of copper-coated graphite powder on performance of copper-based metal-bonded grinding wheel. Superhard Mater. Eng. 2024, 36, 36–39. [Google Scholar]

- Sumiya, H.; Harano, K. Micro-scale abrasion investigations of single-crystal diamonds using nano-polycrystalline diamond wheels. Diam. Relat. Mater. 2022, 126, 109108. [Google Scholar] [CrossRef]

- Xiao, X.W.; Jin, Y.F.; Peng, R.T.; Jiang, S.Q.; Huang, X.F.; Zhao, L.F.; Gao, J.X.; Peng, J.F. Microscale viscous sintering model application to the preparation of metal bonded diamond grinding wheels. Int. J. Refract. Met. Hard Mater. 2023, 114, 106242. [Google Scholar] [CrossRef]

- He, T.; Zhang, S.H.; Yip, W.S.; To, S.; Wu, J.J.; Liu, L.L.; Wu, D.Y.; Kong, X.W.; Rong, L.L. Investigation on the machining performance of copper-based diamond ultra-thin dicing blades manufactured by fused deposition modeling and sintering (FDMS). Tribol. Int. 2023, 187, 11. [Google Scholar] [CrossRef]

- Feng, Y.R.; Li, K.N.; Dou, Z.; Zhang, Z.W.; Guo, B. High-speed dicing of SiC wafers with 0.048 mm diamond blades via rolling-slitting. Materials 2022, 15, 8083. [Google Scholar] [CrossRef]

- Miao, W.P.; Ding, Y.L.; Zhao, Y.J.; Bao, H.; Yan, N.; Yang, W.; Hui, Z.; Liu, B. Modified gel casting technique to fabricate honeycomb structured vitrified-bonded ultrafine diamond grinding wheels. Ceram. Int. 2020, 46, 4462–4469. [Google Scholar] [CrossRef]

- Zhang, C.; Qu, S.; Xi, W.C.; Liang, Y.D.; Zhao, J.; Yu, T.B. Preparation of a novel vitrified bond CBN grinding wheel and study on the grinding performance. Ceram. Int. 2022, 48, 15565–15575. [Google Scholar] [CrossRef]

- Wang, X.Z.; Wang, J.W.; Wang, X.C.; Hou, N.; Wang, M.H. Preparation of Structured Grinding Wheels Based on Nanosecond Pulse Lasers and Their Grinding Experiments. Surf. Technol. 2025, 54, 108–118. [Google Scholar]

- Kong, X.W.; Su, Z.; He, T.; Wu, J.J.; Wu, D.Y.; Zhang, S.H. Development and properties evaluation of diamond-containing metal composites for fused filament fabrication of diamond tool. Diam. Relat. Mater. 2022, 130, 109423. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, H.Y.; Ma, H.Z. Preparation and performance study of electroplated Ni–W/diamond ultrathin dicing blades. Mat. Sci. Semicon. Proc. 2024, 175, 108280. [Google Scholar] [CrossRef]

- Fujita, T.; Izumi, Y.; Watanabe, J. Ultra-fine grooving technology with high aspect ratio for cemented carbide by PCD (poly-crystalline diamond) blade. Precis. Eng. 2018, 55, 381–389. [Google Scholar] [CrossRef]

- Kurniawan, R.; Kiswanto, G.; Ko, T.J.; Chen, S.; Teng, H.; Kwak, Y.; Ali, S.; Han, P.-W.; Kim, G.S. Analysis of novel ultrasonic dicing blade design utilizing resonance impedance model. Int. J. Adv. Manuf. Technol. 2025, 1–20. [Google Scholar] [CrossRef]

- Li, M.; Mu, D.K.; Huang, S.Q.; Wu, Y.Q.; Meng, H.; Xu, X.P.; Huang, H. Ultrathin diamond blades for dicing single crystal SiC developed using a novel bonding method. J. Manuf. Process. 2022, 84, 88–99. [Google Scholar] [CrossRef]

- Li, M.; Liu, J.W.; Xu, X.P.; Mu, D. Influence of sintering temperature on dicing performances of metal-bonded diamond blades on sapphire. J. Mater. Res. Technol. 2024, 29, 991–999. [Google Scholar] [CrossRef]

- Huang, J.L.; Lu, J.; Wang, Y.H.; Ma, Z.Q. Fabrication of porous structure vitrified bond diamond grinding wheel via direct ink writing. Ceram. Int. 2021, 47, 34050–34058. [Google Scholar] [CrossRef]

- Liang, W.Y.; Zhu, W.; Zhang, Y.Y.; Jiang, Y.; Zhou, L.T.; Li, X.N. Tool life prediction of dicing saw based on adaptive golden jackal optimizing GRU. Int. J. Interact. Des. Manuf. 2023, 18, 1059–1074. [Google Scholar] [CrossRef]

- Shi, J.; Du, S.H.; Shi, Y.P.; Cao, W.F.; Zhou, L.T. An adaptive genetic algorithm optimize neural networks approach for wafer dicing saw quality prediction. Int. J. Adv. Manuf. Tech. 2022, 124, 209–218. [Google Scholar] [CrossRef]

- Maia, L.H.A.; Abrão, A.M.; Vasconcelos, W.L.; Júnior, J.L.; Fernandes, G.H.N.; Machado, Á.R. Enhancing Machining Efficiency: Real-Time Monitoring of Tool Wear with Acoustic Emission and STFT Techniques. Lubricants 2024, 12, 380. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, P.Y.; Du, S.H.; Liang, W.Y.; Cao, W.F.; Li, Q.B.; Hou, H.C. Chipping value prediction for dicing saw based on sparrow search algorithm and neural networks. J. Supercomput. 2023, 80, 7483–7506. [Google Scholar] [CrossRef]

- Su, T.J.; Chen, Y.F.; Cheng, J.C.; Chiu, C.L. An artificial neural network approach for wafer dicing saw quality prediction. Microelectron. Reliab. 2018, 91, 257–261. [Google Scholar] [CrossRef]

- Jeon, S.; Zolfaghari, A.; Lee, C.B. Dicing wheel wear monitoring technique utilizing edge diffraction effect. Measurement 2018, 121, 139–143. [Google Scholar] [CrossRef]

- Chen, F.J.; Huang, J.H.; Xu, J.L.; Wang, H.D.; Hu, T. Wear measurement of ultrathin grinding wheel using fiber optical sensor for high-precision wafer dicing. Int. J. Adv. Manuf. Tech. 2023, 125, 2133–2145. [Google Scholar] [CrossRef]

- Deng, Z.C. Application of machine learning algorithms in blade damage detection of Slicers. Ele. Manuf. 2024, 32, 57–61. [Google Scholar]

- Kang, J.Y.; Zhang, J.S.; Zhang, H.; Zhang, Z.Y.; Bai, T.Y.; Gong, Y.T.; Guo, J. Early condition monitoring of circular saw blades with large diameter-to-thickness ratios under high-speed sawing of hard metals. Measurement 2024, 235, 114933. [Google Scholar] [CrossRef]

- He, Y.; Li, X.; Gao, X.J.; Fan, L.; Liu, M.; Xu, Z.C. Modeling of ultra-thin diamond cutting blades and simulation of SiC chip cutting based on Python language. Diam. Abras. Eng. 2023, 43, 621–631. [Google Scholar]

- Jiao, F.; Li, C.L.; Niu, Y.; Ma, X.S. Review and prospect of grinding wheel dressing technique. Chin. Mech. Eng. 2021, 32, 2435–2448. [Google Scholar]

- Xia, J.N.; Yan, Q.S.; Pan, J.S.; Yang, C.Y.; Wang, T. State-of-the-art of ultra-precision grinding technology for hard and brittle materials. J. Guangdong Univ. Technol. 2023, 40, 32–43. [Google Scholar]

- Zhou, L.; Wei, Q.C.; Zheng, N.X.; Chen, X.H.; Zhang, Q.H.; Wang, J. Dressing technology of arc diamond wheel by roll abrading in aspheric parallel grinding. Int. J. Adv. Manuf. Tech. 2019, 105, 2699–2706. [Google Scholar] [CrossRef]

- Karpuschewski, B.; Lierse, T.; Kaul, R.T.; Schulze, S.; Müller-Crammet, D. Kinematic process model and investigation of grain breakout for conditioning with CVD diamond dressing disks. CIRP J. Manuf. Sci. Technol. 2018, 22, 21–29. [Google Scholar] [CrossRef]

- Chen, D.H. Diamond wheel truing machine visual imaging system and application. Precis. Manuf. Aut. 2024, 3, 39–44. [Google Scholar]

- Chen, S.T.; Guo, J.P. Reconditioning of diamond dicing blades via electrolytic dressing. J. Mater. Process. Tech. 2023, 311, 117801. [Google Scholar] [CrossRef]

- Dai, L.Z.; Chen, G.Y.; Li, M.Q.; Yuan, S.Y. Experimental study on dressing concave trapezoidal diamond grinding wheel by electrical discharge grinding method. Diam. Relat. Mater. 2022, 128, 109218. [Google Scholar] [CrossRef]

- Watanabe, K.; Yanagida, D.; Minami, H.; Izumi, Y. Electrical discharge truing of a PCD blade tool on a dicing machine. Procedia CIRP 2020, 95, 494–498. [Google Scholar] [CrossRef]

- Mukhopadhyay, M.; Kundu, K.P. Optimization of dressing infeed of alumina wheel for grinding Ti-6Al-4V. Mater. Manuf. Process. 2018, 33, 1453–1458. [Google Scholar] [CrossRef]

- Khan, M.F.; Dannoun, E.M.A.; Nofal, M.M.; Mursaleen, M. Significance of Camera Pixel Error in the Calibration Process of a Robotic Vision System. Appl. Sci. 2022, 12, 6406. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Haoran, J.; Jia, P.X.; Chen, K.X. An automatic detection method for cutting path of chips in wafer. Micromachines 2022, 14, 59. [Google Scholar] [CrossRef]

- Wei, Z.; Zhang, Y.; Zhang, M.M.; Meng, F.B. Research on trajectory optimization algorithm of visual guide grinding wheel dicing machine. Mech. Electr. Eng. 2019, 37, 38–41. [Google Scholar]

- Rodríguez, A.; González, M.; Pereira, O.; De Lacalle, L.N.L.; Esparta, M. Edge finishing of large turbine casings using defined multi-edge and abrasive tools in automated cells. Int. J. Adv. Manuf. Technol. 2023, 124, 3149–3159. [Google Scholar] [CrossRef]

- Rico, H.; Niranjan, S.; Hassan, S.H.; Ostayen, R.A.J. Air-based contactless wafer precision positioning system. Appl. Sci. 2021, 11, 7588. [Google Scholar] [CrossRef]

- Chen, F.J.; Ye, X.Q.; Yin, S.H.; Ye, Q.S.; Huang, S.; Tang, Q.C. Automated vision positioning system for dicing semiconductor chips using improved template matching method. Int. J. Adv. Manuf. Tech. 2019, 100, 2669–2678. [Google Scholar] [CrossRef]

- Sun, H.C.; Xu, Y. Optimal placement of sensors for modal testing of dicing saws. J. Vib. Shock. 2017, 36, 187–191. [Google Scholar]

- Wu, J.Z.; Chen, G.C.; Chen, F.J. Positioning accuracy control of dual-axis dicing saw for machining semiconductor chip. Int. J. Adv. Manuf. Tech. 2020, 109, 2299–2310. [Google Scholar] [CrossRef]

- Liang, W.Y.; Xie, X.Y.; Lan, J.; Zhu, W.; Shi, J.; Jiang, Y. Design of position controller for dicing saw chuck table based on improved LADRC technology. Microsyst. Technol. 2024, 31, 1547–1560. [Google Scholar] [CrossRef]

- Chen, F.J.; Huang, J.H.; Xu, J.L. High-precision servo control design and optimization for dicing semiconductor wafer. J. Manuf. Process. 2024, 117, 346–354. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, P.Y.; Hou, H.C.; Cao, W.F.; Zhou, L.T. Optimization of servo accuracy of Y axis of dicing saw based on iterative learning control. Int. J. Syst. Assur. Eng. 2024, 15, 3104–3116. [Google Scholar] [CrossRef]

- Cao, W.F.; Zhang, P.Y.; Mi, Q.T.; Sun, Y.H.; Shi, J.; Liang, W.Y. Optimization of X-axis servo drive performance using PSO fuzzy control technique for double-axis dicing saw. Sci. Rep. 2023, 13, 20719. [Google Scholar] [CrossRef]

- Maharof, M.; Jamaludin, Z.; Minhat, M.; Anang, N.A.; Heng, C.T. Force compensation for precise positioning in machine tools via state observer design. Int. J. Adv. Manuf. Technol. 2020, 107, 411–423. [Google Scholar] [CrossRef]

- Wang, J.X.; Zheng, H. Error Compensation for High-Precicion Motion of Dicing Saw Based on Iterative Learning Control. Microprocessor 2021, 42, 58–61. [Google Scholar] [CrossRef]

- Xu, L.; Wu, W.T.; Wang, Z.Y.; Jia, H. Analysis on the parameters of the chuck and the wheel mount of ADT 7100 dicing. Equip. Electron. Prod. Manuf. 2016, 45, 34–38. [Google Scholar]

- Wang, Y.J. Common problems and solutions of air bearing spindle in wafer dicing waw. Equip. Electron. Prod. Manuf. 2023, 52, 49–51. [Google Scholar]

- Hao, J.; Zhang, Z.M.; Li, P.F.; Wang, Y.J. Analysis and research on non-contact height measuring accuracy of grinding wheel scribing machine. Equip. Electron. Prod. Manuf. 2022, 51, 36–38. [Google Scholar]

- Amri, M.S.; Omar, G.; Mispan, M.S.; Harun, F.; Othman, M.N.B.; Ngatiman, N.A.N.; Ibrahim, M.M. Wafer Dicing Vibration Investigation on Novel Wafer Mounting Techniques. IEEE Trans. Semicond. Manuf. 2024, 4, 37. [Google Scholar] [CrossRef]

- Li, C.; Pan, J.X.; Han, H.C.; Jiang, X.Q.; Li, D.X.; Chen, L.X. Research on the influencing factors of corner module on wafer cutting quality. Chin. Equip. Eng. 2022, 6, 88–89. [Google Scholar]

- Wang, M.W.; Wu, K. Regarding the structural design of a cooling water cover for a sand wheel automatic cutting machine. Sci. Tech. Innovat. 2020, 26, 61–62. [Google Scholar]

- Okabe, T.; Somaya, K. Development of a wafer cooling system using ionic liquid under high vacuum condition for semiconductor fabrication device. Vacuum 2024, 229, 113570. [Google Scholar] [CrossRef]

- Yin, S.H.; Liao, Q.S.; Hu, T.; Gong, S.; Chen, F.J. Development of automatic double-spindle precise dicing saw. Diam. Abras. Eng. 2019, 39, 45–50. [Google Scholar]

- Wei, S.L.; Zhang, T.; Pi, J.; Wei, H.J.; Li, W.Z.; Wang, W. Study on wear simulation of diamond abrasive tool for rotary ultrasonic grinding. Int. J. Adv. Manuf. Technol. 2023, 124, 3671–3686. [Google Scholar] [CrossRef]

- Li, W.; Hu, X.L.; Long, G.; Shang, A.S.; Guo, B. Grain wear properties and grinding performance of porous diamond grinding wheels. Wear 2023, 530–531, 204993. [Google Scholar] [CrossRef]

- Zhang, M.H.; Shan, C.W.; Xia, Z.W.; Jia, F.C.; Luo, M. Dynamic mechanical model in grinding C/SiC composites. Int. J. Mech. Sci. 2024, 268, 109042. [Google Scholar] [CrossRef]

- Herbrandt, S.; Ligges, U.; Ferreira, M.P.; Kansteiner, M.; Biermann, D.; Tillmann, W.; Weihs, C. Model based optimization of a statistical simulation model for single diamond grinding. Comput. Stat. 2018, 33, 1127–1143. [Google Scholar] [CrossRef]

- Egea, A.J.S.; Martynenko, V.; Krahmer, D.M.; De Lacalle, L.N.L.; Benítez, A.; Genovese, G. On the Cutting Performance of Segmented Diamond Blades when Dry-Cutting Concrete. Materials 2018, 11, 264. [Google Scholar] [CrossRef]

- Araujo, L.A.O.; Foschini, C.R.; Jasinevicius, R.G.; Fortulan, C.A. Precision dicing of hard materials with abrasive blade. Int. J. Adv. Manuf. Technol. 2016, 86, 2885–2894. [Google Scholar] [CrossRef]

- Gao, Y.F.; Chen, Y. Sawing stress of SiC single crystal with void defect in diamond wire saw slicing. Int. J. Adv. Manuf. Tech. 2019, 103, 1019–1031. [Google Scholar] [CrossRef]

- Li, M.; Mu, D.; Wu, Y.Q.; Huang, G.Q.; Meng, H.; Xu, X.P.; Huang, H. Influence of diamond abrasives on material removal of single crystal SiC in mechanical dicing. J. Mater. Process. Tech. 2024, 327, 118390. [Google Scholar] [CrossRef]

- Kundrák, J.; Fedorovich, V.; Markopoulos, A.P.; Pyzhov, I.; Ostroverkh, Y. Theoretical Assessment of the Role of Bond Material during Grinding of Superhard Materials with Diamond Wheels. Machines 2022, 10, 543. [Google Scholar] [CrossRef]

- Riaz, A.; Yuan, Z.W.; Chohan, B.S. Investigation of the micro-cutting mechanism of T700 CFRP composites using ultra-thin dicing blade. Int. J. Adv. Manuf. Tech. 2024, 135, 3159–3174. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Y.; Wang, X.M.; Zhou, J.J. Study of dicing mechanism influence on PZT-4H composite performance. Int. J. Adv. Manuf. Tech. 2023, 129, 5089–5100. [Google Scholar] [CrossRef]

- Yuan, Z.W.; Hu, J.T.; Wen, Q.; Cheng, K.; Zheng, P. Investigation on an innovative method for high-speed low-damage micro-cutting of CFRP composites with diamond dicing blades. Materials 2018, 11, 1974. [Google Scholar] [CrossRef]

- Duan, N.; Yu, Y.Q.; Shi, W.B.; Xiao, Q.; Liu, Q. Investigation on diamond damaged process during a single-scratch of single crystal silicon carbide. Wear 2021, 486–487, 204099. [Google Scholar] [CrossRef]

- Zahedi, A.; Azarhoushang, B. An analytical force surface roughness model for cylindrical grinding of brittle materials. Int. J. Abras. Technol. 2017, 8, 68–81. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Q.L.; Guo, B. Wear characteristics of electroplated diamond dressing wheels used for on-machine precision truing of arc-shaped diamond wheels. Diam. Relat. Mater. 2022, 129, 109372. [Google Scholar] [CrossRef]

- Liu, Y.S.; Huang, H.; Wang, L.Q.; Liao, X.J. Experimental study on normal force of cutting sapphire with multi-wire swing reciprocating wire saw. Diam. Abras. Eng. 2024, 44, 143–150. [Google Scholar] [CrossRef]

- Agudon, A.M.E.; Bacquian, B.C.S. Backside Chippings Improvement through Wafer Dicing Parameter Optimization and Understanding the Anistropic Silicon Properties. J. Eng. Res. Rep. 2021, 20, 144–152. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, Z.W.; Zhuang, P.; Wu, T.Z.; Feng, S. Study on precision dicing process of SiC wafer with diamond dicing blades. Nanotechnol. Precis. Eng. 2021, 4, 033004. [Google Scholar] [CrossRef]

- Su, T.J.; Chen, Y.F.; Cheng, J.C.; Chiu, C.L. Optimizing the dicing saw parameters of 60 μm wafer dicing street. Microsyst. Technol. 2018, 24, 3965–3971. [Google Scholar] [CrossRef]

- Shi, J.; Liu, W.; Chen, Z.H.; Cao, W.F.; Zhou, L.T. Optimization method of cutting parameters of wafer dicing saw based on orthogonal regression design. SN App. Sci. 2022, 4, 262. [Google Scholar] [CrossRef]

- Ma, Y.; Jiang, X.Q.; Liu, H.; Zhang, Z.Y.; Cao, Z.D. Simulation analysis of influencing factors of grinding wheel scribing quality. J. Phys. Conf. Ser. 2022, 2301, 012022. [Google Scholar] [CrossRef]

- She, F.Q.; Zhang, D.; Wang, Z. Research on the selection method of diamond dicing knife for Al2O3 ceramic substrate cutting. Superhard Mater. Eng. 2024, 36, 15–19. [Google Scholar]

- Wang, F.M.; Shimamoto, H.; Kawagoe, T.; Yamasaki, M.; Okutsu, F.; Masuuda, T.; Kikuchi, K. Warpage Reduction and Thermal Stress Study of Dicing Process in Wafer-to-Wafer Bonding Fabrication. IEEE Trans. Electron Devices 2022, 69, 6265–6269. [Google Scholar]

- Chaudri, A.; Foo, A.; Tsai, D.; Lim, D.K.; Prabhala, R.; Zhuang, D.; Vempaty, V.R.S.P. Advanced digital twin framework for stealth dicing of ultra-thin memory devices using machine learning. Mater. Sci. Semicond. Process. 2025, 185, 109010. [Google Scholar] [CrossRef]

- Li, K.N.; Wang, M.Z.; Chen, F.; Yan, N.; Zou, Q.; Zhao, Y.C.; Li, J.M.; Zhao, F. Analysis of the dynamic diameter of superthin diamond blades in the high speed and precison dicing process. Int. J. Precis. Eng. Manuf. 2019, 20, 1071–1081. [Google Scholar] [CrossRef]

- Tan, H.Y.; Xing, X.; Ge, P.Q.; Bi, W.B. Simulation analysis and experimental research on the fracture strength of photovoltaic monocrystalline silicon slicing wafers. J. Synth. Cryst. 2024, 53, 1369–1377. [Google Scholar]

- Yang, Y.F.; Li, X.; He, Y.; Liu, M.; Xu, Z.C.; Gao, X.J. Simulation and experimental study on micro-cutting silicon carbide crystal with single grain diamond. Diam. Abras. Eng. 2024, 44, 495–507. [Google Scholar] [CrossRef]

| Predictive Model | Application Advantages | Limitations |

|---|---|---|

| AGJO-GRU Predictive model | Rapid convergence and high predictive accuracy | None |

| AGA-BPNN Predictive model | Powerful global search ability, ensuring reliable avoidance of local optima | None |

| CLSSA-BILSTM | High prediction accuracy and smaller error | Systems with numerous variables are prone to getting trapped in local optima. |

| BPNN monitor | Real-time monitoring of chip conditions and buffering of chip accumulation | Unstable training process and convergence to local optima |

| Edge diffraction-based monitoring | Non contact detection, high efficiency, strong anti-interference ability | High requirements for the work environment and large equipment investment |

| Fiber optic sensor detection | High precision, precise wear monitoring | Measurement during contact may result in tool damage |

| Bidirectional Attentive Temporal ResNet with Voting | Accuracy > 95%, minimizing equipment false alarms and shutdowns to the greatest extent possible | High computational complexity and dependence on device computing power requirements |

| Control Algorithm | Advantages | Disadvantages |

|---|---|---|

| Based on nonlinear image enhancement algorithm and template matching algorithm | Image preprocessing, improving the robustness of localization, and high fitting accuracy | Unable to convert physical size accuracy, limiting camera usage |

| Air bearing technology + CCD sensor | Completely non-contact measurement, avoiding physical damage to equipment workpieces | The system is complex, requiring high precision design for air bearing, and the cost is high |

| Image pyramid + improved template matching based on grayscale and line characteristics | Fast search speed, strong robustness, suitable for fast-paced production lines | Poor applicability |

| Bilinear interpolation and sub-pixel edge detection algorithms | Sub-pixel technology has high edge positioning accuracy and halcon platform has trajectory planning capability | Commercial software licensing issues, specific indicators not quantified |

| Optimization of sensor measurement points | Strong perception accuracy and reliability | Dependent on visual positioning system |

| Control Algorithm | Advantage | Disadvantage |

|---|---|---|

| PID + feedforward 2DOF control algorithm | Clear structure, inherent stability, and a balanced dynamic-static performance | Limited suppression of nonlinear/time-varying disturbances |

| Cascaded reduced-order LADRC tuned by Gold Jackal Optimization | High robustness with automated parameter optimization | High complexity in both theory and computation |

| PID+ velocity/acceleration feedforward+ Notch filter control algorithm | Strong practicality and can improve the accuracy of the cutting machine | More accurate system identification models are needed |

| Variable forgetting factor fuzzy iterative learning control (VFF-FILC) with tracking differentiator | Highly suitable for repetitive tasks, with strong disturbance rejection and fast convergence | The algorithm is complex and suitable for repetitive motion trajectories |

| Fuzzy Control + Heuristic Algorithm (PSO/GA) Optimization | Effective for model-free nonlinear systems | The optimization process is complex |

| Data-driven neural network iterative control | Strong nonlinear fitting force | Requires a large amount of data for training |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Du, M.; Feng, M.; Bao, R.; Jing, L.; Hong, Q.; Xiao, L.; Liu, J. Recent Advances in Precision Diamond Wheel Dicing Technology. Micromachines 2025, 16, 1188. https://doi.org/10.3390/mi16101188

Chen F, Du M, Feng M, Bao R, Jing L, Hong Q, Xiao L, Liu J. Recent Advances in Precision Diamond Wheel Dicing Technology. Micromachines. 2025; 16(10):1188. https://doi.org/10.3390/mi16101188

Chicago/Turabian StyleChen, Fengjun, Meiling Du, Ming Feng, Rui Bao, Lu Jing, Qiu Hong, Linwei Xiao, and Jian Liu. 2025. "Recent Advances in Precision Diamond Wheel Dicing Technology" Micromachines 16, no. 10: 1188. https://doi.org/10.3390/mi16101188

APA StyleChen, F., Du, M., Feng, M., Bao, R., Jing, L., Hong, Q., Xiao, L., & Liu, J. (2025). Recent Advances in Precision Diamond Wheel Dicing Technology. Micromachines, 16(10), 1188. https://doi.org/10.3390/mi16101188