The Influence of Thermal Annealing on the Chemical Composition, Nanomechanical, and Nanotribological Properties of Tantalum Thin Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Ta Metal Deposition and Annealing

2.2. X-Ray Photoelectron Spectroscopy

2.3. X-Ray Diffraction

2.4. Nanomechanical Characterization

2.5. Nanotribology of Ta Films

3. Results and Discussions

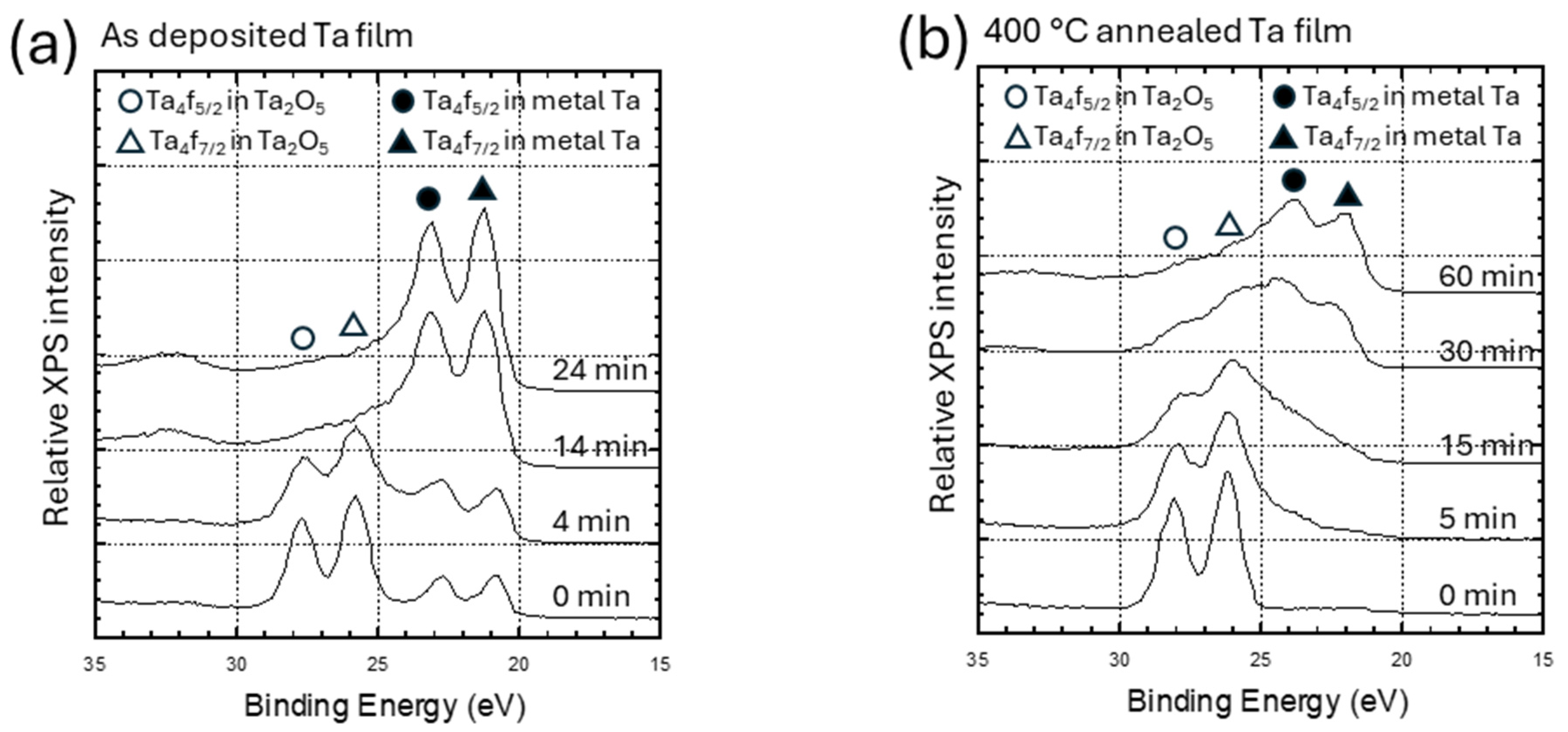

3.1. Chemical Composition of Ta Films

3.2. Crystalline Structure of Ta Films

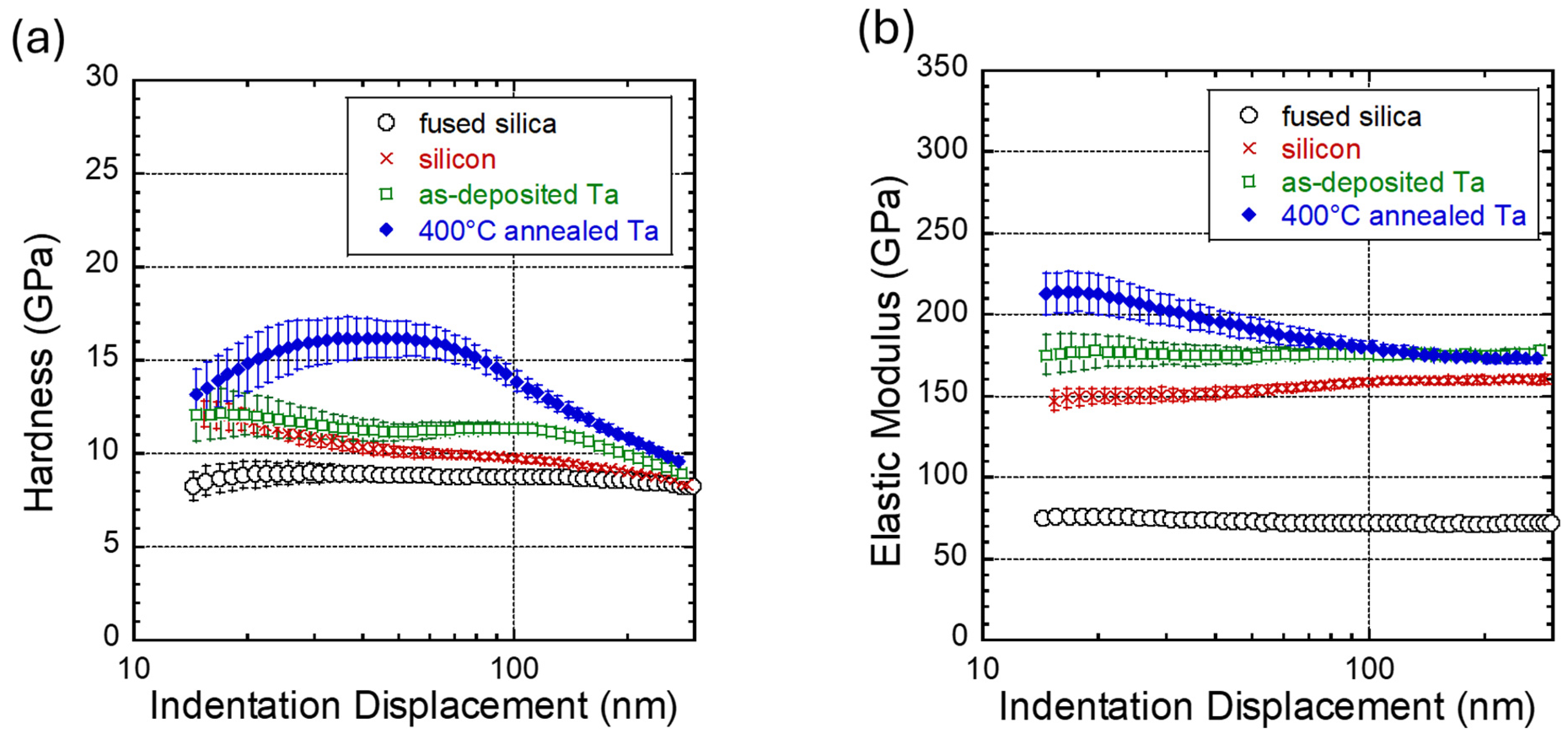

3.3. Nanomechanical Properties of the As-Deposited and Annealed Ta Films

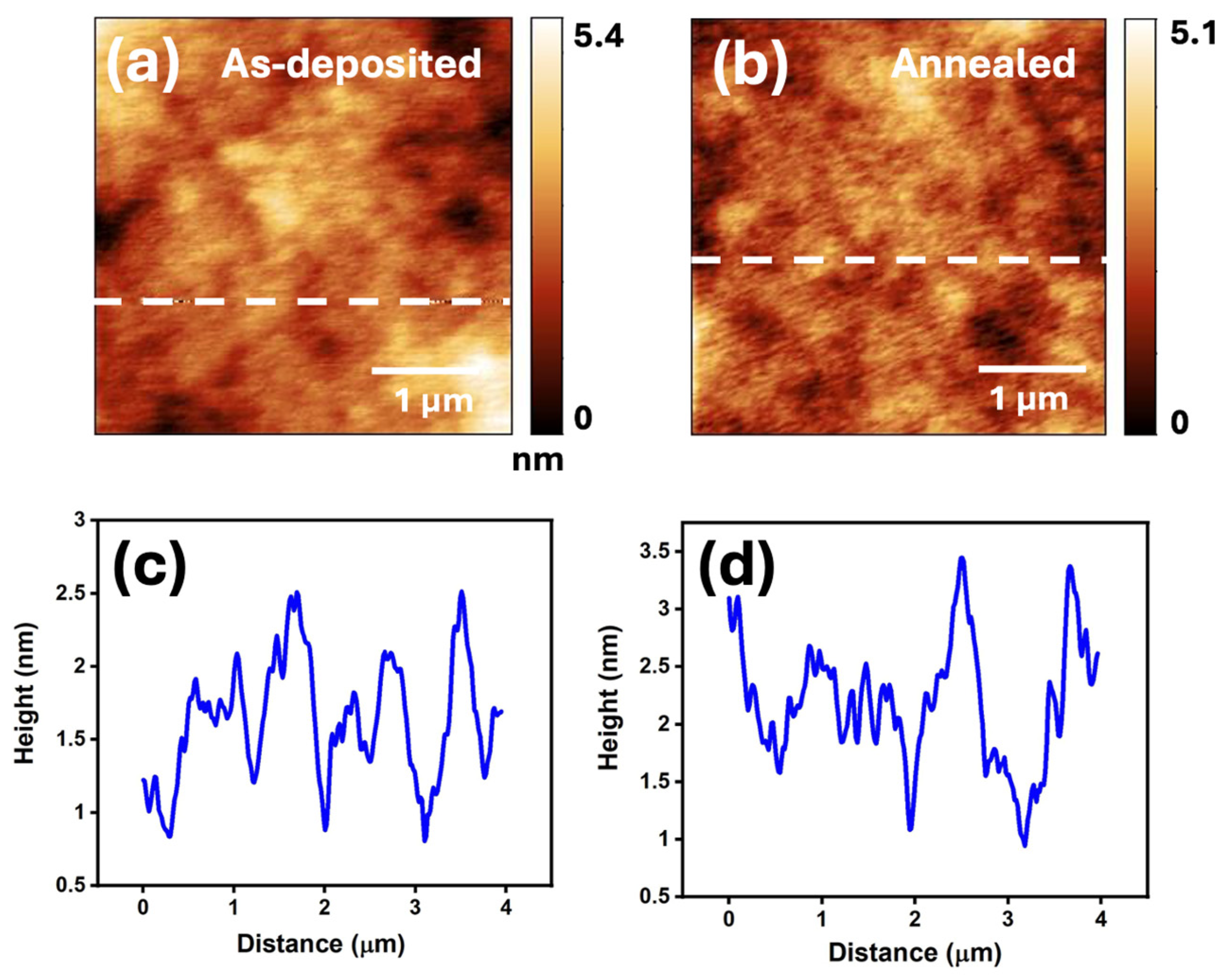

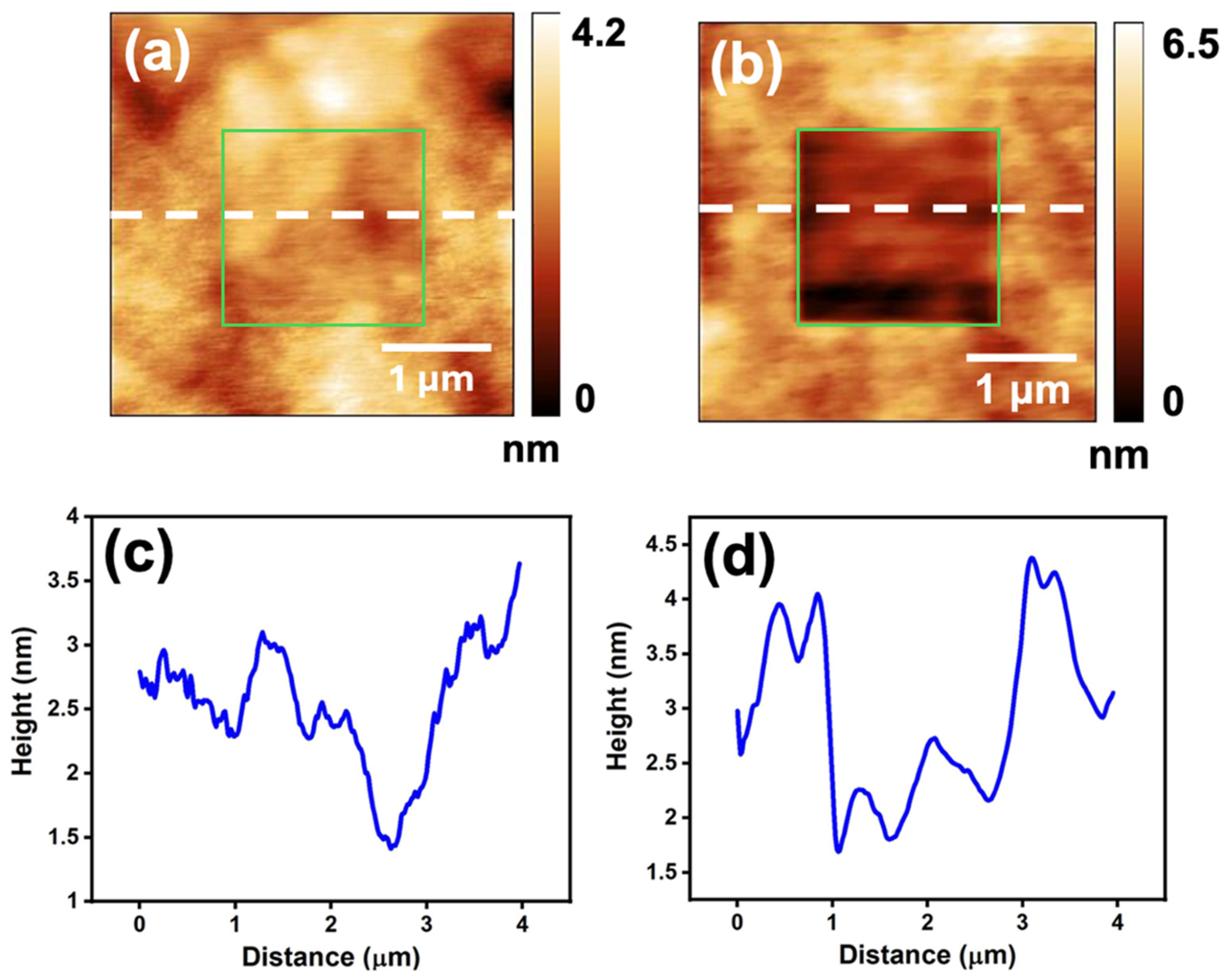

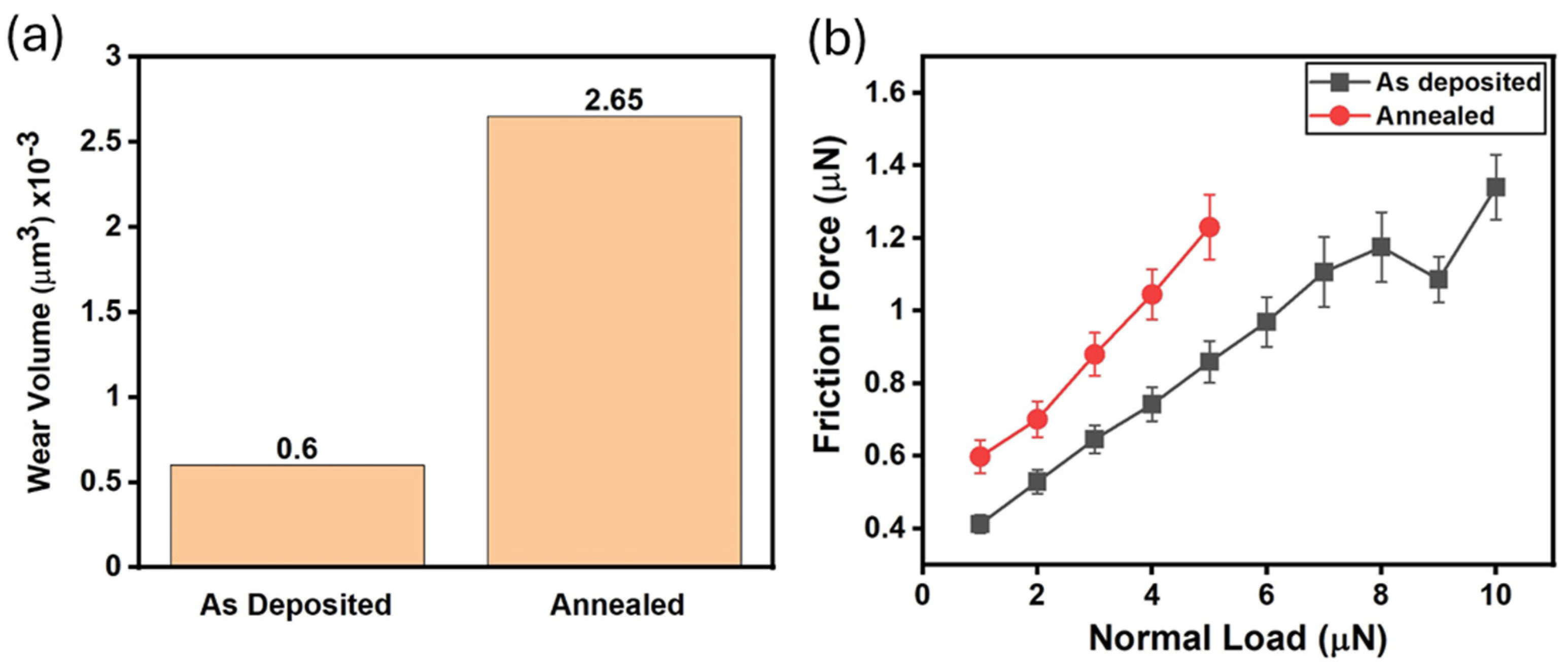

3.4. Nanotribological Properties of As-Deposited and Annealed Ta Films

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kuo, T.C.; Kuo, C.Y.; Chen, L.W. Assessing environmental impacts of nanoscale semi-conductor manufacturing from the life cycle assessment perspective. Resour. Conserv. Recycl. 2022, 182, 106289. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Lu, X.; Luo, J.; Dai, Y. Material removal mechanism of copper CMP from a chemical-mechanical synergy perspective. Tribol. Lett. 2013, 49, 11–19. [Google Scholar] [CrossRef]

- McLellan, R.A.; Dutta, A.; Zhou, C.; Jia, Y.; Weiland, C.; Gui, X.; Place, A.P.M.; Crowley, K.D.; Le, X.H.; Madhavan, T.; et al. Chemical Profiles of the Oxides on Tantalum in State of the Art Superconducting Circuits. Adv. Sci. 2023, 10, e2300921. [Google Scholar] [CrossRef]

- Ren, B.; Zhai, Z.; Guo, K.; Liu, Y.; Hou, W.; Zhu, Q.; Zhu, J. The application of porous tantalum cylinder to the repair of comminuted bone defects: A study of rabbit firearm injuries. Int. J. Clin. Exp. Med. 2015, 8, 5055–5064. [Google Scholar] [PubMed]

- Varitimidis, S.E.; Dimitroulias, A.P.; Karachalios, T.S.; Dailiana, Z.H.; Malizos, K.N. Outcome after tantalum rod implantation for treatment of femoral head osteonecrosis: 26 hips followed for an average of 3 years. Acta Orthop. 2009, 80, 20–25. [Google Scholar] [CrossRef] [PubMed]

- Hallab, N.J.; Bundy, K.J.; Connor, K.O.; Moses, R.L.; Jacobs, J.J. Evaluation of Metallic and Polymeric Biomaterial Surface Energy and Surface Roughness Characteristics for Directed Cell Adhesion. Tissue Eng. 2001, 7, 55–71. [Google Scholar]

- Khalili, A.A.; Ahmad, M.R. A Review of Cell Adhesion Studies for Biomedical and Biological Applications. Int. J. Mol. Sci. 2015, 16, 18149–18184. [Google Scholar] [CrossRef]

- Matassi, F.; Botti, A.; Sirleo, L.; Carulli, C.; Innocenti, M. Porous metal for orthopedics implants. Clin. Cases Miner. Bone Metab. 2013, 10, 111–115. [Google Scholar]

- Bogdanoff, D.W. Use of a Tantalum liner to reduce bore erosion and increase muzzle velocity in two-stage light gas guns. In Proceedings of the 66th Meeting of the Aeroballistic Range Association, San Antonio, TX, USA, 4–9 October 2015; pp. 1–21. Available online: https://ntrs.nasa.gov/citations/20160005034 (accessed on 20 September 2024).

- Matson, D.W.; McClanahan, E.D.; Lee, S.L.; Windover, D. Properties of thick sputtered Ta used for protective gun tube coatings. Surf. Coat. Technol. 2001, 146–147, 344–350. [Google Scholar] [CrossRef]

- Navid, A.A.; Hodge, A.M. Nanostructured alpha and beta tantalum formation-Relationship between plasma parameters and microstructure. Mater. Sci. Eng. A 2012, 536, 49–56. [Google Scholar] [CrossRef]

- Ni, L.; Pocratsky, R.M.; de Boer, M.P. Demonstration of tantalum as a structural material for MEMS thermal actuators. Microsyst. Nanoeng. 2021, 7, 6. [Google Scholar] [CrossRef] [PubMed]

- Knepper, R.; Baker, S.P. Coefficient of thermal expansion and biaxial elastic modulus of Β phase tantalum thin films. Appl. Phys. Lett. 2007, 90, 181908. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, B.; Chu, J.; Nieh, T.G. Hardness enhancement in nanocrystalline tantalum thin films. Scr. Mater. 2006, 54, 1227–1230. [Google Scholar] [CrossRef]

- Abadias, G.; Colin, J.J.; Tingaud, D.; Djemia, P.; Belliard, L.; Tromas, C. Elastic properties of α- and β-tantalum thin films. Thin Solid Film. 2019, 688, 137403. [Google Scholar] [CrossRef]

- Su, Y.; Huang, W.; Zhang, T.; Shi, C.; Hu, R.; Wang, Z.; Cai, L. Tribological properties and microstructure of monolayer and multilayer Ta coatings prepared by magnetron sputtering. Vacuum 2021, 189, 110250. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Y.F.; Rack, P.D.; Miller, M.K.; Nieh, T.G. Nanocrystalline tetragonal tantalum thin films. Scr. Mater. 2007, 57, 1032–1035. [Google Scholar] [CrossRef]

- Myers, S.; Lin, J.; Souza, R.M.; Sproul, W.D.; Moore, J.J. The β to α phase transition of tantalum coatings deposited by modulated pulsed power magnetron sputtering. Surf. Coat. Technol. 2013, 214, 38–45. [Google Scholar] [CrossRef]

- Melnikova, G.; Kuznetsova, T.; Lapitskaya, V.; Petrovskaya, A.; Chizhik, S.; Zykova, A.; Safonov, V.; Aizikovich, S.; Sadyrin, E.; Sun, W.; et al. Nanomechanical and nanotribological properties of nanostructured coatings of tantalum and its compounds on steel substrates. Nanomaterials 2021, 11, 2407. [Google Scholar] [CrossRef]

- Ellis, E.A.I.; Chmielus, M.; Baker, S.P. Effect of sputter pressure on Ta thin films: Beta phase formation, texture, and stresses. Acta Mater. 2018, 150, 317–326. [Google Scholar] [CrossRef]

- Ellis, E.A.I.; Chmielus, M.; Han, S.; Baker, S.P. Effect of sputter pressure on microstructure and properties of β-Ta thin films. Acta Mater. 2020, 183, 504–513. [Google Scholar] [CrossRef]

- Wang, Y.M.; Hodge, A.M.; Bythrow, P.M.; Barbee, T.W.; Hamza, A.V. Negative strain rate sensitivity in ultrahigh-strength nanocrystalline tantalum. Appl. Phys. Lett. 2006, 89, 081903. [Google Scholar] [CrossRef]

- Bing, Z.; Liu, Y.; Liu, Z.; Ma, Y.; Hei, H.; Shi, B.; Wu, Y.; Yu, S. Improved tribological properties of stainless steel by high temperature-alloyed tantalum gradient layer. Vacuum 2022, 196, 110783. [Google Scholar] [CrossRef]

- Albayrak, S.; Gul, C.; Ci, H.; Şahin, Ö. Tribological Characteristics of Tantalum-Oxide Coating Fabricated on Pre-Treated 2024 Aluminum Alloys. J. Tribol. 2023, 145, 101706. [Google Scholar] [CrossRef]

- Surikov, V.I.; Nikolaev, I.V.; Polonyankin, D.A.; Tselykh, E.P.; Rogachev, E.A.; Surikov, V.I. Morphology, composition and tribological properties of tantalum coatings deposited onto a rubber substrate. J. Phys. Conf. Ser. 2017, 858, 012034. [Google Scholar] [CrossRef]

- Pathote, D.; Jaiswal, D.; Singh, V.; Gautam, R.K.; Behera, C.K. Wear behavior and microhardness studies of tantalum (Ta)-coated 316L stainless steel by DC magnetron sputtering for the orthopedic applications. J. Mater. Sci. 2022, 57, 21039–21056. [Google Scholar] [CrossRef]

- Ding, Z.; Tang, Y.; Liu, L.; Ding, Z.; Tan, Y.; He, Q. Improving the adhesive, mechanical, tribological properties and corrosion resistance of reactive sputtered tantalum oxide coating on Ti6Al4V alloy via introducing multiple interlayers. Ceram. Int. 2022, 48, 5983–5994. [Google Scholar] [CrossRef]

- Alcalá, G.; Skeldon, P.; Thompson, G.E.; Mann, A.B.; Habazaki, H.; Shimizu, K. Mechanical properties of amorphous anodic alumina and tantala films using nanoindentation. Nanotechnology 2002, 13, 451–455. [Google Scholar] [CrossRef]

- Dub, S.; Starikov, V. Elasticity module and hardness of niobium and tantalum anode oxide films. Funct. Mater. 2007, 14, 7–10. [Google Scholar]

- Martin, P.J.; Bendavid, A.; Swain, M.; Netterfield, R.; Kinder, T.; Sainty, W.; Drage, D.; Wielunski, L. Properties of thin films of tantalum oxide deposited by ion-assisted deposition. Thin Solid Film. 1994, 239, 181–185. [Google Scholar] [CrossRef]

- Donkov, N.; Walkowicz, J.; Zavaleyev, V.; Zykova, A.; Safonov, V.; Dudin, S.; Yakovin, S. Mechanical properties of tantalum-based ceramic coatings for biomedical applications. J. Phys. Conf. Ser. 2018, 992, 012034. [Google Scholar] [CrossRef]

- Ezhilvalavan, S.; Tseng, T.Y. Preparation and properties of tantalum pentoxide (Ta2O5) thin films for ultra large scale integrated circuits (ULSIs) application—A review. J. Mater. Sci. Mater. Electron. 1999, 10, 9–31. [Google Scholar] [CrossRef]

- Shcherbina, O.B.; Palatnikov, M.N.; Efremov, V.V.; Yanichev, A.A.; Sidorov, N.V.; Pasechnyi, V.V. Effect of ultrarapid quenching on the structure and mechanical properties of Nb2O5 and Ta2O5. Inorg. Mater. 2016, 52, 1244–1249. [Google Scholar] [CrossRef]

- Chao, R.; Cai, H.; Li, H.; Xue, Y. Study on microstructure, optical and tribological properties of self-formed Ta oxide films. Vacuum 2023, 218, 112641. [Google Scholar] [CrossRef]

- Rahmati, B.; Zalnezhad, E.; Sarhan, A.A.D.; Kamiab, Z.; Tabrizi, B.N.; Abas, W.A.B.W. Enhancing the adhesion strength of tantalum oxide ceramic thin film coating on biomedical Ti-6Al-4V alloy by thermal surface treatment. Ceram. Int. 2015, 41, 13055–13063. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar]

- Green, C.P.; Lioe, H.; Cleveland, J.P.; Proksch, R.; Mulvaney, P.; Sader, J.E. Normal and torsional spring constants of atomic force microscope cantilevers. Rev. Sci. Instrum. 2004, 75, 1988–1996. [Google Scholar] [CrossRef]

- Sader, J.E.; Larson, I.; Mulvaney, P.; White, L.R. Method for the calibration of atomic force microscope cantilevers. Rev. Sci. Instrum. 1995, 66, 3789–3798. [Google Scholar] [CrossRef]

- Cheng, M.H.; Cheng, T.C.; Huang, W.J.; Chang, M.N.; Chung, M.K. Influence of oxygen diffusion on residual stress for tantalum thin films. J. Vac. Sci. Technol. B 2007, 25, 147–151. [Google Scholar] [CrossRef]

- Simpson, R.; White, R.G.; Watts, J.F.; Baker, M.A. XPS investigation of monatomic and cluster argon ion sputtering of tantalum pentoxide. Appl. Surf. Sci. 2017, 405, 79–87. [Google Scholar] [CrossRef]

- Lee, S.L.; Doxbeck, M.; Mueller, J.; Cipollo, M.; Cote, P. Texture, structure and phase transformation in sputter beta tantalum coating. Surf. Coat. Technol. 2004, 177–178, 44–51. [Google Scholar] [CrossRef]

- Javed, A.; Durrani, H.G.; Zhu, C. The effect of vacuum annealing on the microstructure, mechanical and electrical properties of tantalum films. Int. J. Refract. Met. Hard Mater. 2016, 54, 154–158. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, J. Microstrain and grain-size analysis from diffraction peak width and graphical derivation of high-pressure thermomechanics. J. Appl. Crystallogr. 2008, 41, 1095–1108. [Google Scholar] [CrossRef]

- Bannenberg, L.J.; Verhoeff, D.J.; Newton, N.J.; Thijs, M.; Schreuders, H. Structural and Optical Properties of Thin Film β-Ta upon Exposure to Hydrogen to Asses Its Applicability as Hydrogen Sensing Material. ACS Appl. Nano Mater. 2024, 7, 1757–1766. [Google Scholar] [CrossRef]

- Jin, Y.; Song, J.Y.; Jeong, S.-H.; Kim, J.W.; Lee, T.G.; Kim, J.H.; Hahn, J. Thermal oxidation mechanism and stress evolution in Ta thin films. J. Mater. Res. 2010, 25, 1080–1086. [Google Scholar] [CrossRef]

- Chandrasekharan, R.; Park, I.; Masel, R.I.; Shannon, M.A. Thermal oxidation of tantalum films at various oxidation states from 300 to 700 °C. J. Appl. Phys. 2005, 98, 114908. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Jakes, J.E.; Stone, D.S. Best practices for quasistatic berkovich nanoindentation of wood cell walls. Forests 2021, 12, 1696. [Google Scholar] [CrossRef]

- Gao, C.; Liu, M. Instrumented indentation of fused silica by Berkovich indenter. J. Non-Cryst. Solids 2017, 475, 151–160. [Google Scholar] [CrossRef]

- Guisbiers, G.; Herth, E.; Buchaillot, L.; Pardoen, T. Fracture toughness, hardness, and Young’s modulus of tantalum nanocrystalline films. Appl. Phys. Lett. 2010, 97, 143115. [Google Scholar] [CrossRef]

- Rahmati, B.; Sarhan, A.A.; Zalnezhad, E.; Kamiab, Z.; Dabbagh, A.; Choudhury, D.; Abas, W. Development of tantalum oxide (Ta-O) thin film coating on biomedical Ti-6Al-4V alloy to enhance mechanical properties and biocompatibility. Ceram. Int. 2016, 42, 466–480. [Google Scholar] [CrossRef]

- Cabral, C.; Clevenger, L.A.; Schad, R.G. Repeated compressive stress increase with 400 °C thermal cycling in tantalum thin films due to increases in the oxygen content. J. Vac. Sci. Technol. B 1994, 12, 2818–2821. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Gong, H. Annealing effects of tantalum films on Si and SiO2/Si substrates in various vacuums. J. Appl. Phys. 2001, 90, 416–420. [Google Scholar] [CrossRef]

| Elastic Modulus, E (GPa) | Hardness, H (GPa) | |

|---|---|---|

| Bulk fused silica | 72.8 ± 1.6 | 8.7 ± 0.2 |

| Bare Si substrate | 155.6 ± 4.2 | 10.0 ± 1.0 |

| As-deposited Ta film | 175.2 ± 12.3 | 12.0 ± 1.4 |

| Annealed Ta film | 213.1 ± 12.7 | 13.1 ± 1.3 |

| Root Mean Square, RMS (nm) | Mean Roughness (nm) | |

|---|---|---|

| As-deposited | 0.7 ± 0.1 | 0.6 ± 0.1 |

| Annealed | 0.5 ± 0.04 | 0.4 ± 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Datta, D.; Eskandari, A.; Syed, J.; Rai, H.; Gosvami, N.N.; Tsui, T.Y. The Influence of Thermal Annealing on the Chemical Composition, Nanomechanical, and Nanotribological Properties of Tantalum Thin Films. Micromachines 2025, 16, 427. https://doi.org/10.3390/mi16040427

Datta D, Eskandari A, Syed J, Rai H, Gosvami NN, Tsui TY. The Influence of Thermal Annealing on the Chemical Composition, Nanomechanical, and Nanotribological Properties of Tantalum Thin Films. Micromachines. 2025; 16(4):427. https://doi.org/10.3390/mi16040427

Chicago/Turabian StyleDatta, Debottam, Ali Eskandari, Junaid Syed, Himanshu Rai, Nitya Nand Gosvami, and Ting Y. Tsui. 2025. "The Influence of Thermal Annealing on the Chemical Composition, Nanomechanical, and Nanotribological Properties of Tantalum Thin Films" Micromachines 16, no. 4: 427. https://doi.org/10.3390/mi16040427

APA StyleDatta, D., Eskandari, A., Syed, J., Rai, H., Gosvami, N. N., & Tsui, T. Y. (2025). The Influence of Thermal Annealing on the Chemical Composition, Nanomechanical, and Nanotribological Properties of Tantalum Thin Films. Micromachines, 16(4), 427. https://doi.org/10.3390/mi16040427