Study on Self-Sharpening Mechanism and Polishing Performance of Triethylamine Alcohol on Gel Polishing Discs

Abstract

1. Introduction

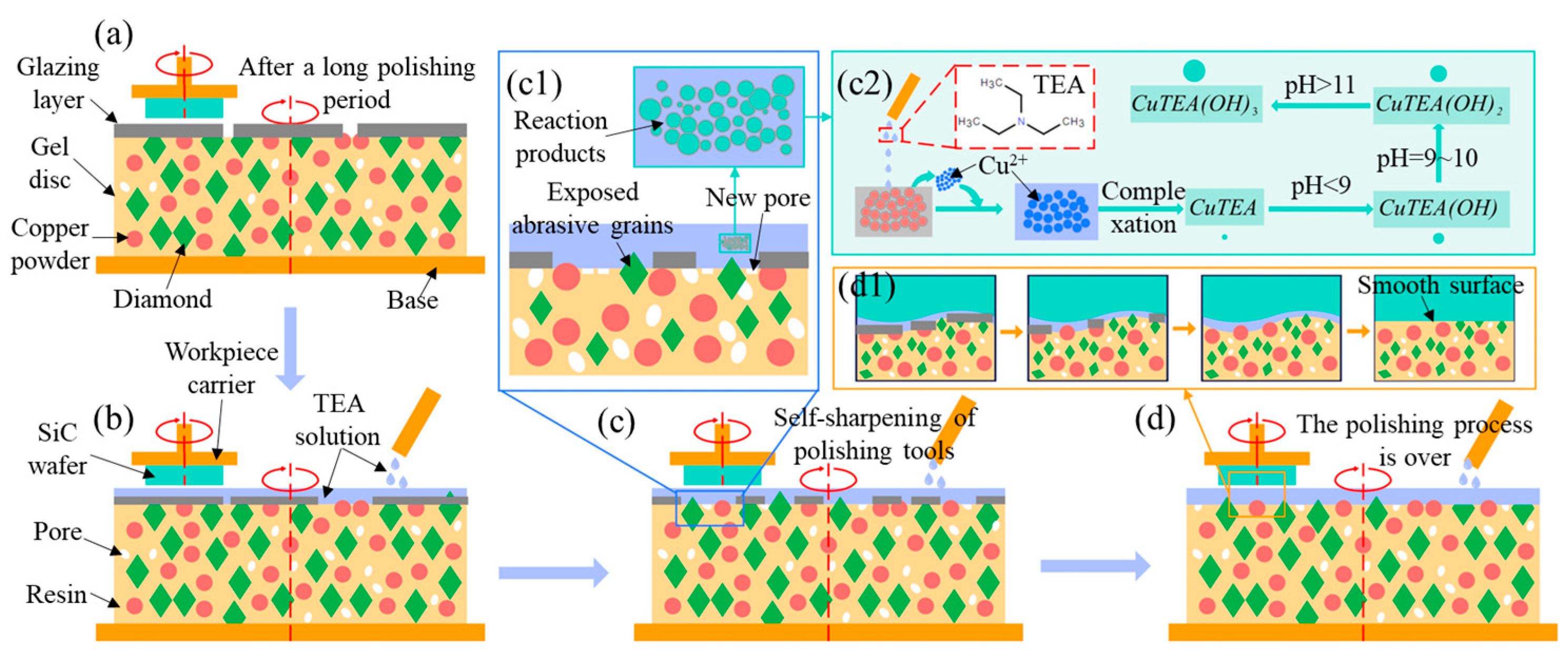

2. Self-Sharpening Mechanism

3. Experimental Set-Up

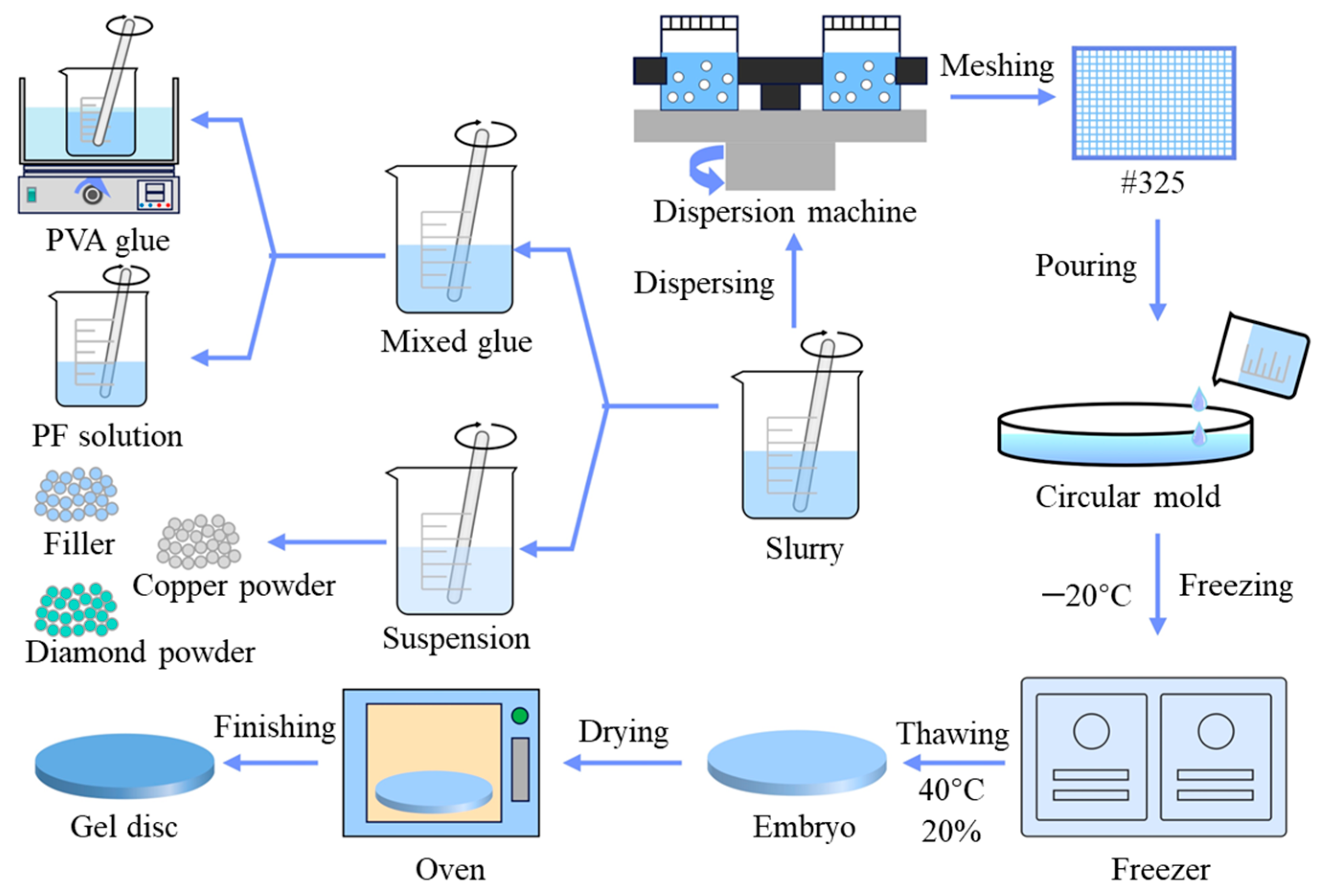

3.1. Manufacturing Process of Polishing Disc

3.2. Material Characterization

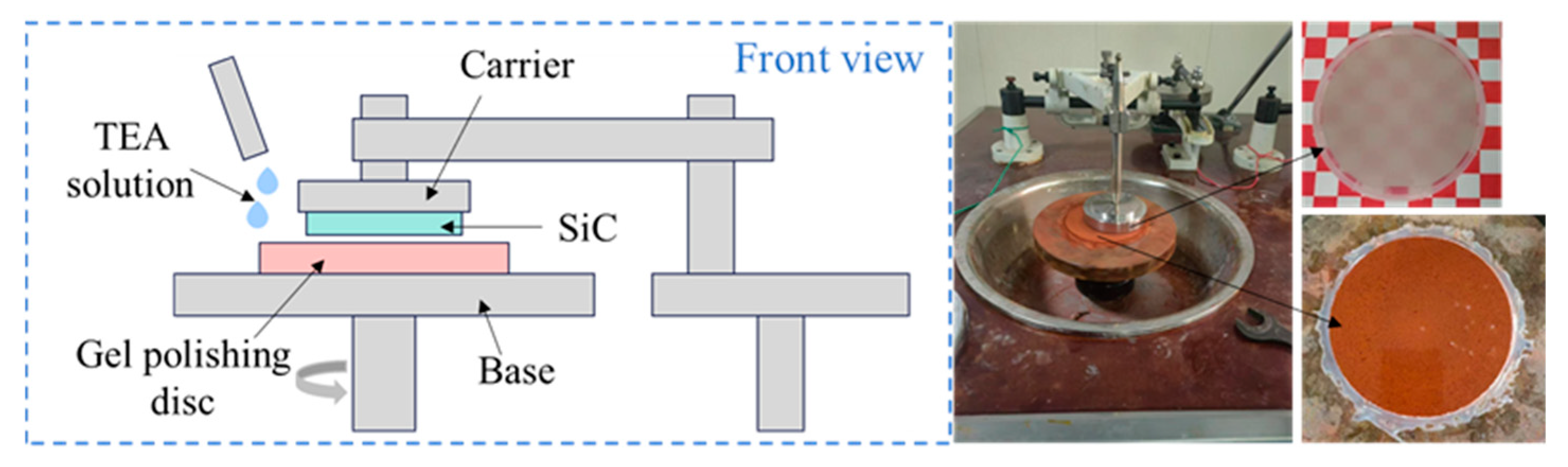

3.3. Polishing Experiment

4. Results and Discussion

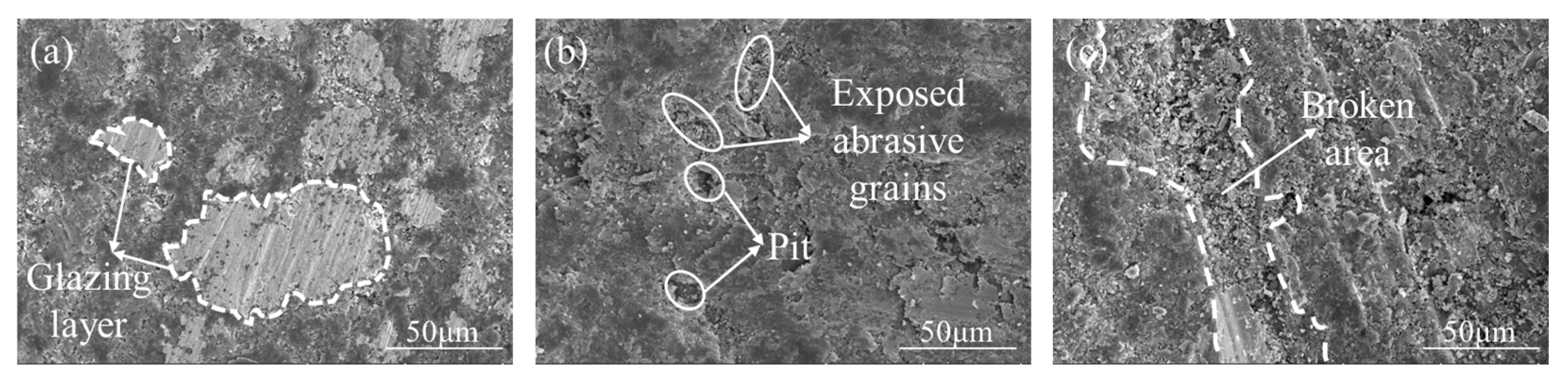

4.1. Effect of TEA Content on Glazing Phenomenon

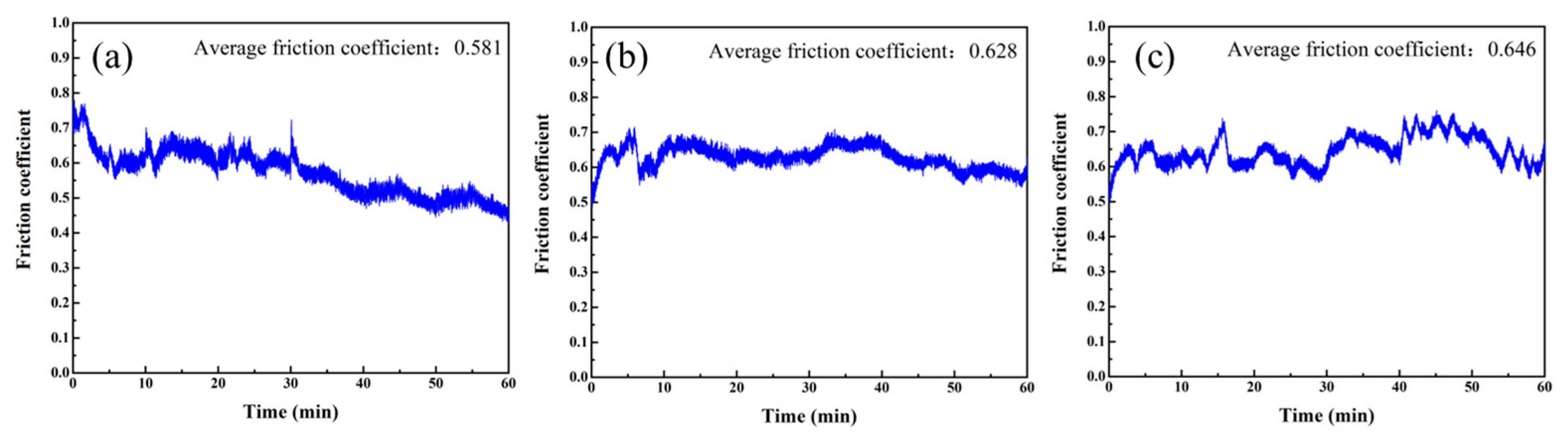

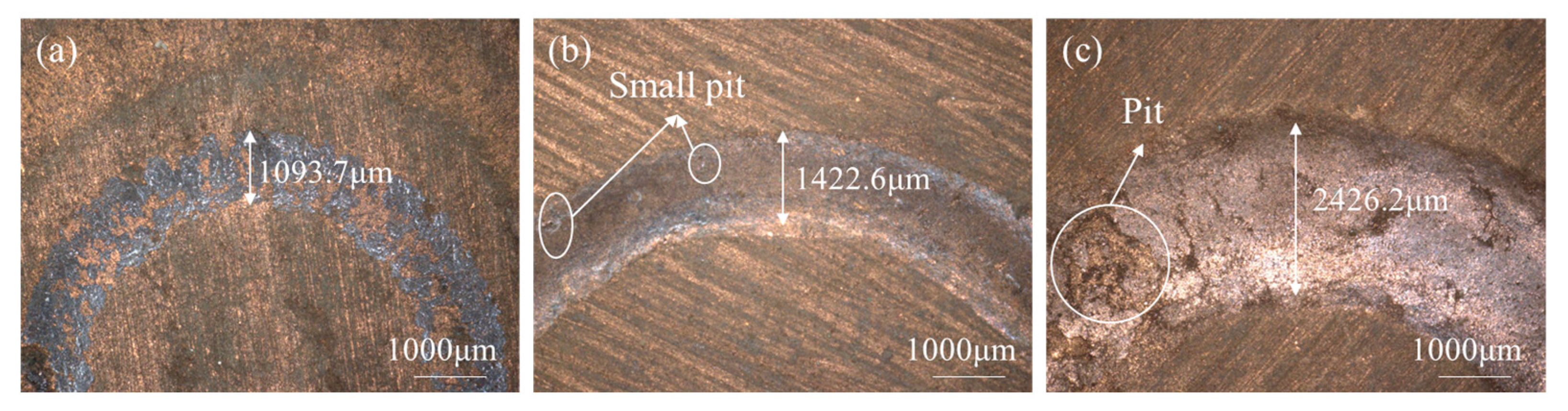

4.2. Friction and Wear Test

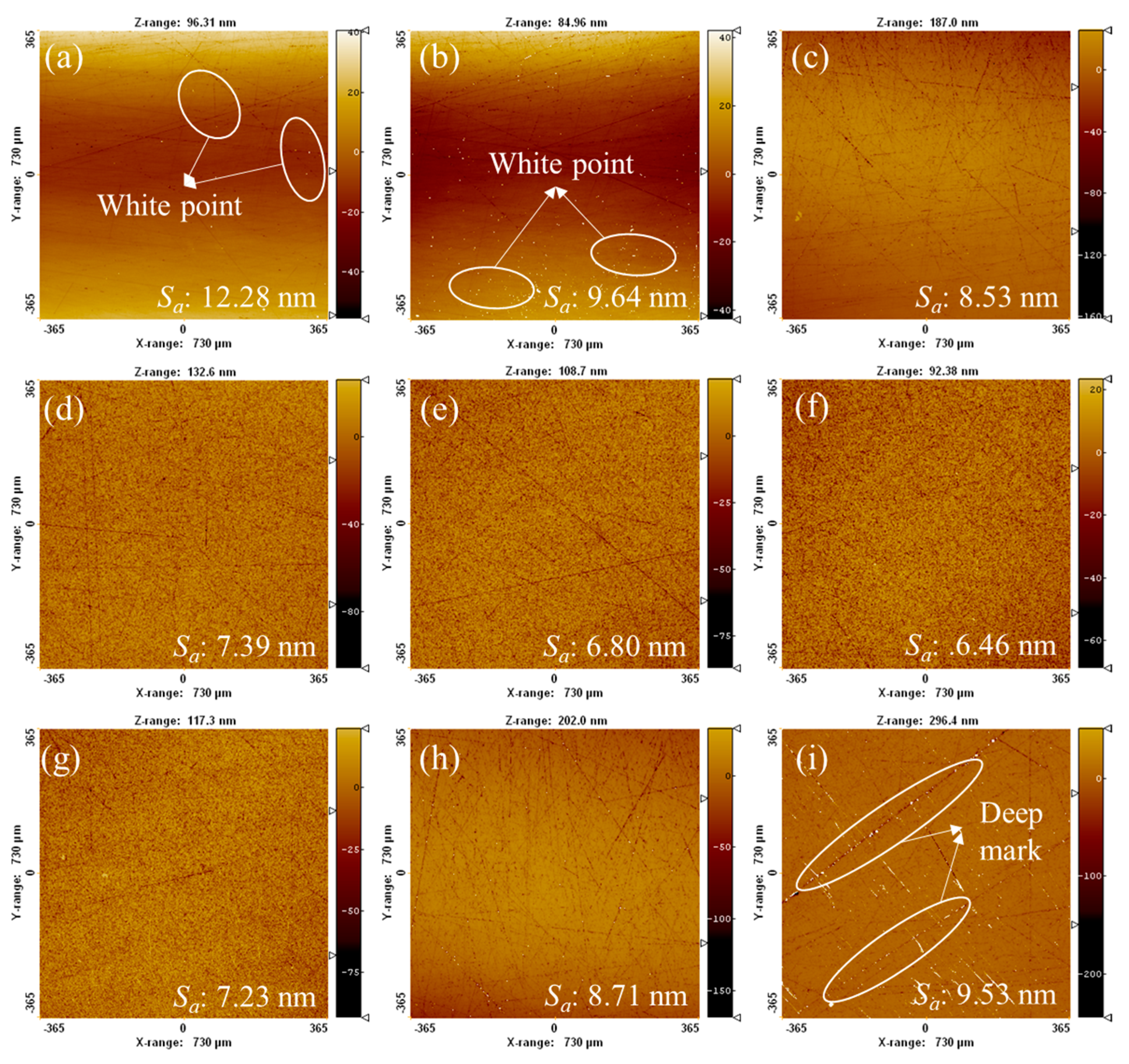

4.3. Orthogonal Experiment

| Experimental Groups | TEA

Content (wt%) | Pressure (N) | Speed (rpm) | Average Sa (nm) | MRR μm/h | SNR/dB | |

|---|---|---|---|---|---|---|---|

| Sa | MRR | ||||||

| 1 | 1 | 0 | 30 | 12.28 | 0.65 | −21.79 | 6.70 |

| 2 | 1 | 49 | 60 | 9.64 | 0.84 | −19.68 | 5.81 |

| 3 | 1 | 98 | 90 | 8.54 | 0.87 | −18.63 | 8.03 |

| 4 | 4 | 0 | 60 | 7.39 | 0.91 | −17.37 | 8.33 |

| 5 | 4 | 49 | 90 | 6.8 | 0.96 | −16.65 | 8.72 |

| 6 | 4 | 98 | 30 | 6.46 | 1.01 | −16.21 | 9.19 |

| 7 | 7 | 0 | 90 | 7.23 | 0.86 | −17.20 | 9.63 |

| 8 | 7 | 49 | 30 | 8.71 | 0.81 | −18.81 | 8.26 |

| 9 | 7 | 98 | 60 | 9.53 | 0.77 | −19.60 | 7.74 |

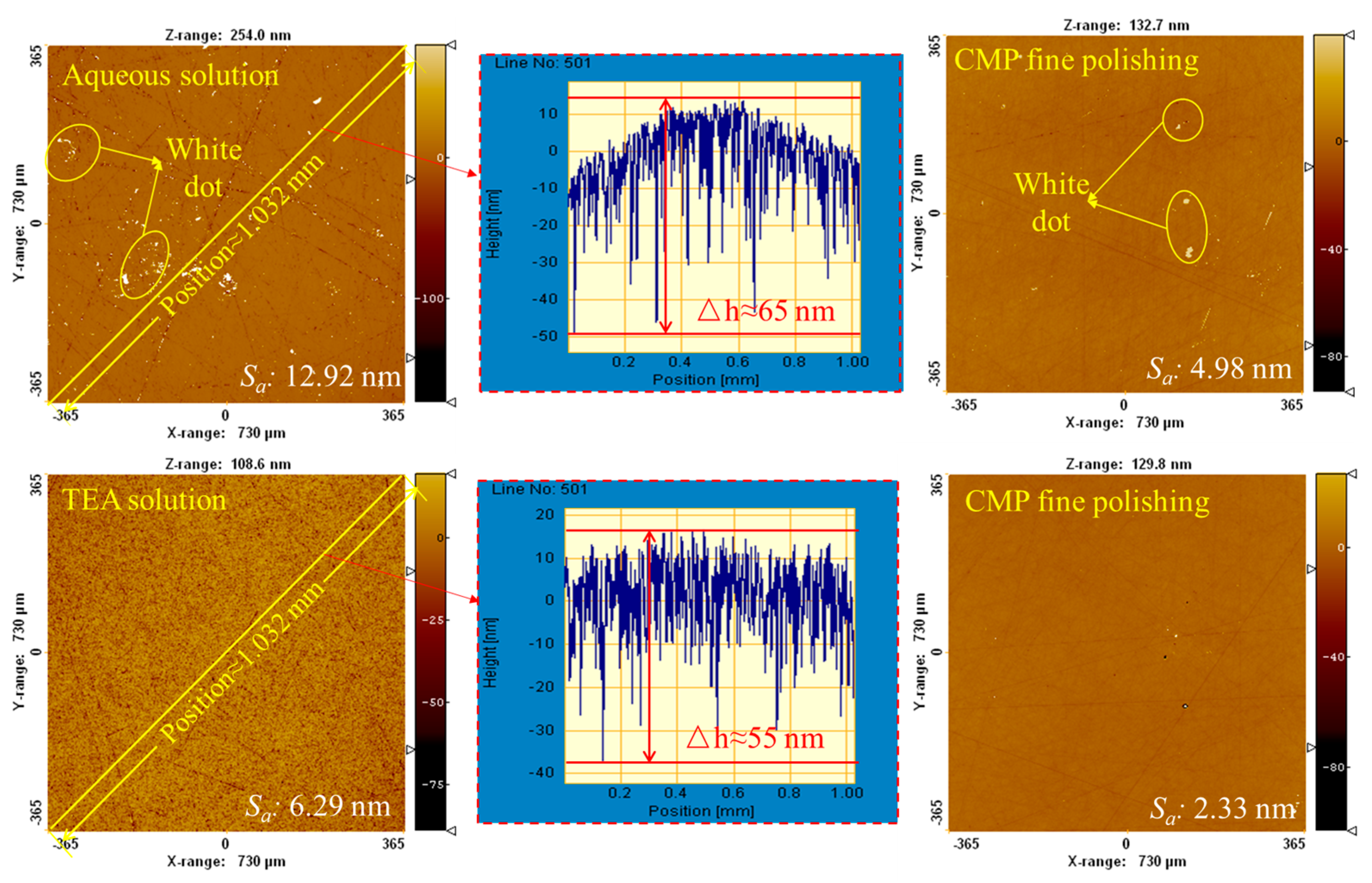

4.4. Comparative Polishing Experiment

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xin, L.J.; Zhao, G.L.; Nian, Z.W.; Yang, H.T.; Li, L.; He, N. Physics-based modeling and mechanism of polycrystalline diamond tool wear in milling of 70 vol% Si/Al composite. Int. J. Extrem. Manuf. 2025, 7, 5. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, F.; Jiang, Z.Y.; Tian, Z.; Qiu, T.; Zhang, T.; Wen, Q.L.; Lu, X.Z.; Lu, J.; Huang, H. Energy beam-based direct and assisted polishing techniques for diamond:A review. Int. J. Extrem. Manuf. 2024, 6, 012004. [Google Scholar] [CrossRef]

- Dong, Z.C.; Cheng, H.B. Study on removal mechanism and removal characters for SiC and fused silica by fixed abrasive diamond pellets. Int. J. Mach. Tools Manuf. 2014, 85, 1–13. [Google Scholar] [CrossRef]

- Chen, J.P.; Zhu, N.N.; Niu, F.L.; Peng, Y.A.; Su, J.X.; Zhu, Y.W. Influence of agglomerated diamond abrasive wear on sapphire material removal behavior. Diam. Relat. Mater. 2020, 108, 107965. [Google Scholar] [CrossRef]

- Feng, K.P.; Lyu, B.H.; Zhao, T.C.; Yin, T.; Zhou, Z.Z. Fabrication and Application of Gel-Forming CeO2 Fixed Abrasive Tools for Quartz Glass Polishing. Int. J. Precis. Eng. Manuf. 2022, 23, 985–1002. [Google Scholar] [CrossRef]

- Luo, Q.; Wen, H.; Lu, J. Sol–gel polishing technology for extremely hard semiconductor substrates. Int. J. Adv. Manuf. Technol. 2022, 120, 1415–1432. [Google Scholar] [CrossRef]

- Luo, Q.F.; Lu, J.; Li, Z.; Wang, J. Fabrication of a sol–gel polishing tool for green manufacturing of the seal stone. J. Sol-Gel Sci. Technol. 2020, 96, 576–588. [Google Scholar] [CrossRef]

- Kong, S.; Liu, Y.B. Effect of surfactants on vitrified bond diamond composites prepared by sol-gel and dispersibility of diamond. Diam. Relat. Mater. 2022, 126, 109128. [Google Scholar] [CrossRef]

- Lin, Y.C.; Lu, J.; Tong, R.L.; Luo, Q.F.; Xu, X.P. Surface damage of single-crystal diamond (100) processed based on a sol-gel polishing tool. Diam. Relat. Mater. 2018, 83, 46–53. [Google Scholar] [CrossRef]

- Xue, Z.; Lu, J.; Yang, L.; Huang, H. Preparation and application of sol-gel polishing tool with carbon fibres as skeleton. Int. J. Surf. Sci. Eng. 2024, 18, 287–303. [Google Scholar] [CrossRef]

- Chen, S.H.; Lu, J.; Wang, J.; Huang, S.G.; Cui, C.C. Research on the Drag Polishing of Irregular Seals Based on the Self-Developed Sol-Gel Ball Tools. J. Mater. Eng. Perform. 2023, 32, 4229–4236. [Google Scholar] [CrossRef]

- Zhao, L.; Feng, K.P.; Lyu, B.H.; Zhao, T.C.; Zhou, Z.Z. Study on Development of Composite PAM/PI Gel Abrasive Tools and Finishing Performance on the Sapphire Substrates. ECS J. Solid State Sci. Technol. 2023, 12, 064002. [Google Scholar] [CrossRef]

- Feng, K.P.; Zhao, T.C.; Lyu, B.H.; Zhou, Z.Z. Ultra-precision grinding of 4H-SiC wafer by PAV/PF composite sol-gel diamond wheel. Adv. Mech. Eng. 2021, 13, 168781402110449. [Google Scholar] [CrossRef]

- Feng, K.P.; Zhao, L.; Lyu, B.; Xu, L.X.; Gu, Y.Z. Study on the Fabrication and Grinding Performance of the Self-sharpening Cr2O3 Gel Abrasive Tool. Int. J. Precis. Eng. Manuf. 2024, 25, 713–729. [Google Scholar] [CrossRef]

- Li, J.W.; Fang, W.J.; Wan, L.; Liu, X.P.; Hu, W.D.; Cao, D.; Han, K.; Li, Y.Y.; Yan, Y.G. Research on the bonding properties of vitrified bonds with porous diamonds and the grinding performance of porous diamond abrasive tools. Diam. Relat. Mater. 2022, 123, 108841. [Google Scholar] [CrossRef]

- Chen, J.P.; Peng, Y.A.; Wang, Z.K.; Sun, T.; Su, J.X.; Zuo, D.W.; Zhu, Y.W. Tribological effects of loose alumina abrasive assisted sapphire lapping by a fixed agglomerated diamond abrasive pad (FADAP). Mater. Sci. Semicond. Process. 2022, 143, 106556. [Google Scholar] [CrossRef]

- Chen, J.P.; Sun, T.; Su, J.X.; Li, J.; Zhou, P.A.; Peng, Y.A.; Zhu, Y.W. A novel agglomerated diamond abrasive with excellent micro-cutting and self-sharpening capabilities in fixed abrasive lapping processes. Wear 2021, 464, 203531. [Google Scholar] [CrossRef]

- Nayak, B.; Babu, N.R. A mixed fluid film lubrication model to predict the tool-life of IBAP tool considering abrasive and molten water interaction with workpiece. J. Manuf. Process. 2024, 124, 365–376. [Google Scholar] [CrossRef]

- Zhu, Y.J.; Ding, W.F.; Rao, Z.W.; Zhao, Z.C. Self-sharpening ability of monolayer brazed polycrystalline CBN grinding wheel during high-speed grinding. Ceram. Int. 2019, 45, 24078–24089. [Google Scholar] [CrossRef]

- Chen, Z.J.; Yan, Q.S.; Pan, J.S.; Liao, Y.L. Magnetization and self-sharpening mechanism of polymerized diamond abrasive based on magnetorheological polishing technology. Diam. Relat. Mater. 2024, 141, 110709. [Google Scholar] [CrossRef]

- Ramirez, C.; Bozzini, B.; Calderon, J.A. Electrodeposition of copper from triethanolamine as a complexing agent in alkaline solution. Electrochim. Acta 2022, 425, 140654. [Google Scholar] [CrossRef]

- Li, N.N.; Zhou, Y.; Zhang, L.; Tian, R.S.; Wang, W.; Zhang, N. BCO Spectrophotometric Determination of Copper in Film Pretreatment Bath of Automobile Factory. Shanxi Chem. Ind. 2025, 45, 114–116. [Google Scholar] [CrossRef]

- Chen, H.Y.; Wu, Z.C.; Hong, B.B.; Hang, W.; Zhang, P.; Cao, X.Z.; Xu, Q.; Chen, P.Q.; Chen, H.; Yuan, J.L.; et al. Study on the affecting factors of material removal mechanism and damage behavior of shear rheological polishing of single crystal silicon carbide. J. Manuf. Process. 2024, 113, 388. [Google Scholar] [CrossRef]

| Component | Granularity/μm | Solid Content/wt% |

|---|---|---|

| PVA + PF | 15 | |

| Diamond powder | 2.5 | 20 |

| Electrolytic copper | 3 | 55 |

| Alumina powder | 0.5 | 5 |

| Wetting agent | ≤1 | |

| Toughening agent | ≤1 | |

| Others | 3 |

| Processing Conditions | Parameters |

|---|---|

| Size of workpiece | 20 × 20 mm |

| Size of polishing disc | Ø 100 mm |

| Rotational speed | 30, 60, 90 rpm |

| Polish fluid | TEA solution |

| TEA concentration | 1 wt%, 4 wt%, 7 wt% |

| Pressure | 0, 49, 98 N |

| Flow rate | 24 mL/min |

| Trial time | 60 min |

| Processing Conditions | Parameters |

|---|---|

| Size of workpiece | Ø 100 mm |

| Size of polishing disc | Ø 280 mm |

| Polish fluid | Water/TEA solution |

| Rotation speed | 90 rpm |

| Pressure | 98 N |

| TEA concentration | 4 wt% |

| Flow rate | 24 mL/min |

| Trial time | 60 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Y.; Xu, L.; Feng, K. Study on Self-Sharpening Mechanism and Polishing Performance of Triethylamine Alcohol on Gel Polishing Discs. Micromachines 2025, 16, 816. https://doi.org/10.3390/mi16070816

Lei Y, Xu L, Feng K. Study on Self-Sharpening Mechanism and Polishing Performance of Triethylamine Alcohol on Gel Polishing Discs. Micromachines. 2025; 16(7):816. https://doi.org/10.3390/mi16070816

Chicago/Turabian StyleLei, Yang, Lanxing Xu, and Kaiping Feng. 2025. "Study on Self-Sharpening Mechanism and Polishing Performance of Triethylamine Alcohol on Gel Polishing Discs" Micromachines 16, no. 7: 816. https://doi.org/10.3390/mi16070816

APA StyleLei, Y., Xu, L., & Feng, K. (2025). Study on Self-Sharpening Mechanism and Polishing Performance of Triethylamine Alcohol on Gel Polishing Discs. Micromachines, 16(7), 816. https://doi.org/10.3390/mi16070816