Micromachined Thermal Flow Sensors—A Review

Abstract

:1. Introduction

2. Theory

2.1. Thermal Flow Sensing Configurations

2.1.1. Hot-Wire and Hot-Film

- ∆V = flow induced voltage difference;

- v = velocity;

- a,b,n = constants.

| Material | Resistivity, ρ (Ω∙m) at 20 °C | TCR, α (10−4/K) |

|---|---|---|

| Aluminum | 2.69 × 10−8 | 42.0 |

| Copper | 1.67 × 10−8 | 43.0 |

| Gold | 2.30 × 10−8 | 39.0 |

| Iron | 9.71 × 10−8 | 65.1 |

| Nickel | 6.84 × 10−8 | 68.1 |

| Palladium | 10.8 × 10−8 | 37.7 |

| Platinum | 10.6 × 10−8 | 39.2 |

| Silver | 1.63 × 10−8 | 41.0 |

| Tungsten | 5.50 × 10−8 | 46.0 |

| Polysilicon | 4 × 10−6 [13]-1 × 101 [14,15,16] | −250–10 [14,15] |

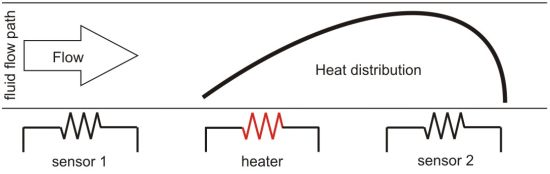

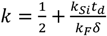

2.1.2. Calorimetric

- Th = heater temperature for constant heat power;

- P = heat power;

- kF = thermal conductivity of fluid;

- wh = heater width;

- lh = heater length;

- δ = boundary layer thickness;

- v = average flow velocity;

- a = thermal diffusivity of fluid;

dimensionless factor;

- kSi = thermal conductivity of silicon substrate;

- td = diaphragm thickness.

- The temperature difference between temperature sensors is given by:

- ∆T = temperature difference;

;

- lu = distance to upstream sensor;

- ld = distance to downstream sensor.

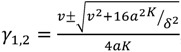

2.1.3. Time-of-Flight

- T = temperature distribution at time t;

- x = distance from heater;

- t = time;

- q0 = pulse signal input strength;

- k = thermal conductivity of fluid;

- v = average flow velocity;

- a = thermal diffusivity.

2.2. Thermal Flow Sensing Transduction Principles

2.2.1. Thermoresistive/Thermoanemometers

2.2.2. Thermoelectric

| Material | Seebeck coefficient (µV/K) at 0 °C | Thermal conductance (W/K∙m) |

|---|---|---|

| Aluminum | −1.7 1 | 237 |

| Chromium | 18.8 | |

| Gold | 1.79 | 318 |

| Copper | 1.70 | |

| Platinum | −4.45 | |

| Nickel | −18.0 | 90 |

| Bismuth | −79 1 | |

| Antimony | 43 2 | |

| p-type silicon | 300–1,000 1 | 149 |

| n-type silicon | −500–−200 1 |

- aa = Seebeck coefficient of material a;

- ab = Seebeck coefficient of material b;

- aab = Seebeck coefficient of thermocouple;

- Thot = Hot junction temperature;

- Tcold = Cold junction temperature;

- ∆Thot-cold = Temperature difference between hot and cold junction.

2.2.3. Thermoelectronic

- I = Current;

- Ir = Reverse saturation current;

- V = Voltage;

- n = Ideality factor; 2 for Si and 1 for Ge;

- VT = Volt equivalent of temperature.

- m = 1.5 for Si and 2 for Ge;

- Vg = Forbidden-gap energy.

2.2.4. Frequency Analog

- α = temperature coefficient of frequency (TCF) of a SAW device

- Ts = change in temperature due to an incremental change in flow rate.

3. Recent Applications of Micro-Thermal Flow Sensors

3.1. Thermoresistive

| Material | Configuration | Gas/liquid | Resolution | Sensitivity | Range | Power Consumption | References |

|---|---|---|---|---|---|---|---|

| Ni | Calorimetric | N2 gas | 40 mV/SLM | 0–20sccm up to 8 SLM | N. Sabaté [40] | ||

| Si3N4 | |||||||

| Ni | Hot-film | Air | <1% | 0–20 m/s | 50 mW | Adamec [41] | |

| Si3N4 | Calorimetric | ||||||

| Pt | Hot-wire | N2 gas | 0–3 m/s | Ito [28] | |||

| CNT for enhanced heat transfer | |||||||

| Ti/Pt | Hot-film | DI H2O | 250 nL/min | 0–1 µL/min | Kuo [26] | ||

| Parylene | |||||||

| W/Ti/Pt | Hot-film | DI H2O | 0.5 µL/min | 25.1–3.92 × 104 μV/(μL/min) | 0–400 µL/min | 3.3–23.5 mW | Meng [47] |

| Parylene | Calorimetric | ||||||

| Time-of-flight | |||||||

| Si | Calorimetric | Water | 0–10 mL/min | 600 mW | Nguyen [43] | ||

| Si3N4 | N2 gas | ||||||

| Pt | Time-of-flight | Hexadecane | 10–10,000 µL/min | 3.3 W | Berthet [49] | ||

| Pyrex | IPA | ||||||

| Polysilicon | Hot-film | Air | 0–30 m/s | Liu [54] | |||

| Si3N4 | |||||||

| Pt | Calorimetric | Air | Heater power dependent | Heater power dependent | 0–4 m/s | 2–20 mW | Fürjes [50] |

| Si3N4 | |||||||

| Pt | Hot-film | CO2 gas | 0.3 m/s | 0–20 m/s | 14 mW | Domnguez [59] | |

| Pyrex | |||||||

| Au | Hot-film | N2 gas | 10 mL/min | 0–200 mL/min | Ahrens [64] | ||

| Polyimide | Water | 10 µL/min | 3–167 µL/min | ||||

| Au | Hot-film | Oil | 0–90 L/min | Ahrens [65] | |||

| Polyimide | |||||||

| Pt | Calorimetric | Air | 0–32 m/s | Ma [57] | |||

| Au | |||||||

| Si3N4 | |||||||

| Ti/Pt | Calorimetric | Air | 0.3 m/s | 0–8 m/s | 100 mW | Shen [58] | |

| Ceramic | |||||||

| Ti/Au | Hot-film | Glucose/PBS (0–60%) | 3.06 mV/(mL/min) | 0–10 mL/min | <5 mW | Li [66] | |

| Kapton | |||||||

| Ti/Au | Hot-film | Glucose/DI H2O | 5 mL/100 gram-min | 1.467 mV/mL/100 gram-min | 0–160 mL/100 gram-min | Li [67] | |

| Cu | |||||||

| Parylene | |||||||

| Ti/Pt | Hot-film | Air | CV 2V: 0.01433 mA (m/s)−1/2 | 0–11 m/s | CV 2V: 14.56 mW | Hung [51] | |

| Si3N4 | CV 4V: 0.04593 mA (m/s)−1/2 | CV 4V: | |||||

| CC 12.96mA: 7.98 mV (m/s)−1/2 | 50.83 mW | ||||||

| CC 23.08mA: 27.35 mV (m/s)−1/2 | CC 12.96mA: | ||||||

| 45.10 mW | |||||||

| CC 23.08 mA: | |||||||

| 157.61 mW | |||||||

| Cr/Pt/Ni/Pt | Hot-wire | Air | Heater power dependent | Heater power dependent | Heater power dependent | Heater power dependent | Chen [60] |

| Polyimide | |||||||

| Cr/Au | Hot-film | N2 gas | 0–6 m/s | Tan [61,62] | |||

| Polyimide | |||||||

| Cr/Ni/Pt | Hot-film | Air | 0.1 m/s | 0–15 m/s | 30 mW | Liu [63] | |

| Polyimide | |||||||

| Pt | Hot-wire | Air | 7–40 m/s | Bailey [46] | |||

| Cr/Ni | Hot-wire | N2 gas | 0.002 m/s | 0–1.6 m/s | Kaanta [42] | ||

| Si3N4 | |||||||

| Polysilicon | Hot-wire | 0.2–0.5 mL/min | Soundararajan [44] | ||||

| Si3N4 | |||||||

| Polysilicon | Hot-wire | Cell medium | Hsiai [53] | ||||

| Silicon dioxide and Si3N4 | |||||||

| Ti/Pt | Hot-film | Rabbit blood | Non-linear | 0.35 mV/(dynes/cm2) | Yu [70,71] | ||

| Parylene | |||||||

| Polysilicon | Hot-film | DI H2O | 10 nL/min | 3.6–361.2 μV/(nL/min) | 0–650 nL/min | 140 µW | Wu [45] |

| Si3N4 | |||||||

| Germanium | Calorimetric | DI H2O | 100 nL/h | 0–90 µL/h | 1 mW | Ernst [76] | |

| Chromium heater | |||||||

| Germanium | Calorimetric | Air | <1 cm/s | 12.99–232.77 V/W/(m/s) | 0–5 m/s | 0.25–5.8 mW | Cubukcu [77] |

| Si3N4 | |||||||

| SiOx | |||||||

| Ti/Pt | Hot-wire | N2 gas | 3.76 mΩ/(m/s) | 0–10 SLPM | Kaltsas [55] | ||

| SU-8 | Calorimetric | ||||||

| Ti/Pt | Calorimetric | DI H2O | 40 nL/min | 485 µV/( µL/min) | 0–6 µL/min | 0–20 mW | Vilares [56] |

| SU-8 | IPA | ||||||

| Pt | Calorimetric | Water | 0.2 µL/min | 218 µV/( µL/min) | 0–2 µL/min | 1.9 mW | Dijkstra [52] |

| Silicon-rich silicon nitride |

3.2. Thermoelectric

| Material | Configuration | Gas/liquid | Resolution | Sensitivity | Range | Power Consumption | References |

|---|---|---|---|---|---|---|---|

| Polysilicon/Al Porous Si | Calorimetric | N2 gas | 4.1 × 10−3 m/s | 0.4 mV/(m/s) | 0–0.4 m/s | 67 mW | Kaltsas [29] |

| Polysilicon/Al Porous Si | Calorimetric | N2 gas | ~0.5 m/s | 175 × 10−3 mV/(m/s)1/2 | 0–4 m/s | Kaltsas [78] | |

| Polysilicon/Al Porous Si | Hot-wireCalorimetric | Not stated | 0.95 mV/(m/s)1/2 | 0–6.67 m/s | 100 mW for hot-wire | Kaltsas [79] | |

| Polysilicon/Ti-Tungsten | Calorimetric | WaterIPA | 0.2 µL/s | 9.5 mV mm−1 s | 0–2 mm/s | Buchner [81] | |

| Polysilicon/ Ti-Tungsten | Calorimetric | Air | −0.12 mV/slm | 10–100 slm | Buchner [30] | ||

| Polyimide | |||||||

| Polysilicon/Al | Calorimetric | N2 gas | 0–8 m/sec | 15 mW | Laconte [82] | ||

| Polysilicon/Al | Pseudo-calorimetric | N2 gas | 0–200 sccm | Bruschi [84] | |||

| Polysilicon heaters | |||||||

| Silicon dioxide membrane | |||||||

| n-polysilicon/p-polysilicon thermopile | Calorimetric | Air | 0.002 sccm | 0.9–8.4 m/s | 4 mW | Bruschi [85] | |

| Polysilicon heater | |||||||

| Al/polysilicon | Calorimetric | Water | 0–500 nL/min | 0.1–0.6 mW | Wiegerink [83] | ||

| Al heater | |||||||

| Silicon-rich silicon nitride |

3.3. Thermoelectronic

| Material | Configuration | Gas/liquid | Resolution | Sensitivity | Range | Power Consumption | References |

|---|---|---|---|---|---|---|---|

| Polysilicon heater | Hot-wire | Air | 0.5 m/s | 0–30 m/s | Sun [35] | ||

| Polysilicon/Al Bipolar transistor | |||||||

| Ceramic | |||||||

| Al/Si PNP transistor | Calorimetric | Air | ±4% | 2–18 m/s | 0.4–1 W | Makinwa [89] | |

| Ceramic | Hot-wire | ||||||

| Bipolar transistor | Hot-wire | Air | 0–15 m/s | 50 mW | Makinwa [93] |

3.4. Frequency Analog

| Material | Configuration | Gas/liquid | Resolution | Sensitivity | Range | Power Consumption | References |

|---|---|---|---|---|---|---|---|

| Tungsten, Aluminum oxide | Hot-wire | Air | 3% | Kiełbasa [38] | |||

| LiNbO3, Au, Cr | Time-of-flight | Liquid, refractive index from 1.33–1.35 | 0.1 °C/10−5 change in refractive index unit | Renaudin [95] | |||

| Si, SiO2, Si3N4, Al | Time-of-flight | Air | Increases with temperature, geometry dependent | 0–20 m/s, geometry dependent | Iker [39] |

3.5. Optical/SPR/Other

4. Conclusions

Acknowledgment

References

- Bolin, Y.; Zhiyin, G.; Shu, C.; Jingping, X.; Sheng, L. A micro channel integrated gas flow sensor for high sensitivity. In Proceedings of the 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITHERM 2008), Orlando, FL, USA, 28-31 May, 2008.

- Cabuz, E.; Schwichtenberg, J.; DeMers, B.; Satren, E.; Padmanabhan, A.; Cabuz, C. MEMS-based flow controller for flow cytometry. In Proceedings of the Hilton Head 2002: Solid-State Sensor, Actuator and Microsystems Workshop, Hilton Head, SC, USA, 4-7 June, 2002.

- Sensirion Sensor Solutions; Sensirion—The Sensor Company: Staefa, Switzerland, 2012.

- Makinwa, K.A.A.; Huijsing, J.H. IEEE, A wind sensor with an integrated low-offset instrumentation amplifier. In Proceedings of the 8th IEEE International Conference on Electronics, Circuits and Systems, ICECS 2001, Malta, 2-5 September, 2001.

- Kaanta, B.C.; Chen, H.; Lambertus, G.; Steinecker, W.H.; Zhdaneev, O.; Zhang, X. High sensitivity micro-thermal conductivity detector for gas chromatography. In Proceedings of theIEEE 22nd International Conference on Micro Electro Mechanical Systems, Sorrento, Italy, 25-29 January, 2009.

- Lennart, L.; Mohamed, G.-E.-H. MEMS-based pressure and shear stress sensors for turbulent flows. Meas. Sci. Technol. 1999, 10, 665–686. [Google Scholar] [CrossRef]

- Po-Yau, J.; Chien-Hsiung, T.; Lung-Ming, F.; Che-Hsin, L. Microfluidic flow meter and viscometer utilizing flow-induced vibration on an optic fiber cantilever. In Proceedings of the 16th International Solid-State Sensors, Actuators and Microsystems Conference (TRANSDUCERS), Beijing, China, 5-9 June, 2011.

- Vanputte, A.F.; Middelho, S. Integrated silicon anemometer. Electron. Lett. 1974, 10, 425–426. [Google Scholar] [CrossRef]

- Nguyen, N.T. Micromachined flow sensors—A review. Flow Meas. Instrum. 1997, 8, 7–16. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Chen, C.-P.; Chang, C.-M.; Lin, C.-P.; Lin, C.-H.; Fu, L.-M.; Lee, C.-Y. MEMS-based gas flow sensors. Microfluid. Nanofluidics 2009, 6, 333–346. [Google Scholar] [CrossRef]

- Meng, E.F.-C. MEMS Technology and Devices for a Microfluid Dosing System. Ph.D. Dissertation, California Institute of Technology, Pasadena, CA, USA, 2003; p. 150. [Google Scholar]

- King, L.V. On the convection of heat from small cylinders in a stream of fluid: Determination of the convection constants of small platinum wires with applications to hot-wire anemometry. Philos. Trans. R. Soc. Lond. Ser. A 1914, 214, 373–U44. [Google Scholar] [CrossRef]

- Madou, M.J. Fundamentals of Microfabrication: The Science of Miniaturization, 2nd ed; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Muller, R.S. Microsensors; IEEE Press: New York, NY, USA, 1991. [Google Scholar]

- Obermeier, E.; Kopystynski, P.; NieBl, R. Characteristics of polysilicon layers and their application in sensors. In IEEE Solid-State Sensors Workshop; IEEE Press: New York, NY, USA, 1986. [Google Scholar]

- Wolf, S.; Tauber, R.N. Silicon Processing for the VLSI Era, 2nd ed; Lattice Press: Sunset Beach, CA, USA, 2002; Volume 1. [Google Scholar]

- El-Kareh, B. Silicon Devices and Process Integration: Deep Submicron and Nano-scale Technologies; Springer: New York, NY, USA, 2009. [Google Scholar]

- Chuang, H.M.; Thei, K.B.; Tsai, S.F.; Liu, W.C. Temperature-dependent characteristics of polysilicon and diffused resistors. IEEE Trans. Electron. Devices 2003, 50, 1413–1415. [Google Scholar]

- Chuang, H.M.; Thei, K.B.; Tsai, S.F.; Lu, C.T.; Liao, X.D.; Lee, K.M.; Chen, H.R.; Liu, W.C. A comprehensive study of polysilicon resistors for CMOS ULSI applications. Superlattices Microstruct. 2003, 33, 193–208. [Google Scholar] [CrossRef]

- Meng, E. Biomedical Microsystems, 1st ed; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Dittmann, D.; Ahrens, R.; Rummler, Z.; Schlote-Holubek, K.; Schomburg, W.K. Low-Cost Flow Transducer Fabricated with the AMANDA-Process; Springer-Verlag: Berlin, Germany, 2001. [Google Scholar]

- Gardner, J.W. Microsensors: Principles and Applications, 1st ed; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Kreider, K.G.; DiMeo, F. Platinum/palladium thin-film thermocouples for temperature measurements on silicon wafers. Sens. Actuat. A 1998, 69, 46–52. [Google Scholar] [CrossRef]

- Mailly, F.; Giani, A.; Bonnot, R.; Temple-Boyer, P.; Pascal-Delannoy, F.; Foucaran, A.; Boyer, A. Anemometer with hot platinum thin film. Sens. Actuat. A 2001, 94, 32–38. [Google Scholar] [CrossRef]

- van Honschoten, J.; van Baar, J.; de Bree, H.E.; Lammerink, T.; Krijnen, G.; Elwenspoek, M. Application of a microflown as a low-cost level sensor. J. Micromech. Microeng. 2000, 10, 250–253. [Google Scholar] [CrossRef]

- Kuo, J.T.W.; Chang, L.-Y.; Li, P.-Y.; Hoang, T.; Meng, E. A microfluidic platform with integrated flow sensing for focal chemical stimulation of cells and tissue. Sens. Actuat. B 2011, 152, 267–276. [Google Scholar] [CrossRef]

- van Kuijk, J.; Lammerink, T.; de Bree, H.E.; Elwenspoek, M.; Fluitman, J. Multi-parameter detection in fluid flows. Sens. Actuat. A 1995, 47, 369–372. [Google Scholar] [CrossRef]

- Ito, Y.; Higuchi, T.; Takahashi, K. Submicroscale flow sensor employing suspended hot film with carbon nanotube fins. J. Therm. Sci. Technol. 2010, 5, 51–60. [Google Scholar] [CrossRef]

- Kaltsas, G.; Nassiopoulou, A.G. Novel C-MOS compatible monolithic silicon gas flow sensor with porous silicon thermal isolation. Sens. Actuat. A 1999, 76, 133–138. [Google Scholar] [CrossRef]

- Buchner, R.; Froehner, K.; Sosna, C.; Benecke, W.; Lang, W. Toward flexible thermoelectric flow sensors: A new technological approach. J. Microelectromechanical Syst. 2008, 17, 1114–1119. [Google Scholar] [CrossRef]

- Akin, T. CMOS-based thermal sensors. In CMOS-MEMS; Brand, O., Fedder, G.K., Eds.; Wiley-VCH: Hoboken, NJ, USA, 2005; pp. 483–487. [Google Scholar]

- Sze, S.M. Semiconductor Sensors; Wiley: New York, NY, USA, 1994. [Google Scholar]

- Volklein, F. Review of the thermoelectric efficiency of bulk and thin-film materials. Sens. Mater. 1996, 8, 389–408. [Google Scholar]

- Millman, J.; Halkias, C.C. Integrated Electronics: Analog and Digital Circuits and Systems; McGraw-Hill: New York, NY, USA, 1972. [Google Scholar]

- Sun, J.-B.; Qin, M.; Huang, Q.-A. Flip-chip packaging for a two-dimensional thermal flow sensor using a copper pillar bump technology. IEEE Sens. J. 2007, 7, 990–995. [Google Scholar] [CrossRef]

- Joshi, S.G. Flow sensors based on surface acoustic waves. Sens. Actuat. A 1994, 44, 191–197. [Google Scholar] [CrossRef]

- Langdon, R.M. Resonator sensors—A review. J. Phys. E 1985, 18, 103–115. [Google Scholar] [CrossRef]

- Kielbasa, J. Measurement of gas flow velocity: Anemometer with a vibrating hot wire. Rev. Sci. Instrum. 2010, 81, 015101:1–015101:4. [Google Scholar]

- Iker, F.; Andre, N.; Pardoen, T.; Raskin, J.P. Three-dimensional self-assembled sensors in thin-film SOI technology. J. Microelectromechanical Syst. 2006, 15, 1687–1697. [Google Scholar] [CrossRef]

- Sabaté, N.; Santander, J.; Fonseca, L.; Gràcia, I.; Cané, C. Multi-range silicon micromachined flow sensor. Sens. Actuat. A 2004, 110, 282–288. [Google Scholar] [CrossRef]

- Adamec, R.J.; Thiel, D.V. Self heated thermo-resistive element hot wire anemometer. IEEE Sens. J. 2010, 10, 847–848. [Google Scholar] [CrossRef]

- Kaanta, B.C.; Chen, H.; Zhang, X. Novel device for calibration-free flow rate measurements in micro gas chromatographic systems. J. Micromech. Microeng. 2010. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Dötzel, W. Asymmetrical locations of heaters and sensors relative to each other using heater arrays: A novel method for designing multi-range electrocaloric mass-flow sensors. Sens. Actuat. A 1997, 62, 506–512. [Google Scholar] [CrossRef]

- Soundararajan, G.; Rouhanizadeh, M.; Yu, H.Y.; De Maio, L.; Kim, E.S.; Hsiai, T.K. MEMS shear stress sensors for microcirculation. Sens. Actuat. A 2005, 118, 25–32. [Google Scholar]

- Wu, S.; Lin, Q.; Yuen, Y.; Tai, Y.-C. MEMS flow sensors for nano-fluidic applications. Sens. Actuat. A 2001, 89, 152–158. [Google Scholar] [CrossRef]

- Bailey, S.C.C.; Kunkel, G.J.; Hultmark, M.; Vallikivi, M.; Hill, J.P.; Meyer, K.A.; Tsay, C.; Arnold, C.B.; Smits, A.J. Turbulence measurements using a nanoscale thermal anemometry probe. J. Fluid Mech. 2010, 663, 160–179. [Google Scholar] [CrossRef]

- Meng, E.; Li, P.-Y.; Tai, Y.-C. A biocompatible Parylene thermal flow sensing array. Sens. Actuat. A 2008, 144, 18–28. [Google Scholar] [CrossRef]

- Chang, L.-Y.; Li, P.-Y.; Zhao, L.; Hoang, T.; Meng, E. Integrated flow sensing for focal biochemical stimulation. In Proceedings of the 3rd IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Sanya Hainan Island, China, 6-9 January 2008.

- Berthet, H.; Jundt, J.; Durivault, J.; Mercier, B.; Angelescu, D. Time-of-flight thermal flowrate sensor for lab-on-chip applications. Lab Chip 2011, 11, 215–223. [Google Scholar] [CrossRef]

- Fürjes, P.; Légrádi, G.; Dücső, C.; Aszódi, A.; Bársony, I. Thermal characterisation of a direction dependent flow sensor. Sens. Actuat. A 2004, 115, 417–423. [Google Scholar] [CrossRef]

- Hung, S.-T.; Wong, S.-C.; Fang, W. The development and application of microthermal sensors with a mesh-membrane supporting structure. Sens. Actuat. A 2000, 84, 70–75. [Google Scholar] [CrossRef]

- Dijkstra, M.; de Boer, M.J.; Berenschot, J.W.; Lammerink, T.S.J.; Wiegerink, R.J.; Elwenspoek, M. Miniaturized thermal flow sensor with planar-integrated sensor structures on semicircular surface channels. Sens. Actuat. A 2008, 143, 1–6. [Google Scholar] [CrossRef]

- Hsiai, T.K.; Cho, S.K.; Wong, P.K.; Ing, M.H.; Salazar, A.; Hama, S.; Navab, M.; Demer, L.L.; Chih-Ming, H. Micro sensors: Linking real-time oscillatory shear stress with vascular inflammatory responses. Ann. Biomed. Eng. 2004, 32, 189–201. [Google Scholar] [CrossRef]

- Liu, C.; Huang, J.-B.; Zhu, Z.; Jiang, F.; Tung, S.; Tai, Y.-C.; Ho, C.-M. A micromachined flow shear-stress sensor based on thermal transfer principles. J. Microelectromechanical Syst. 1999, 8, 90–99. [Google Scholar] [CrossRef]

- Kaltsas, G.; Petropoulos, A.; Tsougeni, K.; Pagonis, D.N.; Speliotis, T.; Gogolides, E.; Nassiopoulou, A.G. A novel microfabrication technology on organic substrates—Application to a thermal flow sensor. J. Phys. Conf. Ser. 2007. [Google Scholar] [CrossRef]

- Vilares, R.; Hunter, C.; Ugarte, I.; Aranburu, I.; Berganzo, J.; Elizalde, J.; Fernandez, L.J. Fabrication and testing of a SU-8 thermal flow sensor. Sens. Actuat. B 2010, 147, 411–417. [Google Scholar] [CrossRef]

- Ma, R.-H.; Wang, D.-A.; Hsueh, T.-H.; Lee, C.-Y. A MEMS-based flow rate and flow direction sensing platform with integrated temperature compensation scheme. Sensors 2009, 9, 5460–5476. [Google Scholar] [CrossRef]

- Shen, G.-P.; Qin, M.; Huang, Q.-A.; Zhang, H.; Wu, J. A FCOB packaged thermal wind sensor with compensation. Microsyst. Technol. 2010, 16, 511–518. [Google Scholar] [CrossRef]

- Domínguez, M.; Jiménez, V.; Ricart, J.; Kowalski, L.; Torres, J.; Navarro, S.; Romeral, J.; Castañer, L. A hot film anemometer for the Martian atmosphere. Planet. Space Sci. 2008, 56, 1169–1179. [Google Scholar] [CrossRef]

- Chen, J.; Fan, Z.F.; Zou, J.; Engel, J.; Liu, C. Two-dimensional micromachined flow sensor array for fluid mechanics studies. J. Aerosp. Eng. 2003, 16, 85–97. [Google Scholar] [CrossRef]

- Tan, Z.; Shikida, M.; Hirota, M.; Xing, Y.; Sato, K.; Iwasaki, T.; Iriye, Y. Characteristics of on-wall in-tube flexible thermal flow sensor under radially asymmetric flow condition. Sens. Actuat. A 2007, 138, 87–96. [Google Scholar] [CrossRef]

- Tan, Z.Y.; Shikida, M.; Hirota, M.; Sato, K.; Iwasaki, T.; Iriye, Y. Experimental and theoretical study of an on-wall in-tube flexible thermal sensor. J. Micromech. Microeng. 2007, 17, 679–686. [Google Scholar] [CrossRef]

- Liu, P.; Zhu, R.; Que, R. A flexible flow sensor system and its characteristics for fluid mechanics measurements. Sensors 2009, 9, 9533–9543. [Google Scholar] [CrossRef]

- Ahrens, R.; Schlote-Holubek, K. A micro flow sensor from a polymer for gases and liquids. J. Micromech. Microeng. 2009. [Google Scholar] [CrossRef]

- Ahrens, R.; Festa, M. Polymer-based micro flow sensor for dynamical flow measurements in hydraulic systems. J. Micromech. Microeng. 2010. [Google Scholar] [CrossRef]

- Li, C.Y.; Wu, P.M.; Han, J.; Ahn, C.H. A flexible polymer tube lab-chip integrated with microsensors for smart microcatheter. Biomed. Microdevices 2008, 10, 671–679. [Google Scholar] [CrossRef]

- Li, C.; Wu, P.-M.; Hartings, J.A.; Wu, Z.; Ahn, C.H.; Narayan, R.K. Cerebral blood flow sensor with in situ temperature and thermal conductivity compensation. In Proceedigns of the 25th International Conference on Micro Electro Mechanical Systems, Paris, France, 29 January-2 February 2012; pp. 1021–1024.

- Li, C.Y.; Wu, P.M.; Hartings, J.A.; Wu, Z.Z.; Ahn, C.H.; LeDoux, D.; Shutter, L.A.; Narayan, R.K. Smart catheter flow sensor for real-time continuous regional cerebral blood flow monitoring. Appl. Phys. Lett. 2011, 99, 233705–1. [Google Scholar]

- Yu, F.; Ai, L.S.; Dai, W.D.; Rozengurt, N.; Yu, H.Y.; Hsiai, T.K. MEMS thermal sensors to detect changes in heat transfer in the pre-atherosclerotic regions of fat-fed New Zealand white rabbits. Ann. Biomed. Eng. 2011, 39, 1736–1744. [Google Scholar] [CrossRef]

- Yu, H.; Ai, L.; Rouhanizadeh, M.; Patel, D.; Kim, E.S.; Hsiai, T.K. Flexible polymer sensors for in vivo intravascular shear stress analysis. J. Microelectromechanical Syst. 2008, 17, 1178–1186. [Google Scholar] [CrossRef]

- Yu, H.; Ai, L.; Rouhanizadeh, M.; Kloner, R.A.; Kim., E.S.; Hsiai, T.K. Flexible shear stress sensors for intravascular testing. In Proceedings of the Solid-State Sensors, Actuators Workshop, Hilton Head, SC, USA, 1-5 June 2008; pp. 142–145.

- Yu, H.Y.; Ai, L.S.; Rouhanizadeh, M.; Hamilton, R.; Hwang, J.; Meng, E.; Kim, E.S.; Hsiai, T.K. Polymer-based cardiovascular shear stress sensors. In Proceedings of the 2nd Frontiers in Biomedical Devices Conference (BioMed2007), Irvine, CA, USA, 7-8 June 2007.

- Ai, L.S.; Yu, H.Y.; Dai, W.D.; Hale, S.L.; Kloner, R.A.; Hsiai, T.K. Real-time intravascular shear stress in the rabbit abdominal aorta. IEEE Trans. Biomed. Eng. 2009, 56, 1755–1764. [Google Scholar] [CrossRef]

- Ai, L.S.; Yu, H.Y.; Rouhanizadeh, M.; Takabe, W.; Meng, E.; Kim, E.S.; Hsiai, T. Polymer-based sensors for dynamic intravascular shear stress analysis. In Proceedings of the 3rd Frontiers in Biomedical Devices Conferences (BioMed2008), Irvine, CA, USA, 18-20 June 2008.

- Ai, L.S.; Zhang, L.Q.; Dai, W.D.; Hu, C.H.; Shung, K.K.; Hsiai, T.K. Real-time assessment of flow reversal in an eccentric arterial stenotic model. J. Biomech. 2010, 43, 2678–2683. [Google Scholar]

- Ernst, H.; Jachimowicz, A.; Urban, G.A. High resolution flow characterization in bio-MEMS. Sens. Actuat. A 2002, 100, 54–62. [Google Scholar] [CrossRef]

- Cubukcu, A.S.; Zernickel, E.; Buerklin, U.; Urban, G.A. A 2D thermal flow sensor with sub-mW power consumption. Sens. Actuat. A 2010, 163, 449–456. [Google Scholar] [CrossRef]

- Kaltsas, G.; Nassiopoulos, A.A.; Nassiopoulou, A.G. Characterization of a silicon thermal gas-flow sensor with porous silicon thermal isolation. IEEESens. J. 2002, 2, 463–475. [Google Scholar]

- Kaltsas, G.; Katsikogiannis, P.; Asimakopoulos, P.; Nassiopoulou, A.G. A smart flow measurement system for flow evaluation with multiple signals in different operation modes. Meas. Sci. Technol. 2007. [Google Scholar] [CrossRef]

- Stamatopoulos, C.; Petropoulos, A.; Mathioulakis, D.S.; Kaltsas, G. Study of an integrated thermal sensor in different operational modes, under laminar, transitional and turbulent flow regimes. Exp. Therm. Fluid Sci. 2008, 32, 1687–1693. [Google Scholar] [CrossRef]

- Buchner, R.; Sosna, C.; Maiwald, M.; Benecke, W.; Lang, W. A high-temperature thermopile fabrication process for thermal flow sensors. Sens. Actuat. A 2006, 130-131, 262–266. [Google Scholar] [CrossRef]

- Laconte, J.; Dupont, C.; Flandre, D.; Raskin, J.P. SOI CMOS compatible low-power microheater optimization for the fabrication of smart gas sensors. IEEE Sens. J. 2004, 4, 670–680. [Google Scholar] [CrossRef]

- Wiegerink, R.J.; Lammerink, T.S.J.; Dijkstra, M.; Haneveld, J. Thermal and Coriolis type micro flow sensors based on surface channel technology. Procedia Chem. 2009, 1, 1455–1458. [Google Scholar] [CrossRef]

- Bruschi, P.; Diligenti, A.; Navarrini, D.; Piotto, M. A double heater integrated gas flow sensor with thermal feedback. Sens. Actuat. A 2005, 123-124, 210–215. [Google Scholar] [CrossRef]

- Bruschi, P.; Dei, M.; Piotto, M. A low-power 2-D wind sensor based on integrated flow meters. IEEE Sens. J. 2009, 9, 1688–1696. [Google Scholar] [CrossRef]

- Bruschi, P.; Nurra, V.; Piotto, M. A compact package for integrated silicon thermal gas flow meters. Microsyst. Technol. Micro Nanosyst. Inf. Storage Process. Syst. 2008, 14, 943–949. [Google Scholar]

- Sturm, H.; Brauns, E.; Froehner, K.; Lang, W.; Buchner, R. Thermoelectric flow sensors on flexible substrates and their integration process. In 2010 IEEE Sensors; IEEE Press: New York, NY, USA, 2010; pp. 575–579. [Google Scholar]

- Makinwa, K.A.A.; Huijsing, J.H. A smart wind sensor using thermal sigma-delta modulation techniques. Sens. Actuat. A 2002, 97-98, 15–20. [Google Scholar] [CrossRef]

- Makinwa, K.A.A.; Huijsing, J.H. A wind-sensor interface using thermal sigma delta modulation techniques. Sens. Actuat. A 2001, 92, 280–285. [Google Scholar] [CrossRef]

- Makinwa, K.A.A.; Huijsing, J.H. Constant power operation of a two-dimensional flow sensor. IEEE Trans. Instrum. Meas. 2002, 51, 840–844. [Google Scholar] [CrossRef]

- Makinwa, K.A.A.; Huijsing, J.H. A smart wind sensor using thermal sigma-delta modulation techniques. Sens. Actuat. A 97-9, 2002, 15–20. [Google Scholar]

- Matova, S.P.; Makinwa, K.A.A.; Huijsing, J.H. Compensation of packaging asymmetry in a 2-D wind sensor. IEEE Sens. J. 2003, 3, 761–765. [Google Scholar] [CrossRef]

- Makinwa, K.A.A.; Huijsing, J.H. A 2nd order thermal sigma-delta modulator for flow sensing. In 2005 IEEE Sensors; IEEE Press: New York, NY, USA, 2005; Volume 1 and 2, pp. 549–552. [Google Scholar]

- Wang, Y.Z.; Li, Z.; Qin, L.F.; Chyu, M.K.; Wang, Q.M. Surface acoustic wave flow sensor. In Proceedings of the IEEE International Frequency Control Symposium on 2011 Joint Conference of the IEEE International Frequency Control Symposium/European Frequency and Time Forum, San Francisco, CA, USA, 2-5 May 2011; pp. 428–431.

- Renaudin, A.; Chabot, V.; Grondin, E.; Aimez, V.; Charette, P.G. Integrated active mixing and biosensing using surface acoustic waves (SAW) and surface plasmon resonance (SPR) on a common substrate. Lab Chip 2010, 10, 111–115. [Google Scholar] [CrossRef]

- Friedt, J.M.; Francis, L.; Reekmans, G.; De Palma, R.; Campitelli, A.; Sleytr, U.B. Simultaneous surface acoustic wave and surface plasmon resonance measurements: Electrodeposition and biological interactions monitoring. J. Appl. Phys. 2004, 95, 1677–1680. [Google Scholar]

- Jewart, C.; McMillen, B.; Cho, S.K.; Chen, K.P. X-probe flow sensor using self-powered active fiber Bragg gratings. Sens. Actuat. A 2006, 127, 63–68. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Kuo, J.T.W.; Yu, L.; Meng, E. Micromachined Thermal Flow Sensors—A Review. Micromachines 2012, 3, 550-573. https://doi.org/10.3390/mi3030550

Kuo JTW, Yu L, Meng E. Micromachined Thermal Flow Sensors—A Review. Micromachines. 2012; 3(3):550-573. https://doi.org/10.3390/mi3030550

Chicago/Turabian StyleKuo, Jonathan T. W., Lawrence Yu, and Ellis Meng. 2012. "Micromachined Thermal Flow Sensors—A Review" Micromachines 3, no. 3: 550-573. https://doi.org/10.3390/mi3030550

APA StyleKuo, J. T. W., Yu, L., & Meng, E. (2012). Micromachined Thermal Flow Sensors—A Review. Micromachines, 3(3), 550-573. https://doi.org/10.3390/mi3030550