1. Introduction

As a new type of flexible manufacturing process for precise mechanical components, laser micro bending is the accumulative forming method under the thermal state condition. Furthermore, it can shape hard or brittle metals, such as Ti-alloys,

etc. However, traditional methods proved to be inapplicable or highly consuming. Moreover, there is no springback in the cooling process because of the forming process in the thermal state. In addition, laser micro bending can be used for compound process with forming, cutting and welding easily [

1].

Up to now, lots of studies have focused on the relationship of bending angle and processing parameters of laser micro bending method. Guan

et al. [

2] established an experimental system introducing the characteristic of the laser polarization into laser micro bending. Dearden

et al. [

3] described a number of new techniques in laser bending for macro-and micro-scale applications. Gartner

et al. [

4] realized the highest precision deformation of silicon microstructures using laser bending technology. Zhang

et al. [

5] described a laser based technique to adjust curvatures of silicon micro-cantilevers used for chemical and biological detection. Zhang

et al. [

6] proposed an uncoupled thermo-mechanical computational model and analyzed laser bending process of a hard disk suspension. Tan

et al. [

7] conducted 3D numerical simulations on a micro-scale suspension flexure due to laser beam scanning, and established relationships between the permanent bending angle of the flexure and the scanning parameters. Pence

et al. [

8] investigated the different mechanism of laser shock bending using nanosecond-pulsed laser. Wang

et al. [

9] proposed a new approach for the miniaturized structures in sapphire dies using laser-assisted micro-forming. Coupled with mechanical and ultrasonic cleaning, this could create structures with vertical walls, acceptable surface quality and minimal size effects.

These researches above gave many helpful instructions for the plate or foil in laser micro bending. The attention on laser micro bending has been focused on linear and curve irradiation paths. However, few researches have been focused on the laser micro bending of square bar with spot irradiation. Micro square bar has the characteristics of good stability compared with plate or foil. The main application area for micro square bar is the electronic sector, MEMS and other fields, are playing an increasingly important role. The laser micro bending mechanisms of square bar and plate are different due to the size difference. This paper aims at a systematic understanding of the thermo-mechanical reaction of square bar during laser micro bending. The finite element analytical model including establishment of laser spot heat flux and boundary conditions is built. The temperature fields, displacement fields, stress fields and strain fields under provided conditions are analyzed. Effects of laser power and irradiation time on temperature and deformation are also investigated.

2. Finite Element Analytical Model

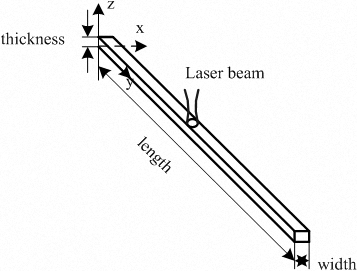

Figure 1 shows the schematic diagram of the laser micro bending process of square bar. The

z-axis is defined as the direction of laser beam irradiation. The

x- and

y-axes are defined in the plane of the bar. The length of the bar is 25 mm, the width and the thickness is 0.5 mm. The end of the bar is constrained, and the other end is in a free state. The middle position of the bar surface is irradiated by laser beam. The material is Ti6Al4V, its thermo-physical property parameters taken from [

10].

The distribution of laser intensity follows the Gaussian mode. During the laser bending process, the heat flux density obeys the normal distribution as Equation (1).

where

I is the thermal flux density of the laser beam,

A is the absorption coefficient on the sheet metal surface,

P is the output power of laser,

R is the radius of the laser beam irradiated to the surface of the sheet metal, and

r is the distance from the laser beam center.

The other boundary condition is as follow:

where

n expresses the direction of the surface,

h is the natural convection exchange coefficient, and

kr = εσ(

T2 +

T02)(

T +

T0), where є is the surface emissivity and σ is the Boltzmann constant.

Figure 1.

Schematic diagram of laser spot bending process.

Figure 1.

Schematic diagram of laser spot bending process.

In the present work, laser micro bending process is simulated as thermal-mechanical coupling process by using Finite Element Software ANSYS, and the decoupling calculation method is used here. The model is meshed using the element SOLID70 for the thermal analysis. Then, the deformation field, stress field and strain field are obtained with the conversion of the element SOLID 70 to SOLID 45, based on the result of the thermal analysis. The model is meshed with global way. The mesh size is 0.1 mm. The temperature data of laser spot center is extracted for the thermal analysis. The displacement data of free end of bar is extracted for the deformation analysis.

Nd:YAG laser device is used to verify the simulated results with continuous output mode. The initial processing parameters are 100 W for laser power, 0.5 mm for laser beam diameter and 0.5 s for the continued irradiation time. The bending angles are measured by an exclusive protractor.

3. Results and Discussion

3.1. Analysis of Temperature Fields

Figure 2 shows the temperature distribution at

t = 1 s. It can be observed that obvious temperature gradient in the irradiation region can be found due to the heat exchange. As can be seen in

Figure 3, irradiation of the laser beam yields to a rapid temperature increase at the irradiated surface, which leads to high temperature gradients between the upper and lower surfaces. So, the mechanism of laser micro bending is the temperature gradient mechanism.

Figure 2.

Temperature distribution at t = 1 s.

Figure 2.

Temperature distribution at t = 1 s.

Figure 3.

Temperature of the upper and lower surface along with time.

Figure 3.

Temperature of the upper and lower surface along with time.

3.2. Analysis of Displacement Fields

Figure 4 shows the bending angles along with irradiation time. It can be seen that the simulated results during the laser bending process and the experimental results demonstrate good correlation. A noticeable counter-bending occurs due to thermal expansion in the irradiation zone when the laser beam has just irradiated the square bar. After the laser beam irradiating the bar, the irradiation surface begins to show shrinkage and the lower surface begins to expand due to heat transfer, which causes the deformation in the direction of the laser beam. The final displacement can be gained while cooling to room temperature, which can be seen as

Figure 5.

Figure 4.

Bending angles along with irradiation time.

Figure 4.

Bending angles along with irradiation time.

Figure 5.

Displacement distribution at t = 1 s: (a) x direction; (b) y direction; and (c) z direction.

Figure 5.

Displacement distribution at t = 1 s: (a) x direction; (b) y direction; and (c) z direction.

3.3. Analysis of Stress and Strain Fields

The simulation results shown that the temperature and displacement distributions referred above, the yield stress and plastic strain distributions displayed in

Figure 6 and

Figure 7. It can be seen that compressive stresses occur in the irradiation zone because the materials around the radiation zone are cold, and slight tensile stresses occur in the neighboring areas. The unirradiated surface keeps compressive strain during the irradiation process. Moreover, there exists a large strain difference between the irradiated surface and the unirradiated surface in the three directions in the irradiation zone, which leads to the bending deformations.

Figure 6.

Stress distribution at t = 1 s: (a) x direction; (b) y direction; and (c) z direction.

Figure 6.

Stress distribution at t = 1 s: (a) x direction; (b) y direction; and (c) z direction.

Figure 7.

Strain distribution at t = 1 s. (a) x direction; (b) y direction and (c) z direction.

Figure 7.

Strain distribution at t = 1 s. (a) x direction; (b) y direction and (c) z direction.

3.4. Effects of Laser Power and Irradiation Time on Temperature

In practical work, laser micro bending is a thermo-mechanical coupling process, but solving the coupling problem is too complicated. The main mechanism of the laser micro bending process is the temperature gradient mechanism.

Figure 2 shows a steep thermal gradient into the material that result in a differential thermal expansion through the thickness due to the laser beam rapid irradiation. For the spatial work piece, the temperature gradients are mainly concerned with the temperatures of laser beam irradiated surface. So, the temperature of irradiated surface can evaluate the variation mechanism of the laser micro bending process. Moreover, the effects of the laser power and the irradiation time on the temperature fields are investigated systemically using the finite element simulation.

Figure 8 shows variation of temperature with laser power. It can be seen that the temperature increase when the laser power increases.

Figure 9 shows variation of temperature with irradiation time. The temperature increases with the increasing of the irradiation time. Effects of laser power and irradiation time on the temperature play the same role. However, the relationships between temperatures and processing parameters are non-linear.

Figure 8.

Variation of temperature with laser power.

Figure 8.

Variation of temperature with laser power.

Figure 9.

Variation of temperature with irradiation time.

Figure 9.

Variation of temperature with irradiation time.

3.6. Surface Quality Analysis

Figure 12 shows surface morphology of laser radiation zone. The morphology in the laser irradiation region is circular due to the laser beam Gaussian profile. Morphology change is mainly oxidation of material under the action of laser radiation, which can be seen in

Figure 13. The degree of oxidation of the material is very small, which does not affect the application requirements.

Figure 12.

Surface morphology of laser radiation zone.

Figure 12.

Surface morphology of laser radiation zone.

Figure 13.

Element analysis of laser radiation zone.

Figure 13.

Element analysis of laser radiation zone.

4. Conclusions

A finite element model of heat flux based on laser micro bending was built. The proposed model can be used to make the thermo-physical process simulation of laser micro bending. Finite element simulation of transient temperature fields, displacement fields, stress fields and strain fields produced by laser beam radiation on the forming square bar were carried out. The simulated results are in good agreement with experimental results. The temperatures of sheet increase with the increase of the laser power and the radiation time. The z displacement of forward direction and reverse direction increase when the laser power increases. However, z displacement of the reverse direction is mainly. The bending deformation time increases when the radiation time increases. However, the effect of radiation time on the bending deformation of the bar is lesser. The radiation of the laser beam yields to a rapid temperature increase at the irradiated surface, which leads to high temperature gradients between the upper surface and the lower surface. The mechanism of laser micro bending is the integrated effects of the temperature gradient mechanism.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (Grant No. 51207031), China Postdoctoral Science Foundation (Grant No. 2013M541368).

Author Contributions

Peng Zhang contributed on the process design. Gang Chen contributed on the process analysis. Gang Chen and Peng Zhang wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Matsushita, N. Laser Micro-Bending for Precise Micro-Fabrication of Magnetic Disk-Drive Components. In Proceeding of the 4th International Symposium on Laser Precision Microfabrication, 20 November 2003; International Society for Optics and Photonics: Munich, Germany; Volume 5063, pp. 24–29.

- Guan, Y.; Zhang, H.; Liu, J.; Sun, S. Laser micro-bending process based on the characteristic of the laser polarization. J. Mater. Process. Technol. 2012, 212, 662–671. [Google Scholar] [CrossRef]

- Dearden, G.; Edwardson, S.P. Some recent developments in two- and three- dimensional laser forming for ‘macro’ and ‘micro’ applications. J. Opt. A Pure Appl. Opt. 2003, 5, S8–S15. [Google Scholar] [CrossRef]

- Gartner, E.; Fruhauf, J.; Loschner, U.; Exner, H. Laser bending of etched silicon microstructures. Microsyst. Technol. 2001, 7, 23–26. [Google Scholar]

- Zhang, X.R.; Xu, X.F. Laser bending for high-precision curvature adjustment of microcantilevers. Appl. Phys. Lett. 2005, 86, 021114. [Google Scholar] [CrossRef]

- Zhang, X.R.; Xu, X.F. Laser bending for adjusting curvatures of hard disk suspensions. Microsyst. Technol. 2005, 11, 1197–1203. [Google Scholar] [CrossRef]

- Tan, M.; Zhang, Z.Q.; Liu, G.R. Numerical investigation of micro-scale sheet metal bending using laser beam scanning. Int. J. Comput. Eng. Sci. 2004, 5, 345–355. [Google Scholar] [CrossRef]

- Pence, C.; Ding, H.; Shen, N.; Ding, H. Experimental analysis of sheet metal micro-bending using a nanosecond-pulsed laser. Int. J. Adv. Manuf. Technol. 2013, 269, 319–327. [Google Scholar] [CrossRef]

- Samm, K.; Terzi, M.; Ostendorf, A.; Wulfsberg, J. Laser-assisted micro-forming process with miniaturized structures in sapphire dies. Appl. Surf. Sci. 2009, 255, 9830–9834. [Google Scholar] [CrossRef]

- Wlsch, G.; Boyer, B.; Collings, E.W. Ti-6Al-4V. In Materials Properties Handbook: Titanium Alloys; ASM International: Geauga County, OH, USA, 2007; pp. 483–593. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).