Nano-Workbench: A Combined Hollow AFM Cantilever and Robotic Manipulator †

Abstract

:1. Introduction

2. Experimental Section

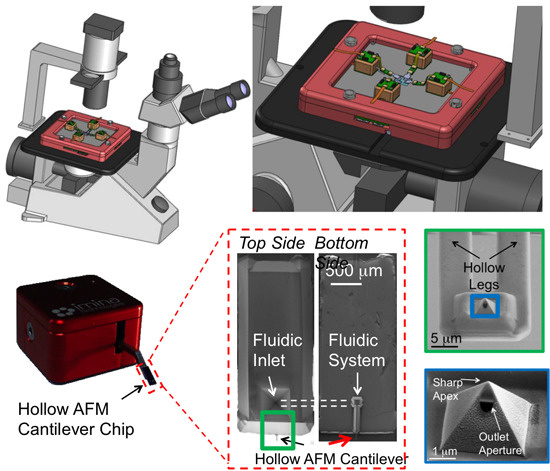

2.1. Nano-Workbench (NWB)

2.2. Experiments with the Nano-Workbench

- Clamping suspended graphene: In a micro-electro-mechanical system (MEMS) based tensile tester, there are two suspended shuttle beams with a separation of about 5 microns. The poly-silicon chevron-type thermal actuators connected to one of the shuttle pulled the sample suspended between the shuttle beams. Care was taken to keep the sample at room temperature with heat sinks attached to the shuttle. The detailed design and fabrication of the device is given elsewhere [6]. The sample under investigation for their tensile properties is placed between the shuttles to bridge the separation. In our experiment, we have transferred graphene between the shuttles. The van der Waals forces with the shuttle surface held the graphene. The shuttles were actuated such that the graphene would experience a tensile force. However, the graphene was always slipping away as the tensile force was overcoming the existing adhesion due to van der Walls forces between graphene and shuttle surface. To overcome this problem, clamping graphene was necessary. Using our NWB, we have locally dispensed epoxy on the shuttle-graphene interface present on both the shuttles of the MEMS device. The hollow cantilever was carefully brought to the point of interest by means of the remotely controlled robot. Once positioned in the vicinity of the graphene, the robot arm displaced the hollow cantilever slowly and accurately towards the edge of the graphene. Then, the hollow cantilever was snapped-in multiple times to locally dispense the epoxy along the edge of the shuttle over an area ranging about 10 μm × 10 μm (Figure 3). This area covered the entire graphene edge on the shuttle. The process was repeated on both edges, thus clamping graphene on both shuttles with epoxy. The graphene was stretched while recording the Raman spectra of the graphene. The 2D band and G band peaks were monitored in situ during stretching.

- Mixing microdroplets: In this experiment, we have used the NWB to enable local deposition and controlled synthesis of gold nanoparticles. A chip containing a transmission electron microscopy (TEM) window of 50 nm thick Si3N4 and two different robots that were equipped with their own respective hollow cantilevers were used. One of them was filled with aqueous metallic salt solution (chloroauric acid–AuCl4), while the other was filled with aqueous reducing agent solution (sodium azide–NaN3). We first brought the robot carrying the metal salt solution near the TEM chip and approached the hollow cantilever towards the membrane window to dispense a droplet of controlled volume. After deposition, we brought the second robot containing the reducing agent and a droplet with the same volume was dispensed, allowing both reagents to coalesce and mix (Figure 4). Nanoparticles were synthesized in different droplet volumes ranging from 2.4 to 0.25 fL in equal quantities of both reagents on different windows. The results of the triggered chemical mixture were analyzed under TEM.

- Dispensing electrolyte for nanobattery: In situ transmission electron microscope (TEM) with single grain electrode material can be used to visualize the lithium (de)intercalation process in real-time to understand the exact lithium transport mechanism inside the electrode material and thus better nanostructured electrode materials can be synthesized to improve the state of art lithium ion battery technology [6,13,14]. However, to prepare such a nanobattery assembly with single grain material, one needs to dispense tiny liquid electrolyte between the two electrodes with high accuracy [15]. The NWB was used to dispense not only tiny droplets of the ionic liquid (having low vapor pressure, stable in the high vacuum of TEM), namely 1 M lithium bis(trifluoromethane sulfonyl)imide (LiTFSI) in 1-Butyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl)imide, electrolyte but also precisely at the required position to complete the nanobattery assembly. Since the electrolyte was sensitive to air, dispensing was carried out inside the glove box, by placing the entire NWB setup inside the glove box. Battery assembly was made on a 20 nm silicon nitride membrane with appropriate electrical connections already fabricated before dispensing the electrolyte droplet.

3. Results and Discussion

4. Conclusions

| Hollow AFM Cantilever Resonance Frequency: 153.94 kHz Spring Constant: 3.48 N/m Typical Dispensed Volume: 30 fL Storage Volume: 20 nL Aperture Diameter: 300–2000 nm |

| Robot Travelling Range (a) Stepping Mode: X: 25 mm, Y: 25 mm, Z: 8 mm (b) Scanning Mode: X: 150 nm, Y:150 nm, Z: 300 nm Positioning Resolution (a) Stepping Mode: X: 50 nm, Y: 50 nm, Z: 150 nm (b) Scanning Mode: X: 5 nm, Y: 5 nm, Z: 5 nm |

| Controller Output Frequency: 0.7 Hz to 23.5 kHz Output Voltage: 55–185 V (AC) and 0–185 V (DC) |

Acknowledgments

Author Contributions

Supplementary Materials

Conflicts of Interest

References

- Research, I.A. Boy and His Atom: The World’s Smallest Movie. Available online: Http://www.research.ibm.com/articles/madewithatoms.shtml (accessed on 27 February 2015).

- Müller, D.J.; Dufrêne, Y.F. Atomic force microscopy: A nanoscopic window on the cell surface. Trends Cell. Biol. 2011, 21, 461–469. [Google Scholar] [CrossRef] [PubMed]

- Mohn, F.; Gross, L.; Moll, N.; Meyer, G. Imaging the charge distribution within a single molecule. Nat. Nanotechnol. 2012, 7, 227–231. [Google Scholar] [CrossRef]

- Li, G.; Xi, N. Overview of Nanomanipulation by Scanning Probe. In Introduction to Nanorobotic Manipulation and Assembly; Artech House: Norwood, MA, USA, 2012; pp. 93–110. [Google Scholar]

- Xi, N.; Fung, C.; Yang, R.; Seiffert-Sinha, K.; Lai, K.W.C.; Sinha, A.A. Bionanomanipulation using atomic force microscopy. IEEE Nanotechnol. Mag. 2010, 4, 9–12. [Google Scholar] [CrossRef]

- Ghatkesar, M.K.; Garza, H.H.P.; Staufer, U. Hollow AFM cantilever pipette. Microelectron. Eng. 2014, 124, 22–25. [Google Scholar] [CrossRef]

- Ghatkesar, M.K.; Garza, H.H.P.; Heuck, F.; Staufer, U. Scanning Probe Microscope-Based Fluid Dispensing. Micromachines 2014, 5, 954–1001. [Google Scholar] [CrossRef]

- Zambelli, T.; Meister, A.; Gabi, M.; Behr, P.; Studer, P.; Voros, J.; Niedermann, P.; Bitterli, J.; Polesel-Maris, J.; Liley, M.; Heinzelmann, H. Fluid FM: Combining Atomic Force Microscopy and Nanofluidics in a Universal Liquid Delivery System for Single Cell Applications and Beyond. Nano Lett. 2009, 9, 2501–2507. [Google Scholar] [CrossRef] [PubMed]

- Shibata, T.; Nakamura, K.; Horiike, S.; Nagai, M.; Kawashima, T.; Mineta, T.; Makino, E. Fabrication and characterization of bioprobe integrated with a hollow nanoneedle for novel AFM applications in cellular function analysis. Microelectron. Eng. 2013, 111, 325–331. [Google Scholar] [CrossRef]

- Kang, W.M.; Yavari, F.; Minary-Jolandan, M.; Giraldo-Vela, J.P.; Safi, A.; McNaughton, R.L.; Parpoil, V.; Espinosa, H.D. Nanofountain Probe Electroporation (NFP-E) of Single Cells. Nano Lett. 2013, 13, 2448–2457. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Onal, C.; Régnier, S.; Sitti, M. Automated Control of AFM Based Nanomanipulation. In Atomic Force Microscopy Based Nanorobotics; Springer: Berlin, Germany, 2012; pp. 237–311. [Google Scholar]

- Hou, J.; Liu, L.; Wang, Z.; Wang, Z.; Xi, N.; Wang, Y.; Wu, C.; Dong, Z.; Yuan, S. Afm-based robotic nano-hand for stable manipulation at nanoscale. IEEE Trans. Autom. Sci. Eng. 2013, 10, 285–295. [Google Scholar] [CrossRef]

- Scrosati, B.; Garche, J. Lithium batteries: Status, prospects and future. J. Power Sources 2010, 195, 2419–2430. [Google Scholar] [CrossRef]

- Liu, X.H.; Huang, J.Y. In situ TEM electrochemistry of anode materials in lithium ion batteries. Energy Environ. Sci. 2011, 4, 3844–3860. [Google Scholar] [CrossRef]

- Wu, H.; Cui, Y. Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today 2012, 7, 414–429. [Google Scholar] [CrossRef]

- Mohiuddin, T.; Lombardo, A.; Nair, R.; Bonetti, A.; Savini, G.; Jalil, R.; Bonini, N.; Basko, D.; Galiotis, C.; Marzari, N. Uniaxial strain in graphene by Raman spectroscopy: G peak splitting, Grüneisen parameters, and sample orientation. Phys. Rev. B 2009, 79, 205433. [Google Scholar] [CrossRef]

- Ni, Z.H.; Yu, T.; Lu, Y.H.; Wang, Y.Y.; Feng, Y.P.; Shen, Z.X. Uniaxial strain on graphene: Raman spectroscopy study and band-gap opening. ACS Nano 2008, 2, 2301–2305. [Google Scholar] [CrossRef] [PubMed]

- Pérez Garza, H.H.; Kievit, E.W.; Schneider, G.F.; Staufer, U. Controlled, Reversible, and Nondestructive Generation of Uniaxial Extreme Strains (>10%) in Graphene. Nano Lett. 2014, 14, 4107–4113. [Google Scholar]

- Pérez-Garza, H.H.; Kievit, E.W.; Schneider, G.F.; Staufer, U. Highly strained graphene samples of varying thickness and comparison of their behaviour. Nanotechnology 2014, 25, 465708. [Google Scholar] [CrossRef] [PubMed]

- Garza, H.H.P.; Ghatkesar, M.K.; Löthman, P.; Manz, A.; Staufer, U. Enabling local deposition and controlled synthesis of Au-nanoparticles using a femtopipette. In Proceedings of the 2014 9th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Waikiki Beach, HI, USA, 13–16 April 2014; pp. 323–328.

- Garza, H.; Stoute, R.; Ghatkesar, M.; Staufer, U. Self-sensing nanopipette for liquid dispensing and AFM imaging. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Madrid, Spain, 16–20 June 2013; pp. 2648–2651.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garza, H.H.P.; Ghatkesar, M.K.; Basak, S.; Löthman, P.; Staufer, U. Nano-Workbench: A Combined Hollow AFM Cantilever and Robotic Manipulator. Micromachines 2015, 6, 600-610. https://doi.org/10.3390/mi6050600

Garza HHP, Ghatkesar MK, Basak S, Löthman P, Staufer U. Nano-Workbench: A Combined Hollow AFM Cantilever and Robotic Manipulator. Micromachines. 2015; 6(5):600-610. https://doi.org/10.3390/mi6050600

Chicago/Turabian StyleGarza, Héctor Hugo Pérez, Murali Krishna Ghatkesar, Shibabrata Basak, Per Löthman, and Urs Staufer. 2015. "Nano-Workbench: A Combined Hollow AFM Cantilever and Robotic Manipulator" Micromachines 6, no. 5: 600-610. https://doi.org/10.3390/mi6050600

APA StyleGarza, H. H. P., Ghatkesar, M. K., Basak, S., Löthman, P., & Staufer, U. (2015). Nano-Workbench: A Combined Hollow AFM Cantilever and Robotic Manipulator. Micromachines, 6(5), 600-610. https://doi.org/10.3390/mi6050600