2.1. Concept of Design

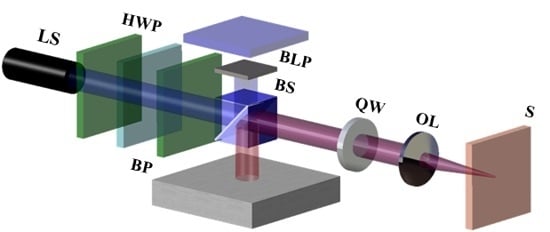

As shown in

Figure 1, the variations in the divergence angle and CCD camera spot size depend on to the specimen’s position.

Figure 1a–c show the cases where the specimen is located at the focal position, in front of the focal position, and behind the focal position, respectively. The laser beam passes through the beam splitter, the quarter-wave plate, and the focusing lens before focusing on the specimen. The beam reflected from the specimen passes through the lens and quarter-wave plate to reach the beam splitter, where it is reflected to ultimately arrive at the CCD camera. A silicon wafer was used as the specimen for the beam-profile testing. All of the specimen surfaces were polished before the experiment for the optimal reflection.

Figure 1.

Variation in divergence angle according to specimen’s position. (a) Specimen located at the focal position; (b) Specimen located in front of the focal position; (c) Specimen located behind the focal position. LS: Laser source, BS: Beam splitter, QW: Quarter-wave plate, OL: Objective lens, S: Specimen, BP: Beam profiler.

Figure 1.

Variation in divergence angle according to specimen’s position. (a) Specimen located at the focal position; (b) Specimen located in front of the focal position; (c) Specimen located behind the focal position. LS: Laser source, BS: Beam splitter, QW: Quarter-wave plate, OL: Objective lens, S: Specimen, BP: Beam profiler.

Charge-coupled device (CCD) cameras are optical sensors with an array of photodiodes that can measure the beam profile of an arriving beam, and are thus commonly referred to as “beam profilers”. We denote the beam size on the CCD camera as D. As the specimen moves from left to right, the value of D decreases monotonically. As shown in

Figure 1a, the specimen is located at the focal position; thus, the reflected rays are parallel and are measured to have a beam size of D = D

focus at the CCD camera. In

Figure 1b, the specimen is located in front of the focal position; thus, the reflected rays diverge and D is larger than D

focus. In

Figure 1c, the specimen is located behind the focal position; hence, the reflected rays converge and D is measured to be smaller than D

focus.

Figure 2 shows the ray-tracing results according to the specimen position obtained with Zemax (Zemax LLC, Stansted, United Kingdom). As expected, the reflected rays are parallel when the specimen is located at the focal position, and they diverge when the specimen is in front of the focal position. Furthermore, the converging rays enter the CCD camera when the specimen is located behind the focal position.

Figure 2.

3D layout ray-tracing results according to specimen position. The specimen is located at (a) the focal position; (b) in front of the focal position; and (c) behind the focal position.

Figure 2.

3D layout ray-tracing results according to specimen position. The specimen is located at (a) the focal position; (b) in front of the focal position; and (c) behind the focal position.

2.2. Calibration Method for Focus-Finder System

We can discover whether the specimen is at the focal position by determining the spot size D

focus, which is obtained when the specimen is at the focal position. To determine D

focus, a mirror and a quarter-wave plate are placed in parallel to the beam splitter surface (on the side opposite to the beam profiler), as shown in

Figure 3, and a blocking plate is installed at the focusing lens on the specimen side to prevent beam reflection. Thus, some of the beam reflected from the beam splitter is reflected by the quarter-wave plate and mirror. This reflected beam is measured by the CCD camera and inferred to have a beam size of D

focus. After D

focus is measured, the blocking plate, which is currently installed beside the focusing lens, is removed and then reinstalled at the mirror side. At this point, the beam reflected from the specimen is received by the beam profiler. The specimen is moved until the beam size is equal to D

focus, at which point it becomes known that the specimen is located at the focal position.

One issue that must be considered when locating the focal position using the method described above concerns the inaccuracy of the laser beam measurement when the CCD camera is used. We define spot size as the radius of the beam. Because laser beams are Gaussian, the laser beam size can depend on the laser power. As the laser power increases, the irradiance of the beam decreases gradually at the edges. The distance across the center of the beam for which the irradiance (intensity) equals 1/e

2 of the maximum irradiance (1/e

2 = 0.135) is defined as the beam diameter. The spot size (

w) of the beam is defined as the radial distance from the central point of maximum irradiance to the point at which the irradiance drops by a factor of 1/e

2. Therefore, in order to accurately measure the laser beam size, the CCD camera must be adjusted to the optimal laser power. The laser beam was initially transmitted over the beam splitter and linearly polarized. After passing over the quarter plate, the beam was circularly polarized. Next, the beam was reflected on the specimen. The circular polarization of the incoming beam is opposite to that of reflected beam. Then the beam was again passed over quarter plate; the polarization phase shift is

in total. Next, the laser beam passed through the beam splitter again and was reflected without any transmission. The entire laser power was thus transmitted to the CCD camera without any loss.

Figure 4 shows the limitations of the CCD camera laser beam measurement.

Figure 3.

Schematic of the focus finder with an added mirror. BLP: Blocking plate.

Figure 3.

Schematic of the focus finder with an added mirror. BLP: Blocking plate.

Figure 4.

Measurement limitations of the charge-coupled device (CCD) camera. (a) Optimized laser power; (b) high laser power; and (c) low laser power.

Figure 4.

Measurement limitations of the charge-coupled device (CCD) camera. (a) Optimized laser power; (b) high laser power; and (c) low laser power.

Consider three cases of the beam size profile: optimal laser power, laser power greater than the optimal laser power, and laser power lower than the optimal power.

Figure 4a–c show images obtained by the CCD camera, along with a graph demonstrating the CCD threshold and the laser profiles for the three cases listed above. The laser beam sizes are 3.084, 3.669, and 1.989 mm in

Figure 4a–c, respectively. An SPI laser (G4, 50 W; beam diameter ~3 mm, wavelength 1064 nm, pulse duration 5 ns,

M2 = 1.3, random polarization, SPI Lasers Ltd, Southampton, United Kingdom) was used along with a BeamOn 2/3 CCD camera (Duma Optronics, Nesher, Israel). Furthermore, in order to optimize the laser power, as shown in

Figure 4a, we used a laser power control apparatus that included a polarizer, and half-wave plate. The optical components were arranged such that the distance between the beam splitter and the mirror was 100 mm; the distance between the beam splitter and the focusing lens was 300 mm; and the distance between the beam splitter and the beam profiler was 800 mm, as shown in

Figure 5. Different spot sizes can be measured according to the laser power, even for the same laser source. This means that the laser beam’s peak value must be adjusted to the CCD camera’s threshold value in order to obtain accurate measurements of the laser beam size.

The main objective of this study is to determine the specimen’s focal position. To this end, we used a microstage to move the specimen. To begin, we picked an arbitrary position and defined it to be the origin of the axis. Next, the focal position required to locate the specimen was determined, and its coordinate was referred to as l. The beam that was reflected by the mirror passed through the beam splitter, and was then measured by the beam profiler; this beam was measured to be 1.988 mm in the horizontal direction and 2.222 mm in the vertical direction. The horizontal and vertical dimensions differed because the beam was not an ideal Gaussian beam. The average of the horizontal and vertical dimensions was 2.105 mm, and Dmirror was defined to be this value.

Figure 5.

Schematic of the laser power control unit, which employs two polarizers and a half-wave plate (HWP).

Figure 5.

Schematic of the laser power control unit, which employs two polarizers and a half-wave plate (HWP).